Honeywell ST9500C Installation Instructions Manual

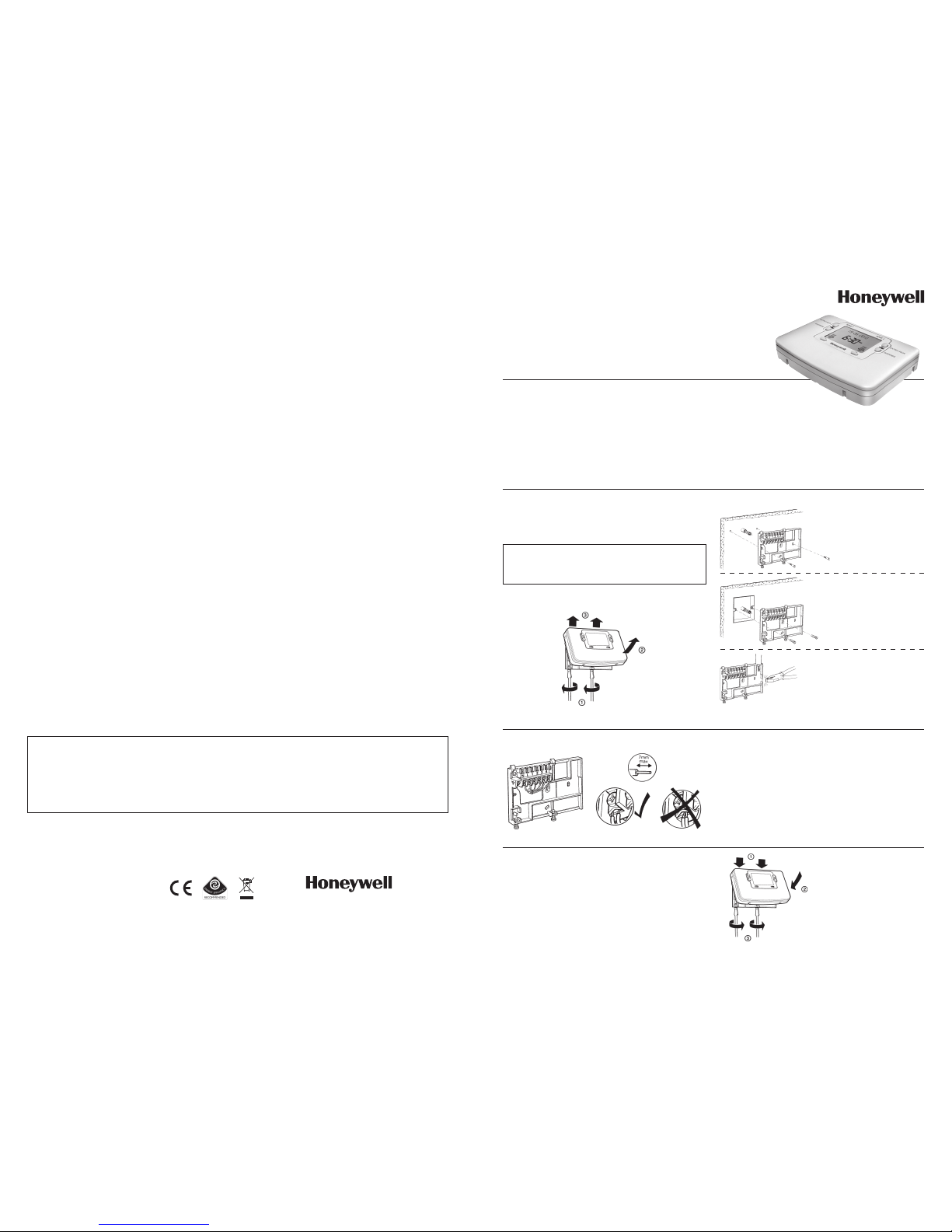

Mounting

The Programmer should be mounted at a level where the display can be

seen clearly, (1.2 to1.5m from the floor) and the ambient temperature is

within the range of 0 to 40°C. The ST9500 is for use in normal domestic

environments.

CAUTION

Isolate power supply and make safe before wiring the unit to prevent

electric shock and equipment damage. Installation should be carried

out by a qualified electrician or competent heating engineer.

To remove the unit from the wall-plate, slacken the two securing screws at

the bottom of the ST9500 and hinge the unit up to separate the two halves.

50022736-007 A

© 2007 Honeywell International Inc.

ST9500C 2-Zone Programmer

INSTALLATION INSTRUCTIONS

50022736-007 A

Introduction

ST9500 is an Electronic Programmer which provides accurate time

control for central heating systems with separate 7 day programmes for

two independent heating zones.

ST9500 Programmers can be combined with other Honeywell controls such

as Room Thermostats, Cylinder Thermostats, Wiring Centres and Zone or

Diverting Valves to form a fully automatic central heating control system.

4 1

Honeywell Control Systems Ltd.

Arlington Business Park,

Bracknell

Berkshire

RG12 1EB

Technical Help Desk: 08457 678999

www.honeywelluk.com

Specification

Power Supply: 230V~, 50…60Hz, 10W

Switch Action: 2 x SPDT

Switch Rating: 230V~, 50…60Hz, 3(3)A

Factory set clock

Power Reserve: lifetime battery

Programmes/Settings: permanently stored in NV RAM

Approvals: Conforms to protection requirements of

Directives 2006/95EC and 89/336EC

Mounting Options

RECOMMENDED CLEARANCE DISTANCES:

ABOVE WALLPLATE: 110mm

BELOW WALLPLATE: 100mm

LEFT/RIGHT OF WALLPLATE: 10mm

a. Sur face mounting

concealed wiring

b. Flush switchbox

Fixing holes are

spaced to suit BS4662

requirements

c. Sur face mounting with

surface wiring in

mini trunking

Wiring

ALL WIRING MUST BE IN ACCORDANCE WITH I.E.E. REGULATIONS.

THIS UNIT IS FOR FIXED WIRING ONLY.

A switch, having contact separation of at least 3mm in all poles (formerly

Class ‘A’), must be incorporated in the fixed wiring as a means of

disconnecting the supply.

The unit is a Class II (double insulated) device. A parking terminal is

provided for external earth continuity.

The system must be appropriately fused. A fuse rated at no more than

3 Amps should be installed.

The unit has 4 knockouts for surface wiring, care must be taken to ensure

that the cable or mini-trunking completely fills the knockout hole without

leaving any gaps.

Final Assembly

Clip the unit onto the hinges on the top of the wallplate and hinge down

into position. Tighten the two securing screws using a screwdriver.

Switch on the power – the unit will now be operating according to the

built-in programme. Note : the ST9500 is supplied with a factory set

clock for faster installation .

Refer to ST9500 User Guide for programming details.

Replacing Other Manufacturers’ Time Controls

Refer to Honeywell for wiring conversion diagrams.

Completion Checklist for Installation

1. Check unit powers up correctly, and that the display does not remain blank.

2. Set Zone 1 and Zone 2 operating modes to AUTO and switch Zone 1 and Zone 2 on and off using the OVERRIDE buttons, to ensure the system

is operating correctly.

3. Check the factory-set day, date, and time are correct and adjust if necessary. Refer to the User Guide for details.

4. If required, enter Installer Mode and adjust Installer Parameters to match the lifestyle and needs of the User. Remember to make a note of these

parameter changes in the Configuration Data section of the User Guide. Also note here how the zones have been set.

5. Explain the operation of the product to the User and help them to set their Zone 1 and Zone 2 programmes. There are 3 built-in profiles that can

be used as a basis for typical User programmes.

6. If required, attach the self-adhesive programme guide label to the underside of the cover flap. The label is supplied in the box and requires to be

peeled away from the backing material before use. Write details of how the zones have been configured in the space provided.

7. Explain when the User should contact someone to arrange a Service Visit.

8. Write the date of installation, your name and telephone number in the space provided in the User Guide, in the section ‘Boiler & System Service

Log’

9. Remember to leave the User Guide and Installation Instructions with the User and remind them to keep them in a safe place. This forms part of a

Home Information Pack.

This product and its associated documentation and packaging are protected by various intellectual property rights belonging to Honeywell Inc and its subsidiaries

and existing under the laws of the UK and other countries. These intellectual and property rights may include patent applications, registered designs, unregistered

designs, registered trade marks, unregistered trade marks and copyrights.

Honeywell reserves the right to modify this document, product and functionality without notice. This document replaces any previously issued instructions and is only

applicable to the product(s) described.

This product has been designed for applications as described within this document. For use outside of the scope as described herein, refer to Honeywell for guidance.

Honeywell cannot be held responsible for misapplication of the product(s) described within this document.

Manufactured for and on behalf of the Environment and Combustion Controls Division of Honeywell Technologies Sarl, Ecublens, Route du Bois 37, Switzerland by its

Authorised Representative Honeywell Inc.

Ensure the mounting surface is supporting and fully covers the wiring

wall-plate.

2 ST9500C Programmer Installation Guide 3

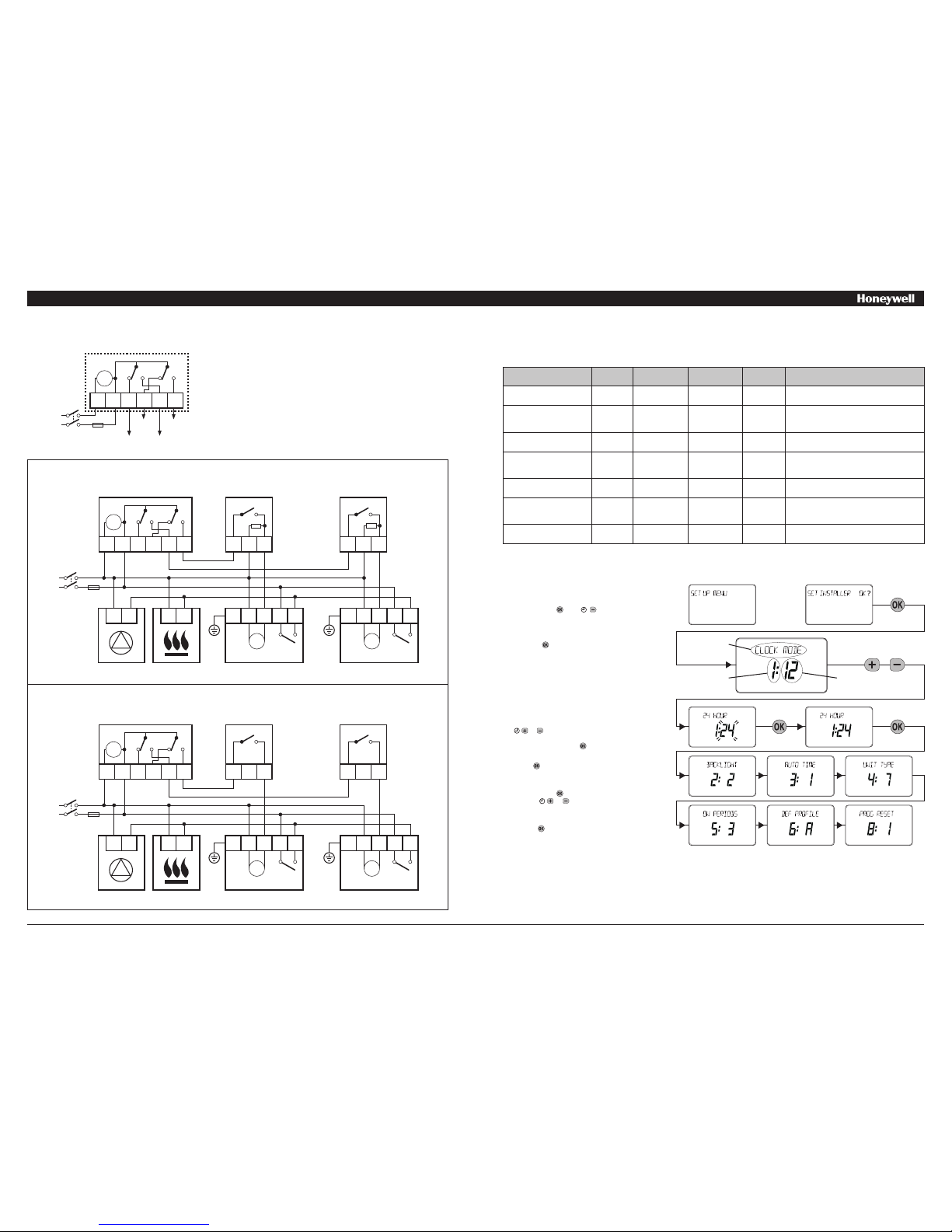

WIRING CONNECTIONS

ST9500 Internal Wiring

Notes

1. The ST9500 is a Class II (double insulated) device. A parking

terminal is provided for earth wiring continuity, if required.

2. In the wiring schematics below, connections are shown to basic

boilers only. For wiring connections to Pump over-run boilers

refer to the boiler manufacturers instructions or to Honeywell for

assistance.

3. Wiring schematics are shown for 2-Zone control using ST9500C and

2 Zone-valves. Please refer to Honeywell for other wiring and control

options.

Control using Zone-valves: Wiring to Mechanical Thermostats

ADDITIONAL PRODUCT FEATURES

Installer Mode

The ST9500 has a special Installer Mode where some features can be adjusted to suit user lifestyle or preferences – these are called installer

Parameters, and are listed in the table below, along with a description of the options that are possible.

INSTALLER PARAMETER Parameter

Number

LoT™ Display

Description

Default Value Range of

Values

Description [LoT™ Display Description]

24hr or am/pm clock display 1 CLOCK MODE 12 12, 24 12 = am/pm display,

24 = 24hr display

[AM-PM]

[24 HOUR]

Configure backlight operation

(backlight consumes no

additional energy)

2 BACKLIGHT 2 0, 1, 2 0 = off,

1 = on if button pressed,

2 = on continuously

[NO B-LIGHT]

[B-L DELAY]

[B-LIGHT ON]

Enable/disable auto time

change

3 AUTO TIME 1 0, 1 0 = disabled,

1 = enabled

[NO CHANGE]

[TIME CHANGE]

1-day or 5/2-day or 7-day

operation

4 UNIT TYPE 7 1, 5, 7 1 = 1-day operation,

5 = 5/2-day operation,

7 = 7-day operation

[1-DAY]

[5-2 DAY]

[7-DAY]

Number of ON/OFFs per

day

5 ON PERIODS 3 2, 3 2 = 2 on/offs per day,

3 = 3 on/offs per day

[2 PER DAY]

[3 PER DAY]

Select default time

programme

6 DEF PROFILE A A, b, C A = standard,

b = at home,

C = economy

[PROFILE A]

[PROFILE B]

[PROFILE C]

* Reset all parameters 8 PROG RESET 1 0, 1 0 = do not reset

1 = default parameters

[RESET OFF]

[RESET ON]

To Enter Installer Mode:

a.

Ensure the slider is in the RUN position, then press

and hold the and buttons together for 8

seconds. Ignore the ‘NOT VALID’ that is displayed

for a few seconds. The message ‘SET UP MENU’ will

show briefly, followed by ‘SET INSTALLER OK ?’

b. Press the button to take you into the Installer Mode

Parameter Menu.

c. Parameter 1 is now available to change. This is to

allow you to change the clock format from 12 hour

AM/PM to 24 hour. At every step, the LoT™ Display

will inform you what the parameter means and what

option you have selected. The parameter number is

shown on the display separated by a colon from the

parameter value.

d. You can change the parameter value by pressing the

or buttons. At this point the description in the

LoT™ Display will change and the parameter value

will flash. If you press the value will stop flashing

and will be saved for use.

e. Press to move to the next parameter available

for editing. The parameter number will change

accordingly.

f. Keep pressing to step around the list of parameters,

and use or buttons to change the parameter

value.

g. Any parameter changes that have been confirmed

with the button will be saved and used.

* this parameter by default has a value of 1, unless you change any other parameter, when it will change to 0. Set it to 1 to reset all parameters back to defaults.

LoT™ Display

Parameter

Number

Parameter

Value

or

Clock

N L 1 2 3 4

3 AMPS MAX

Zone 1

OFF

Zone 1

ON

Zone 2

OFF

Zone 2

ON

N

L

OFF ON OFF ON

To Exit Installer Mode:

You can exit Installer Mode at any time by moving the slider to the next position and then back again to RUN.

Note: Installer Mode will exit automatically after 10 minutes if the slider is not moved.

230V~

50...60Hz

Clock

N L 1 2 3 4

3 AMPS MAX

N

L

OFF ON OFF ON

230V~

50...60Hz

1 2 3

ST9500

1 2 3

T6360B (ZONE 2) T6360B (ZONE 1)

PUMP

N L

BOILER

N L

V4043H (ZONE 2)

G/Y BL BR GR O

M

V4043H (ZONE 1)

G/Y BL BR GR O

M

Control using Zone-valves: Wiring to Digital Thermostats

Clock

N L 1 2 3 4

3 AMPS MAX

N

L

OFF ON OFF ON

230V~

50...60Hz

A B

ST9500

A B

T6620B (ZONE 2) T6620B (ZONE 1)

PUMP

N L

BOILER

N L

V4043H (ZONE 2)

G/Y BL BR GR O

M

V4043H (ZONE 1)

G/Y BL BR GR O

M

Loading...

Loading...