Honeywell ST9120U Installation Manual

ST9120B,U

WARNING

Universal Electronic Fan Timers

INSTALLATION INSTRUCTIONS

APPLICATION

The ST9120B,U Universal Electronic Fan Timers

integrate control of all combustion blower and circulating

fan operations in a gas warm air appliance. This control

is the central wiring point for most of the electrical

components in the furnace. The basic purposes of the

ST9120B,U are to monitor the thermostat for heat, cool

and fan demands, run the induced draft blower motor

and run a circulating fan (up to two speeds) as required.

The ST9120B,U also monitors limit switch strings and

energizes separate ignition control systems through

pressure switches. The ST9120B,U can replace any

ST9101, ST9120, ST9141 or ST9160 listed in Table 3

below. The ST9120B,U features a field-adjustable heat

fan-on delay, a field-adjustable heat fan-off delay, a fieldadjustable cool fan-on delay and a field-adjustable cool

fan-off delay.

Electronic air cleaner (EAC) and humidifier (HUM)

convenience terminal connections and continuous low

speed indoor air circulation are provided.

SPECIFICATIONS

On/Off Delay Settings:

NOTE: Timing is derived from 24 VAC supply frequency

and is valid for 60Hz. At 50 Hz, the timings are

lengthened 20%.

Heat Speed:

Delay On: Field-adjustable, 30 or 60 seconds. Delay

timing starts when gas valve is energized.

Delay Off: Field-adjustable, 60, 120, 150 or 180 sec-

onds. Delay timing starts when gas valve is deenergized.

Cool Speed:

Delay On: Field Adjustable, 4 or 30 seconds.

Delay Off: Field Adjustable, 30 or 60 seconds.

Timing Tolerance: Larger of ±2% or ±2 seconds.

Post Purge Timing:

5 seconds.

Environmental Ratings:

Temperature: -40°F (-40°C) to +175°F (+79°C).

Humidity: 5 to 95 percent, noncondensing.

Approvals:

Underwriters Laboratories Inc.

Electrical Ratings:

Power Voltage Requirements: 18 to 30 VAC, 50/60 Hz.

Contact Ratings:

Combustion Blower:

1.5A full load, 10A locked rotor at 115 VAC.

0.75A full load, 5A locked rotor at 230 VAC.

(Reduce full load rating by humidifier [HUM] load.)

Circulating Fan:

Heat-Cool speed:

15A full load, 30A locked rotor at 115 VAC.

7.5A full load, 15A locked rotor at 230 VAC.

(Reduce full load rating by electronic air cleaner [EAC]

load.)

Continuous speed (optional):

8A full load, 16A locked rotor at 115 VAC.

4A full load, 8A locked rotor at 230 VAC.

EAC and HUM:

0.8A maximum combined load at 115 VAC

0.4A maximum combined load at 230 VAC

Thermostat W Load: 100mA at 24 VAC, plus ignition sys-

tem load.

Thermostat G, Y, Primary Limit, Burner Limit, Pressure

Switch Load: 22mA at 24 VAC load/cleaning current.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings and specifications given in the

instructions and on the product to make sure the

product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out the product

operation as provided in these instructions.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before wiring to prevent

electrical shock or equipment damage. More than

one disconnection can be required.

69-2252EF—07

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

CAUTION

CAUTION

CAUTION

Location and Mounting

Mount the ST9120B,U Electronic Fan Timer in the

appliance wiring compartment using the two # 8 1/2-in.

self-tapping screws.

Wiring

Explosion or fire hazard.

When installing the ST9120B,U, carefully check all

appliance wires to make sure they are all

connected to desired terminals at ST9120B,U.

Incorrect wiring can lead to explosion hazard, fire,

or equipment damage.

Make sure that all wiring complies with local codes and

ordinances. Disconnect power before making wiring

connections. Refer to Fig. 1–6 for standard wiring

connections. Refer to Fig. 7–9 for schematic of provided

wiring adapters.

Adjustable DIP Switch

The ST9120B,U control provides a wide variety of

configurable heat on, heat off, cool on and cool off delays.

Set the delay DIP switches as shown in Fig. 10 The heaton delay time starts when the main gas valve is energized

at the start of a thermostat call for heat; the heat-off delay

time starts when the main gas valve is deenergized at the

end of a thermostat call for heat. The cool fan-on delay

time starts when the compressor is energized at the start

of a thermostat call for cool. The cool fan-off delay time

starts when the compressor is deenergized at the end of

thermostat call for cool.

Twinning

Twinning mode is used when two ST9120B,U controls

operate in parallel. In this mode blower outputs (heat, cool

and continuous speed) are activated or deactivated at

both controls at the same time. Both ST9120B,U are

synchronized through a communication bridge utilizing

TWIN quick connect terminals, communication hardware

and special software package.

To get into twinning mode both ST9120B,U must share

common 24 VAC ground, both must be supplied off the

same 24 VAC transformer or two identically-phased

transformers and the TWIN terminals must be

interconnected together. One or both ST9120B,U must be

connected to the thermostat.

If two 24 VAC transformers are used (one for each

ST9120B,U) then the transformers must be phased in (24

VAC HOT legs connected to X terminals at each

ST9120B,U unit must be in the same phase relative to the

24 VAC common ground). If the transformers are phased

out the twinning mode will not be achieved.

It is permissible to interconnect just two ST9120B,U to

operate in the twinning mode. The ST9120B,U Twinning

mode is not backwards compatible with legacy Electronic

Fan Timers.

To operate in twinning mode:

1. Interconnect C quick connect terminals at both

twinned ST9120B,U.

2. Interconnect TWIN quick connect terminals at both

twinned ST9120B,U.

3. Use insulate wires of wire gauge at least AWG 24

for the interconnections. Wire lengths shall not

exceed 5 m (15 ft.). Both C and TWIN wires shall

lead in parallel to each other. Keep the wires out of

wires under line voltage, ignition cable and other

sources of electrical noise.

ST9120B,U Wiring Conversion Instructions

1. Turn off power to appliance. Carefully remove each

wire and connect directly to the corresponding location on the new ST9120B,U control board. Be careful to directly connect to the new terminal with the

same labeled identity or label each wire prior to

removing from the original board.

2. Identify the model number of the board being

replaced and set the dip switches based on Table 3.

Explosion Hazard/Fire Hazard

ST9101 wiring harness adapter and ST9141

wiring harness adapter are very similar because

both use identical connectors. Ensure proper

harness is selected for the target system. Using

the wrong wiring harness adapter leads to target

system and/or ST9120B,U control damage.

ST9101 to ST9120B,U Wiring Conversion Instructions

1. Turn off power to appliance and carefully remove

each wire and connect directly to the new

ST9120B,U control board before removing the

existing control. Use Table 1 to determine the

proper ST9120B,U terminal for each corresponding

ST9101 connection. Connect the wiring in accordance with schematic at Fig. 3. Be careful to directly

connect to the new terminal or label each wire prior

to removal from original board.

Electronic air cleaner use.

If electronic air cleaner is used in systems with

continuous blower speed, connect the electronic

air cleaner to line voltage input L1.

2. Unplug the 9-pin connector and plug existing wiring

harness directly into the 9-pin connector found on

the ST9101 wiring adapter 50011959. See Fig. 7

and Table 4 for further wire harness adapter

description.

3. Plug the 6-pin connector found on the ST9101 wir-

ing adapter directly to the open 6-pin connector on

the new ST9120B,U control board.

4. Take the two remaining white wires on the ST9101

wiring adapter and connect to Neutral quick connect

terminals on the ST9120B,U.

5. Take the black wire on the ST9101 wiring adapter

and connect to the L1 quick connect terminal on the

ST9120B,U.

6. Take the blue wire on the ST9101 wiring adapter

and connect to the IND quick connect terminal on

the ST9120B,U.

7. Identify the model number of the board being

replaced and set the dip switches based on Table 3.

8. Check proper connection using Fig. 3.

69-2252EF—07 2

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

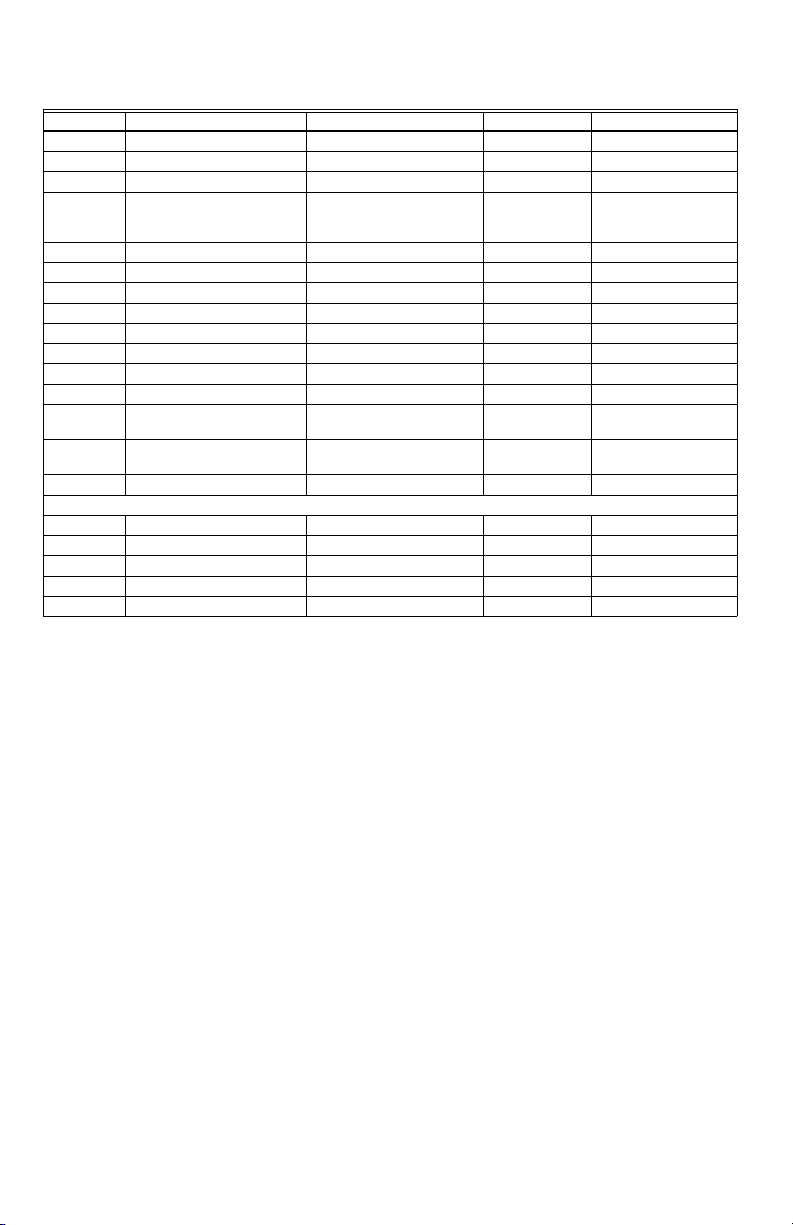

ST9101 ST9120 ST9141 ST9160 ST9120B,U

HEAT HEAT HEAT HEAT HEAT

COOL COOL COOL COOL COOL

CONT CONT CONT CONT

ACC --- --- --- * for systems with one

DI DI --- IND

S S1 to S3 S1 to S3 L1 L1

M1 UNUSED MOTOR LEADS UNUSED MOTOR LEADS M1 UNUSED

M2 UNUSED MOTOR LEADS UNUSED MOTOR LEADS M2 UNUSED

N N N N N

X X XI 24 VAC X

C C C COM C

--- SPEED UP SPEED UP --- ---

--- Z1 Z1 TWIN H ** TWIN (see note

--- Z2 Z2 TWIN C ** TWIN (see note

--- --- --- DATA DATA

Thermostat Terminals

R R R R R

Y Y Y Y Y

C C C C C

W W W W W

G G G G G

* ACC terminal is used in ST9101 systems, which use the same fan speed for both heating and cooling. In order to use

the ST9120B,U to replace ST9101 devices in this type of system, the fan connection that originally was connected to

ACC on the ST9101 needs to be connected to both heat and cool connections on the ST9120B,U.

**TWIN terminal is used to interconnect two ST9120B,U units to operate blower outputs simultaneously. Twinning at

new ST9120B,U control is not backwards compatible with legacy controls.

Table 1. ST9101 to ST9120B,U Wiring Conversions.

ON fan speed (see

note below)

below)

below)

ST9141 to ST9120B,U Wiring Conversion Instructions

1. Turn off power to appliance and carefully remove

each wire and connect directly to the new

ST9120B,U control board before removing the

existing control. Use Table 1 to determine the

proper ST9120B,U terminal for each corresponding

ST9141 connection. Be careful to directly connect

the new terminal or label each wire prior to removal

from original board.

2. Unplug the 9-pin connector and plug existing wiring

harness directly into the 9-pin connector found on

the ST9141 wiring adapter 50034962. See Fig. 8

and Table 5 for further wire harness adapter

description.

3. Plug the 6-pin connector found on the ST9141 wir-

ing adapter directly to the open 6-pin connector on

the new ST9120B,U control board.

4. Take the gray wire on the ST9141 wiring adapter

and connect to the LIM quick connect terminal on

the ST9120B,U.

5. Take the brown wire on the ST9141 wiring adapter

and connect to the PRSW quick connect terminal

on the ST9120B,U.

6. Identify the model number of the board being

replaced and set the dip switches based on Table 3.

7. Check proper connection using Fig. 4.

ST9160 to ST9120B,U Wiring Conversion Instructions

1. Turn off power to appliance and carefully remove

each wire and connect directly to the new

ST9120B,U control board before removing the

existing control. Use Table 1 to determine the

proper ST9120B,U terminal for each corresponding

ST9160 connection.

2. Unplug the 6-pin connector and plug it into the J3

connector found on ST9120B,U.

3. Plug the jumper plug into the J1 connector at

ST9120B,U.

4. Identify the model number of the board being

replaced and set the dip switches based on Table 3.

5. Check proper connection using Fig. 5 or 6.

LED Diagnostic

The ST9120 control provides the following status

information and diagnostic troubleshooting code

sequence as shown in Table 2.

3 69-2252EF—07

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

Table 2. LED Diagnostic Troubleshooting Codes.

No. of flashes Condition

dim/on (heartbeat) Device works correctly.

1 Limit switch (ST9120) or burner limit switch (ST9141) is open.

2 Primary limit switch (ST9141) is open.

3

Pressure switch is improperly closed or pressure switch open when inducer blower has been

running for >30 sec.

4 Control is in lockout due to air not circulating (overheated).

5 Smart Valve II limit switch is open.

6 Twinning communication corrupted (check system transformers' phasing).

7 Wrong 24 VAC supply condition.

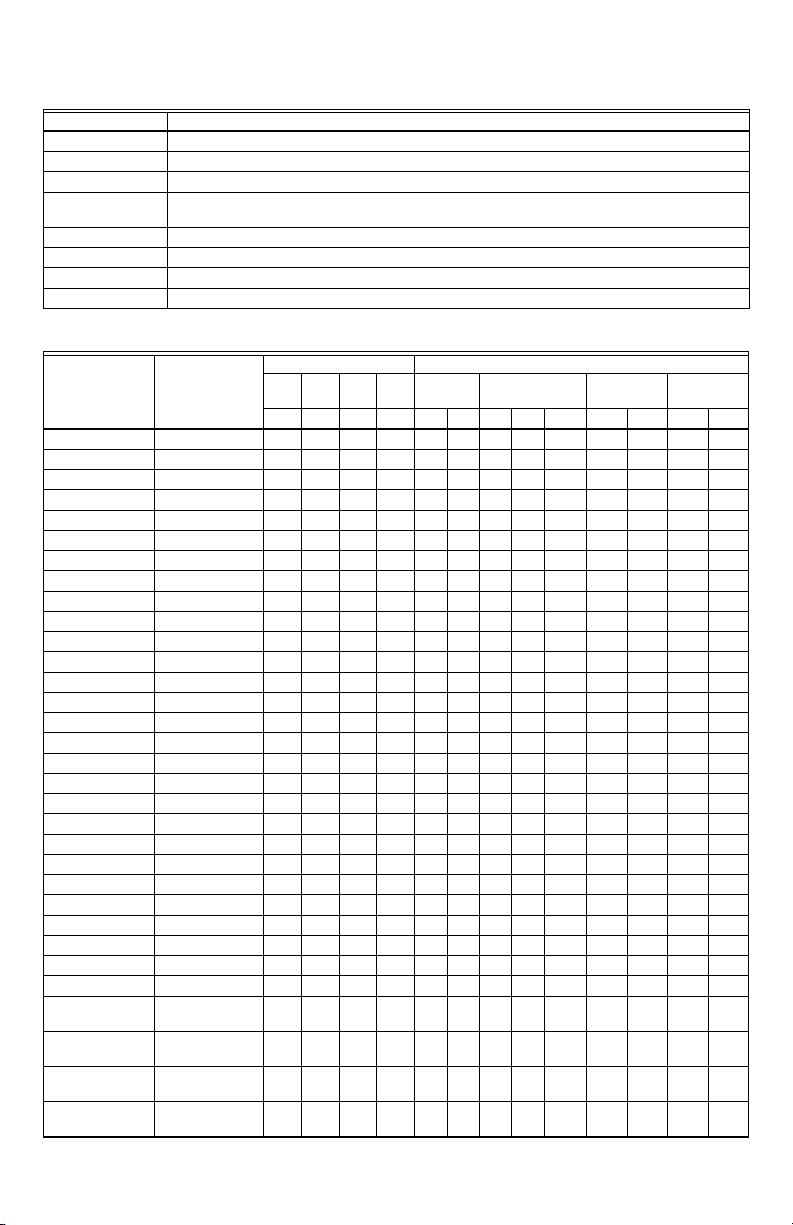

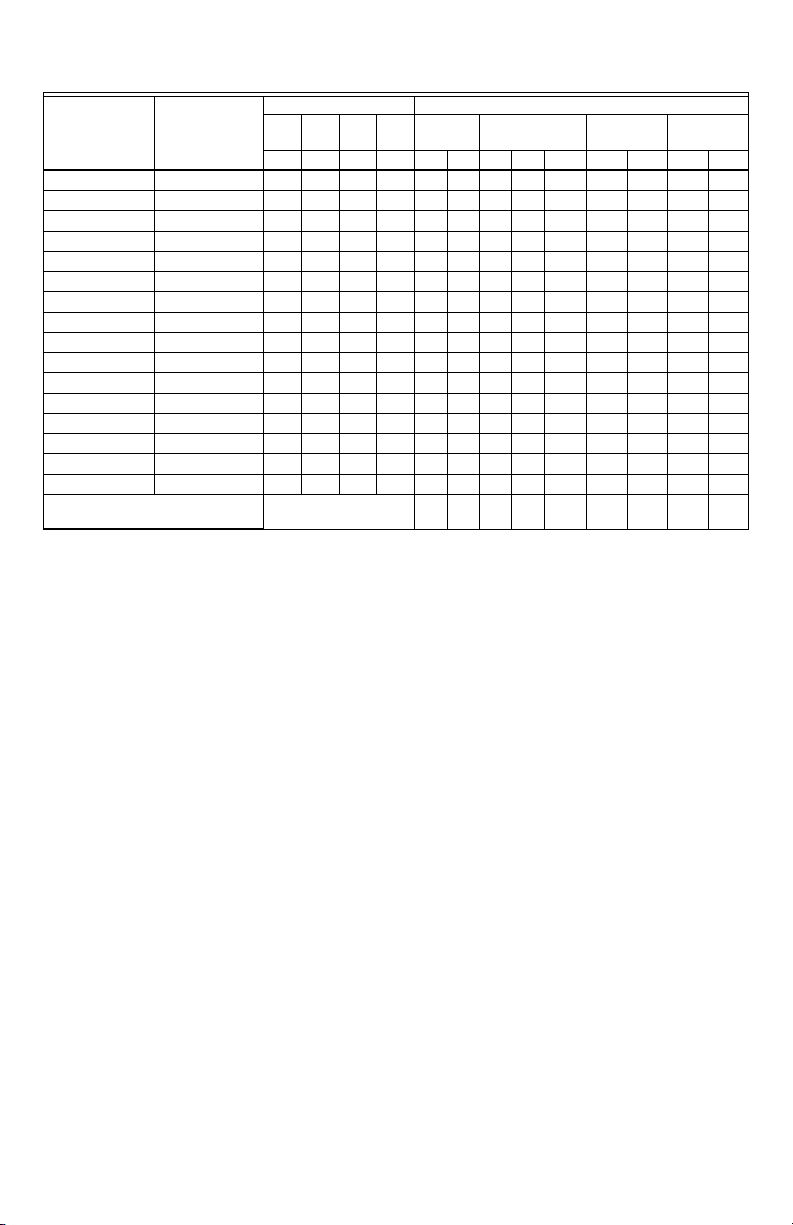

Table 3. Recommended Default Dip Switch Settings.

Legacy Timing New ST9120B,U

Replaced

Control Model

Number

Original OEM

Appliance

Heat OnHeat

sec sec sec sec 1 sec 2 3 sec 4 sec 5 sec

Off

Cool OnCool

Off Heat On Heat Off Cool On Cool Off

ST9101A1006 Rheem 30 100 4 0 off 30 off off 120 off 4 off 30

ST9101A1014 Rheem 30 100 4 0 off 30 off off 120 off 4 off 30

ST9101A1022 Trade 30 100 4 0 off 30 off off 120 off 4 off 30

ST9120A1006 Armstrong 30 100 4 0 off 30 off off 120 off 4 off 30

ST9120A2004 Armstrong 30 140 4 0 on 30 off on 150 off 4 off 30

ST9120B1005 Ducane 30 60 4 0 off 30 on off 60 off 4 off 30

ST9120C1012 Snyder General 60 100 4 0 on 60 off off 120 off 4 off 30

ST9120C1020 Nordyne 60 100 4 0 on 60 off off 120 off 4 off 30

ST9120C2002 York 30 100 4 30 off 30 off off 120 off 4 off 30

ST9120C2010 Ducane 30 100 4 30 off 30 off off 120 off 4 off 30

ST9120C2028 Armstrong 30 100 4 60 off 30 off off 120 off 4 on 60

ST9120C3000 ICP 30 140 30 30 off 30 off on 150 on 30 off 30

ST9120C3018 Bard 60 100 4 60 on 60 off off 120 off 4 on 60

ST9120C4008 ICP 30 140 30 30 off 30 off on 150 on 30 off 30

ST9120C4016 ICP 30 140 30 30 off 30 off on 150 on 30 off 30

ST9120C4040 ICP 30 140 30 30 off 30 off on 150 on 30 off 30

ST9120C4057 ICP 30 140 30 30 off 30 off on 150 on 30 off 30

*ST9120C5005 ICP 30 140 4 30 off 30 off on 150 off 4 off 30

*ST9120C5013 ICP 30 140 4 30 off 30 off on 150 off 4 off 30

*ST9120D3009 Goodman 30 140 4 60 off 30 off on 150 off 4 on 60

ST9120G2008 ICP 60 100 30 0 on 60 off off 120 on 30 off 30

ST9120G2016 ICP 30 100 30 30 off 30 off off 120 on 30 off 30

ST9120G2024 Skymark 30 60 30 30 off 30 on off 60 on 30 off 30

ST9120G2032 Skymark 30 60 4 100 off 30 on off 60 off 4 on 60

ST9120G4004 ICP 30 140 30 30 off 30 off on 150 on 30 off 30

ST9120G4012 ICP 30 140 30 30 off 30 off on 150 on 30 off 30

ST9120G4038 Trade 30 140 30 30 off 30 off on 150 on 30 off 30

ST9120U1003 Trade 30 140 4 30 off 30 off on 150 off 4 off 30

ST9141A1002

ST9141A1028

ST9141B1001

ST9150A1003

Consolidated

Industries

Consolidated

Industries

Consolidated

Industries

Consolidated

Industries

30 140 6 60 off 30 off on 150 off 4 on 60

30 140 6 60 off 30 off on 150 off 4 on 60

75 180 6 60 on 60 on on 180 off 4 on 60

36 168 7 72 off 30 on on 180 off 4 on 60

*Heat fan off delay setting may need adjustment based on performance. See Fig. 10 to adjust timings.

69-2252EF—07 4

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

Table 3. Recommended Default Dip Switch Settings. (Continued)

Legacy Timing New ST9120B,U

Replaced

Control Model

Number

Original OEM

Appliance

Heat OnHeat

sec sec sec sec 1 sec 2 3 sec 4 sec 5 sec

Off

Cool OnCool

Off Heat On Heat Off Cool On Cool Off

ST9150B2000 36 144 7 0 off 30 off on 150 off 4 off 30

ST9150B2018 ICP 30 140 30 30 off 30 off on 150 on 30 off 30

ST9150B2026 Ducane 36 144 7 36 off 30 off on 150 off 4 off 30

ST9150B2034 36 144 7 36 off 30 off on 150 off 4 off 30

ST9160A1002 Armstrong 30 90 6 60 off 30 off off 120 off 4 on 60

ST9160B1001 30 120 6 30 off 30 off off 120 off 4 off 30

ST9160B1019 30 120 6 30 off 30 off off 120 off 4 off 30

ST9160B1027 30 120 6 60 off 30 off off 120 off 4 on 60

ST9160B1035 30 120 6 30 off 30 off off 120 off 4 off 30

ST9160B1043 ICP 30 140 6 30 off 30 off on 150 off 4 off 30

ST9160B1050 ICP 30 140 6 60 off 30 off on 150 off 4 on 60

ST9160B1068 Armstrong 30 120 6 60 on 30 off off 120 off 4 on 30

ST9160B1076 Ducane 30 120 6 30 off 30 off off 120 off 4 off 30

ST9160B1084 ICP 30 140 6 90 off 30 off on 150 off 4 on 60

ST9160C1000 30 140 30 30 off 30 off on 150 on 30 off 30

ST9160C1018 30 140 30 30 off 30 off on 150 on 30 off 30

*ST9120B,U Factory Default

Setting

off 30 off off 120 off 4 off 30

*Heat fan off delay setting may need adjustment based on performance. See Fig. 10 to adjust timings.

NOTE: Timings may not be exactly the same as the replaced control and adjustments may need to be made.

5 69-2252EF—07

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

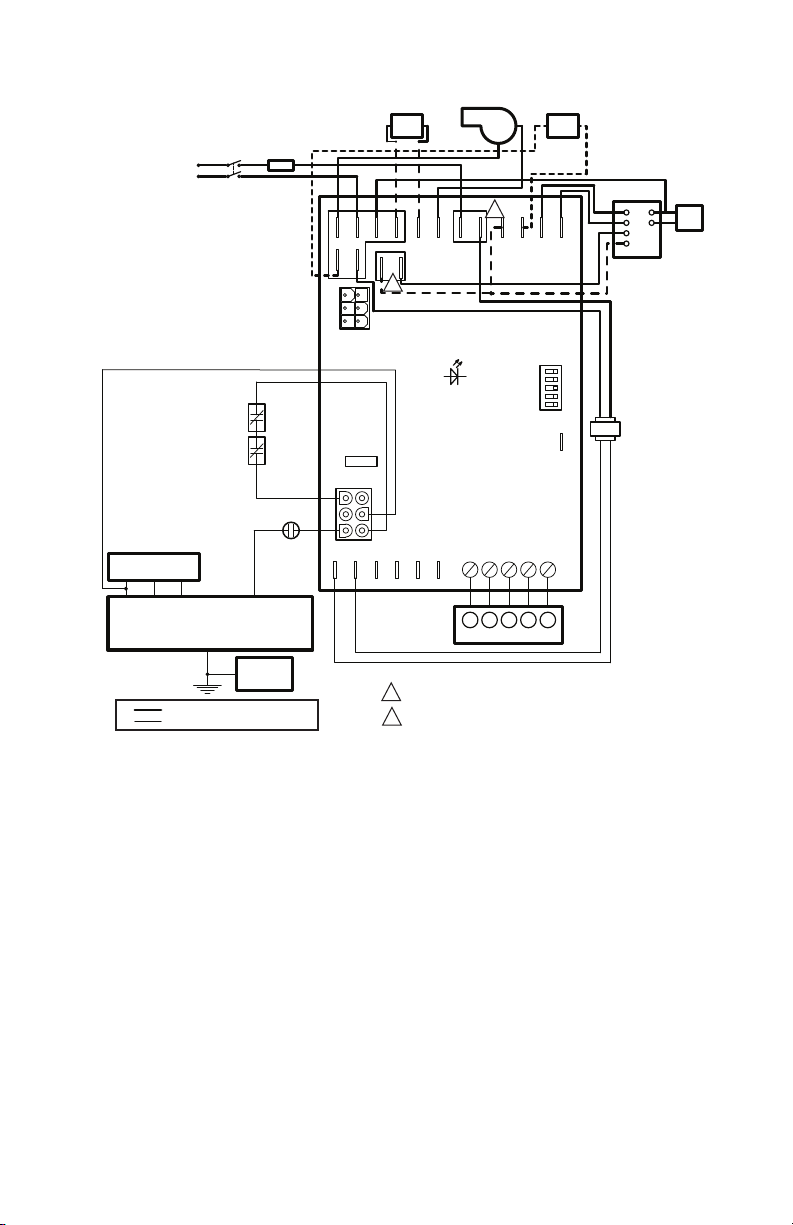

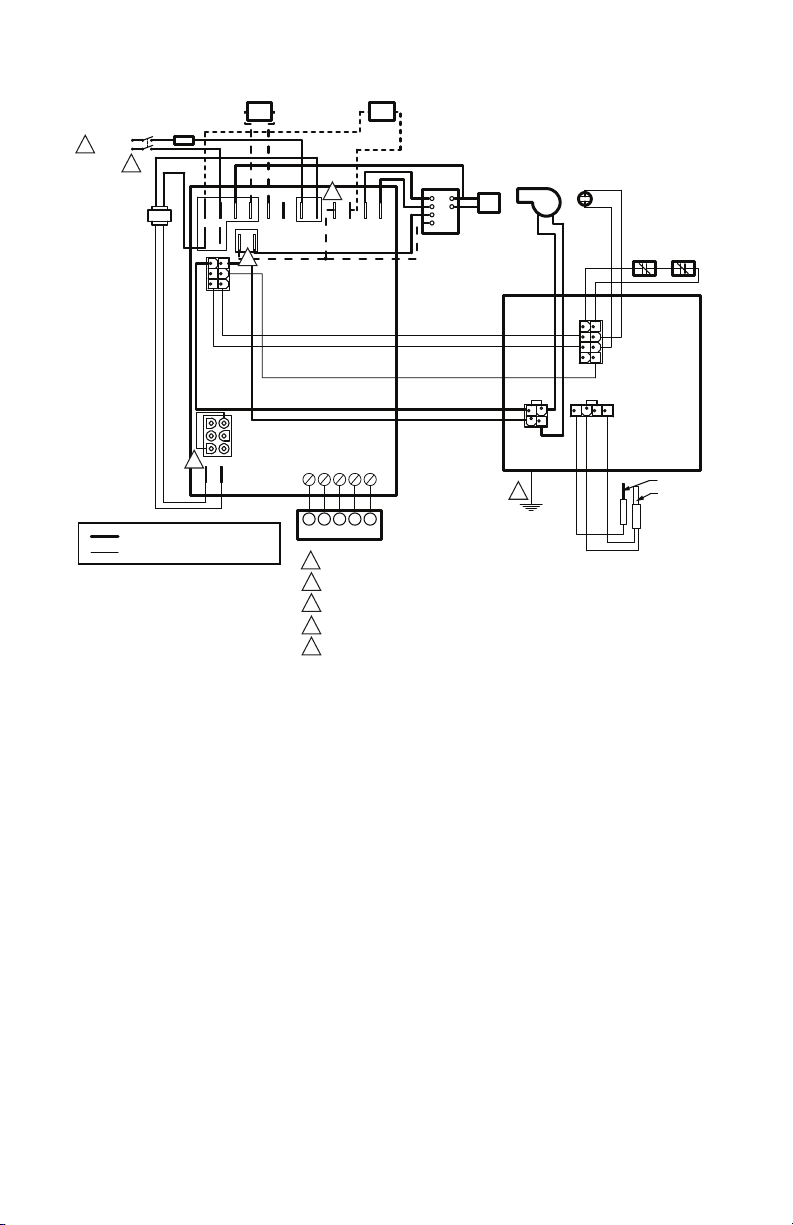

TO 115/230 VAC

POWER SUPPLY

L1 (HOT)

L2 (N)

MV MV/PV PV

MV MV/PV PV BRN 24V 24V SPARK

S8600 IGNITION CONTROL

GND

DENOTES LINE VOLTAGE WIRING

DENOTES LOW VOLTAGE WIRING

GND

FUSE

PRESSURE

PILOT

BURNER

LIMIT

SWITCH

ROLLOUT

SWITCH

SWITCH

SENSE

NEUTRAL

UNUSED

J3

FUSE

J1

CXLIM

HUMIDIFIER

INDUCER

AIR

CLEANER

1

L1

HUM

IND

CONT

EAC

COOL

HEAT

2

STATUS

C G Y W R

YC

PRSW

CGYW

CONNECT ONLY IF CONTINUOUS SPEED IS AVAILABLE AND USED.

1

2

CONNECT ONLY IF CONTINUOUS SPEED IS NOT USED.

DELAY

TWIN

R

THERMOSTAT

STARTING

FAN

HI

ML

MH

LO

115/230 VAC

TRANSFORMER

24 VAC

CAP

M27704

Fig. 1. Typical ST9120B,U wiring connections in ST9120 system with S8600 Intermittent Pilot Ignition Control.

69-2252EF—07 6

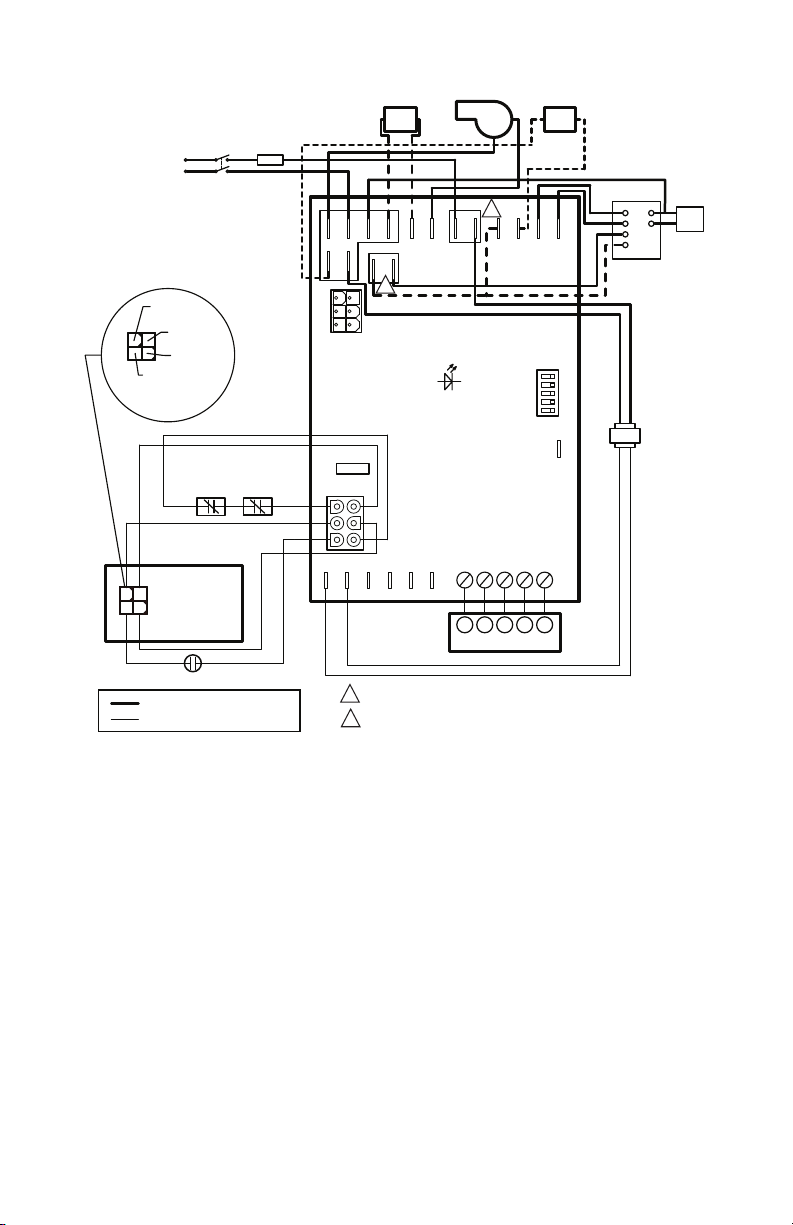

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

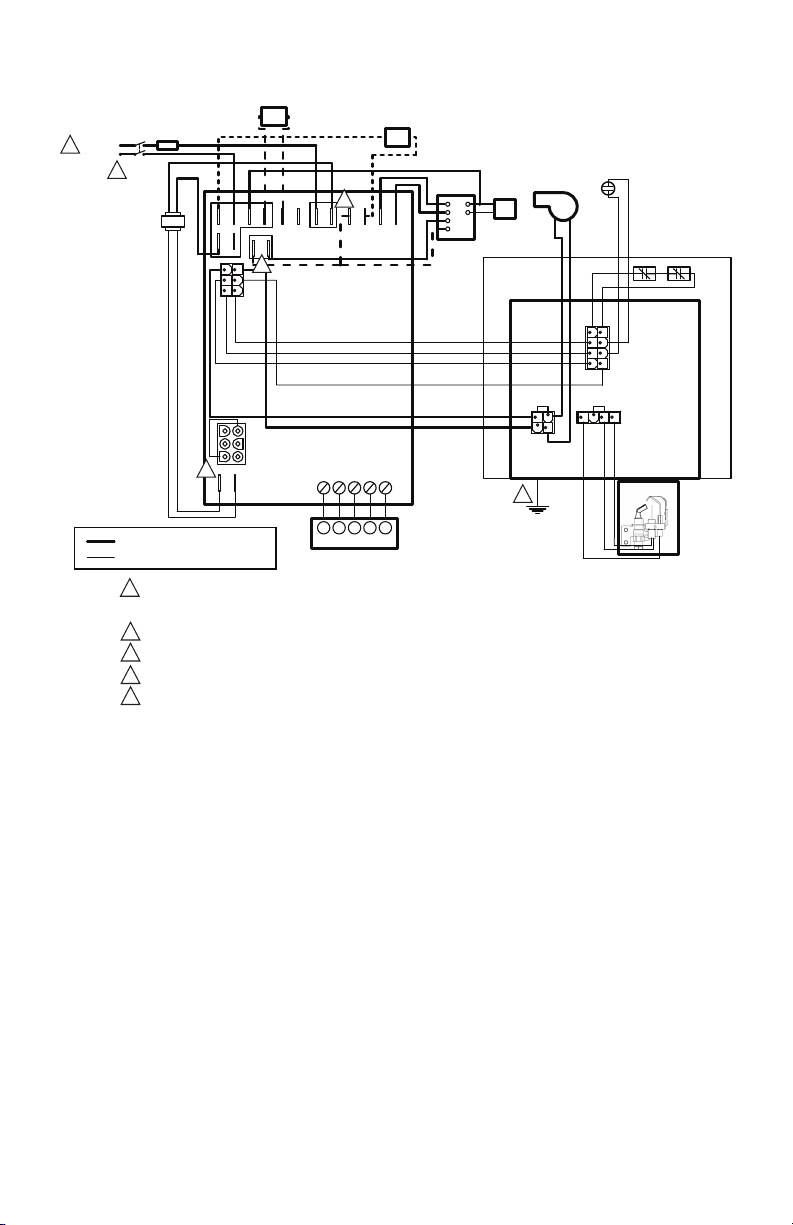

CGYW

R

HUM

IND

NEUTRAL

C G Y W R

THERMOSTAT

115/230 VAC

TRANSFORMER

24 VAC

CONNECT ONLY IF CONTINUOUS SPEED IS AVAILABLE AND USED.

CONNECT ONLY IF CONTINUOUS SPEED IS NOT USED.

PRESSURE SWITCH

ROLLOUT

SWITCH

LIMIT

SWITCH

SV9500

HOT SURFACE

IGNITION CONTROL

CXLIM

PRSW

YC

FAN

STARTING

CAP

ML

LO

HI

MH

AIR CLEANER

HUMIDIFIER

TO 115/230 VAC

POWER SUPPLY

L2 (N)

L1 (HOT)

FUSE

INDUCER

DELAY

CONT

EAC

COOL

HEAT

J3

TWIN

FUSE

J1

L1

STATUS

UNUSED

DENOTES LINE VOLTAGE WIRING

DENOTES LOW VOLTAGE WIRING

M27705

1

2

24 VOLT

COMMON

24 VOLT

HOT

EFT

OUTPUT

24 VOLT

THERMOSTAT

OR PRESSURE

SWITCH

1

2

Fig. 2. Typical ST9120B,U wiring connections in ST9120 system with SV9500/SV9501 SmartValve™ Control.

7 69-2252EF—07

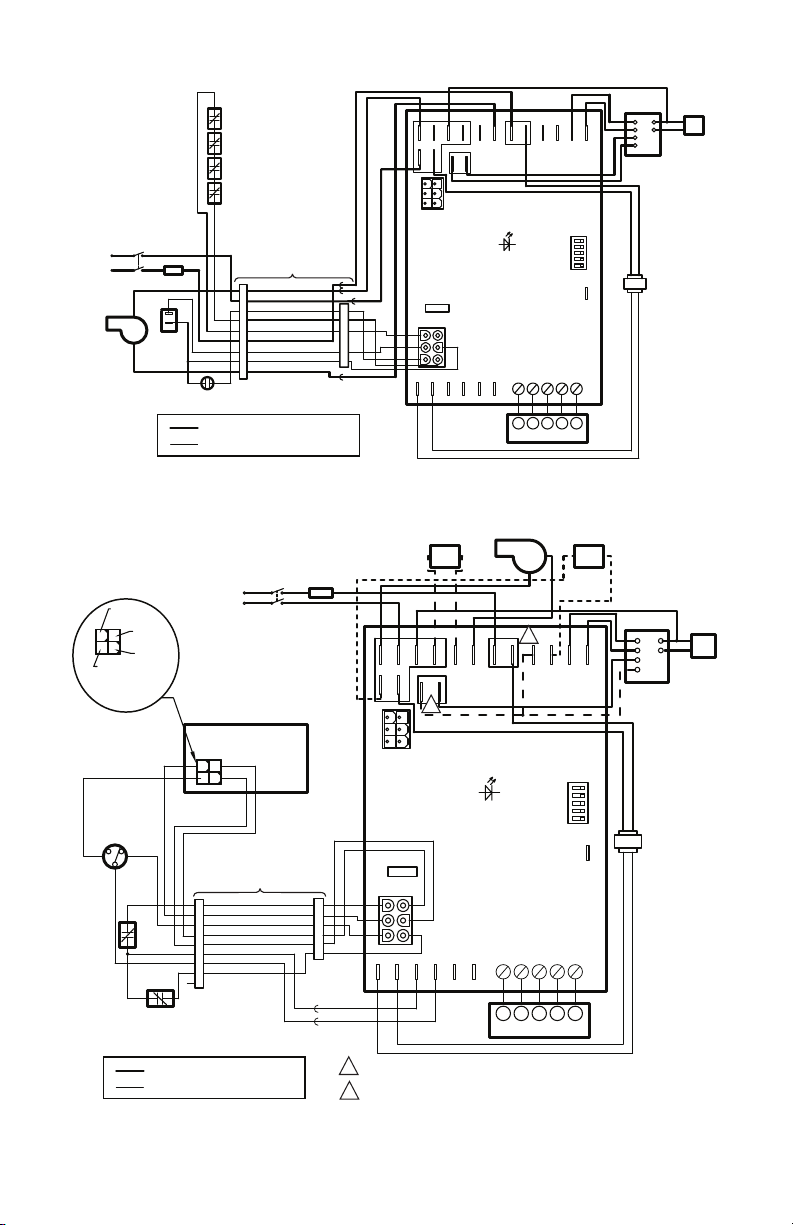

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

C G Y W R

DELAY

NEUTRAL

HUM

IND

CONT

EAC

COOL

HEAT

UNUSED

J3

TWIN

CXLIM

PRSW

YC

STATUS

C

G

Y

W

R

THERMOSTAT

FAN

STARTING

CAP

115/230 VAC

TRANSFORMER

24 VAC

LO

HL

HH

HI

AUX

VENT

ROLLOUT

MAIN

LIMIT

PRESSURE

SWITCH

FUSE

L2 WHITE

PS/MV DRIVE ORANGE

LIMIT RED

LIMIT RED

L1 BLACK

24V GND YELLOW

MV SENSE VIOLET

INDUCER BLUE

J1

L1

NC

WIRE HARNESS ADAPTER

GAS

VALV E

TO 115/230 VAC

POWER SUPPLY

L2 (N)

L1 (HOT)

FUSE

INDUCER

L2 WHITE

DENOTES LINE VOLTAGE WIRING

DENOTES LOW VOLTAGE WIRING

3

6

1

4

2

5

1

2

3

4

5

6

7

8

9

M27777

C G Y W R

CXLIM

PRSW

YC

CGYW

R

THERMOSTAT

115/230 VAC

TRANSFORMER

24 VAC

PRESSURE

SWITCH

TO 115/230 VAC

POWER SUPPLY

L2 (N)

L1 (HOT)

1

2

3

4

5

6

7

8

9

24V

24V GND

W

24V

FT

BRN LIM

PRSW

PRIM LIM

1

2

3

4

5

6

ST9141 WIRE HARNESS ADAPTER

SV9500

HOT SURFACE

IGNITION CONTROL

N.C.

N.O.

COM

N.C.

FUSE

PRIMARY

LIMIT

BURNER

LIMIT

24 VOLT

COMMON

24VOLT

HOT

EFT

OUTPUT

24 VOLT

THERMOSTAT

OR PRESSURE

SWITCH

FAN

STARTING

CAP

ML

LO

HI

MH

AIR

CLEANER

HUMIDIFIER

INDUCER

DELAY

HUM

IND

CONT

EAC

COOL

HEAT

J3

TWIN

FUSE

J1

STATUS

NEUTRAL

UNUSED

RED

YELLOW

RED

VIOLET

ORANGE

GRAY

BROWN

RED

CONNECT ONLY IF CONTINUOUS SPEED IS AVAILABLE AND USED.

CONNECT ONLY IF CONTINUOUS SPEED IS NOT USED.

DENOTES LINE VOLTAGE WIRING

DENOTES LOW VOLTAGE WIRING

1

2

M27722

2

1

Fig. 3. Typical ST9120B,U wiring connections in ST9101 system.

Fig. 4. Typical ST9120B,U wiring connections in ST9141 system with SV9500/SV9501 SmartValve™ Control.

69-2252EF—07 8

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

TO 115 VAC

POWER SUPPLY

L1 (HOT)

1

L2 (N)

2

115 VAC

TRANSFORMER

24 VAC

LOAD

DENOTES LINE VOLTAGE WIRING

DENOTES LOW VOLTAGE WIRING

FUSE

COMMON

3

NEUTRAL

X

C

HUMIDIFIER

UNUSED

5

J3

J1

AIR CLEANER

STARTING

CAP

INDUCER

NEUTRAL

SV9501;

SV9520

C3

2

4

L1

HUM

IND

EAC

COOL

CONT

C G Y W R

G

C

R

Y

W

THERMOSTAT

1

THERE MUST BE 115 VAC CONNECTED TO L1 (HOT) ON ST9120U, ST9120B.

2

APPLIANCE CHASSIS MUST HAVE RELIABLE CONNECTION TO EARTH GROUND.

3

JUMPER PLUG MUST BE ATTACHED TO J1 CONNECTOR.

CONNECT ONLY IF CONTINUOUS SPEED IS AVAILABLE AND USED.

4

5

CONNECT ONLY IF CONTINUOUS SPEED IS NOT USED

FAN

HI

ML

MH

LO

HEAT

C

R

DATA

NEUTRAL

L1

PRESSURE

SWITCH

HOT

C1

ROLLOUT

LIMIT

SWITCH

SWITCH

C2

FLAME ROD

HOT

SURFACE

IGNITER

M16880

Fig. 5. Typical ST9120B,U wiring connections in ST9160 system with SV9510/SV9520 SmartValve™ Control.

9 69-2252EF—07

ST9120B,U UNIVERSAL ELECTRONIC FAN TIMERS

TO 115/230 VAC

POWER SUPPLY

L1 (HOT)

1

L2 (N)

2

115/230 VAC

TRANSFORMER

24 VAC

DENOTES LINE VOLTAGE WIRING

DENOTES LOW VOLTAGE WIRING

1

FOR 115 VAC / 50, 60 HZ INSTALLATIONS, THERE MUST BE 115 VAC CONNECTED TO L1 (HOT) ON ST9120U, ST9120B.

FOR 230 VAC / 60 HZ INSTALLATIONS, THERE MUST BE 115 VAC BETWEEN L1 (HOT) AND APPLIANCE CHASSIS.

FOR 230 VAC / 50 HZ INSTALLATIONS, USE ONLY WITH SMART VALVE RATED FOR THE SAME LINE VOLTAGE PARAMETERS.

APPLIANCE CHASSIS MUST HAVE RELIABLE CONNECTION TO EARTH GROUND.

2

3

JUMPER PLUG MUST BE ATTACHED TO J1 CONNECTOR.

CONNECT ONLY IF CONTINUOUS SPEED IS AVAILABLE AND USED.

4

CONNECT ONLY IF CONTINUOUS SPEED IS NOT USED

5

FUSE

LOAD

COMMON

3

C

HUMIDIFIER

NEUTRAL

UNUSED

J3

J1

X

AIR

CLEANER

PRESSURE

INDUCER

HOT

SWITCH

C1

LIMIT

ROLLOUT

SWITCH

SWITCH

C2

Q345

IGNITERSENSOR

M27724A

STARTING

FAN

4

L1

IND

HUM

5

EAC

CONT

C G Y W R

Y

C

W

G

THERMOSTAT

COOL

R

HEAT

HI

ML

MH

LO

C

R

24VAC

DATA

NEUTRAL

L1

CAP

NEUTRAL

SV9540;

SV9640

C3

2

Fig. 6. Typical ST9120B,U wiring connections in ST9160 system with SV9540/SV9640 SmartValve™ Control.

69-2252EF—07 10

Loading...

Loading...