Page 1

SPM Flex

Single Point Monitor Gas Detector

User’s Manual

Page 2

Page 3

SPM Flex Gas Detector

Introduction ����������������������������������������������������������������������������������������������������������������5

Safety Information ��������������������������������������������������������������������������������������������������6

Contact Information ������������������������������������������������������������������������������������������������ 7

Glossary ���������������������������������������������������������������������������������������������������������������������� 8

Product Overview ������������������������������������������������������������������������������������������������������� 9

Battery operation �������������������������������������������������������������������������������������������������� 11

The handle (portable model) ��������������������������������������������������������������������������������12

Opening the cover ������������������������������������������������������������������������������������������������12

Main power rocker switch ������������������������������������������������������������������������������������13

Turning the detector on and off ���������������������������������������������������������������������������� 14

Navigation �������������������������������������������������������������������������������������������������������������15

Menu Map �������������������������������������������������������������������������������������������������������������16

Installing a Chemcassette cartridge ��������������������������������������������������������������������18

Wiring and tubing �����������������������������������������������������������������������������������������������������20

Typical fixed installation topologies ��������������������������������������������������������������������� 20

Wiring diagrams ���������������������������������������������������������������������������������������������������� 22

4-20 mA wiring ������������������������������������������������������������������������������������������������������ 23

Tubing (optional) ��������������������������������������������������������������������������������������������������� 26

Setup ������������������������������������������������������������������������������������������������������������������������� 27

Installation drawing �����������������������������������������������������������������������������������������������27

Dimensions ������������������������������������������������������������������������������������������������������������28

Mounting options �������������������������������������������������������������������������������������������������� 28

Standard mounting bracket ����������������������������������������������������������������������������������29

Backward-compatible mounting bracket ������������������������������������������������������������30

Sun shield ��������������������������������������������������������������������������������������������������������������31

Converting a fixed detector into a portable unit �������������������������������������������������32

In-line filters �����������������������������������������������������������������������������������������������������������32

Optional sampling wand ��������������������������������������������������������������������������������������� 33

Operation ����������������������������������������������������������������������������������������������������������������� 34

Controls ����������������������������������������������������������������������������������������������������������������� 35

Setup menu ����������������������������������������������������������������������������������������������������������� 40

Troubleshooting ������������������������������������������������������������������������������������������������������� 46

Maintenance ������������������������������������������������������������������������������������������������������������� 50

Storing the detector ���������������������������������������������������������������������������������������������� 58

Recycling ���������������������������������������������������������������������������������������������������������������58

Storing Chemcassette

Labels ������������������������������������������������������������������������������������������������������������������������59

Detectable Gases ����������������������������������������������������������������������������������������������������� 60

Specifications ���������������������������������������������������������������������������������������������������������� 61

Accessories and Parts ���������������������������������������������������������������������������������������������62

Certifications ������������������������������������������������������������������������������������������������������������65

Warranties ����������������������������������������������������������������������������������������������������������������� 66

SPM Flex warranty ������������������������������������������������������������������������������������������������66

Chemcassette

®

cartridge warranty ���������������������������������������������������������������������� 66

Index �������������������������������������������������������������������������������������������������������������������������68

®

cartridges �����������������������������������������������������������������������58

3

Page 4

SPM Flex Gas Detector

4

Page 5

SPM Flex Gas Detector

Introduction

The SPM Flex gas detector is an extractive gas monitoring system that draws gas

®

samples locally or from a remote point to a Chemcassette

detection system� A wide range of toxic gas Chemcassette cartridges are available

that enable detection of gases used or generated in semiconductor manufacturing

and industrial environments�

The SPM Flex gas detector, available in wall mounted and portable versions,

locally displays gas concentration, alarm, fault and status information via its backlit

color LCD and LEDs� A simple to use 4-button keypad adjacent to the display

provides the ability to set-up, review, operate and make changes to the detector’s

configuration� The intuitive display and menu structure are designed to require

minimal training� The SPM Flex has a local audio alarm with user-configurable

output levels� The detector can be used both indoors and outdoors in a wide range

of weather conditions�

The detector has flexible power and communications capabilities� These include

3 on-board relays, 4-20 mA analog output and Modbus/TCP outputs for signal

and service connectivity� The gas detector is equipped with a USB port for

configuration-sharing firmware updates and data downloads� For web-enabled

devices, web pages are available via the Ethernet port�

tape-based optical gas

Standard operation conditions

The SPM Flex gas detector is designed for use in temperatures between 32ºF

and 104ºF (0ºC and 40ºC) and relative humidities between 0 and 100% (the

relative humidities are limited by tape and calibration)� The sample line will require

additional hardware to remove moisture in high relative humidity conditions where

condensing may occur (the sample must be non-condensing)� Dry conditions may

require humidification�

High-altitude applications

The SPM Flex pump is optimized for operation at altitudes between –1000 feet

(–305 meters) and 3000 ft� (945 m) above sea level� At altitudes above 3,000 ft�

(915 m), up to a maximum of 6,000 ft� (1,830 m), contact Honeywell Analytics for

calibration� (At 6,000 feet, pump capacity is reduced 18% and a flow-system

adjustment to the bypass valve is required� This must be performed by a Honeywell

Analytics certified technician� Contact Customer Service�)

5

Page 6

SPM Flex Gas Detector

DANGER

!

Safety Information

Danger notices contain information that could prevent death or serious injury�

!

WARNING

Warnings contain information that could prevent injury or equipment damage�

!

CAUTION

Caution notices contain information that could prevent equipment damage�

NOTE

Notes contain helpful information�

6

Page 7

Contact Information

Find out more:

www�honeywellanalytics�com

Americas

Honeywell Analytics

405 Barclay Boulevard

Lincolnshire, IL 60069

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8208

detectgas@honeywell�com

Europe, Middle East, and Africa

Life Safety Distribution AG

Javastrasse 2

8604 Hegnau

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

gasdetection@honeywell�com

SPM Flex Gas Detector

Asia Pacic

Honeywell Analytics Asia Pacic Co., Ltd.

#701 Kolon Science Valley (1)

43 Digital-Ro 34-Gil, Guro-Gu

Seoul, 152-729

Korea

Tel: +82 2 6909 0321

VOIP: +8 5401 0321

analytics�ap@honeywell�com

Technical Services

ha�global�service@honeywell�com

www�honeywell�com

7

Page 8

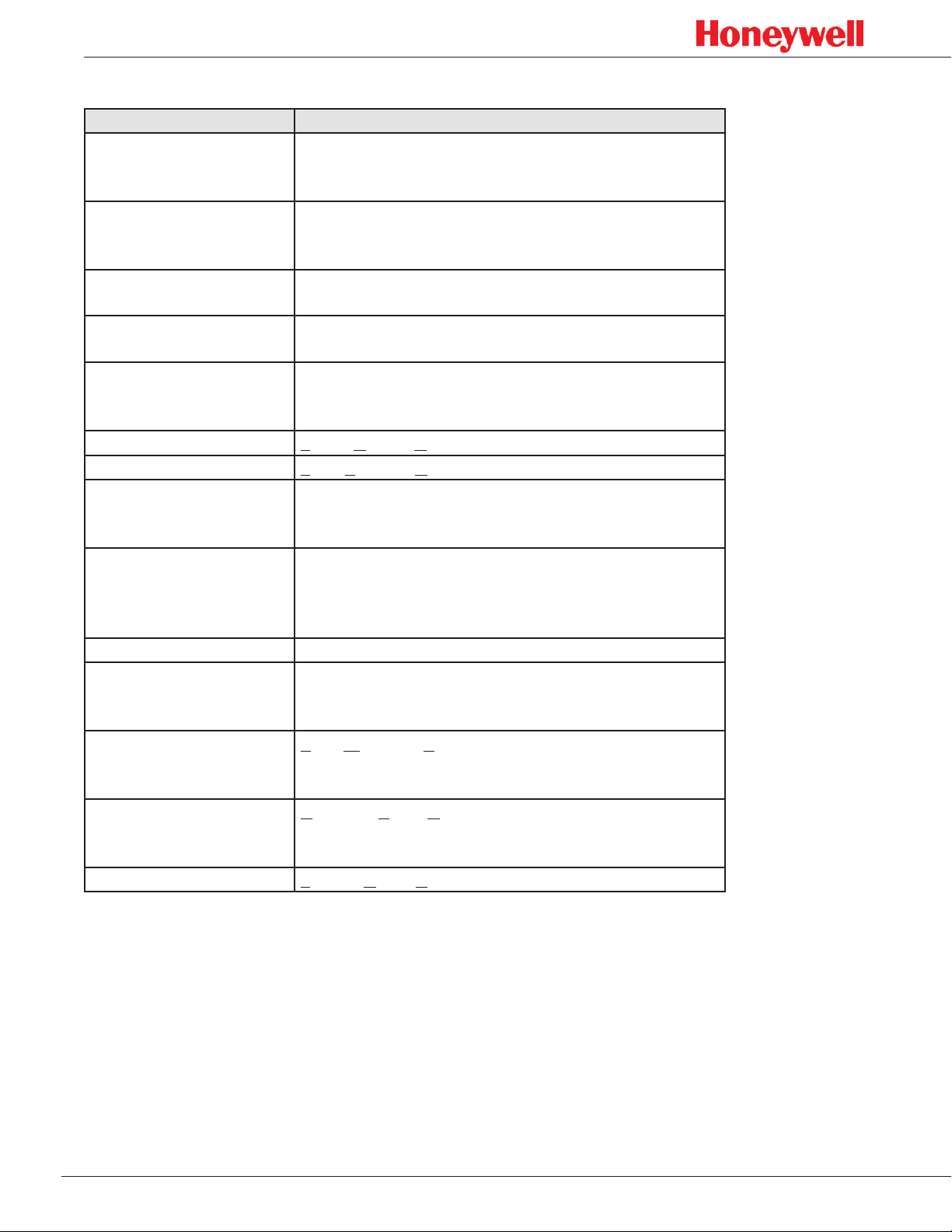

SPM Flex Gas Detector

Glossary

Term Description

An analog communication method using a current

4-20 mA loop

®

Chemcassette

Ethernet

In monitor

Latching alarm or fault

LCD

LED

Modbus TCP

Non-latching alarm or

fault

Out of monitor The detector is on but idle

Relay

TWA

USB

VDC

cartridge

loop to indicate concentration readings and fault

status�

An easy-to-install case that carries Honeywell’s

Chemcassette tape� Cartridges are specific to

different gas types/families�

Commonly used network technology for wired Local

Area Networks�

The unit is actively monitoring the specified gas or

family of gases

When configured, the SPM Flex will hold the alarm or

fault status active until the user performs an alarm/

fault reset�

Liquid Crystal Display

Light Emitting Diode

Communications protocol running over Ethernet that

is commonly used for communicating with industrial

devices�

An alert in which the SPM Flex will reset

automatically when the condition is no longer

present (i�e�, the detector does not have to be reset

by the user)�

An electrical-operation output switch that can be

used to indicate the presence of alarm and fault

conditions�

Time Weighted Average, the average exposure to a

harmful gas, usually calculated over a period of eight

hours (a the typical workday)�

Universal Serial Bus is an industry standard

communications protocol and bus that is commonly

available on personal computers�

Volts of Direct Current

8

Page 9

SPM Flex Gas Detector

WARNING

!

Product Overview

The SPM Flex gas detector is available in two configurations, portable and fixed�

The portable model is equipped with a handle assembly and a shoulder strap�

The fixed unit is supplied with a mounting bracket� If replacing an old SPM

detector, a retrofit bracket is available (these are shown on pages 29 and 30)�

1

All units are supplied with a power adaptor

manual, and a printed quick start guide�

Operate and service the SPM Flex gas detector only as specified in this manual

and the accompanying quick start guide� Failure to do so may impair the

protection provided by the detector and may also void the warranty�

Initial setup

Prior to use, the detector requires some minimal setup:

• Unpack the unit (save the packaging to re-use for service requests)

• Read the quick start guide and this manual

• For most gases, install a filter at the unit or at the end of a sample line (see

the Detectable Gases table on page 60)

and cable, a CD containing the user

Portable detectors

• Connect the power adaptor (in a dry, indoor location)

• Charge for at least 4 hours (the detector can be used while being charged)

• Open the detector’s cover

• Remove the rocker switch cover

• Turn the rocker switch to the on position

• Replace the rocker switch cover

• Remove the paper optics card from the gate (save the card for later use)

• Install a chemcassette

• Configure the detector and begin to monitor (see pages 15-16 for basic

display usage)

• See detailed Operation (pages 34-45) and Optional accessories (pages 62-64)

1 FSP Group Model FSP135-AAAN rated 1 5.62A / 24V (UL Listed QQGQ (E190414))

9

Page 10

SPM Flex Gas Detector

Fixed detectors

• Install the wall-mount bracket and mount the detector to it (see pages 29-30)

• Wire in accordance with local electrical codes utilizing a trained electrician

(see pages 20-26)

• Input

• Honeywell-supplied power adaptor (indoor, dry location use only) or

• 24 VDC power supply

• Signal (as desired)

• 4-20 mA

• Relays

• Ethernet

• Open the detector’s cover

• Remove the rocker switch cover

• Turn the rocker switch to the on position

• Replace the rocker switch cover

• Remove the paper optics card from the gate (save the card for later use)

• Install a Chemcassette cartridge

• Configure the detector and begin to monitor (see pages 15-16 for basic display

usage)

• See detailed Operation (pages 34-45) and Optional accessories (pages 62-64)

Additional accessories

• External dust filters (required on inlet for most gases; see the Detectable Gases

table on page 60)

• Tubing

• Sampling wand

• Mating signal connectors for fixed installations

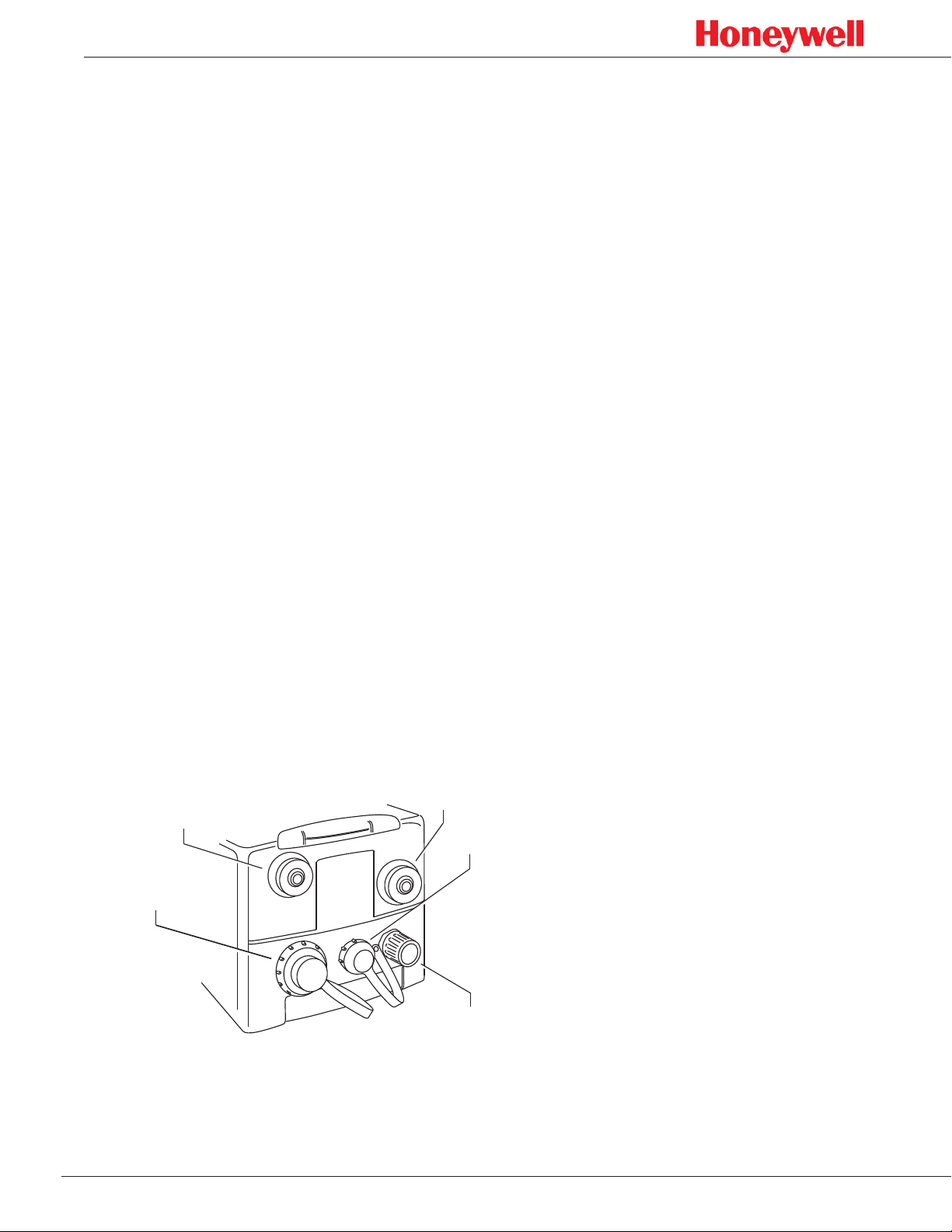

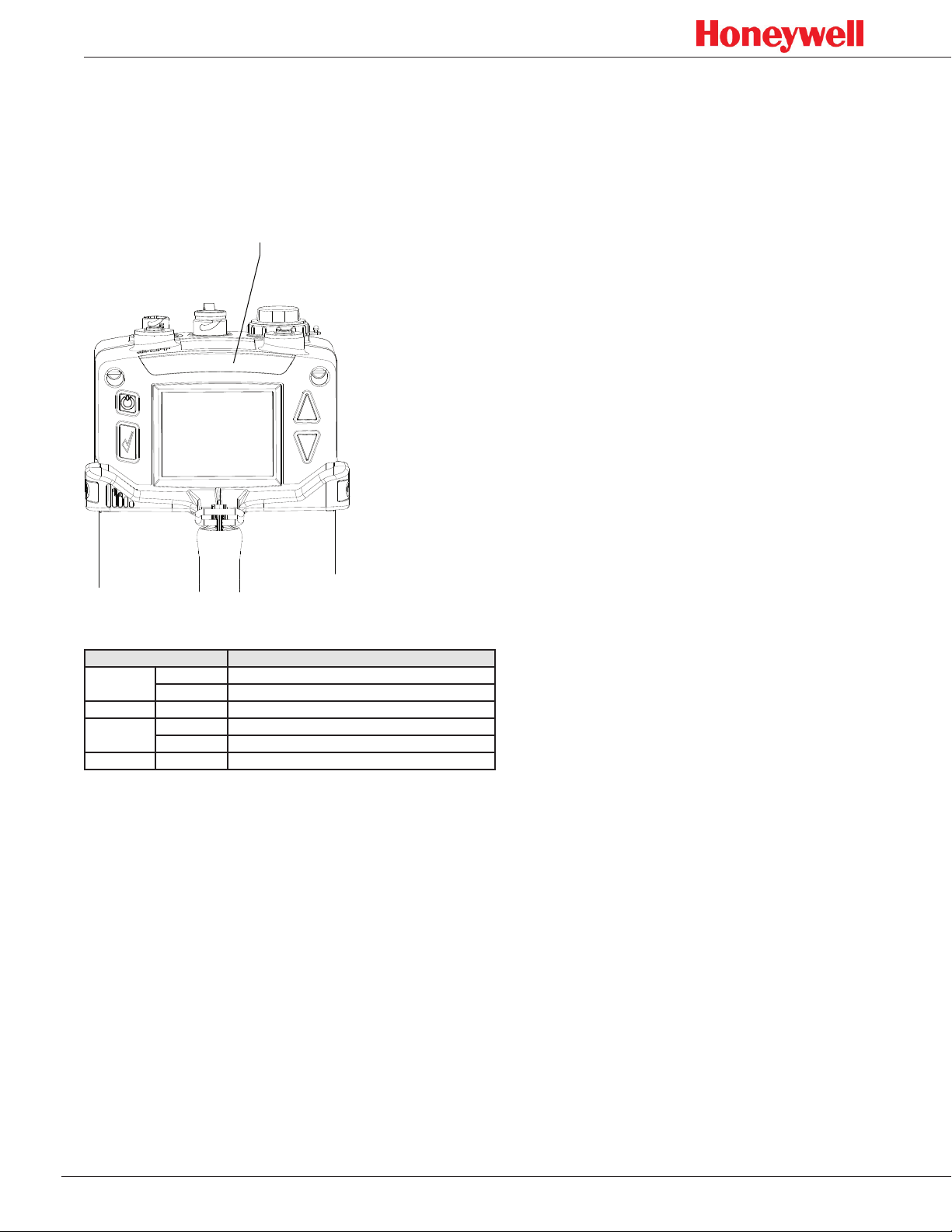

The connectors and ports of a typical installation are shown in the figure below�

Sample in port

Ethernet

connector

Exhaust out port

Power connector

Relays or 4-20 mA connector

Figure 1. Connectors and ports

10

Page 11

SPM Flex Gas Detector

Battery operation

The SPM Flex gas detector is supplied with a power supply/charger than can

connect the detector’s power connection and a standard wall outlet� (Ensure that

the correct power cable has been ordered for local operation�) The power supply/

charger is designed for indoor, dry-location use only� The lithium-ion battery pack

provides continuous operation of 6+ hours, depending on sampling conditions

and unit configuration� The battery’s charge time is typically 4 hours� The

detector can be operated while its battery is being charged (this may increase

the charge time)� Because batteries discharge slowly when not in use, Honeywell

Analytics recommends keeping the detector connected to the power supply/

charger when not in use�

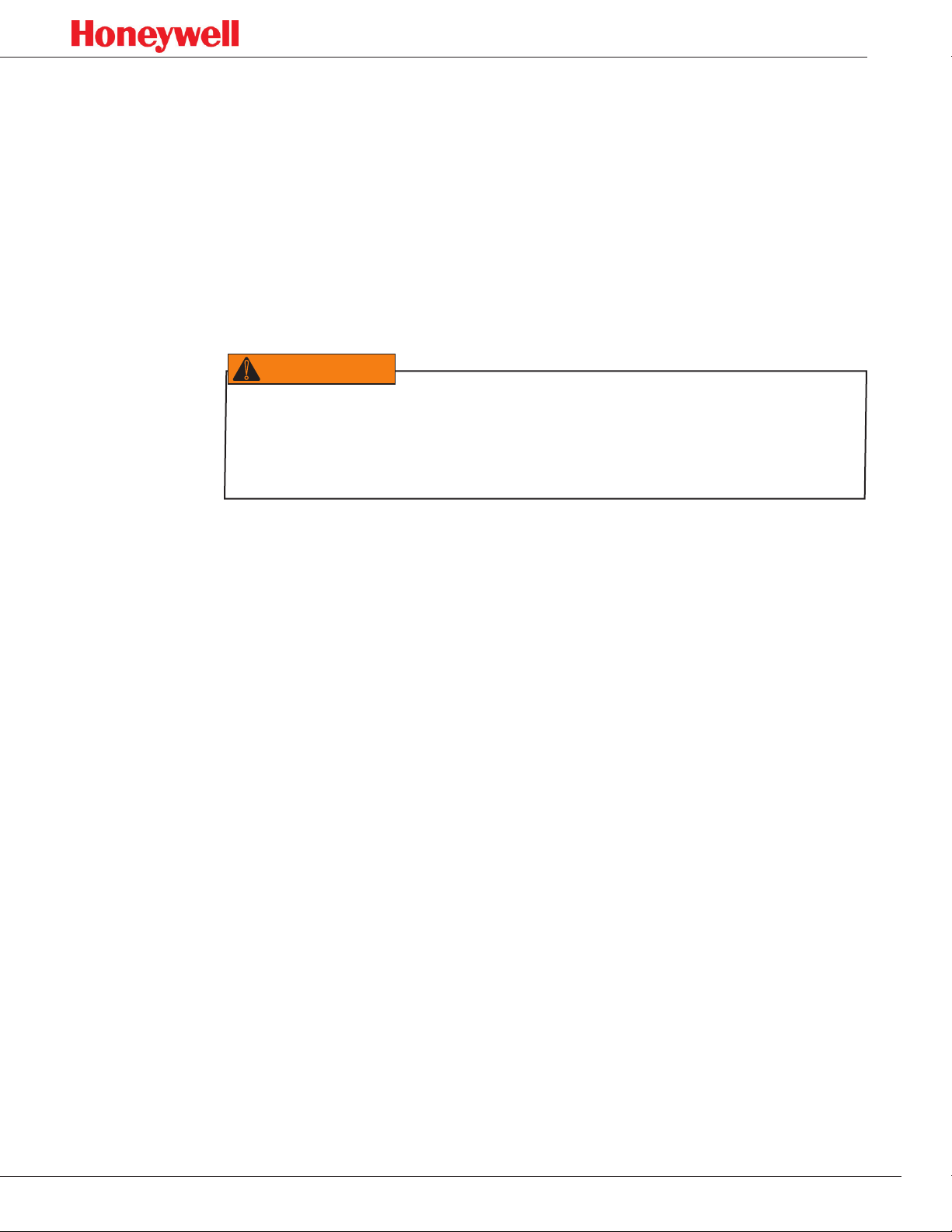

!

WARNING

• The battery is not field-replaceable� Return the unit to Honeywell Analytics if

a battery replacement is necessary�

• Risk of fire and burns� Do not open, crush, heat above 140ºF (60ºC), or

incinerate the battery� Follow manufacturer’s instructions�

How to extend battery life

Power consumption is optimized to extend battery life when not in monitor

mode� In addition, the unit should not be exposed to extreme temperatures

which shortens battery life� The time before recharging is required can be

extended by taking the detector out of monitor mode when it is not in use�

How to recharge an overly-discharged battery

If the battery indicates 0% charge and does not appear to be charging when

plugged into the power supply, it may be overly discharged� Follow these steps:

1� Verify that the latest software has been installed� The detector’s software

version can be found by navigating to the

menu� If necessary, the current software can be downloaded from the SPM

Flex section of the Honeywell Analytics website (see page 7)� Install the

new software from a USB flash drive by following the prompts in the

Program

2� Turn the detector off and then power it up again� This will reinitiate the

charging circuit� Initially (until the battery reaches the normal charge range),

the detector will slow charge� The process can take 6 hours�

option on the

Maintenance

Software

menu�

option on the

Review

Update

11

Page 12

SPM Flex Gas Detector

The handle (portable model)

The detector can be conveniently carried with the optional handle, which is

mounted onto the cover at three locations� If necessary, the handle can be

removed by the user by removing two bolts� All of the detector’s functions

can be performed with the handle attached� The handle swings out of the

way for access to the Chemcassette cartridge area�

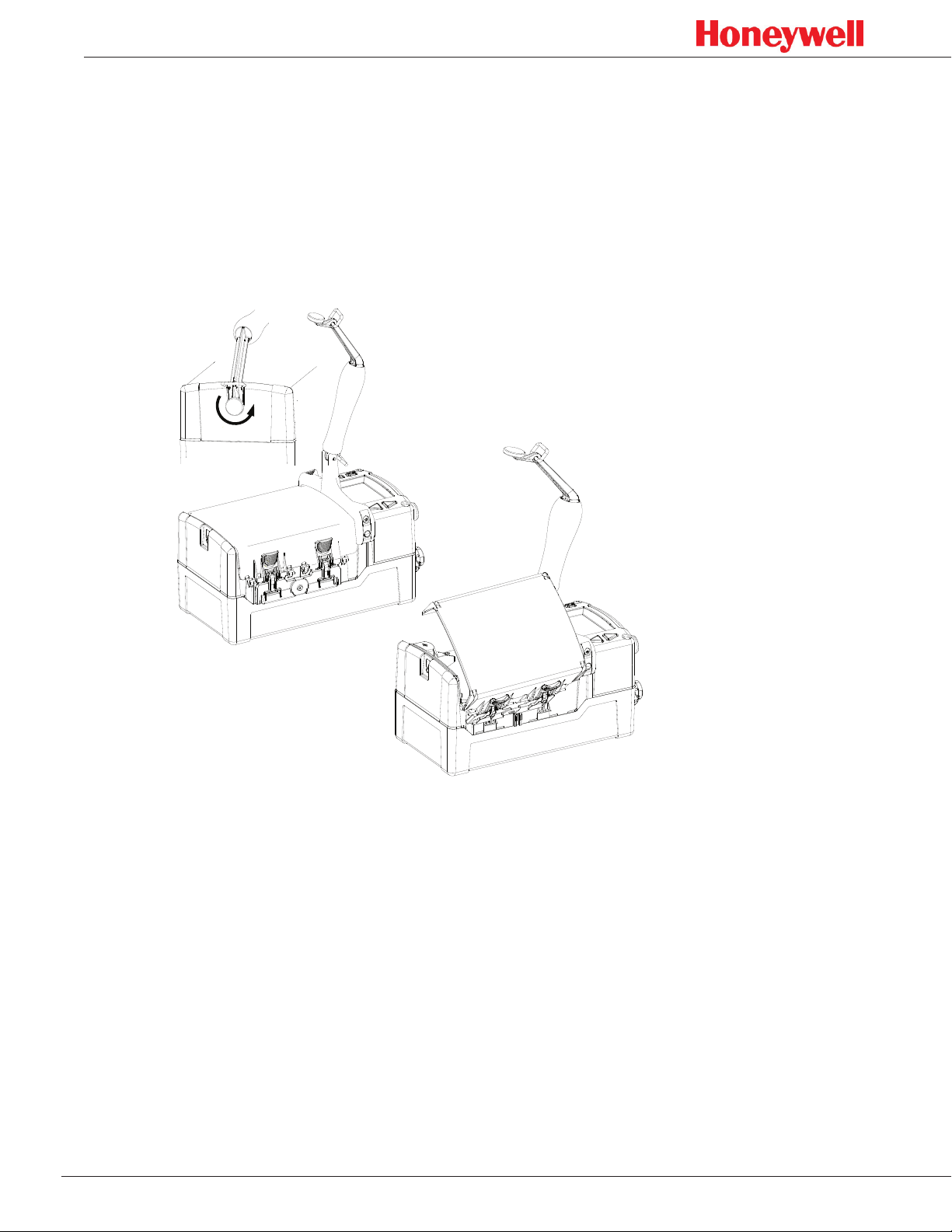

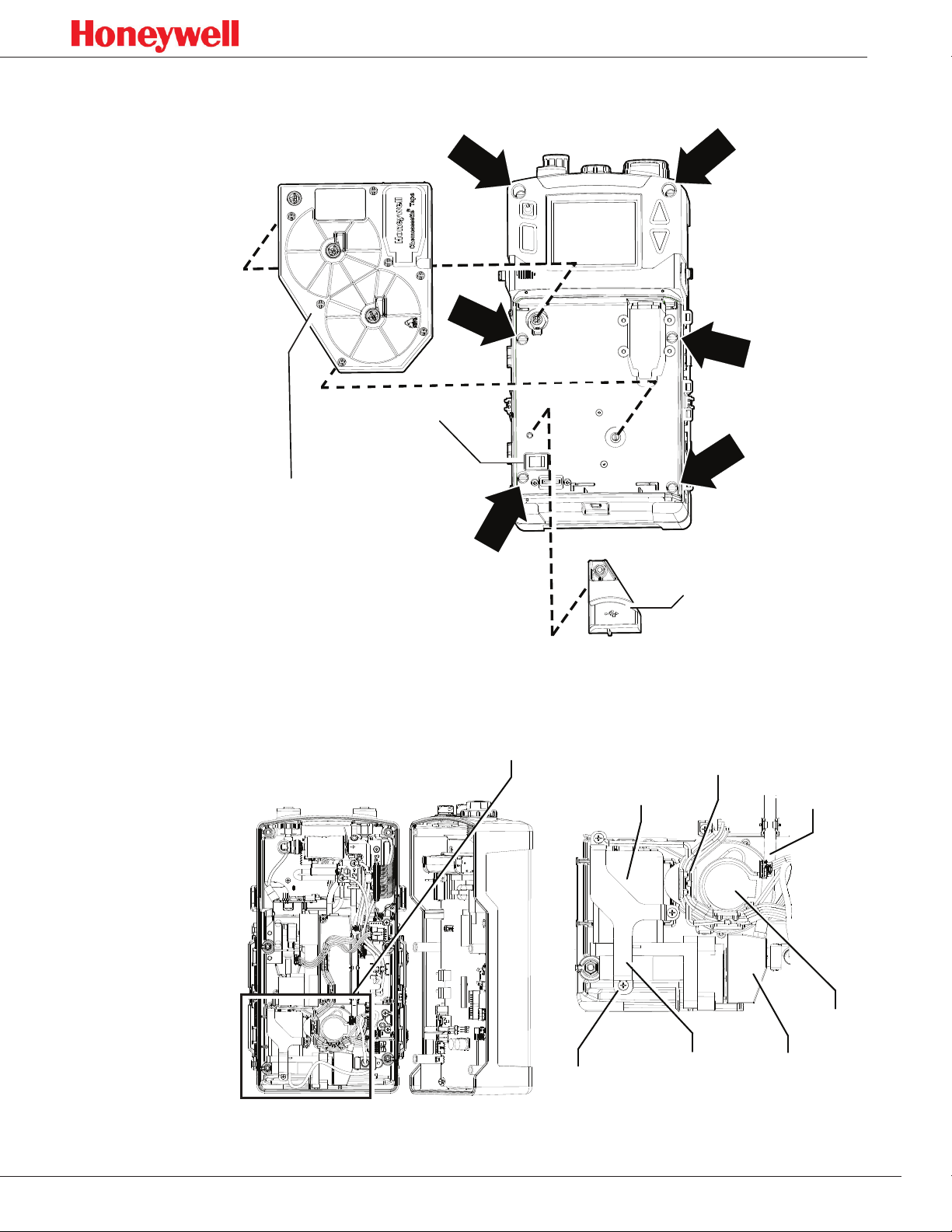

Opening the cover

Figure 2. Opening the detector cover

Release the cover by first unscrewing the handle pin� Pivot the handle up as

shown in the illustration and push down the four latches (two on each side)�

The detector cover will then be free to swing open, allowing a Chemcassette

cartridge to be inserted or replaced, the power switch to be turned on or off,

or the USB data port to be accessed�

12

Page 13

Main power rocker switch

SPM Flex Gas Detector

Rocker switch cover

Main power rocker switch

Figure 3. SPM Flex main power rocker switch

After the detector’s cover is open, use a Phillips screwdriver to remove the

rocker switch cover� Turn the main power rocker switch to the on position and

replace the rocker switch cover�

The detector can now be turned on�

13

Page 14

SPM Flex Gas Detector

Turning the detector on and off

Press and hold the Power/Cancel button until the green LED begins blinking�

The detector will begin a startup sequence that lasts about 30 seconds�

The four LEDs provide at-a-glance information about the current state of the

detector:

LEDs (red, green, yellow, blue)

Figure 4. SPM Flex LEDs

LED Description

Red

Green blinking The detector is active

Yellow

Blue solid Connected to external power

solid Alarm 1

blinking Alarm 2

solid Maintenance fault

blinking Instrument fault

To turn the detector off, press and hold the Power/Cancel button for 5

seconds or select “Power Off” from the menu�

14

Page 15

Navigation

SPM Flex Gas Detector

Display

Power/Cancel

Accept/Select

Figure 5. SPM Flex controls

Up arrow

Down arrow

All SPM Flex menus are navigated by the four buttons shown in Figure 5�

Pressing either of the arrows or the Accept/Select button will access the

menu from the main display screen� The arrows also are used to scroll up and

down through lists of options� The Accept/Select button is used to initiate a

highlighted option� During navigation, the Power/Cancel button will cancel a

command or, when pressed for more than 3 seconds, it will exit to the main

display�

15

Page 16

SPM Flex Gas Detector

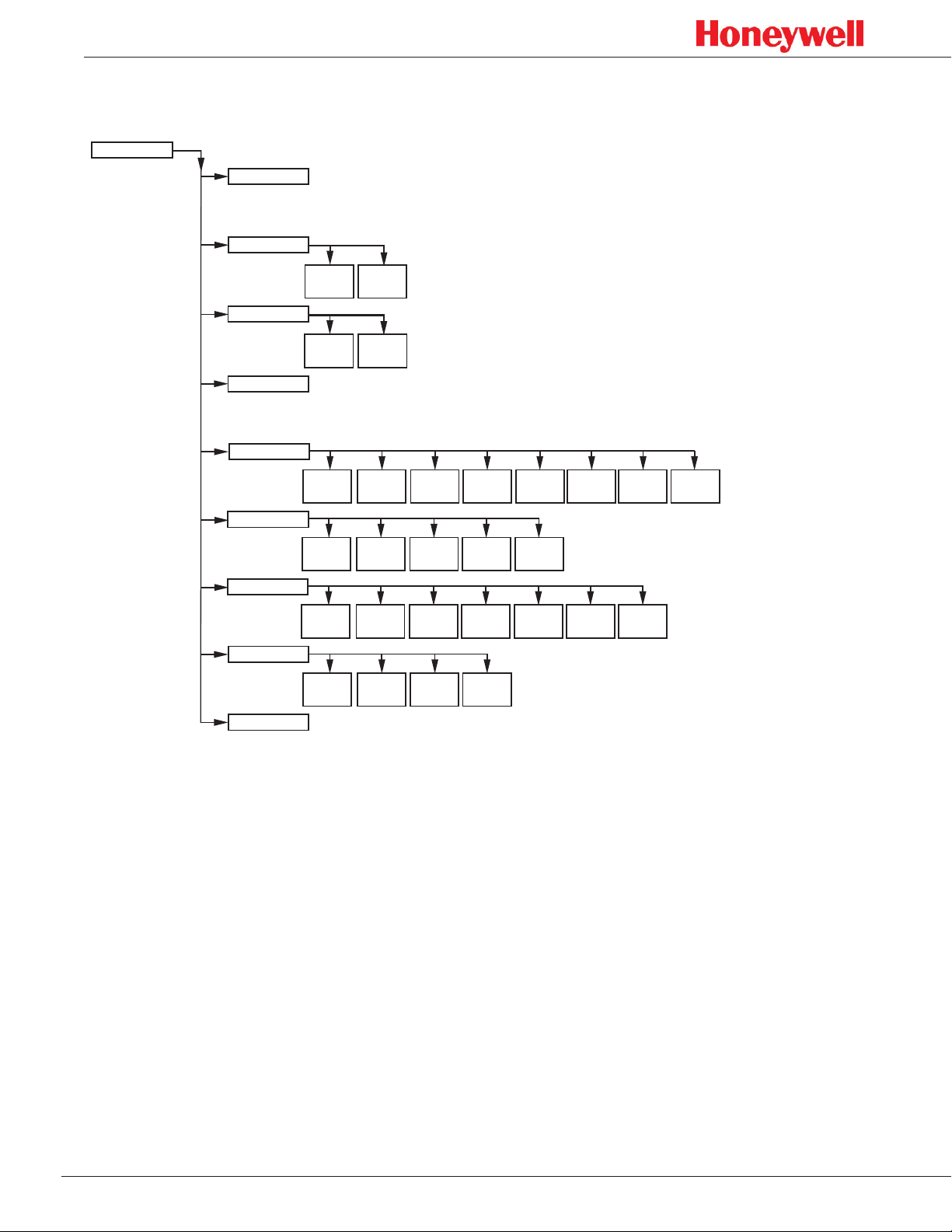

Menu Map

Main Menu

Login/Logout

Reset Alarms & Faults

Monitor Mode

Change Chemcassette

Review Mode

Maintenance

Setup

Test

Power Off

Reset all

Enter

monitor mode

Event

History

Inhibit

General

Optics

Verification

Silence

audio alarm

Out of

monitor mode

Chem-

cassette

4-20 mA

Current Loop

Calibration

Monitoring Latching

Simulation

Settings

Flow Char-

acterization

Force

Relay

Gas

Gate

Force

Additional

Status

Update

Program

Network

Open/Close

Outputs Network

4-20 mA

Output

State

Security

Trend/Plot

Configuration

Manager

Software

The SPM Flex detector’s menus are easily navigated� As an example, this is

how a user could review the detector’s gas settings when starting from the In

Monitor screen:

1� Press the Up Arrow to open the Main Menu�

2� Press the Down Arrow 4 times to highlight the Review Mode option�

3� Press the Accept/Select button to enter Review Mode�

4� Press the Up Arrow or Down Arrow until the Gas settings option is

highlighted�

5� Press the Accept/Select button to display the Gas Summary�

To return to the detector to the In Monitor display, press the Power/Cancel

button three times to back out of the Main Menu options�

16

Page 17

SPM Flex Gas Detector

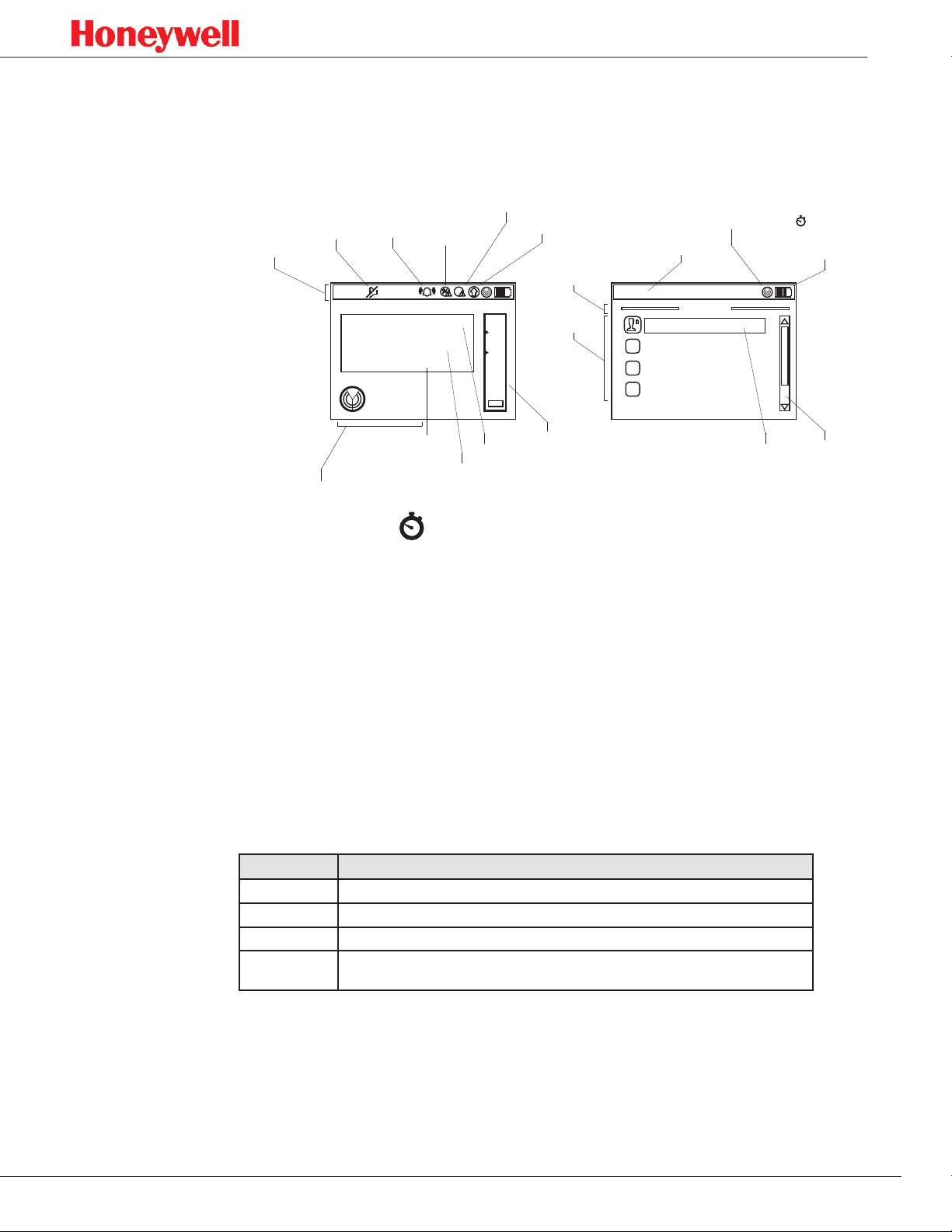

The display

Figure 6 shows the elements of the display that will be seen in various

situations�

Status bar

Mute

Alarm 1/

Alarm 2/

Inhibit

indicator

Instrument

Maintenance

Fault

Fault

Concentration

trend

indicator

Menu

Monitor mode indicator

or

Duty cycle indicator:

Clock

Battery indicator

title

15:

42:

01

0

123

.

-

H2S

Hydrogen Sulfide

In monitor

Gas name

Gas concentration

2

Menu

ppm

5.678

1.234

options

Bar graph

Units

w/upper, lower

alarm limits

42:

01

15:

Login / Logout

Reset alarms/faults

Monitor mode

Change Chemcassette

Main menu

Highlighted

Scroll bar

option

Monitor mode indicator

or

Duty cycle waiting state:

01:59

min sec

Figure 6. Elements of typical SPM Flex detector displays

The bar graph on the right shows the current concentration relative to the Alarm

1 and Alarm 2 setpoints� (The bar’s range is relative to the alarm levels, not to

the full scale of the selected gas)�

The color of the status bar changes according to the system status (green =

OK/in monitor, yellow = fault, red = alarm, blue = Out of Monitor mode)�

Display and navigation

Under normal operation the LCD and LED display system status, gas

concentrations, and alarms� In set-up, review, calibration, and test modes, the

LCD shows the relevant menu options and system status bar� The interface is

navigated using the four buttons:

Control Function

Up arrow Scroll up through lists of options

Down arrow Scroll down through lists of options

Accept/Select Accept or select a highlighted option

Power/Cancel

In the main display mode, the display shows the current gas name and

concentration, the monitoring states and faults and/or alarm status, if

applicable�

Power/Cancel will turn the unit on if it’s in the off state, will exit back to the previous menu level, and will

enter Reset mode (quick press), or Power Off mode (long press and hold) from the main display.

17

Page 18

SPM Flex Gas Detector

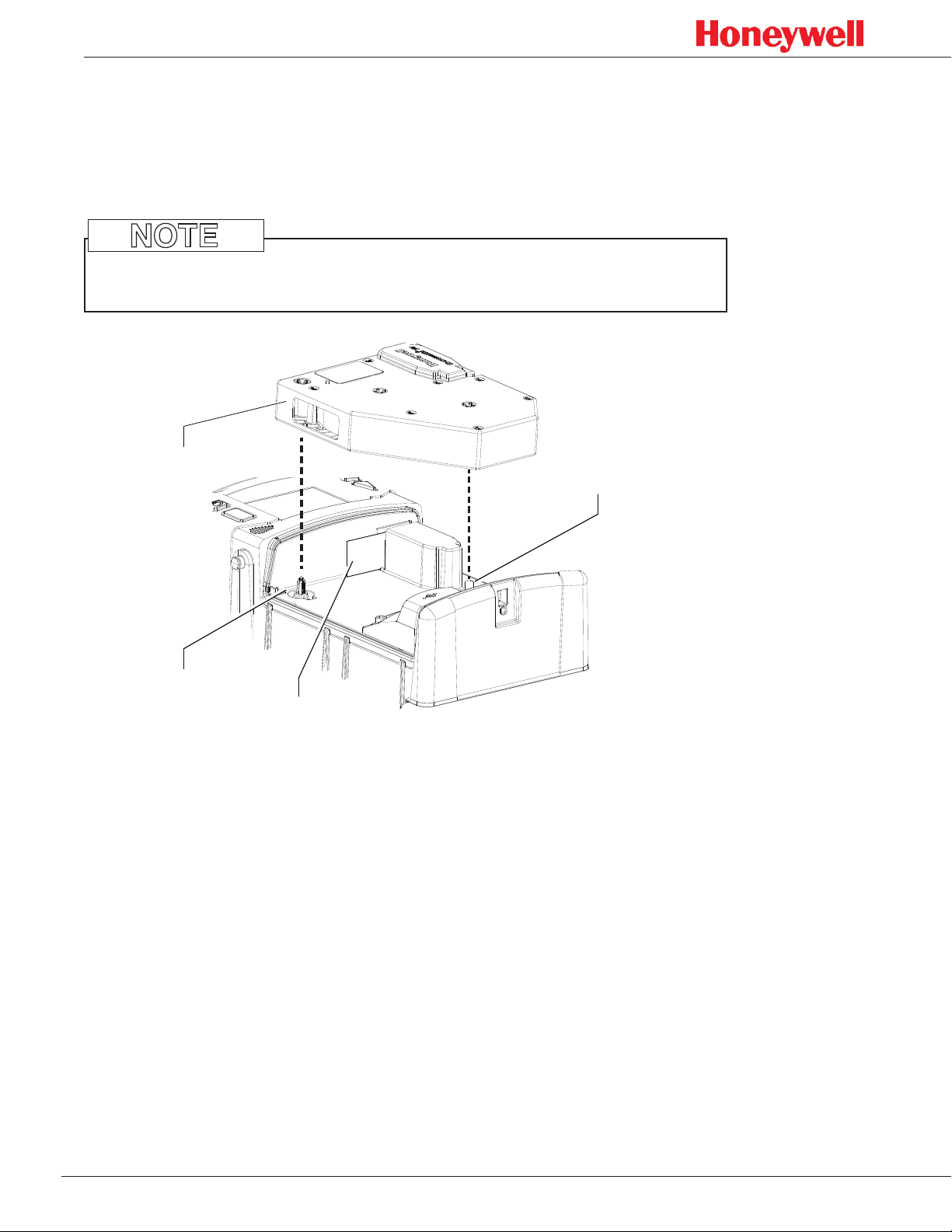

Installing a Chemcassette cartridge

Close the Chemcassette cartridge door before putting the detector into

Monitor mode (this holds the Chemcassette cartridge in place)� Take the

detector out of Monitor mode before opening the door�

NOTE

Chemcassette cartridges must be stored according to the manufacturer’s

guidelines when not in use�

Chemcassette

cartridge

Take-up spindle

Encoder

Optics gate card

Figure 7. The optics gate card and Chemcassette cartridge

1. If the detector’s handle is installed, release it by unscrewing the thumbscrew.

For fixed installations, skip to Step 3.

2. Tilt the handle up as far as possible.

3. Unfasten the latches on the sides of the detector (two on each side) that secure

the Chemcassette cartridge access cover.

4. The detector has slotted hinges. Lift up the cover slightly and then open it all

the way to the right.

5. Select the Change Chemcassette menu option and follow the on screen

instructions.

6. If required, remove the old Chemcassette cartridge. When prompted, snap the

new Chemcassette cartridge into place. It will t in only one orientation. The

take-up spindle will rotate slightly to allow the cartridge to snap into place.

7. To close the cover, position it over the base and press so that it contacts the

gasket uniformly.

8. Close the latches on the sides of the detector to secure the cover.

18

Page 19

SPM Flex Gas Detector

If there is an error (i�e�, the same cartridge was reinserted, the new cartridge

has expired, or an unqualified user is attempting to insert a cartridge that

detects a different gas than the last one), an error message will be displayed

and the installation will be canceled� If the installation is successful, a summary

of the current configuration will be displayed and the user can then choose

whether to enter Monitor Mode or exit the Change Chemcassette Mode out of

monitor�

Removing a Chemcassette cartridge

1. Navigate to Maintenance > Open/Close gate.

2. Select “Open Gate.”

3. Remove the cartridge.

4. Insert the optics gate card.

5. Select “Close Gate.”

Changing the target gas within a gas family

Refer to the Detectable Gases table on page 60 for details about gas families�

1. If necessary, install a Chemcassette cartridge.

2. While out of monitor mode, navigate to Set-up > Monitoring > Gas.

3. Select “Current gas” and pick the desired gas from the selection box

4. Select “Save.”

Selecting a target gas from a different gas family

Refer to the Detectable Gases table on page 60 for details about gas families�

1. Remove the Chemcassette cartridge.

2. Clean the tape-contact surfaces (see page 57).

3. Install the new Chemcassette cartridge.

4. Select the desired target gas from the menu.

Entering monitor mode

From the main menu, navigate to the “Monitor Mode” option and select “Enter

monitor mode�”

1. If a Chemcassette cartridge has been installed, the detector will enter Monitor

Mode.

2. If a Chemcassette cartridge has not been installed, a user with the necessary

passcode can inititate the Chemcassette wizard. Otherwise, the detector will not

enter monitor mode.

19

Page 20

SPM Flex Gas Detector

CAUTION

!

Wiring and tubing

Typical fixed installation topologies

The SPM Flex gas detector has flexible installation options that allow the

user to select the one most suitable for a specific application� The detector

is supplied with weather-sealed connectors for power, Ethernet, and

communications (for relays or 4-20 mA)� The Ethernet port can be replaced

with an appropriate connection in accordance with local codes (allowing

the user to wire directly to the terminal block)� Install each detector near a

dedicated circuit breaker�

• The safety of any system incorporating the SPM Flex gas detector is

the responsibility of the assembler of the system�

• Position a permanently-installed SPM Flex gas detector so that it does

not interfere with access to the dedicated circuit breaker�

• Use only the power adaptor described in the Specifications section

(see page 61)�

• Use the power adaptor only in indoor applications�

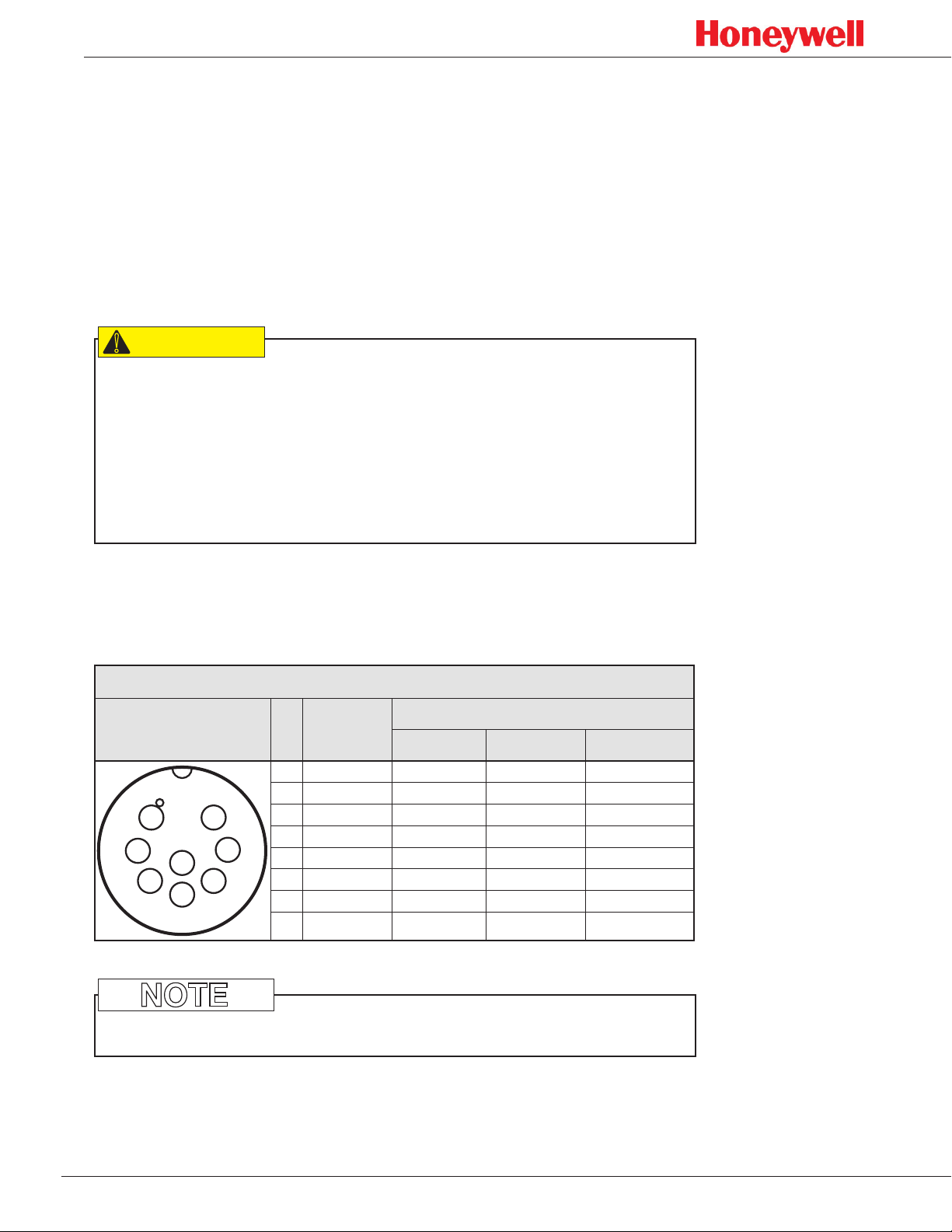

This table shows the default wiring configuration for the IP-rated

communication connector when installed by Honeywell Analytics� The relays

are labeled for the factory default but the configuration can be modified to

have a single alarm and separate faults�

Relay/mA Terminal Connections

Relay/mA Terminal Connections

Front View No. Color

mA Sink mA Source Isolated mA*

Alarm2 NO Alarm2 NO Alarm2 NO

Alarm2 COM Alarm2 COM Alarm2 COM

Alarm1 NO Alarm1 NO Alarm1 NO

Alarm1 COM Alarm1 COM Alarm1 COM

Fault NO Fault NO Fault NO

Fault COM Fault COM Fault COM

24 VDC + 4-20 mA - 4-20 mA -

4-20 mA + 24 VDC - 4-20 mA +

1

2

3

7

6

8

5

4

*default pin configuration

1 Red

2 Black

3 White

4 Green

5 Brown

6 Blue

7 Yellow

8 White/Black

Do not wire relays and 4-20 mA in the same wire bundle�

Electrical connection is made via conduit directly to ports or via the

connector (see Figure 1 on page 10)� The terminals used are suitable for

conductors of 20 to 14 AWG (0�8 to 1�6 mm dia�)�

20

NOTE

Page 21

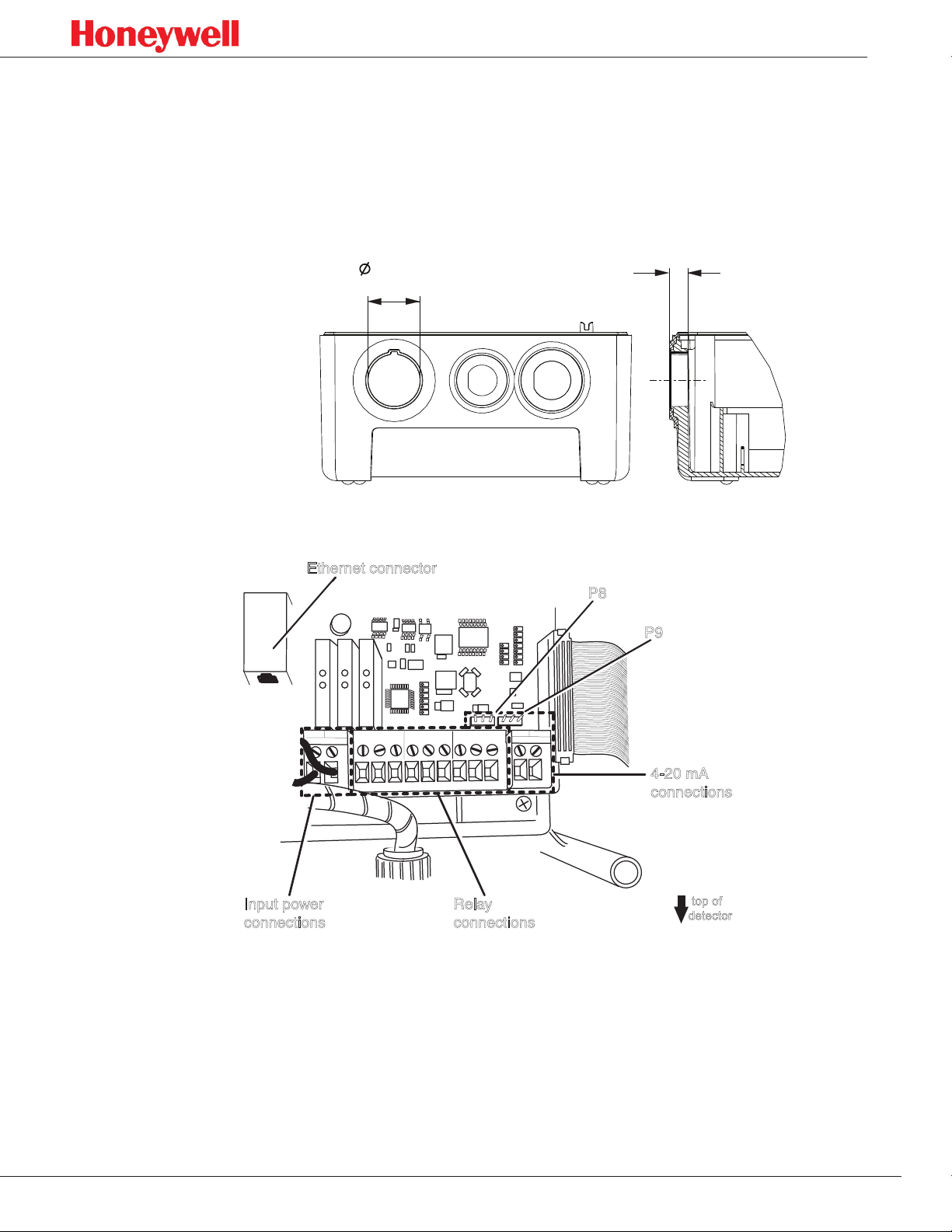

SPM Flex Gas Detector

The SPM Flex Ethernet connector is removable and can be replaced by

the customer with a suitable conduit connector� The opening dimensions

are shown in the following illustration� When selecting a conduit connector,

consider its ability to seal to the SPM Flex case, the depth of the thread

(enough to attach to case without interfering with internal components), and

adequate space for the intended wiring� The IP rating can be maintained only

with the original factory connectors�

1.068 in.

(27.13 cm)

Figure 8. Ethernet opening dimensions

Ethernet connector

0.386 in.

(9.81 cm)

P8

P9

+

24 VDC

-

Fault

Relay 2

NO

NC

COM

COM

Relay 1

NO

COM

NC

NC

+

-

4-20 mA

NO

4-20 mA

connections

Input power

connections

Relay

connections

top of

detector

Figure 9. SPM Flex connections

Terminal Module

The terminal module is located on the main PCB inside the gas detector� All

power, relay, and 4-20 mA connections to SPM Flex are made via this module�

Wire entry to the terminal module area is via the cable entry/conduit entry

located at the top of the detector�

21

Page 22

SPM Flex Gas Detector

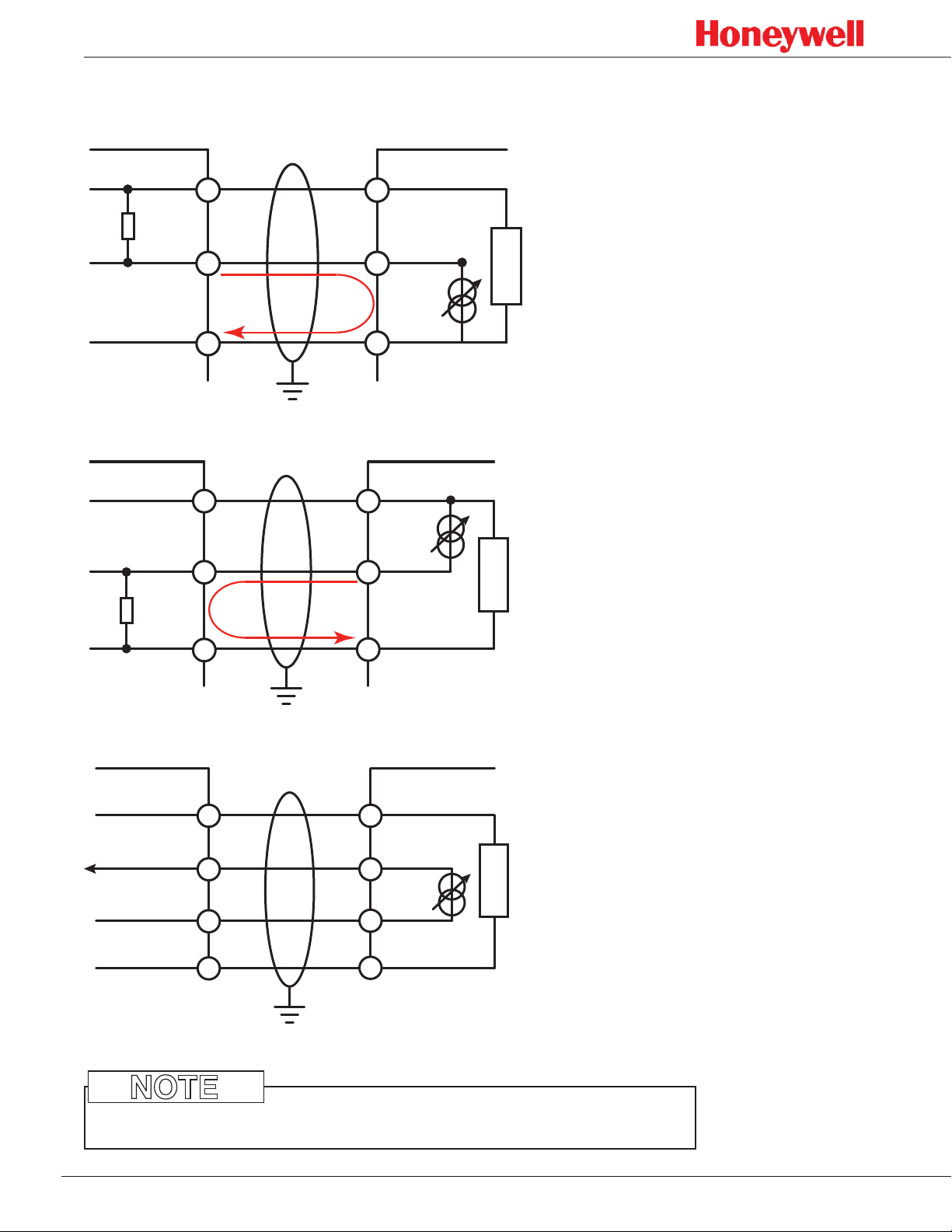

Wiring diagrams

Controller

R

L

Signal

Figure 10.

Controller

Signal

R

L

+VE

1

2

-VE

4-20 mA sink wiring diagram

+VE

-VE

3

1

2

Current

Flow

3

SPM Flex

24V+

4-20 mA+

Current

Flow

24V-

SPM Flex

24V+

4-20 mA -

24V-

Figure 11.

Controller

Figure 12.

4-20 mA source wiring diagram

+V1

+V2

-V2

-V1

4-20 mA isolated wiring diagra

SPM Flex

24V+

4-20 mA+

4-20 mA-

24V-

NOTE

Do not wire relays and 4-20 mA in the same wire bundle�

22

Page 23

SPM Flex Gas Detector

4-20 mA wiring

4-20 mA output is a three-wire connection that is configurable as sink, source,

or isolated (isolated is the default), as shown in these following figures� Use a

hex key to remove the wiring cover for access to the terminals� There must be a

200-600-ohm load on the 4-20 mA line�

To ensure adequate resolution to overcome tolerance in the 4-20 mA reading,

set the full scale at an appropriate level� The SPM Flex issues a fault if the

measured 4-20 mA reading is more than 0�8 mA (5% full scale) off from the

expected drive value�

jumpers

Figure 13. 4-20 mA sink conguration

jumpers

Figure 14. 4-20 mA source conguration

jumpers

Figure 15. 4-20 mA isolated conguration (the default)

23

Page 24

SPM Flex Gas Detector

Relays

The detector is equipped with three relays� Connect the unit as shown in this

figure�

+

24 VDC

-

COM

Fault

Terminals

Fault

NC

Relay 2

NO

COM

NC

Relay 2

Terminals

NO

COM

Relay 1

NC

NO

Relay 1

Terminals

+

4-20 mA

-

Figure 16. Relay conguration

The relays can be wired as normally closed or normally open� It can also be

configured as normally energized or normally de-energized via software�

NOTE

Do not wire relays and 4-20 mA in the same wire bundle�

By default, the relays are set to Alarm 1, Alarm 2, and Instrument Fault�

Modbus Q&A

Q: What is the byte order used, Little Endian or Big Endian ?

A: Honeywell uses Big Endian (Most Significant Byte first) for all data�

Q: The gas name is displayed in the register 40007-40011 – how are the bites

stored, since it is a text string?

A: First letter is MSB of 40007, second letter is LSB of 40007, third letter is

MSB of 40008, etc�

Q: In which bit sequence is register 40003 and 40004 stored?

A: Big Endian with 40003 being the first 2 bytes and 40004 the last 2 bytes�

Q: Is there an example how a REQUEST/RESPONSE section is processed?

A: It is a standard Read Holding Register command as described in the

MODBUS specification� (Modicon Modbus Protocol Reference Guide PI–

MBUS–300 Rev. J Function 3)�

Q: How fast/often (in seconds) is the Modbus register update sequence?

A: The fastest updates are once per second�

Q: What are the details of Modbus/IP configuration?

A: The IP configuration is the unit’s IP address, set (and enabled) in the

standard

of the unit�

configuration of the unit� The IP address is used for the address

24

Page 25

SPM Flex Gas Detector

Modbus register definitions

Register Address/Name Bits Description Values

0: No Inhibit

1: Inhibit Alarm

0-2 Inhibit State

3 Instrument Fault 1 = Active

4 Maintenance Fault 1 = Active

5-6 Alarm State

40001 System Status

40002 Lastest Active Fault Code

40003-40004 Reported Concentration 32 bit Float

40005-40006 Actual Concentration 32 bit Float

40007-40011 Gas Abbreviation

40012 Concentration Display Format

40013-40014 Gas Table LDL 32 bit Float

40015-40016 LAL 32 bit Float

40017-40018 TLV 32 bit Float

40019-40020 Fullscale 32 bit Float

40021 Unused

40022 Alarm Enable

40023-40024 Alarm 1 Setpoint 32 bit Float

40025-40026 Alarm 2 Setpoint 32 bit Float

40027-40028 User LDL 32 bit Float

40029-40030 4-20 mA Fullscale 32 bit Float

40031 Chemcassette Code 16 bit Integer

40032 Chemcassette Days Remaining 16 bit Integer

40033 Flow 16 bit Integer

40034 Battery Level 16 bit Integer

40039 Heartbeat Counter

7 Monitor State

8 Conc Over Fullscale 1 = True

9-10 Concentration Trend

11 Alarm 1 Simulation 1 = Active

12 Alarm 2 Simulation 1 = Active

13 Instr. Fault Simulation 1 = Active

14 Maint. Fault Simulation 1 = Active

15 Unused

16 bit Integer

(0 = No fault)

9 byte string

including

terminator

0-1 Units 0: PPB

2-3 Decimal Places 0, 1 or 2

4-15 Unused

0 Alarm 1 Enabled 1 = Enabled

1 Alarm 2 Enabled 1 = Enabled

2-15 Unused

16 bit Integer

(increments

once per

second)

2: Inhibit Fault

3: Inhibit Alarm & Fault

4: Inhibit All

0: No Alarm

1: Alarm 1

2: Alarm 2

0: Not Monitoring

1: Monitoring

0: Stable

1:Rising

2: Falling

1: PPM

25

Page 26

SPM Flex Gas Detector

CAUTION

!

Tubing (optional)

Sample and exhaust tubing calculations

This table shows the flow rate, tubing length, transport time, and maximum

pressure and vacuum at the inlet and exhaust points�

Allowable tubing lengths vary among gases (see the Detectable Gases table

on page 60)� If the pressure or vacuum on the inlet/exhaust lines does not

meet the recommended values, the detector may encounter flow faults� The

maximum total tubing length (inlet + outlet) is 100 ft� (30 m)�

Sample Specifications

Description Value

33 (10)

Inlet

Outlet

Tubing length, ft. (m)

Transport time (sec)

Flow rate (cc/min.)

Tubing OD. in. (mm)

Tubing ID, in. (mm)

Tubing length, ft. (m) 100 (30)

Tubing OD, in. (mm) 0.25 (6.35)

Tubing ID, in. (mm) 0.188 (4.76)

100 (30) 66 (20)

19 13

700-1200 (flow is set and controlled per calibration)

0.25 (6.35)

0.125 (3.18)

0

7

1

The overall maximum load on the pump between the inlet and the exhaust should not exceed 10 inches H2O.

NOTE

Use Teflon Fluorinated Ethylene Polymer (FEP) tubing to ensure proper

sample transport�

Do not operate the detector in a positive-pressure environment� Refer to

TechNote 1998-0195 R1 Sampling Point Guidelines.

26

Page 27

SPM Flex Gas Detector

An external filter must be installed on the detector’s “in” line for most gases

(see the Detectable Gases table on page 60)� Filters can be placed either at

the detector, for local monitoring, or at the end of the sampling line, for remote

monitoring� A filter can also be installed on the exhaust port to reduce noise�

filter

Figure 17. External lter

(arrow indicates

direction of flow)

Setup

Installation drawing

push

fittings

Figure 18. Installation drawing

27

Page 28

SPM Flex Gas Detector

Dimensions

13.2 in.

(33.6 cm)

9.5 in.

(24.1 cm)

6.4 in.

(16.3 cm)

12.3 in. (31.2 cm)

7.2 in.

(18.3 cm)

Figure 19. Dimensions of the SPM Flex Gas Detector

Mounting options

!

CAUTION

The SPM Flex detector must be installed only by qualified professional

personnel in accordance with local codes�

The SPM Flex gas detector has an optional mounting bracket assembly that

is easily affixed to a suitable vertical surface such as a wall, tool housing,

mounting plate on a pole etc�

Two mounting bracket options are available for fixed units: The standard

kit is for typical/new applications in which the detector is to be mounted

to, for example, a wall� A second option, a retrofit mounting, is a plate to be

used when replacing a Honeywell Analytics SPM detector with the SPM Flex

detector�

Mount the detector with at least two appropriate fasteners (e�g�, concrete screws

when mounting on concrete, etc�)� The fastener combination must be capable of

securely holding four times the detector’s weight, approximately 40 lbs (18�2 kg)�

When mounting the detector on sheetrock, the fasteners must be attached to

studs�

28

Page 29

SPM Flex Gas Detector

Standard mounting bracket

Figure 20 shows the detector’s standard mounting bracket�

12.5 in. (31.8 cm)

drilling holes:

10.2 in. (26.0 cm)

0.6 in. (1.6 cm)

6.3 in.

(15.9 cm)

Figure 20.

When installing the standard mounting bracket, use the bracket as a template

for determining the location of the holes to be drilled� Use 2 screws to secure

the bracket� See the Specifications section on page 61 for a description of

appropriate screws�

Standard mounting bracket

29

Page 30

SPM Flex Gas Detector

Backward-compatible mounting bracket

Figure 21 shows the detector’s backward-compatible mounting bracket (used

when replacing an SPM detector with an SPM Flex detector)�

13.0 in. (32.9 cm)

5.4 in.

(13.7 cm)

13.0 in. (33.0 cm)

0.4 in. (1.1 cm)

Figure 21. Backward-compatible mounting bracket

Use 4 screws when mounting the backward-compatible bracket in the

location of a current SPM installation� See the Specifications section on page

61 for a description of appropriate screws�

30

Page 31

SPM Flex Gas Detector

Sun shield

Figure 22 shows the sun shield for outdoor applications� The shield has three

sides, which protect the detector from the elements� It is designed to facilitate

convenient servicing of the detector� (The shield is not necessary for the

detector’s IP 65 rating�)

12.3 in.

31.2 cm

16.0 in.

40.6 cm

15.0 in.

38.1 cm

Figure 22. Sun shield

The detector, a standard bracket, and the sun shield can be mounted to a wall

using a minimum of 6 screws� If the backward-compatible mounting bracket is

used, at least 4 screws are necessary� When using either of the brackets, insert

the screws through the bracket, then through the inside of the sun shield, and

then into the wall� See the Specifications section on page 61 for a description of

the appropriate screws�

The optional sun shield can be used with either mounting plate�

31

Page 32

SPM Flex Gas Detector

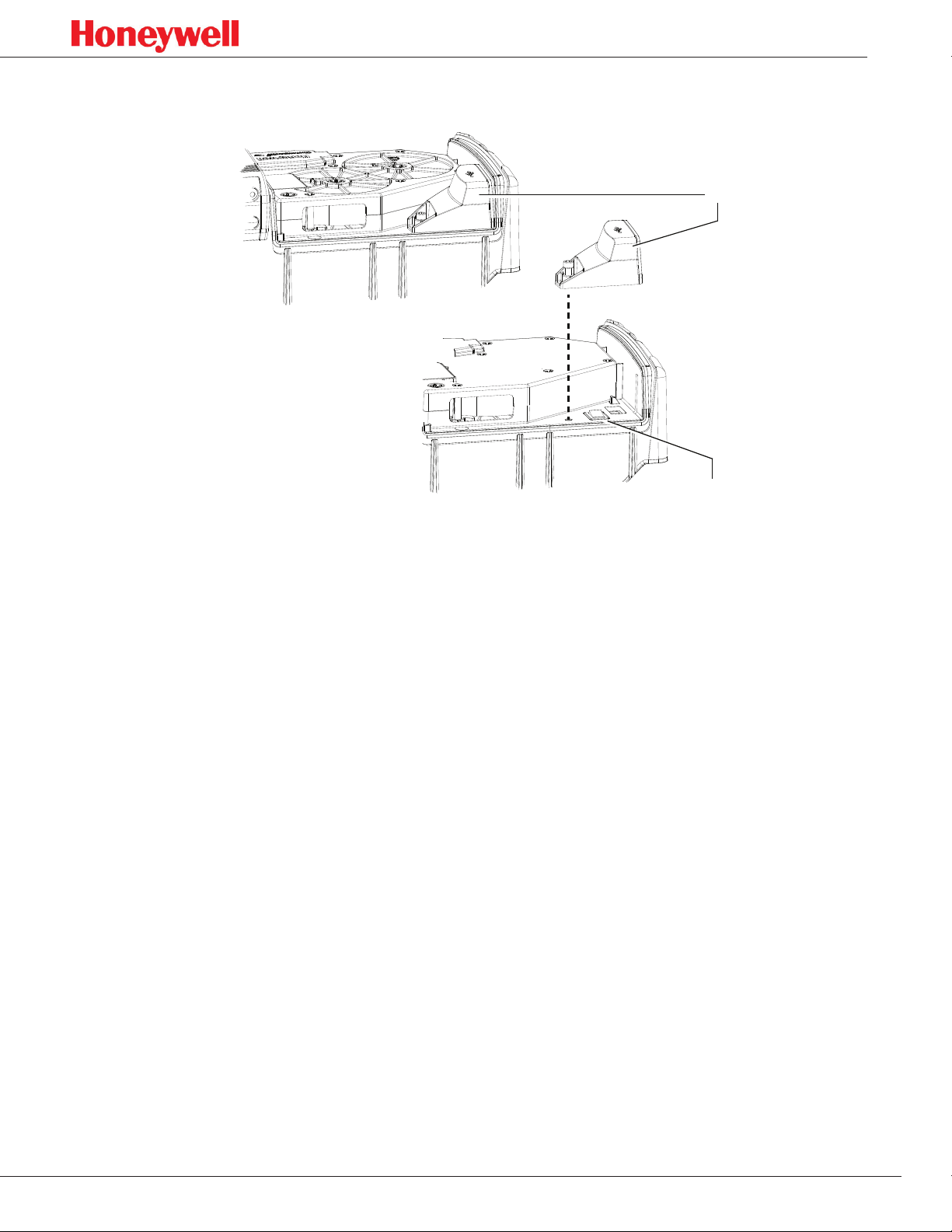

Converting a fixed detector into a portable unit

A fixed-installation SPM Flex gas detector can be converted for portable

applications following this procedure:

1. Remove the detector from its mounting bracket (see page 29 or 30).

Handle Shoulder

strap

ring (2)

Thumbscrew

Hex screw (2)

Detail

Snap-in

bracket

Hex

screw

Bracket

pin

2. Slide the handle into place as shown above.

3. Secure the snap-in bracket on the bracket pin with one of the 1/8-inch hex

screws, as shown in the detail illustration.

4. Repeat on the other side of the detector.

5. The handle is hinged to allow access to the Chemcassette cartridge

compartment. Lower the handle and secure it with the thumbscrew.

6. If the optional shoulder strap is to be used, attach its spring clips to each of

the rings on the detector’s handle. The strap must be laundered before use in

clean-room applications.

In-line filters

Use an external filter to protect the tubing and the detector from

contamination� Use particulate filter part number 780248 for non-corrosive

gases� Use filter 1991-0147 for corrosive gases� Refer to the Detectable

Gases table

3 to 6 months of operation, depending on the cleanliness of the installation

environment� Note that filters are not used with diisocyanates, hydrazine,

ozone, or hydrogen peroxide so regular maintenance cleaning is especially

important for detectors exposed to those gases�

on page 60 for specific gases� Filters should be replaced every

32

Page 33

SPM Flex Gas Detector

Optional sampling wand

The sampling wand is connected to the inlet port and used to detect toxic gas

2

at specific locations

from entering the unit� All gas-wet surfaces are either Teflon-coated or made of

Kynar to be compatible with sticky corrosive gases� An appropriate filter should

be used for the gas type being monitored� Refer to the Detectable Gases table

on page 60�

The sampling wand is supplied with the mounting bracket and required

hardware�

� An inlet filter is installed in the grip to prevent debris

filter

wand

back of

detector

bracket

Figure 23. Attaching the sampling wand bracket to the detector

filter

sampling wand

Figure 24. Wand with sampling lter

The sampling filter is replaced by unscrewing the halves of the wand’s grip� It

will fit in only one orientation�

2 Do not use the sampling wand with diisocyanates, hydrazine, ozone, or hydrogen peroxide.

33

Page 34

SPM Flex Gas Detector

WARNING

!

Operation

• Protection afforded by the SPM Flex gas detector may be impaired if it is

not used according to the manufacturer’s instructions�

• Operate two-way radios at least 18 inches (46 cm) from the detector�

• When the detector is in monitor mode and is moved between

environments with large differences in temperatures or humidity,

condensation on the optics may cause it to report a false low gas

concentration reading� Allow the unit to stabilize in the new environment

before monitoring gas levels�

Power

Before operation, verify that external power is present (the blue LED will

be on) or that the internal battery is charged� The physical power switch,

located under the Chemcassette access door, should be on� Typically, it

is recommended to leave the physical switch in the on position unless

transporting/shipping the unit where there is a possibility of the detector

accidentally being turned on with the soft power switch�

When the detector’s startup sequence ends, an “In Monitor,” or “Out of

Monitor” display, depending on how it is configured in the Setup menu�

The default startup mode can be configured under Power Options (Setup/

General)�

Most options will require acknowledgment (i�e�, pressing the Select button)�

Those that don’t will be displayed for 3 seconds� Pressing the Power button

briefly will return the user to the previous screen� Do not power up the

detector with a flash drive attached�

To turn the unit off, hold the Power button for 5 seconds while on the main

display� This will bring up the power off options� Alternately, the power off

mode can be accessed via the menu� The user must have the appropriate

security level to access�

The detector can be used intermittently as long as the Chemcassette

cartridge is removed and stored according to manufacturer’s guidelines�

34

Page 35

SPM Flex Gas Detector

CAUTION

!

Controls

The arrows are used to scroll up and down through lists of options, highlighting

one at a time� The select button is used to select a highlighted selection� During

operation, the power button will cancel a command or, when pressed for more

than 3 seconds, will display the main menu�

The Open/Close Gate function (see

open the gate and remove the cartridge for storage�

The detector provides tactile and visual feedback (clicks and the unit’s LCD

display) to all key presses� The display reflects key presses by illuminating

icons representing each of the buttons�

The blinking green LED indicates that the unit is on� The green LED blink

rate is faster during bootup� The yellow LED indicates a fault; it blinks during

instrument faults and is steady during maintenance faults� The red LED

indicates alarms; a steady light indicates an Alarm 1, a blinking LED indicates

and Alarm 2� The blue LED indicates that the unit is receiving external power�

The concentration level of the gas is displayed with the name of the gas below

the left side of the display and the units of concentration below its right side�

Maintenance

on page 50) can be used to

Do not leave the optics gate of fixed units open� Doing so may allow

pressurized gases to escape through the tubing into the unit and then into the

local environment�

Time

There is a real-time clock in the header bar� The real-time clock also verifies

that the detector is active�

Audible alarm

The alarm can be configured for high, medium, and low sound levels� The

sound can also be turned off� Low is approximately 75 dB at 1 meter (for

office/lab use), Medium is approximately 85 dB at 1 meter (for light industrial

use), and High is greater than 90 dB at 1 meter (for heavy industrial use)�

Monitoring icons

A round green icon in the lower left of the display indicates that the detector

is on and detecting� “In monitor” is shown next to the icon and the current

gas concentration is displayed� The icon changes to indicate that the detector

is out of monitor mode, or is in a fault or alarm state� Alarms and faults can

be present simultaneously (the alarm will supercede fault notification on the

main display and status bar color)� When the detector is not detecting, “Out of

monitor” is displayed and 4 dashes are shown instead of a gas concentration�

When the detector is out of monitor mode, the status bar will change to blue�

When a gas concentration exceeds the limit, “Over limit” is displayed and the

gas concentration is preceded by the greater-than symbol (“>”)�

35

Page 36

SPM Flex Gas Detector

Battery

The detector’s battery level is indicated from 0 (fully discharged) to 100%

(fully charged)� The battery icon displays the approximate battery level on

the status bar, while a more accurate value can be found in the Review mode

under Additional Status� If the battery’s charge is too low for safe operation,

a “Critically low battery!” message will be displayed and the detector will turn

off�

Bar graph

The bar graph displays the concentration reading up to double the Alarm

2 value for the gas being monitored� The Alarm 1 and Alarm 2 values are

indicated numerically on the bar graph�

The display can be configured for different backlight and dimming options�

By default the backlight will dim after a few minutes of no activity� The display

can be configured to turn off the backlight entirely after a set period of time�

Inhibit

When the detector is in inhibit mode, it will show a bell icon with a red slash

through it�

1. Use the [Up] or [Down] buttons to select the “Inhibit” on the Maintenance

menu.

2. Press the [Accept] button.

3. The Inhibit Type menu or the Time Out menu can then be selected. Possible

inhibit types are none, alarms only, faults only, alarms and faults, and all,

as shown in the following table). The Time Out options (the time until the

detector exits inhibit mode and returns to active monitoring) are from 1 to 60

minutes.

4. To take the unit out of inhibit, select “None” from the Inhibit Type menu and

press the [Accept] button twice to return to the Maintenance menu.

NOTE

If the inhibit times out before the inhibit state is returned to “none,”

maintenance fault code M17 will be displayed�

36

Page 37

Inhibit Modes

SPM Flex Gas Detector

Parameter

Concentration > Full

Scale

Concentration Above

Alarm Threshold

1

Inhibit -

None

Over-range

Level

Concentration

Level

Inhibit -

Alarms

Only

Over-range

Level

Concentration

Level

Inhibit

- Faults

Only

Over-range

Level

Concentration

Level

Inhibit -

Alarms &

Faults

Over-range

Level

Concentration

Level

Inhibit -

Inhibit Level

Inhibit Level

Instrument Fault < 1 mA < 1 mA #N/A #N/A #N/A

Non-Zero Concentration

Maintenance Fault

Simulated Instrument

4-20 mA Operation

Fault

Simulated Maintenance

Fault

Concentration

Level

Maint Fault

Level

< 1 mA < 1 mA #N/A #N/A #N/A

Maint Fault

Level

Concentration

Level

Maint Fault

Level

Maint Fault

Level

Concentration

Level

Concentration

Level

#N/A #N/A #N/A

#N/A #N/A #N/A

Inhibit Level

Zero Concentration 4 mA Inhibit Level Inhibit Level Inhibit Level Inhibit Level

Out Of Monitor 4 mA Inhibit Level Inhibit Level Inhibit Level Inhibit Level

Red LED Yes Ye s Yes Yes Ye s

Yellow LED Yes Yes Ye s Ye s Yes

Alarm 1 Relay Ye s No Ye s No No

Alarm 2 Relay Ye s No Ye s No No

Any Alarm Relay Yes No Yes No No

Maintenance Fault Relay Ye s Yes No No No

Instrument Fault Relay Yes Ye s No No No

2

Any Fault Relay Ye s Ye s No No No

Buzzer Yes

Yes

3

Yes

4

No No

LCD - Alarm Yes Ye s Yes Yes Yes

LCD - Fault Ye s Ye s Ye s Ye s Yes

LCD - Concentration Yes Yes Ye s Ye s Yes

Other I/O Behavior

Web - Alarm Yes Ye s Yes Yes Ye s

Web - Fault Yes Yes Ye s Ye s Yes

Web - Concentration Yes Ye s Yes Yes Ye s

MODBUS/TCP - Alarm Yes No Yes No No

MODBUS/TCP - Fault Ye s Yes No No No

MODBUS/TCP Concentration

Yes Ye s Yes Yes No

Event History Yes Ye s Yes Yes Ye s

1

Conditions are listed with the highest priority at the top� The 4-20 mA output will take the state of the highest priority

applicable condition that is present�

2

Yes = operates normally

Yes with conditions = active only under some conditions

No = not active

3

For real and simulated faults only

4

For real and simulated alarms only

All

37

Page 38

SPM Flex Gas Detector

Review menu

Event History

The detector’s history can be reviewed from the Review menu� It can be

searched by event (alarms, faults, alarms and faults, or all events) or by a

range of dates� The results of a search can be displayed as a list of events�

Results of searches can be sorted by oldest event first or most recent event

first� An event can be highlighted and selected with the check button to get

extended details about the event, including the data field� The results can

also be exported to a USB flash drive to be accessed by another device such

as a PC�

The web interface can also be used to view and export events�

USB port

Figure 25. Locations of the USB port and on/off rocker switch

NOTE

FAT32 is the default file system of the SPM Flex detector� The detector does

not read or write NTFS disks�

38

Page 39

SPM Flex Gas Detector

WARNING

!

Chemcassette

The Chemcassette review screen displays the Chemcassette type, its serial

number, expiration date, and the days remaining before it must be changed�

The expiration date of the ChemCassette when viewed in Review Mode

is based on the date it was installed in the gas detector� (The date on the

Chemcassette’s label is for a properly-stored Chemcassette cartridge in its

sealed package�)

Gas Settings

The gas being detected, its abbreviation, the CAS number, the LDL, the full

scale, the Alarms 1 and 2 setpoints, and the 4-20 mA full scale can be seen on

the Gas Settings review screen�

Network

The Network Summary option displays the IP address, the Subnet mask, the

Gateway, and the MAC address�

Additional Status

The flow rate of the gas, the battery level, and the pump drive can be found on

the Additional Status Summary screen�

Output State

The detector’s relay assignment (i�e�, Alarm 1, Alarm 2, or Instrument Fault), the

current relay states (e�g�, off, off, on), the current mA output (driven value and

measured value), and the current inhibit state are displayed in the Output State

Summary�

Trend/Plot

The Trend/Plot review screen shows the date, time, and time range selection�

A trend plot over the specified time range can be displayed� The data can be

exported to a flash drive via the USB port as a csv file�

Software

The Software summary screen displays the number of the current version

numbers of the software, the user interface, the gas detection algorithm, the

optics algorithm, and the RFID algorithm�

Calibration, set-up, and test modes are intended for use by trained personnel or

service engineers only� Access to these modes can be passcode protected�

39

Page 40

SPM Flex Gas Detector

Maintenance menu

Inhibit

Alarms or alarms and faults can be inhibited from the Maintenance menu�

The timeout period (the length of time before inhibit mode is exited and

monitoring resumes) can also be configured here� The range is 1 to 60

minutes� The default timeout period is 30 minutes� A timeout period of 0

minutes means that the feature is disabled�

4-20 mA current loop calibration

This feature allows the detector’s output to match an external monitoring

device�

Flow characterization

Flow characterization is an optional function� When utilized, it allows a flow

system to be optimized with a certain type of Chemcassette cartridge� This

allows the SPM Flex detector to quickly reach the correct flow rate�

Open/close gate

The gate can be opened and closed manually (from the Maintenance menu)�

For intermittent use, this allows Chemcassette cartridges to be conveniently

removed and stored�

Update program

Through the

USB port�

Update program

option, the new firmware can be loaded via the

Factory service mode

For Honeywell Analytics service personnel only�

Setup menu

Many of the functions of the SPM Flex detector can be configured from the

Setup menu�

General

The backlight intensity and timeout period are chosen from this menu as

well� The power-up options are chosen from this menu� The detector can

be programmed to be in monitoring mode or out of monitoring mode when

powered up� Out of monitoring mode is the default state� It can also be

programmed to power up in the state it was in when it was powered down�

Finally, if languages other than English are loaded in the detector’s software,

the language can be chosen from the General menu�

40

Page 41

SPM Flex Gas Detector

The unit IDs, either short (up to 20 characters) or long (up to 35 characters) and

an idle timeout period of from 1 to 60 minutes (20 minutes default) can also be

entered from the General menu� An idle timeout period of 0 minutes will disable

the idle timeout function�

Monitoring

The available gases are displayed and can be selected from the Gas menu�

Alarms 1 and 2 can be enabled or disabled and their respective setpoints can be

adjusted� The LDL can also be enabled or disabled and user-defined LDL limits

can be entered� The minimum and maximum values for the 4-20 mA full scale

can be entered�

The TWA mode can be set for either a fixed start time or a floating start time at

the TWA menu� The default is 08:00 but another time can be entered by the user�

In this case, the detector will calculate the second time (8 hours later) and third

time (16 hours later)�

Before storing the detector following a gas event, purge the flow system by

operating the detector in clean air until it returns to zero� If the case must be

wiped down, install push fittings in the Sample In/Out ports to prevent fluids

from entering the detector�

NOTE

The detector’s continuous monitoring algorithm enables a fast response and

high sensitivity� It also rapidly indicates trends� However, in some cases, this

algorithm can cause the decay time to be substantial, especially with gases

having slow stain development, specifically low level AsH3 and GeH4� In

the absence of gas, it may be necessary to continue monitoring for several

minutes before zero concentration is reported�

Latching

The SPM Flex detector’s alarms and faults can be either latching or nonlatching, depending on the settings on the Latching menu� The default for both

is latching�

Outputs

The detector’s display characteristics (e�g�, brightness, time to dim/time to off)

are set at the Display menu� The volume of the alarms (silent, low, medium,

or high) are chosen from the Audio menu options� Parameters set from the

Relays menu are relay assignments, that alarm relay’s normal state (energized

or de-energized), and the maintenance fault’s normal state (energized or deenergized)� Three parameters can be set from the 4-20 mA Levels menu: the

inhibit level from 1�5 mA to 3�5 mA (the default is 2�0 mA), the maintenance fault

level from 1�5 mA to 3�5 mA (the default is 3 mA), and the overrange level from

21�0 mA to 22�0 mA (the default is 21�5 mA)� The mA levels are adjusted in 0�5

mA increments�

41

Page 42

SPM Flex Gas Detector

Network

The Ethernet mode can be set for either auto or manual� The Modbus TCP

menu can also be enabled or disabled (disabled is the default)� To enable the

Ethernet connection:

1� Connect the Ethernet cable to the detector’s connector (see page 10)�

2� Navigate to Main Menu > Set up > Network > Ethernet > Accept�

3� Select Mode > Auto > Accept > Accept� (Alternatively, instead of following

the Auto setup procedure, Enter Select Mode and scroll down to manually

enter the IP address, Subnet mask, and Default Gateway�)

4. To return to the Main menu, press Cancel twice.

The IP address can be found at Main menu > Review > Network� Enter this

number in any browser to open the detector’s dedicated webpage:

Figure 26. Typical Ethernet web server screen

This web server screen displays details about the detector and its

Chemcassette cartridge� Faults and alarms can also be reset, a history of the

detector’s activity can be filtered and reviewed, and a graph of recent activity

can be created and exported�

NOTE

The web server is designed for no more than ten simultaneous connections�

(Responses will be slower with more connections�)

42

Page 43

SPM Flex Gas Detector

WARNING

!

Security

Follow local and site procedures when working with the SPM Flex gas

detector� If needed, ensure that the associated control panel is inhibited in

order to prevent false alarms� The following procedures must be followed

carefully and performed only by suitably trained personnel�

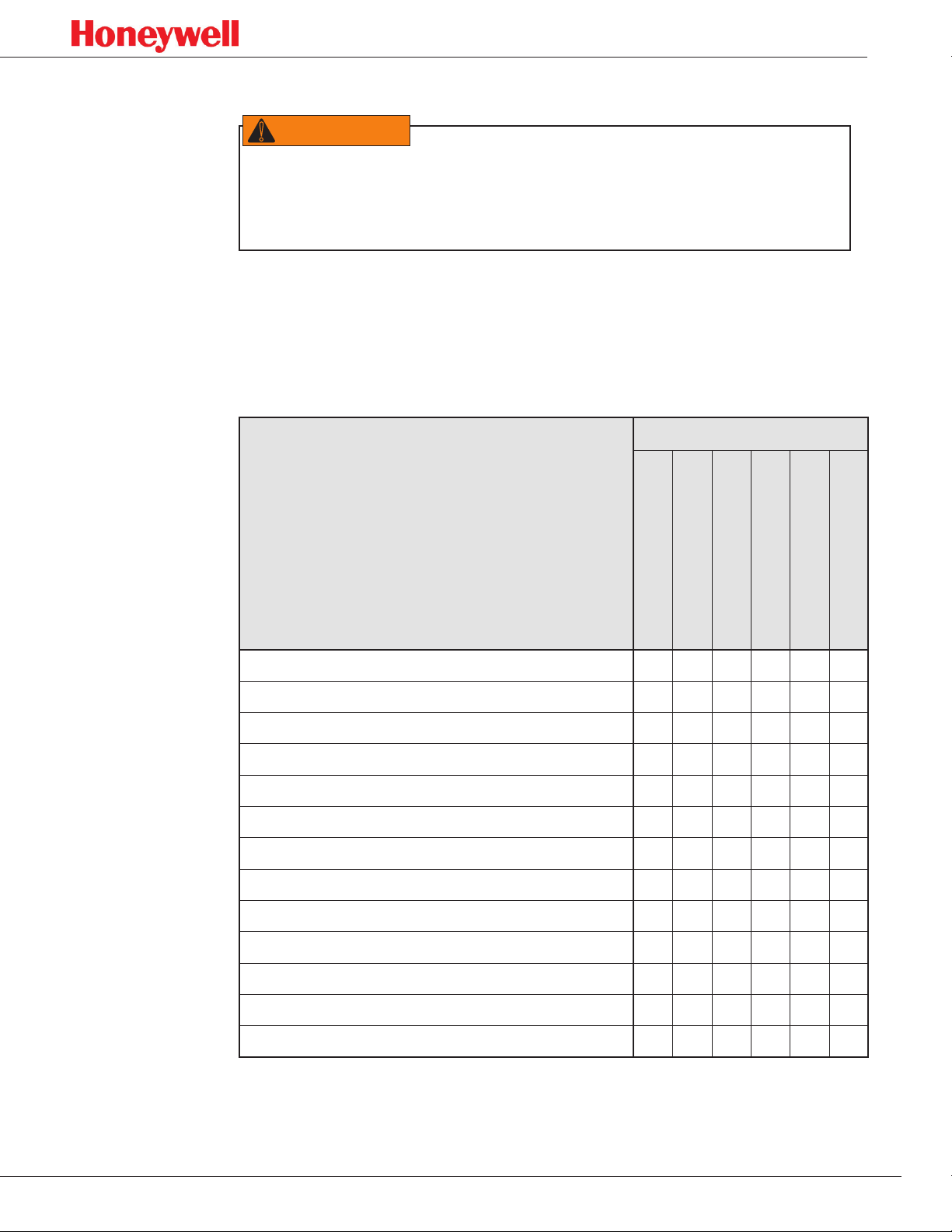

When enabled, the detector has five security levels, summarized in this table�

Passcodes are entered at the login menu beginning with the highest level

first (e�g�, set the 4 Admin passcode, then the 3 Power User passcode, then

the 2 Advanced Maintenance passcode, etc�)� Store the Admin passcode in a

secure location; if it is forgotten, the detector’s security can be reset only by a

Honeywell Analytics service technician�

Security Levels

Access Rights

Log in/log out

Reset alarms and faults

Review mode

Limited maintenance access

Change Chemcassette (to same type)

Testing

Maintenance

Limited setup

Full setup

Change Chemcassette (to any type)

Security

0 Not Logged In

1 Routine Maintneance

2 Advanced Maintneance

3 Power User

4 Admin

l l l l l l

l l l l l l

l l l l l l

l l l l l

l l l l l

l l l l

l l l l

l l l l

l l l

l l l

l l

5 Factory Service

Program update

Factory service menu (Honeywell personnel only)

l l

l

43

Page 44

SPM Flex Gas Detector

CAUTION

!

Configuration Manager

Access to options for up to five internal flash slots can be chosen from the

Configuration Manager menu� Information can also be imported to or exported

from the detector via the USB option�

Test menu

The detector’s optical system can be checked from the Optics Verification screen

(using the verification card�) Alarms 1 and 2, maintenance faults, and instrument

faults can be tested from the Simulate menu� The alarms and faults can also be

reset from the Simulate menu� The Force Relays and Force 4-20 mA options are

also available through the Test menu�

Power off

Select “Power off” to shut off the detector� Selecting this option has the same

effect as pressing and holding the power button for 5 seconds�

Duty cycle

This function allows the user to extend the duration of the tape advance interval�

This is useful in applications in which a background level of gas is expected in

normal operation� This interval can be configured for up to seventeen minutes�

When in monitor mode, if the detector reaches its maximum concentration for

that window, it will hold and display a countdown informing that it is waiting for

the duty cycle to expire�

The Duty Cycle menu can be found at Main menu > Set up > Monitoring > Duty

Cycle.

The detector does not monitor gas levels while the duty cycle is counting

down�

44

Page 45

SPM Flex Gas Detector

K-factor

K-factor is a feature that allows gases’ cross-sensitivity to be employed to

measure a target gas after calibrating the detector with a different gas� The

advantage for the user is that a small number of calibration gases can be used

to calibrate a detector for a wide range of target gases� The detector’s readings

are modified by the known relationship between the two� For example, a 5

ppm concentration of Gas A is seen by the detector as the same as a 5�8 ppm

concentration of Gas B� The K-factor is 1�2 (5�8 ÷ 5 = 1�16 = 1�2 when rounded

to one decimal place)� Therefore, the detector with a Gas A Chemcassette

cartridge can be used to accurately detect Gas B by multiplying the Gas A

reading by 1�2�

The feature can also be used to compensate for diluted samples� For example,

when reading a gas that has been diluted 5:1, the K-factor feature will will

enable the detector to yield a reading of the undiluted gas�

K-factor conversions are performed by the detector automatically� The K-factor

is at Main menu > Set up > Monitoring > Gas.

If desired, an alternative name can be assigned to the K-factor target gas� This

would be useful if, for example, a certain dilution of a gas was being detected�

With K-factor enabled, navigate to Setup > Monitoring > Gas > K-factor > Alt�

gas name > Edit� A name with up to eight characters can be entered from that

screen� Save the name by pressing the Accept button�

Stale tape feature

When a Chemcassette cartridge is installed, the detector reads information

about it, including the Allowable Days After First Use from its RFID tag (see the

Detectable Gases table on page 60)� By default, the detector will issue a Stale

Tape maintenance fault after that number of days� For situations in which the

cartridge will be used for a short period of time and then properly stored in its

Chemcassette cartridge bag, the user may turn off the maintenance fault� If

a cartridge is installed and in Monitor mode and then reaches the Stale Tape

date or the Expired Tape date, it will continue monitoring� (While the “CAUTION:

Chemcassette is XXX days past recommended use” screen is displayed, press

the Accept button to acknowledge the maintenance fault and continue using

the cartridge�) The cartridge can then be used past the Stale Tape date (but not

past the Expired Tape date)� A history event is created for all expiration faults�

45

Page 46

SPM Flex Gas Detector

Troubleshooting

Symptom Cause Corrective Action

No blue light

Detector does

not appear on the

network

No power to the detector

Incorrect network connection

Detector not configured

for the network

No external power (blue

light)

Turn the circuit breaker on

Check the power cable

Check cable connection to Ethernet port

System is for internal use only

Verify that network configuration is enabled

Use the “Auto���” setting

Check external connection

Check power supply is plugged in

Check circuit breaker

SPM Flex won’t

turn on

No display

SPM Flex is not on

Ethernet network

Cannot get Modbus TCP data over

network

Detector does not

communicate via

USB

Detector cannot

provide a 4-20 mA

output

Relay not activated

when unit states

that it has been

No date or time

Chemcassette

cartridge will not

install properly

Unit will not read

Chemcassette

Chemcassette

gate won’t open

Plug SPM Flex in to recharge the battery or use external power supply� Confirm that the

blue light is present in the LED status bar� If the battery pack is overly discharged the

Battery too low

Blue light present but

won’t turn on

Faulty connection Check ribbon cable is properly seated

Broken display or interface board

Unit is not powered on See section for turning unit on and troubleshooting power issues

Physical connection

issue

Incorrect configuration

Incorrect configuration

Faulty connection Check the connection

Faulty connection Check the cable connection

Faulty connection Check the cable connection

Real-time battery

expired

Shipping tab still in

place

Gate closed Use Change Chemcassette wizard to open gate and guide you through the process

Security lockout

Defective RFID chip Replace Chemcassette

Gate open command

not sent

Gate motor is broken Replace gate motor or contact HA

unit will not turn on unless plugged in to the external power� When fully discharged, the

battery pack will initially charge at a slower rate than normal until it reaches a minimum

voltage� Keep portable units plugged into the charger when not in use�

Check physical power switch (located in Chemcassette cartridge bay) is in the on position� Press and hold the on switch on the top left of the display until you see activity�

Replace display/interface board� Contact HA

Check correct CAT5 cable is used� Check cable is properly connected at both ends� Confirm network port is active�

If possible, use Auto detect configuration to automatically get IP configuration from network� Otherwise, check IP configuration is correct� Reboot�

Confirm network configuration for SPM Flex and target device� Confirm target device is

on the same network/subnet� Confirm SPM Flex IP address on Review/Network Summary�

Replace the real-time battery

Contact Honeywell Analytics

Confirm that the red shipping tab has been removed from the payout spool

Confirm you are logged in with an account with appropriate security level to change

Chemcassette cartridge

Use either Change Chemcassette wizard or Maintenance / Open/Close gate�

continued���

46

Page 47

Symptom Cause Corrective Action

Chemcassette

tape will not advance

Chemcassette

tape continues to

advance

Chemcassette gate will

not open

Cannot remove Chemcassette cartridge

Chemcasette cartridge

door will not latch closed

Pump will not turn on No power Check the cable connection

Cannot achieve target

flow rate

No power Check the cable connection

Encoder Check the cable connection

Hall effect sensor Check the cable connection

No power Check the cable connection

Gate open command not sent Use either Change Chemcassette wizard or Maintenance / Open/Close gate.

Make sure Chemcassette cartridge is fully seated.

Door is not properly closed or

aligned

Inlet or outlet tube is blocked Confirm inlet and outlet tube are free of restrictions or kinks, and that all filters are clean.

Gate is not sealing correctly

Pump is old Replace pump. Contact HA.

Filters are clogged Check filters (internal and external) and replace as needed

Make sure USB stick is not interfering with door.

Make sure door is fully seated on both sides – latches should hook under the tabs on the side of the case easily.

Make sure all four latches are properly secured.

Confirm Chemcassette cartridge is fully seated.

Exit and enter monitor to pull a fresh part of the tape.

SPM Flex Gas Detector

Tubing connections are not

properly seated

SPM Flex will not connect properly or stay on

mounting plate

Gas readings are not as

expected

Buzzer does not activate No power Check the cable connection

SPM Flex won’t turn off

SPM Flex unintentionally

turns on during transport

Detector will not charge Faulty connection Check the cable connection

Incorrectly installed mounting

plate

Mounting screws not installed Confirm the mounting screws have been installed on the back of the SPM Flex

Flow system issue

Chemcassette cartridge issue

Power button on top left / menu

option not available

Physical power switch is on,

unintentionally pushing power

switch by display

Confirm all tubing connections are properly seated (internal and external).

Make sure the mounting plate is installed the correct direction so that the mounting heads on the back of the SPM

Flex can slot in and slide down to secure.

Confirm all tubing connections are properly inserted.

Confirm correct filter type is used for the target gas. When in doubt use the corrosive filter.

Confirm target flow rate is achieved.

Confirm correct Chemcassette cartridge is selected for the target gas.

Confirm Chemcassette cartridge is within operating age, sampling conditions, and has been correctly stored.

If generating a gas bump test gas to confirm performance, refer to gas generation document located in the online

High Tech Technical Library.

Refer to individual Chemcassette type technical notes for specific performance information.

Ensure that user is logged in with the correct security level

Put the physical power switch located behind the Chemcassette door in the off position. Place switch back in the on

position when ready to use again.

*corrective actions vary with security levels

47

Page 48

SPM Flex Gas Detector

Instrument Fault/Maintenance Fault/Information Codes

Sub-

Type

type

101 Flow Failure Flow failure Flow, cc/min

103 Gate Motor Failure Gate timeout N/A

104 Tape Advance Failure Tape advance timeout N/A

105 High Background optics counts too low after multiple pulls N/A Tape issue Check, replace

106 Gas Table Invalid Gas table invalid error code CC RFID issue Replace, contact HA

107 Comm� Failure RFID� comm� fail to RFID reader N/A RFID PCB failure Replace

108 Chemcassette Read Failure RFID read failure N/A CC RFID issue Replace, contact HA

109 Temperature Too High overtemperature Temperature, C

110 Temperature Too Low undertemperature Temperature, C

Instrument Faults

111 Optics Error

112 Low Voltage Fault DC input voltage low voltage in Volts Faulty power circuit Contact HA

113 Chemcassette Expired

114 Optics Subsystem Fail no comm� to optics block N/A

115 Comm� Failure GD no comm� to GD N/A Main PCB failure Contact HA

117 NV Memory Corrupt CRC error code to which test failed� PCB failure Replace

118 mA Output Mismatch Feedback ADC mismatches DAC Error magnitude in mA�

119 Ethernet Fail Ethernet hardware in UI failed to initialize N/A

120 Battery Very Low Battery critically low, shutting down Battery level Low battery Charge unit

1 Flow Warning Flow is unregulated Flow, cc/min

2 Chemcassette Low Tape will run out in 24 hrs N/A Low tape Replace

3 Idle Timeout out of monitor too long N/A Out of monitor

4 Low Voltage Warning DC input voltage low voltage in Volts

5 Comm Failure SPI no SPI comm� to UI N/A Contact HA

6 File System Error File system error in NAND or USB� N/A Contact HA

7 Comm� Invalid GD Invalid SPI parameter data from GD� N/A Contact HA

8 Warn CC Expiring

9 Software Error catch all error code Contact HA

10 Optics Adjust Fail Calibration failure error code Calibration failure

Display

String

value of LED drive or reference detector signal

out of range

Now>LifeInBag+Mfg or

Now>LifeOutOfBag+FirstUse

A stored tape will expire in 7 days; if enabled,

the same fault will be issued for cartridges in

use�

Maintenance Faults

11 Flow Cal Fail Calibration failure error code Calibration failure

12 Inhibit Timeout Timed out N/A

13 Force mA Timeout Timed out N/A

14 Force Relay Timeout Timed out N/A

15 Battery Low Battery Low Battery level Battery is low Charge battery

Technical

Description

Meaning of

Parameter

N/A Optics PCB failure Replace

1�0 or 2�0 for two causes

N/A Old tape Replace

Probable

Cause

Pump failure

-Flow line obstruction

-Positive pressure

Gate motor failure

-Gate motor sensor

failure

Broken tape

-Tape drive motor

failure

-Encoder failure

Environment is