Page 1

Warnings and cautions

WARNING

!

CAUTION

!

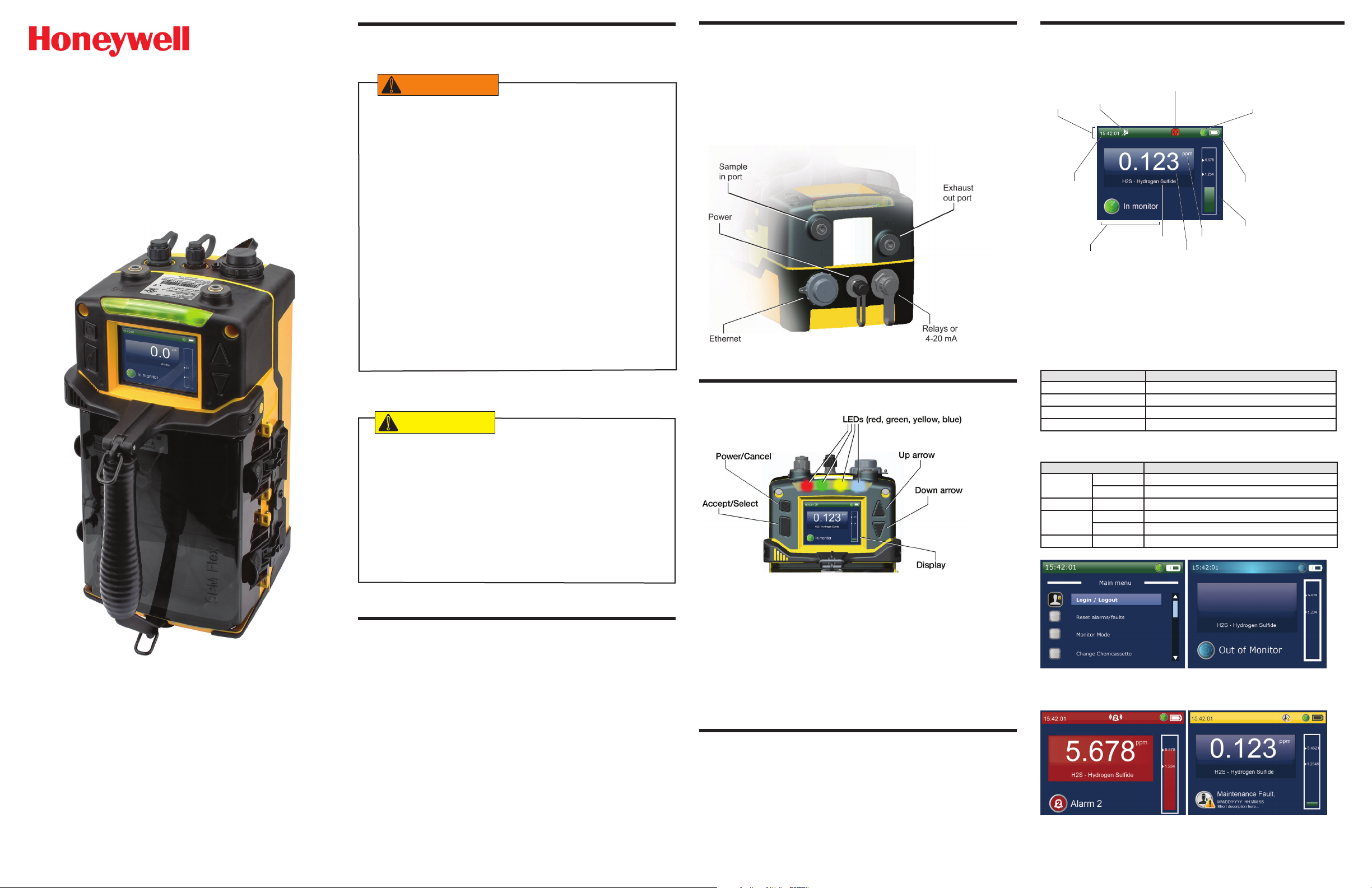

External connections

The display

SPM Flex® Single Point

Monitor Gas Detector

Quick Start Guide

• Operate and service the SPM Flex gas detector only as specied in this

quick start guide and the accompanying manual. Failure to do so may

impair the protection provided by the detector and may also void the

warranty.

• The battery is not eld-replaceable. Return the unit to Honeywell

Analytics if a battery replacement is necessary.

• Risk of re and burns. Do not open, crush, heat above 140ºF (60ºC), or

incinerate. Follow manufacturer’s instructions.

• Protection afforded by the SPM Flex gas detector may be impaired if it

is not used according to the manufacturer’s instructions.

• Do not operate two-way radios near the detector.

• Calibration, set-up, and test modes are intended for use by trained

personnel or service engineers only. Access to these modes can be

passcode protected.

• Follow local and site procedures when working with the SPM Flex

gas detector. If needed, ensure that the associated control panel is

inhibited in order to prevent false alarms. The following procedures

must be followed carefully and performed only by suitably trained

personnel.

• Use only accessories and parts meeting or exceeding Honeywell

Analytics’ specications.

• The SPM Flex detector must be installed only by qualied professional

personnel in accordance with local codes.

• The safety of any system incorporating the SPM Flex gas detector is

the responsibility of the assembler of the system.

• Position a permanently-installed SPM Flex gas detector so that it does

not interfere with access to the dedicated circuit breaker.

• Use the supplied power adaptor/connector only. (The adaptor is rated

for indoor use only.)

• Do not leave the optics gate open. Doing so may allow pressurized

gases to escape through the tubing into the unit and then

environment.

into the local

The detector is supplied with weather-sealed connectors for power,

Ethernet, and communications (for relays or 4-20 mA). See the SPM Flex

manual if the detector is being mounted in a xed location.

Portable detectors must be charged at least four hours. (They can be used

while charging.) Honeywell Analytics recommends leaving the detector

connected to the power source/charger when not in use to keep the battery

fully charged.

Figure 1:

terminals and ports

Turning the detector on and off

Figure 2: SPM Flex buttons and color LCD display

Figure 3 shows the common elements of the display.

Concentration

Sound

Status bar

Figure 3:

In the status bar, the color of the status bar changes according to the

conditions (blue = out of Monitor mode, green = status OK, yellow = fault,

red = alarm).

See Figure 10 (over) for the detector’s menu map.

The interface consists of a color LCD, a 4-button keypad, and four color

status LEDs. The menu options are navigated using these buttons:

The four LEDs provide at-a-glance information about the current state of

the detector:

on/o

Clock

Current status indicator

SPM Flex display - In Monitor mode

Interface Button Function

Up arrow Scroll up through lists of options

Down arrow Scroll down through lists of options

Accept/Select Accept a highlighted option

Power/Cancel Cancel

LED Description

Red

Green blinking The detector is active

Yellow

Blue solid Connected to external power

solid Alarm 1

blinking Alarm 2

solid Maintenance fault

blinking Instrument fault

indicator

Gas name

Gas concentration

Units

Monitor mode

Indicator

Battery

indicator

Bar graph

w/upper, lower

alarm limits

Unpacking the box

The contents of the box:

• the SPM Flex gas detector

• the handle assembly (for portable models only)

• power adaptor and cable

• shoulder strap (for portable models only)

• mounting bracket (for xed units only)

• a CD containing the Technical Manual

• this Quick Start Guide

Save the packaging to re-use for service requests.

1. Verify that the rocker switch under the cover is in the on position.

(Typically, it is switched off only for transport or service.) Do not power

up the detector with a ash drive attached.

2. Press and hold the Power/Cancel button until the green LED begins

blinking. The detector will then complete the start-up sequence.

3. To turn the detector off, press and hold the Power/Cancel button for 5

seconds or select “Power Off” from the menu.

Navigation

All SPM Flex menus are navigated by the four buttons shown in Figure 2.

Pressing either of the arrows or the Accept/Select button will access the

menu from the main display screen. The arrows are used to scroll up and

down through lists of options. The Accept/Select button is used to initiate a

highlighted option. During navigation, the Power/Cancel button will cancel a

command or, when pressed for more than 3 seconds, it will exit to the main

display.

Figure 4: Main menu Figure 5: Out of monitor mode

Figure 6: Alarm mode Figure 7: Maintenance fault

Part No. 1998M0846

Revision 02

April 2015

Page 2

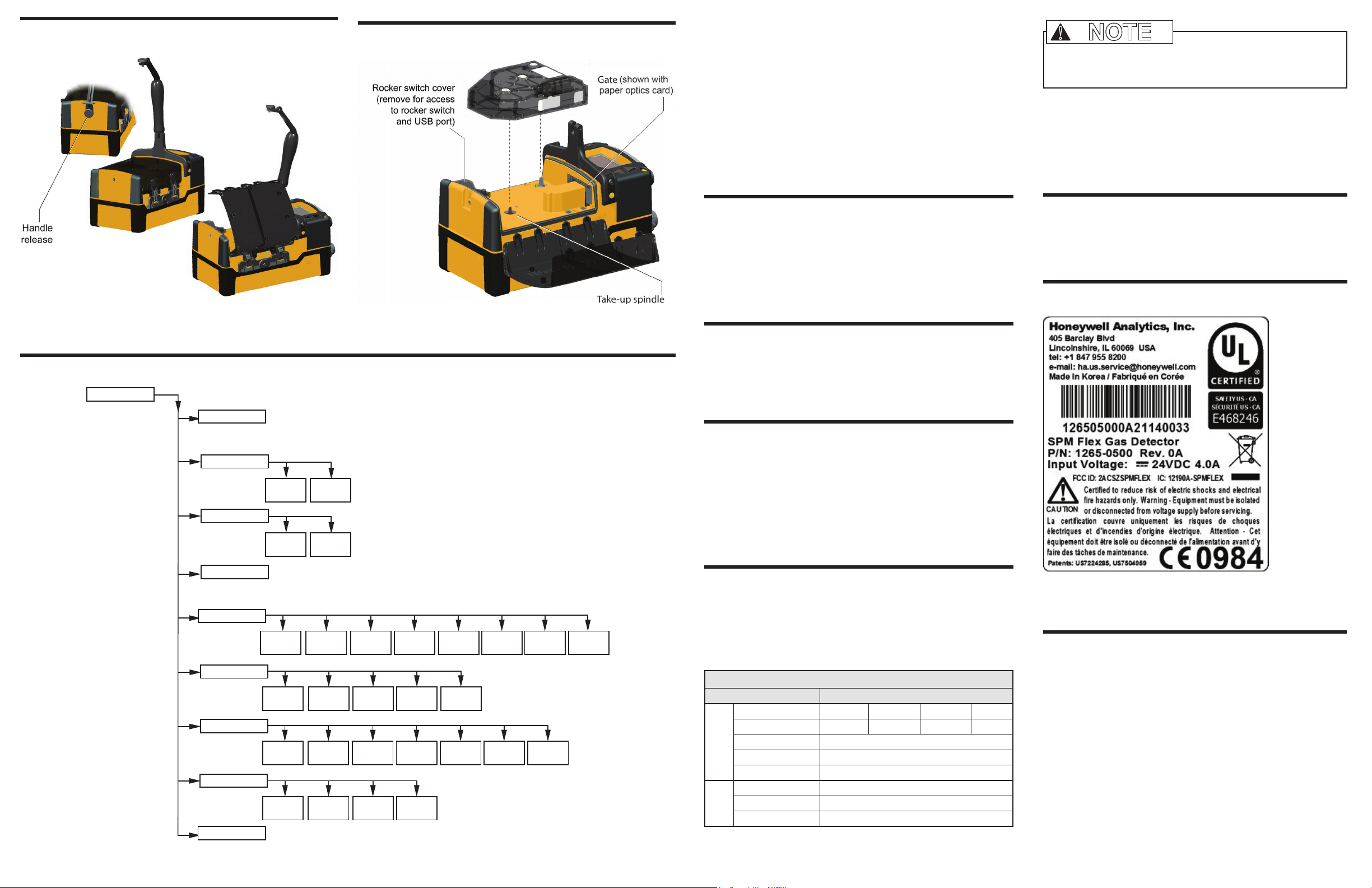

Opening the Chemcassette® cartridge door

Loading a Chemcassette® cartridge

1. Navigate to the “Change Chemcassette” menu option.

2. Follow the on-screen instructions to install or change the cartridge.

3. Remove the paper optics card from the gate.

4. Insert the Chemcassette cartridge in the detector (it will t in only

one orientation). The take-up spindle will rotate slightly to allow the

cartridge to snap into place easily.

5. Close the cover.

6. A summary of the current conguration will be displayed. Select

either to enter monitor mode or to remain out of monitor mode (i.e.,

idle).

!

NOTE

Use Teon Fluorinated Ethylene Polymer (FEP) tubing to ensure proper

sample transport.

The SPM Flex detector is supplied with the standard Ethernet, power,

and communications connectors installed. The Ethernet connector can

be removed and provides a 1-inch conduit port which allows a direct

connection to the PCB communication terminals. Refer to the

tubing

section of the user manual for more information.

Wiring and

Figure 8: Opening the Chemcassette cartridge door

Menu Map

Main Menu

Login/Logout

Reset Alarms & Faults

Monitor Mode

Reset all

Enter

monitor mode

Silence

audio alarm

Out of

monitor mode

Figure 9: Loading a Chemcassette cartridge

Removing a Chemcassette® cartridge

1. Navigate to Maintenance > Open/Close gate.

2. Select “Open Gate.”

3. Remove the cartridge.

4. Inert the optics card in the gate if the detector will be stored or

transported.

5. Select “Close Gate.”

Changing the selected gas

1. While out of monitor mode, navigate to Set-up > Monitoring > Gas.

2. Select “Current gas” and pick the desired gas from the selection box

3. Select “Save.”

Entering monitor mode

From the main menu, navigate to the “Monitor Mode” option and select

“Enter monitor mode.”

1. If a Chemcassette cartridge has been installed, the detector will enter

Monitor Mode.

2. If a Chemcassette cartridge has not been installed, a user with

the necessary passcode can inititate the Chemcassette wizard.

Otherwise, the detector will not enter monitor mode.

Attaching the shoulder strap

If the shoulder strap is to be used with a portable detector, attach its

spring clips to each of the rings on the detector’s handle.

Product label

Figure 10. SPM Flex menu map

Change Chemcassette

Review Mode

Maintenance

Setup

Test

Power Off

Event

History

Inhibit

General

Optics

Verification

Chem-

cassette

4-20 mA

Current Loop

Calibration

Monitoring Latching

Simulation

Gas

Settings

Flow Char-

acterization

Force

Relay

Network

Open/Close

Gate

Outputs Network

Force

4-20 mA

Additional

Status

Update

Program

Output

State

Security

Configuration

Manager

Wiring and tubing

The SPM Flex detector has exible installation options to allow the user to

select the one most suitable for a specic application. The 4-20 mA output

is a three-wire connection that is congurable as sink, source, or isolated.

SoftwareTrend/Plot

The detector is equipped with three relays.

Figure 11. SPM Flex label

Have questions?

Honeywell Analytics

Sample Tubing Specications

Description Maximum

Tubing length, ft. (m) 100 (30) 66 (20) 33 (10) 0

Transport time (sec) 19 13 7 1

Flow rate (cc/min.) 700-1200 (flow is set and controlled per calibration)

Inlet

Tubing OD, in. (mm) 0.25 (6.35)

Tubing ID, in. (mm) 0.125 (3.18)

Tubing length, ft. (m) 100 (30)

Outlet

Tubing OD, in. (mm) 0.25 (6.35)

Tubing ID, in. (mm) 0.188 (4.76)

The overall maximum load on the pump between the inlet and the exhaust should not exceed 10 inches H2O.

405 Barclay Boulevard

Lincolnshire, Ilinois 60069

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8208

detectgas@honeywell.com

Loading...

Loading...