Page 1

SP970A, B, C and D Manual and

Minimum Position Pressure Regulators

INSTALLATION INSTRUCTIONS

DESCRIPTION

The SP970A, B, C and D Manual and Minimum Position

Pressure Regulators provide regulated pressure to a

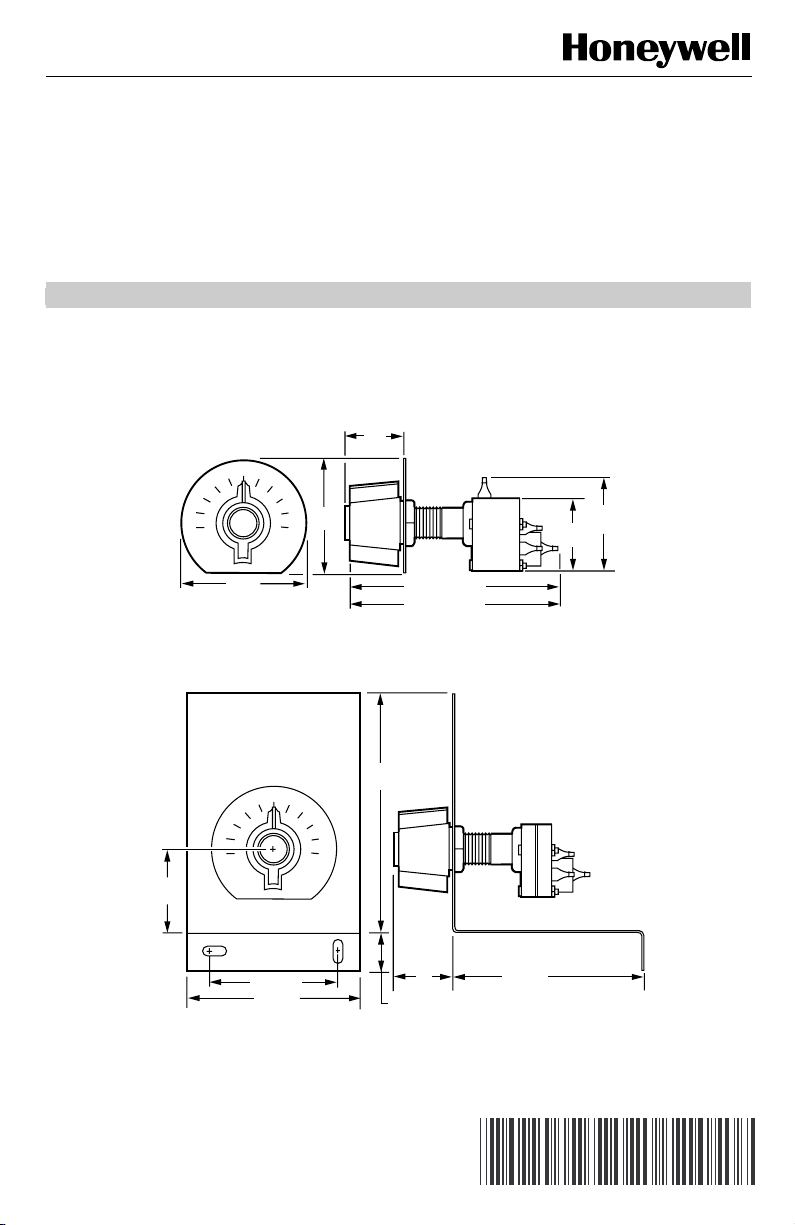

(22)

60

40

20

0

FRONT VIEW SIDE VIEW

1-9/16

(40)

80

2-1/4

100

(57)

2-1/2

(63)

Fig. 1. SP970A and C dimensions in in. (mm).

60

40

20

0

80

100

controlled device such as a pneumatic damper operator.

It provides either manually set pressure or manually set

minimum pressure with variable maximum pressure.

Figs. 1 and 2 show approximate dimensions.

7/8

1-7/8

(48)

1-1/2

(38)

SP970C 3-7/8 (98)

4-1/2

(114)

SP970A 3-1/2 (89)

C4857

2-1/16 (62)

3-1/4 (83)

FRONT VIEW

Fig. 2. SP970B and D dimensions in in. (mm).

® U.S. Registered Trademark

Copyright © 2002 Honeywell •All Rights Reserved

7/8

(22)

(25)

1

3-1/2 (89)

SIDE VIEW

C4858

95-7237EF

Page 2

SP970A, B, C AND D MANUAL AND MINIMUM POSITION PRESSURE REGULATORS

BEFORE INSTALLATION

SP970A and C only

For panels having a thickness greater than 5/16 in.

(8 mm) but less than one in. (25 mm), use 315677A Bus

Assembly.

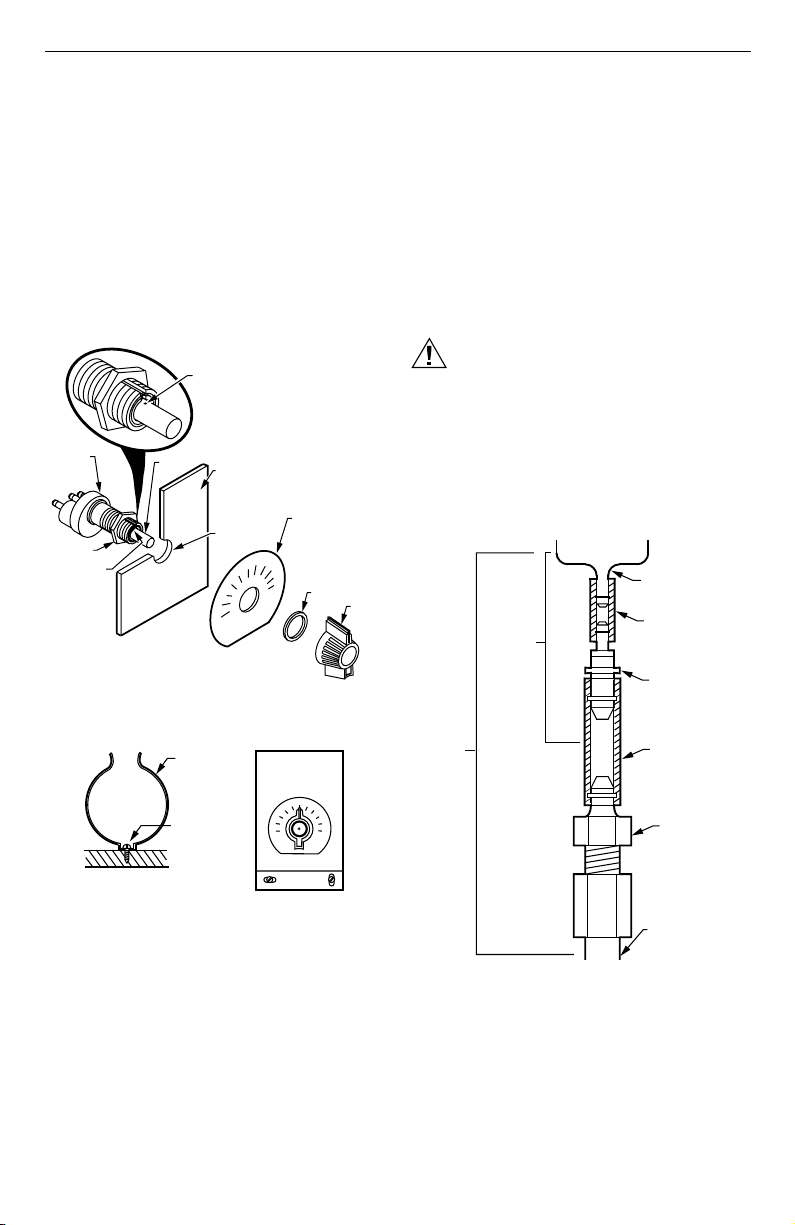

INSTALLATION

Mounting

The SP970A and C can be panel, surface or wall

mounted. The SP970B and D are surface or wall

mounted. See Fig. 3 and 4.

8 PSI

CENTER PUNCH MARK IN "V" GROOVE

SHOWING 8 PSI (55 kPa) CALIBRATION ENLARGED

SP97O

HEX NUT

CENTER

PUNCH

MARK

IN "V"

GROOVE

Fig. 3. SP970A and C panel mounting.

SP970A AND C

SP970 SWITCH

Fig. 4. SP970 surface or wall mounting.

Panel Mounting SP970A and SP970C

1. Drill a 5/8 in. (16 mm) hole.

2. Lock the SP970 switch and scaleplate to the panel

with a hex nut on the back of the panel. Use a second hex nut on the front panel. See Fig. 3.

MOUNTED

HERE

SHAFT

SCREW

SPRING

CLIP

C8275

PANEL-UP TO 5/16 IN.

(8MM) THICK

5/8 IN. (16MM)

DIA. HOLE

60

80

40

100

20

0

SP970B AND D

40

20

0

SCALEPLATE

HEX NUT

60

80

100

C8277

KNOB

C8278

NOTES:

√ The scaleplate, knob and two mounting nuts

are furnished with SP970A and C.

√ Do not mount the knob during installation.

Refer to the Calibration section of this document.

Surface Mounting

Use the mounting bracket as a template and secure

mounting bracket to surface. See Fig. 4. Screws are not

provided.

Piping

All connections are sharp barb 5/32 in. (4 mm) O.D.

polyethylene tubing.

CAUTION

Equipment Damage Hazard.

To prevent damage to the sharp barb

connections, do not attempt to cut or pull tubing.

To remove the tubing from the barb connections,

cut tubing a few inches from the control device.

Use a coupling to reconnect tubing.

NOTES: When the system is not copper or polyethylene

tubing, adapt as shown in Fig.5. Some models

provide parts for adapting.

SP970A-D

POST FOR

5/32 IN. (4 MM) O.D.

PLASTIC TUBING

CONNECT

1/4 IN.

(6 MM)

PLASTIC

CONNECT

1/4 IN.

(6 MM)

COPPER

Fig. 5. Adaptation piping.

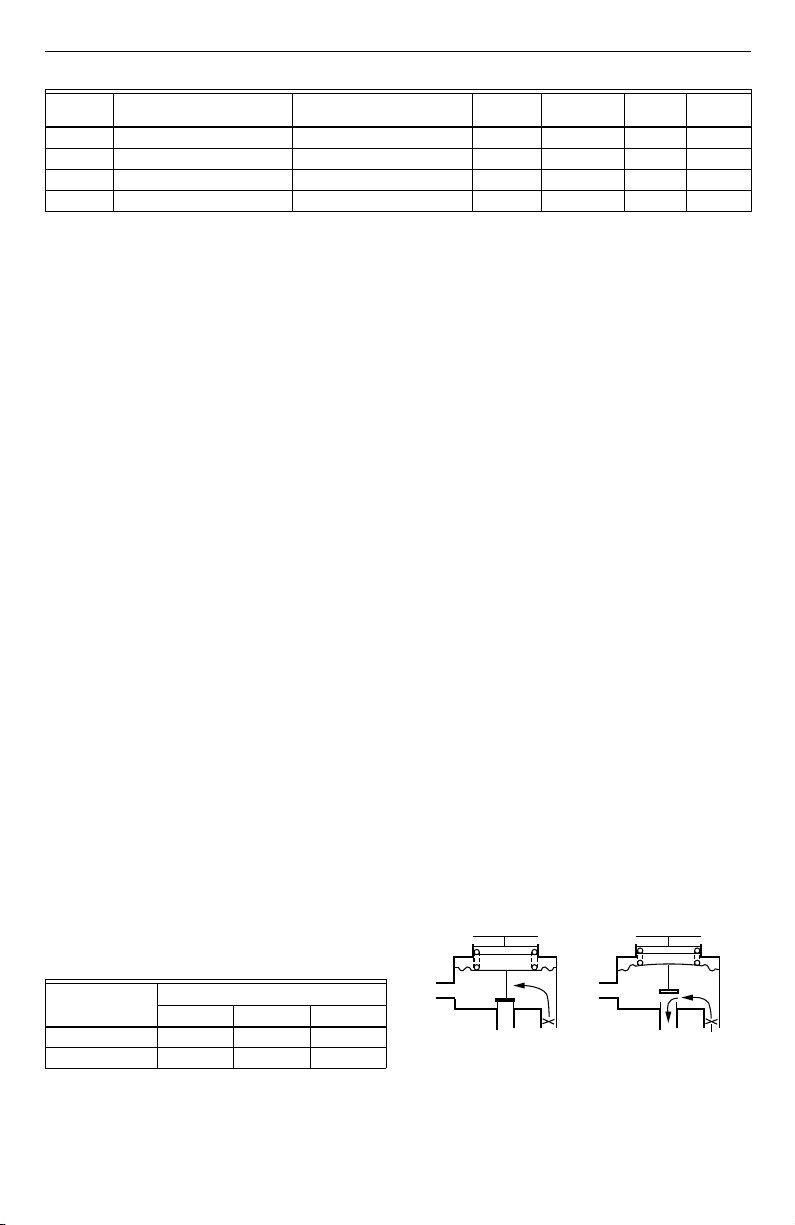

Port Identification Table

The two right columns in Table 1 identifies the ports of

older Honeywell pneumatic relays when upgrading

installation.

5/32 IN. (4 MM)

O.D. PLASTIC

TUBING CUT

TO LENGTH

5/32 IN. X 1/4 IN.

(4 MM X 6 MM)

O.D. PLASTIC

CONNECTOR

(CCTI606B)

1/4 IN. (6 MM)

O.D. PLASTIC

TUBING CUT TO

LENGTH

1/4 IN. (4 MM) O.D.

PLASTIC/COPPER

ADAPTER

(CCTI633BT)

1/4 IN. (6 MM) O.D.

COPPER TUBING

C8276

95-7237EF 2

Page 3

SP970A, B, C AND D MANUAL AND MINIMUM POSITION PRESSURE REGULATORS

Table 1. Port Identification.

SP970A Pressure

Regulator SP970A Minimum Position SP970B SP970C, D SP92 SP93

Main 1 1 1 1 2 M

Pilot √ 4 √ 3 4 P

Branch 2 2 2 2 3 B

Exhaust 4 √ 4 4 √ √

Calibration

All SP970A and C models are calibrated at 8 psi (55 kPa)

when the calibration mark (center punch) on the shaft is

centered at the bottom of the molded V. To calibrate,

align the center punch mark on the shaft with the bottom

of the molded V groove on the plastic surrounding shaft.

See Fig. 3. This setting equals 8 psi (55 kPa). Secure the

knob to the shaft at the proper scale setting. The knob

should be pointing to 8 psi (55 kPa). See Fig. 4.

All SP970B and D models are calibrated at 8 psi (55 kPa)

when the knob is set at 50 percent.

The large range device can be field recalibrated to other

end points with the same span from 0 psi (0 kPa) lower

limit to 26 psi (179 kPa) upper limit. The small range

device can be field recalibrated to other end points with

the same span from 0 psi (0 kPa) lower limit to 16 psi

(110 kPa) upper limit.

Checkout and Test for All Models

1. With main air connected, insert a pressure gage

into the branch line.

2. Check pressures equivalent to knob settings.

3. When minimum position is used, attach input and

increase pilot pressure.

4. Verify correct operation.

ENGINEERING DATA

Specifications

Models:

- SP970A: A bleed type pressure regulator.

- SP970B: A bleed type pressure regulator mounted

on a sheet metal panel.

- SP970C: A bleed type pressure regulator with a

dead ended pilot chamber for minimum pressure

applications.

- SP970D: A bleed type pressure regulator with a

dead ended pilot chamber for minimum pressure

applications mounted on a sheet metal panel.

Selectable Spans for psi (kPa): See Table 2.

Table 2. Selectable Spans.

Knob Rotation

Model

188 244 300

Small span 5 (34) 6.5 (45) 8 (55)

Large span 10 (69) 13 (90) 16 (110)

a

The setpoint knob normally rotates 188 degrees. Two

breakaway stops on the knob allow rotation of 244 and

300 degrees.

a

Operating Pressure (Switch and Pilot) Range:

Normal Main: 18 psi (124 kPa)

Branch: 3 to 15 psi (21 to 103 kPa)

Pilot: 3 to 15 psi (21 to 103 kPa)

Maximum Safe Air Pressure: 30 psi (207 kPa)

Ambient Operating Limits:

Temperature: 0 to 140°F (-18 to 60°C)

Relative Humidity : 5 to 95%

Air Handling Capacity:

SP970A, B: above minimum position, device feeding

pilot determines capacity. Below minimum position,

air capacity is 0.022 scfm (10 ml/s)

SP970C, D: 0.022 scfm (10 ml/s)

Air Consumption: 0.022 scfm (10 ml/s)

Scaleplate: All models ship with a 0 to 100 scaleplate

(including knob and locknuts).

Construction: Molded plastic with neoprene diaphragm,

steel spring and shaft.

Operation

SP970A and B: Three Port Switches

PRESSURE REGULATOR OPERATION

Main line air flows through the restriction into the

branchline chamber and out the nozzle. Branchline

pressure increases until it is strong enough to compress

the spring and lift the diaphragm off the nozzle. Airflow

out the nozzle is controlled by the balance between the

branchline pressure and spring force.

MINIMUM POSITION OPERATION

An external signal is connected to port 4 (exhaust port).

When the external signal is greater than the spring load,

the nozzle opens and branchline pressure is the same as

the external signal. When the external signal is less than

the spring load, branchline pressure is controlled as

described in the previous paragraph. See Fig. 6.

2 2

BRANCH

PILOT

4

MAIN

Fig. 6. SP970A/B operation.

SP970A,B

BRANCH

1

PILOT

4

SP970A,B

MAIN

1

C4298

3 95-7237EF

Page 4

SP970A, B, C AND D MANUAL AND MINIMUM POSITION PRESSURE REGULATORS

SP970C and D: Four Port Switches

These minimum position devices have a separate dead

ended chamber connected to port 3 to receive an

external signal. When the external signal is less than the

spring load, the signal has no effect and functions similar

PILOT

CHAMBER

3

PILOT

BRANCH

3

A. BUILDING TO MINIMUM SETTING

3

PILOT

BRANCH

3

B. BALANCED AT MINIMUM SETTING

SP970C,D

4

VENT MAIN

SP970C,D

4

VENT MAIN

Fig. 7. SP970C and D operation.

Application

Fig. 8A shows a typical manual position application using

the three port SP970A, B. This control system manually

positions a damper between OPEN and CLOSED.

Turning the setpoint knob clockwise increases the

branchline pressure to the damper actuator and opens

the damper. Turning the position knob counterclockwise

decreases the branchline pressure and closes the

damper.

The three port SP970A, B is also used with a controller

for automatic damper positioning with minimum position.

See Fig. 8B. When the external signal is less than the

to the SP970A, B as a pressure regulator. When the

external signal is greater than the spring load, the spring

load is isolated and the device duplicates the input

signal. See Fig. 7.

SP970C,D

DISC

3

PILOT

BRANCH

1

1

3

C. PILOT BUILDING BRANCH ABOVE

MINIMUM SETTING

3

PILOT

BRANCH

3

D. BALANCED AGAINST PILOT

knob setting, the spring maintains the branchline

pressure as previously described. When the external

signal rises above the knob setting, air from the signal

flows directly to the branch. During steady state

conditions, the external automatic controller must be

capable of exhausting the air flowing through the exhaust

(pilot) port 4.

Fig. 8C shows a typical four port SP970C, D application.

The minimum position switch keeps the pneumatic

actuator at a minimum position until the thermostat

pressure is greater than the minimum position valve. The

thermostat then controls the actuator.

4

VENT MAIN

SP970C,D

4

VENT MAIN

1

1

C4300

DAMPER DAMPER

ACTUATOR ACTUATOR ACTUATOR

BRANCH

2

M

1

EXH

A. MANUAL POSITION

APPLICATION

4

SP970A OR B

BRANCH BRANCH

2

M

1

2

4

SP970A OR B

M

1

CONTROLLER

B. MINIMUM POSITION C. MINIMUM POSITION

APPLICATION WITH APPLICATION

CONTROLLER INPUT WITH THERMOSTAT

EXH

DAMPER

2

M

1

SP970C OR D

3

4

M

INSERTION

THERMOSTAT

C8279

Fig. 8. Typical SP970 application.

Automation and Control Solutions

Honeywell Honeywell Limited-Honeywell Limité e

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

95-7237EF J.H. Rev. 2-02 customer.honeywell.com

M1V 4Z9

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Page 5

Sélecteurs de pression manuels et à

position minimale SP970A, B, C et D

NOTICE D'INSTALLATION

DESCRIPTION

Les appareils SP970 A, B, C et D sont utilisés pour régler

la pression destinée aux appareils asservis tels que les

servomoteurs pneumatiques de registres. Ils servent à

22

(7/8)

60

40

20

0

VUE DE FACE VUE DE PROFIL

40

(1-9/16)

80

57

100

(2-1/4)

63

(2-1/2)

Fig. 1. Encombrement des SP970A et C, en mm (po).

60

40

20

0

(4-1/2)

80

100

régler manuellement soit la pression d'air soit la pression

minimale dans les applications à pression maximale

variable.

Les Fig. 1 et 2 donnent l'encombrement approximatif des

appareils.

48

(1-7/8)

38

(1-1/2)

SP970C 98 (3-7/8)

SP970A 89 (3-1/2)

114

CF4857

62 (2-1/16)

83 (3-1/4)

VUE DE FACE VUE DE PROFIL

Fig. 2. Encombrement des SP970B et D, en mm (po).

® Marque de commerce déposée aux É.-U.

Copyright © 2002 Honeywell • Tous droits réservés

22

(7/8)

25

(1)

89 (3-1/2)

CF4858

95-7237EF

Page 6

SÉLECTEURS DE PRESSION MANUELS ET Ω POSITION MINIMALE SP970A, B, C ET D

AVANT D'INSTALLER CE PRODUIT…

Modèles SP970A et C seulement

Sur un panneau dont l'épaisseur est supérieure à 8 mm

(5/16 po) mais inférieure à 25 mm (1 po), utiliser un

ensemble bus 315677A.

INSTALLATION

Montage

Les SP970A et C peuvent être montés sur un panneau,

en surface ou sur un mur. Les modèles SP970B et D

peuvent être montés en surface ou sur un mur. Voir les

Fig. 3 et 4.

55 kPa

VUE AGRANDIE - MARQUE AU POINTEAU ALIGNÉE SUR LA RAINURE EN

«V», MONTRANT L'ÉTALONNAGE À

55 kPa (8 psi)

SP97O

ÉCROU

HEXAGONAL

MARQUE

AU POINTEAU

ALIGNÉE SUR

LA RAINURE

EN «V»

Fig. 3. Montage des SP970 A et C sur un panneau.

SP970A ET C

SP970 MONTÉ

À CET

ENDROIT

ARBRE

PINCE À

RESSORT

VIS

PANNEAU D'UNE ÉPAISSEUR

MAXIMALE DE 8 mm (5/16 po)

TROU DE

0

16 mm

(5/8 po)

DIAM.

20

40

ÉCHELLE

60

80

100

SP970B ET D

60

40

20

0

ÉCROU

HEXAGONAL

BOUTON

80

100

CF8278

REMARQUES :

√ L'échelle, le bouton et les deux écrous

de montage sont fournis avec les SP970A

et C.

√ Ne pas poser le bouton au moment de

l'installation. Consulter la section Étalonnage de la présente notice technique.

Montage en surface

Utiliser le support de montage comme gabarit, puis le

fixer à la surface. Voir la Fig. 4. Les vis ne sont pas

fournies.

Tuyaux

Tous les raccords sont effectués avec des tuyaux à crans

en polyéthylène de 4 mm (5/32 po) de diam. ext.

MISE EN GARDE

Risque de dommage matériel.

Ne pas couper ni tirer les canalisations afin de ne

pas endommager les raccords à crans. Pour

enlever la canalisation fixée au raccord à crans,

la couper à quelques centimètres au-dessus du

dispositif de régulation puis la raccorder au

moyen d'un manchon.

REMARQUE : Si les canalisations ne sont pas en cuivre

RACCORD EN

CUIVRE DE

6 mm (1/4 po)

ou en polyéthylène, suivre les indications

à la Fig. 5. Certains modèles comprennent les pièces à utiliser pour le raccordement.

SP970A-D

TIGE POUR

CANALISATION

EN PLASTIQUE

DE 4 mm (5/32 po)

RACCORD EN

PLASTIQUE

DE 6 mm

(1/4 po)

CANALISATION EN

PLASTIQUE

DE 4 mm (5/32 po)

DIAM. EXT.,

COUPÉE À LA

LONGUEUR

VOULUE

DIAM. EXT.

RACCORD EN

PLASTIQUE DE

4 mm X 6 mm

(5/32 po X 1/4 po)

DIAM. EXT.

(CCT1606B)

CANALISATION

EN PLASTIQUE

DE 6 mm (1/4 po)

DIAM. EXT.,

COUPÉE À LA

LONGUEUR VOULUE

ADAPTATEUR EN

PLASTIQUE/CUIVRE

DE 6 mm (1/4 po)

DIAM. EXT.

(CCT1633BT)

CF8275

CF8277

Fig. 4. Montage du SP970 en surface ou sur un mur.

Montage des SPA970A et SP970C sur un

panneau

1. Percer un trou de 16 mm (5/8 po).

2. Fixer le sélecteur SP970 et l'échelle au panneau à

l'aide d'un écrou hexagonal au dos du panneau.

Sur le devant du panneau, utiliser un deuxième

écrou hexagonal. Voir la Fig. 3.

95-7237EF 2

CANALISATION EN

CUIVRE DE 6 mm

(1/4 po) DIAM. EXT.

CF8276

Fig. 5. Adaptateurs de tuyaux.

Tableau des divers orifices

Les deux dernières colonnes du Tableau 1 donnent les

orifices des anciens modèles de relais pneumatiques

Honeywell. Cette information est utile lors de travaux de

modernisation.

Page 7

SÉLECTEURS DE PRESSION MANUELS ET Ω POSITION MINIMALE SP970A, B, C ET D

Tableau 1. Identification des orifices.

Sélecteur de

Canal. princ. 1 1 1 1 2 M

Pilote √ 4 √ 3 4 P

Canal. sec. 2 2 2 2 3 B

Purge 4 √ 4 4 √ √

pression SP970A

Étalonnage

Tous les modèles SP970A et C sont étalonnés à 55 kPa

(8 psi) lorsque la marque d'étalonnage (au pointeau) sur

l'arbre est centrée sur la partie inférieure du V moulé.

Pour étalonner l'appareil, aligner la marque au pointeau

sur l'arbre avec la partie inférieure du V moulé sur le

plastique qui entoure l'arbre. Voir la Fig. 3. Ce réglage

correspond à 55 kPa (8 psi). Fixer le bouton à l'arbre

selon le réglage approprié sur l'échelle. Ce bouton doit

indiquer 55 kPa (8 psi). Voir la Fig. 4.

Tous les SP970B et D sont étalonnés à 55 kPa (8 psi)

lorsque le bouton est réglé à 50 pour cent.

Les appareils à grandes échelles peuvent être réétalonnés en clientèle dans le même intervalle de

mesure, entre la limite inférieure de 0 kPa (0 psi) et la

limite supérieure de 179 kPa (26 psi). Les appareils à

petites échelles peuvent être ré-étalonnés en clientèle

dans le même intervalle de mesure, entre la limite

inférieure de 0 kPa (0 psi) et la limite supérieure de

110 kPa ( 16 ps i).

Vérification et essai de tous les modèles

1. Une fois la canalisation principale raccordée, introduire

un manomètre dans la canalisation secondaire.

2. Vérifier les pressions correspondant aux réglages

du bouton.

3. Si l'appareil est en mode position minimale, raccorder

l'orifice d'entrée et augmenter la pression pilote.

4. Vérifier si l'appareil fonctionne normalement.

FICHE TECHNIQUE

Caractéristiques

Modèles :

SP970A : sélecteur de pression de type purgeur.

SP970B : sélecteur de pression de type purgeur

monté sur un panneau de tôle.

SP970C : sélecteur de pression de type purgeur avec

chambre pilote isolée pour les applications à pression minimale.

SP970D : sélecteur de pression de type purgeur avec

chambre pilote isolée pour les applications à pression minimale, monté sur un panneau de tôle.

Choix d'intervalles de mesure en kPa (psi) : voir le

Tableau 2.

Tableau 2. Choix d'intervalles.

Intervalle - petites échelles 34 (5) 45 (6,5) 55 (8)

Intervalle - grandes échelles 69 (10) 90 (13) 110 (16)

a

Modèle

Le bouton de réglage du point de consigne tourne habituellement sur 188 degrés. Si on enlève les deux butées, le bouton

peut tourner sur 244 et 300 degrés.

Sélecteur à position

minimale SP970A SP970B SP970C, D SP92 SP93

Gamme de pression de service (commutation et

pilote) :

Canal. princ., normale : 124 kPa (18 psi)

Canal. sec. : 21 à 103 kPa (3 à 15 psi)

Pilote : 21 à 103 kPa (3 à 15 psi)

Pression d'air admissible maximale : 207 kPa (30 psi)

Limites ambiantes de service :

Température : -18 à 60 °C (0 à 140 °F)

Humidité relative : 5 à 95 %

Débit d'air

SP970A, B : au-dessus de la position minimale,

l'appareil alimentant l'orifice pilote détermine le

débit. Au-dessous de la position minimale, le débit

est de 10 ml/s (0,022 pi

SP970C, D : 10 ml/s (0,022 pi3/min standard)

3

/min standard)

Consommation d'air : 10 ml/s (0,022 pi

Échelle : Tous les modèles sont expédiés avec une

échelle de 0 à 100 (avec bouton et contre-écrous)

Fabrication : en plastique moulé, membrane en

néoprène et siège de soupape en acier inoxydable.

Fonctionnement

SP970A et B : Sélecteurs à trois orifices

FONCTIONNEMENT DU SÉLECTEUR DE PRESSION

L'air de la canalisation principale traverse le réducteur,

pénètre dans la chambre de la canalisation secondaire et

sort par la buse. La pression dans la canalisation

secondaire augmente jusqu'à ce qu'elle soit

suffisamment élevée pour comprimer le ressort et

soulever la membrane de la buse. Le débit d'air est réglé

par l'équilibre qui se produit entre la pression dans la

canalisation secondaire et la force du ressort.

FONCTIONNEMENT EN MODE POSITION MINIMALE

Un signal extérieur est relié à l'orifice 4 (orifice de purge).

Lorsque la pression du signal extérieur est plus élevée

que la force du ressort, la buse s'ouvre et la pression

dans la canalisation secondaire est identique à celle du

signal extérieur. Lorsque la pression du signal extérieur

est inférieure à la force du ressort, la pression dans la

canalisation secondaire est réglée de la façon décrite au

paragraphe précédent. Voir la Fig. 6.

Rotation du bouton

188 244 300

a

2

CANAL.

SEC.

Fig. 6. Fonctionnement de SP970A/B.

3 95-7237EF

SP970A,B SP970A,B

2

CANAL.

SEC.

4

PILOTE

1

CANAL.

PRINC. PRINC.

3

/min standard)

4

PILOTE

CANAL.

1

CF4298

Page 8

SÉLECTEURS DE PRESSION MANUELS ET Ω POSITION MINIMALE SP970A, B, C ET D

SP970C et D : Sélecteurs à quatre orifices

Ces appareils à position minimale ont une chambre

isolée distincte, raccordée à l'orifice 3, qui reçoit un

signal extérieur. Lorsque la pression du signal extérieur

est inférieure à la force du ressort, le signal ne produit

aucun effet et l'appareil fonctionne de la même manière

CHAMBRE

PILOTE

3

PILOTE

CANAL. SEC.

3

A. ÉTABLISSEMENT DE LA PRESSION AU RÉGLAGE MINIMAL

3

PILOTE

CANAL. SEC.

3

B. PRESSION ÉQUILIBRÉE AU RÉGLAGE MINIMAL

SP970C,D

DISQUE

4

4

1

SP970C,D

1

ÉVENT CANAL. PRINC.

ÉVENT CANAL. PRINC.

Fig. 7. Fonctionnement des SP970C et D.

Application

La Fig. 8 montre une application type de sélection

manuelle avec des SP970A et B à trois orifices. Ces

appareils sont utilisés pour positionner manuellement un

registre entre OUVERT et FERMÉ. En tournant le

bouton de réglage du point de consigne dans le sens

horaire, on augmente la pression dans la canalisation

secondaire vers le servomoteur et le registre s'ouvre. En

tournant le bouton dans le sens anti-horaire, on abaisse

la pression dans la canalisation secondaire et le registre

se ferme.

Les appareils SP970A et B à trois orifices sont aussi

utilisés avec des régulateurs pour positionner

automatiquement un registre en position minimale. Voir

la Fig. 8B. Lorsque la pression du signal extérieur est

que les SP970A et B, c'est-à-dire comme un sélecteur de

pression. Lorsque la pression du signal extérieur est

plus élevée que la force du ressort, la force du ressort est

isolée et l'appareil reproduit le signal d'entrée. Voir la

Fig. 7.

SP970C,D

3

PILOTE

CANAL. SEC.

3

C. PILOTE ÉTABLISSANT LA PRESSION DANS LA CANALISATION

SECONDAIRE AU-DESSUS DU RÉGLAGE MINIMAL

3

PILOTE

CANAL. SEC.

3

D. PRESSION ÉQUILIBRÉE PAR RAPPORT AU PILOTE

inférieure à celle du réglage du bouton, le ressort

maintient la pression dans la canalisation secondaire

comme il est décrit précédemment. Lorsque la pression

du signal extérieur est plus élevée que celle du réglage

du bouton, l'air qui provient du signal circule directement

vers la canalisation secondaire. Lorsque les conditions

ne changent pas, le régulateur externe doit pouvoir

purger l'air par l'orifice de purge 4 (pilote).

La Fig. 8C montre une application type avec des

SP970C et D à quatre orifices. Le sélecteur à position

minimale maintient le servomoteur pneumatique à une

position minimale jusqu'à ce que la pression du

thermostat atteigne une valeur supérieure à celle de la

vanne à position minimale. Ω ce moment, le thermostat

commande le servomoteur.

4

4

1

SP970C,D

1

ÉVENT CANAL. PRINC.

ÉVENT CANAL. PRINC.

CF4300

SERVOMOTEUR

DU REGISTRE

2

M

1

PURGE

A. APPLICATION POSITION MANUELLE B. APPLICATION POSITION MINIMALE C. APPLICATION POSITION MINIMALE

4

SP970A OU B

SERVOMOTEUR

DU REGISTRE

CANAL. SEC.

2

M

1

M

12

RÉGULATEUR

AVEC ENTRÉE DU RÉGULATEUR AVEC THERMOSTAT

4

SP970A OU B

PURGE

CANAL. SEC.CANAL. SEC.

M

SERVOMOTEUR

DU REGISTRE

2

1

3

4

M

SP970C OU D

THERMOSTAT

D'INSERTION

CF8279

Fig. 8. Application type du SP970.

Solutions de régulation et d'automatisation

Honeywell Honeywell Limited-Honeywell Limité e

1985 Douglas Drive North 35, Dynamic Drive

Golden Valley, MN 55422 Scarborough (Ontario)

95-7237EF J.H. Rév. 2-02 customer.honeywell.com

M1V 4Z9

Imprimé aux États-Unis sur du papier

recyclé contenant au moins 10 %

de fibres post-consommation.

Loading...

Loading...