Page 1

31-00132-02

SP3000, PT3000 Sensors

5/8 (16)

1-1/4 INCH (32)

HEAT SHRINK

M37070

2 (51)

Ø1/4

(6)

60 (1524) ±1 (25)

ELECTRICAL RATING: 30 Vac maximum.

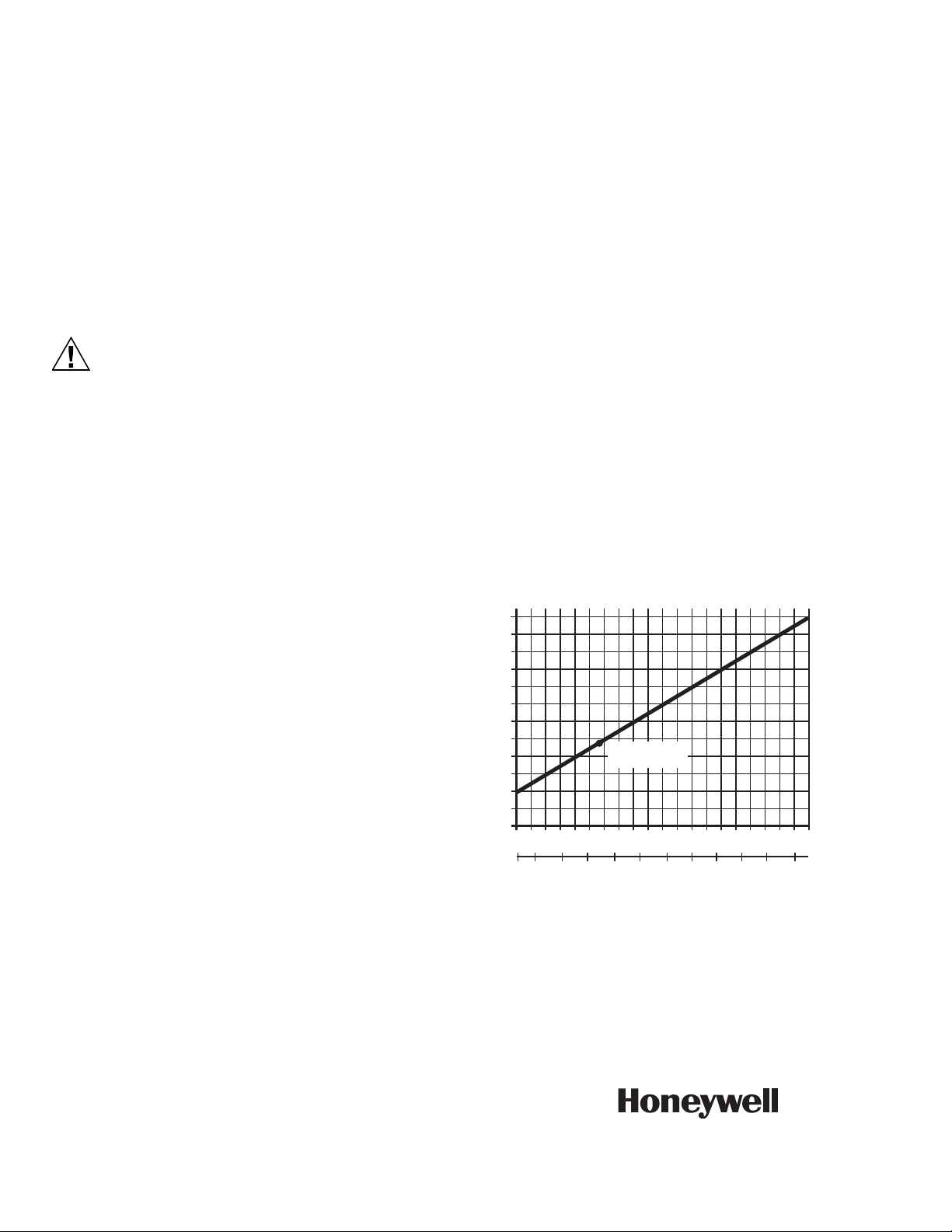

TEMPERATURE SENSOR RESISTANCE:

(see Fig. 3)

Temperature °C -10 0 10 20 30 40

Temperature °F 14 32 50 68 86 104

APPLICATION

The SP3000 Temperature Sensors are for use with

electronic controllers where linear PTC sensors are

required (T7075, Series 1000, W7100, W7600, W7620,

R7380J,L) in immersion or strap-mounted discharge

applications.

FEATURES

• Requires no settings or calibration.

• Platinum positive temperature coefficient (PTC)

sensing element.

• Resistance range is 2900 to 4400 ohms.

• Suitable for mounting in immersion well.

• Can be strapmounted to discharge pipe of boiler or

chiller.

Resistance in

ohms—SP3000

SENSING ACCURACY: +/-2° F [1.1° C].

AMBIENT TEMPERATURE RANGES:

Operating and Shipping:

For SP3000-2 and SP3000-15: -40 to +302° F

(-40 to +150° C)

For SP3000-WR: -40 to +248° F (-40 to +120° C)

DIMENSIONS: See Fig. 1 and 2.

Ø1/4 (6)

2 (51)

Fig. 1. Approximate dimensions of SP3000-2 and

SP3000-15 Encapsulated Temperature Sensor in in.

3,178 3,266 3,353 3,440 3,527 3,613

ITEM NUMBER

TABLE A

SP3000-2

SP3000-15

SEE TABLE A

(mm).

PRODUCT DATA

LEAD LENGTH

INCHES (MM)

24 (610)

180 (4572)

M37069

SPECIFICATIONS

IMPORTANT:

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore, an individual unit may not exactly match the

listed specifications. Also, this product is tested

and calibrated under closely controlled conditions

and some minor differences in performance can

be expected if those conditions are changed.

Fig. 2. Approximate dimensions of SP3000-WR

Encapsulated Temperature Sensor in in. (mm).

Page 2

SP3000, PT3000 SENSORS

CAUTION

RESISTANCE

(OHMS)

4200

4000

3800

3600

3400

3200

20 40

60

80 100 120

140 160

180 200 220

-7

0

10

20 30

40 50

60

70 80 90

100

F

C

3484 ± 6.5 OHMS

AT 77¡F (25¡C)

M2829A

TEMPERATURE (DEGREES)

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Disconnect power supply before making wiring

connections to prevent electrical shock or

equipment damage.

Location and Mounting

The SP3000 Encapsulated Temperature Sensor can be

installed by strapping the sensor to the outside of a boiler

or chiller output pipe, or by placing the sensor in the fluid

of a boiler or chiller using an immersion well. Instructions

for both types of installations follow.

Strapping The SP3000 To A Boiler Or

Chiller Output Pipe

Some applications require that the sensor be strapped to

the outside of a pipe. Strap-on mounting avoids the need

for an immersion well and pipe fittings, and also

eliminates the system draining, refilling, and bleeding

necessary to install the immersion well.

2. Clean the pipe surface for good sensor-to-pipe con-

tact. Apply heat conductive compound to the pipe at

the selected location.

3. Press the sensor bulb into the heat conductive com-

pound and fasten to the discharge pipe with 105900

Pipe Clamp, duct hanger wire or with metal hose

clamps.

IMPORTANT:

Erratic temperature readings from a sensor can be

caused by the wiring practices described below.

These must be avoided to assure proper operation.

Use shielded cable to reduce interference if

rerouting of sensor wiring is not possible.

1. Do not route temperature sensor wiring with building power wiring, next to control contactors or near

light dimming circuits, electric motors or welding

equipment.

2. Avoid poor wiring connections.

3. Avoid intermittent or missing building earth

ground. Do not mount sensor in incorrect environment.

Resistance in the SP3000 Sensor wiring positively offsets

the temperature sensed by 1 degree F for every 4.8 ohms

[8.6 ohms/°C] of resistance. Use larger gauge wire when

longer lengths are necessary.

OPERATION AND CHECKOUT

External mounting of the sensor produces a slight offset

in the temperature control point. The control temperature

could be increased up to 5° F [2.8° C] with a bare sensor

strapped to the discharge pipe. Use a heat conductive

compound and apply insulation around the SP3000 and

pipe to decrease the temperature offset. Obtain any

necessary straps, clamps and insulation locally.

The sensor bulb should be located at a point on the

discharge pipe approximately 3 ft [1 m] from the boiler or

chiller.

1. Remove any insulation on the pipe, leaving about 6

Home and Building Technologies

In the U.S.:

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

in. [15 cm] of the pipe exposed. With care, most insulating materials may be able to be reused to cover

the sensor when the installation is complete.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or

modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any

liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

® U.S. Registered Trademark

© 2020 Honeywell International Inc.

31-00132—02 M.S. Rev. 04-20

Printed in United States

Fig. 3. SP3000 temperature/resistance curve.

Loading...

Loading...