Page 1

SN0500 / SN0501

REFRIGERANT GAS LEAK DETECTOR

INSTALLATION / USER GUIDE

Copyright © 2004 Honeywell Control Systems Ltd.

All Rights Reserved EN1B-0014UK07 R0404

Page 2

GAS LEAK DETECTOR INSTALLATION & USER GUIDE

1. INTRODUCTION.................................................................................................... 3

2. EXTERNAL CONNECTIONS................................................................................. 3

3. POWER SUPPLY................................................................................................... 4

4. ANALOGUE OUTPUTS......................................................................................... 4

5. RELAY CONTACTS............................................................................................... 5

6. GAS DETECTION RANGE .................................................................................... 5

7. STANDARD DEFAULT SETTINGS....................................................................... 6

8. CONNECTIONS AT A GLANCE............................................................................ 7

At the time of writing, this User Guide accurately describes the product. However, in

the course of development of our products we may make changes without

notification. Honeywell shall not be liable for errors or for incidental or consequential

damages, directly or indirectly, in connection with the furnishing, performance or

misuse of this product or document. All Installation and Commissioning work on

Honeywell equipment should be carried out by suitably qualified personnel only.

Normal safety precautions and good working practice should be observed, to prevent

damage or injury at all times. We welcome comments about our products and

documentation.

Contact us at :

Address on back cover of this guide

CONTENTS

EN1B-0014UK07 R0404

2

Page 3

GAS LEAK DETECTOR INSTALLATION & USER GUIDE

1. INTRODUCTION

The Honeywell Refrigerant Gas Detection sensors, SN0500 (for refrigerant R404a)

and SN0501 (for refrigerant R410) are used to detect the leakage of refrigerant gas

and notify a monitoring system or provide a local indication (i.e. audible or visual

signal).

Remedial action can then be taken to stop and replace the lost gas.

2. EXTERNAL CONNECTIONS

All external connections are made to the motherboard through a cable gland. A cable

tie should be fitted within 20mm of the cable gland inside the enclosure. The

connectors will accept wire of 0.5-1.5mm sq.

Note: Earth connection must be made when using the vented metal enclosure or Exd

enclosure. The safety of this equipment is dependent on the integrity of the power

supply and the earthing of the enclosure.

On power up the sensor may take some time (minutes up to hours) to fully normalize.

You can monitor this by checking the 0-10V output as it falls towards zero. If during

this normalisation period the red / yellow LED activates indicating the high / low level

relay has switched then the reset button (see Fig. 1.) on the sensor must be pushed

(if in latched position) after normalisation is complete.

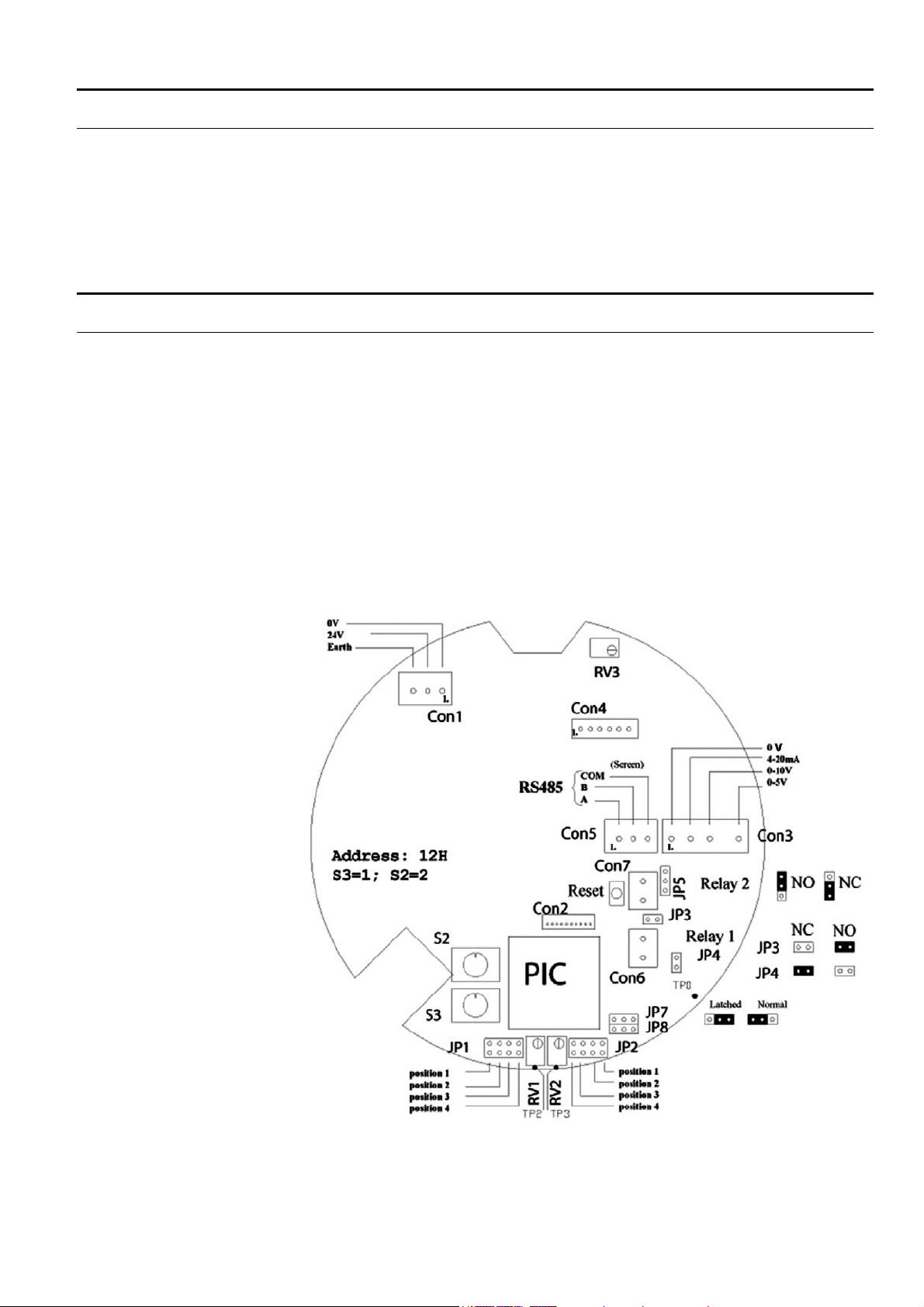

Figure 1. External Connections

3

EN1B-0014UK07 R0404

Page 4

GAS LEAK DETECTOR INSTALLATION & USER GUIDE

The Power supply is connected at Con 1 (see Fig. 1)

Green LED on - shows power connected.

Pin 1 = 0V,

Pin 2 = 12 to 24 VAC or 12 to 30VDC,

Pin 3 = Earth.

The 0V (pin 1) on the power supply terminal block (CON 1) can withstand 50V

AC or DC with respect to the 0V (Pin 1) on the output terminal block (CON 3). If

this is likely to be exceeded use an isolated power supply.

On the power supply side 12V is the minimum voltage at the terminals. Power

consumption is 4W max. It can draw 0.33Amp at 12V, so voltage drop along the

supply cable should be considered when selecting supply cable, type and length. For

example, for cable resistance 10ohm/100m allowing for the flow and return total cable

resistance for 100m is 20ohm and voltage drop along the cable is 6.6V. Minimum DC

supply then should be 19V.

If you need to use a cable of greater diameter that 1.5 mm sq, you can use a terminal

block at each sensor position capable of taking the larger cable and connect from that

into the CON1 terminal block using 1mm sq wire. Alternatively use local power

supplies to reduce cable runs and voltage loss.

3. POWER SUPPLY

4. ANALOGUE OUTPUTS

Analogue Outputs which indicate the concentration of gas refrigerant in the air, are at

Con 3 (see Figure 1.)

A two-core communication cable should be used to connect the outputs to a

monitoring and control system; a screen is not required.

Pin 1 = 0V

Pin 2 = 4-20mA. Load resistance must be less than 400Ω

Pin 3 = 0-10V. Load resistance must be greater than 100Ω

Pin 4 = 0-5 V. Load resistance must be greater than 10KΩ

When connecting the 4-20mA to the control panel, we suggest using Belden 8761,

22awg single pair shielded or alternatively an alarm type cable of 7/0.2mm, 22awg.

EN1B-0014UK07 R0404

4

Page 5

GAS LEAK DETECTOR INSTALLATION & USER GUIDE

5. RELAY CONTACTS

Note: If changing any jumper - power must be removed.

There are two relays rated up to 1 Amp at 24V DC/AC. The status of the relays is

jumper selectable.

Relay 1 at Con 6. Low-level alarm. Yellow LED on when in alarm.

Normally closed when JP4 link inserted, JP3 link removed, as shown on Fig. 1.

Normally open when JP3 link inserted, JP4 link removed, as shown on Fig. 1.

Latching (manual reset by push button located next to CON 7) - Not latching

(automatic reset) set by JP8 see Fig. 1. for link position.

Alarm threshold level is set by pot RV1 and can be set by putting a meter between

TP0 (negative) and TP2 (positive) (below RV1) and adjusting RV1 (scale is 0 to 5V

e.g. 2.5V is 50% of scale).

Delayed response time is set at JP1 by inserting the link in the required position.

Default settings are:

Position 1: No delay

Position 2 : 1 Minute

Position 3 : 5 Minutes

Position 4 : 10 Minutes

Note: If changing any jumper - power must be removed.

Relay 2 at Con 7. High-level alarm. Red LED on when in alarm.

Normally open/closed when JP5 link inserted, as shown on Fig.1.

Latching (manual reset by push button located next to CON 7) / Not latching

(automatic reset) set by JP7 see Fig. 1. for link position.

Alarm threshold level is set by pot RV2 and can be set by putting a meter between

TP0 (negative) and TP3 (positive) (below RV2) and adjusting RV2 (scale is 0 to 5V

e.g. 2.5V is 50% of scale).

Delayed response time is set at JP2 by inserting the link in the required position.

Position 1 No delay

Position 2 1 Minute

Position 3 5 Minutes

Position 4 10 Minutes

Note: If changing any jumper - power must be removed.

6. GAS DETECTION RANGE

Gas Detection Range and default settings vary with model and set up, see below for

sample settings.

Gas R404a R410

Range 0-1000 PPM 0-1000 PPM

5

EN1B-0014UK07 R0404

Page 6

GAS LEAK DETECTOR INSTALLATION & USER GUIDE

Relay 1 Low-level relay set at 500 PPM, NO, Auto reset mode

Relay 2 High-level relay set at 900 PPM, NO, Auto reset mode.

Delays on both alarm outputs are 0 minutes (no delay).

CON 1: Power Supply input

Power on indicated by Green LED.

Supply voltages to be either 12V to 24V AC or 12 to 30V DC

Power consumption is 4W max at 12V.

The connectors will accept wire of 0.5-1.5mm² Refer to Section 3 for maximum cable

run.

CON 2: Not Used.

CON 3: Analogue Output

Pin 1: 0V

Pin 2: 4-20mA. Load resistance<400Ω

Pin 3:0-10V. Load resistance>100Ω

Pin 4: 0-5V. Load resistance>10KΩ

CON 4: Plug-in detection sensor

CON 5: Not Used

CON 6: Relay 1 contacts (1Amp 24V AC/DC)

Low-level alarm. Indicated by Yellow LED.

Normally closed when JP4 link inserted, JP3 link removed, as shown on Fig. 1.

Normally open when JP3 link inserted, JP4 link removed, as shown on Fig. 1.

Latching (manual reset by push button located next to CON 7) / Not Latching set by

JP8 (see Fig. 1. in Connection Instructions)

Alarm Threshold level set by RV1 and can be set by putting a meter between TP0

(negative) and TP2 (positive) and adjusting RV1 (scale is 0 to 5V e.g. 2.5V is 50% of

scale).

Delayed response time set by JP1 link (see Fig. 1. in External Connections)

Position 1= No delay Position 3=5 min

Position 2=1 min Position 4=10 min

CON 7: Relay 2 contacts (1Amp 24V AC/DC)

High-level alarm. Indicated by Red LED on.

Normally open/closed when JP5 link inserted, as shown on Fig. 1.

Latching (manual reset by push button located next to CON 7) / Not Latching set by

JP7 (as above)

Alarm threshold level set by RV2 and can be set by putting a meter between TP0

(negative) and TP3 (positive) and adjusting RV2 (scale is 0 to 5V e.g. 2.5V is 50% of

scale).

Delayed response time is set by JP2 link (see Fig. 1. in External Connections).

Position 1= No delay Position 3=5 min

Position 2=1 min Position 4=10 min

If changing any jumper - power must be removed.

7. STANDARD DEFAULT SETTINGS

EN1B-0014UK07 R0404

6

Page 7

GAS LEAK DETECTOR INSTALLATION & USER GUIDE

8. CONNECTIONS AT A GLANCE

Connector Pin Description

CON1 1 0V Supply Voltage.

CON1 2 24V Supply Voltage.

CON1 3 Earth.

CON2 1 Display Connection – not used.

CON2 2 Display Connection – not used.

CON2 3 Display Connection – not used.

CON2 4 Display Connection – not used.

CON2 5 Display Connection – not used.

CON2 6 Display Connection – not used.

CON2 7 Display Connection – not used.

CON2 8 Display Connection – not used.

CON2 9 Display Connection – not used.

CON2 10 Display Connection – not used.

CON3 1 Analogue Output – 0V.

CON3 2 Analogue Output – 4-20mA, load resistance <400Ω.

CON3 3 Analogue Output – 0-10V, load resistance >100Ω.

CON3 4 Analogue Output – 0-5V, load resistance>10KΩ.

CON4 1 Plug-in detection sensor module.

CON4 2 Plug-in detection sensor module.

CON4 3 Plug-in detection sensor module.

CON4 4 Plug-in detection sensor module.

CON4 5 Plug-in detection sensor module.

CON4 6 Plug-in detection sensor module.

CON5 1 RS485 Communication – A.

CON5 2 RS485 Communication – B.

CON5 3 RS485 Communication – Screen.

CON6 1 NO relay contact.

CON6 2 NO relay contact.

CON7 1 NO relay contact.

CON7 2 NO relay contact.

7

EN1B-0014UK07 R0404

Page 8

Automation & Control Solutions

Refrigeration Control

Newhouse Industrial Estate

Motherwell

Lanarkshire ML1 5SB

Phone: (44) 01698 481698

Fax: (44) 01698 481699

www.honeywell.com/refrigeration

Subject to change without notice.

EN1B-0014UK07 R1204

Loading...

Loading...