Page 1

GENERAL

Honeywell FEMA's Smart DCM Electronic Pressure Switches

are microprocessor-controlled pressure measurement

devices for relative pressures of -1…+1 bar and 0…40 bar.

They are suitable for an extremely wide range of applications,

including the precision recording, monitoring, and control of

system pressures. They come complete with an angled

M12x1 plug and are screwed (G1/2”) directly into the line /

vessel to be monitored.

FEATURES

• Open-collector

• Configurable as min./max./window monitor

• Adjustable drop-in/drop-out delay

• Hysteresis defined by set-point and reset-point

• Backlit LCD graphical display (Human-Machine-Interface

models, only) can be swiveled for better readability;

display can be rotated in 90° steps by software

• Self-monitoring

TECHNICAL DATA

Materials

Parts in contact w/ medium Stainless steel (1.4571)

Chemical resistance 4C4 as per EN 60721-3-4

HMI PA66 GF25

Total weight 300 g without, 350 g with HMI

Storage temperature

Versions without HMI -40...+80 °C (≤ 16 bar)

-40...+100 °C (> 16 bar)

Versions with HMI -30...+80 °C

Smart DCM

ELECTRONIC PRESSURE SWITCHES

PRODUCT DATA

Ambient (operating) temperature and humidity

Versions without HMI -20...+80 °C

Versions with HMI -20...+70 °C

Humidity 0...95% r.h., non-condensing

Temperature of medium -20…+80 °C

Climate class

Indoors 4K4H as per EN 60721-3-4

Outdoors 3K8H as per EN 60721-3-3

Mechanical stability

Vibration 20 g as per IEC 68-2-6 (up to

2000 Hz)

Mechanical shock 100 g as per IEC 68-2-27

Device resistance / Accuracy (combined non-linearity,

hysteresis, and repeatability at 20 °C)

pressure range P ≤ 16 bar P > 16 bar

overpressure safety 2x P

burst pressure 4x P

sensor type piezo thin-film

accuracy

Pressure meas. range 0…40 bar, -1…1 bar

Cycle time 100 ms

Protection rating

Models without HMI IP67 as per EN 60529-2

Models with HMI IP65 as per EN 60529-2

EMC Conforms to EN 61326

Protection class 2 as per EN 61010

Process connection G1/2" external thread

Electrical connection 4-prong A-coded M12x1 plug

Power supply 18…35 Vdc, max. 30 mA

Main switch load 250 mA (overcurrent protection)

Switch output

Output, high level (min.) V

Output, low level (max.) GND plus 0.5 V

WARN output voltage passive: V

active: ≤ 0.5 V

Reaction time max. 300 ms

Span, offset, and long-term drift (within temperature

compensation range of 0…80 °C)

temp. effect on span ±0.3% FS / 10 K ±0.2% FS / 10 K

temp. effect on offset ±0.3% FS / 10 K ±0.2% FS / 10 K

long-term drift* ±0.3% FS / year ±0.2% FS / year

max. ±0.8% FS

±0.5% FS (typ.)

(without load)

SUPPLY

2x P

nominal

10x P

nominal

minus 2 V

SUPPLY

max. typical

nominal

nominal

max. ±1% FS

±0.6% FS (typ.)

- 2 V

® U.S Registered Trademark

Copyright © 2008 Honeywell Inc. • All Rights Reserved MU0B-0561GE51 R0608

Page 2

SMART DCM – PRODUCT DATA

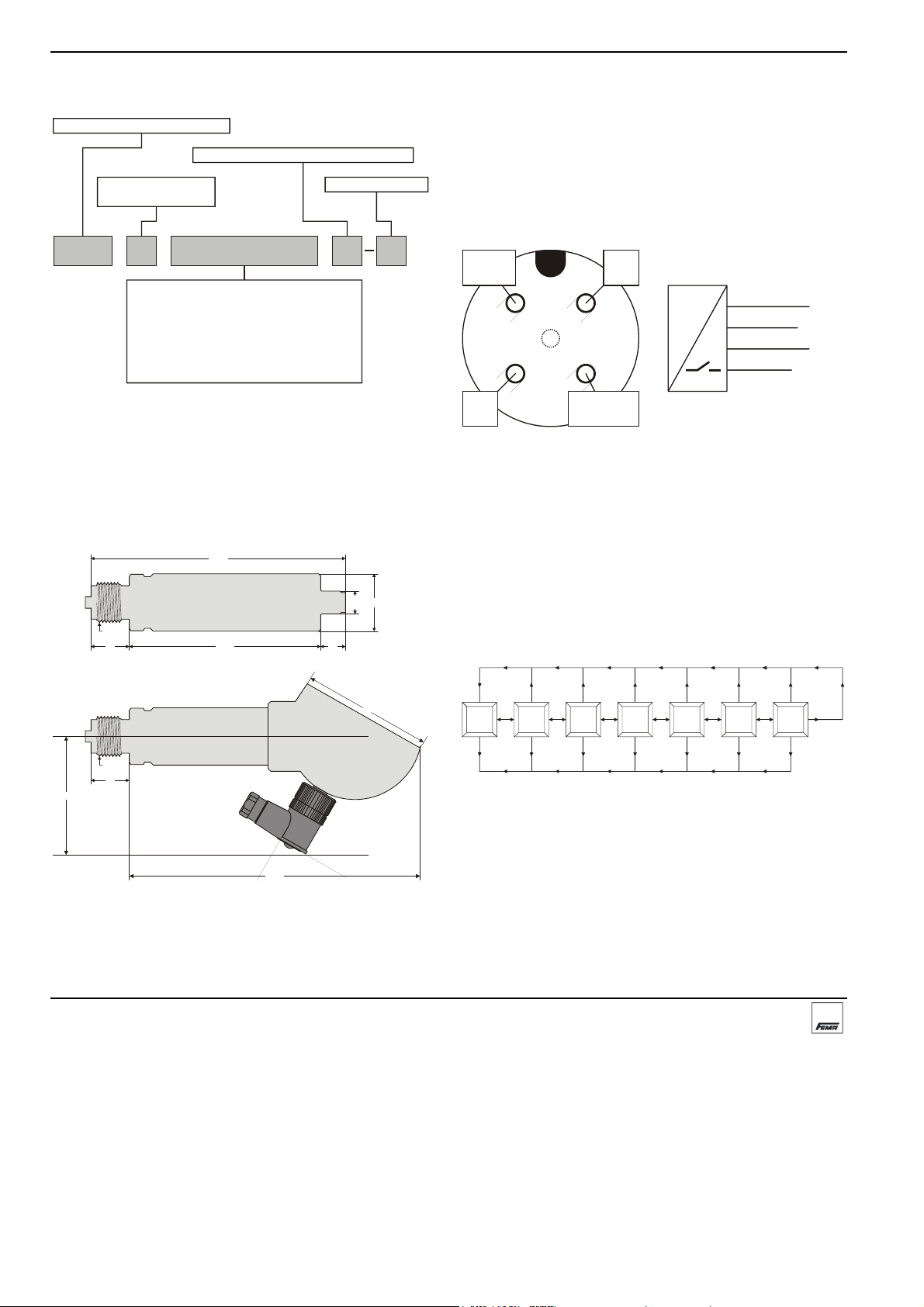

MODEL KEY

PS Pressure Switch=

1 G½” pressure connection=

H HMI

=

S Standard

=

PS H

RV101 = ...1 bar (rel.)

-1

RB001 = 0...1 bar (rel.)

RB004 = 0...4 bar (rel.)

RB010 = 0...10 bar (rel.)

RB016 = 0...16 bar (rel.)

RB025 = 0...25 bar (rel.)

RB040 = 0...40 bar (rel.)

*Only in combination with non-HMI models.

1

S Service*=

1

SRB

00

Fig. 1. Overview of models

INSTALLATION

Dimensions

The geometry of the G1/2" connection conforms to DIN EN

837. See also Fig. 2.

G 1/2”

20

133

100

30

M12

13

Mounting and Electrical Wiring

The device is mounted directly to the pipe via a G1/2"

(standard manometer) process connection (size 27 wrench).

This process connection serves to fasten and secure the

device in place. All mounting orientations are permitted.

Pin Assignment of Plug

The plug is an A-coded, four-prong M12 plug (see Fig. 3).

WARN

2

1

L+

P

1

2

3

4

4

L-

3

OC PNP

Fig. 3. A-coded M12 plug

Electrical Protection

The pressure switches are protected against pole-reversal

(d.c. power) and miswiring. The switches' outputs are not

electrically isolated.

LCD (HMI-MODELS, ONLY)

HMI models feature a 19 X 19 mm LCD equipped with a

bicolor backlight (white = normal operation; red = fault mode).

LCD display information refresh is adjustable to between 1

and 9 seconds.

L+

WARN

L-

OC PNP

6

7

G 1/2”

20

64

PREVIOUS

-0.90

bar

Closed

MENU

ESCAPE ESCAPE ESCAPE ESCAPE ESCAPE ESCAPE

Set-pt.

5.00bar

MENU

PREVIOUS

NEXT

PREVIOUS

NEXT

PREVIOUS

Reset-pt.

4.00bar Window

Monitor Function

NEXT

MENU MENU MENU MENU MENU

PREVIOUS

NEXT

PREVIOUS

Drop in

NEXT

N.C.

Fig. 4. Menu structure (excerpt)

delay

PREVIOUS

Drop

out delay

NEXT

0s

NEXT

0s

Accessories

Included in delivery: M12x1 Angled plug.

152

Fig. 2. Dimensions (in mm)

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Fema Controls

Honeywell GmbH

P.O. Box 1254

71099 Schönaich

Germany

phone: (49) 7031-637-02

fax: (49) 7031-637-850

http:/honeywell.de/fema

Subject to change without notice. Printed in Germany

MU0B-0561GE51 R0608

Optional:

• DMW Pressure surge reducer

• ST12-5-G Straight M12x1 plug.

Page 3

ALLGEMEINES

Die mikroprozessorunterstützten elektronischen Druckschalter der Baureihe Smart DCM von Honeywell FEMA

messen Relativdrücke von -1…+1 bar und 0…40 bar. Sie

sind bestens geeignet für vielfältige Einsatzbereiche, u.a. zur

genauen Erfassung, Überwachung und Regelung von

Systemdrücken. Der M12x1 Winkelstecker ist im Lieferumfang enthalten. Die Geräte werden direkt in die Druckleitung oder den Druckbehälter eingeschraubt (G1/2").

MERKMALE

• Open-Kollector

• Konfigurierbar als min./max./Fenster-Monitor

• Einstellbare Ein- und Ausschaltverzögerung

• Hysterese durch Stellpunkt und Rückstellpunkt definiert

• LCD-Anzeige (nur Human-Machine-Interface-Versionen),

zur besseren Ablesung schwenkbar, Anzeige per

Software in 90°-Schritten drehbar

• Selbstüberwachend

TECHNISCHE DATEN

Werkstoffe

Mediumberührte Teile Edelstahl (1.4571)

Chemische Beständigkeit 4C4 gemäß EN 60721-3-4

HMI PA66 GF25

Gesamtgewicht 300 g ohne, 350 g mit HMI

Lagertemperatur

Versionen ohne HMI -40...+80 °C (≤ 16 bar)

-40...+100 °C (> 16 bar)

Versionen mit HMI -30...+80 °C

Smart DCM

ELEKTRONISCHE DRUCKSCHALTER

PRODUKTDATEN

Umgebungstemperatur und -feuchtigkeit (bei Betrieb)

Versionen ohne HMI -20...+80 °C

Versionen mit HMI -20...+70 °C

Rel. Luftfeuchtigkeit 0...95%, nicht-kondensierend

Mediumtemperatur -20...+80 °C

Klimaklasse

Innenräume 4K4H gemäß EN 60721-3-4

Im Freien 3K8H gemäß EN 60721-3-3

Mechanische Festigkeit

Schwingungen 20 g gem. IEC 68-2-6 (bis

2000 Hz)

Mechan. Erschütterungen 100 g gemäß IEC 68-2-27

Druckbeständigkeit / Genauigkeit (kombinierte

Nichtlinearität, Hyst. und Reproduzierbarkeit bei 20 °C)

Druckbereich P ≤ 16 bar P > 16 bar

Überdruckbeständigkeit 2x P

Berstbeständigkeit 4x P

Fühlertyp Piezo Dünnfilm

Genauigkeit

Druckmeßbereich 0…40 bar, -1…1 bar

Taktzeit 100 ms

Schutzart

Versionen ohne HMI IP67 gemäß EN 60529-2

Versionen mit HMI IP65 gemäß EN 60529-2

EMV Gemäß EN 61326

Schutzklasse 2 gemäß EN 61010

Prozeßanschluß G1/2" Außengewinde

Elek. Anschluß 4-poliger M12x1-Stecker, "A"

Stromversorgung 18…35 Vdc, max. 30 mA

Hauptschaltlast 250 mA (gegen Überspannung

Schaltausgang

Ausg., oberer Wert (min.) V

Ausg., unterer Wert (max.) GND plus 0,5 V

WARN Ausg.-Spannung passiv: V

aktiv: ≤ 0,5 V

Antwortzeit max. 300 ms

Meßbereich, Kalibration und Langzeitdrift (innerhalb

Temperaturkompensationsbereich von 0…80 °C)

Temp.-Einfluß auf Meßb. ±0,3% FS / 10 K ±0,2% FS / 10 K

Temp.-Einfluß auf Kalib. ±0,3% FS / 10 K ±0,2% FS / 10 K

Langzeitdrift ±0,3% FS p.a. ±0,2% FS p.a.

max. ±0,8% FS

±0,5% FS (typ.)

(ohne Last)

geschützt)

VERSORG

2x P

nominal

10x P

nominal

minus 2 V

VERSORG

max. typisch

nominal

nominal

max. ±1% FS

±0,6% FS (typ.)

- 2 V

® U.S. eingetragene Handelsmarke

Urheberrechtlich geschützt © 2008 Honeywell Inc.

Alle Rechte Vorbehalten MU0B-0561GE51 R0608

Page 4

SMART DCM – PRODUKTDATEN

TYPENSCHLÜSSEL

PS Druckschalter=

1 G½” Druckanschluss=

H HMI

=

S Standard

=

PS H

RV101 = ...1 bar (rel.)

-1

RB001 = 0...1 bar (rel.)

RB004 = 0...4 bar (rel.)

RB010 = 0...10 bar (rel.)

RB016 = 0...16 bar (rel.)

RB025 = 0...25 bar (rel.)

RB040 = 0...40 bar (rel.)

*Nur in Verbindung mit Modellen ohne HMI.

1

S Service*=

1

SRB

00

Abb. 1. Typenübersicht

MONTAGE

Dimensionen

Die Geometrie des G1/2"- Anschlusses ist gemäß DIN EN

837. Siehe auch Abb. 2.

G 1/2”

20

G 1/2”

20

64

Abb. 2. Abmessungen (mm)

133

100

152

30

M12

13

6

7

Montage und Ausrichtung

Das Gerät wird mittels Prozeßanschlußgewinde G½"

(Schlüsselweite 27) direkt in die Druckleitung geschraubt.

Damit wird der Druckanschluß hergestellt und das Gerät

sicher in Position gehalten. Sämtliche Einbaulagen sind

zulässig.

Kontaktbelegung des Steckers

Der Stecker ist ein A-codierter 4-poliger Stecker (s. Abb. 3).

WARN

2

3

L-

Abb. 3. A-codierter M12-Stecker

L+

1

4

OC PNP

P

1

2

3

4

Elektrischer Schutz

Bei Betrieb mit Gleichstrom ist das Gerät gegen eine

Vertauschung der Strompolen geschützt. Die Ausgänge sind

nicht galvanisch isoliert.

LCD (nur Typen mit HMI)

Die HMI-Modelle sind mit einem 19 X 19 mm LCD ausgestattet mit zweifarbiger Hintergrundbeleuchtung (weiß =

Normalbetrieb; rot = Fehlbetrieb; 2-Leiter-Modelle ohne

Hintergrundbeleuchtung). Die Aktualisierungszeit der LCD

läßt sich zwischen 0 und 9 Sekunden einstellen.

PREVIOUS

-0.90

bar

Closed

MENU

ESCAPE ESCAPE ESCAPE ESCAPE ESCAPE ESCAPE

Set-pt.

5.00bar

MENU

PREVIOUS

NEXT

PREVIOUS

NEXT

PREVIOUS

Reset-pt.

4.00bar Window N.C.

Monitor Function

NEXT

MENU MENU MENU MENU MENU

PREVIOUS

NEXT

PREVIOUS

Drop in

NEXT

delay

PREVIOUS

NEXT

0s

Abb. 4. Menüstruktur (Auszug)

Zubehör

Im Lieferumfang enthalten: M12x1 Winkelstecker.

Optional:

• DMW Druckstoßminderer

• ST12-5-G Gerader M12x1 Stecker.

WARN

OC PNP

Drop

out delay

0s

L+

L-

NEXT

Hergestellt für und im Auftrag des Geschäftsbereichs Environmental and Combustion Controls der Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Schweiz in Vertretung durch:

Fema Controls

Honeywell GmbH

P.O. Box 1254

71099 Schönaich

Deutschland

Tel.: (49) 7031-637-02

Fax: (49) 7031-637-850

http:/honeywell.de/fema

Änderungen vorbehalten. Gedruckt in Deutschland

MU0B-0561GE51 R0608

Loading...

Loading...