SLN 700

SmartLine Le vel Tran sm it ter

Non-Contact Radar

User’s Manual

34-SL-25-13

Revision 1

October 2020

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page i

Copyrights, Notices and Trademarks

© Copyright 2020 by Honeywell International

Revision 1.0, October 2020

While the information in this document is presented in good faith and believed to be

accurate, Honeywell disclaims any implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in the written

agreement with and for its customers. In no event is Honeywell liable to anyone for any

indirect, special, or consequential damages. The information and specifications in this

document are subject to change without notice.

Honeywell, TDC3000, SFC, SmartLine, PlantScape, Experion PKS, and TotalPlant are

registered trademarks of Honeywell International Inc. Other brand or product names are

trademarks of their respective owners.

Honeywell Process Solutions

1250 W Sam Houston Pkwy S

Houston, TX 77042

Page ii SLN 700 SmartLine NCR Level Transmitter User’s Manual Revision 1

About This Manual

Version

Date released

History

Rev. 1.0

October 2020

First release

This manual is a detailed how to reference for installing, wiring, configuring, starting up,

operating, maintaining, calibrating, and servicing Honeywell’s family of SLN 700

SmartLine Non-Contact Radar Level Transmitters.

For details on the HART

Option User’s Manual, Document #34-SL-25-16.

The configuration of your Transmitter depends on the mode of operation and the options

selected for it with respect to operating controls and mechani ca l instal lat ion. Thi s manual

provides detailed procedures to assist first-time users, and it further includes keystroke

summaries, where appropriate, as quick reference or refreshers for experienced personn el.

To digitally integrate a Transmitter with one of the following systems:

• For the Experion PKS, you will need to supplement the information in this document

with the data and procedures in the Experion Knowledge Builder.

• For Honeywell’s TotalPlant Solutions (TPS), you will need to supplement the

information in this document with the data in the PM/APM SmartLine Transmitter

Integration Manual, which is supplied with the TDC 3000 book set. (TPS is the

evolution of the TDC 3000).

protocol, users are referred to the SLN 700 Series HART

Revision History

SLN 700 SmartLine Level Non-Contact Radar Transmitter User’s Manual,

Document #34-SL-25-13.

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page iii

References

hfs-tac-support@honeywell.com

The following list id entifies publ ications that m ay contain inform a tion re levant to the

information in this document.

• SLN 700 SmartLine Non-Contact Radar Level Transmitter HART Option Manual,

#34-SL-25-16

• SLN 700 SmartLine NCR Level Transmitter Specification, #34-SL-03-06

• SLN 700 SmartLine NCR Quick Start Guide (in the box), #34-SL-25-14

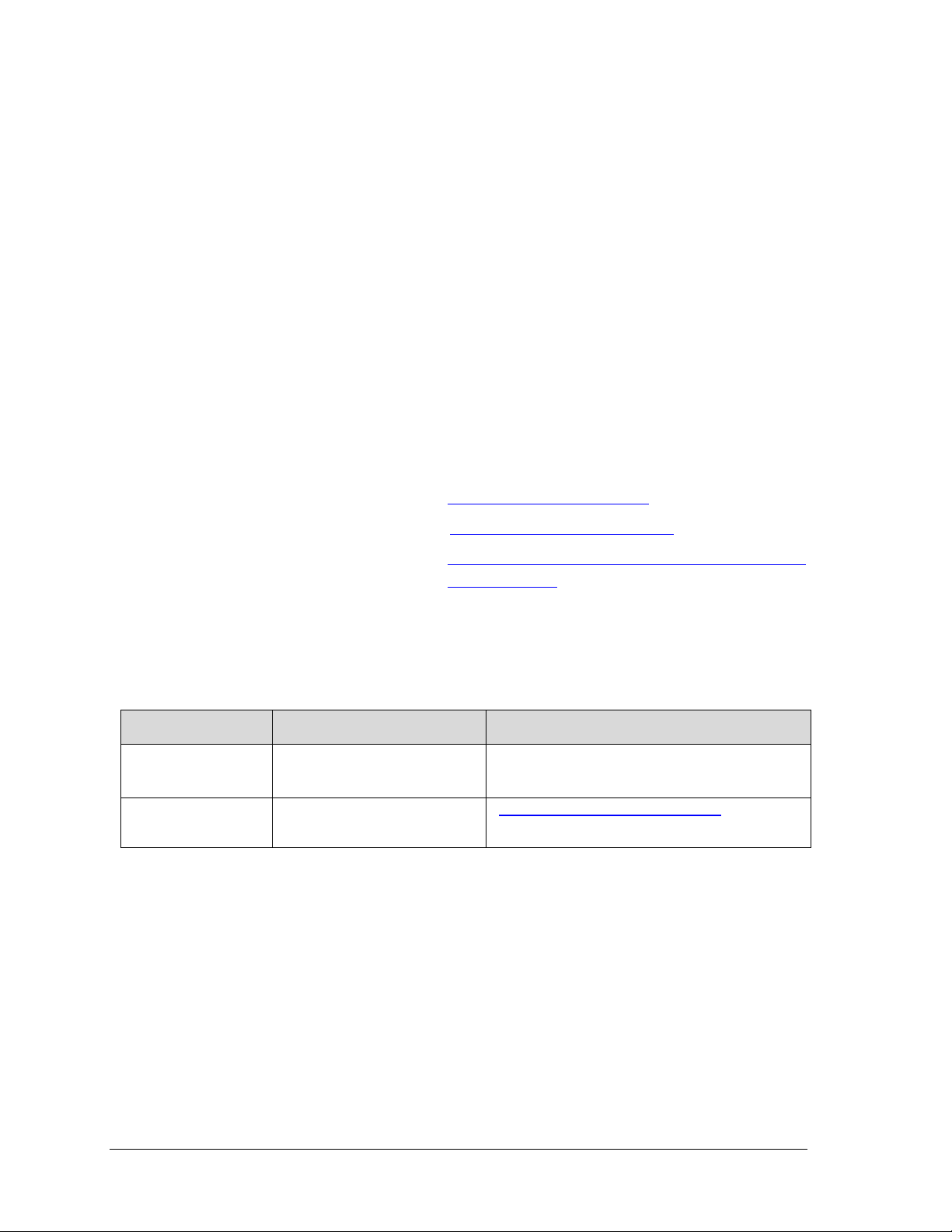

Support and Contact Information

For Europe, Asia Pacific, North and South America contact details, refer to the back page

of this manual or the appropriate Honeywell Support web site:

Honeywell Corporate www.Honeywellprocess.com

Honeywell Process Solutions hfs-tac-support@honeywell.com

Honeywell SmarLine Level https://www.honeywellprocess.com/smartline-level-

Telephone and Email Contacts

transmitter.aspx

Area Organization Phone Number

United States and

Canada

Global Email

Support

Honeywell Inc.

Honeywell Process

Solutions

1-800-343-0228 Customer Service

1-800-423-9883 Global Technical Support

Page iv SLN 700 SmartLine NCR Level Transmitter User’s Manual Revision 1

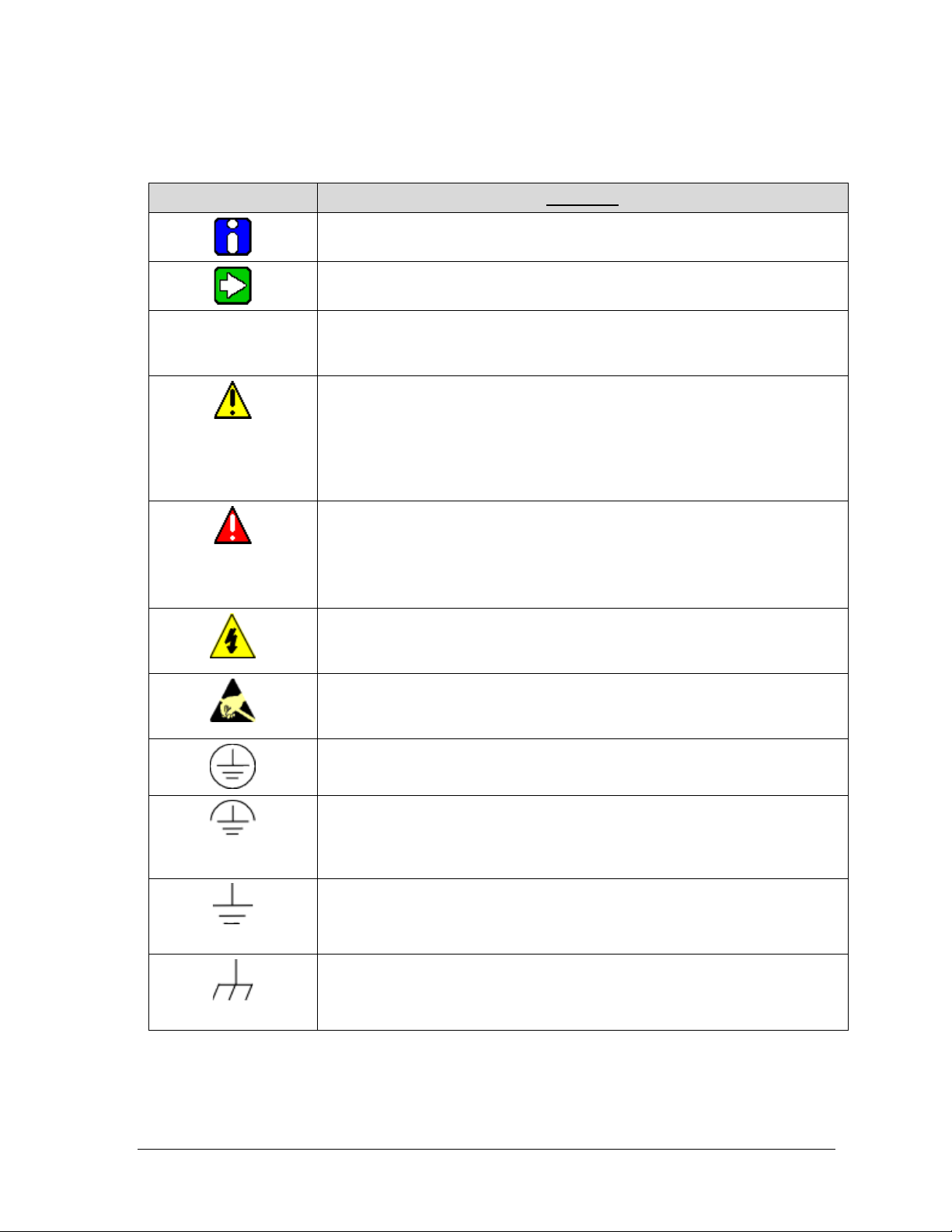

Symbols Descriptions and Definitions

The following symbols may appear in this document.

Symbol Definition

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advice or hints for the user, often in terms of performing a

task.

CAUTION Indicates a situation which, if not avoided, may result in equipment or

work (data) on the system being damaged or lost, or may result in the

inability to properly operate the process.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

CAUTION symbol on the equipment refers the user to the product manual

for additional information. The symbol appears next to required

information in the manual.

WARNING: Indicates a potentially hazardous situation, which, if not

avoided, could result in serious injury or death.

WARNING symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to required

information in the manual.

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60

VDC may be accessible.

ESD HAZARD: Danger of an electro-static discharge to which equipment

may be sensitive. Observe precautions for handling electrostatic sensitive

devices.

Protective Earth (PE) terminal: Provided for connection of the protective

earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as noise

immunity improvement. Note: This connection shall be bonded to

Protective Earth at the source of supply in accordance with national local

electrical code requirements.

Earth Ground: Functional earth connection. Note: This connection shall

be bonded to Protective Earth at the source of supply in accor danc e with

national and local electrical code requirements.

Chassis Ground: Identifies a connection to the chassis or frame of the

equipment shall be bonded to Protective Earth at the source of supply in

accordance with national and loc al electrical code requirements.

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page v

The Factory Mutual® Approval mark means the equipment has been

rigorously tested and certified to be reliable.

The Canadian Standards mark means the equipment has been tested

and meets applicable standards for safety and/or performance.

The Ex mark means the equipment complies with the requirements of the

European standards that are harmonized with the 2014/68/EU Directive

(ATEX Directive, named after the French "ATmosphere EXplosible").

Page vi SLN 700 SmartLine NCR Level Transmitter User’s Manual Revision 1

Contents

1 Introduction .......................................................................................................... 1

1.1 Overview ................................................................................................................................. 1

1.2 Transmitter Models ................................................................................................................. 1

1.3 Transmitter Components ........................................................................................................ 1

1.3.1 Overview of components .................................................................................................... 1

1.3.2 Electronics .......................................................................................................................... 2

1.3.3 Process Connector ............................................................................................................. 2

1.4 Communicating with the Transmitter ...................................................................................... 3

1.5 SLN 700 Transmitter Label ..................................................................................................... 3

1.6 Transmitter Model Number Description .................................................................................. 4

1.7 Safety Certification Information .............................................................................................. 4

2 Radar Level Measurement ................................................................................... 5

2.1 Overview ................................................................................................................................. 5

2.2 Theory of Operation ................................................................................................................ 5

3 Mounting .............................................................................................................. 6

3.1.1 Moisture-proof ..................................................................................................................... 7

3.1.2 Installation position ............................................................................................................. 8

3.1.3 Nozzle installations ........................................................................................................... 10

3.1.4 Correct and incorrect Installation position ........................................................................ 11

3.1.5 Installations with Agitation ................................................................................................ 12

4 Transmitter Installation ....................................................................................... 13

4.1 Supply voltage ...................................................................................................................... 13

4.2 Installation of connecting cables ........................................................................................... 14

4.2.1 General introduction ......................................................................................................... 14

4.3 Wiring mode .......................................................................................................................... 14

4.3.1 2-Wire ............................................................................................................................... 14

4.4 Hazardous Location – Intrinsic Safety .................................................................................. 15

5 Operating the Transmit ter .................................................................................. 17

5.1 Functions of keys .................................................................................................................. 17

6 Maintenance ...................................................................................................... 36

6.1 Configuration method ........................................................................................................... 36

6.1.1 Configuration with Display ................................................................................................ 36

6.1.2 Configuration .................................................................................................................... 37

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page vii

6.2 Procedures ............................................................................................................................ 38

6.2.1 Output Check Procedures ................................................................................................. 38

6.2.2 Constant Current Source Mode Procedure (Loop Test) ................................................... 38

6.2.3 Error Codes: ...................................................................................................................... 39

Glossary ................................................................................................................... 40

List of Figures

Figure 1-1 Components of the Level transmitter ................................................................................... 1

Figure 1-2: SLN 700 Transmitter label example ................................................................................... 3

Figure 1-3: Standard SLN 700 Model Number ..................................................................................... 4

Figure 3-1: Graphical illustration ........................................................................................................... 6

Figure 3-2: Moisture-proof diagram ...................................................................................................... 7

Figure 3-3: Installation position, >200 mm ........................................................................................... 8

Figure 3-4: Conical vessel installation ................................................................................................... 9

Figure 3-5: nozzle specifications diagram ........................................................................................... 10

Figure 3-6: Correct and incorrect installation position ........................................................................ 11

Figure 3-7: Correct and incorrect installation position ........................................................................ 11

Figure 3-8: Installation of reflecting plate ........................................................................................... 12

Figure 3-9: Agitation ............................................................................................................................ 12

Figure 4-1: Maximum Loop Resistance (Ω) ........................................................................................ 13

Figure 4-2: 2-wire wiring for HART ................................................................................................... 14

Figure 4-3: Intrinsically Safe Wiring ................................................................................................... 16

Figure 5-1: Instrument panel 4-key ...................................................................................................... 17

Figure 5-2: Representation of an echo curve defining the Echo Threshold and the Envelope Offset

quantities. ............................................................................................................................................. 35

Figure 6-1: Connect via HART hand-held ........................................................................................... 37

List of Tables

Table 1-1: Process Connector ................................................................................................................ 2

Table 3-1: Minimal distance to tank wall .............................................................................................. 8

Table 3-2: nozzle specifications table .................................................................................................. 10

Table 4-1: Maximum Loop Resistance (Ω) ......................................................................................... 13

Table 4-2: Hazardous Location Ratings ............................................................................................... 15

Table 4-3: Intrinsic Safety Entity Parameters ...................................................................................... 15

Table 4-4: Process Temperature Vs Tem pera tur e Class ...................................................................... 15

Table 5-1: Keys of LCD ...................................................................................................................... 17

Table 5-2: Display Menu Tree Basic Settings, Display and Diagnostics ............................................ 32

Table 5-3: Display Menu Tree Advanced Settings and System .......................................................... 34

Page viii SLN 700 SmartLine NCR Level Transmitter User’s Manual Revision 1

1.1 Overview

The SLN 700 SmartLine 80 GHz Non-Contact Radar transmitter is an electron ic i nstrument

designed to measure levels of liquid and solid materials. Non-Contact Radar (NCR) transmitters

use Frequency Modulated Continuous Wave (FMCW) radar signals that are reflected by the

material to be measured. The difference in frequency between the received and transmitted

signal is directly proportional to the distance to the liquid and can be measured with high

precision. Its small beam angle and small antenna size makes it easy to install. In com parison to

other level measurement technologies, NCR provides a highly-accurate, cos t-effective, reliable

measurement in applications where Guided Wave Radar (GWR) are not suitable.

1.2 Transmitter Models

The SLN 700 SmartLine 80 GHz NCR transmitter is available as a part of the family of

SLN700L models for liquid and SLN700S for solid applications. The pressure and temperature

range is -40 to 200°C/-1 to 40 bar for both, and each model is available with a range of flange or

threaded antenna, lens diameters, process connection, and accessories to suit most applications.

1 Introduction

1.3 Transmitter Components

Overview of components

As shown in Figure 1-1, the transmitter consists of:

• Electronics housing containing the core measurement module and optional display

module

• Process connection

• RF antenna

Figure 1-1 Components of the Level transmitter

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page 1

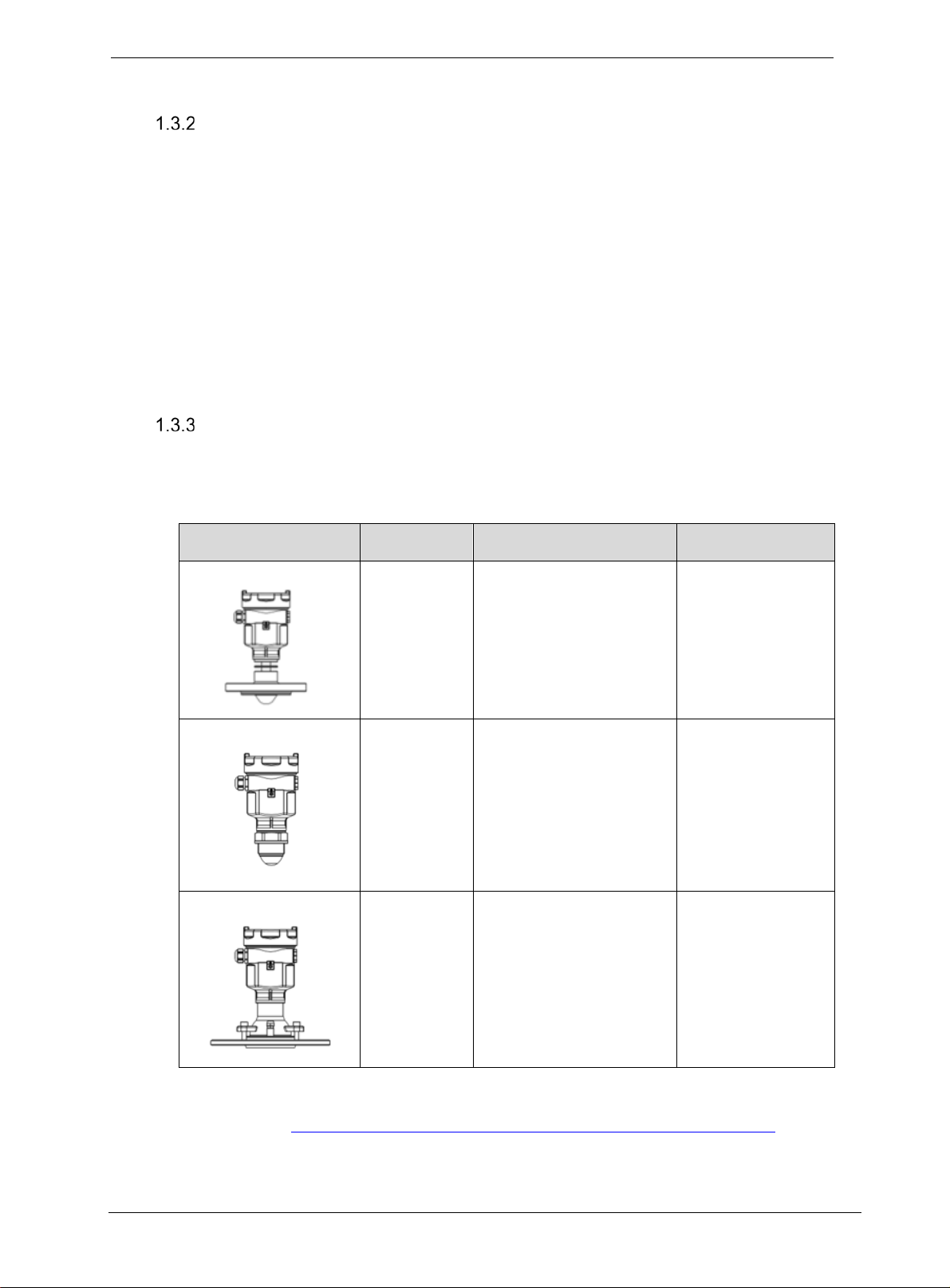

Series

Medium

Applications

Process

connections

82 Series

Liqid

Strong corrosive liquid

Flangeoptions

83 Series

Liquid

Strong corrosive or

Thread options

87 Series

Solid

Storage vessel/process

Flange options

Electronics

The Electronics consists of 2 distinct modules; core measurement electronics module and an

optional display module. Both are replaceable in the field.

To make changes to the transmitter setup or configuration without the use of an external device

such as a handheld or PC, an optional 4-Button interface is available.

The Optional Display module has the following features. (needs to be updated)

• Echo stem plot for checking measurement accuracy

• Standard and custom engineering units

• Diagnostic alerts and diagnostic messaging

• English and Chinese language options

Process Connector

The 80 GHz non-contact radar transmitter has 3 different series of products and associated

process connections.

Table 1-1: Process Connector

vapors o foam

pressure resistant liquid

vessel or high dust

applications

Page 2 SLN 700 SmartLine NCR Level Transmitter User’s Manual Revision 1

For list of all options and accessories please refer to the product specifications, which is

available, here: https://www.honeywellprocess.com/smartline-level-transmitter.aspx.

1.4 Communicating with the Tr a ns mi t t er

Level monitoring is possible through either the analog current (4-20 mA) or HART. It is possible

to configure a transmitter using HART

©

protocol or using the four-button interface and display.

Refer to manual 34-SL-25-16, SLN700 NCR HART Option Manual for details on available

HART commands

1.5 SLN 700 Transmitter Label

The transmitter label is mounted on the side of the electronics housing

(see Figure 1-2) and lists the following properties:

• Model number

• Physical con fig u ra tio n

• Power supply voltage

• Maximum working pressure rating

• Certification, if ordered (SIL and CRN)

Figure 1-2: SLN 700 Transmitter label example

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page 3

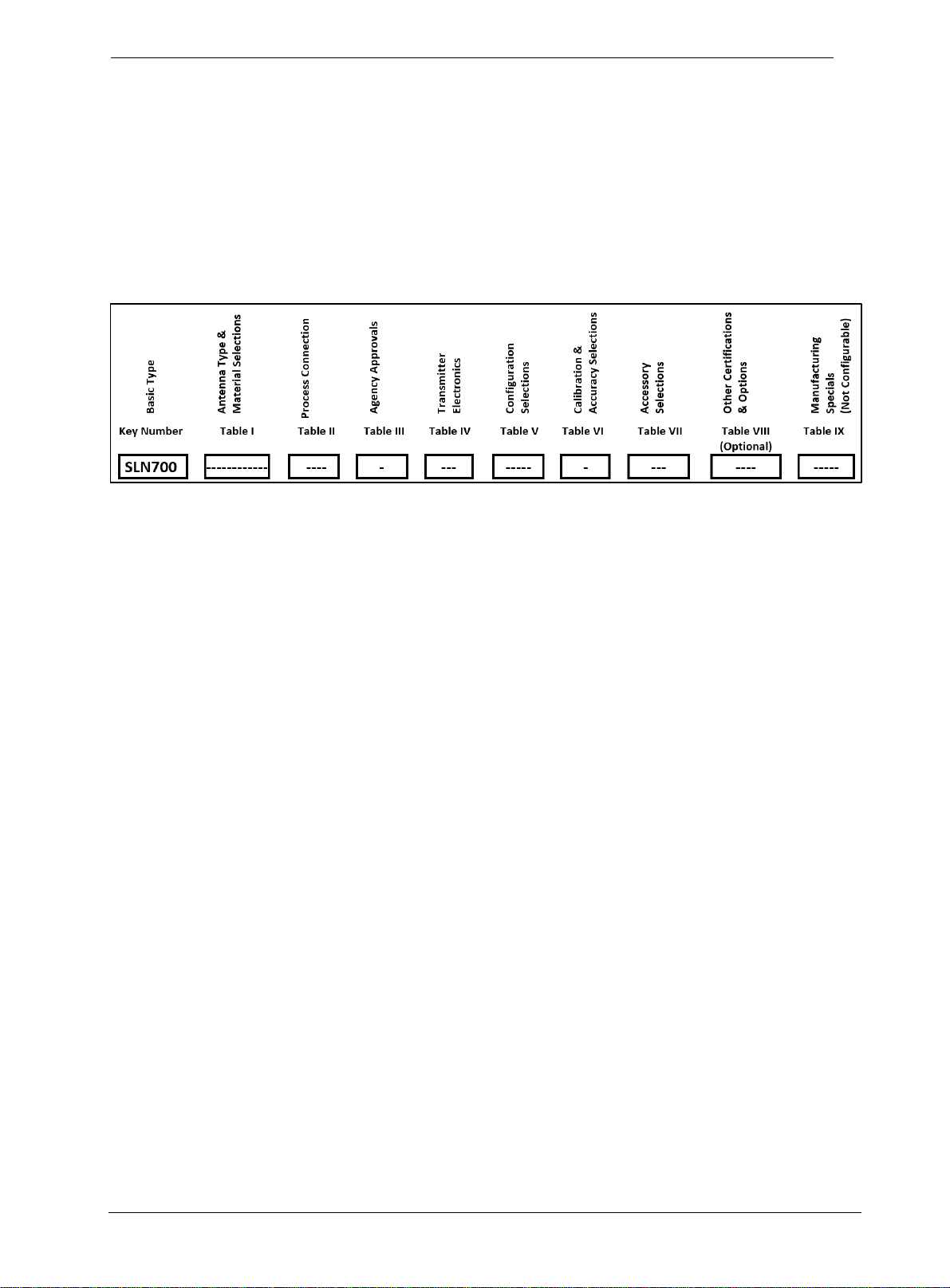

1.6 Transmitter Model Number Description

The model number is comprised from a number of selections and options that can be specified

when ordering the transmitter. It includes a basic transmitter type such as SLN720 (standard

temperature, standard pres s ure) followed by a maximum of nine additional character strings that

can be selected from a corresponding Table in the Model Selection Guide (MSG).

The basic model number structure is shown in Figure 1-3.

Figure 1-3: Standard SLN 700 Model Number

For a more complete description of the various configuration items and options, refer to the SLN

700 Product Specification (34-SL-03-06) and Model Selection Guide (34-SL-16-20).

1.7 Safety Certification Information

SLN transmitter models are available for use in Intrinsic Safe locations, including IECEx,

ATEX, and NEPSI approvals. See SLN 700 Product Specification (34-SL-03-06) or SLN 700

Quick Start Guide (34-SL-25-14) for details and other approvals.

Page 4 SLN 700 SmartLine NCR Level Transmitter User’s Manual Revision 1

2 Radar Level Measurement

2.1 Overview

This chapter describes the theory of operation of the transmitter and discusses how

measurements are affected by tank and process conditions.

2.2 Theory of Operation

The fundamental principle of operation is level measurement through the reflection of frequency

modulated radar waves (FMCW technique). The antenna emits a continuous wave of radiation

near 80 GHz whose frequency linearly increases in time in a saw tooth pattern. When the return

pulse is detected by the same antenna, the processing electronics use a Fourier Transform

technique to calculate the difference between the frequency of the generated and reflected signal.

This difference is proportional to the distance of reflection.

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page 5

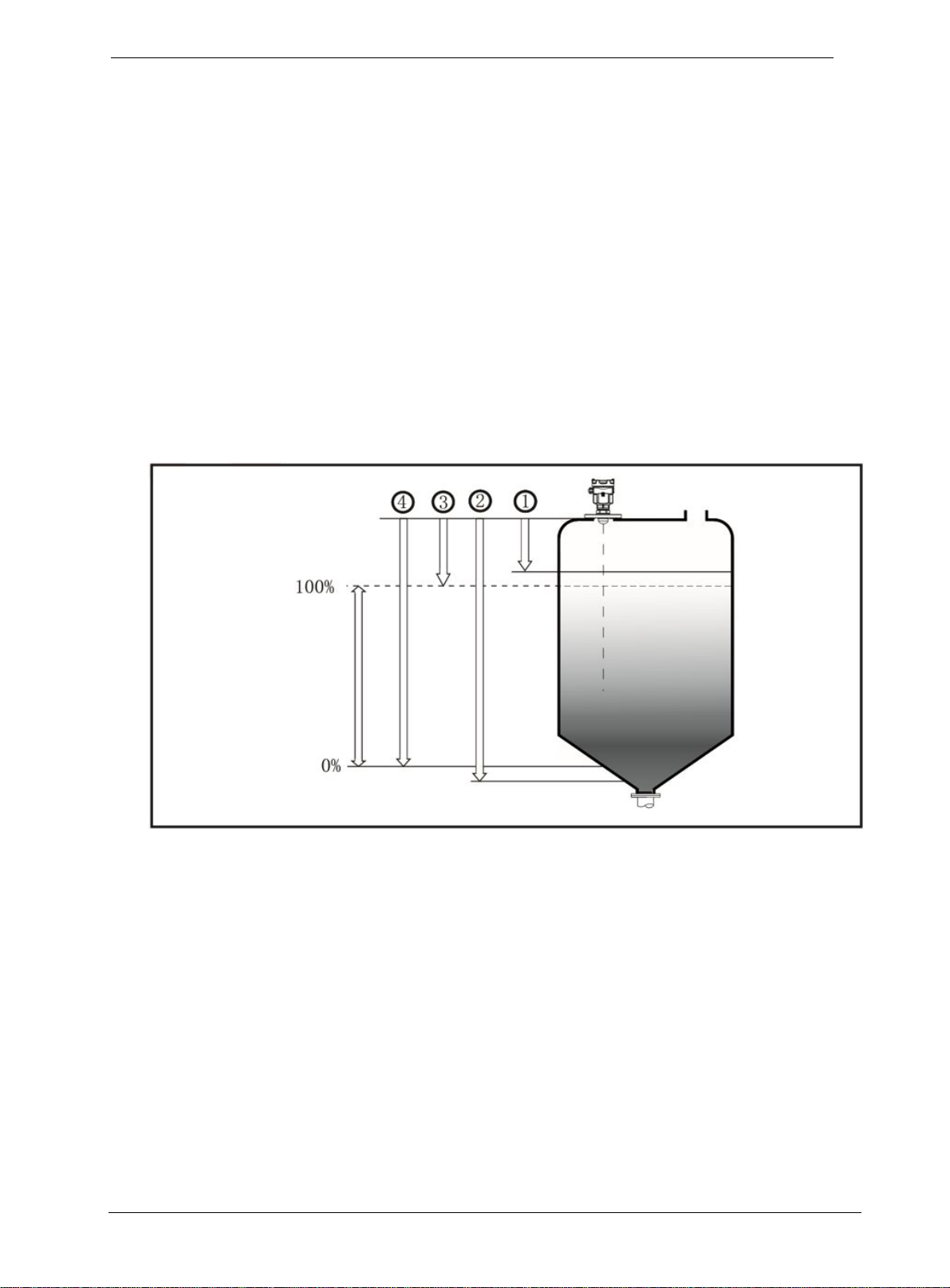

3 Mounting

Due to the finite beam angle and resulting transmission cone, there should be no obstacles in the area

radiated by the transmitted microwave beam from the lower edge of the antenna to the material su rf ace to

be measured. Therefore, it is necessary to avoid these facilities in the tank during installation. These

include ladders, limit switches, heating equipment, supports, etc. If necessary, some of the obstacles can

be removed from the measurement using background subtraction ("Virtual Echo Learning"). In addition,

please note that the microwave beam should not intersect with tank fluid in or out flows. Please also note

that the highest material level should not enter the near range (see Figure 3-1), the instrument should be

kept at a certain distance from the wall of tank wall and the transmitting antenna should be perpendicular

to the measured material surface as much as possible. The instruments installed in a hazardous classified

area shall follow the local national installation regulations.

The reference plane for measurement is the sealing surface of threads or flang es.

1. Near distance

2. Far distance

3. Distance at which sensor reads 100 % level (or current)

4. Distance at which sensor reads 0 % level (or current)

Figure 3-1: Graphical illustration

Page 6 SLN 700 SmartLine NCR Level Transmitter User’s Manual Revision 1

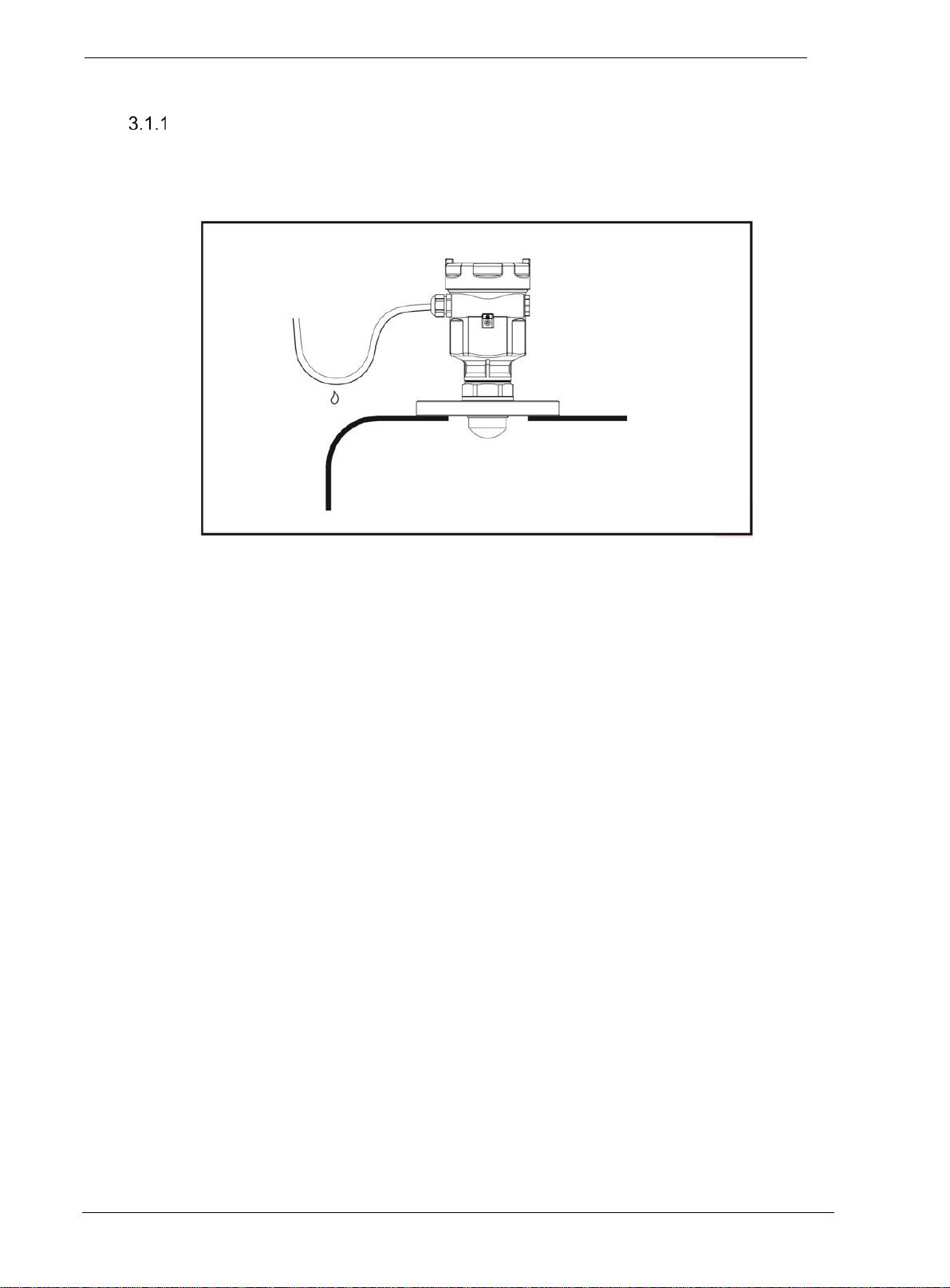

Moisture-proof

For instruments that are installed outside, in a wet environment, and cooling or heating tanks, the

cable gland must be tightened. The cable, at the cable gland entry, must be bent downward to

prevent moisture as shown in Figure 3-2.

Figure 3-2: Moisture-proof diagram

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page 7

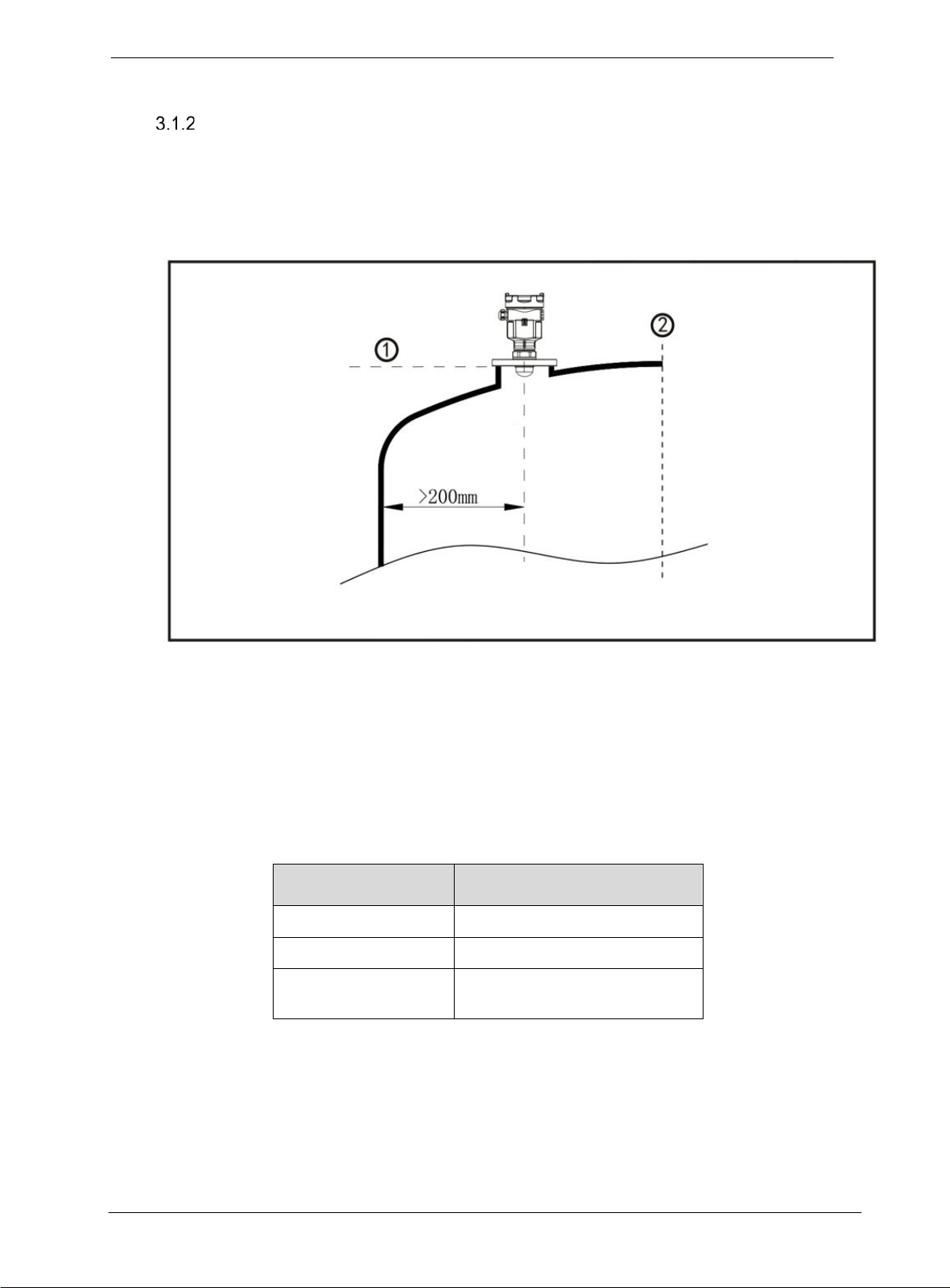

Installation position

During the installation, please note that the instrument should be kept minimal distance to tank

wall from the vessel wall. For different antenna, please refer to Table 3-1.

However, the instrument must not under any circumstances be mounted closer than 200mm to

the vessel wall or values calculated from Table 3-1.

1. Reference plane

2. Center of the vessel or symmetry axis

Figure 3-3: Installation position, >200 mm

Table 3-1: Minimal distance to tank wall

SLN700 Model Min distance to tank wall

83A 1/5 × Tank Height

82A 82B 83B 83C 1/10 × Tank Height

82C 82D 83D 83E

87A 87B 87C 87D

1/20 × Tank Height

Page 8 SLN 700 SmartLine NCR Level Transmitter User’s Manual Revision 1

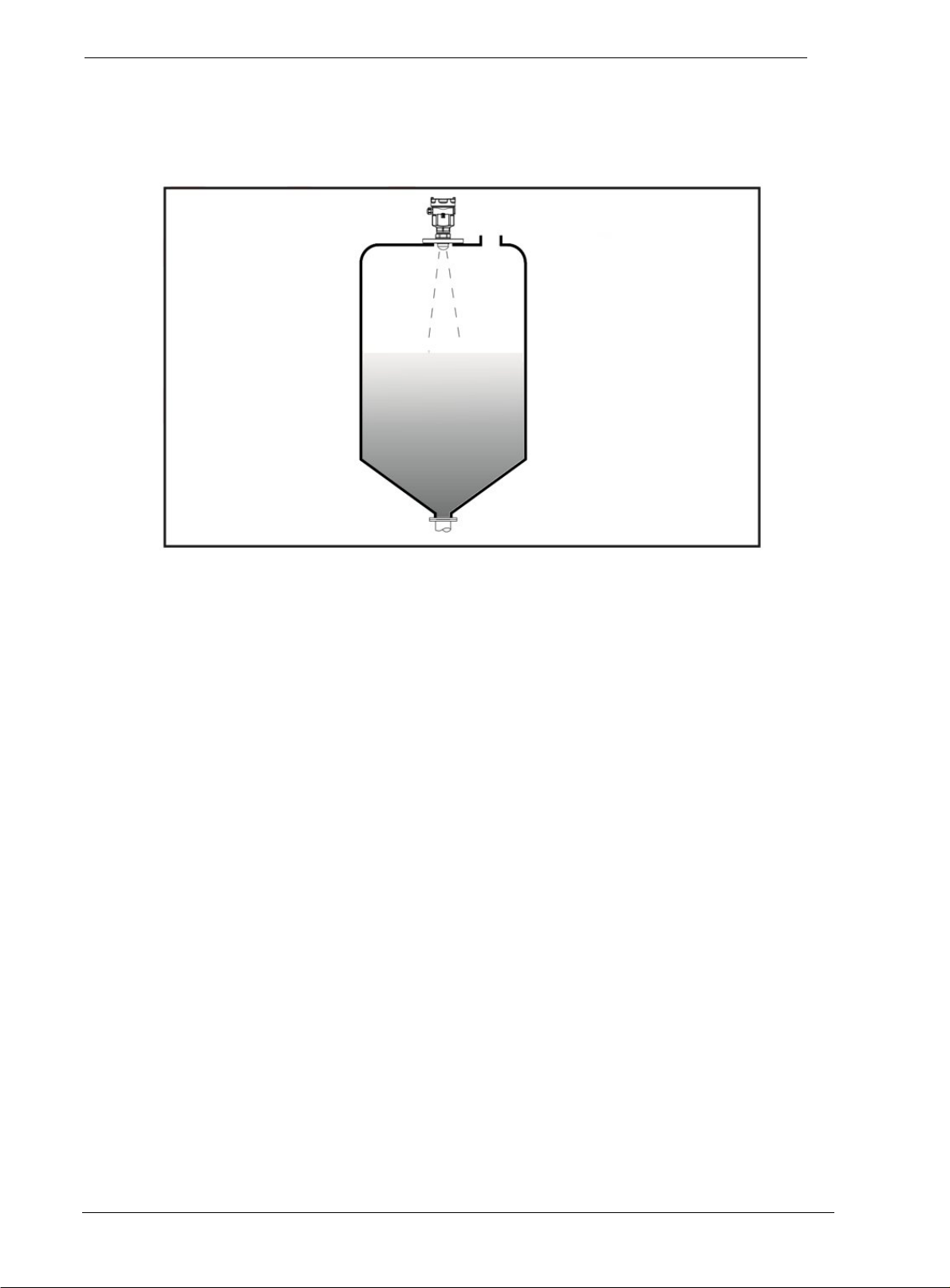

For the conical vessel with a flat tank top, the best installation position of instrument is the top

center of the vessel, which ensures that the bottom of the container is measured.

Figure 3-4: Conical vessel installation

Revision 1 SLN 700 SmartLine NCR Level Transmitter User’s Manual Page 9

Loading...

Loading...