Honeywell SLN 700 Installation Guide

SLN 700 Quick Start I nst allation Guide

34-SL-25-14, Revision 2, November 2020

Revision History

2.0 – November 2020

°C °F °C °F

Ambient

-25 to 80

-13 to 176

-40 to 80

-40 to 176

Humidity %RH

0 to 100

0 to 100

Series

Medium

Applications

Process

connections

82 Series

Liquid

Strong

Flange options

83 Series

Liquid

Strong

Thread

87 Series

Solid

Storage

Flange

SmartLine Level Non-Contact Radar

This document provides descriptions and

procedures for the quick installation of

Honeywell’s SmartLine Non-Contact Radar

Level Transmitters.

The SmartLine Level Non-Contact Radar is

available as a family of SLN72x models for

liquid and solid applications.

Copyrights, Notices and Trademarks

Copyright 2020 by Honeywell

Revision 1.0, July 2020

Documentation

To access complete documentation, including language variants, scan

the QR code below using your smart phone/device or QR code scanner.

Go to the APP store for your free Smartphone QR scanner

Or you can follow the URL to access the online SmartLine HUB page.

The HUB page will contain direct links to open SmartLine product

documentation.

URL QR Code

https://hwll.co/SmartLineHUB

INTRODUCTION

The Smartline SLN700L is available for both liquid and solid non-contact rada r level

measurement. Each model is available with a range of flange or threaded antenna,

lens diameters, process connection, and accessories to suit most applications.

Mounting the Transmitter

INSTALLATION

Evaluate the site selected for the SmartLine SLN700 installation with respect to the

process system design specifications in table 1. Please note that the display can

become unreadable below -20C (-4

increases.

Operating conditions

°F)

Parameter

Temperature

Table 1: Operating Conditions

Operative Limits

1

Trademarks

SFC, SmartLine, ST 800 and ST 700

are U.S. registered trademarks of

Honeywell Inc.

HART® and FOUNDATION™ are

trademarks of the FieldComm

Group™

but it will recover once the temperature

Transportation and

Storage

Table of Contents

INTRODUCTION ........................................................................................................ 1

INSTALLATION .......................................................................................................... 1

MOUNTING THE TRANSMITTER .............................................................................. 2

Installation position ..................................................................................................... 2

Conduit Entry Plugs and Adaptors .............................................................................. 3

WIRING ...................................................................................................................... 3

Hazardous Locations & Intrinsic Safety .................................................................... 4

EU Declaration of Conformity .................................................................................... 4

The full text of the EU declaration of conformity is available at the following internet

address:

https://www.honeywellprocess.com/library/support/Public/Documents/50164363.pdf 4

The SLN700 transmitters comply with the following directives ................................... 4

EMC Conformity ......................................................................................................... 4

The SLN700 transmitters comply with the following EMC standards .......................... 4

Table 1: Operating Conditions .................................................................................... 1

Table 2: Process Connectors ...................................................................................... 1

Table 3: Minimal distance to tank wall ........................................................................ 2

Table 4: Nozzle specification table.............................................................................. 2

Table 5: Maximum Loop Resistance (Ω) ..................................................................... 3

Table 6: Hazardous Location Ratings ......................................................................... 4

Table 7: Intrinsic Safety Entity Parameters ................................................................. 4

Table 8: Process Temperature Vs Temperature Class ............................................... 4

Table 9: Display Menu Tree Basic Settings, Display and Diagnostics ........................ 4

Figure 1: Graphical illustration .................................................................................... 2

Figure 2: Installation position, >200 mm ..................................................................... 2

Figure 3: Conical vessel installation ............................................................................ 2

Figure 4: Nozzle specifications diagram ..................................................................... 2

Figure 5: Agitation ....................................................................................................... 3

Figure 6: Electronic Housing Conduit Entries .............................................................. 3

Figure 7: Maximum Loop Resistance (Ω).................................................................... 3

Figure 8: 2-wire wiring for HART ................................................................................. 3

Process Connector

The 80 GHz non-contact radar transmitter has three different series of products and

associated process connections.

For list of all options and accessories please refer to the product specifications,

which is available, here: https://www.honeywellprocess.com/smartline-level-

transmitter.aspx.

Table 2: Process Connectors

Tables

Figures

corrosive liquid

vapors or

foam

corrosive or

pressure

resistant

liquid

vessel/proces

s vessel or

high dust

applications

options

options

SLN700 Quick Start Installation Guide 1

82C 82D 83D 83E

87A 87B 87C 87D

Nozzle

d(mm)

Maximum Nozzle Height h(mm)

82A 82B

83B 83C

82C 82D

83D 83E

87A 87B

87C 87D

40

150

NA

NA

NA

50

150

150

NA

NA

80

200

200

200

NA

100

300

300

300

300

125

400

400

400

400

150

500

500

500

500

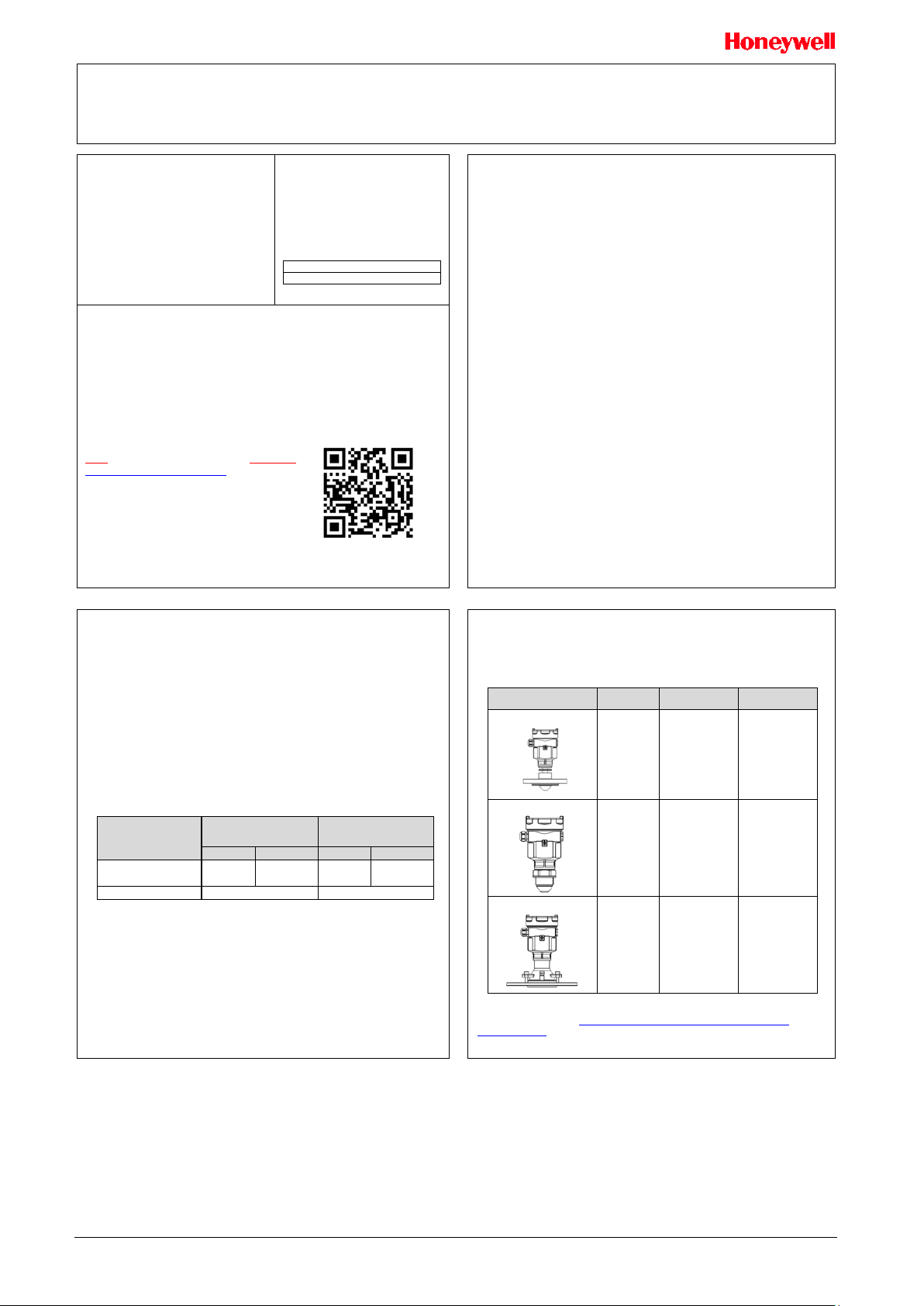

MOUNTING THE TRANSMITTER

There should be no obstacles in the area radiated by the transmitted microwave

beam from the lower edge of the antenna to the material surface to be measured

within the cone angle of the radar beam. These obstacles include ladders, limit

switches, heating equipment, supports, etc. When these are unavoidable, the gauge

offers background subtraction (“Virtual Echo Learning”) so that obstacles will be

ignored during level measurement. In addition, please note that the microwave beam

should not intersect with tank fluid in or out flows. In addition, the highest liquid or

solid tank level should not encroach into the upper blocking distance of the gauge

(typically a few cm). (see Figure 1), The instrument should be kept at a certain

distance from the tank wall and the transmitting antenna should be perpendicular to

the measured material surface as much as possible.

The instruments installed in a hazardous classified area shall follow the local national

installation regulations.

The reference plane for measurement is the sealing surface of threads or flanges.

1. Near (blocking) distance

2. Far distance

3. Distance at which sensor reads 100% level (or current)

4. Distance at which sensor reads 0 % level (or current)

For a conical vessel with a flat tank top, the best installation position of the instrument

is the top center of the vessel, which ensures that the bottom of the container is

measured.

Figure 1: Graphical illustration

Figure 3: Conical vessel installation

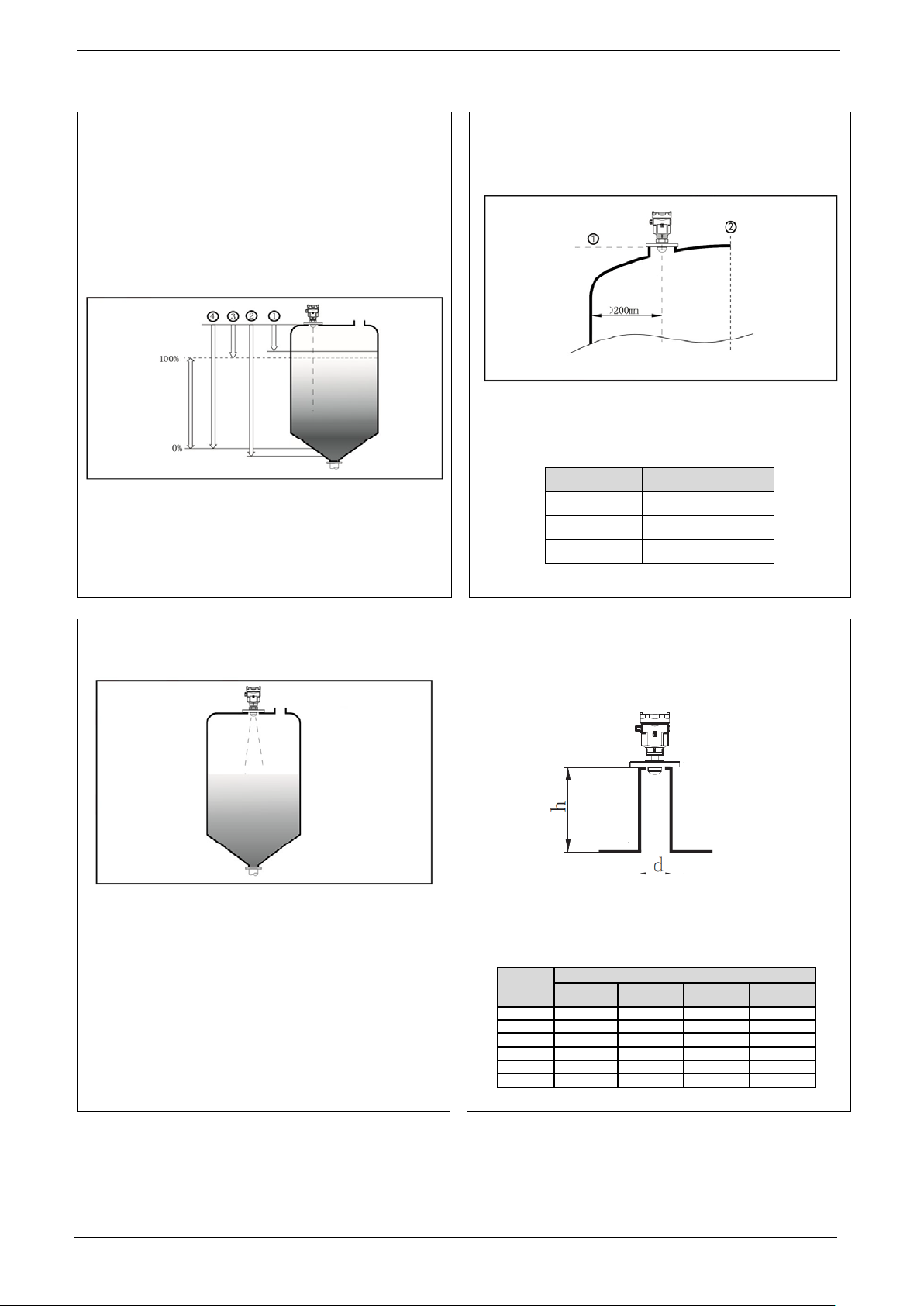

Installation position

The minimum distance between the antenna and tank wall is variable for different

antenna. Please refer to Table 3.to calculate the minimum distance for your particular

model. In no instance, should the instrument be mounted closer than 200 mm to the

tank wall.

1. Reference plane

2. Center of the vessel or symmetry axis

Nozzle installations

In the case of a tank fluid or solid with good reflection properties (high dielectric

constant), the sensor may be mounted on a nozzle. The background subtraction ("virtual

echo learning") feature can further reduce false echoes from nozzle openings.

Table 4 shows detail of the size limitations of the nozzle.

Diameter

Figure 2: Installation position, >200 mm

Table 3: Minimal distanc e to tank wall

SLN700 Model Min distance to tank wall

83A 1/5 × Tank Height

82A 82B 83B 83C 1/10 × Tank Height

Figure 4: Nozzle specifications diagram

Table 4: Nozzle specification table

83A

1/20 × Tank Height

SLN700 Quick Start Installation Guide 2

Loading...

Loading...