Page 1

SLG 700

SmartLine Level Transmitter

Guided Wave Radar

User’s Manual

34-SL-25-11

Revision 9.0

July 2020

Honeywell Process Solutions

Page 2

Copyrights, Notices and Trademarks

© Copyright 2020 by Honeywell International

Revision 9.0, July 2020

While the information in this document is presented in good faith and believed to be

accurate, Honeywell disclaims any implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in the written

agreement with and for its customers. In no event is Honeywell liable to anyone for any

indirect, special, or consequential damages. The information and specifications in this

document are subject to change without notice.

Honeywell, TDC3000, SFC, SmartLine, PlantScape, Experion PKS, and TotalPlant are

registered trademarks of Honeywell International Inc. Other brand or product names are

trademarks of their respective owners.

Honeywell Process Solutions

1250 W Sam Houston Pkwy S

Houston, TX 77042

Page ii SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 3

About This Manual

This manual is a detailed how to reference for installing, wiring, configuring, starting up,

operating, maintaining, calibrating, and servicing Honeywell’s family of SLG 700 SmartLine

Guided Wave Radar Level Transmitters. Users who have a Honeywell SLG 700 SmartLine

Guided Wave Radar Level Transmit ter con figu red fo r HA RT

SLG 700 Series HART

Option User’s Manual, Document #34-SL-25-06. Users who have a

Honeywell SLG 700 SmartLine Guided Wave Radar Level Transmitter configured for

Fieldbus operation are referred to the SLG 700 Series Foundation

Manual, Document #34-SL-25-07.

The configuration of your Transmitter depends on the mode of operation and the options

selected for it with respect to operating controls, displays and mechanical installation. This

manual provides detailed procedu res to ass ist first-time users, and it further includes

keystroke summaries, where appropriate, as quick reference or refreshers for experienced

personnel.

To digitally integrate a Transmitter with one of the following systems:

• For the Experion PKS, you will need to supplement the information in this document

with the data and procedures in the Experion Knowledge Builder.

• For Honeywell’s TotalPlant Solutions (TPS), you will need to supplement the

information in this document with the data in the PM/ A PM Sm artLine Tran smitter

Integration Manual, which is supplied with the TDC 3000 book set. (TPS is the evolution

of the TDC 3000).

protocol are referred to the

TM

Fieldbus Option User’s

Revision Histo r y

SLG 700 SmartLine Level Guided Wave Radar Transmitter User’s Manual,

Document #34-SL-25-11

Rev. 1.0 March 2015 First release

Rev. 2.0 April 2015 Updates to troubleshooting and Display menus

Rev. 3.0 June 2015 Security Considerations and Vulnerability added.

Rev. 4.0 June 2016 Updates for the R101 release. Including SLG726.

Rev. 5.0 July 2016 Display menus updated.

Rev. 6.0 December 2016 False Echo suppression, improved interface thickness

Rev. 7.0 February 2017 Troubleshooting section and Fieldbus updates

Rev. 8.0 December 2017 Saturated Steam application (R200)

Rev. 9.0 July 2020 approvals update (INMETRO)

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page iii

Page 4

References

The following list id entifies publ ica tions that may contain information rele v an t to th e in fo rmation

in this document.

SLG 700 SmartLine Guided Wave Radar Level Transmitter Quick Start Guide,

Document #34-SL-25-04

SLG 700 SmartLine Guided Wave Radar Level Transmitter Safety Manual,

Document #34-SL-25-05

SLG 700 SmartLine Guided Wave Radar Level Transmitter HART Option Manual,

Document #34-SL-25-06

SLG 700 SmartLine Level Transmitter Guided Wave Radar FOUNDATION Fieldbus Option

Manual, Document #34- SL-25-07

SLG 700 SmartLine Level Transmi tter Product Specification Document #34-SL-03-03

Patents

The Honeywell SLG 700 SmartLine Guided Wave Radar Level Transmitter family is covered by

U. S. Patents 9329072, 9329073, 9476753 and 9518856 and 9329074, 9574929, 9618612,

9711838 and their foreign equivalents and other patents pending.

Support and Contact Information

For Europe, Asia Pacific, North and South America contact details, refer to the back page of this

manual or the appropriate Honeywell Support web site:

Honeywell Corporate www.honeywell.com

Honeywell Process Solutions https://www.honeywellprocess.com/*

Honeywell SmartLine Level https://www.honeywellprocess.com/smartline-level-transmitter.aspx

Telephone and Email Contacts

Area Organization Phone Number

United States and

Canada

Global Email

Support

Honeywell Inc.

Honeywell Process

Solutions

1-800-343-0228 Customer Service

1-800-423-9883 Global Technical Support

hfs-tac-support@honeywell.com

Page iv SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 5

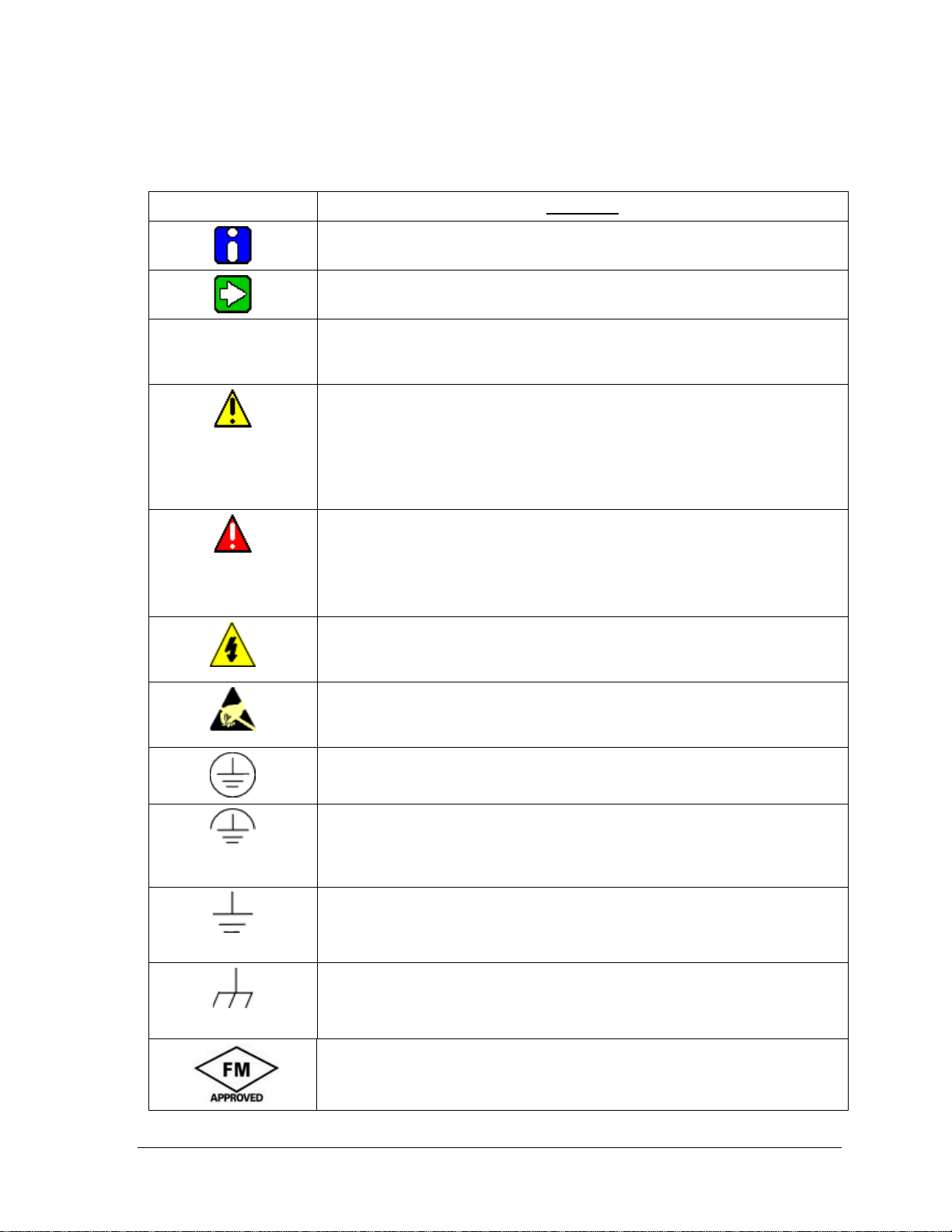

Symbols Descriptions and Definitions

The following symbols may appear in this document.

Symbol Definition

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advice or hints for the user, often in terms of performing a

CAUTION Indicates a situation which, if not avoided, may result in equipment or

task.

work (data) on the system being damaged or lost, or may result in the

inability to properly operate the process.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used to

alert against unsafe practices .

CAUTION symbol on the equipment refers the user to the product manual

for additional information. The symbol appears next to required

information in the manual.

WARNING: Indicates a potentially hazardous situation, which, if not

avoided, could result in serious injury or death.

WARNING symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to required

information in the manual.

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60

VDC may be accessible.

ESD HAZARD: Danger of an electro-static discharge to which equipment

may be sensitive. Observe precautions for handling electrostatic sensitive

devices.

Protective Earth (PE) terminal: Provided for connection of the protective

earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as noise

immunity improvement. Note: This connection shall be bonded to

Protective Earth at the source of supply in accordance with national local

electrical code requirements.

Earth Ground: Functional earth connection. Note: This connection shall

be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

Chassis Ground: Identifies a connection to the chassis or frame of the

equipment shall be bonded to Protective Earth at the source of supply in

accordance with national and local electrical code requirements.

The Factory Mutual® Approval mark means the equipment has been

rigorously tested and certified to be reliable.

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page v

Page 6

Symbol Definition

The Canadian Standards mark means the equipment has been tested

and meets applicable standards for safety and/or performance.

The Ex mark means the equipment complies with the requirements of the

European standards that are harmonized with the 2014/68/EU Directive

(ATEX Directive, named after the French "ATmosphere EXplosible").

Page vi SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 7

Contents

1 Introduction .......................................................................................................... 1

1.1 Overview ................................................................................................................................. 1

1.2 Transmitter Models ................................................................................................................. 1

1.3 Transmitter Components ........................................................................................................ 1

1.3.1 Overview of components .................................................................................................... 1

1.3.2 Electronics Housing ............................................................................................................ 2

1.3.3 Sensor Housing .................................................................................................................. 3

1.3.4 Process Connector ............................................................................................................. 3

1.3.5 Probe .................................................................................................................................. 4

1.4 Communicating with the Transmitter ...................................................................................... 6

1.4.1 4-20 mA HART .................................................................................................................. 6

1.4.2 FOUNDATIONTM Fieldbus (FF) .......................................................................................... 8

1.4.3 DTM-based tools and Experion .......................................................................................... 9

1.5 SLG 700 Transmitter nameplate .......................................................................................... 11

1.6 Transmitter Model Number Description ................................................................................ 13

1.7 Safety Certification Information ............................................................................................ 13

1.7.1 Safety Integrity Level (SIL) ............................................................................................... 13

1.8 Security Considerations ........................................................................................................ 14

1.9 Measurement Options Licensing .......................................................................................... 14

2 Radar Level Measurement ................................................................................. 15

2.1 Overview ............................................................................................................................... 15

2.2 Theory of Operation .............................................................................................................. 15

2.2.1 TDR for Interface and Flooded Measurements ................................................................ 17

2.3 Signal processing configuration ............................................................................................ 18

2.3.1 Amplitude Tracking ........................................................................................................... 19

2.3.2 Full-tank Detection ............................................................................................................ 19

2.3.3 Maximum Fill Rates, Latching and Timeouts.................................................................... 20

2.4 Signal Interferences and background echoes ...................................................................... 21

2.4.1 Field and Obstacle background ........................................................................................ 21

2.4.2 Static and Dynamic backgrounds ..................................................................................... 21

2.4.3 Accuracy and measurement range specifications ............................................................ 22

2.5 Process Applications ............................................................................................................ 28

2.5.1 Single Liquid ..................................................................................................................... 28

2.5.2 Two Liquid Applications .................................................................................................... 28

2.5.3 Low Dielectric Applications ............................................................................................... 30

2.5.4 Steam Boiler Applications ................................................................................................. 31

2.6 Process Condition Considerations ....................................................................................... 32

2.6.1 Turbulence ........................................................................................................................ 32

2.6.2 Foam or Emulsions ........................................................................................................... 32

2.6.3 FEP Pr ob e ........................................................................................................................ 32

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page vii

Page 8

2.7 Container Considerations ...................................................................................................... 33

2.7.1 Shapes .............................................................................................................................. 33

2.7.2 Materials (plastic vs. metal) ............................................................................................... 33

2.8 Blocking distance high and blocking distance low guidance ................................................ 34

2.8.1 Blocking distance high (BDH) guidance ............................................................................ 34

2.8.2 Blocking distance low (BDL) guidance .............................................................................. 34

2.8.3 Blocking Distance, Full Tank Detection and Latching modes ........................................... 34

3 Transmitter Installation ....................................................................................... 36

3.1 Preparation ............................................................................................................................ 36

3.1.1 Installation sequence ........................................................................................................ 36

3.1.2 Tools .................................................................................................................................. 37

3.2 Mechanical Installation .......................................................................................................... 38

3.2.1 Check for correct probe dimensions and strength ............................................................ 38

3.2.2 Accuracy and measuring range specifications .................................................................. 38

3.2.3 Trim the probe length ........................................................................................................ 47

3.2.4 Attach/assemble the probe ............................................................................................... 48

3.2.5 Centering Disks and configured probe length ................................................................... 61

3.2.6 Mounting the transmitter ................................................................................................... 67

3.2.7 Suitable mounting position ................................................................................................ 73

3.2.8 Optimum Operating Temperature ..................................................................................... 74

3.2.9 Temperature requirements ................................................................................................ 75

3.2.10 Mounting on a non-metallic container ........................................................................... 83

3.2.11 Rotate transmitter housing ............................................................................................ 86

3.2.12 Secure the probe ........................................................................................................... 86

3.2.13 Install conduit entry plugs and adapters ....................................................................... 89

3.2.14 Flange pressure ratings ................................................................................................ 90

3.2.15 Material Exposed to Tank Atmosphere ......................................................................... 90

3.3 Electrical Installation ............................................................................................................. 91

3.3.1 Wiring a transmitter ........................................................................................................... 91

3.3.2 HART / 4-20mA Voltage Operating Ranges ..................................................................... 91

3.3.3 Terminal Connections ....................................................................................................... 93

3.3.4 FOUNDATION Fieldbus .................................................................................................... 94

3.3.5 Wiring Procedure............................................................................................................... 94

3.3.6 Lightn ing Prot ec tio n .......................................................................................................... 95

3.3.7 Supply Voltage Limiting Requirements ............................................................................. 95

3.3.8 Process Sealing ................................................................................................................ 95

3.3.9 Explosion-Proof Conduit Seal ........................................................................................... 95

4 Operating the Transmit ter .................................................................................. 96

4.1 User interface options ........................................................................................................... 96

4.1.1 Transmitter advanced displays with buttons ..................................................................... 96

4.1.2 DTM or DD – HART and FF .............................................................................................. 96

4.2 Three-Button Operation ........................................................................................................ 97

4.2.1 Three-button operation without displ a y ............................................................................. 97

4.2.2 Menu Navigation ............................................................................................................... 99

4.2.3 Data Entry ......................................................................................................................... 99

4.2.4 Editing a Numeric Value .................................................................................................. 100

4.2.5 Selecting a new setting from a list of choices ................................................................. 100

Page viii SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 9

4.3 The Advanced Display Menu .............................................................................................. 101

4.3.1 Correlation Model Recalculation ..................................................................................... 102

4.4 Monitoring the Advanced Display ....................................................................................... 120

4.4.1 Advanced Displays ......................................................................................................... 120

4.4.2 Button operation during monitoring ................................................................................ 122

4.5 Changing the Failsafe Direction and Write Protect Jumpers (Including Simulation mode) 123

4.5.1 Procedure to Establish Failsafe Operation ..................................................................... 123

5 Maintenance .................................................................................................... 126

5.1 Overview ............................................................................................................................. 126

5.2 Preventive Maintenance Practices and Schedules ............................................................ 126

5.3 Procedures ......................................................................................................................... 129

5.3.1 Output Check Procedures .............................................................................................. 129

5.3.2 Constant Current Source Mode Procedure .................................................................... 130

5.3.3 Replacing the Terminal Block ......................................................................................... 131

5.3.4 Replacing the Display Assembly .................................................................................... 131

5.3.5 Replacing the Communication Module ........................................................................... 131

5.4 How to replace the Sensor Housing ................................................................................... 132

5.4.1 Tools required. ................................................................................................................ 134

5.4.2 Hazar dous Loc at ions ...................................................................................................... 140

5.4.3 Appendix: Reconciling Model Numbers .......................................................................... 140

5.5 Replacing the Wire Probe ................................................................................................... 142

5.5.1 Tools required ................................................................................................................. 142

5.5.2 Procedures ..................................................................................................................... 143

5.6 Trimming Coaxial Probes ................................................................................................... 147

5.6.1 Tools required ................................................................................................................. 147

5.6.2 Procedure ....................................................................................................................... 147

5.7 Saturated Steam Probe Installation .................................................................................... 150

5.7.1 Tools required ................................................................................................................. 150

5.7.2 Procedure ....................................................................................................................... 150

6 Troubleshooting ............................................................................................... 154

6.1 Error Messages .................................................................................................................. 154

6.1.1 Diagnostics ..................................................................................................................... 154

6.2 Diagnosing SLG720 Coaxial Probe misassembly .............................................................. 157

7 Parts List .......................................................................................................... 161

7.1 Overview ............................................................................................................................. 161

8 Glossary ........................................................................................................... 162

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page ix

Page 10

9 Appendix Certifications ..................................................................................... 165

9.1 Safety Instrumented Systems (SIS) Installations ................................................................ 165

9.2 European Directive Information (EU) .................................................................................. 165

9.3 Hazardous Locations Certifications .................................................................................... 166

9.4 Marking ATEX Directive ...................................................................................................... 171

9.5 Conditions of Use for Ex Equipment, “Hazardous Location Equipment” or "Schedule of

Limitations" ...................................................................................................................................... 172

9.6 Control Drawing................................................................................................................... 174

9.7 China RoHS ........................................................................................................................ 178

10 Security ............................................................................................................ 179

10.1 How to report a security vulnerability .................................................................................. 179

Page x SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 11

List of Figures

Figure 2-1: Components of the Level transmitter ................................................................................... 2

Figure 2-2: Example of HART connection RL ........................................................................................ 7

Figure 2-3: Example of FF connection ................................................................................................... 8

Figure 2-4: Example of a FF network ................................................................................................... 11

Figure 2-5: Transmitter nameplate example ........................................................................................ 12

Figure 2-6: Standard SLG 700 Model Num ber ..................................................................................... 13

Figure 2-7: Safety certification example ............................................................................................... 13

Figure 2-1: GWR measurement ........................................................................................................... 16

Figure 2-2: Sample Echo Curve ........................................................................................................... 17

Figure 2-3: Interface measurement ...................................................................................................... 18

Figure 2-4 Radar Impulse Reflection model ......................................................................................... 19

Figure 2-5: Upper transition zone length and minimum blocking distance high (BDH) and minimum

blocking distance low (BDL) for coax probes in water.......................................................................... 23

Figure 2-6: Upper transition zone length and minimum blocking distance high (BDH) and minimum

blocking distance low (BDL) for coax probes in oil. .............................................................................. 23

Figure 2-7: Transition zone lengths and minimum blocking distance high (BDH) for single lead probes

in water. ................................................................................................................................................ 24

Figure 2-8: Transition zone lengths and minimum blocking distance high (BDH) for single lead (i.e.

rod and rope) probes in oil. ................................................................................................................... 25

Figure 2-9 Minimum blocking distances, steam application for a threaded HTHP process connector 25

Figure 2-10 Minimum blocking distance, steam application for a flanged HTHP process connector .. 26

Figure 2-11: Two-liquids Flooded ......................................................................................................... 28

Figure 2-12: Two-liquids non-flooded. .................................................................................................. 29

Figure 2-13 Typical Echo steam application echo with vapor reference rod........................................ 31

Figure 2-14: Top vertical and angled mounting .................................................................................... 33

Figure 3-1 SLG720 probe dimensions, mm [in] .................................................................................... 40

Figure 3-2: SLG720 FEP probe dimensions, mm [in] ........................................................................... 41

Figure 3-3: SLG726 Threaded process connection probe dimensions; mm [in] .................................. 42

Figure 3-4 SLG726 Flanged process connection probe dimensions; mm [in] ..................................... 43

Figure 3-5: SLG726 Saturated steam application threaded process connection probe dimensions; mm

[in] ......................................................................................................................................................... 44

Figure 3-6: SLG726 Saturated steam application flanged process connection probe dimensions; mm

[in] ......................................................................................................................................................... 44

Figure 3-7: Example bending torque values ......................................................................................... 47

Figure 3-8: Drill 6-mm diameter hole at the position shown on the coaxial outer conductor. .............. 48

Figure 3-9: Rod probe assem bl y .......................................................................................................... 49

Figure 3-10: SLG726 flanged process connection, probe nut installation position, mm [in] ................ 50

Figure 3-11: Wire probe assembly ....................................................................................................... 51

Figure 3-12: SLG720 Coaxial probe assembly (single outer tube depicted) ....................................... 54

Figure 3-13: SLG720 Coaxial probe assembly (single outer tube depicted) ....................................... 54

Figure 3-14: SLG726 Coaxial pro be ass embly .................................................................................... 59

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page xi

Page 12

Figure 3-15 Saturated steam application rod probe assembly ............................................................ 60

Figure 3-16: Saturated steam application coaxial probe assembly ..................................................... 60

Figure 3-17: Recommended location of holes for rod probes .............................................................. 63

Figure 3-18: Centering disks for wire and rod probes. ......................................................................... 64

Figure 3-19: Centering disks for FEP coated wire and rod probes ...................................................... 64

Figure 3-20: Probe length definition for rod probes using a centering disk ......................................... 67

Figure 3-21: Flanged SLG720 Transmitter, mm [in] ............................................................................ 67

Figure 3-22: Threaded (NPT ¾", 1", 1½", 2") SLG720 Transmitter, mm [in] ....................................... 68

Figure 3-23: Threaded (BSP/G ¾”, 1”, 1½”) SLG720 Transmitter, mm [in] ......................................... 69

Figure 3-24: Flanged SLG726 transmitter, mm [in] ............................................................................. 70

Figure 3-25: Threaded (NPT 1½", 2”) SLG726 transmitter, mm [in] .................................................... 71

Figure 3-26: Threaded (BSP/G 1½") SLG726 transmitter, mm [in] ..................................................... 72

Figure 3-27: Mounting posit ion ............................................................................................................ 73

Figure 3-28: SLG720 temperatur e limits .............................................................................................. 75

Figure 3-29: SLG726 temperatur e limits .............................................................................................. 76

Figure 3-30: SLG726 Maximum pressure based on maximum operating temperature ....................... 76

Figure 3-31: Flanged tank connection ................................................................................................. 78

Figure 3-32: Flange mounting .............................................................................................................. 79

Figure 3-33: Oversized nozzle configuration ....................................................................................... 80

Figure 3-34: Threaded tank connection ............................................................................................... 81

Figure 3-35: Tank roof mounting using threaded connection .............................................................. 81

Figure 3-36: Bypass installation ........................................................................................................... 82

Figure 3-37: Mounting on a non-metallic vessel .................................................................................. 83

Figure 3-38: Mounting in concrete silos ............................................................................................... 84

Figure 3-39: Remote mount ................................................................................................................. 85

Figure 3-40: Rotate transmitter housing .............................................................................................. 86

Figure 3-41: Anchoring wire probes ..................................................................................................... 87

Figure 3-42: Wire probe slack .............................................................................................................. 87

Figure 3-43: Anchoring coaxial probes ................................................................................................ 88

Figure 3-44: Transmitter operating ranges .......................................................................................... 91

Figure 3-45: HART 3-Screw Terminal Board and Grounding Screw ................................................... 93

Figure 4-1: Three-Button Option .......................................................................................................... 98

Figure 4-2: Advanced Display Formats with the Process Variable .................................................... 120

Figure 4-3: Locating the Failsafe and Write Protect Jumpers ............................................................ 124

Figure 5-1: Current Loop Test Connections....................................................................................... 130

Figure 5-2: Electronic Housing Components ..................................................................................... 131

Figure 5-3: Sensor Housing ............................................................................................................... 132

Figure 5-45-5: Part Number and Date Code (D/C) label on bottom of Terminal PCBA assembly .... 134

Figure 5-6: Location of sensor housing and attachment set screws.................................................. 135

Figure 5-7: Communications Housing Assembly ............................................................................... 136

Page xii SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 13

Figure 5-8: Rook Assembly ................................................................................................................ 137

Figure 5-9: - Sensor ribbon cable ...................................................................................................... 138

Figure 5-10: Location of RF-connector at bottom of sensor housing ................................................. 139

Figure 5-11- Model Number Mismatch Critical Error .......................................................................... 141

Figure 5-12 - Reconcile Model Numbers feature ............................................................................... 141

Figure 5-13 - No Trimming Zones on Outer Tube and Inner Rod ...................................................... 148

Figure 5-14 - Drill Hole Position on Outer Tube ................................................................................. 149

Figure 5-15 - Spacer and Locking Pin Installation .............................................................................. 149

Figure 5-16 - SLG726 flanged process connection, probe nut installation position, mm [in] ............. 151

Figure 5-17 - Saturated steam application rod probe assembly ........................................................ 152

Figure 5-18 - Saturated steam application coaxial probe assembly .................................................. 153

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page xiii

Page 14

List of Tables

Table 2-1: Features and Options ........................................................................................................... 1

Table 2-2: Available SmartLine GWR display characteristics ................................................................ 3

Table 2-3: Probe Selection ..................................................................................................................... 4

Table 2-1: Blocking Distance High ....................................................................................................... 26

Table 3-1: Installation sequence .......................................................................................................... 36

Table 3-2: Mechanical insta lla tio n sequenc e ....................................................................................... 38

Table 3-3: Sensor Details – All Models ................................................................................................ 39

Table 3-4: Minimum blocking distances and transition zones for the various probe types. ................ 39

Table 3-5: Minimum blocking distances and Minimum distance to inlet or surface with DC corrected

level for the Saturated Steam Application. ........................................................................................... 39

Table 3-6: Maximum measurement range for each probe type versus dielectric constant. ................ 39

Table 3-7: Tensile load limits for flexible probe.................................................................................... 45

Table 3-8: Rigid (i.e. rod and coaxial) probe mounting angle limits ..................................................... 45

Table 3-9: Rod probe bending torque limits (all lengths) ..................................................................... 45

Table 3-10: Coaxial probe bending load limits (all lengths) ................................................................. 45

Table 3-11: Recommended probe diameter and material of construction ........................................... 61

Table 3-12: Centering disk determination from pipe size and schedule .............................................. 65

Table 3-13: Centering disk dimensions ................................................................................................ 65

Table 3-14: Probe length for different probe types .............................................................................. 66

Table 3-15: Minimum recommended distance to container wall and obstacles (mm) ......................... 73

Table 3-16: SLG726 Maximum pressure based on maximum operating temperature in tabular form 77

Table 3-17: SLG720: Recommended nozzle dimensions ................................................................... 79

Table 3-18: SLG720 bypass and stillwell recommended diameters .................................................... 82

Table 3-19: SLG726 bypass and stillwell recommended diameters .................................................... 83

Table 3-20: Conduit entry plug installation ........................................................................................... 89

Table 3-21: Conduit adapter installation .............................................................................................. 89

Table 4-1: Three-Button Option Functions ........................................................................................... 99

Table 4-2: Three-Button Data Entry ................................................................................................... 100

Table 4-3: Advanced Display Main Menu Structure .......................................................................... 101

Table 4-4: Correlation Model Recalculation ....................................................................................... 102

Table 4-5: Display Config sub-menu .................................................................................................. 103

Table 4-6: Basic Configuration sub-menu .......................................................................................... 105

Table 4-7: Advanced Config sub-menu ............................................................................................. 109

Table 4-8: Monitor sub-menu ............................................................................................................. 114

Page xiv SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 15

Table 4-9: Advanced Displays with PV Format Display Indications ................................................... 121

Table 4-10: HART Failsafe and Write Protect Jumpers ..................................................................... 125

Table 4-11: FOUNDATION Fieldbus Simulation and W rite Protec t Jumpers .................................... 125

Table 5-1: Probe length calculated from spare probe model number. ............................................... 145

Table 6-1: SLG 700 Standard Diagnostics Messages ....................................................................... 155

Table 7-1: Parts .................................................................................................................................. 161

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page xv

Page 16

This page has been intentionally left blank

Page xvi SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 17

Standard Temperature Liquid Level Measurement

(-40 to 200°C/-1 to 40 bar)

High Temperature / High Pressure Liquid Level Measurement

(-60 to 450°C /-1 to 400 bar)

1.1 Overview

The SLG 700 Guided Wave Radar SmartLine transmitter is an electronic instrument

designed to measure levels of liquid and solid materials. Guided Wave Radar (GWR)

transmitters use time domain reflectometry with radar pulses guided by a metal probe and

reflected off a product surface to determine levels in tanks. In comparison to other level

measurement technologies, GWR provides a highly-accurate, cost-effective, reliable

measurement over a wide range of process conditions.

1.2 Transmitter Models

The SmartLine Guided Wave Radar (GWR) transmitter is available as a family of

SLG72X models for liquid applications. The pressure and temperature application ranges

for each model are summarized in Table 2-1.

1 Introduction

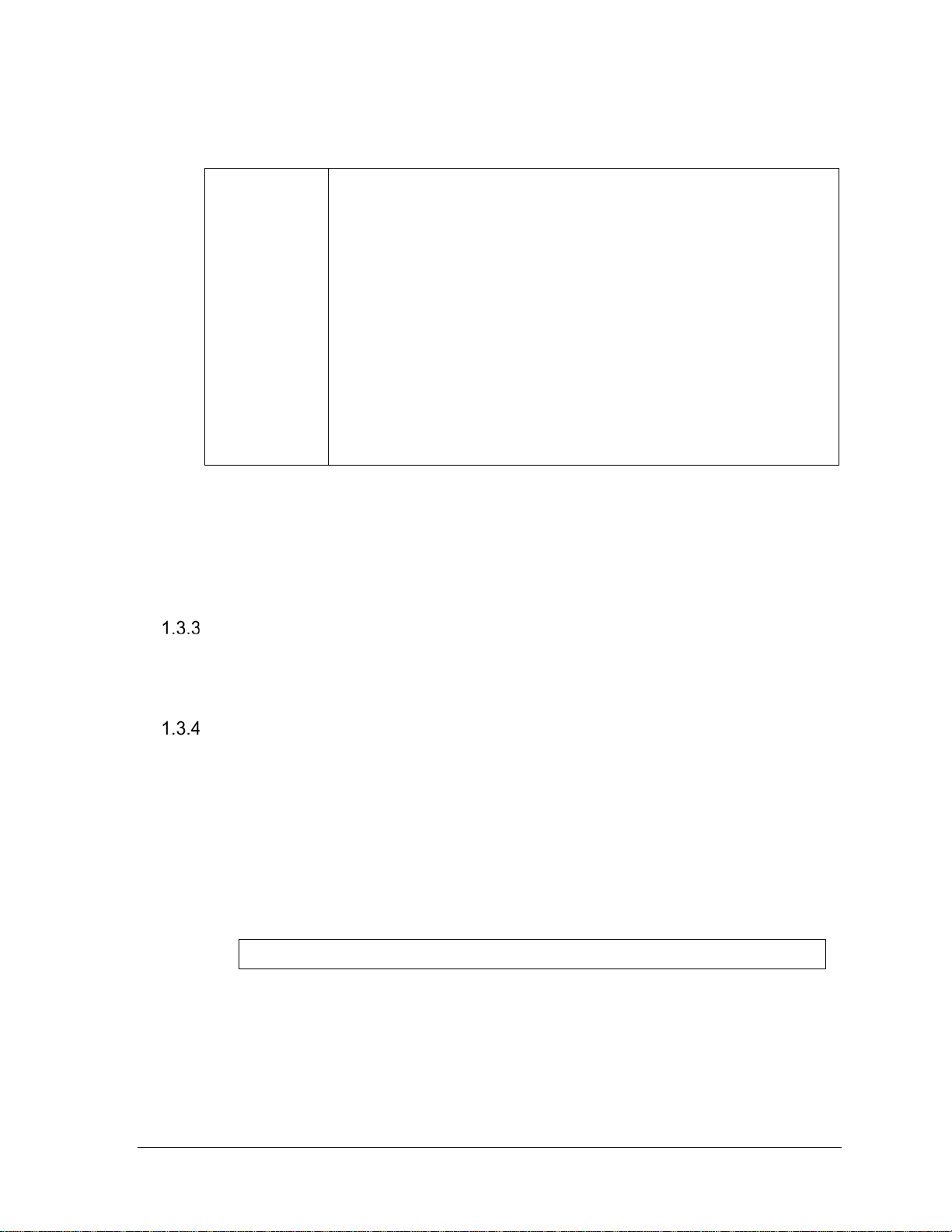

Table 2-1: Features and Options

Range Model

Each model is available with a range of probes, wetted materials, and accessories to suit

most applications.

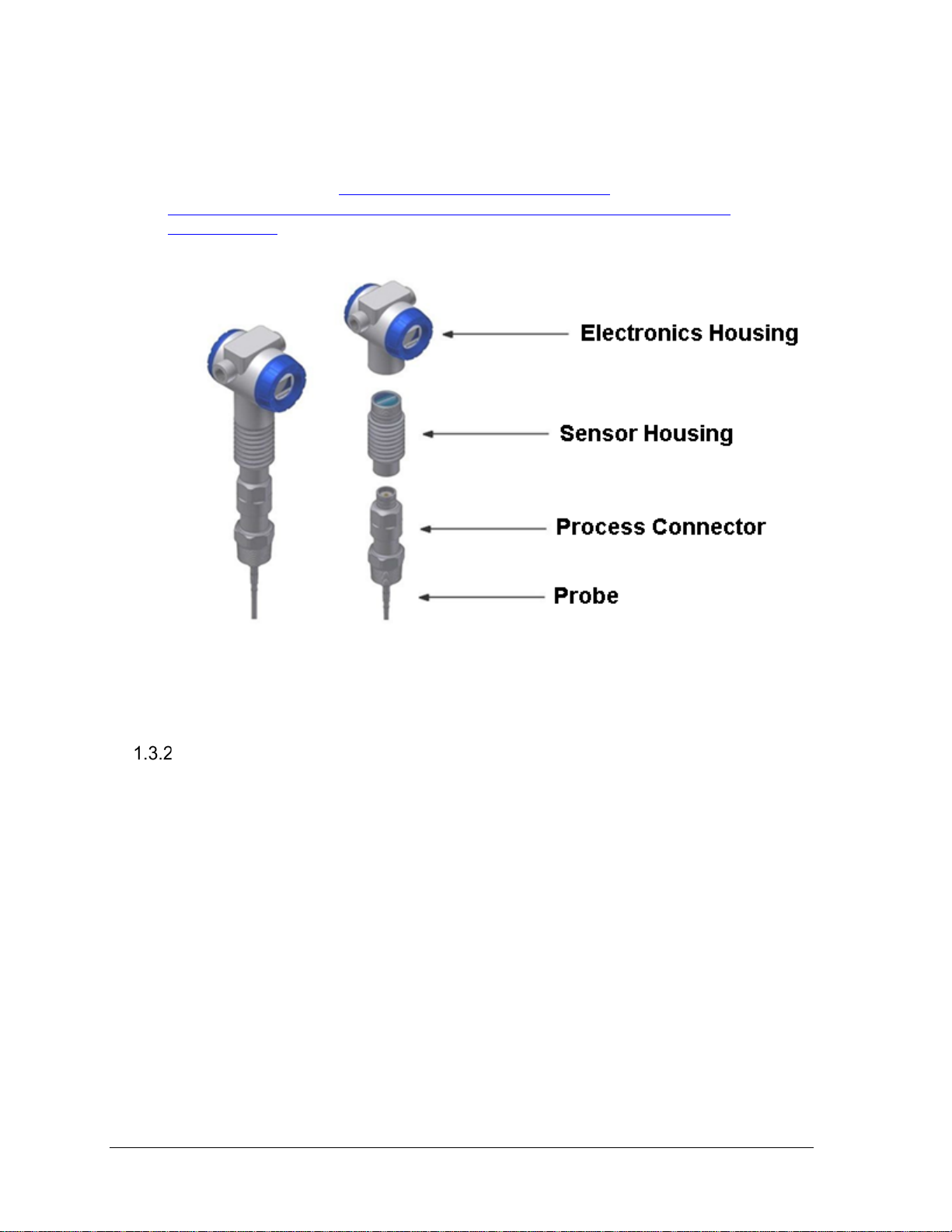

1.3 Transmitter Components

Overview of components

As shown in

Figure 2-1 the transmitter consists of:

• Electronics housing containing

o Display module (optional)

o Buttons module (optional)

o Communications module

o Electrical terminal block assembly

SLG720

SLG726

• Sensor housing

• Process connector

• Probe, also known as a waveguide

Revision 9 SLG 700 SmartLine Guided Wave Radar User’s Manual 1

Page 18

These components are described below.

Additional mounting and optional accessories are available, such as centering discs for

probes. For list of all options and accessories please re fer to the purchasing specifications,

which is available, here:

https://www.honeywellprocess.com/enUS/explore/products/instrumentation/process-level-sensors/Pages/smartline-leveltransmitter.aspx.

Figure 2-1: Components of the Level transmitter

Electronics Housing

The Electronics Housing contains these components. All components are replaceable in

the field.

Terminal Assembly: Provides connection points for the measurement signal and

power. Different terminal modules are required for HART

and FOUNDATION

TM

Fieldbus versions of the transmitters. Th e terminal is polarity insensitive. Lightning

protection is optional.

Communications module: The platform provides separate electronics modules for

HART

and FOUNDATIONTM Fieldbus versions of the transmitters. The

communication board for a certain communication protocol always requires terminal

assembly for the same type of communication. Descriptions of the communications

protocols are in the Glossary.

Optional Display: Table 2-2 lists features of the available display module.

Optional Buttons: Refer to Figure 4-1: Three-Button Option for more information.

Page 2 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 19

Advanced

• 360° rotation in 90° increments

Supports transmitter messaging and maintenance mode indications

Table 2-2: Available Smar tL ine GW R displa y char a cterist i cs

Display

• Three configurable screen formats with configurable rotation timing

o Large process variable (PV)

o PV with bar graph

o PV with trend (1-999hrs, configurable)

• Echo stem plot for checking measurement accuracy

• Eight Screens with 3-30 sec. rotation timing and the use of 3-butto ns for

configuration.

• Standard and custom engineering units

• Diagnostic alerts and diagnostic messaging

• Multiple language support options:

o Option 1: EN, FR, GE, SP, RU, TU, IT

o Option 2: EN, CH, JP (Kanji)

• Supports 3-button configuration and calibration

•

To make changes to the transmitter setup or configuration without the use of an external

device such as a handheld or PC, an optional 3-Button Assembly is available. Use the

buttons and menus to:

• Configure transmitter

• Configure and navigate displays

Sensor Housing

The sensor housing contains the pulse generation and analysis hardware.

These electronics are potted to provide flame path resistance.

The sensor housing is available as a replaceable part.

Process Connector

Note:

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 3

The process connector has the following functions.

• Separates the process environment from the external environment.

• Provides a threaded insert to the tank which removes the need for brackets to

mount the transmitter. Various mounting types are available, including popular

threads and flanges.

• Provides electrical feed-through to the probe.

Each of the SLG720 and SLG726 models have different process connector designs.

Each process connector design accepts a sub-set of the full range of probe types.

Page 20

Legend

Level

Interface

Bubbling/boiling

Low-dielectric

Foam (liquid surface

Probe

The purpose of a Guided Wave Radar probe is to guide radar pulses produced by the radar

transmitter towards the material being measured. It also guides the reflected pulse back to the

transmitter for processing into a level measurement. The probe can be made of a single

conductor such as for single wire or rod probes, or two conductors for coaxial probes. For rigid

probes (rod and coaxial), multiple segments, each up to 2m long, can be connected.

The probe is also known in the industry as “waveguide”.

A single wire probe is the most common design; other designs are provided based on

application needs. For the purposes of this document the term “Wire” is being used, however

the term “Wire” and “Rope” are interchangeable.

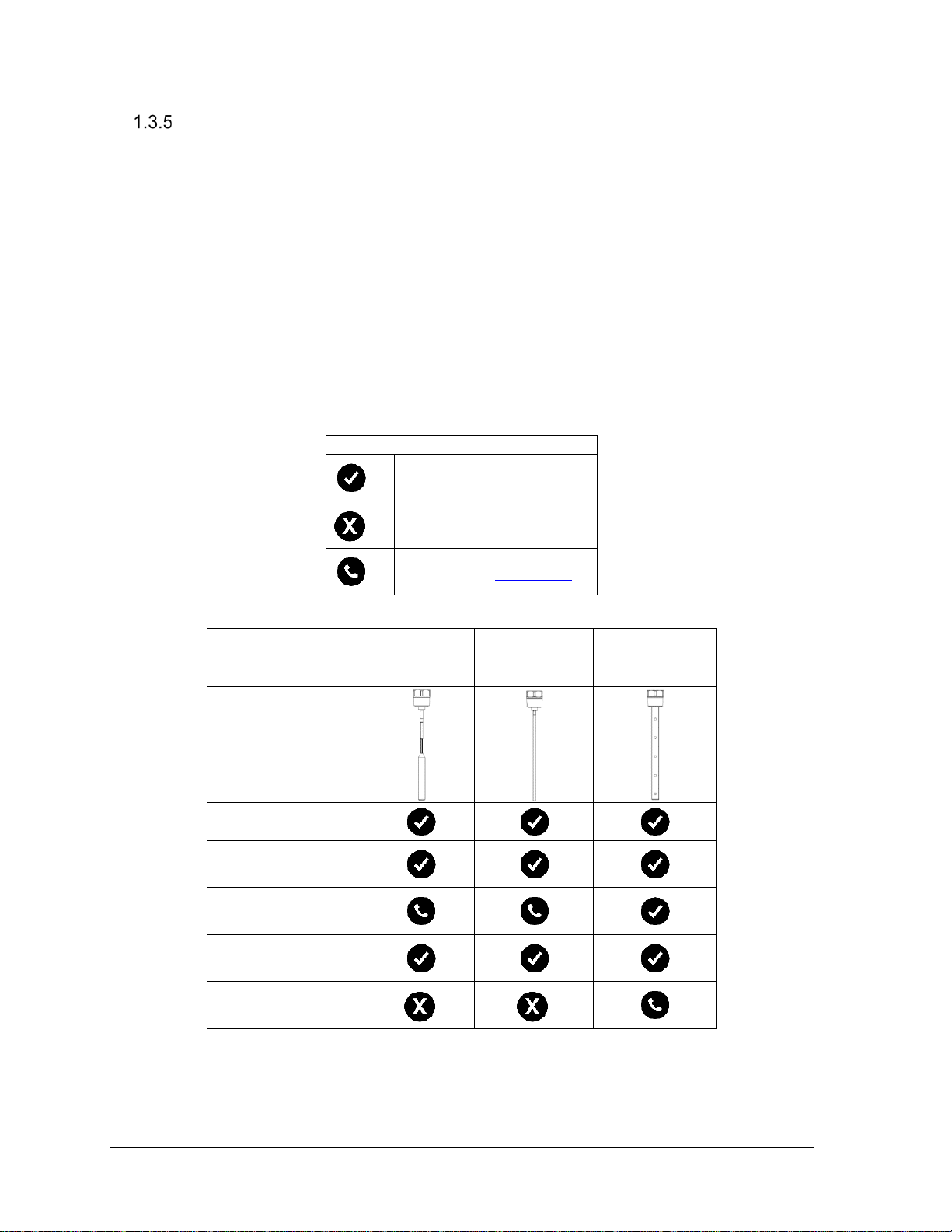

Table 2-3 summarizes advantages and disadvantages of different probe constructions.

Installation details of each probe are described in Chapter 3.

Table 2-3: Probe Selection

Yes

No

Contact the TAC team

(liquid/liquid)

surfaces

constant liquids 1

Single wire

Single rod Coaxial

(Wire)

Page 4 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

measurement)

Page 21

Foam (top of foam

Foam (top of foam

measurement)

Coating/tack y liquids

Crystallizing liquids

Viscous liquids

Probe is close to

objects (<12″/30cm)

Probe could contact

disturbing objects

Turbulent Surface

Turbulent fluid

stress on probe

Tall, narrow nozzles1

Liquid or vapor

probe above surface

Disturbing

interference in tank

Ability to clean

measurement)

and liquid surface

tank wall/disturbing

tank wall, nozzle or

causing mechanical

spray could contact

electromagnetic

probe

1

See the SLG 700 SmartLine Guided-Wave Radar Level Specification, Document

#34-SL-03-03.

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 5

Page 22

1.4 Communicating with the Tr a ns mi t t er

It is possible to remotely monitor and configure a transmitter using either the HART or

TM

FOUNDATION

transmitter can be monitored using the analog current, and with both interfaces, can be

configured using the three-button interface and display.

Note:

4-20 mA HART

The output of a transmitter configured for the HART pro to co l includes two primary modes:

• Point-to-Point Mode: one transmitter is connected via a two-conductor, 4-20mA

current loop to one receiver.

• Multi-Drop Mode: several transmitters are connected through a two-conductor

network to a multiplexed receiver device.

The major difference between the two modes is that in Point-to-Point mode, the average

value of the loop current represents the current value of an analog signal representing the

process inside the tank. In multi-drop mode, the average value of the loop current is fixed,

usually at 4mA. Therefore, in Point-to-Point mode, an external control system can read the

Primary Variable (PV) through an analog input without HART messaging, whereas in multidrop mode, the PV can only be read as a digital value using HART messaging.

Fieldbus (FF) protocols. Alternatively, with the HART option, the

The protocols are not interchangeable. Each protocol uses

significantly different terminal and communication boards that are

installed before shipping.

Note: In the HART system, the abbreviation PV is used to denote the

Primary Variable which may be only one of a number of process or

device variables that may be available.

SLG 700 supports HART version 7 and its associated backward compatibility. The analog

signal is modulated by Frequency Shift Keying (FSK), using frequencies and current

amplitude that do not affect analog sensing at the receiver. The accuracy of the analog level

must be precisely controlled for accurate sensing. HART communication will not bump

process variables. In multi-drop mode, theoretically up to 16 devices in HART 5 (addresses

0-15) or up to 64 devices in HART6/7 (add resse s 0-63) can exist on the two-conductor

network. Practically, the number of devices in a multi-drop installation is limited due to

design constraints. When installing into a multi-drop network, consider that the SLG700

requires a minimum startup current of 17mA and a minimum terminal voltage of 11V during

startup. After this initial startup period (approximately 0.5 seconds), the loop current will be

fixed at 4mA, and the minimum terminal voltage is 14V. The power source, wiring, intrinsic

safety barriers, and other devices in the network be considered to ensure these requirements

can be met.

Note: The SLG700 requires a minimum startup current of 17mA, even when configured in

multi-drop mode. The minimum terminal voltage is 11V during startup. After startup, the

loop current will be fixed at 4mA, and the minimum terminal voltage should be 14V.

Page 6 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 23

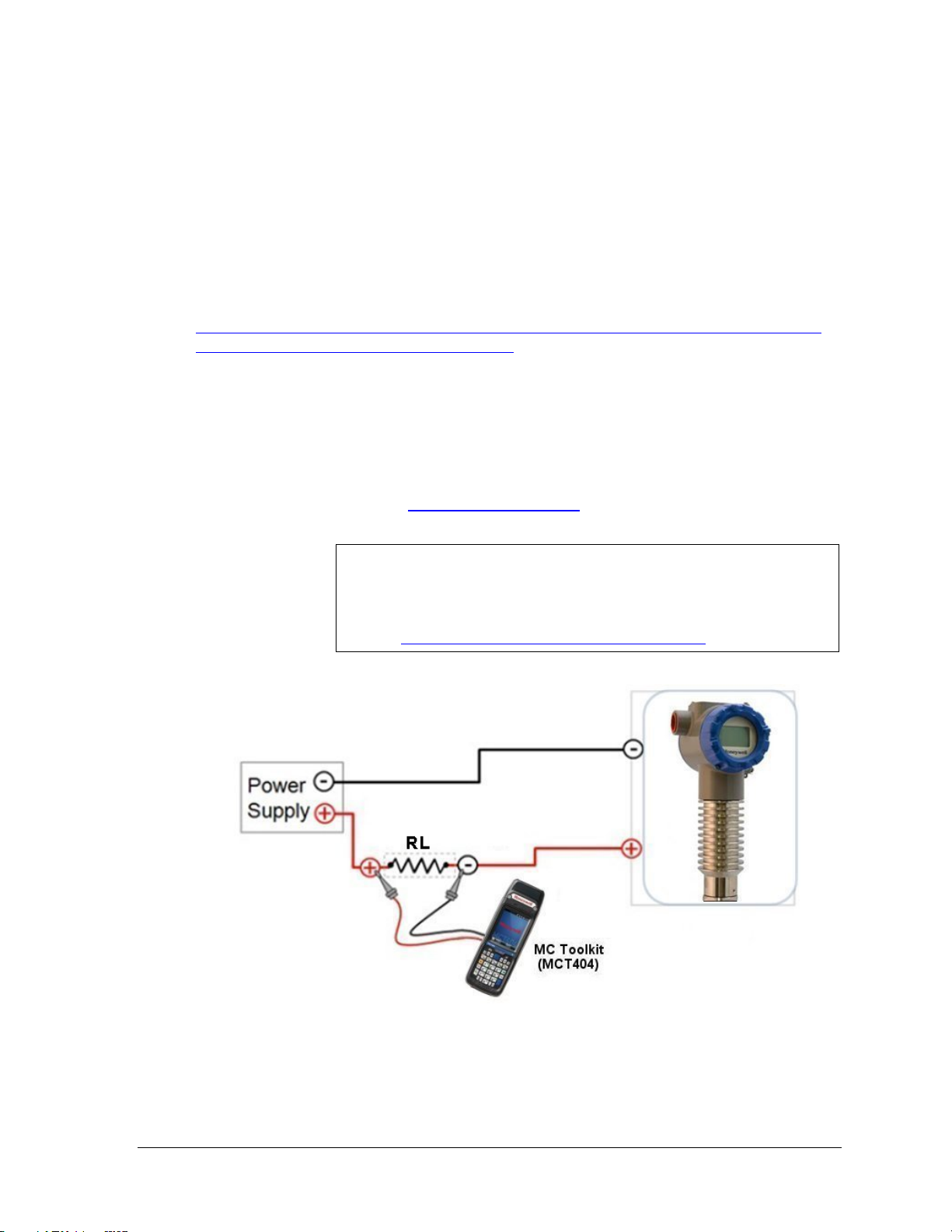

Figure 2-2 is an example of a HART connection to the transmitter. The communication

resistor RL may be inserted anywhere in the 4-20 mA loop but it is recommended to be

installed close to the positive supply. Refer to section 0 for acceptable power supply and RL

ranges

The MC Toolkit is a dedicated Honeywell communication tool that uses Device Description

(DD) files to communicate with multiple transmitter models. Also, other equ ivalent tools or a

HART-to-USB converter may be used. Device Desc rip tion fi le s are availab le from:

• HONEYWELL: Go to:

https://www.honeywellprocess.com/en-US/explore/products/instrumentation/process-levelsensors/Pages/smartline-level-transmitter.aspx

Select the “Software” tab.

Scroll/search for file name:

“HART Device Description (DD) files for Honeywell HART Devices”

This .zip file contains the latest version of the DD files for all of Honeywell’s HART field

devices.

Unzip the file to locate the DD files applicable to the SLG 700 series.

®

• HART

FOUNDATION: http://en.hartcomm.org

Device Descriptions (DD) are HART data files which are

gathered from field device manufacturers which describes the

Note:

features and functions of a device.

HART provides a detailed definition here:

http://en.hartcomm.org/hcp/tech/faq/faq.html

Figure 2-2: Example of HART connection RL

Refer to section 0 for RL information

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 7

Page 24

FOUNDATIONTM Fieldbus (FF)

The Honeywell SLG 700 is a SmartLine Level transmitter that has a wide range of additional

features along with supporting the FOUNDATION

TM

Fieldbus (FF) communication protocol.

The SLG 700 level transmitter with FF protocol provides a FOUNDATION Fieldbus

interface to operate in a compatible distributed Fieldbus system. The transmitter includes

FOUNDATION Fieldbus electronics for operating in a 31.25 Kbit/s Fieldbus network and

can interoperate with any FOUNDATION Fieldbus registered device.

The Honeywell SmartLine SLG 700 is a high-performance transmitter offering high

accuracy, reliability and resolution over a wide range of process conditions.

The SLG 700 Fieldbus device is fully tested and compliant with Honeywell Experion® PKS

providing the highest level of compatibility assurance and integration capabilities.

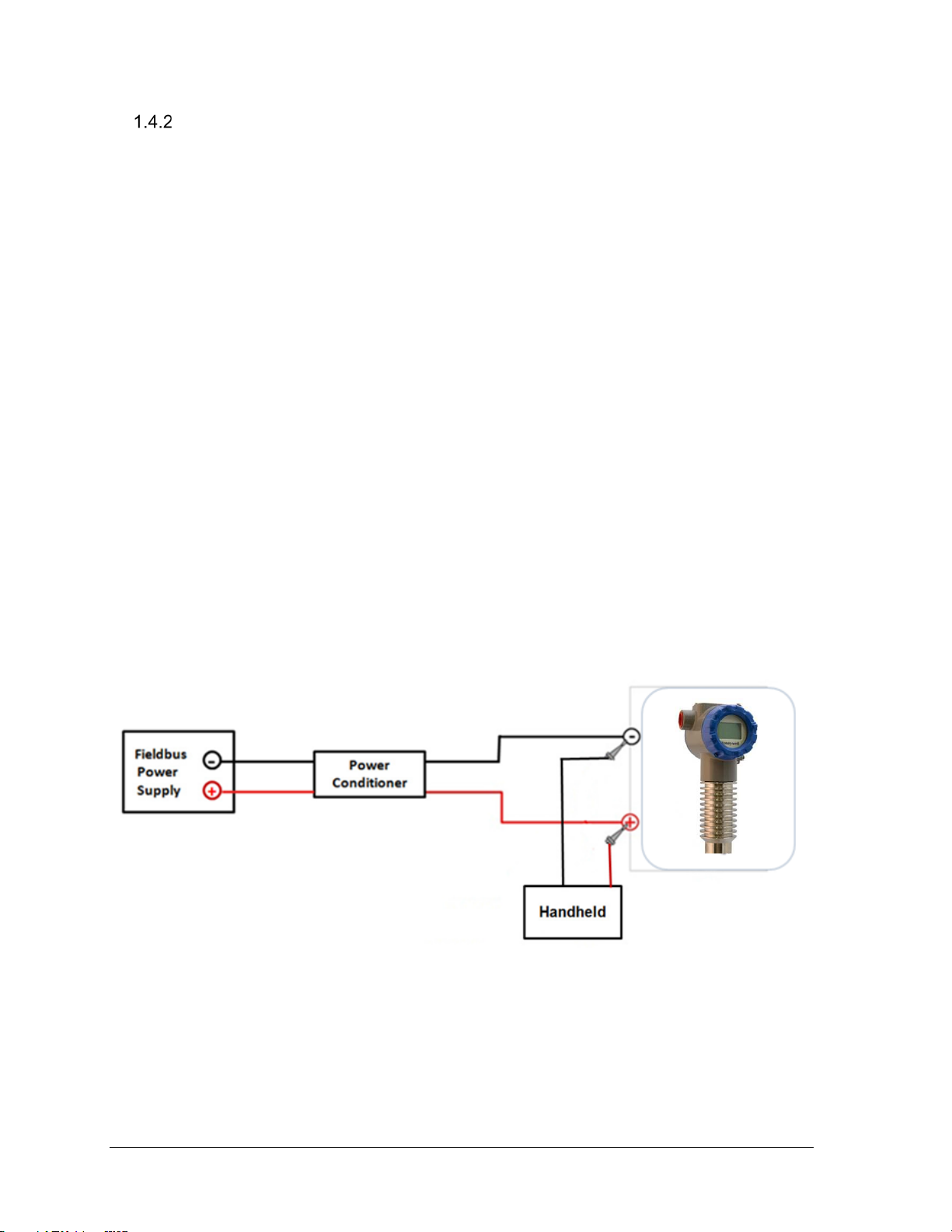

Figure 2-3 graphically represents the connection of the transmitter to a FF handheld device. A

similar connection may be realized using PC configuration software.

Each transmitter includes a configuration database that stores its operating characteristics in a

non-volatile memory.

The handheld or PC software is used to establish and/or change selected operating parameters

in a transmitter database. The process of viewing and/or changing database parameters is

called configuration.

Configuration can be accomplished both online and offline with the transmitter powered up

and connected to the handheld.

Online configuration immediately changes the transmitter operating parameters. For offline

configuration, transmitter operating characteristics are entered into the handheld memory for

subsequent downloading to transmitter.

Figure 2-3: Example of FF connection

Page 8 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 25

DTM-based tools and Experion

HART and FOUNDATION Fieldbus models support Device Type Managers (DTMs)

running on Field Device Technology

Manager (FDM) / Experion.

The transmitter establishes communication with the host systems using DD or DTM.

Device Description (DD)

DD is a binary file that provides the definition for parameters in the FBAP of the

transmitter. For example, DD refers to the function blocks that a transmitter contains, and

the corresponding parameters in the blocks that are critical to the interoperability of

Fieldbus devices. They define the data required to establish communications between

different Fieldbus devices from multiple vendors with control system hosts. The DD

provides an extended description of each object in the Virtual Field Device (VFD).

The Fieldbus Foundation provides the DD for all registered devices on its website,

http://www.fieldbus.org/index.php?option=com_mtree&task=viewlink&link_id=1991&ff

bstatus=Registered&Itemid=324

®

(FDT) hosts such as PACTware or Field Device

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 9

Page 26

Enhanced Device Description (EDD)

There are two types of EDDs are available, namely .ff5/.sy5 and .ffo/sym. The .ffo/.sym

binary files are generated for the legacy hosts to load the dev ice DD that is generated using

latest tokenizer. Few constructs like Images that are supported in .ff5/.sy5 binaries, are not

supported in .ffo/.sym binary files.

Device Type Manager (DTM)

The DTM is similar to a device driver that enables usage of devices in all the asset

management and device configuration software like FDM or PACTware, with the help of the

FDT-DTM technology.

The DTM has the following primary functions:

• Provides a graphic user interface for device configuration.

• Provides device configuration, calibration, and management features for the

particular device.

The DTM provides functions for accessing device parameters, configuring and operating the

devices, calibrating, and diagnosing problems.

Download the DTM from:

https://www.honeywellprocess.com/enUS/explore/products/instrumentation/process-level-sensors/Pages/smartline-leveltransmitter.aspx

Go to the Software tab

To set up the DTM on the FDM/Experion refer to the FDM/Experion User Guide.

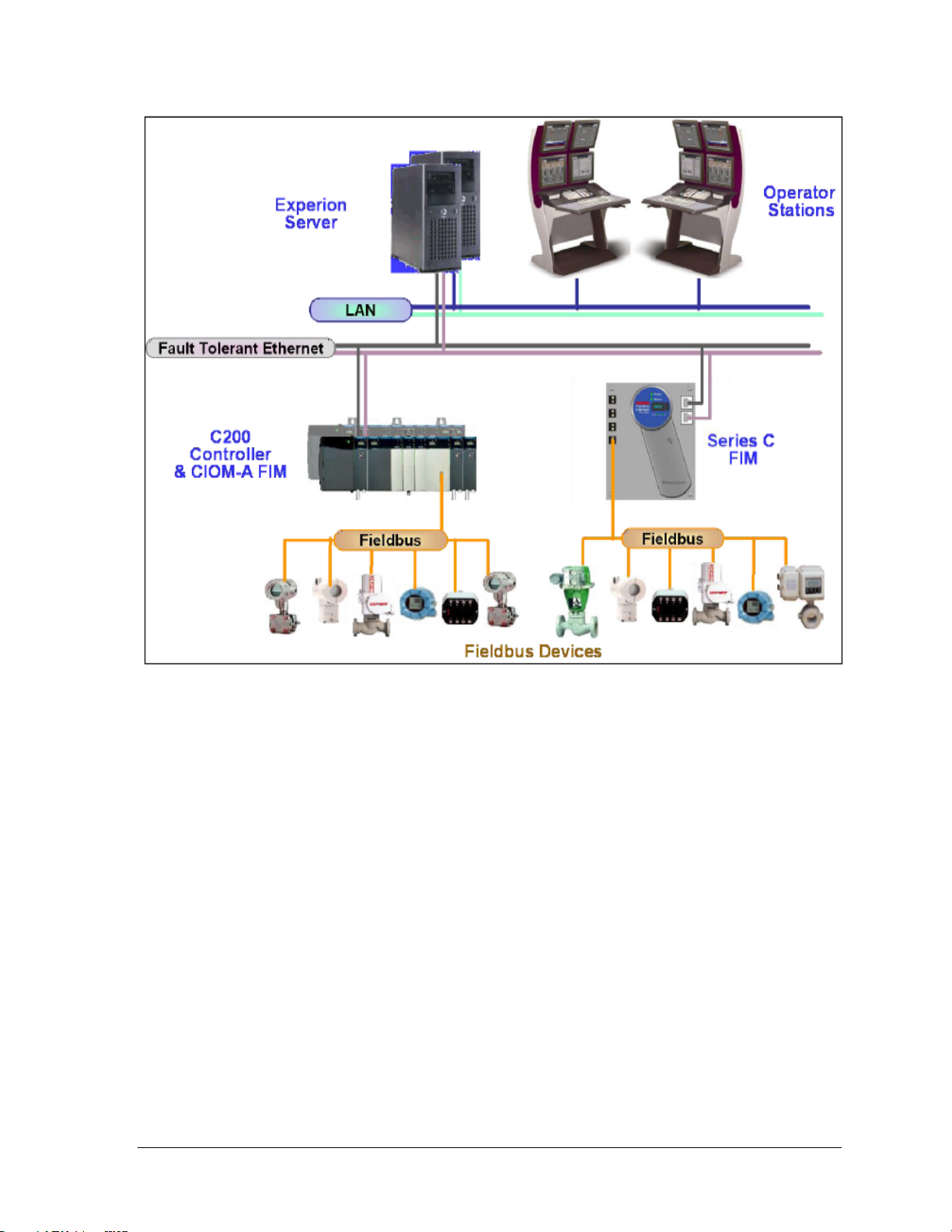

Figure 2-4 shows an example of a FF network setup.

For more information on Experion go to:

https://www.honeywellprocess.com/integrated-control-and-safety-systems/experion-pks/

Page 10 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 27

Figure 2-4: Example of a FF network

1.5 SLG 700 Transmitter nameplate

The Transmitter nameplate is mounted on the top of the electronics housing

(see Figure 2-5) and lists the following properties:

• Model number

• Physical configuration

• Power supply voltage

• Maximum working pressure rating

• Certification, if ordered (SIL and CRN)

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 11

Page 28

Product ID

Nameplate

Figure 2-5: Transmitter nameplate example

The nameplate contains the following information:

MODEL NO.: The transmitter model number per the model selection guide.

SERIAL NO.: The unique transmitter serial number.

CRN: The CSA Registration number.

SUPPLY: The DC power supply voltage range as measured at the terminal assembly.

MAWP: Maximum Allowable Working Pressure.

PROCESS TEMPERATURE: The Process temperature range.

CUST. CAL.: Specifies any custom calibration, if ordered, otherwise blank.

PROBE LG: Length of the probe as defined in the model number.

WETTED MATERIAL: A list of the wetted materials.

CUSTOMER ID: User-defined identifier, if ordered, otherwise blank.

HOUSING CONNECTION TYPE: Conduit fitting size: ½” NPT or M20

ASSEMBLED IN / MADE BY HONEYWELL: The country where the transmitter was

assembled and tested.

SIL INFORMATION: SIL 2/3 Capable is indicated if SIL certification applies, otherwise blank.

COMMUNICATION INTERFACE: A symbol indicating the supplied communications

interface, HART or FOUNDATION Fieldbus.

or

Page 12 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 29

1.6 Transmitter Model Number De s cri pt ion

The model number is comprised from a number of selections and options that can be specified

when ordering the transmitter. It includes a basic transmitter type such as SLG720 (standard

temperature, standard pres s ure) followed by a maximum of nine additional character strings

that can be selected from a corresponding Table in the Model Selection Guide (MSG).

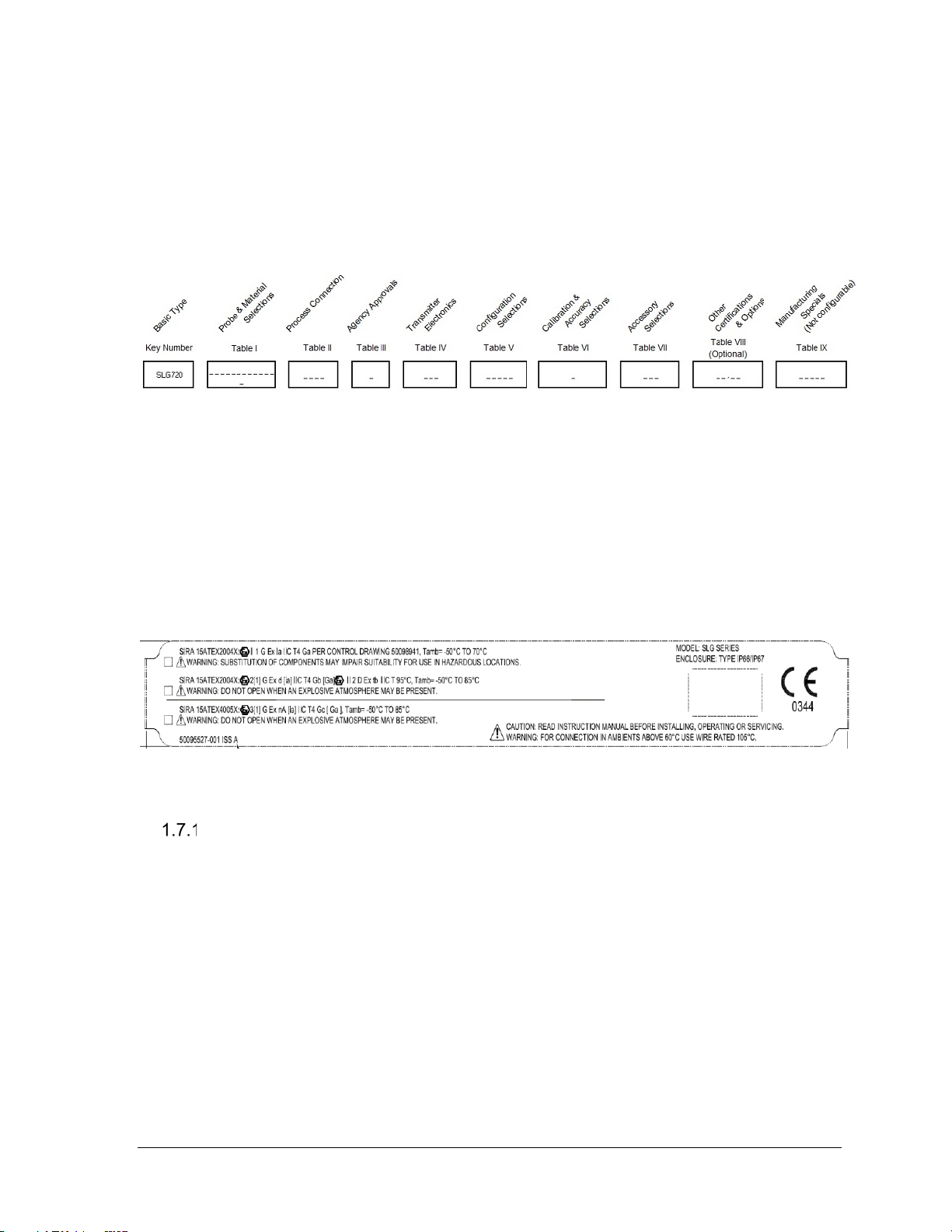

The basic model number structure is shown in Figure 2-6.

Figure 2-6: Standard SLG 700 Model Number

For a more complete description of the various configuration items and options, refer to the

SLG 700 Product Specification (34-SL-03-03) and Model Selection Guide (34-SL-16-01).

1.7 Safety Certification Information

SLG transmitter models are available for use in hazardous locations, including CSA, IECEx,

ATEX, and FM approvals. See Appendix Certifications for details and other approvals. The

transmitter will include an “approvals” nameplate mounted on the electronics housing with the

necessary compliance infor m ation.

Figure 2-7: Safety certification example

Safety Integrity Level (SIL)

The SLG 700 is intended to achieve sufficient integrity against systematic errors by the

manufacturer’s design. A Safety Instrumented Function (SIF) designed with this product must

not be used at a SIL level higher than the statement, without “prior use” justification by the

end user or diverse technology redundancy in the design. Refer to the SLG 700 Safety Manual,

Document #34-SL-25-05, for additional information. The SIL level will be indicated on the

SLG 700 nameplate.

See the SLG 700 Transmitter nameplate for additional information, Figure 2-5.

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 13

Page 30

1.8 Security Considerat ions

The SLG 700 provides several features designed to prevent accidental changes to the device

configuration or calibration data. These features include a local display password (HART

option), a communication password (HART option), a Hardware Write Protect Jumper and a

Software Write Protect configuration parameter. These features can be used in combination to

provide multiple layers of change protection.

For both the local display and communication passwords, the initial user passwords are

defined as "0000". A "0000" password indicates that the user has not set a user- defined

password and the password protection is disabled. The password used on the local keyboard

display is separate from the password provided for communication. Password protection from

the local keyboard display does not inhibit changes by way of communication over the current

loop. A master password is available that allows recovery if the set user password is unknown.

A hardware write-protect locks out changes regardless of the entry of a password. The

hardware jumper requires phy sical access to the dev ice as well as partial disassembly and

should not be modified where the electronics are exposed to harsh conditions or where unsafe

conditions exist. For configuration or calibration changes without changing the hardware

jumper position the user may choose to rely on the password and software lockout features.

A tamper mode feature (see SLG 700 SmartLine Guided Wave Radar Level Transmitter HART

Option Manual, Document #34-SL-25-06) is available that can indicate that an attempt was

made to change either the configuration or calibration of the device (whether or not a change

was actually made). These security features are designed to avoid accidental changes and to

provide a means to detect if an attempt was made to change the configuration and calibration.

Note: FF does not support tamper mode.

1.9 Measurement Options Li c e nsi ng

As of software revision R200, the sensor checks whet her the user has a licen se req uired to

operate the device in a particular measurement mode (see also 2.5 for the various

measurement modes). Licenses are required to measure two-liquid interfaces, use the low

DC measurement mode and for steam applications. Any sensor ordered for these application

will have a valid license key stored in the transmitter and no user action is required.

The license key depends on the device ID which can be checked using the display (see

Table 4-8 or DTM. It is possible to obtain new license keys for application types other than

which the gauge was originally bought for by supplying the device ID to Honeywell and

entering the newly obtained license key.

Gauges that were installed prior to R200 do not lose access to the interface measurement

when they are upgraded to the new software - the sensor will internally generate a license key

for this applica tion after the first startup and store it in memory.

Page 14 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 31

2 Radar Level Measurement

2.1 Overview

This chapter describes the theory of operation of the transmitter and discusses how

measurements are affected by tank and process conditions.

2.2 Theory of Operation

Guided wave radar provides level measurement based on the Time-Domain Reflectometry

(TDR) principle. Electromagnetic measurement pulses are guided to the measured material by a

metallic probe. When the pulses reach a product surface or interface, a portion of the pulse will

propagate through the surface and the rest will be reflected backwards. The same probe

transports the reflected pulses from the measured material back to the transm itter.

The SLG 700 uses many very-low-power pulses with a technique called Equivalent-Time

Sampling (ETS) to efficiently extract level information. Figure 2-2 is an example of a

waveform acquired with the ETS method. The levels can be extracted from waveforms

knowing the expected positions and shapes of the flange, surface or interface, and end of probe

reflections.

The electromagnetic measuring signal travels at the speed of light for the medium in which it is

propagating in and the probe on which it propagates.

The pulse speed will be less than the speed of light in air by an amount which can be calculated

knowing the ‘dielectric constant’ of the material.

The transmitter measures the time of travel of the reflected signal and calculates distance to the

reflection point. The level of the material can be calculated based on the distance from the

transmitter to the material and the dimensions of the container as illustrated in Figure 2-1.

Distance to Surface calculation:

×

=

Where:

= Distance to surface

d

S

t = time for the pulse to tra vel distance, dS

= speed of light in a vacuum on the probe

v

wg

= dielectric constant of the material in the head space above the level

DC

V

(for air, DC = 1)

2×DC

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 15

Page 32

DCv =

= Dielectric Constant of Vapor

DCU = Dielectric Constant of Level (Upper Product)

DC

= Dielectric Constant of Interface (Lower Product)

L

Figure 2-1: GWR measurement

Page 16 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 33

TDR for Interface and Flooded Measurements

The Time -Domain Reflectometry (TDR) principle can also be us ed to m easure an Interface

Level as well as the upper level. The position of the level interface has to be calculated with

knowledge of the dielectric constant (DC

) of the upper layer.

U

The SLG 700 can measure levels of different materials in the same tank and can detect the

echo from the boundary between Vapor and the Upper Product (UP), and between the Upper

Product (UP) and the Lower Product (LP). This allows calculating the level for each material

and the interface thickness as in Figure 2-3.

If an interface level is being measured, the pulses pass through the upper medium before

reaching the interface.

Distance to Product in the Interface equation:

×

=

+

2 ×

Where:

dS = Distance to surface

∆t = change in time for a pulse to travel the distance through the Upper Product

= speed of light in a vacuum on the probe

v

wg

= Dielectric Constant of Upper Product

DC

U

Surface and interface measurements can be made if:

= where the DC Upper Product is less than 9 and the DC difference between the

DC

U

upper and lower product is greater than 8.

The minimum thickness of the interface layer is 7cm.

Figure 2-2 shoes the distances to surface and interface can be calculated as shown in this

sample echo curve.

Figure 2-2: Sample Echo Curve

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 17

Page 34

Figure 2-3: Interface measurement

2.3 Signal processing configuration

SLG 700 series level transmitters employ advanced signal processing techniques in order to

get the most accurate measurements possible.

Complete pulse-shape information including amplitude, width and side-lobe attenuation is

used for level detection in order to minimize the influence of signal interferences. A typical

pulse and the associated parameters is shown on Figure 2-4.

The sensor is programmed with default values for all parameters, determined by the dielectric

constants of the materials being measured. Either through the advanced display or using the

Honeywell DTM (SLG 700 HART option manual 34-SL-25-06) these parameters can be

adjusted to match the measurement conditions. Typically, the amplitude (also referred to as

gain) of the model is the only parameter that needs to be adjusted, and this is generally only

required if the dielectric constant of the medium is uncertain. No te that the ‘attenu ati o n’

parameter of the model should not be confused with the attenuation of the radar pulse as it

propagates down the waveguide.

Page 18 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 35

Figure 2-4 Radar Impulse Reflection model

Although the algorithms are tolerant of signal amplitude variation, a good match is important

to discern the true level signal from that caused by obstacles near the probe or secondary

reflections. Both the DTM and the advanced display module show the signal quality, a

measure of the match between radar pulse model and acquired echo curve.

Amplitude Tracking

Release R102 introduced an additional feature to improve level tracking under difficult

conditions or when the medium attenuation is not well known. The amplitude tracking feature

(off by default) enhances the user specified pulse model information using historical

measurement data. It can improve the quality of the match when there are slowly varying

conditions in the tanks, such temperature variations, vapor density changed, turbulence or

even dirt build up on the probe. Amplitude tracking is not a substitute for model tuning and

will not track signals more than 35% different in amplitude from those expected. It should be

noted that tracked amplitudes are periodically saved to permanent memory. When the sensor

starts up it will first attempt to locate the levels using the tracked signal amplitudes and if this

fails, will revert to the initial amplitudes when the sens or loses pow er sin ce it is impossible to

predict whether the conditions that caus ed the pulse to change (say turbulence) exist when the

sensor is repowered.

Full-tank Detection

This feature enables the transmitter to perform additional analysis on the data in the region

near the reference plane where the product refle ct ions become mixed with reflections from

the physical mounting components such as a flange or nozzle. This additional analysis allows

the transmitter to detect the presence of product in this region even if the shape of the product

reflections deviate significantly from the expected shape. This option should only be enabled

if a recently captured Field or Obstacle background is in use and the Dielectric Constant of

the Upper Product is above 12. It should not be enabled for products with low Dielectric

Constants or when the Built-in background type is being used.

Revision 9 SLG 700 SmartLine Level Transmitter User’s Manual Page 19

Page 36

Maximum Fill Rates, Latching and Timeouts

The maximum fill rate, also referred to as Rate of Change (ROC) limits the expected level

changes between two successive measurements. Software revision prior to R200 allowed a

range of 4 - 20 cm/s. As of R200 this limit is increased to 90 cm/s. If a level is detected to

have moved further then the ROC limit, the level status is considered bad. See also Table 4-5:

Display Config sub-menu.

The Echo Lost Timeout setting is the number of seconds that the transmitter will wait after

the reflection from the product has been lost before setting a critical alarm and entering

failsafe (burnout) mode. The sam e behavior w ill resu lt if instead of the measurement being

completely lost, the rate of change has been exceeded.

The latching mode parameter allows selecting the behavior of the GWR transmitter in case of

a measurement fault critical error. If the Latching option is selected, the GWR transmitter

will stay in the critical error state once the Echo Lost Timeout has expired, unti l a user

performs a hardware or software reset. Th e latching mode option has a significant effect on

behavior of the sensor when levels are considered lost. If the Non-latching option is selected,

the GWR transmitter will leave the critical error state automatically (after the Echo Lost

Timeout expires) and attempt to re-measure level over the entire probe length. Latching mode

can only be enabled with HART transmitters.

Page 20 SLG 700 SmartLine Level Transmitter User’s Manual Revision 9

Page 37

2.4 Signal Interferences and back ground echoes

Interfering reflections can occur near the top and bottom of the probe. These interfering

echoes occur or when the pulse encounters a transition, such as from nozzle to tank, or when

the pulse exits the process connector for a rod or wire probe, or when the pulse is reflected

from the end of the probe. Unwanted reflections can also occur, from deposits on the probe or

from interfering structures such as inlets, outlets, ladders and so forth, which are positioned

near the probe. If the user suspects deposits on the probe then it should be inspected and

cleaned, if necessary. The top and bottom zones in which these interferences occur can be

configured as blocking distances within which no measurement will occur.

Coaxial probes are less susceptib le to these in terfe renc es and have smaller upper blocking

distances. For all probes, the effects of interfering reflections near the process connector can

be reduced by background subtraction.

Release R102 offers two type of background echo acquisition modes and either can be