Honeywell S8700, S8700B, S8700D, S8700E, S8700F Installation Instructions Manual

...

9

9

S8700B,D-F,J-M Direct Spark

Ignition Controls

INSTALLATION INSTRUCTIONS

APPLICATION

S8700 Direct Spark Ignition Controls are designed for

use in a wide range of gas-fired appliance applicat ion s

that require direct main burner ignition and flame safety

control of gas burners. The S8700 is used to ignite the

main burner, sense the flame and control the gas valve.

See Table 1 for the model that best meets your

application needs.

The S8700B,E,J,L models provide sin gle r od flame

sensing (i.e., the spark rod also acts as the flame sense

rod). The S8700D,F,K,M models provide dual rod flame

sensing (i.e., the spark rod and flame rod are separate).

The S8700J,K,L,M models provide 30-second minimum

time delay between application of 24V power to the

control and initiation of the trial for ignition period for

applications that require prepurge. Al l m odel s have an

LED status indicator.

Table 1. S8700 Models.

Model

S8700B 1-rod local 1 0

S8700D 2-rod remote 1 0

S8700E 1-rod local 3 0

S8700F 2-rod remote 3 0

S8700J 1-rod local 1 30 minimum

S8700K 2-rod remote 1 30 minimum

S8700L 1-rod local 3 30 minimum

S8700M 2-rod remote 3 30 minimum

Flame

Sense

Trials for

Ignition

Prepurge

(seconds)

SPECIFICATIONS

Electrical

Input Voltage: 24 Vac (20.5 Vac minimum to 28.5 Vac

maximum) at 60 Hz.

Current Draw: 0.15A maximum in run mode at 24 Vac.

Thermostat Anticipator Setting: 0.15A plus actual v alve load.

Valve Output: 2.0A maximum run; 6.0A maximum

inrush at 24 Vac.

Alarm Output: 0.5A maximum resistive loa d (Out put is

positive phase, one-half wave rectified, 24 Vac).

Spark Output: 14 KV minimum into 25 picofar ad

capacitive load.

Environmental

Ambient Operating Temperature: -40°F to +175°F

(-40°C to +79°C).

Relative Humidity: 5% to 95% at 95°F (35°C ) ,

noncondensing.

Ignition Sequence/Flame Sense

Prepurge: See Table 1.

Ignition Trials to Lockout: See Table 1.

Trial for Ignition Times: 4.6, 6.6, 11.1 or 21.1 second

nominal available.

Between Trial Purge: 30 second minimum

(S8700E,F,L,M only).

Auto Reset from Lockout: 60 minutes minimum

(S8700E,F,L,M only).

Flame Failure Re-ignition Time: 0.8 second maximum

at 1 microamp flame current.

Flame Current:

Minimum Threshold: 1 microamp.

Appliance Application: 2.5 microamp mini m um reco m-

mended under all appliance operating conditions.

Approvals:

CSA International Design Certi fi ed to ANS I Z21.20,

Report Number C2030026.

PLANNING THE INSTALLATION

WARNING

Fire or Explosion Hazard.

Gas leaks can cause property da m age,

severe injury or death.

Follow these warnings exactly:

Plan the installation using the following out li ne.

Plan for frequent maintenance as described in

the Maintenance section.

Review the following conditions that apply to your

specific installation and take the precautionar y step s

suggested.

® U.S. Registered Trademark

Copyright © 2000 Honeywell Inc. • All Rights Reserved

69- 12

S8700B,D-F,J-M DIRECT SPARK IGNITION CONTROLS

Frequent Cycling

The S8700 is designed to cycle three to four times each

hour during the heating season. Year-round applications and applications with more frequent cycling ra tes

can wear out the controls more quickly than normal

operation. Perform monthly system checks to make

sure the system operates properly.

Water or Steam Cleaning

If a control gets wet, replace it. If the appliance is likely

to be cleaned with water or steam, cover the control and

wiring to protect them from water or steam flow. Mount

the control high enough above the floor so it does not

get wet during normal cleaning procedures.

High Humidity or Dripping Water

Dripping water can cause the control to fail. Never

install an appliance where water can drip on the control.

In addition, high ambient humidity can cause the control

to corrode and fail. If the appliance is in a humid atmosphere, make sure air circulation around the control is

adequate to prevent condensation. Also, regul ar ly

check out the system.

IMPORTANT

Always install a splash cover to protect the

control from water damage.

Corrosive Chemicals

Corrosive chemicals can attack the control, eventual ly

causing a failure. If chemicals are used for routine

cleaning, avoid contact with the control. Where

chemicals are suspended in air, as in some industrial or

agricultural applications, protect the con trol with an

enclosure.

Dust or Grease Accumulation

Heavy accumulations of dust or grease can cause the

control to malfunction. Where dust or grease can be a

problem, provide covers for the control to limit

contamination.

INSTALLATION

When Installing this Product…

Read these instructions carefully. Failure to follow

1.

them could damage the product or cause a

hazardous condition.

Check the ratings given in the instructions and on

2.

the product to make sure it is suitable for your

application.

The installer must be a trained, experienced

3.

service technician.

After installation is complete, check out system

4.

operation.

WARNING

Fire or Explosion Hazard.

Gas leaks can cause property damage ,

severe injury or death

Always turn off gas supply before installing a

new gas control.

Be sure to conduct a gas leak test after installing

the control.

CAUTION

Electric Shock Hazard.

Power supply can cause personal inj ur y or

equipmen t damage.

Disconnect power supply before installation.

IMPORTANT

If this is a replacement application, follo w th e

appliance manufacturer’s instructions, if

available.

The manufacturer usually provides wiri ng dia grams, start-up and checkout instructions and

service procedures for their system. If the

manufacturer’s instructions ar e not available,

use these instructions as a general guide.

Heat

Excessively high temperatures can damage the control.

Make sure the maximum ambient temperature at the

control does not exceed the rating of the control, see

Specifications section. If the appliance operates at very

high temperatures, use insulation, shielding and air

circulation, as necessary, to protect the control. Proper

insulation or shielding should be provided by the

appliance manufacturer; verify proper air circulation is

maintained when the appliance is installed.

System Requirements

S8700 system requirements:

— Q 347A Spark Igniter and Q354A Flame Sensor, or a

Q366 with separate spark igniter and flame sensor

mounted on a common bracket. (Equivalent ignit io n

hardware may be used.)

— Honeywell VR8205 Gas Valve (or equivalent)

designed for DSI applications. Valve loads must be

within the range listed in the Specifications section.

69-1299 2

MOUNTING

S8700 Control

Select a location within 6 ft (1.8m) of the burner that

permits a direct cable route to the spark igniter terminal.

Ready access to the S8700 terminals is necessary for

wiring and servicing. Do not exceed the ambient temperature rating given in the Specifications section.

To mount the S8700:

Mount the S8700 in any position. See Fig. 1 for

1.

mounting dimensions.

Use No. 6-32 machine screws or 1 in. No. 8 sheet

2.

metal screws for fastening.

Fasten the screws securely.

3.

13/16 (21)

2

(50)

1-1/8

(29)

2-13/16 (72)

3-15/16 (100)

3-3/8 (86)

3/16 (4)

5/17 (7)

3-3/8

(86)

7/8 (23)

M16233

5-3/16

(130)

Fig. 1. S8700 mounting dimensions in in. (mm).

Auxiliary Controls

Mount the spark igniter, flame sensor, temperature

control, transformer, gas control and any other auxiliary

controls according to the manufacturer’s instructions .

NOTE: NOTE: Make sure the 24V system transformer

is rated to handle both the S8700 current and

the total gas valve curren t.

WIRING

General Precautions

For circuits that differ from the diagrams in Fig. 2

1.

and 3, check the wiring diagrams from the heating

appliance manufacturer, if available. Carefully follow any special instructions that would affect the

following general procedures.

All wiring must comply with applicable elect ri cal

2.

codes and ordinances.

Disconnect the power supply before wiring to

3.

prevent electrical shock or equipment damage.

When installing a separate flame sensor, the

4.

sensor leadwire should be kept as short as

possible and should not be allowed to rest against

grounded metal surfaces.

gnition cable should not touch any metal surface

5. I

or current carrying wires. It must not be more than

6 ft (1.8m) long. See Table 2 for recommended

ignition cable.

Do not short valve terminals as this can damage

6.

the temperature controller, the transformer or the

S8700 control.

S8700B,D-F,J-M DIRECT SPARK IGNITION CONTROLS

Table 2. Recommended Ignition Cable.

Maximum

Ambient

Temperature

Rating

FC

Cable Type

RMS Voltage

Rating

UL Style 3257 10,000 482 250

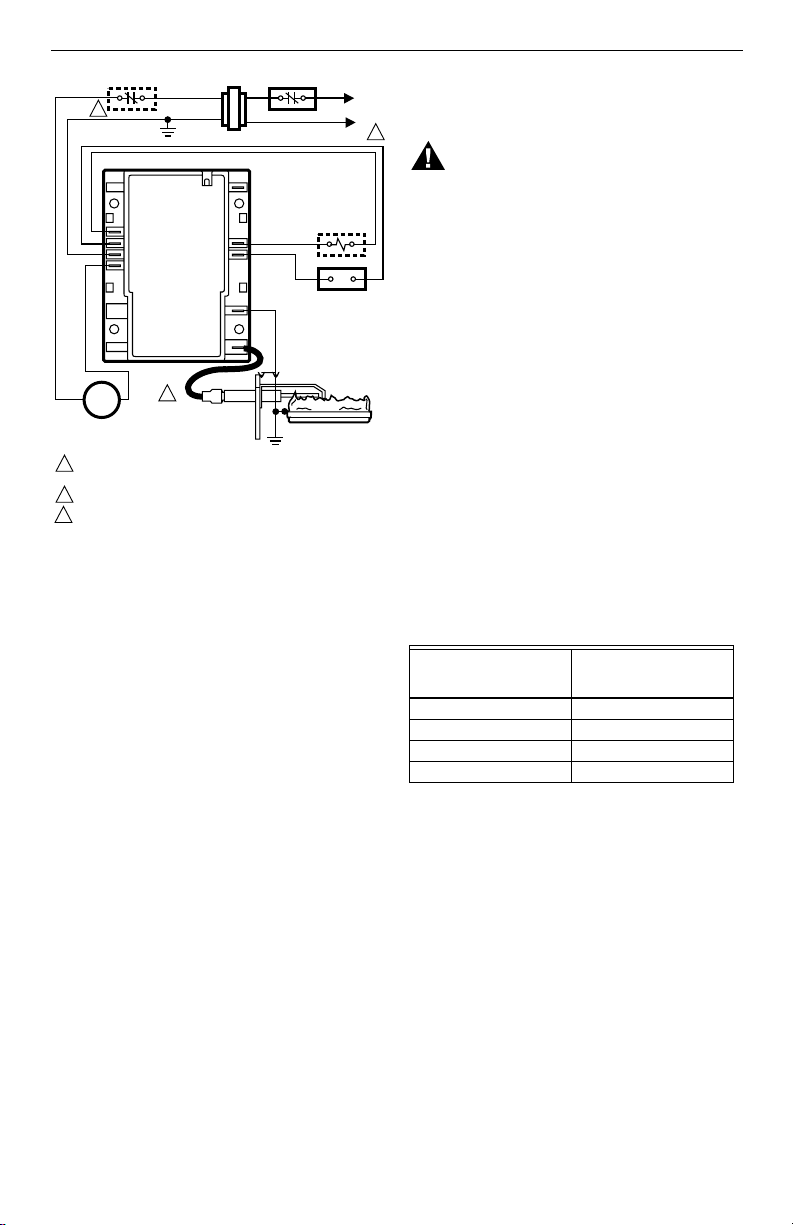

Wiring the S8700 Control

Connect the system components to the S8700

1.

terminals as shown in the wiring diagrams, Fig. 2

and 3. Refer to the heating appliance manufacturer’s instructions for wiring any other auxiliar y

controls.

Adjust the temperature control heat anticipato r (if

2.

provided) to match the system current draw. The

current draw equals the total current requir ed for

the S8700 (0.15A) plus the gas valve and all other

24V control loads (vent dampers, and pre pur ge

relays). Gas valve must be designed for the DSI

application.

NOTE: NOTE: Use only recommended igni tion cable

(see Table 2), or equivalent, to connect the

S8700 with the spark igniter. Cable must not

run in continuous contact with a metal surface

or spark voltage is greatly reduced; use

ceramic standoff brackets if necessary. Cable

length must not exceed 6 ft (1.8m).

TRANSFORMER

FLAME

SENSE

ALARM

VALVE

(GND)

SPARK

3

LIMIT CONTROLLER

Q347

SPARK

IGNITER

IGNITER AND

BURNER GROUND

L1

(HOT)

L2

ALARM, IF USED

ANY COMBINATION

GAS CONTROL

2.0A MAX.

Q354 FLAME

SENSOR

BURNER

1

M16527

2

S8700D,F,K,M CONTROL

GND

VALVE (GND)

24 Vac (GND)

24 Vac

BURNER

TEMPERATURE

CONTOL

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

3

MAXIMUM IGNITER-SENSOR CABLE LENGTH: 6 FT (1.8 M).

Fig. 2. Typical wiring diagram for

S8700D,F,K,M dual rod models.

3 69-1299

S8700B,D-F,J-M DIRECT SPARK IGNITION CONTROLS

L1

2

S8700E,J,L CONTROL

GND

VALVE (GND)

24 Vac (GND)

24 Vac

BURNER

(GND)

SPARK

3

TEMPERATURE

CONTOL

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

3

MAXIMUM IGNITER-SENSOR CABLE LENGTH: 6 FT (1.8 M).

Fig. 3. Typical wiring diagram for

S8700E,J,L single rod models.

NOTE: NOTE: Proper system operation requires that

the S8700 GND (Burner) terminal is wired to

be electrically common with the spark

electrode bracket, flame sensor bracket (if a

separate flame sensor is used) and the main

burner. In many applications, this is

accomplished through connecting the S8 700

GND (Burner) terminal to the appliance

chassis, as the other noted components are

presumed to be electrically common with the

appliance chassis. If flam e sensing problems

are noted, it may be due to corroded or loose

electrical connections between the noted

components and the appliance chassis.

TRANSFORMER

FLAME

SENSE

ALARM

VALVE

LIMIT CONTROLLER

Q347

SPARK

IGNITER

IGNITER AND

BURNER GROUND

(HOT)

L2

ALARM, IF USED

ANY COMBINATION

GAS CONTROL

2.0A MAX.

BURNER

M16528

1

STARTUP

The following start-up procedures are basic to all S8700

controls. If this is a replacement application, refer to the

specific instructions provided by the heating appliance

manufacturer, if available. Also, since the auxiliary

controls used on any DSI system can differ, refer to the

manufacturer’s instructions for start-up and checkout

procedures for other system components.

NOTE: If the S8700 does not perform as outlined in

the following Start System and Check Trial for

Ignition steps, refer to the Service section to

determine the cause.

Gas Leak Test

If the gas control has been replaced as a part of the S8700

installation, perform the following test for gas leaks.

WARNING

Explosion or Fire Hazard.

Gas Leaks can cause property dam age,

severe injury or death.

To avoid possible explosion or fire, perform the

Gas Leak Test.

With the main burner in operation, paint the pipe joint s

and valve gasket with a rich soap and water solution.

Bubbles indicate a gas leak. To stop a leak, tighten the

joints and screws. Never use a flame to check for gas

leaks.

Start System

Turn on the power and the gas supply.

1.

Set the temperature control to call for heat and

2.

watch for a spark at the igniter (S8700B,D,E,F

models have no delay on start-up; S8700J,K,L,M

models have a predetermined delay on start- up

for prepurge).Check that the system starts as

follows: Prepurge delay (if provided), spark turns

on, gas valve opens at once and burner ignites

after gas reaches the main burner. Once the

burner flame is established, spark igniter cuts off.

NOTE: NOTE: If the gas control has been replaced or

serviced, lightoff may not be satisfactory until

air has been purged from the gas line or the

gas input and combustion air have been

adjusted (see manufacturer’s instru ctions).

Table 3. S8700 Trial for Ignition Periods.

Specified Trial for

Ignition (TFI) (stamped

on control)

4.6 sec 5.0 sec

6.6 sec 7.0 sec

11.1 sec 11.5 sec

21.1 sec 21.5 sec

Check Trial for Ignition

Check device label on the control to determine

1.

the correct trial for ignition time.

With the system power off and the thermostat or

2.

temperature control set to call for heat, manual ly

shut off the gas supply.

Turn power on to energize the S8700 and

3.

immedia t e l y start tim ing when the gas valve is

energized.

Determine the number of seconds to drop-out of

4.

the gas valve. It should not exceed the trial for

ignition time shown in Table 5.

After spark cutoff, manually reopen the gas sup-

5.

ply cock. No gas should flow to the main burner.

Reset the system as described in Resetting

6.

S8700 After Safety Lockout section.

Trial for Ignition Should

Not Exceed

69-1299 4

Loading...

Loading...