Page 1

INTERMITTENT PILOT MODULES

S8600, S8610, S8660, S8670

APPLICATION

These ignition modules provide ignition sequence, flame

monitoring and safety shutoff for intermittent pilot central

furnaces and heating appliances. S8600 and S8660 models provide up to 1.0 A pilot and 1.0 A main valve current

rating. S8610 and S8670 provide up to 1.0 A pilot and 2.0

A main valve current rating. Minimum ambient temperature

IGNITER- 100

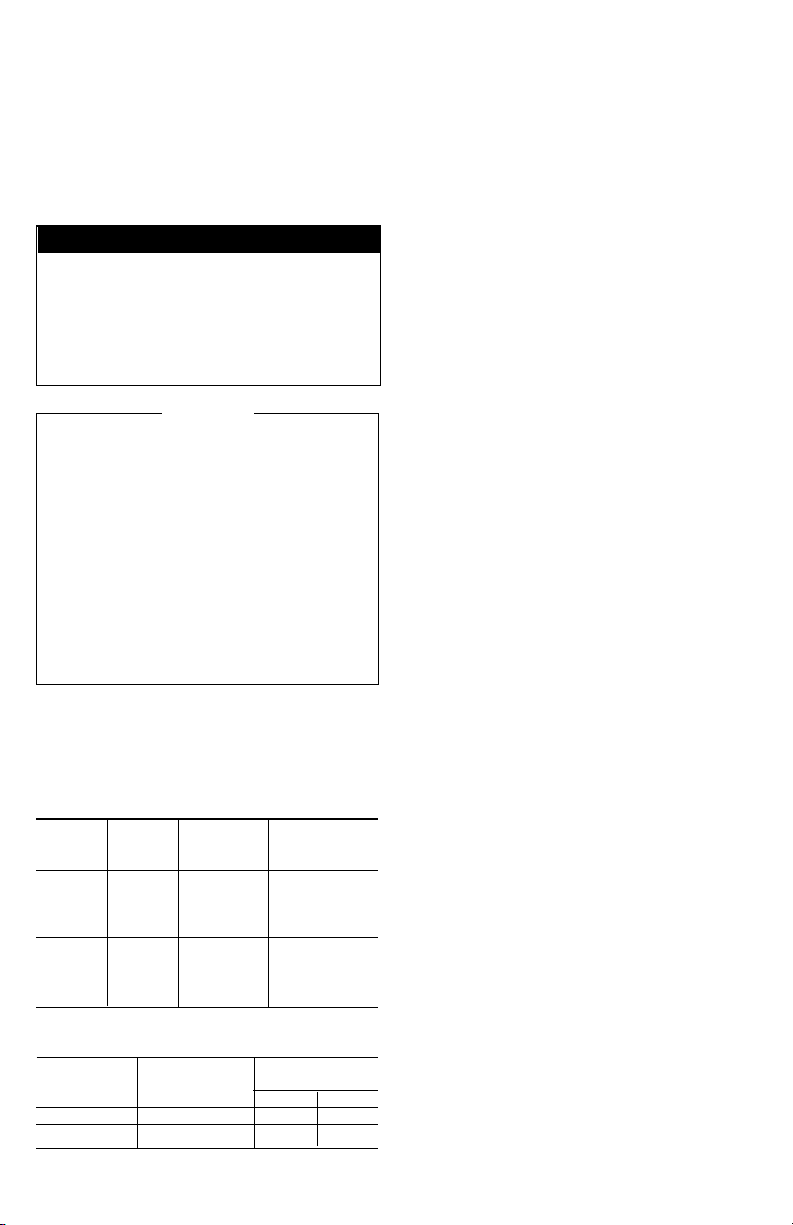

MODEL TYPE OF GAS TIMING SHUTOFF TIMING SEQUENCE

S8600A, Separate Natural None No No Spark on until pilot

S8610A lightoff or manual

S8600F, Combination shutoff; pilot valve

S8610F open until manual

S8600B, Separate Natural None Yes, at 15 or 90 Spark on until

S8610B or LP lockout sec. max., lightoff or lockout;

S8600H, Combination as ordered pilot valve closes

S8610H on lockout.

S8600M Combination Natural None Yes, at 90 No, Spark and pilot gas

S8660D, Combination Natural 45 sec. Yes, at 15 or 90 Ignition trial follows

S8670D or LP lockout sec. max., prepurge; spark on

a

If established flame is lost, all models restart ignition trial.

PLANNING THE INSTALLATION

Intermittent pilot systems are used on a wide variety of

central heating equipment and on heating appliances such

as commercial cookers, agricultural equipment, industrial

heating equipment and pool heaters. Some of these applications may make heavy demands on the controls, either

because of frequent cycling, or because of moisture, corrosive chemicals, dust or excessive heat in the environment.

In these situations, special steps may be required to prevent nuisance shutdowns and premature control failure.

These applications require Honeywell Residential Division

Engineering review; contact your Honeywell Sales Representative for assistance.

FREQUENT CYCLING

These controls are designed for use on space heating

appliances that typically cycle 3 to 4 times an hour during

the heating season and not at all during the cooling season.

In an application with significantly greater cycling rates and

closer to year-round use, we recommend monthly checkout

because the controls may wear out more quickly.

WATER OR STEAM CLEANING

Once a module or gas control has been wet, it may

operate unreliably and must be replaced. If the appliance is

SENSOR TYPE PREPURGE PERCENT LOCKOUT IGNITION

TABLE 1—INTERMITTENT PILOT IGNITION MODULES.

or LP sec. max. continuous on until shutoff.

rating is -40° F [-40° C]. Maximum ambient rating is +175°

F [+79° C] for S8600, S8660 and for S8610, S8670 used

with 1.0 A or less main valve. Maximum ambient rating for

S8610, S8670 used with 1.0 to 2.0 A main valve is +165° F

[+74° C]. See Table I for a summary of other differences

between models.

shutdown.

retry After 5 min. min.

as ordered until lightoff or

likely to be cleaned with water or steam, the controls and

associated wiring should be covered so water or steam flow

cannot reach them. The controls should be high enough

above the bottom of the cabinet so they will not be subject

to flooding or splashing during normal cleaning procedures.

If necessary, shield the controls to protect them from

splashing water. A NEMA 4 enclosure is recommended for

the ignition module; see the Electronic Ignition Service

Manual, form 70-6604.

HIGH HUMIDITY OR DRIPPING WATER

Over time, dripping water or high ambient humidity can

create unwanted electrical paths on the module circuit

board, causing the module to fail.

where water can drip on the controls.

In addition, high ambient humidity can cause the gas

control to corrode, and finally to fail.

Where the appliance may be installed in a humid atmosphere, make sure air circulation around the module and gas

control is adequate to prevent condensation. It’s also important to regularly check out the system. A NEMA 4

enclosure may be needed; see the Electronic Ignition

Service Manual, form 70-6604.

(6 min. nom.) delay,

ignition starts again.

Ignition, wait, retry

repeats until pilot

lights or system is

shut down manually.

lockout; pilot valve

closes on lockout.

Never

install an appliance

a

J.A. Form Number 69-0463

11-89 ©Honeywell Inc. 1989.

Page 2

CORROSIVE CHEMICALS

Corrosive chemicals can also attack the module and gas

control and eventually cause a failure. Where chemicals

may be used routinely for cleaning, make sure the cleaning

solution cannot reach the controls. Where chemicals are

likely to be suspended in air, as in some industrial and

agricultural applications, protect the ignition module from

exposure with a NEMA 4 enclosure; see the Electronic

Ignition Service Manual, form 70-6604.

DUST OR GREASE ACCUMULATION

Heavy accumulation of dust or grease may cause the

controls to malfunction. Where dust or grease may be a

problem, provide covers for the module and the gas control

that will limit environmental contamination. A NEMA 4

enclosure is recommended for the ignition module; see the

Electronic Ignition Service Manual, form 70-6604.

HEAT

The controls can be damaged by excessively high

temperatures. Make sure the maximum ambient temperature at the control locations will not exceed the rating of the

control. If the appliance normally operates at very high

temperatures, insulation, shielding, and air circulation may

be necessary to protect the controls. Proper insulation or

shielding should be provided by the appliance manufacturer; make sure adequate air circulation is maintained

when the appliance is installed.

INSTALLATION

WHEN INSTALLING THIS IGNITION SYSTEM…

1. Read these instructions carefully. Failure to follow

them could damage the components or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

components to make sure they are suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out component

operation as provided in these instructions.

WARNING

FIRE OR EXPLOSION HAZARD.

CAN CAUSE SERIOUS INJURY OR DEATH.

1. The ignition module can malfunction if it gets

wet, leading to accumulation of explosive gas.

• Never install where water can flood, drip or

condense on module.

• Never try to use a module that has been

wet—replace it.

2. Liquefied petroleum (LP) gas is heavier than

air and will not vent upward naturally.

• Do not light pilot or operate electric

switches, lights, or appliances until you are

sure the appliance area is free of gas.

1. Disconnect power supply before beginning wiring

to prevent electrical shock or equipment damage.

2. If a new gas control is to be installed, turn off gas

supply before starting installation. Conduct Gas

Leak Test according to gas control manufacturer’s instructions after the gas control is installed.

3. If module must be mounted near moisture or

water, provide suitable waterproof enclosure.

PERFORM PREINSTALLATION SAFETY INSPECTION

The preinstallation checks described in ANSI Standard

Z21.71 on page 19

module is installed. If a condition which could result in

unsafe operation is detected, the appliance should be shut

off and the owner advised of the unsafe condition. Any

potentially unsafe condition must be corrected before proceeding with the installation.

Maintenance Requirements in Severe Environments

Regular preventive maintenance is important in any

application, but especially so in commercial cooking, agricultural, and industrial applications because:

CAUTION

must

be done before the replacement

• In many such applications, particularly commercial

cooking, the equipment operates 100,000-200,000

cycles per year. Such heavy cycling can wear out the

gas control in one to two years. A normal forced air

furnace, for which the controls were originally intended, typically operates less than 20,000 cycles

per year.

• Exposure to water, dirt, chemicals, and heat can

damage the module or the gas control and shut down

the control system. A NEMA 4 enclosure can reduce

exposure to environmental contaminants. See Electronic Ignition Service Manual, form 70-6604.

The maintenance program should include regular check-

out of the system as outlined under Checkout, page 11.

WARNING

FIRE OR EXPLOSION HAZARD

MAY CAUSE PROPERTY DAMAGE, SEVERE

INJURY OR DEATH

Do not attempt to take the module apart or to clean

it. Improper reassembly and cleaning may cause

unreliable operation.

Maintenance frequency must be determined individually

for each application. Some considerations are:

•

Cycling frequency

than 20,000 times annually should be checked

monthly.

•

Intermittent use

should be checked before shutdown and again before the next use.

•

Consequence of unexpected shutdown

cost of an unexpected shutdown would be high, the

system should be checked more often.

•

Dusty, wet, or corrosive environment.

environments can cause the controls to deteriorate

more rapidly, the system should be checked more

often.

Any control should be replaced if it does not perform

properly on checkout or troubleshooting. In addition, replace any module if it is wet or looks like it has ever been

wet. Protective enclosures as outlined under “Planning the

Installation” are recommended regardless of checkout frequency.

MOUNT IGNITION MODULE

Select a location close enough to the burner to allow a

short (3 ft. [0.9 m] max.), direct cable route to the igniter.

Ambient temperature at the module must be within the

range listed under APPLICATION, page 1. The module

must be protected from water, moisture, corrosive chemicals and excessive dust and grease.

2

. Appliances that may cycle more

. Appliances that are used seasonally

. Where the

Since these

Page 3

We recommend mounting the module with the terminals

down to protect them from dripping water and dust. It can

also be mounted with the terminals on either side. DO NOT

MOUNT with terminals pointing up. Fasten securely with

four No. 6-32 machine or No. 8 sheetmetal screws.

MOUNT THE SYSTEM CONTROLS

Mount any required controls, such as the gas control,

spark igniter, flame sensor, thermostat, limit and transformer according to manufacturer’s instructions.

WIRE THE SYSTEM

CAUTION

1. Check the wiring diagram furnished by the appliance manufacturer, if available, for circuits differing from the wiring hookups shown. Carefully

follow any special instructions affecting the general procedures outlined below.

2. Disconnect the power supply before making wiring connections to prevent electrical shock or

equipment damage.

1. As shown in the wiring diagrams, a common

ground is required on:

a. The pilot burner mounting bracket, and

b. The GND(BURNER) terminal on the ignition

module. Failure to use the GND(BURNER) terminal may result in intermittent loss of spark and/or

loss of flame current sensitivity.

2. Make sure the transformer has adequate VA. The

ignition module requires at least 0.2 A at 24 Vac.

Add the current draws of all other devices in the

control circuit, including the pilot and main valves

in the gas control, and multiply by 24 to determine

the total VA requirement of these components.

Add this total to 4.8 VA (for the ignition module).

The result is the minimum transformer VA rating.

Use a Class II transformer if replacement is required.

Connect Ignition Cable

Use Honeywell ignition cable or construct an ignition

cable that conforms to suitable national standards such as

Underwriters Laboratories Inc. See Tables 2 and 3.

TABLE 2—HONEYWELL PREASSEMBLED IGNITION

CABLE

PART MODULE IGNITER

NUMBER LENGTH END END

394800-30 30 in. 1/4 in. quick Rajah connec-

394801-30 30 in. 1/4 in. quick Rajah connec-

TABLE 3—RECOMMENDED IGNITION CABLE FOR

CABLE VOLTAGE RATING

TYPE RATING (rms) C F

UL Style 3217 10,000 150 302

UL Style 3257 10,000 250 484

IMPORTANT

CABLES (UL STYLE 3257).

connect, tor receptacle,

insulated 90 deg. rubber

boot

connect, tor receptacle,

insulated straight rubber

boot

FIELD ASSEMBLY.

TEMPERATURE

Cable must be no longer than 36 in. [0.9 m]. To construct

a cable, fit one end of ignition cable with 1/4 in. diameter

Rajah connector receptacle and the other with a 1/4 in.

female quick connect. Protect both ends with insulated

boots.

NOTE: The cable must not run in continuous contact with a

metal surface or spark voltage will be greatly reduced.

Use ceramic or plastic standoff insulators as required.

To install:

1. Connect one end of the cable to the male quick

connect SPARK terminal on the ignition module.

2. Connect the other end of the cable to the igniter or

igniter-sensor stud on the pilot burner/igniter-sensor.

Connect Vent Damper

The D80B Vent Damper can be used with all ignition

modules, although the Molex plug provided on some modules simplifies wiring connections when used with the D80D

Plug-In Vent Damper.

plug has powered a vent damper circuit, it cannot be used

in a gas system without a vent damper

fuse in the module blows on initial power-up. Once this fuse

has blown the module won’t work unless the vent damper

is connected.

To connect the plug-in model to D80D:

1. Remove the plug from the terminal strip on the ignition

module case and discard.

2. Using the wiring harness supplied, insert the matching

pin plug into receptacle on case and other end to vent

damper.

To connect the D80B, follow the wiring diagrams supplied with the vent damper or see Fig. 7 for typical connections.

Connect Ignition Module

1. Connect remaining system components to the ignition

module terminals as shown in the appropriate wiring diagram, Figs. 1 to 10.

• Fig. 1 is a basic circuit for a heating only atmospheric burner with S8600F,H,M; S8610F,H;

S8660D or S8670D.

• Fig. 2 shows S8600F,H,M; S8610F,H with vent

damper plug in a heating only atmospheric burner

system with D80D vent damper.

damper in an LP gas system or in a fan-assisted

combustion system.

• Figs. 3 and 4 show S8600A,B; S8610A,B with

separate sensor and igniter, with and without the

D80D vent damper.

• Figs. 5-10 show S8600F,H,M; S8610F,H; S8660D;

and S8670D in a variety of systems, with alternate

connections for modules with vent damper plug.

Remember, however, that a vent damper should

not be used in an fan-assisted combustion system

or an LP gas system and that the vent damper plug

must not be removed except to connect the module to a D80D with the plug-in cable. S8600A,B;

S8610A,B can be substituted in these drawings by

simply connecting the igniter and sensor as shown

in Figs. 3 and 4.

2. Refer to heating appliance manufacturer’s instruc-

tions for wiring auxiliary controls.

3. Adjust thermostat heat anticipator to match system

current draw. The current draw equals the total current

required for the ignition module (0.2 A) plus the gas control

and any other auxiliary equipment in the control circuit.

Connect Gas Control

Use No 18 gauge solid or stranded wire. Use 1/4 in.

female quick connects for module connections. Connect to

gas control terminals as shown in wiring diagrams, using

terminals appropriate to the gas control.

3 69-0463

Once a module with vent damper

. A non-replaceable

Never

use a vent

Page 4

Ground Control System

The igniter, flame sensor and ignition module must

share a common ground with the main burner. Use thermoplastic insulated wire with a minimum rating of 105° C [221°

F] for the ground wire; asbestos insulation is not acceptable. If necessary, use a shield to protect the wire from

radiant heat generated by the burner. Connect the ground

wire as follows:

1. Fit one end of the ground wire with a female 1/4 in.

quick-connect terminal and connect it to the male quickconnect GND(BURNER) terminal on the ignition module.

2. Strip the other end of the wire and fasten it under the

igniter bracket mounting screw. If necessary, use a shield

to protect the ground wire from radiant heat.

3. The burner serves as the common grounding area. If

there is not good metal-to-metal contact between the burner

and ground, run a lead from the burner to ground.

NOTE: “Earth” ground is not required.

REPLACING MODULE WITH TH-R, TH-W TERMINALS

On modules that do not have a vent damper plug, the

thermostat must be connected between the transformer

and the 24V terminal on the module. To change out a

module with TH-R, TH-W terminals:

1. Remove the wires from the 25V(2) and TH-R terminals on the old module. Connect these two wires with a

solderless connector.

2. Tag and remove the remaining wires from the old

module.

3. Remove the old module and mount the new one in the

same location.

4. Reconnect the remaining wires as shown in Table 4.

5. Increase the thermostat anticipator setting by 0.2 A.

TABLE 4—TERMINAL CROSS REFERENCE.

TERMINAL ON TERMINAL ON

OLD MODULE: NEW MODULE:

25 V (1) 24 V (GND)

TH-W 24 V

MV MV

MV/PV MV/PV

PV PV

GND (Burner) GND (Burner)

S8600F,H,M; S8610F,H; S8660D; S8670D

MV MV/PV PV

PILOT COM

1ST

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

2ND

OPERATOR

Q345, Q346,

Q348, Q362, Q381

PILOT BURNER/

IGNITER-SENSOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

3

CONTROLS IN 24V CIRCUIT MUST NOT BE IN GROUND

4

LEG TO TRANSFORMER.

FOR MODULE WITH TH-W TERMINAL AND VENT DAMPER PLUG, CONNECT THERMOSTAT TO TH-W. LEAVE

5

24V OPEN. DO NOT REMOVE VENT DAMPER PLUG.

MAIN

VALVE

GND

(BURNER)

PILOT GAS

SUPPLY

24V

GND

THERMOSTAT

PILOT BURNER

GROUND

24V

M1175C

TH-W

(OPT)

5

5

VENT

DAMPER

PLUG (OPT)

2

LIMIT

CONTROLLER

SPARK

3

4

L1

L2

(HOT)

1

Fig. 1—S8600F,H,M; S8610F,H; S8660D; S8670D connections in a heating system with an atmospheric burner.

4

Page 5

S8600F,H,M; S8610F,H

MV MV/PV PV

GND

(BURNER)

24V

GND

24V TH-W

5

VENT

DAMPER

PLUG

SPARK

197516A

THERMOSTAT

LIMIT

CONTROLLER

2ND

OPERATOR

IGNITER

WIRING

HARNESS

D80D VENT

DAMPER

S8600A,B; S8610A,B

MV MV/PV PV

MAIN

VALVE

PILOT GAS

SUPPLY

MAIN

2ND

OPERATOR

VALVE

PILOT BURNER

GROUND

PILOT GAS

SUPPLY

2

4

PILOT COM

1ST

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

PILOT COM

1ST

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

Q345, Q346,

Q348, Q362, Q381

PILOT BURNER/

IGNITER-SENSOR

Fig. 2—S8600F,H,M; S8610F,H with a vent damper plug in a heating system with an atmospheric burner and a D80D

vent damper.

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

3

4

CONTROLS IN 24V CIRCUIT MUST NOT BE IN

GROUND LEG TO TRANSFORMER.

5

FOR MODULE WITH TH-W TERMINAL AND VENT

DAMPER PLUG, CONNECT THERMOSTAT TO TH-W.

LEAVE 24V OPEN. DO NOT REMOVE VENT DAMPER PLUG.

M1186C

L1

(HOT)

L2

SENSOR

1

GND

(BURNER)

3

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

3

MAXIMUM CABLE LENGTH 3 FEET [0.9 METERS].

4

CONTROLS IN 24V CIRCUIT MUST NOT BE IN

GROUND LEG TO TRANSFORMER.

5

REMOVE PLUG ONLY IF USING VENT DAMPER.

FUSE BLOWS ON STARTUP WHEN PLUG IS REMOVED;

THEN MODULE WILL OPERATE ONLY WHEN VENT

DAMPER IS CONNECTED.

VENT

5

TH-W

(OPT)

5

THERMOSTAT

2

LIMIT

CONTROLLER

DAMPER

PLUG (OPT)

GROUND

24V

GND

24V

4

1

L2

L1

(HOT)

SENSE

M1176D

SPARK

3

Fig. 3—S8600A,B; S8610A,B connections in a heating system with an atmospheric burner.

5 69-0463

Page 6

S8600A,B; S8610A,B

MV MV/PV PV

GND

(BURNER)

24V

GND

24V

TH-W

VENT

DAMPER

PLUG

5

SENSE

SPARK

3

M1177C

TH-W

(OPT)

5

AIR

PROVING

SWITCH

VENT

5

DAMPER

PLUG (OPT)

MAIN

VALVE

SENSOR

PILOT GAS

SUPPLY

THERMOSTAT

4

L1

L2

(HOT)

1

2

LIMIT

CONTROLLER

GROUND

SPARK

3

197516A

WIRING

HARNESS

THERMOSTAT

2

D80D VENT DAMPER

1

4

LIMIT

CONTROLLER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

3

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

4

CONTROLS IN 24V CIRCUIT MUST NOT BE IN

GROUND LEG TO TRANSFORMER.

FOR MODULE WITH TH-W TERMINAL AND VENT

5

DAMPER PLUG, CONNECT THERMOSTAT TO TH-W.

LEAVE 24V OPEN. DO NOT REMOVE VENT DAMPER PLUG.

L2

L1

(HOT)

PILOT COM

2ND

1ST

OPERATOR

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

2

ALTERNATE LIMIT CONTROLLER LOCATION.

3

MAXIMUM CABLE LENGTH 3 FEET [0.9 METERS].

4

CONTROLS IN 24V CIRCUIT MUST NOT BE IN

GROUND LEG TO TRANSFORMER.

5

REMOVE PLUG ONLY IF USING VENT DAMPER.

M1185D

Fig. 4—S8600A,B; S8610A,B with vent damper plug in an atmospheric burner heating system with a D80D vent

damper.

S8600F,H,M; S8610F,H; S8660D; S8670D

MV MV/PV PV

PILOT COM

2ND

1ST

OPERATOR

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

Q345, Q346,

Q348, Q362, Q381

PILOT BURNER/

IGNITER-SENSOR

MAIN

VALVE

GND

(BURNER)

PILOT

BURNER

GROUND

PILOT GAS

SUPPLY

24V

GND

L1

(HOT)

IGNITER

24V

L2

1

COMBUSTION

AIR BLOWER

RELAY

COMBUSTION

AIR BLOWER

MOTOR

Fig. 5—S8600F,H,M; S8610F,H; S8660D; S8670D connections in a heating system with power-assisted combustion.

6

Page 7

S8600F,H,M; S8610F,H; S8660D; S8670D

MV MV/PV PV

GND

(BURNER)

24V

GND

24V

TH-W

(OPT)

VENT

5

DAMPER

PLUG (OPT)

SPARK

5

L1

(HOT)

L2

1

AIR

PROVING

SWITCH

Q345, Q346,

Q348, Q362,

Q381PILOT

BURNER/

IGNITERSENSOR

COMBUSTION

AIR BLOWER

MOTOR

VALVE

MAIN

STAGE 2

MAIN

VALVE

2ND

OPERATOR

STAGE 1

COM

GROUND

PILOT

1ST

OPERATOR

TWO STAGE DUAL VALVE

COMBINATION GAS CONTROL

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

ALTERNATE LIMIT CONTROLLER LOCATION.

2

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

3

CONTROLS IN 24V CIRCUIT MUST NOT BE IN GROUND LEG TO TRANSFORMER.

4

FOR MODULE WITH TH-W TERMINAL AND VENT DAMPER PLUG, CONNECT THERMOSTAT TO TH-W. LEAVE

5

24V OPEN. DO NOT REMOVE VENT DAMPER PLUG.

THERMOSTAT

LIMIT

CONTROLLER

RW2W1

2

4

1

L2

L1

(HOT)

COMBUSTION

AIR BLOWER

RELAY

PILOT

BURNER

GROUND

PILOT GAS

SUPPLY

3

M1178C

Fig. 6—S8600F,H,M; S8610F,H; S8660D; S8670D connections in a heating system with a two-stage gas control and

power-assisted combustion.

7 69-0463

Page 8

S8600F,H,M; S8610F,H; S8660D; S8670D

MV MV/PV PV

GND

(BURNER)

24V

GND

24V

TH-W

(OPT)

VENT

5

DAMPER

PLUG (OPT)

SPARK

5

MOTOR

1K3

1

6

ORANGE

D80B

1K2

1K1

R

1K

2345

RED

THERMOSTAT

OR

CONTROLLER

LIMIT

CONTROLLER

MAIN

2ND

OPERATOR

VALVE

L2

L1

(HOT)

PILOT GAS

SUPPLY

LIMIT

CONTROLLER

1

PILOT

BURNER

GROUND

4

TRANSFORMER

2

END SWITCH

N.O. N.C.

BLACK

PILOT COM

1ST

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

Q345, Q346,

Q348, Q362, Q381

PILOT BURNER/

IGNITER-SENSOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

2

3

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

4

CONTROLS IN 24V CIRCUIT MUST NOT BE IN GROUND LEG TO TRANSFORMER.

5

FOR MODULE WITH TH-W TERMINAL AND VENT DAMPER PLUG, CONNECT THERMOSTAT TO TH-W.

LEAVE 24V OPEN. DO NOT REMOVE VENT DAMPER PLUG.

6

COLORS REFER TO WIRE HARNESS, IF USED.

3

BLUE

YELLOW

M1180C

Fig. 7—S8600F,H,M; S8610F,H; S8660D; S8670D in a heating system with an atmospheric burner and a D80B vent

damper.

8

Page 9

S8600F,H,M; S8610F,H; S8660D; S8670D

MV MV/PV PV

GND

(BURNER)

24V

GND

24V

VENT

5

TH-W

DAMPER

(OPT)

PLUG (OPT) SPARK

L2

L1

(HOT)

LIMIT

CONTROLLER

FAN

MOTOR

1

L

C H

PILOT COM

1ST

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

THERMOSTAT

R

G

W Y

R8239

FAN

CENTER

R C

4

WGY

COIL

FAN

CONTROL

2ND

OPERATOR

COOLING

CONTROL

L1

(HOT)

MAIN

VALVE

1

2

L2

COMBUSTION

AIR BLOWER

MOTOR

COMBUSTION

AIR BLOWER

RELAY

AIR PROVING

SWITCH

PRESSURE

CONTROLLER

PILOT

BURNER

GROUND

3

M1182C

5

Q345, Q346,

Q348, Q362,

Q381PILOT

BURNER/

IGNITERSENSOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

2

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

3

CONTROLS IN 24V CIRCUIT MUST NOT BE IN

4

GROUND LEG TO TRANSFORMER.

5

FOR MODULE WITH TH-W TERMINAL AND VENT DAMPER

PLUG, CONNECT THERMOSTAT TO TH-W. LEAVE

24V OPEN. DO NOT REMOVE VENT DAMPER PLUG.

PILOT GAS

SUPPLY

Fig. 8—S8600F,H,M; S8610F,H; S8660D; S8670D connections in a heating-cooling system with power-assisted

combustion.

9 69-0463

Page 10

S8600F,H,M; S8610F,H; S8660D; S8670D

MV MV/PV PV

GND

(BURNER)

24V

GND

24V

VENT

4

TH-W

DAMPER

(OPT)

PLUG (OPT) SPARK

PILOT COM

1ST

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

2ND

OPERATOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

CUT PLUG OFF MODULE END OF D80D WIRE HARNESS, CONNECT LEADWIRE COLORS AS SHOWN.

3

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

FOR MODULE WITH TH-W TERMINAL AND VENT DAMPER PLUG, CONNECT THERMOSTAT TO TH-W.

4

LEAVE 24V OPEN. DO NOT REMOVE VENT DAMPER PLUG.

5

LEAVE TP-Z AND Z-W JUMPERS IN PLACE.

MAIN

VALVE

CABLE

L1

(HOT)

L2

1

2

1K

N.C.

N.O.

YELLOW

G

L1

1K3

L2

THERMOSTAT

D80 MOTOR

C.

1K3

BLUE

5

D80D

1K2

BLACK

TP

1K

ZB3W T

1K1

ORANGE

TV

1234

BR

1K2

AUTO

MANUAL

SWITCH

B2 C2

4

Q345, Q346,

Q348, Q362,

Q381PILOT

BURNER/

IGNITERSENSOR

B1

L8148J

C1

1K1

PILOT

BURNER

GROUND

PILOT GAS

SUPPLY

FAN

MOTOR

3

M1181C

Fig. 9—S8600F,H,M; S8610F, H; S8660D; S8670D connections in a hydronic heating sytem with a D80D vent damper.

10

Page 11

MVMV/PVPV

GND

(BURNER)

24V

GND

S8610

U

24

V

TH-W

(OPT)

4

VENT

DAMPER

PLUG

SENSE

SPARK

MAIN

PILOT

1ST

OPERATOR

DUAL VALVE COMBINATION

GAS CONTROL

1

2

3

4

5

6

COM

2ND

OPERATOR

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION AS

REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

CONTROLS IN 24V CIRCUIT MUST NOT BE IN

GROUND LEG TO TRANSFORMER.

DO NOT REMOVE VENT DAMPER PLUG.

REMOVE JUMPER AND CONNECT SENSE

TERMINAL ON TWO ROD APPLICATION ONLY.

VALVE

5

(HOT)

L1

L8100

2

ECO

CONTROLLER

4

1

L2

6

GROUND

PILOT GAS

SUPPLY

3

M1179A

Fig. 10—S8600F,H,M; S8610F,H; S8660D; S8670D connections in a commercial water heater control system.

CHECKOUT

Check out the gas control system:

• At initial installation of the appliance.

• As part of regular maintenance procedures. Mainte-

nance intervals are determined by the application.

See PLANNING THE INSTALLATION, page 1, for

more information.

• As the first step in troubleshooting.

• Any time work is done on the system.

WARNING

FAILURE TO HEED THESE WARNINGS MAY

CAUSE FIRE OR EXPLOSION WITH PROPERTY

DAMAGE, INJURY, OR LOSS OF LIFE.

1. If you smell gas or suspect a gas leak, turn off

gas at manual service valve and evacuate the

building. Do not try to light any appliance, do

not touch any electrical switch or telephone in

the building until you are sure no spilled gas

remains.

2. Gas leak test must be done as described in

Steps 1 and 5 below on initial installation and

any time work is done involving the gas piping.

STEP 1: Perform Visual Inspection.

❏ With power off, make sure all wiring connections are

clean and tight.

❏ Turn on power to appliance and ignition module.

❏ Open manual shutoff valves in the gas line to the

appliance.

❏ Do gas leak test ahead of gas control if piping has been

disturbed.

GAS LEAK TEST: Paint pipe joints with rich soap and water

solution. Bubbles indicate gas leak. Tighten joints to stop

leak. Recheck with soap and water.

STEP 2: Review Normal Operating Sequence and Module

Specifications.

❏ See OPERATION, page 12, and APPLICATION,

page 1.

STEP 3: Reset the Module.

❏ Turn the thermostat to its lowest setting.

❏ Wait one minute.

As you do Steps 4 and 5, watch for points where operation

deviates from normal. Refer to Troubleshooting Chart to

correct problem.

STEP 4: Check Safety Shutoff Operation.

This step applies to lockout and continuous retry modules

only.

❏ Turn gas supply off.

❏ Set thermostat or controller above room temperature to

call for heat.

❏ Watch for spark at pilot burner either immediately or

following prepurge. See device label.

❏ Time spark from start to shutoff. See device label.

On S8600M, wait 6 min. nom. Ignition sequence should

start again followed by shutoff after 90 sec. max.

❏ Open manual gas cock and make sure no gas is flowing

to pilot or main burner.

❏ Set thermostat below room temperature and wait one

minute before continuing.

STEP 5: Check Normal Operation.

❏ Set thermostat or controller above room temperature to

11 69-0463

Page 12

call for heat.

❏ Make sure pilot lights smoothly when gas reaches the

pilot burner.

❏ Make sure main burner lights smoothly without flash-

back.

❏ Make sure burner operates smoothly without floating,

lifting, or flame rollout to the furnace vestibule or heat

buildup in the vestibule.

OPERATION

Module operation can be conveniently divided into two

phases for S8600, S8610 and three for S8660, S8670. The

phases are

• Prepurge (S8660, S8670 only)

• Trial for ignition (all models)

• Main burner operation (all models)

Figs. 11 and 12 summarize the normal operating sequences of the modules.

1

START

1

THERMOSTAT (CONTROLLER)

CALLS FOR HEAT

❏ If gas line has been disturbed, complete gas leak test.

GAS LEAK TEST: Paint gas control gasket edges and all

pipe connections downstream of gas control, including pilot

tubing connections, with rich soap and water solution.

Bubbles indicate gas leaks. Tighten joints and screws or

replace component to stop gas leak. Recheck with soap

and water.

❏ Turn thermostat or controller below room temperature.

Make sure main burner and pilot flames go out.

PREPURGE (S8660,S8670 ONLY)

When the S8660 is used in a fan-assisted combustion

system, the combustion air blower starts on a call for heat.

On proof of airflow, the air proving switch closes and

energizes the S8660, S8670. When the module is used in

an atmospheric system, the call for heat energizes the

module.

In either case, the module first initiates a 45 sec. delay

to allow system prepurge. After prepurge, the module starts

the pilot ignition sequence.

STAGE 1

TRIAL FOR

IGNIITION

STAGE 2

MAIN BURNER

OPERATION

END

2

SPARK GENERATOR POWERED

First valve (pilot) operator opens

3

Pilot burner lights.

Module senses

flame current.

4

FLAME CURRENT SENSED

Spark generator off.

Second valve operator (main)

opens.

5

MAIN BURNER OPERATION

Module monitors pilot flame

current.

6

THERMOSTAT (CONTROLLER)

SATISFIED

Valves close, pilot and main

burners are off.

PILOT BURNER OPERATION

OR

Pilot burner does not light.

Module Response

S8600A,F

S8610A,F

S8600B,H

S8610B,H

S8600M

a

Shutoff/lockout timing is stamped on module

POWER INTERRUPTION

System shuts off, restarts when power is

restored.

PILOT FLAME FAILURE

Main valve closes.

Module starts trial for ignition.

Ignition spark continues, pilot

valve remains open until system

is reset

After 15 or 90 sec system

locks out; must be

manually reset.

After 90 sec. system shuts off;

after 5 minutes min. (6 minutes

nom.), module restarts trial for

ignition; ignition trial, shutoff, wait

sequence repeats until pilot lights

or call for heat ends.

a

a

M1172B

Fig. 11—S8600, S8610 normal operating sequence.

12

Page 13

TRIAL FOR IGNITION

Pilot Ignition

Following prepurge timing (S8660, S8670), or on the call

for heat (S8600, S8610), the module energizes the first

main valve operator. The first main valve opens, which

allows gas to flow to the pilot burner. At the same time, the

electronic spark generator in the module produces an over

10,000 volt spark pulse output. The voltage generates a

spark at the igniter (S8600A,B; S8610A,B) or igniter-sensor

(S8600F,H,M; S8610F,H; S8660; S8670) that lights the

pilot.

If the pilot does not light, or the pilot flame current is not

at least 1.0 µA and steady, the module will not energize the

second (main) valve and the main burner will not light.

S8600A,F; S8610A,F will continue to spark as long as the

thermostat calls for heat, or until the pilot lights.

Safety Lockout (S8600B,H; S8610B,H; S8660D; S8670D)

These modules provide 100 percent shutoff and safety

lockout. A timer in these models starts timing the moment

the trial for ignition starts. Ignition spark continues only until

the timed trial for ignition period ends. Then the module

goes into safety lockout. Lockout de-energizes the first

main valve operator and closes the first main (pilot) valve in

the gas control, stopping pilot gas flow. The control system

must be reset by setting the thermostat below room tem-

perature for one minute or by turning off power to the

module for one minute.

Safety Shutoff with Continuous Retry (S8600M)

The S8600M provides 100 percent gas shutoff, followed

by retry for ignition. Operation on ignition failure is the same

as lockout modules, except that a timer starts timing immediately following shutoff. Six minutes nom. (five minutes

min.) after shutoff, the module restarts the ignition sequence. The ignition trial, shutoff, wait sequence continues

until either the pilot lights or the thermostat is set below

room temperature to end the call for heat. The module can

also be reset by setting down the thermostat for one minute.

MAIN BURNER OPERATION

When the pilot flame is established, a flame rectification

circuit is completed between the sensor and burner ground.

The flame sensing circuit in the module detects the flame

current, shuts off the spark generator and energizes the

second main valve operator. The second main valve opens

and gas flows to the main burner, where it is ignited by the

pilot burner. On lockout models, the flame current also

holds the safety lockout timer in the reset (normal) operating condition.

When the call for heat ends, both valve operators are deenergized, and both valves in the gas control close.

START

STAGE 1

PREPURGE

STAGE 2

TRIAL FOR IGNITION

STAGE 3

MAIN BURNER

OPERATION

END

1

THERMOSTAT

CALLS FOR HEAT

2

PREPURGE

Combustion air blower starts.

3

SPARK GENERATOR POWERED

First valve (pilot) operator opens.

4

Pilot burner lights.

S8660, S8670 senses flame

current.

FLAME CURRENT SENSED

5

Spark generator off.

Second valve operator (main)

opens.

6

MAIN BURNER OPERATION

Module monitors pilot flame

current.

7

THERMOSTAT SATISFIED

Valves close, pilot and main

burners are off.

PILOT BURNER OPERATION

OR

POWER INTERRUPTION

System shuts off, restarts when power is

restored.

PILOT FLAME FAILURE

Main valve closes.

S8660, S8670 starts trial for ignition.

Pilot burner does not light.

After 15 or 90 sec , system

locks out; must be manually reset.

a

Lockout timing is

stamped on module.

a

M1171B

Fig. 12—S8660, S8670 normal operating sequence.

13 69-0463

Page 14

TROUBLESHOOTING

1. The following service procedures are provided as

a general guide. Follow appliance manufacturer’s

service instructions if available.

2. On lockout and retry models, meter readings

between gas control and ignition module must be

taken within the trial for ignition period. Once the

ignition module shuts off, lockout models must be

reset by setting the thermostat down for at least

one minute before continuing. On retry models,

wait for retry or reset at the thermostat.

3. If any component does not function properly,

make sure it is correctly installed and wired before

replacing it.

4. The ignition module cannot be repaired. If it malfunctions, it must be replaced.

5. Only trained, experienced service technicians

should service intermittent pilot systems.

Perform the checkout on page 11 as the first step in

troubleshooting. Then check the appropriate troubleshooting guide (Fig. 14 or 15) and the schematic diagram (Figs.

16-17) to pinpoint the cause of the problem. If troubleshooting indicates an ignition problem, see Ignition System

Checks below to isolate and correct the problem.

Following troubleshooting, perform the checkout procedure (page 11) again to be sure system is operating

normally.

IGNITION SYSTEM CHECKS

STEP 1: Check ignition cable.

Make sure:

❏ Ignition cable does not run in contact with any metal

surfaces.

❏ Ignition cable is no more than 36 in. [0.9 m] long.

❏ Connections to the ignition module and to the igniter or

igniter-sensor are clean and tight.

❏ Ignition cable provides good electrical continuity.

STEP 2: Check ignition system grounding.

downs are often caused by a poor or erratic ground.

❏ A common ground, usually supplied by the pilot burner

bracket, is required for the module and the pilot burner/

igniter-sensor.

• Check for good metal-to-metal contact between the

pilot burner bracket and the main burner.

• Check the ground lead from the GND(BURNER)

terminal on the module to the pilot burner. Make sure

connections are clean and tight. If the wire is damaged or deteriorated, replace it with No. 14-18 gauge,

moisture-resistant, thermoplastic insulated wire with

105° C [221° F] minimum rating.

— Check the ceramic flame rod insulator for cracks

or evidence of exposure to extreme heat, which

can permit leakage to ground. Replace pilot burner/

igniter-sensor and provide shield if necessary.

— If flame rod or bracket are bent out of position,

restore to correct position.

STEP 3: Check spark ignition circuit.

jumper wire made from ignition cable or other heavily

insulated wire

❏ Close the manual gas valve.

❏ Disconnect the ignition cable at the SPARK terminal on

the module.

IMPORTANT

Nuisance shut-

You will need a short

.

WARNING

When performing the following steps, do not touch

stripped end of jumper or SPARK terminal. The

ignition circuit generates over 10,000 volts and

electrical shock can result.

❏ Energize the module and immediately touch one end of

the jumper firmly to the GND terminal on the module. Move

the free end of the jumper slowly toward the SPARK

terminal until a spark is established.

❏ Pull the jumper slowly away from the terminal and note

the length of the gap when sparking stops. Check table

below.

ARC LENGTH ACTION

No arc or arc less Check external fuse, if provided.

than 1/8 in. [3 mm] Verify power at module input

Arc 1/8 in. [3 mm] Voltage output is okay.

or longer.

STEP 4: Check pilot and main burner lightoff.

❏ Set the thermostat to call for heat.

❏ Watch the pilot burner during the ignition sequence. See

if:

• Ignition spark continues after the pilot is lit.

• The pilot lights and the spark stops, but main burner

does not light.

•

S8600B,H,M; S8610B,H; S8660D; S8670D only:

pilot lights, the spark stops and main burner lights, but

the system shuts down.

❏ If so, ensure adequate flame current as follows.

• Turn off furnace at circuit breaker or fuse box.

• Clean the flame rod with emery cloth.

Fig. 13—Examples of unsatisfactory pilot flames.

terminal.

Replace module if fuse and

power ok.

The

14

Page 15

• Make sure electrical connections are clean and tight.

Replace damaged wire with moisture-resistant No.

18 wire rated for continuous duty up to 105° C [221°

F].

• Check for cracked ceramic insulator, which can cause

short to ground, and replace igniter-sensor if necessary.

• At the gas control, disconnect main valve wire from

the TH or MV terminal.

• Turn on power and set thermostat to call for heat. The

pilot should light but the main burner will remain off

because the main valve actuator is disconnected.

• Check the pilot flame. Make sure it is blue, steady and

envelops 3/8 to 1/2 in. [10 to 13 mm] of the flame rod.

See Fig. 13 for possible flame problems and their

causes.

• If necessary, adjust pilot flame by turning the pilot

Before troubleshooting, familiarize yourself with the startup and checkout procedure.

Models with TH-W terminal (7) must have call for heat 24 Vac supply connected to the TH-W terminal.

START

TURN GAS SUPPLY OFF.

TURN THERMOSTAT

(CONTROLLER) TO CALL

FOR HEAT

POWER TO MODULE?

(24V NOMINAL)

YES

SPARK ACROSS

IGNITER/SENSOR GAP?

(S8660, S8670, S8680

HAVE 45 SECOND [NOMINAL]

PREPURGE BEFORE SPARK

STARTS.)

YES

NO

NO

NOTE:

Models with no TH-W terminal must have call for heat 24 Vac supply connected to 24V terminal (6).

Check line voltage power, low voltage transformer, limit controller, thermostat (controller) and wiring. Also,

check air proving switch on combustion air blower system (if used) and that vent damper (if used) is open and

end switch is made.

Pull ignition lead and

check spark at module.

Spark okay?

YES

Check ignition cable, ground wiring, ceramic insulator and gap, and correct.

Check boot of the ignition cable for signs of melting or buckling. Take protective action to shield cable and

boot from excessive temperatures.

adjustment screw on the gas control

clockwise to decrease or

counterclockwise to increase pilot flame. Following adjustment, always replace pilot adjustment

cover screw and tighten firmly to assure proper gas

control operation.

• Set thermostat below room temperature to end call

for heat.

❏ Recheck ignition sequence as follows.

• Reconnect main valve wire.

• Set thermostat to call for heat.

• Watch ignition sequence at burner.

• If spark still doesn’t stop after pilot lights, replace

ignition module.

• If main burner doesn’t light or if main burner lights but

system locks out, check module, ground wire and gas

control as described in appropriate troubleshooting

chart, Fig. 14 or 15.

NO

On models with vent damper plug, make sure vent damper

has not been installed, then removed. Replace vent damper

if necessary.

On other models, replace module.

TURN GAS SUPPLY ON

AND RECYCLE CALL

FOR HEAT

PILOT BURNER LIGHTS?

YES

SPARK STOPS WHEN

PILOT IS LIT?

YES

MAIN BURNER LIGHTS?

YES

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS?

YES

CALL FOR HEAT ENDS

SYSTEM SHUTS OFF?

YES

TROUBLESHOOTING

ENDS

NO

NO

NO

NO

NO

Repeat procedure until troublefree operation is obtained.

Check that all manual gas valves are open, supply tubing and pressures are good, and pilot burner orifice

is not blocked.

Check electrical connections between module and pilot operator on gas control.

Check for 24 Vac across PV-MV/PV terminals on module. If voltage is okay, replace gas control; if not,

replace module.

NOTE: It may be necessary to recycle the call for heat to clear the pilot supply tubes of air.

NOTE: If S86XXB,H,D,J goes into lockout, reset system. For S86XXC,M,U,J,K, wait 6 min.

nom. for retry or reset system.

Check continuity of ignition cable and ground wire.

Clean flame rod.

Check electrical connections between flame rod and module.

Check for cracked ceramic flame rod insulator.

Check that pilot flame covers flame rod and is steady and blue.

Adjust pilot flame.

If problem persists, replace module.

Check for 24 Vac across MV-MV/PV terminals. If no voltage, replace module.

Check electrical connections between module and gas control. If okay, replace gas control or gas control

operator.

NOTE: If S86XXB,H,D,J goes into lockout, reset system. For S86XXC,M,U,J,K, wait 6 min.

nom. for retry or reset system.

Check continuity of ignition cable and ground wire.

NOTE: If ground is poor or erratic, shutdowns may occur occasionally even though operation is normal at

the time of checkout.

Check that pilot flame covers flame rod and is steady and blue.

If checks are okay, replace module.

Check for proper thermostat (controller) operation.

Remove MV lead at module; if valve closes, recheck temperature controller and wiring; if not, replace gas

control.

Fig. 14—S8600, S8610 troubleshooting guide.

15 69-0463

M1174F

Page 16

START

TURN GAS SUPPLY OFF.

TURN THERMOSTAT TO

CALL FOR HEAT

POWER TO MODULE

(24V NOMINAL)

YES

45 SECOND

DELAY

YES

SPARK ACROSS

IGNITER/SENSOR GAP

YES

NOTE: Before troubleshooting, familiarize yourself with the startup and checkout procedure.

Check line voltage power, low voltage transformer, limit controller, thermostat and wiring. Also, check air

NO

NO

NO

proving switch on combustion air blower system and that vent damper (if used) is open and end switch is

made.

Replace S8670.

Pull ignition lead and check

spark at S8670.

Spark okay?

YES

Check ignition cable, ground wiring, ceramic insulator and gap, and correct.

Check boot of the ignition cable for signs of melting or buckling. Take protective action to shield cable and

boot from excessive temperatures.

Replace module.

NO

TURN GAS SUPPLY ON

PILOT BURNER LIGHTS?

YES

SPARK STOPS WHEN

PILOT IS LIT?

YES

MAIN BURNER LIGHTS?

YES

SYSTEM RUNS UNTIL

CALL FOR HEAT ENDS?

YES

CALL FOR HEAT ENDS

SYSTEM SHUTS OFF?

YES

TROUBLESHOOTING

ENDS

NO

NO

NO

NO

NO

Repeat procedure until troublefree operation is obtained.

Check that all manual gas cocks are open, supply tubing and pressures are good, and pilot burner orifice is

not blocked.

Check electrical connections between module and pilot operator on gas control.

Check for 24 Vac across PV-MV/PV terminals on module; If voltage is okay, replace gas control; if no

voltage, replace module.

NOTE: If module goes into lockout, reset system.

Check continuity of ignition cable and ground wire.

Clean flame rod.

Check electrical connections between flame rod and module.

Check for cracked ceramic flame rod insulator.

Check that pilot flame covers flame rod and is steady and blue.

Adjust pilot flame.

If checks are okay, replace module.

Check for 24 Vac (nominal) across MV-MV/PV terminals. if no voltage, replace module.

Check electrical connections between module and gas control. If okay, replace gas control.

NOTE: If module goes into lockout, reset system.

Check continuity of ignition cable and ground wire.

NOTE: If ground is poor or erratic, shutdowns may occur occasionally even though operation is normal at the

time of checkout.

If checks are okay, replace module.

Check for proper thermostat (controller) operation.

Remove MV lead at module; if valve closes, recheck temperature controller and wiring; if not, replace gas

control.

M1173C

Fig. 15—S8660, S8670 troubleshooting guide.

16

Page 17

THERMOSTAT OR

CONTROLLER

L1

L2

LIMIT

CONTROLLER

2

24V

TRANSFORMER

ON-OFF

SWITCH

(HOT)

1

24V

ARC

2K1

SPARK

DRIVE

CIRCUIT

FLAME

DETECTOR

CIRCUIT

HYBRID CIRCUIT

TIMING

CIRCUITS

MAIN

VALVE

MV

PILOT

VALVE

PV

TO 24V (GND)TO 24V

MV/

1K1

2K2

1K2

3K1

1K

2K

3K

RELAY

DRIVERS

3

3K2

1K2

LOW

VOLTAGE

POWER

SUPPLY

1K1

2K2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

2

3K RELAY ON 100 PERCENT SHUTOFF MODELS ONLY. ON NON-SHUTOFF MODELS, PV AND MV

3

WIRED AS FOLLOWS.

GAP

SPARK

PV

IGNITER

SENSOR

MV

PV

INTERNAL WIRING

EXTERNAL WIRING

BURNER

GROUND

MAIN

VALVE

PILOT

VALVE

GND

(BUR-

NER)

24V

(GND)

MV/

M1165C

PV

Fig. 16—Representative schematic for S8600F,H, M; S8610F,H. See Fig. 1 for hookup. S8660 and S8670 are similar

except the timing circuit includes a purge timer. See Fig. 6 for hookup.

17 69-0463

Page 18

THERMOSTAT OR

CONTROLLER

L1

L2

LIMIT

CONTROLLER

2

24V

TRANSFORMER

ON-OFF

SWITCH

(HOT)

1

24V

ARC

MV/

PV

GAP

SENSE

SPARK

2K1

SPARK

DRIVE

CIRCUIT

FLAME

DETECTOR

CIRCUIT

HYBRID CIRCUIT

TIMING

CIRCUITS

MAIN

VALVE

MV

PILOT

VALVE

PV

TO 24V (GND)TO 24V

1K1

2K2

1K2

3K1

1K

RELAY

2K

DRIVERS

3K

3

3K2

1K2

LOW

VOLTAGE

POWER

SUPPLY

1K1

2K2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

2

3K RELAY ON 100 PERCENT SHUTOFF MODELS ONLY. ON NON-SHUTOFF MODELS, PV AND

3

MV WIRED AS FOLLOWS.

SENSOR

IGNITER

MV

PV

INTERNAL WIRING

EXTERNAL WIRING

GND

(BURNER)

BURNER

GROUND

MAIN

VALVE

PILOT

VALVE

M1166C

24V

(GND)

MV/

PV

Fig. 17—Representative schematic for S8600A,B; S8610A,B. See Fig. 3 for hookup.

18

Page 19

ANSI STANDARDS

RECOMMENDED PROCEDURE FOR SAFETY INSPECTION OF AN EXISTING

APPLIANCE INSTALLATION AS A PRELIMINARY STEP TO APPLYING

The following procedure is intended as a guide to aid

in determining that an appliance is properly installed and

is in a safe condition for continuing use.

This procedure is predicated on central furnace and

boiler installations equipped with an atmospheric gas

burner(s) and not of the direct vent type. It should be

recognized that generalized test procedures cannot

anticipate all situations. Accordingly, in some cases,

deviation from this procedure may be necessary to

determine safe operation of the equipment.

a. This procedure should be performed prior to any

attempt at modification of the appliance or the instal-

lation.

b. If it is determined there is a condition which could

result in unsafe operation, the appliance should be

shut off and the owner advised of the unsafe condi-

tion.

The following steps should be followed in making the

safety inspection:

1. Conduct a Gas Leakage Test of the appliance

piping and control system downstream of the shutoff

valve in the supply line to the appliance.

2. Visually inspect the venting system for proper size

and horizontal pitch and determine there is no blockage

or restrictions, leakage or corrosion or other deficiencies

which could cause an unsafe condition.

3. Shut off all gas to the appliance and shut off any

other fuel-burning appliance within the same room. Use

the shutoff valve in the shutoff valve in the supply line to

each appliance.

4. Inspect burners and crossovers for blockage and

corrosion.

5. Applicable only to warm air heating appliances.

Inspect heat exchangers for cracks, openings or excessive corrosion.

6. Applicable only to boilers. Inspect for evidence of

water or combustion product leaks.

7. Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliance is located and other spaces of the building.

Turn on clothes dryers. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they will

AN AUTOMATIC INTERMITTENT PILOT SYSTEM

EXHIBIT A

operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers. If, after completing steps 7 through 12, it is believed sufficient combustion air is not available, refer to 1.3.4 of the National Fuel

Gas Code (Z223.1) for guidance.

8. Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

9. a. Determine that the pilot is burning properly and

that main burner ignition is satisfactory by interrupting and re-establishing the electrical supply to

the appliance in any convenient manner.

b. Determine manifold pressure in order to match

input after the new control is installed.

a.Visually determine that main burner gas is burning properly; i.e., no floating, lifting or flashback.

Adjust the primary air shutter(s) as required.

b.If appliance is equipped with high and low flame

control or flame modulation, check for proper main

burner operation at low flame.

11. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use a draft

gauge, the flame of a match or candle, or smoke from a

cigarette, cigar or pipe.

12. Return doors, windows, exhaust fans, fireplace

dampers and all other fuel-burning appliances to their

previous conditions of use.

13. Applicable only to warm air heating appliances.

Check both limit controller and fan controller for proper

operation. Limit controller operation can be checked by

temporarily disconnecting the electrical supply to the

blower motor and determining that the limit control acts

to shut off the main burner gas.

14. Applicable only to boilers:

a. Determine that the circulating water pumps are

in operating condition.

b. Test low water cutoffs, automatic feed controls, pressure and temperature limit controls and

relief valves in accordance with the

manufacturer’s recommendations and instructions to determine they are in operating condition.

EXHIBIT A OF ANSI STANDARD Z21.71 FOR AUTOMATIC INTERMITTENT PILOT IGNITION SYSTEMS FOR FIELD

INSTALLATION

19 69-0463

Page 20

EXHIBIT B

PROCEDURE FOR INSTALLING AUTOMATIC INTERMITTENT PILOT SYSTEMS

Prior to beginning this procedure, a preliminary examination of the appliance and the automatic intermittent pilot system should be made to determine that the

automatic intermittent pilot system can be properly

applied to the appliance.

This procedure is intended as a guide to aid in safely

installing a listed automatic intermittent pilot system on

an existing listed appliance equipped with an atmospheric gas burner(s) and not of the direct vent type.

This procedure is based on the assumption that the

history of the specific installation has been one of safe

and satisfactory operation.

This procedure is predicated on central furnace and

boiler installations, and it should be recognized that

generalized procedures cannot anticipate all situations.

Accordingly, in some cases, deviation from this procedure may be necessary to determine safe operation of

the equipment.

The following steps should be followed in making the

modifications:

1. Perform a safety inspection of the existing appliance installation. See Exhibit A for a recommended

procedure for such a safety inspection.

2. Shut off all gas and electricity to the appliance. To

shut off gas, use the shutoff valve in the supply line to the

appliance. Do not use the shutoff valve which is provided as part of a combination control.

3. Install the automatic intermittent pilot system in

strict accordance with the manufacturer’s installation

instructions.

4. Turn on all gas and electricity to the appliance.

5. Determine that the appliance transformer has

adequate capacity by following the steps outlined below:

a. Compute the approximate current draw by adding

the current draw of the automatic intermittent pilot

system to (1) the current draw of the associated

valving, and (2) the current draw of any relays or

other devices operated by the transformer.

b. Multiply the total current draw as computed above

by 24 V to determine the total VA (volt-ampere)

required.

c. The total VA (volt-ampere) required should be

equal to or less than the VA rating of the transformer.

d. If the total VA (volt-ampere) required is greater

than the VA rating of the transformer, the transformer

must be replaced with a Class 2 transformer of

adequate rating.

6. Check the heat anticipator in the comfort thermostat to determine if it is properly adjusted to the current

draw of the control system. Follow the thermostat

manufacturer’s instructions.

EXHIBIT B OF ANSI STANDARD Z21.71 FOR AUTOMATIC INTERMITTENT PILOT IGNITION SYSTEMS FOR FIELD

INSTALLATION.

7. Make certain wiring connections are tight and

wires are positioned and secured so they will not be able

to contact high temperature locations.

8. Conduct a Gas Leakage Test of the appliance

piping and control system downstream of the shutoff

valve in the supply line to the appliance.

9. a. Adjust the thermostat to its highest tempera-

ture setting, and test manifold pressure and adjust

the pressure regulator to match original input as

required (refer to Exhibit A, step 9b).

b. Visually determine that main burner is burning

properly; i.e., no floating, lifting or flashback. Adjust the primary air shutter(s) as required.

10. If the appliance is equipped with high and low

flame control or flame modulation, check for proper main

burner operation at both high and low flame.

11. Determine that the pilot is igniting and burning

properly and that main burner ignition is satisfactory by

interrupting and re-establishing the electrical supply to

the appliance in any convenient manner. Make this

determination with the appliance burner both cold and

hot. Perform this step as many times as is necessary to

satisfy yourself that the automatic intermittent pilot system is operating properly.

12. Test the pilot safety device (1) to determine if it is

operating properly, and (2) for turndown characteristics

according to the manufacturer’s installation instructions.

No adjustments should be made other than those recommended by the system manufacturer.

13. Sequence the appliance through at least three

operating cycles.

14. Applicable only to furnaces. Check both the limit

controller and the fan controller for proper operation.

Limit control operation can be checked by blocking the

circulating air inlet or temporarily disconnecting the

electrical supply to the blower motor and determining

that the limit controller acts to shut off the main burner

gas.

15. Applicable only to boilers.

a. Determine that the circulating water pumps are

in operating condition.

b. Test low water cutoffs, automatic feed water

controls, pressure and temperature limit controllers and relief valves in accordance with the

manufacturer’s recommendation to determine

they are in operating condition.

16. Add the labels (see 1.6.1-n and -o) on the appliance.

Home and Building Control Home and Building Control

Honeywell International, Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

Loading...

Loading...