Page 1

S7999B, S7999C SOLA

Local Operator Interface

• From behind into a panel cutout (5.45 in. W X 4.3 in. H)

using 4 #6-32 screws, nuts and 4 standoffs (provided).

Wiring connections to the S7999C are made via a 4-pin

connector on the back of the display.

NOTE: If display S7999B is used to monitor a lead/lag sys-

tem, display S7999C can NOT be used.

FEATURES

• Individual boiler status, configuration, history, and

diagnostics.

• Allows configuration and monitoring of the Sola

Controls (R7910A Hydronic Controls or R7911 Steam

Control) burner control sequence, flame signal,

diagnostics, historical files, and faults.

APPLICATION

The S7999B and S7999C are microprocessor-based touchscreen Operator Interface (OI) displays that provide an

operator interface for monitoring and configuring parameters

in the Sola Hydronic Control and Sola Steam Control system.

The S7999B can be used to monitor an individual boiler but is

primarily used for multiple boiler applications in a lead/lag

arrangement. COM 2 port is available for Building Automation

applications. The S7999B display is flush mounted into a

panel cutout (8-1/8 in. W x 5-7/8 in. H). Wiring connections to

the S7999B are through a removable 9-pin wiring header.

The S7999C display is used for individual boiler monitoring.

The S7999C is mounted:

• onto a panel using the wallplate provided.

• from the front into a panel cutout (7.6 in. W X 5.4 in. H)

using 4 #6-32 screws and nuts (provided).

• S7999B OI Display only:

— Allows switching view between multiple boilers

— Allows viewing Lead-Lag Master

— Ethernet port for downloading software upgrades

(when required)

— Real-time data trending analysis and transferring

saved trend data to Excel spreadsheet.

— Audible Alarm

— COM 2 Modbus port for Building Automation System

applications.

— LED indicators:

• Power

•Network

•COM 2

•COM 1

— Models available:

• S7999B1026 has Blue Border

• S7999B1067 has Black Border

• S7999C OI Display only:

PRODUCT DATA

Contents

Preface ............................................................................. 2

Specifications ................................................................... 3

Installation Instructions (S7999B OI Display) ................... 4

Wiring (S7999B OI Display) ............................................. 4

Starting the S7999B OI Display ........................................ 7

Configuration .................................................................... 20

Details .............................................................................. 38

R7910A or R7911 Diagnostics ......................................... 44

S7999B or S7999C Display Setup and Diagnostics ......... 47

Advanced Setup ............................................................... 48

Table 61 Configurable Parameters. .................................. 53

Table 62 Other Tables. ..................................................... 61

65-0303-05

Page 2

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

— MMC Port for installing software upgrades (when

required)

— LED indicators:

• Power

•COM

— Models available:

• S7999C1008 has white border

• S7999C1016 has blue border

• S7999C1040 has black border

• Allows for lead/lag commissioning.

• Locates attached boiler(s).

• Allows boiler naming.

• Color 3.5 in. x 4.625 in. (5.7 in. diagonal) user interface

display.

• Graphic user interface.

• Touch screen.

• Communication between the OI Displays and the

SOLA Controls uses Modbus™.

• LED indicators (S7999C):

•Power

•COM

• Flush mounting.

• Touch screen disable for screen cleaning.

• 12 Vdc power supply (included).

• Screen saver.

• Contrast control.

• Volume control.

PREFACE

This User Guide is intended to provide a general overview of

the S7999B or S7999C Operator Interface (OI) Displays. The

general overview goes to page 20 and the actual configuration

begins on page 20.

It is intended to guide you through the features and operation

of the OI Display as you interface with the R7910A or R7911

Sola control and establish the Parameter points of the system.

Note that this sheet shows all parameters. The actual product

may have parameters made invisible or Read Only by

Honeywell as they may not apply to the product.

Use the Product Data Sheet for the Sola Controls (form 65-

0303) as a guide and explanation of the parameters that are

being programmed.

SOFTWARE UPGRADE

S7999B Only

You can download new software for the OI Display through

the Internet. Downloading software should only be done when

recommended by Honeywell. This feature is intended to

permit field upgrades for bug fixes and to install new features.

Requirements for downloading new software:

• Ethernet connection for Internet access (RJ45 male

connector). Carefully insert the RJ45 connector into the

Ethernet jack in the lower right corner on the back of the

display to ensure no damage to the jack.

• Dynamic IP addressing (from DHCP server).

IMPORTANT

If these requirements can’t be met at the location of

the OI Display, this procedure should not be done or

the OI Display should be moved to a location where

these requirements can be met. Failure to satisfy

these requirements can result in the OI Display

becoming inoperable when the upgrade steps are

followed.

The above requirements can be checked prior to execution of

the software upgrade procedure on the Ethernet Setup page

(see Advanced Setup section). On the Ethernet Setup page a

connectivity check can be performed to validate whether

access to the Honeywell server is possible.

The OI Display must be reset to initiate the download

procedure. Initial boot procedure of the device permits the

user to enter into Advanced Startup options within the first five

seconds after power up.

Follow these steps:

1. Select the Advanced Startup Options button. A Warning

message is displayed. If you don’t want to proceed with

the software upgrade, you can cancel the procedure at

this time.

2. Select OK to proceed.

3. Select the “Force Application Update” checkbox.

4. Deselect the “Use Existing Application” checkbox.

5. Select the Continue button.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

65-0303—05 2

Page 3

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

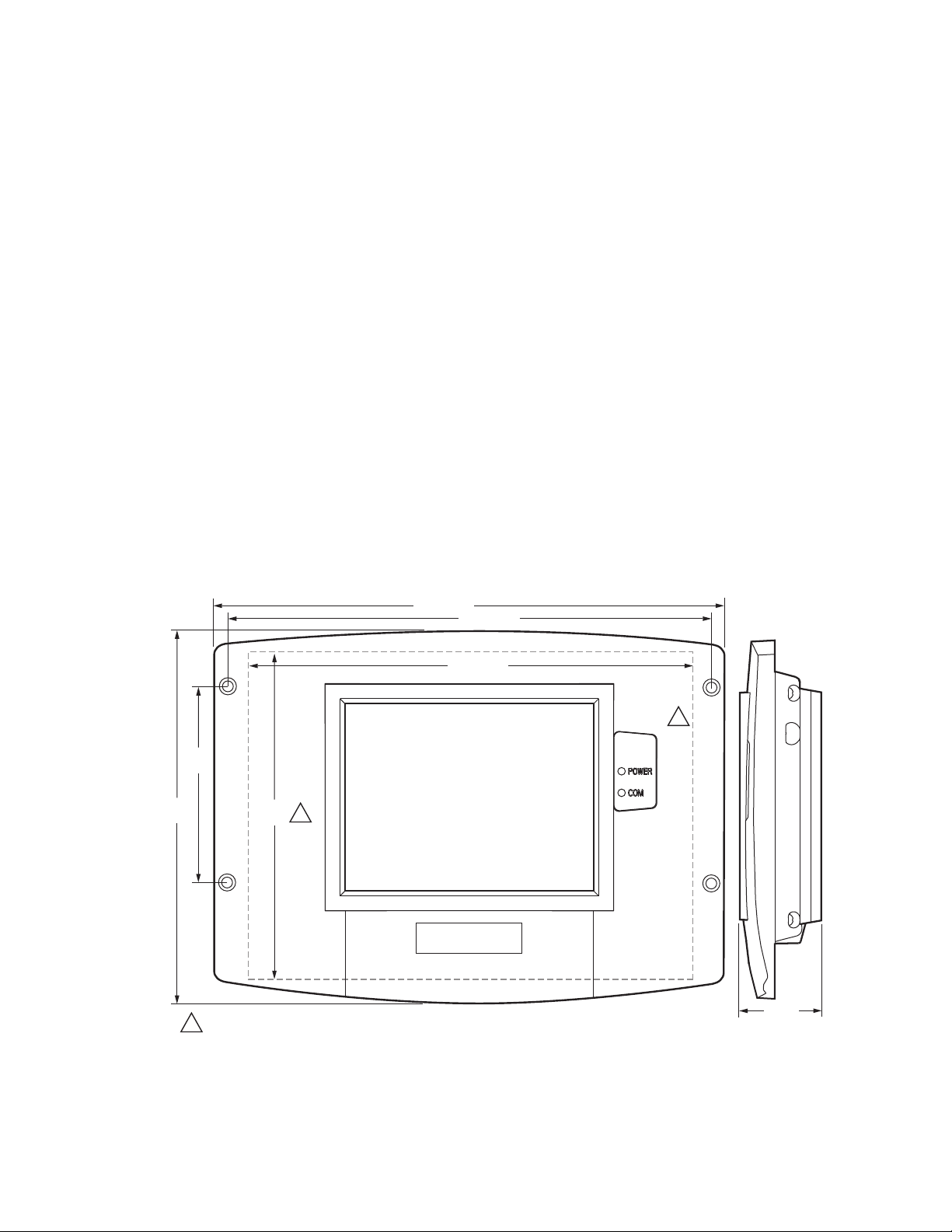

6-21/32

(169)

9-7/16 (240)

7-19/32 (193)

1-33/64

(39)

M29867A

PANEL HOLE CUTOUT SIZE 7-19/32 (193) WIDE X 5-13/32 (137) HIGH FOR S7999B DISPLAY 7.6 WIDE X 5.4 HIGH..1

1

5-13/32

(137)

1

8-15/16 (227)

3-1/2

(89)

The software upgrade is automatic after the above steps. The

OI Display connects to the Honeywell server, which verifies the

configuration file, erases the old application and downloads the

new one.

The OI Display may have difficulty finding the new

configuration file at first. In this case, the procedure

automatically starts over again until it works.

S7999C Only

Software upgrades for S7999C OI Display (when needed) will

be provided by Honeywell and are accomplished through the

MMC port located on the top back of the device.

SPECIFICATIONS

Electrical Ratings:

+12 Vdc input, maximum of 500 mA current drain.

Included Power Supply for S7999B:

Inputs: 85 to 264 Vac, 47 to 63 Hz; 120 to 370 Vdc.

Output: 12 Vdc; 0 to 2.1 A.

Power: 25 W.

Included Power Supply for S7999C:

Inputs: 100 to 240 Vac.

Output: 12 Vdc; 0.42 A.

Power: 25 W.

Operating Temperature: 32°F to 122°F (0°C to 50°C)

Storage/Shipping Temperature: -40°F to 158°F

(-40°C to 70°C).

Humidity:

85% maximum relative humidity.

Approvals:

FCC Part 15, Class A Digital Device

Underwriter’s Laboratories, Inc. (UL) (cUL) Component

Recognized (for non-continuous operation): File Number

MH20613 (MCCZ)

Canada: ICES-003

Dimensions: See Fig. 1.

Replacement Parts (S7999B)

• 9-pin connector—50020034-001

• Power Supply—Manufactured by MeanWell,

Model S-25-12 (order from manufacturer).

• #6-32 X1-in. screws(4) with nuts (4)

Supplied Parts (S7999C)

• Mounting Plate - see Fig. 9 for dimensions and hole

locations.

• #6-32 X 1-in. screws (4) with nuts (4)

• Standoffs 5/16-in. dia. X 3/8 in. long (4)

• Power Supply—Manufactured by V-infinity

Model FSC-S5-12U (order from manufacturer).

Fig. 1. OI Display dimensions (S7999C shown) in in. (mm).

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

3 65-0303—05

Page 4

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

WARNING

required to correct the interference at his own expense.

This Class A digital apparatus complies with Canadian ICES-003.

Cet Appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

SAFETY FEATURES

The OI Displays contain software that incorporates many

features that are designed to guide you safely through the

commissioning process. Safety, however, is your responsibility.

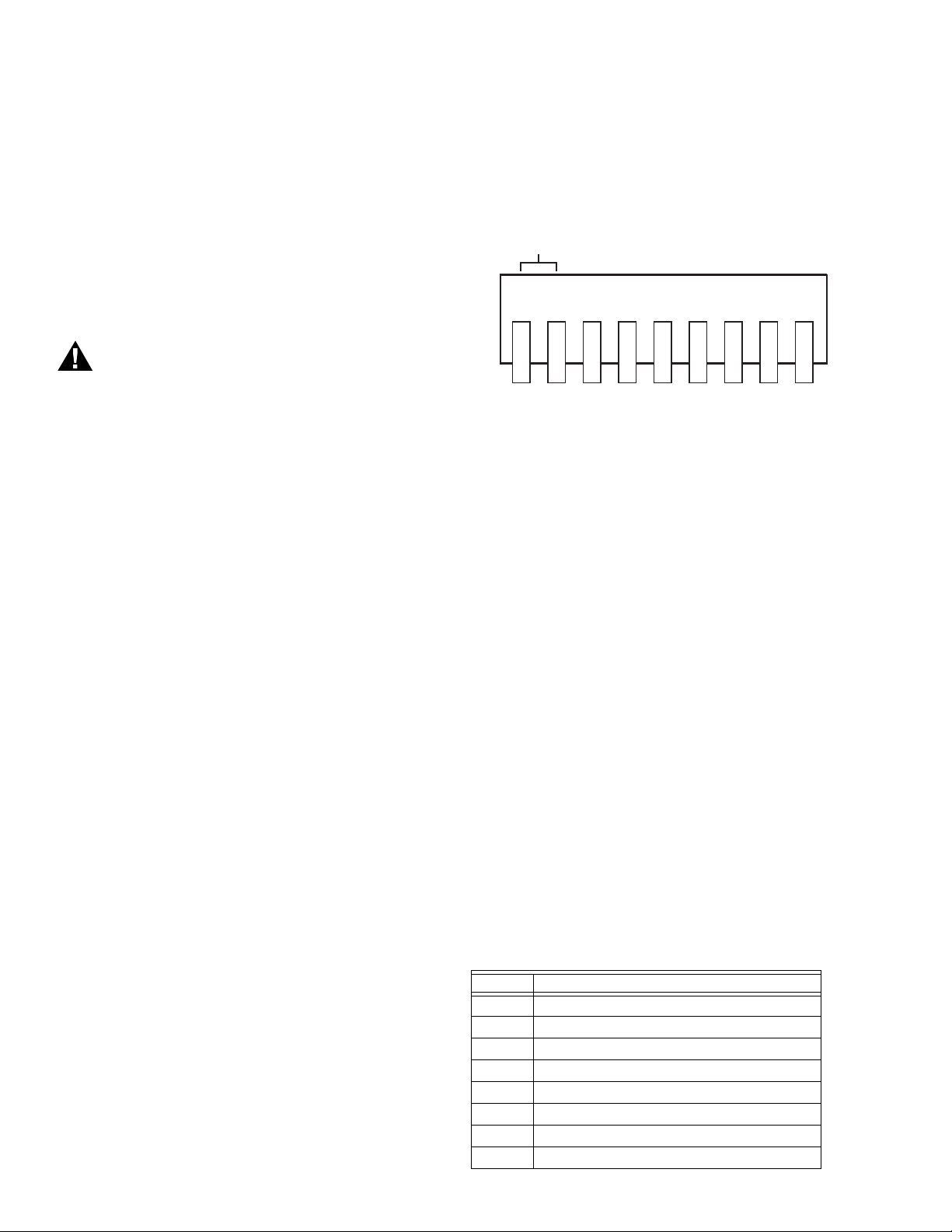

+12V

COMMON (c)

COM1 (b)

COM1 (a)

N/C

N/C

COM2 (a)

COM2 (b)

Read all documentation carefully and respond appropriately to

all error messages.

Explosion Hazard.

Improper configuration can cause fuel buildup and

explosion.

Improper user operation may result in PROPERTY

LOSS, PHYSICAL INJURY or DEATH.

Using the OI Displays to change parameters, must be

attempted by only experienced and/or licensed

burner/boiler operators and mechanics.

INSTALLATION INSTRUCTIONS (S7999B OI DISPLAY)

NOTE: For S7999C OI Display installation instructions, see

page 9.

Mounting the S7999B OI Display and Power Supply

The OI Display can be mounted on the door panel of an

electrical enclosure.

1. Select the location on the door panel to mount the display; note that the device will extend into the enclosure

at least one inch past the mounting surface.

2. Provide an opening in the panel door 8-1/8 in. wide by 57/8 in. high.

3. Place the OI Display in the opening and use it as a template to mark the location of the four mounting screw

holes. Remove the device.

4. Using pilot holes as guides, drill 1/4 in. holes through the

door panel.

5. Place the display in the opening, aligning the mounting

holes in the device with the drilled holes in the panel.

6. Secure the display to the panel with four #6-32 screws

and nuts provided.

1 2 3 4 5 6 7 8 9

M28859A

Fig. 2. S7999B OI Display connector terminals.

7. Select a location inside the enclosure for mounting the

power supply.

8. Using the power supply as a template, mark the locations of the two mounting holes in the enclosure.

9. Remove the power supply.

10. Drill 1/4 in. holes through the panel at the marked loca-

tions and secure the power supply with the two #6-32

screws and nuts provided.

11. Remove the 9-pin connector plug from the back of the OI

Display.

12. Wire the connector to the power supply and the RS-485

cables using the wiring diagram in Fig. 3.

13. Ensure the 9-pin connector plug is aligned with the

header pins when inserting the 9-pin connector plug

back onto the Display. Secure firmly.

WIRING (S7999B OI DISPLAY)

The S7999B OI Display must be appropriately wired for both

power and communications. An external 12V power supply

(provided) with an appropriate power rating is connected to

pins 1, 2 and 3 to power the device.

Communication is done over a RS-485 bus:

• COM1 connected directly to the SOLA Device J3 connector

to either Modbus (MB1 or MB2).

• COM2: A bus to the Building Automation System.

See Fig. 2 for S7999B Display connector terminals. Wiring

connections are listed in Table 1. See Fig. 3 for wiring.

Table 1. 9-pin Connector Terminals

Pin # Function

1 12V input

2 12V input

3 Common (Power, COM 1)

4 COM 1 (b) to MB1 or MB2 terminal

5 COM 1 (a) to MB1 or MB2 terminal

6 Not used

7 Not used

8COM 2 (a)

65-0303—05 4

Page 5

Table 1. 9-pin Connector Terminals

Pin # Function

9 COM 2 (b)

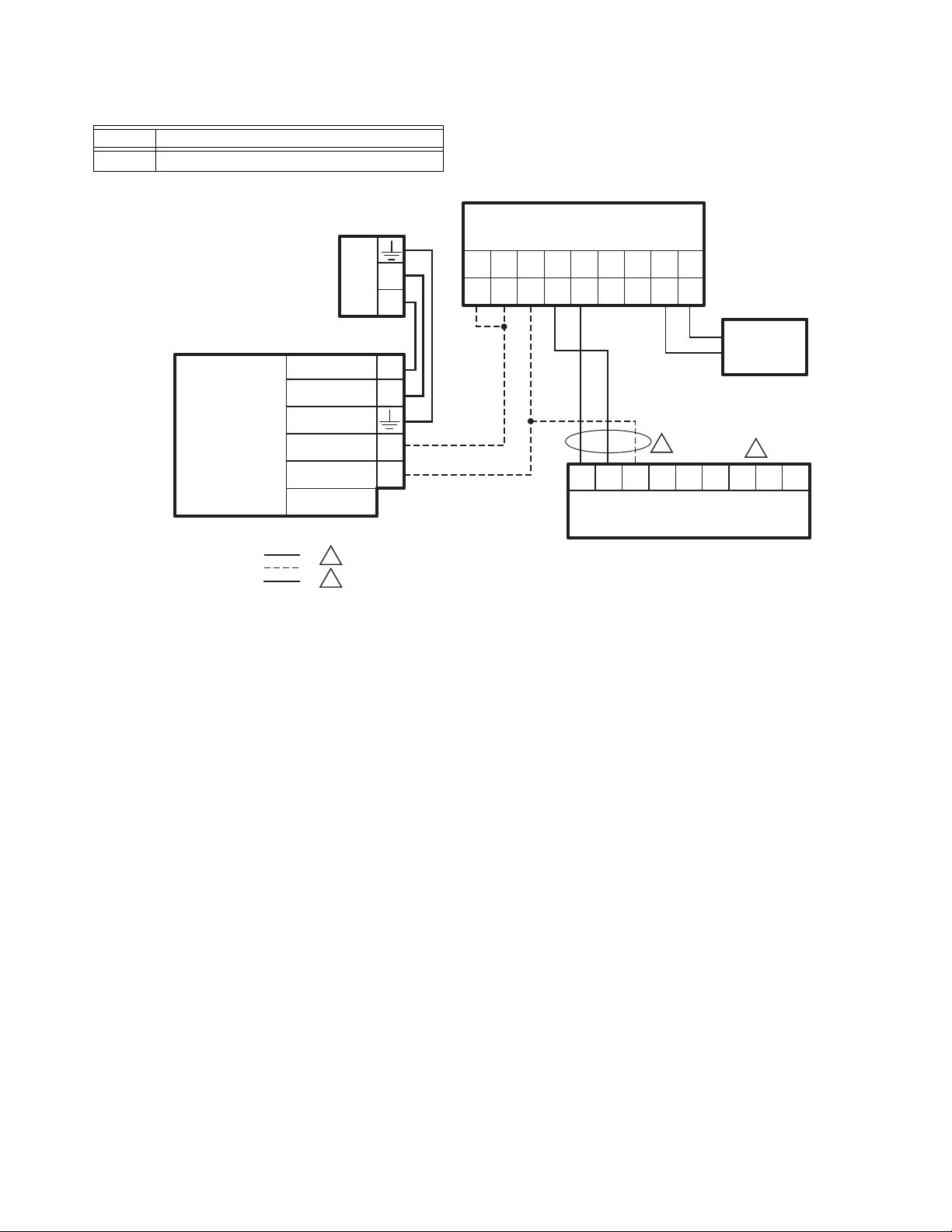

MEAN WELL S-25-12

POWER SUPPLY

(COMMON GND)

WIRING KEY

LINE VOLTAGE

LOW VOLTAGE

DATA

120

VAC

NEUTRAL (L2)

120VAC (L1)

EARTH

GROUND

12 DC OUT +

DC OUT

V ADJ

1

DO NOT CONNECT THE S7999B TO TERMINALS 1 2 3. THIS WILL RENDER THE DISPLAY INOPERABLE.

DISPLAY CAN ALSO BE CONNECTED TO MB2; A, B, C.

2

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

S7999B

AS LOCAL DISPLAY

COM1

L1

L2

N

L

V+

V-

+12

214567893

+12

GND

(C)

(B) (A)

N/C

MB1 ECOMMB2

COM2

(A)

N/C

2

SOLA CONTROL

(B)

BAS

1

23CBACBA1

J3

M32004

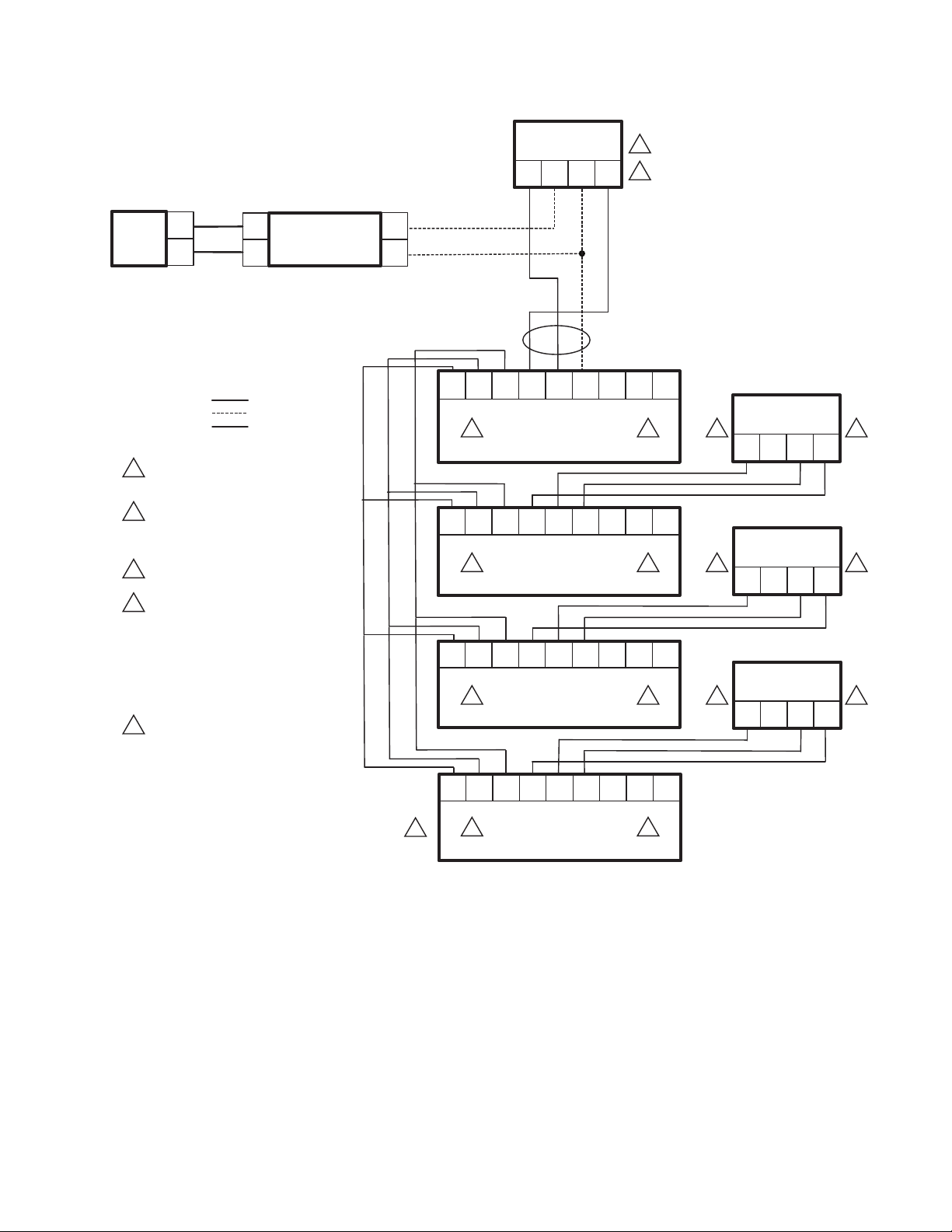

Fig. 3. S7999B wiring diagram.

5 65-0303—05

Page 6

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

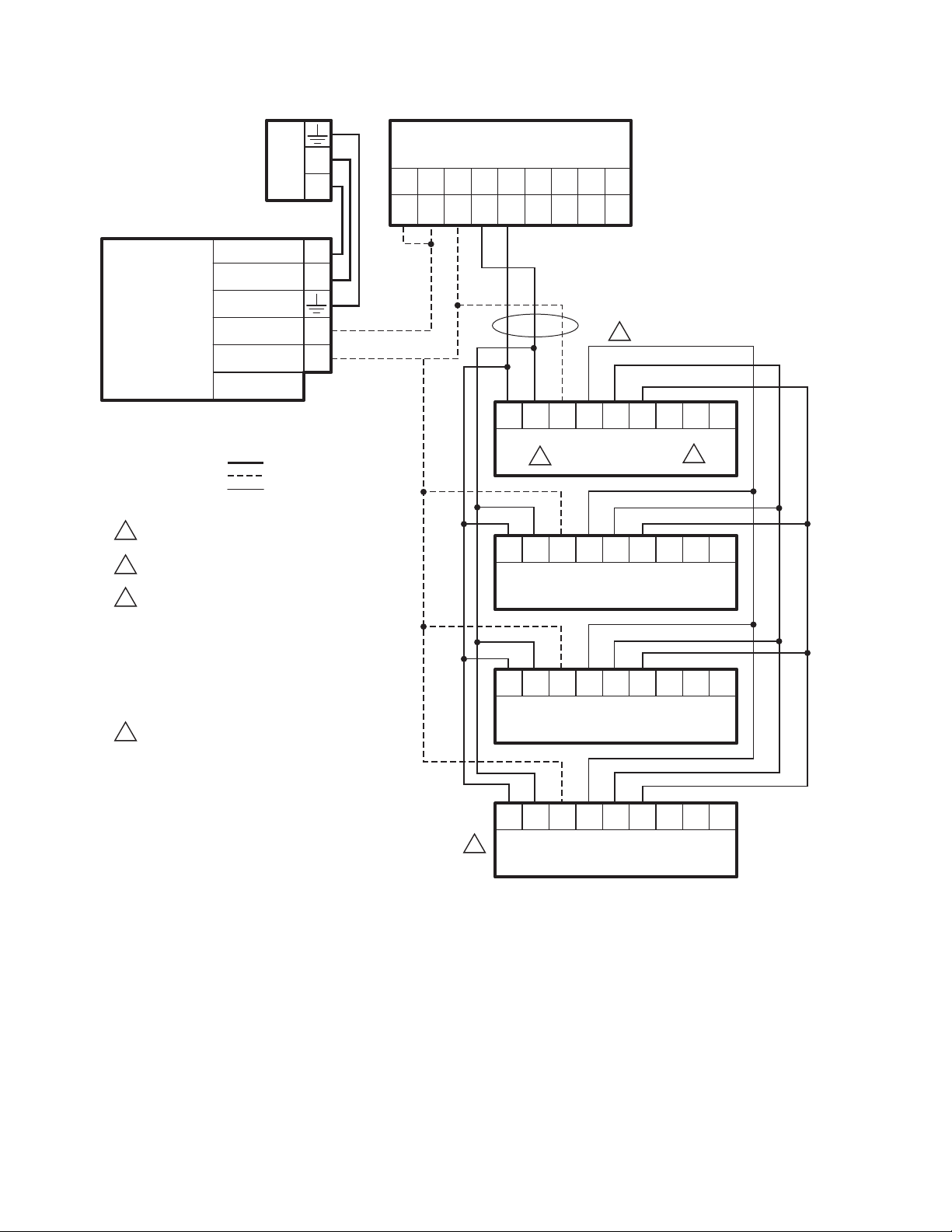

M32005

2

1

4

567 89

3

+12

(B)

(A)

N/C

GND

(C)

+12

N/C

(A)

(B)

S7999B

AS SYSTEM DISPLAY

COM1

COM2

L1

L2

120

VAC

VAD J

V+

N

L

V-

DC OUT

(COMMON GND)

12 DC OUT +

EARTH

GROUND

120VAC (L1)

NEUTRAL (L2)

MEAN WELL S-25-12

DO NOT CONNECT THE S7999B TO TERMINALS 1 2 3.

THIS WILL RENDER THE DISPLAY INOPERABLE.

DISPLAY CAN ALSO BE CONNECTED TO MB2; A, B, C

AND THE SOLA SLAVES NEED TO BE WIRED TO MB1.

CONTROLLER HAS TWO AVAILABLE MODBUS

CONNECTIONS: THIS CONFIGURATION REQUIRES ONE

FOR CONTROL LEAD LAG COMMUNICATION AND ONE

FOR A S7999B SYSTEM DISPLAY.

THERE IS NOT A CONNECTION AVAILABLE FOR A

LOCAL TOUCHSCREEN DISPLAY (S7999C).

THE ECOM CONNECTION IS AVAILABLE FOR

CONNECTIONS OF A LOCAL KEYBOARD

DISPLAY MODULE.

UP TO A MAXIMUM OF 8 SOLA SLAVES IN A

LEAD LAG NETWORK.

POWER SUPPLY

WIRING KEY

LOW VOLTAGE

DATA

LINE VOLTAGE

SOLA LL MASTER

AND SLAVE 1

23CBACBA1

J3

MB1 ECOMMB2

23CBACBA1

SOLA SLAVE 2

J3

MB1 ECOMMB2

23CBACBA1

SOLA SLAVE 3

J3

MB1 ECOMMB2

23CBACBA1

SOLA SLAVE 4

J3

MB1 ECOMMB2

1

1

2

3

3

4

4

2

BUILDING AUTOMATION SYSTEM (BAS) CONFIGURATION

Connect the BAS Modbus wiring to COM2 of the S7999B as

shown in Fig. 5.

Fig. 4. S7999B wiring diagram for lead lag.

Ensure all S7999B devices have unique Modbus addresses as

defined in Fig. 5.

65-0303—05 6

Page 7

WARNING

BAS

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

COM 2

S7999B

COM 1

1

SOLA

1

EACH SOLA IN THE BAS WILL HAVE A DIFFERENT MODBUS ADDRESS.

COM 2

S7999B

COM 1

SOLA

2

SOLA

Fig. 5. S7999B in a Building Automation System.

BAS Modbus message timeout should be set to 1.0 seconds or

higher. This means it could take up to 1.0 seconds (max) for

the System Display to reply to a BAS message.

Retries: BAS must setup retries upon timeout to ensure the

Modbus request is accepted.

BAS Modbus poll rate should be set to 1.0 seconds. This

means that the BAS should wait for a minimum of 1.0 seconds

after receiving a Modbus message from Sola before sending a

new Modbus message.

COM 2

S7999B

COM 1

3

SOLA

UP TO 8

SOLAS

4

5

SOLA

1

M32006

If the screen is dim, check the pin 1 and 2 wiring connections.

NOTE: An Advanced Startup screen displays for five seconds

after power-up before the Home page displays. This

screen allows the user to upgrade the software in the

System Display (see “Preface” on page 2) and should

normally be bypassed.

Three LEDs exist for I/O traffic: one for the Ethernet network

port and two for Modbus™ ports. The ethernet port should only

be used if instructed by Honeywell that an update is necessary.

Modbus Com Port 2 is not active on this device.

QUICK SETUP (S7999B OI DISPLAY)

1. Make sure the S7999B 9-pin connector is properly

aligned and pressed firmly in place.

2. Make sure the wires between the 9-pin connector and

the controller are properly wired and secure.

Electrical Shock Hazard.

Can cause severe injury, death or equipment

damage.

Line voltage is present at the 120 Vac power supply.

3. Make sure the power supply is connected securely to the

120 Vac power source.

STARTING THE S7999B OI DISPLAY

Power-up Validation

The Home page will appear and the “Power” LED will be

blinking when the device is properly powered. Select the 1234

Setup button to adjust the contrast and sound as desired.

1. Make sure the Power and COM1 LEDs are blinking.

2. If the LEDs are not blinking:

a. Make sure the proper connections have been made

between the Modbus COM1 Port and the first controller device in the Modbus network.

b. See “Wiring (S7999B OI Display)” on page 4 for

proper wiring of the OI Display 9-pin Header

Connections.

3. If connected to a BAS application, COM2 LED will blink

indicating BAS traffic.

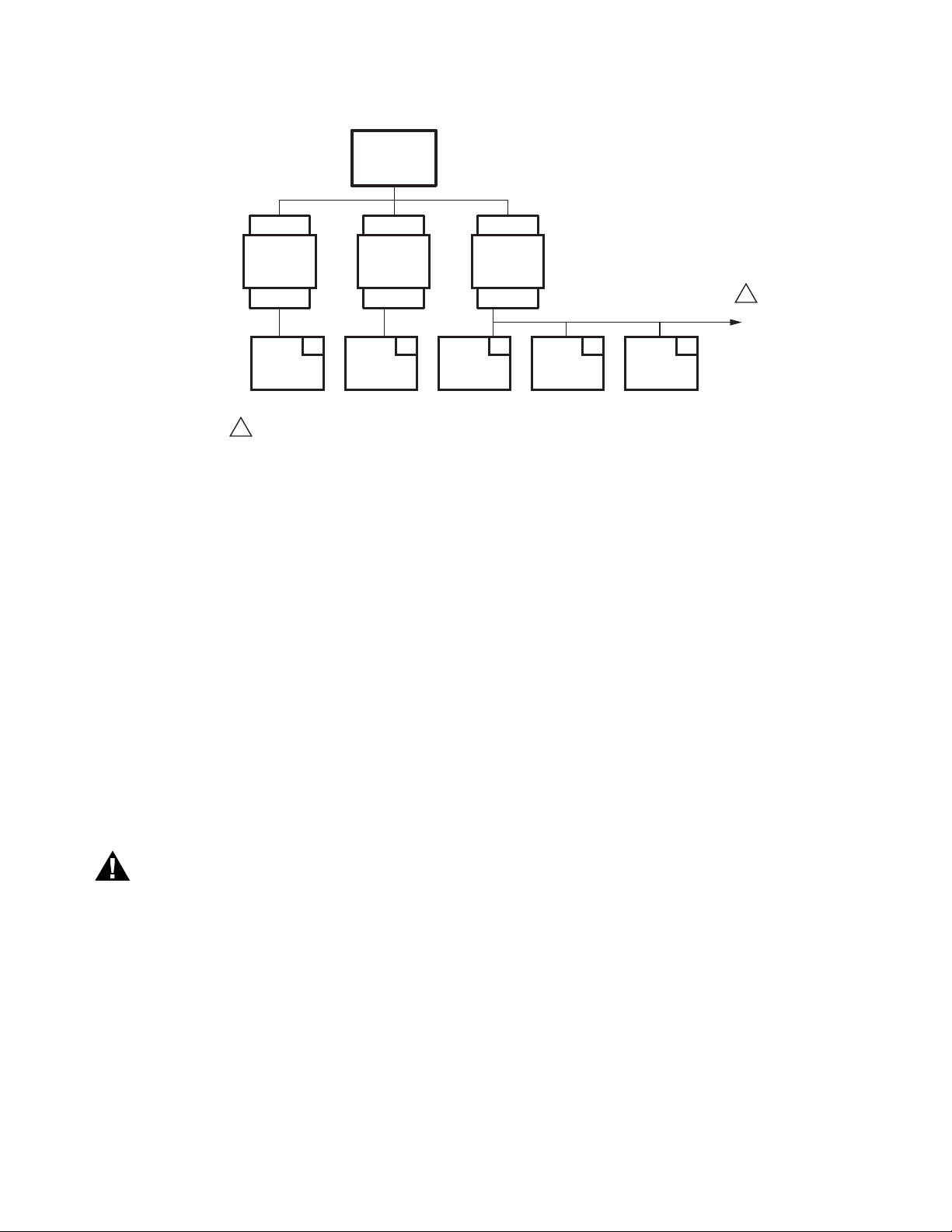

Home Page (S7999B OI Display)

Make sure a screen similar to Fig. 6 appears after the OI

Display has completely powered up.

On System applications, each SOLA Control is represented on

the Home page by an icon and name. Pressing the icon allows

the user to zoom in on that boiler and see its specific details.

These details are provided on a new page, which can include

additional buttons that display additional detail and operation

information, which itself leads to other pages. The pages are

traversed in a tree structure method, as shown in Fig. 8.

The Sola icons will appear in one of four colors indicating the

boiler status.

• Blue: Normal operation

• Red: Lockout condition

• Gray: Standby mode (burner switch off)

7 65-0303—05

Page 8

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

• Gray and crossed out: communication error (disconnected

or powered off)

Up to 8 Systems can be displayed on the Home page. The

name of each boiler is displayed next to the Sola icon button.

When Lead Lag is enabled, the system header temperature

and firing rate are displayed for each System. When the burner

is in standby or not firing the firing rate is not displayed.

NOTE: The boiler name may be cut off on the Home page

when all icons are present.

The Home page also includes a System Analysis button that

allows the user to view status information on a system-wide

(that is, multiple boiler) basis. The user can choose which

status information to compare from the SOLA Controls in the

system.

Pressing the 1 2 3 4 Setup button on the Home page displays

miscellaneous setup and diagnostic functions beginning on

page 47 (see also Table 61 on page 53). It also contains the

setup configuration for BAS applications, under the Advanced

Setup button.

Pressing the SOLA icon opens that control’s status page. Go to

“Configure Button” on page 13 to continue.

Fig. 6. S7999B Home page (Boiler 1 in normal operation).

65-0303—05 8

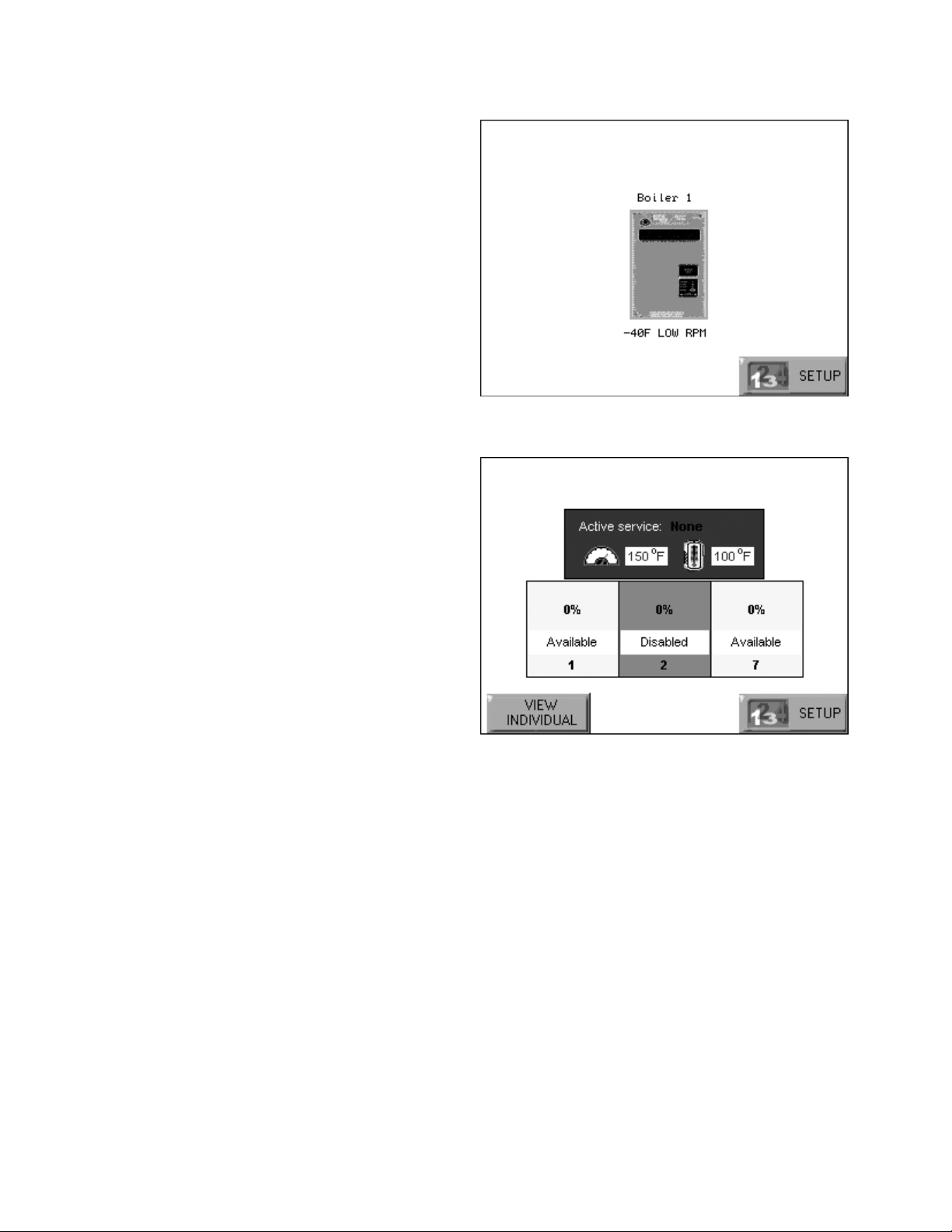

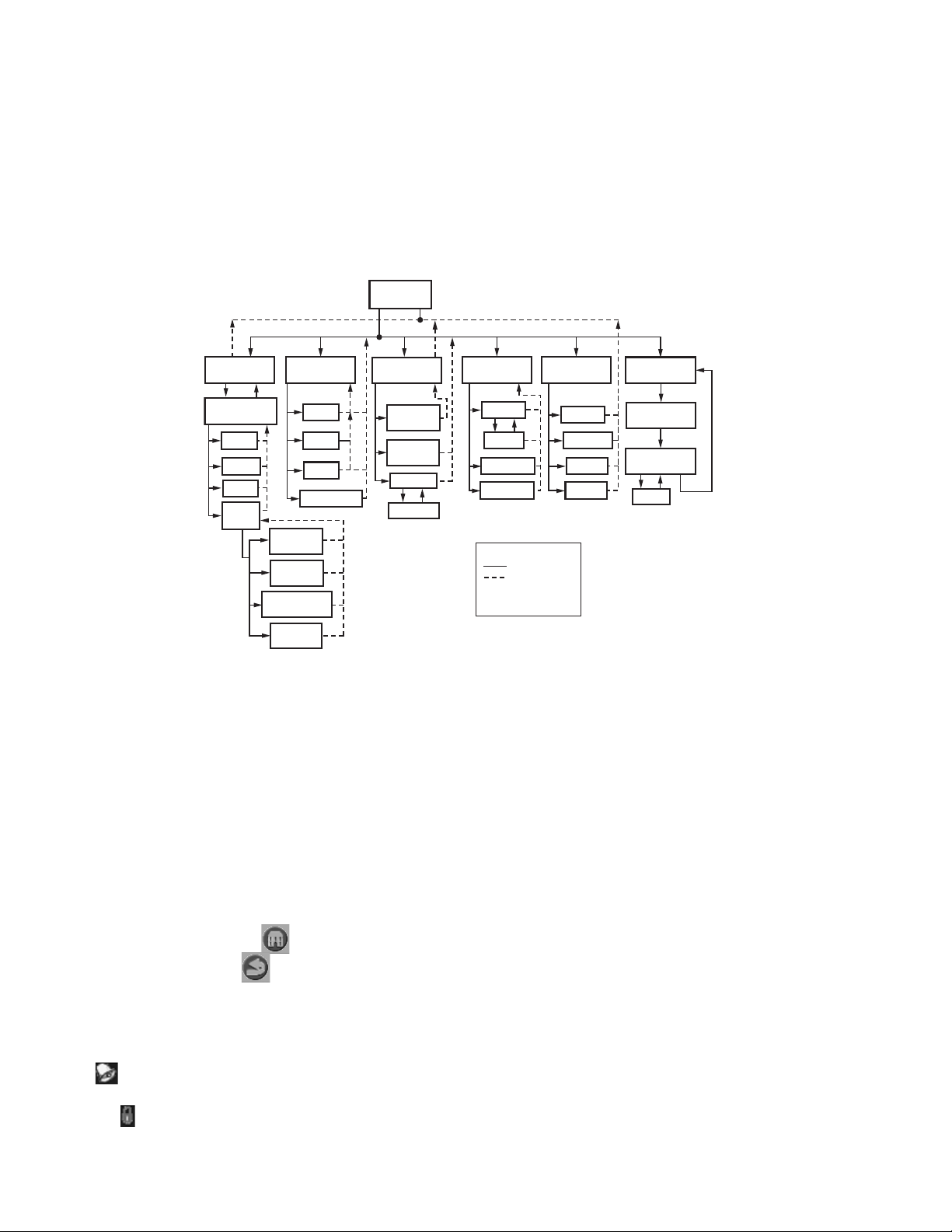

Fig. 7. S7999B Lead Lag Home page.

Page 9

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

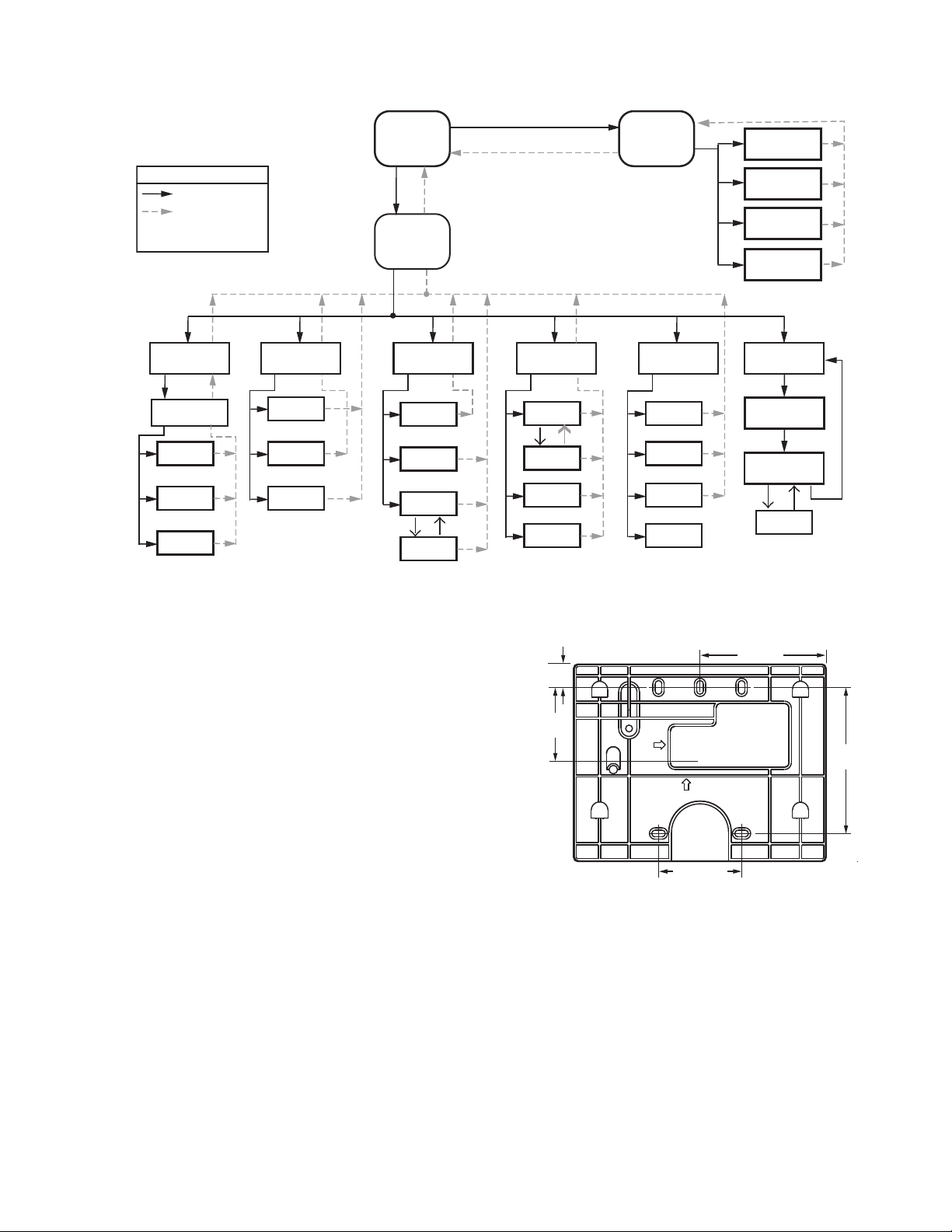

KEY

BUTTON FLOW

BACK ICON FLOW

HOME ICON ALWAYS TAKES

YOU TO THE HOME PAGE

CONFIGURE

Configuration

Groups

Login

Logout

Veri fy

OPERATION

CH

Login

DHW

HOME

PAG E

SUMMARY

PAG E

DIAGNOSTICS

Diagn.

Te st

Burner

Control

Digital

I/O

Analog

I/O

DETAILS

History

Alerts

Diagn.

Analysis

1 2 3 4

SETUP

HISTORY

Lockouts

Silence

OK

Alerts

PROGRAM

MODULE

CLEAN

SCREEN

SYSTEM

CONFIG.

ADVANCED

SETUP

MODULATION

SETPOINTS

PUMPS

?

M13965

Fig. 8. S7999B display page flow.

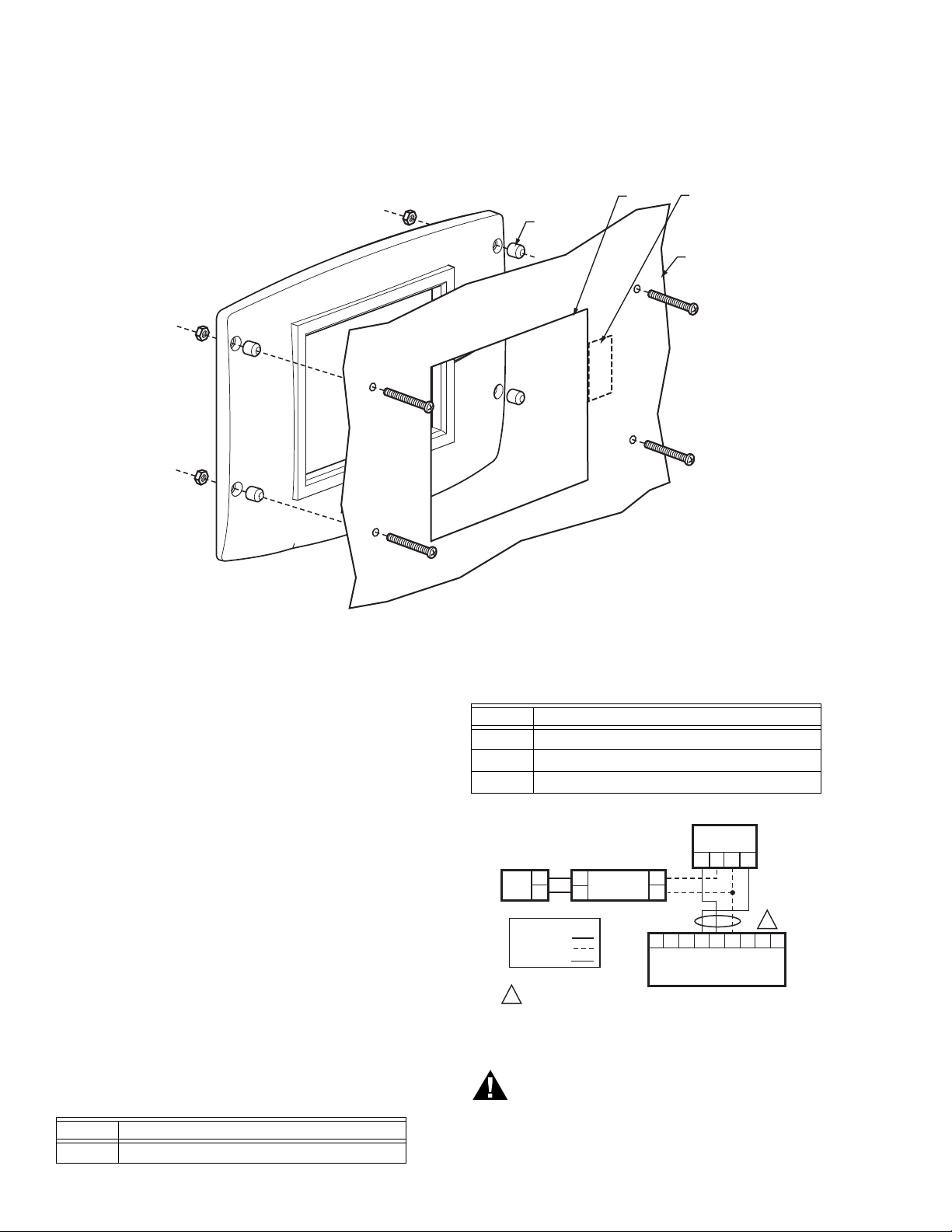

INSTALLATION INSTRUCTIONS (S7999C OI DISPLAY)

NOTE: For S7999B OI Display installation instructions, see

page 4.

The S7999C display is used for individual boiler monitoring.

The S7999C is mounted:

• onto a panel using the wallplate provided.

• from the front into a panel cutout (7.6 in. W X 5.4 in. H)

using 4 #6-32 screws and nuts (provided).

• From behind into a panel cutout (5.45 in. W X 4.3 in. H)

using 4 #6-32 screws, nuts and 4 standoffs (provided).

Mounting the S7999C OI Display using the wallplate (provided)

1. Select the location to mount the OI display; this could be

a location up to 1000 feet from the SOLA control.

2. Use the device wallplate as a template to mark the location of three or four mounting screw holes. See Fig. 9.

3. Drill 3/16 in. holes for mounting the wallplate.

4. Secure the wallplate with three or four #6-32 screws.

5. Bring power and communication wire through the wall

plate and attach to the terminals on the back of the display before installing the display to the wall plate.

1/2

(13)

1-21/32

(42)

1-13/16 (46)

2-3/4 (70)

3-13/64

(81)

M27606

Fig. 9. S7999C wallplate dimensions in in. (mm).

Mounting the S7999C OI Display directly to the Door Panel

1. Select the location to mount the display.

2. Cut an opening to facilitate mounting the display into the

door panel. See Fig. 1 for the dimensions for mounting

the display from the front of the door. See Fig. 10 for

mounting the display to the back of the door. If desired,

cut a notch so the LEDs will be visible as well. Tear off

templates are also available on the back pages of this

Manual (see Fig. 121 on page 63 and Fig. 122 on page

65).

3. Fit the display into the opening and use the screw holes

in the device as a template to mark the location of the

four mounting screw holes.

9 65-0303—05

Page 10

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

WARNING

M29868

SPACER (4)

WALL

CUTOUT

OPTIONAL

CUTOUT

4. Drill 3/16 in. holes for mounting the display. 5. Secure the OI Display to the panel using the four #6-32

screws and nuts, as shown in Fig. 10. (Standoffs are provided for mounting the OI Display from the back of the

door.)

Fig. 10. Mounting the S7999C OI Display behind the door panel.

S7999C OI Display Power supply mounting.

1. Select a location inside the enclosure for mounting the

power supply.

2. Using the power supply as a template, mark the loca-

tions of two mounting holes in the enclosure.

3. Remove the power supply.

4. Drill 1/4 in. holes through the panel at the marked loca-

tions and secure the power supply with the two #6-32

screws and nuts provided.

WIRING (S7999C OI DISPLAY)

The S7999C OI display must be appropriately wired for both

power and communications.

1. Wire the power supply and the RS-485 communication

cables per Table 2 and the wiring diagram in Fig. 11.

• Y and G are connected directly to the display and

either SOLA Control connector J3 Modbus (MB1) or

Modbus (MB2).

2. Make sure the 12 Vdc power supply (supplied with the

S7999C) is connected securely to the 120 Vac power

source.

Table 2. 4-pin Connector Terminals (located on the

back of the S7999C OI Display).

Pin # Function

Y Data (-) Output (Modbus b)

Table 2. 4-pin Connector Terminals (located on the

back of the S7999C OI Display).

Pin # Function

+ 12Vdc input

- 12Vdc Input

G Data (+) Output (Modbus a)

L2

L1

WIRING KEY

N

L

V-INFINITY

FSC-S5-12U

120

VAC

LINE VOLTAGE

LOW VOLTAGE

DATA

1

DO NOT CONNECT S7999C TO TERMINALS 1 2 3 AS THIS WILL RENDER

THE DISPLAY INOPERABLE.

V+

V–

A

S7999C MID-

LEVEL DISPLAY

+

−G

Y

AB

B

C

C

MB2

MB1

R7910 HYDRONIC CONTROL OR

R7911 STEAM CONTROL

1

ECOM J3

Fig. 11. S7999C wiring diagram.

Electrical Shock Hazard.

Can cause severe injury, death or equipment

damage.

Line voltage is present at the power supply.

S7999C CAN BE

CONNECTED TO

EITHER MB1 OR

MB2 A, B, C

TERMINALS

1

3

2

M32008

65-0303—05 10

Page 11

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

L2

120

VAC

L1

WIRING KEY

LINE VOLTAGE

LOW VOLTAGE

DATA

1

DO NOT CONNECT THE S7999C TO

TERMINALS 1 2 3. THIS WILL RENDER

THE DISPLAY INOPERABLE.

2

DISPLAY CAN BE CONNECTED TO MB1

OR MB2; A, B, C AS LONG AS THE

REMAINING MB TERMINAL IS USED

FOR THE SLAVE COMMUNICATIONS.

3

WIRE V-INFINITY POWER SUPPLY

TO + AND - TERMINALS.

S7999C CONNECTED TO THE MASTER

4

CAN CONFIGURE THE MASTER.

IT CAN ALSO CONFIGURE THE SLAVE

INFORMATION IN THIS CONTROL AS WELL

AS MONITOR THIS SLAVE’S ACTIVITIES.

S7999C CONNECTED TO EACH SLAVE

CAN ONLY CONFIGURE THAT SLAVE AS

WELL AS MONITOR THAT SLAVE’S ACTIVITY.

5

UP TO A MAXIMUM OF 8 SOLA SLAVES

IN A LEAD LAG NETWORK.

N

L

V-INFINITY

FSC-S5-12U

S7999C

MID-LEVEL DISPLAY

+YG–

V+

V-

C

BA

MB1 ECOMMB2

2

LL MASTER AND SLAVE 1

BA1

C

MB1 ECOMMB2

2

BA1

MB1 ECOMMB2

2

SOLA SLAVE 2

C

SOLA SLAVE 3

CBA

SOLA

3

4

23

1

J3

1 3

23CBA

J3

1

23CBA

J3

1

4

4

4

S7999C

MID-LEVEL DISPLAY

+YG–

S7999C

MID-LEVEL DISPLAY

+Y

S7999C

MID-LEVEL DISPLAY

+YG–

–

3

G

3

BA1

C

MB1 ECOMMB2

5

2

SOLA SLAVE 4

Fig. 12. S7999C wiring diagram for lead lag.

11 65-0303—05

23CBA

J3

1

M32007

Page 12

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

STARTING THE S7999C OI DISPLAY

Power-up Validation

The Home page will appear and the “Power” LED will be on

continuously and the “COM” LED will be blinking when the

device is properly powered and communicating to the Sola

Control.

HOME

PAG E

CONFIGURE

CONFIGURATION

GROUPS

LOGIN

LOGOUT

VERIFY

DISPLAY

SETUP

OPERATION

CH

LOGIN

DHW

ANNUNCIATION

PROGRAM

MODULE

CLEAN

SCREEN

SYSTEM

CONFIGURATION

ADVANCED

SETUP

DIAGNOSTICS

DIAGNOSTIC

TEST

BURNER

CONTROL

DIGITAL I/O

ANALOG I/O

The “COM” LED exists for I/O traffic.

1. Make sure the LED is blinking.

2. If the LED is not blinking:

a. Make sure the proper connections have been made

between the display and the Sola Control.

b. See “Wiring (S7999C OI Display)” on page 10 for

proper wiring of the display connections.

DETAILS

HISTORY

ALERTS

DIAGNOSTIC

ANALYSIS

BUTTON FLOW

BACK ICON FLOW

HOME ICON ALWAYS

TAKES YOU TO THE

HOME PAGE

KEY

HISTORY

OK

LOCKOUTS

ALERTS

SILENCE

MODULATION

SETPOINTS

PUMPS

?

M29774

Fig. 13. S7999C display page flow.

PAGE NAVIGATION

The Sola OI Displays present information and options in a

paged manner. Pages are displayed in a tree structure in which

the user navigates up and down to arrive at the desired

Function (see Fig. 8 for S7999B or Fig. 13 for S7999C). The

page descriptions are provided below so that you can

understand the purpose of each and view the selections,

parameters, and information that is available or required on

each.

Common OI Display Page Symbols

Most pages have a Home button in the top-left corner of

the screen and a Back button in the top-right corner of

the screen. The Home button returns the user to the Home

page and terminates any operation in progress. The Back

button returns the user to the previous page.

Two other icons may be noticed near the boiler name.

A bell will be displayed if the system is in Lockout that

reset will be required.

A padlock will be shown on screens that require a password

to change the parameter. An unlocked padlock indicates the

password has been entered to change the parameter.

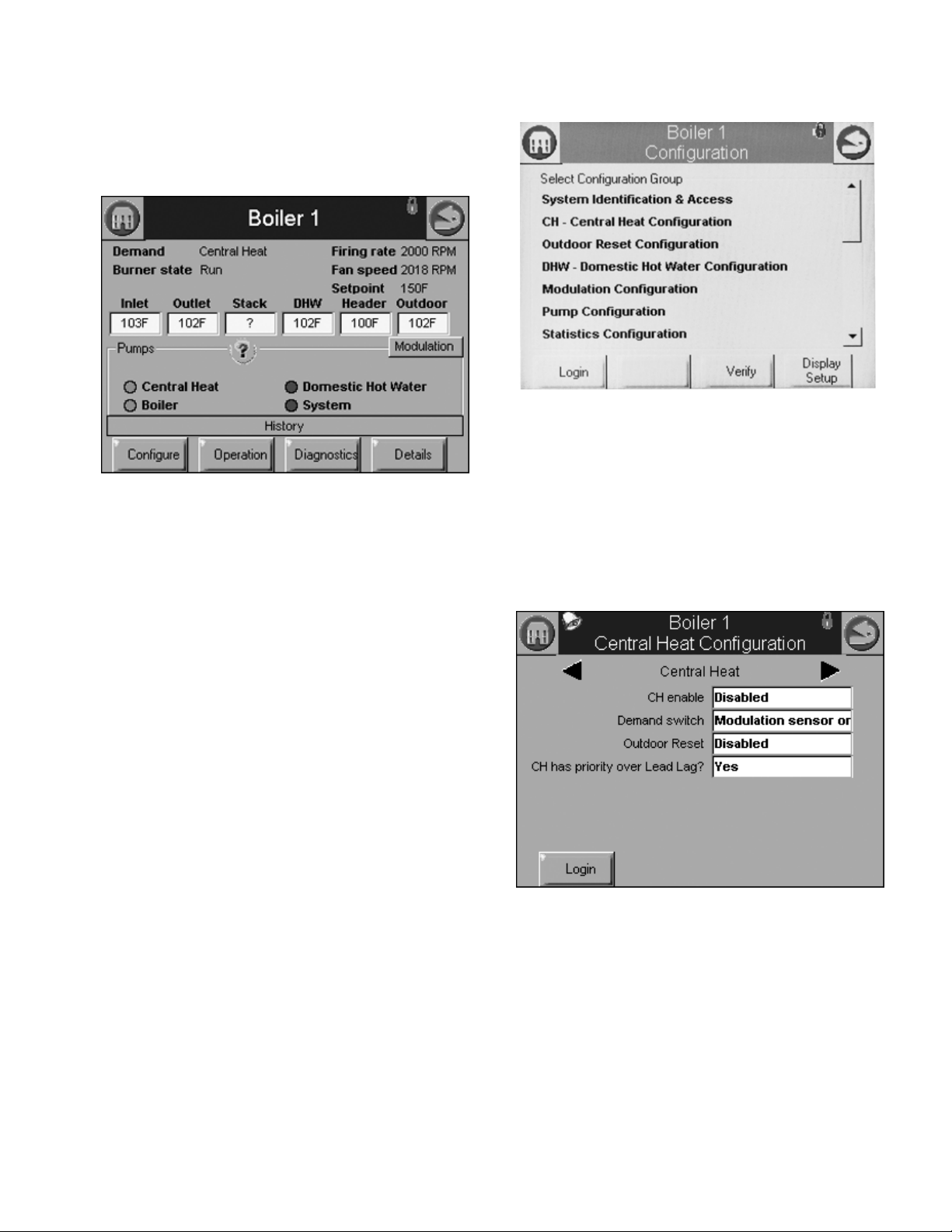

Status or Home Page

A status (summary) page (Fig. 14) is displayed when the

S7999C display is connected. This status page appears on the

S7999B when the Sola control icon is pressed on the “Home”

page. The status page displays the current condition of the

burner control and displays some of the more important

configuration settings.

The boiler name associated with the burner control is

displayed in the title on the status page.

NOTE: When the burner control has no boiler name defined,

Modbus address is used to identify the boiler.

The initial status page displayed contains summary status

information as shown in Fig. 14. Any status information not

applicable for the installation is grayed/blanked out on the

screen.

Buttons on this screen include:

• Configure: used to configure the burner control (see

“Configure Button” on page 13 for more details).

• Operation: used to perform daily or frequent functions with

the burner control, such as setpoint adjustment, etc. See

“Operation Button” on page 18 for details.

• Diagnostic: used to view burner control diagnostic

information (see “Diagnostics Button” on page 19 for more

details).

• Details: used to view burner control detail status

information (see “Details” on page 38).

65-0303—05 12

Page 13

• History: used to view burner control history (see “History

Button” on page 16 for more details).

• ?: used to expand the pump status information.

• Modulation: used to toggle between status displays: pump,

setpoints, and modulation.

Fig. 14. Summary status page (Hydronic Control shown).

Configure Button

Pressing the Configure button (bottom left) on the Status page

opens the Configuration page. The Configuration page shown

in Fig. 15 is for the S7999C OI display.

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Fig. 15. Configuration menu page. Shown is the S7999C on

a Hydronic Control.

No specific order for configuration is required. All parameters

are enabled for editing, though some may not be applicable

(e.g., a configuration parameter may disable a control feature).

Selecting a parameter group from the menu displays

parameters exclusively applicable for the functional group on

the page (see Fig. 16). These parameters can be edited, and

when the user is finished, control returns back to the

configuration menu page.

The S7999B Configuration page does not have a “Display

Setup” button.

Display Setup (S7999C only): Pressing the Display Setup

button displays miscellaneous S7999C OI Display setup and

diagnostic functions (See page 47 for options). (The same

function as the 1234 Setup on the S7999B home page.)

The configuration page allows the user to view and set

parameters that define how the connected R7910A functions in

the hydronic heating system or the R7911 steam heating

system.

The configuration page contains a menu of parameters

grouped into functional areas that the user selects for

configuration (see Fig. 16). See Table 61 on page 53 for all

parameters available for configuration. If some parameters are

not visible, they have been made invisible by Honeywell.

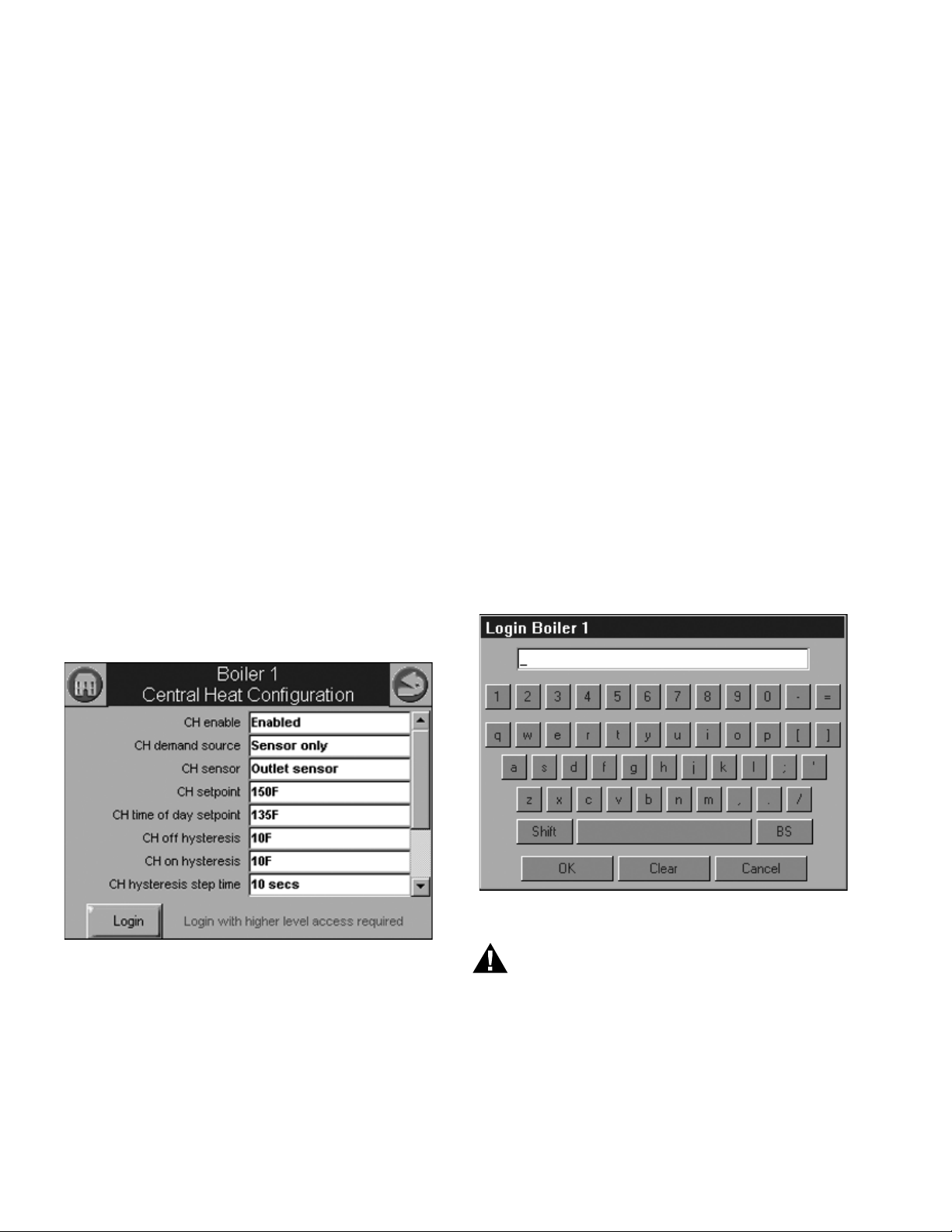

Fig. 16. Sample configuration page for the S7999B

Hydronic Control.

Each parameter is displayed in its group. If there are more

parameters than will fit on the screen, a vertical scroll bar

allows the user to scroll up and down to view all parameters.

The parameter name is displayed on the left and the current

setting is displayed in the text box on the right.

Configuration Password

Some parameters require a valid configuration password be

entered by the user before the parameter can be changed. The

password need only be entered once while the user remains

on the configuration pages. Leaving the configuration pages

ends the scope of the password.

13 65-0303—05

Page 14

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

WARNING

Three levels of access to Sola Control parameters are

permitted. Each access level has defined rights when

interfacing with configuration and status parameters within the

controls.

• End user: The end user can read or view the control

parameters and be allowed to change some operating

parameters, CH setpoint as an example.

• Installer: The installer can read all control parameters and

change Honeywell's allowed parameters. This access level

is used to customize the control for a particular installation.

• OEM: The OEM can read and change all parameters,

change sensor limits and burner control safety parameters.

Different passwords exist in the Sola Control for each access

level. The end user level requires no password, but the

installer and OEM levels have unique passwords defined for

them.

The installer and OEM passwords can be changed in the Sola

Control after logging in with the current password. When the

password is changed, it is saved for all future logins.

NOTE: For the S7999B System OI display, each boiler in a

multi-boiler configuration has its own set of installer

and OEM passwords. To avoid user confusion, the

passwords should be changed to the same password

in each control, but there is no requirement to do so.

Make sure to record your password.

The user is notified that a new password is needed to change a

parameter (or until a password is entered successfully)—see

Fig. 17. The user can continue viewing the configuration

parameters regardless of whether a password is entered

successfully.

The user is not required to enter a configuration password for a

parameter that has a lower access level than the access level

achieved by an earlier password entry for any configuration

group (as long as the user stays in the configuration pages).

The user only needs to enter a password once until a

parameter that has a higher access level is selected.

Keyboard

Some pages request user entry of characters. When this type

of input is required, a keyboard page appears, as shown in Fig.

18. The text box at the top of the screen displays the current

(or default) setting of the user input. The user can add to this

text, clear it, or change it.

The Shift key on the left side of the screen shifts between

upper and lowercase characters. Pressing the Shift key

toggles the keyboard from one mode to the other (continuous

pressing of the Shift button is not required). The OK button

should be pressed when the user is done entering the text

input. The Cancel button on the bottom of the screen allows

the user to ignore any text changes that have been made and

keep the original text value. Pressing the OK or Cancel buttons

returns the user to the page displayed prior to the keyboard

page.

Login

Pressing the Login button allows entering the password from a

keyboard as shown in Fig. 18. After the password is entered,

the OK button is selected. The Cancel button aborts the

password login.

Fig. 17. Login required. (S7999B Hydronic Control Shown.)

The Sola Controls maintain a password time-out that limits the

scope of the password entry. Once a password is successfully

entered, the control starts an internal timer that expires after 10

minutes of inactivity. After the timer expires, the user is

required to re-enter a password before a parameter can be

changed.

65-0303—05 14

Fig. 18. Device login screen.

Explosion Hazard.

Improper configuration can cause fuel buildup and

explosion.

Improper user operation may result in PROPERTY

LOSS, PHYSICAL INJURY or DEATH.

Using the OI Displays to change parameters must be

attempted by only experienced and/or licensed

burner/boiler operators and mechanics.

Page 15

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Change Parameter Settings

Change parameter settings by selecting the parameter on the

page. A dialog box displays for the parameter with controls

allowing the user to change the value (see Fig. 19). After

changing the setting to a new value, press the OK button.

Pressing the Cancel button leaves the parameter unchanged.

The changed setting is reflected on the screen and sent to the

control when the OK button is pressed.

Like operating parameters, safety parameters can be viewed

without the need to enter a password.

Safety parameter blocks that have been changed require

verification. The verification steps do not have to be completed

immediately; the installer can move between and change

parameter groups before the verification is done. A Verify

button is enabled that allows the installer to conduct verification

sessions (the example of the Verify button in Fig. 15 is not yet

enabled because the installer hasn’t logged in).

NOTE: When the installer proceeds with the safety parameter

configuration, the control unlocks the safety parameters in this group and marks them unusable. Failure to

complete the entire safety configuration procedure

leaves the control in an un-runnable state (lockout 2).

All safety configuration parameters in the group should have

the same access level. If this condition isn’t so, the user is

asked to enter another password when a higher access level is

needed.

Successful login is noted by the lock icon, which changes to

“unlocked” on the page. The installer may begin to change

safety parameters (or any other parameters) at that time. (See

Fig. 21.) If the Sola Control is in an unconfigured (or new)

state, then this warning doesn’t appear. All parameters that

need changes should be changed during the login.

Fig. 19. Change configuration parameter page example of

a Hydronic Control.

Verify

Pressing the Verify button displays safety configuration

parameters for an additional verification step to commit the

changes.

Safety parameters are grouped into blocks that include only

safety parameters, not a mixture of safety data and non-safety

data. All parameters within the safety group undergo a

verification process. A safety parameter group is identified on

the display to indicate when the configuration parameters are

safety-related. Each safety parameter group is verified one at a

time until all have been verified. See Fig. 20.

Fig. 21. Edit safety data.

If the safety configuration session is terminated after it has

started (in the Edit or Verify stages), the Sola Control is left in

an unconfigured (unrunnable) state.

The installer can terminate the session by pressing the Menu

button or by attempting to leave the Verification page with the

Home or Back buttons (top-left and -right screen corners,

respectively). However, leaving the session at this point leaves

the control in an unrunnable state and confirms whether the

installer still wants to do so.

Fig. 20. Safety verification.

The settings of all parameters in each safety block must be

verified to save them in the control.

When the installer is done changing safety parameters,

pressing the Verify button on the configuration screen begins

the Verification process. The settings for all safety parameters

in each changed block are presented and Verified by the

installer (see Fig. 22).

15 65-0303—05

Page 16

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Fig. 22. Safety parameter confirmation.

Press the Yes button to confirm each safety parameter block. If

the No button is selected, the safety parameter block remains

unconfirmed and the Configuration menu page is displayed.

The control remains in an unconfigured state in this case.

After all safety parameter blocks have been confirmed, the

installer is asked to press and hold the Reset button on the

Sola Control to complete the safety verification session (see

Fig. 23).

Safety lockouts are indicated on each configuration page as an

alarm bell symbol. At the home (for S7999C) or status page

(for S7999B), the History button turns red. If the S7999B is

displaying the system status icons, the control in alarm will turn

red.

The lockout history can be displayed by pressing on the

History button. The state information about each lockout is

displayed along with the date/time that the lockout occurred

(see Table 3). Current date/time stamp is a display setup

feature.

NOTE: In the event of a power interruption, the date/time

must be reset. The OI Display does NOT have a

backup means.

Table 3. Sola Control Lockout History.

Data Comment

Lockout time Set by display

Fault code Unique code defining which

lockout occurred.

Annunciator first out First interlock in limit string

results in a shutdown.

Description Fault description

Burner Lockout/Hold Source/reason for lockout/

hold

Burner control state

Sequence time Burner control state timer at

time of fault

Cycle Burner control cycle

Run Hours Burner control hours

I/O All digital I/O status at time of

fault

Annunciator 1-8 states All annunciator I/O status at

time of fault

Fault data Fault dependent data

Fig. 23. Safety parameter reset.

When the Reset button is pressed and held for 3 seconds the

confirmed safety parameters are saved in the control. The

above Reset dialog box automatically closes when this step is

completed.

If this step is not performed, the control remains in a safety

lockout state until the installer resolves the unverified safety

parameters.

Fault/Alarm Handling

Each Sola Control reports to the OI display when a safety

lockout or an Alert occurs.

65-0303—05 16

An alert log can be displayed for each control by pressing the

Alert button on the bottom of the history status page. A

description of the alert is displayed along with the time when

the alert occurred (see Table 4).

Table 4. Sola Control Alert Log.

Data Comment

Alert time Set by display

Alert code Unique code defining which

fault occurred.

Description Alert description

History Button

The History button on the Home page serves not only as a

button, but also displays Sola Control lockouts, holds, and

alerts as they occur. The History button can be selected at any

time, regardless of which type of information is displayed, to

view history information. Pressing the History button displays a

dialog box (see Fig. 24) that allows the user to select the type

Page 17

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

of history to view. The user can also silence an audible alarm

generated by the control during a lockout or alert by alarm

condition.

This History dialog box provides an exploded view of the status

information displayed in the History button (the font is larger).

One of the four buttons (OK, Lockouts, Alerts, or Silence) can

be selected. If none of these buttons are selected the dialog

box closes after 30 seconds.

The date and time that each fault occurred is displayed in the

lockout history. The lockout timestamp displays in both the

lockout summary and detail information.

The Sola Control does not maintain date or time of day

information. The date and time stamp is assigned by the OI

display. When the OI display first obtains the lockout and alert

history from the control (during the display data

synchronization), no timestamps are assigned since the times

that the lockouts occurred are unknown. All new lockouts that

occur after the synchronization are assigned timestamps.

NOTE: The system time can be set in the OI display to

ensure that correct timestamps are given to the controls’ lockouts and alerts. Power interruptions will

require the time to be reset as the display DOES NOT

have a time backup means.

The Clear Lockout button allows the user to acknowledge and

clear (reset) the lockout when in lockout state, much the same

as pressing the reset button on the front of the Sola Control.

The user can toggle between displaying the controls’ lockout

history and alert log by pressing the Alerts or Lockouts button

on the bottom of the pages.

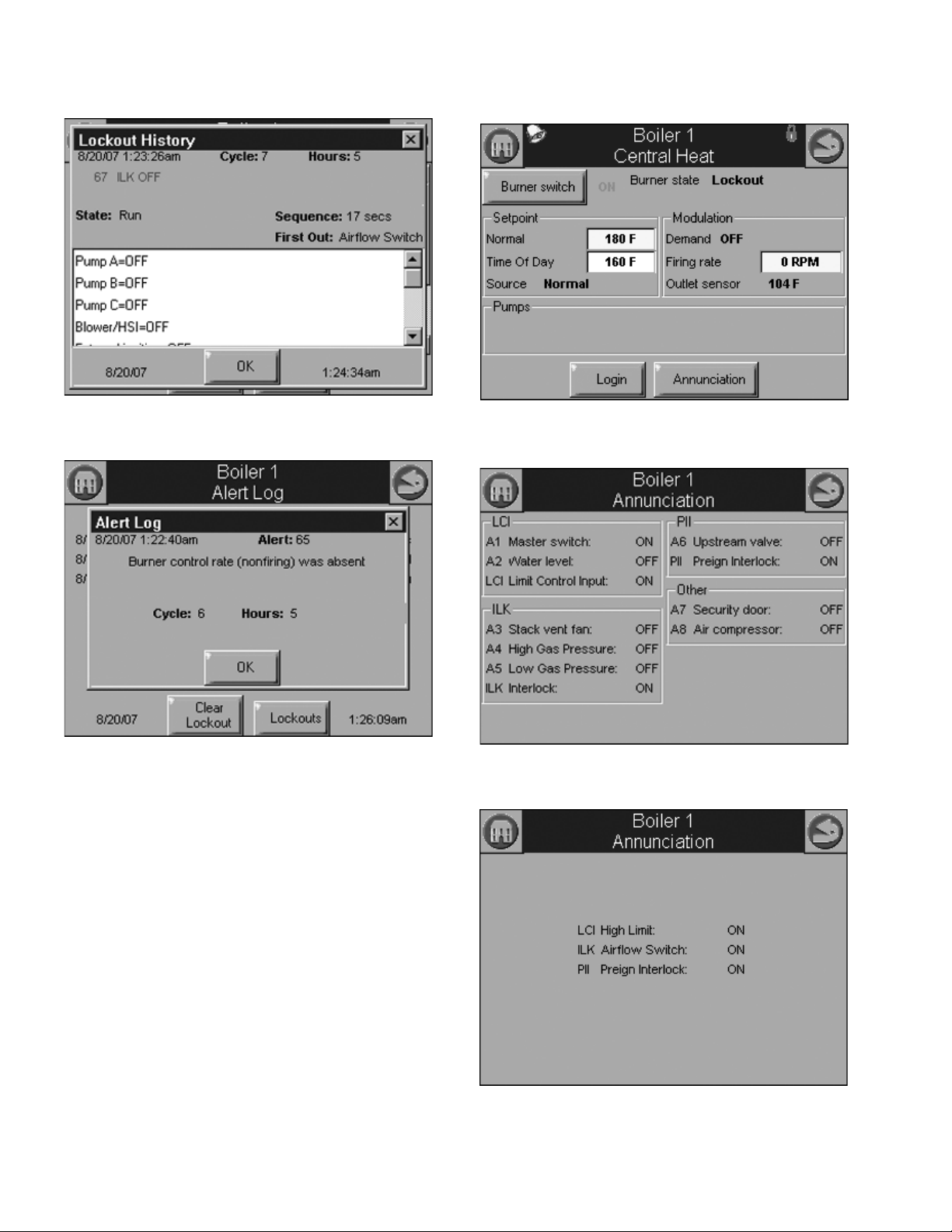

Fig. 24. Hydronic history example shown—exploded view.

Two types of historical data can be displayed on the history

page: lockout history and alert log.

The entire 15 fault code history is displayed in a scrollable list

with the most recent fault displayed first followed by the next

most recent fault. Summary information is displayed for each

fault entry, including the burner cycle count, fault code, and

fault number with description. Detailed information for a

specific fault entry that also includes burner control sequence

state, burner run-time hours, annunciation status, etc., is

viewed by selecting (touching the History line) the lockout entry

in the list (see “Fault/Alarm Handling” on page 16 for details).

Fig. 26. Alert log example shown.

To see additional detail about a lockout or alert, touching on the

lockout or alert in the list expands the view of that lockout or

alert, as shown in Fig. 27 and 28.

Fig. 25. Lockout history example shown.

17 65-0303—05

Page 18

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Fig. 27. Control expanded lockout detail.

Fig. 28. Control expanded alert detail.

Operation Button

The operation button displays the SOLA Control running

operation, including setpoint and firing rate values. From this

page the user can change setpoints, manually control the

boiler’s firing rate, manually turn pumps on, view annunciation

information, and switch between hydronic heating loops

(Central Heat and Domestic Hot Water), as shown in Fig. 22. If

a password is required to change any of the settings on this

page, the user can press the Login button to enter the

password.

Fig. 29. Hydronic operation page shown.

Fig. 30. Programmable annunciation.

Annunciation information is shown in Fig. 23 and Fig 24.

65-0303—05 18

Fig. 31. Fixed annunciation.

Page 19

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

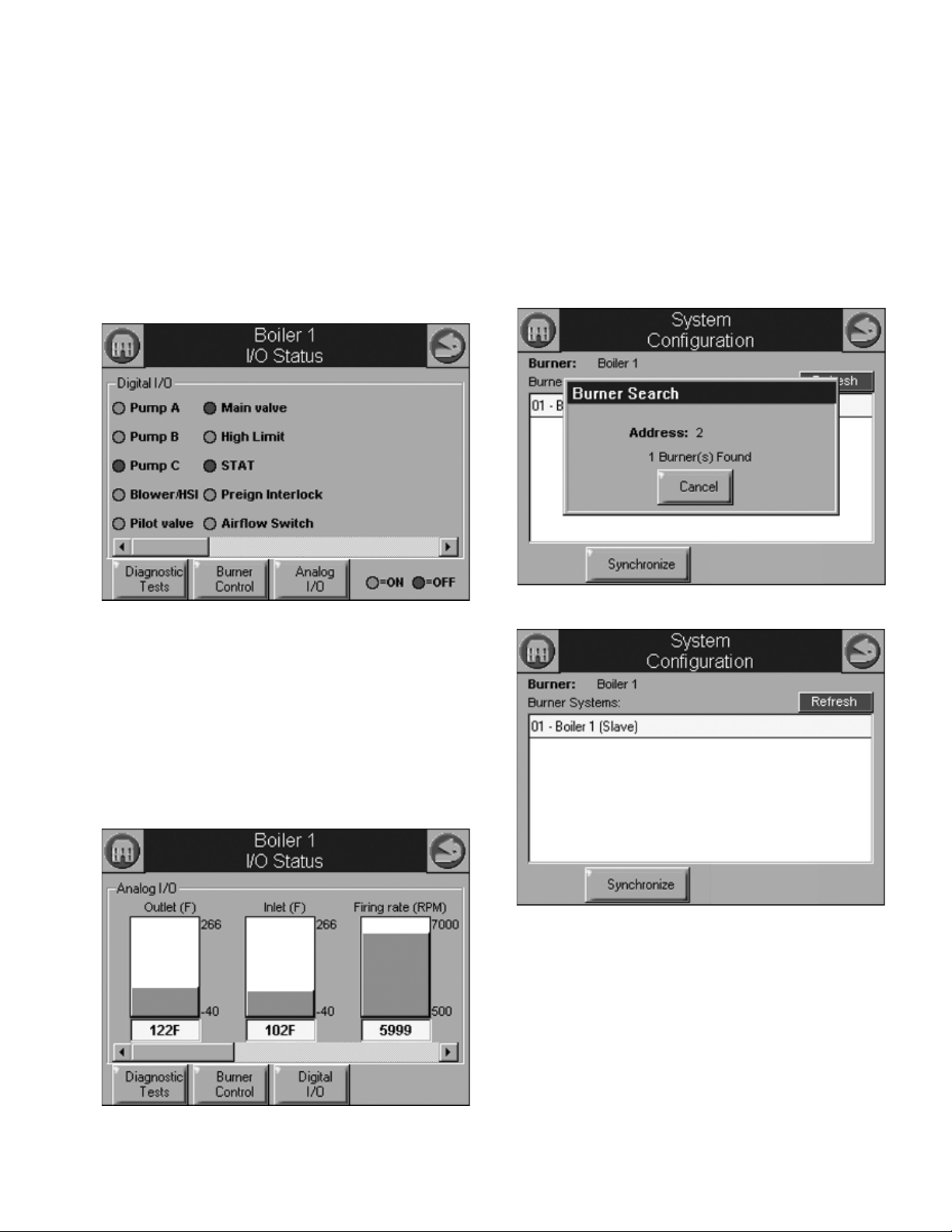

Diagnostics Button

The Diagnostics button displays analog and digital I/O status of

the SOLA Control. A snapshot of the diagnostic status is

displayed and updated once per second as it changes in the

control. See “R7910A or R7911 Diagnostics” on page 44 for

more information about this status.

The digital I/O data is displayed as LEDs that are either on

(green) or off (red) (See Fig. 23). Not all digital I/O can be

displayed at the same time on the page, so a horizontal scroll

bar is used to move the view left and right to show all digital

I/O data.

System Configuration (S7999B OI DisplayOnly)

The OI Display has some functions related to general

configuration for the control in the end user installation.

Pressing the Display Refresh button invokes a search

procedure (see Fig. 34). A new R7910A Hydronic Control or

R7911 Steam Control is identified by “Unknown” status next to

its name in the boiler system list (see Fig. 35). “Unknown”

indicates that configuration data has not been retrieved from

the control yet.

Fig. 32. Diagnostic page (digital I/O).

The control analog I/O can also be viewed on the OI Display. A

snapshot of the diagnostic status is displayed and updated as

it changes in the control.

The analog I/O data is displayed as bar charts with I/O level

represented in the I/O range (see Figure 24.) Analog I/O that is

not enabled for the installation displays a blank I/O level. Not

all analog I/O can be displayed at the same time on the page,

so a horizontal scroll bar is used to move the view left and right

to show all analog I/O status.

Fig. 34. System refresh.

Fig. 35. System configuration page.

The control connected to the Modbus network is indicated to

the user after the search procedure has concluded.

Once the control is located it must be synchronized with the OI

Display before it can be displayed. New controls are not

displayed on the Home page until this synchronization (see

below) is performed.

Fig. 33. Diagnostics page (analog I/O).

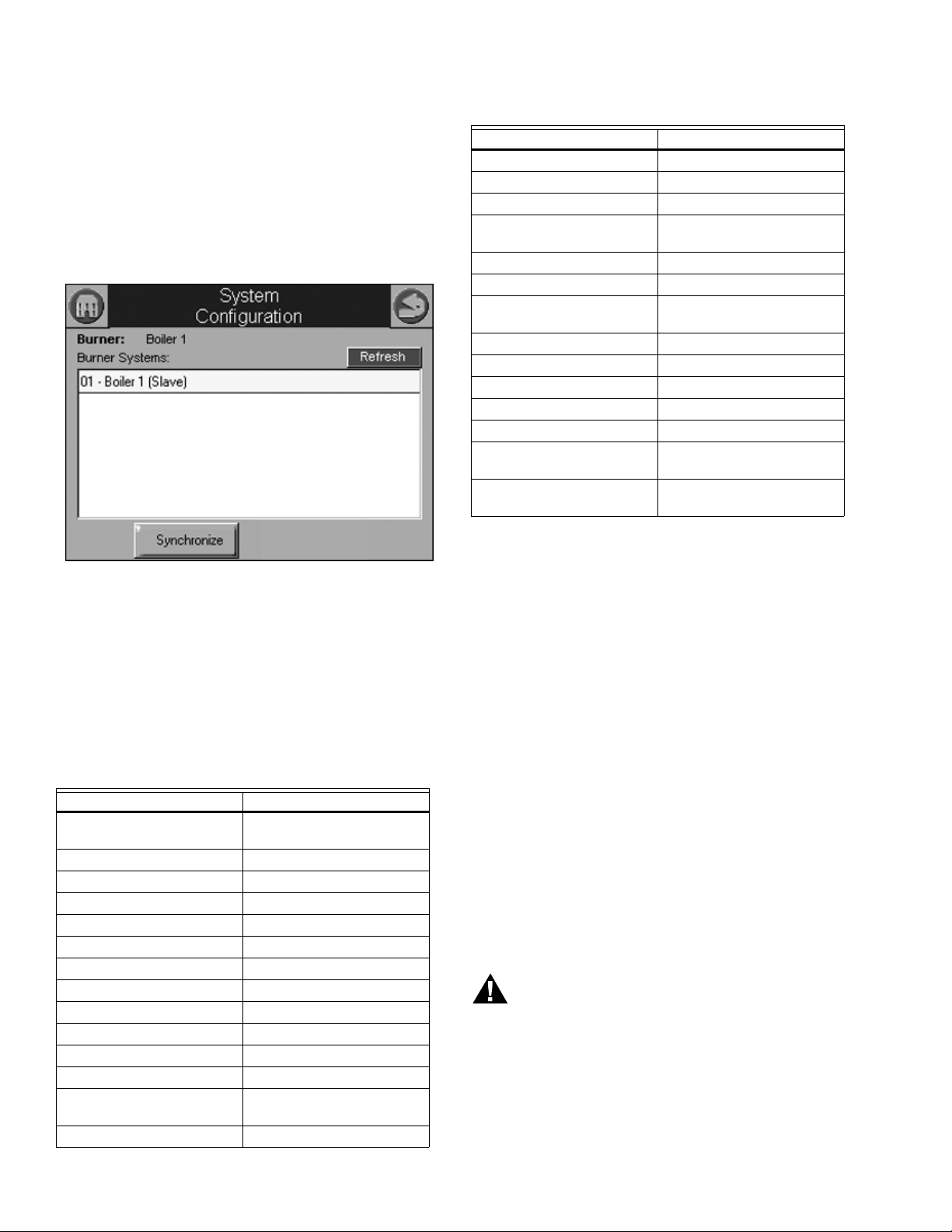

System Synchronization (S7999B OI Display Only)

The user can manually synchronize configuration data from the

connected controls at any time.

19 65-0303—05

Page 20

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

WARNING

A new control is visible when configuration and status data is

gathered from it. This collection procedure takes a few

minutes. The control is marked as “Unknown” when no

configuration information exists. Normally, control configuration

data collection only needs to be performed when the control is

initially installed. However, a re synchronization is necessary

after the OI Display is reset. See Fig. 36.

The user presses the Synchronize button to begin

synchronization with the control. See Fig. 36.

Fig. 36. System synchronization.

Status of the synchronization is reflected in the dialog box. The

synchronization can be aborted by selecting the Cancel button.

Table 5. Functional Configuration Groups.

Hydronic Control Steam Control

T-Rise Limit

Heat Exchanger High Limit

Anti-condensation Burner Control Flame Failure

Frost Protection

Configuration

Annunciation Configuration Fan Configuration

Burner Control Interlocks Lead Lag Configuration

Burner Control Timings and

Rates

Burner Control Ignition

Burner Control Flame Failure

System Configuration

Fan Configuration

Sensor Configuration

Lead Lag Slave

Configuration

Lead Lag Master

Configuration

Most of this configuration is performed by either the contractor/

installer or at Honeywell. Each functional group is displayed on

the Configuration menu page.

Parameters in functional groups that are not applicable for the

installation can be ignored. In some cases, features in a

functional group are disabled by default and are enabled when

needed for the installation.

System Configuration

Configuration

The SOLA Control can be configured from the OI Display. The

control configuration is grouped into the functional groups seen

in Table 5.

Table 5. Functional Configuration Groups.

Hydronic Control Steam Control

System Identification and

Access

CH - Central Heat Steam Configuration

Outdoor Reset Modulation Configuration

DHW - Domestic Hot Water Pump Configuration

DHW Storage

DHW Plate

Warm Weather Shutdown

Demand Priority

Modulation Configuration Statistics Configuration

Pump Configuration Stack Limit

Statistics Configuration Annunciation Configuration

High Limit Burner Control Interlocks

Stack Limit Burner control Timings and

Delta T Limits

Steam Identification and

Access

Rates

R7910A HYDRONIC CONTROL, R7911 STEAM CONTROL CONFIGURATION PARAMETERS

The following pages list the configuration parameters available

for the R7910A or R7911 installed.

NOTE: Individual Configuration pages may differ from this

text as features are added or amended by Honeywell.

A password is required to make changes to the Configuration

Parameters. The SOLA Control will be in a Lockout 2 “waiting

for safety data verification” as received or will go to a Lockout 2

when changes are made to the safety data.

Explosion Hazard.

Improper configuration can cause fuel buildup and

explosion.

Improper user operation may result in PROPERTY

LOSS, PHYSICAL INJURY or DEATH.

The OI Display used to change parameters, must be

attempted by only experienced and/or licensed

burner/boiler operators and mechanics.

65-0303—05 20

Page 21

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Central Heat Parameters (R7910A Hydronic Control Only)

Table 8 displays Central Heat Hydronic Control configuration

parameters.

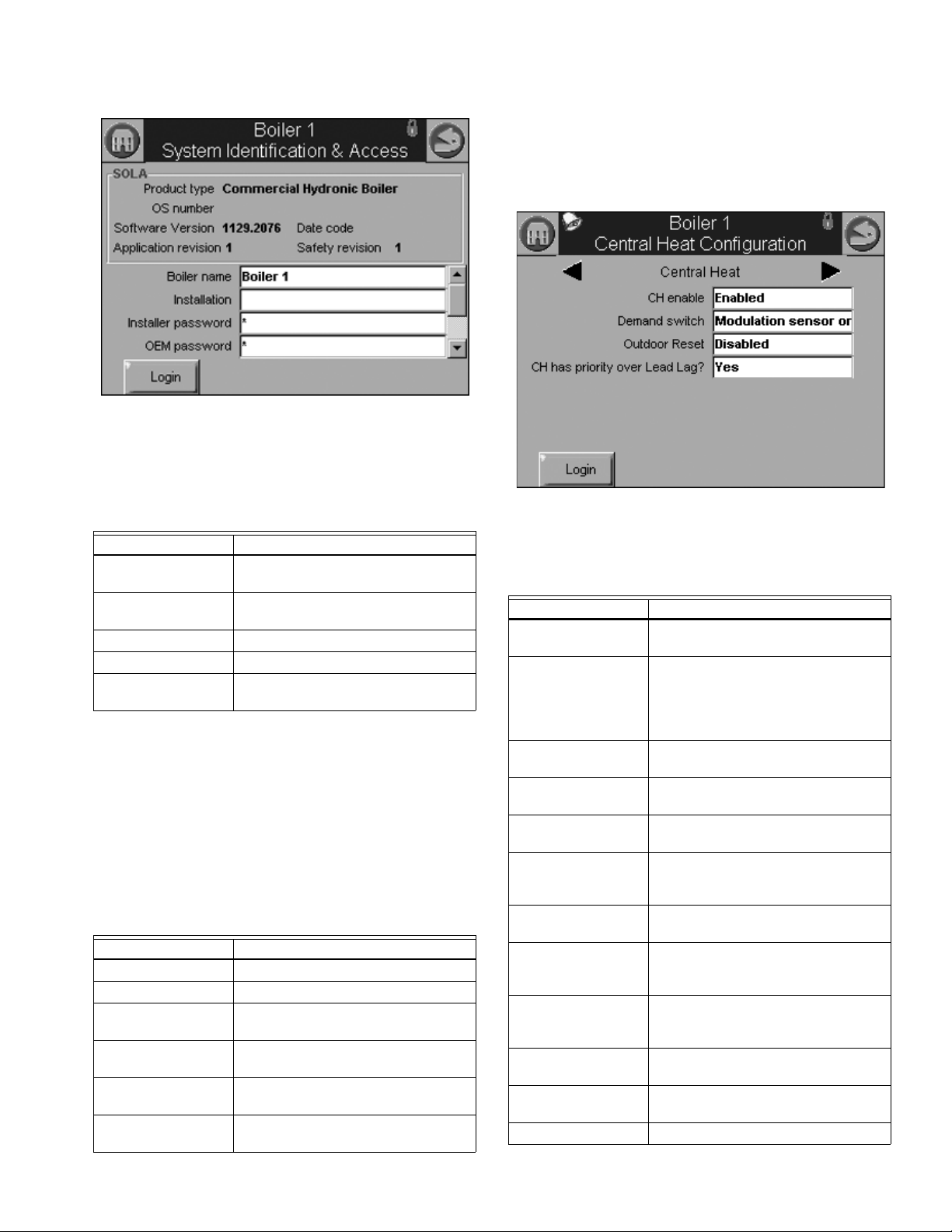

Fig. 37. System identification and access configuration.

(Hydronic Screen Shown.)

Table 6 displays System Identification and Access parameters.

Table 6. System Identification and Access Parameters.

Parameter Comment

Boiler Name Name to identify boiler (up to 20

characters)

Installation Notes regarding installation (up to 20

characters)

Installer password Change installer password setting

OEM password Change OEM password setting

Factory Data OEM name to associate with boiler

(up to 20 characters)

When the burner name is changed, the name is saved in the

R7910A or R7911 and displayed in the title of all pages that

zoom into the control.

Default parameter settings for installer and Honeywell

passwords are “sola” and “solaoem,” respectively. These

passwords most likely have been changed by Honeywell.

Factory Data gives Honeywell an option to display a brand

name other than Sola on this configuration page. Additional

information displayed on this page is listed in Table 7.

Table 7. System Identification Information.

Status Comment

Product Type Type of product that the burner is

OS Number Model number associated with burner

Software Version Version of software running in the

R7910A or R7911

Date Code Date when R7910A or R7911 was

assembled

Application Revision Version of application data in the

R7910A or R7911

Safety Revision Revision of safety data in the R7910A

or R7911

Fig. 38. Central Heat hydronic configuration.

Table 8. Central Heat Hydronic

Configuration Parameters.

Parameter Comment

CH enable Disable or Enable Central Heating

Loop

Demand switch Sensor for Central Heat demand:

Sensor only

Sensor & STAT terminal

Sensor & Remote Stat

LCI & Sensor

Outdoor reset Enabled

Disabled

CH has priority over

Lead Lag

Setpoint source Local

Setpoint Setpoint for normal Central Heat

Time of day setpoint Setpoint when Time Of Day switch is

Off hysteresis Differential above setpoint when boiler

On hysteresis Differential from setpoint when boiler

4 mA water

temperature

20 mA water

temperature

Modulation sensor Outlet sensor, Inlet sensor, S5 (J8-11)

Yes, No, Cancel

S2 (J8-6) 4-20mA

modulation:

-40 °F to 266 °F (-40 °C to 130 °C)

on. -40 °F to 266 °F (-40 °C to 130 °C)

is turned off.

32 °F to 266 °F (0 °C to 130 °C)

is turned on. 32 °F to 266 °F (0 °C to

130 °C)

-40 °F to 266 °F (-40 °C to 130 °C)

-40 °F to 266 °F (-40 °C to 130 °C)

21 65-0303—05

Page 22

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Table 8. Central Heat Hydronic

Configuration Parameters. (Continued)

Parameter Comment

Modulation Rate

Sensor

P-gain Gain applied for the P portion of the

I-gain Gain applied for the I portion of the

D-gain Gain applied for the D portion of the

Hysteresis step time Time between hysteresis step

Local

PID equation

0-400

PID equation

0-400

PID equation

0-400

changes: 0-600 seconds (0=Disable

hysteresis stepping)

Table 9. Steam Configuration Parameters

Parameter Comment

Steam pressure on

hysteresis

Steam hysteresis

step time

Steam P Gain Gain applied for the P portion of the

Steam I Gain Gain applied for the I portion of the PID

Steam D Gain Gain applied for the D portion of the

Steam 4-20 ma

remote control

Differential from setpoint when boiler

is turned on.

Adjustable 0 to 15 or 0 to 150 (sensor

dependant)

Time between hysteresis changes 0 to

600 seconds (0=disable)

PID equation

0-400

Equation - 0-400

PID equation

0-400

uses 4-20ma remote control function to

control either the setpoint or

modulation for Steam

Disable, setpoint, modulation

Outdoor Reset Parameters (R7910A Hydronic Control Only)

Table 10 displays Outdoor Reset configuration parameters.

Pressing the left or right arrow displays Lead Lag, which lists

the same parameters.

Fig. 39. R7911 Steam Configuration.

Table 9. Steam Configuration Parameters

Parameter Comment

Steam enable Disable/enable steam feature

Steam demand

source

Steam pressure

setpoint

Steam time of day

setpoint

Minimum steam

pressure

Steam pressure off

hysteresis

65-0303—05 22

Sensor and LCI

Sensor and Remote Stat

Sensor and Stat Terminal

Sensor Only

Setpoint for normal modulation

Adjustable 0 to 15 or 0 to 150 (sensor

dependant)

Setpoint when TOD switch on

Adjustable 0 to 15 or 0 to 150 (sensor

dependant)

Establishes setpoint for the 4ma. input.

Adjustable 0 to 15 or 0 to 150 (sensor

dependant)

Differential below setpoint when boiler

is turned off

Adjustable 0 to 15 or 0 to 150 (sensor

dependant)

Fig. 40. Outdoor reset configuration.

Table 10. Outdoor Reset Configuration Parameters.

Parameter Comment

Maximum outdoor

temperature

Minimum outdoor

temperature

Low water

temperature

Minimum water

temperature

Maximum off point -40 °F to 266 °F (-40 °C to 130 °C)

-40 °F to 266 °F (-40 °C to 130 °C)

-40 °F to 266 °F (-40 °C to 130 °C)

-40 °F to 266 °F (-40 °C to 130 °C)

-40 °F to 266 °F (-40 °C to 130 °C)

Page 23

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Domestic Hot Water (DHW) Configuration Parameters (R7910A Hydronic Control Only)

Table 11 displays Domestic Hot Water (DHW) configuration

parameters.

Fig. 41. Domestic Hot Water (DHW) configuration.

Table 11. Domestic Hot Water (DHW)

Configuration Parameters. (Continued)

Parameter Comment

Hysteresis step

time

DHW priority vs CH Which system has priority:

DHW priority vs

Lead Lag

DHW P-gain Gain applied for the P portion of the

DHW I-gain Gain applied for the I portion of the

DHW D-gain Gain applied for the D portion of the

___hour ___min ___sec

Central Heat over Domestic Hot

Water, or

Domestic Hot Water over Central Heat

Which system has priority:

Lead Lag over Domestic Hot Water,

Domestic Hot Water over Lead Lag

PID equation

0-400

PID equation

0-400

PID equation

0-400

DHW Storage Configuration

Table 12 displays DHW Storage configuration parameters.

Table 11. Domestic Hot Water (DHW)

Configuration Parameters.

Parameter Comment

Enable Disable or Enable Domestic Hot

Water Loop

Demand switch Sensor for Central Heat demand:

DHW sensor only,

DHW sensor & Remote Stat,

DHW switch & inlet sensor, or

DHW switch & outlet sensor

Priority source Which system has priority:

Disabled or

Heat Demand

Priority method Boost during priority time

Modulation sensor DHW Sensor

Setpoint -40 °F to 240 °F (-40 °C to 115 °C)

Time of day setpoint Setpoint when Time Of Day switch is

Off hysteresis Differential above setpoint when boiler

On hysteresis Differential from setpoint when boiler

DHW priority

override time

Drop after priority time

Outlet Sensor

Inlet Sensor

Auto: DHW (S6) or Inlet Sensor

Auto: DHW (S6) or Outlet Sensor

on. -40 °F to 240 °F (-40 °C to 115 °C)

is turned off. -40 °F to 240 °F (-40 °C

to 115 °C)

is turned on.

2 °F to 234 °F (-16 °C to 112 °C)

___hour ___min ___sec

Table 12. DHW Storage Configuration Parameters.

Parameter Comment

DHW storage

enable

Storage time ___hour ___min ___sec

Setpoint -40 °F to 266 °F (-40 °C to 130 °C)

Off hysteresis -0 °F to 180 °F (-17 °C to 82 °C)

On hysteresis -0 °F to 180 °F (-17 °C to 82 °C)

Enabled, Disabled

DHW Plate Heat Exchanger Configuration

Table 13 displays DHW Plate Heat Exchanger configuration

parameters.

Table 13. DHW Plate Heat Exchanger

Configuration Parameters.

Parameter Comment

Tap detect degrees -0 °F to 180 °F (-17 °C to 82 °C)

Tap detect on

recognition time

Tap detect on

threshold

Tap detect minimum

on time

Tap stop inlet-DHW

degrees

Tap stop outlet-Inlet

degrees

___hour ___min ___sec

-0 °F to 180 °F (-17 °C to 82 °C)

___hour ___min ___sec

-0 °F to 180 °F (-17 °C to 82 °C)

-0 °F to 180 °F (-17 °C to 82 °C)

23 65-0303—05

Page 24

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Table 13. DHW Plate Heat Exchanger

Configuration Parameters. (Continued)

Parameter Comment

Plate preheat

setpoint

Plate preheat on

recognition time

Plate preheat on

hysteresis

Plate preheat off

hysteresis

Plate preheat detect

on threshold

Plate preheat detect

off threshold

Plate preheat

minimum on time

Plate preheat delay

after tap

-40 °F to 266 °F (-40 °C to 130 °C)

___hour ___min ___sec

-0 °F to 180 °F (-17 °C to 82 °C)

-0 °F to 180 °F (-17 °C to 82 °C)

-0 °F to 180 °F (-17 °C to 82 °C)

-0 °F to 180 °F (-17 °C to 82 °C)

___hour ___min ___sec

___hour ___min ___sec

Warm Weather Shutdown Configuration

Table 14 displays Warm Weather Setpoint configuration

parameters.

Table 14. Warm Weather Setpoint

Configuration Parameters.

Parameter Comment

Enable Enabled, disabled

Setpoint -40 °F to 266 °F (-40 °C to 130 °C)

Demand Priority Configuration Parameters

Fig. 42 displays R7910A Hydronic Control Demand Priority

configuration options. Press the arrows to change the priority

order.

Fig. 42. Demand priority configuration.

65-0303—05 24

Page 25

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Modulation Configuration Parameters

Table 15 displays R7910A Hydronic Control Modulation

configuration parameters.

Fig. 43. Modulation configuration.

Table 15. R7910A Hydronic Control Modulation Configura-

tion Parameters.

Steam Modulation Configuration Parameters

Table 16 displays R7911 Steam Modulation Configuration

parameters.

Fig. 44. Steam modulation configuration.

Table 16. R7911 Steam Modulation Configuration

Parameters.

Parameter Comment

CH maximum

modulation rate

DHW maximum

modulation rate

Minimum modulation

rate

CH forced rate time 0-600 seconds

CH forced rate RPM or %

DHW forced rate time 0-600 seconds

DHW forced rate RPM or %

CH slow start enable Enabled

DHW slow start

enable

Slow start degrees -40 °F to 266 °F (-40 °C to 130 °C)

Slow start ramp RPM /minute or %/minute

0-10/4-20 mA Output

hysteresis

RPM or %

RPM or %

RPM or %

Disabled

Enabled

Disabled

Parameter Comment

CH maximum

modulation rate

Minimum modulation

rate

CH forced rate time 0-600 seconds

CH forced rate RPM or %

0-10/4-20 mA Output

hysteresis

RPM or %

RPM or %

25 65-0303—05

Page 26

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Pump Configuration Parameters

Table 17 displays Pump configuration parameters. Use the left

and right arrows to switch between Central Heat, Boiler, DHW,

System, Auxiliary 1, and Auxiliary 2 pumps. The parameters

are the same for all pumps.

Pressing the Advanced Settings button brings up a number of

other advanced configuration options for each pump. Press the

Control Settings button to return to the screen shown in Fig.

45.

Fig. 45. Pump configuration.

Table 17. Pump Configuration Parameters for

R7910A Hydronic System.

Parameter Comment

Pump control Auto

On

Pump output Pump A

Pump B

Pump C

None

Pump start delay ___hour ___min ___sec

Overrun time ___hour ___min ___sec

*Table 61 on page 53 has more parameters listed.

NOTE: The R7911 Steam Control does not have pumps, but

the outputs are available to operate air dampers or

accessories. CH Pump, Boiler Pump and System

Pump are used for these output options.

Table 17a. Pump Configuration Parameters for R7911

Steam Modulation Configuration Parameters.

Parameter Comment

Auxiliary pump control Auto

On

Auxiliary pump is on when CH pump is ON

Slave command

Auxiliary pump output Pump A

Pump B

Pump C

None

Boiler pump control Auto

On

Boiler pump output Pump A

Pump B

Pump C

None

Boiler pump overrun time 0-600 seconds

0 = Not configured

CH pump control Auto

On

CH pump output Pump A

Pump B

Pump C

None

CH pump overrun time 0-600 seconds

0 = Not configured

System pump control Auto

On

System pump output Pump A

Pump B

Pump C

None

System pump ourrun time 0-600 seconds

0 = Not configured

Pump exercise time 0-600 seconds

0= Not configured

65-0303—05 26

Page 27

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Statistics Configuration Parameters

Table 15 displays Statistics configuration parameters.

Fig. 46. Statistics configuration.

Table 18. Statistics Configuration Parameters.

Parameter Comment

Auxiliary pump cycles 0-999,999

Boiler pump cycles 0-999,999

Burner cycles 0-999,999

Burner run time 0-999,999

CH pump cycles 0-999,999

DHW pump cycles 0-999,999

System pump cycles 0-999,999

Auxiliary 2 pump

cycles

0-999,999

High Limit Configuration Parameters (R7910A Hydronic Control Only)

Table 19 displays outlet high limit configuration parameters.

Fig. 47. High Limits configuration.

Table 19. High Limit Configuration Parameters.

Parameter Comment

DHW high limit Enabled

Disabled

DHW high limit

response

DWH high limit

setpoint

Outlet high limit Enabled

Outlet high limit

response

Outlet high limit

setpoint

Recycle & hold

Lockout

-40 °F to 266 °F (-40 °C to 130 °C)

Disabled

Recycle & hold

Lockout

-40 °F to 266 °F (-40 °C to 130 °C)

27 65-0303—05

Page 28

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Stack Limit Configuration Parameters

Table 20 displays stack limit configuration parameters.

Fig. 48. Stack Limit configuration.

Table 20. Stack Limit Configuration Parameters.

Parameter Comment

Stack limit Enabled dual sensor safety

Enabled single sensor non safety

Disabled

Stack limit delay ___hour ___min ___sec

Stack limit response Lockout

Recycle & delay

Stack limit setpoint 32 °F to 266 °F (0 °C to 130 °C)

Delta T Limit Configuration Parameters (R7910A Hydronic Control Only)

Table 21 displays other limit parameters. Use the left and right

arrows to switch between Inlet to Outlet Flow and Exchanger to

Outlet Flow. The parameters are the same for all pumps.

Fig. 49. Delta T Limit configuration.

Table 21. Delta T Limit

Configuration Parameters.

Parameter Comment

Delta T enable Enabled

Delta T degrees 0 °F to 234 °F (-17 °C to 112 °C)

Delta T delay ___hour ___min ___sec

Delta T response Recycle & delay

Delta T retry limit 0–100

Delta T rate limit

enable

Delta T inverse limit

time

Delta T inverse limit

response

Disabled

Recycle & Delay with retry limit

Lockout

Enabled

Disabled

___hour ___min ___sec

Recycle & delay

Recycle & delay with retry limit

Lockout

65-0303—05 28

Page 29

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

T-Rise Limit Configuration Parameters

Table 22 displays T-Rise limit parameters.

Table 22. T-Rise Limit Configuration Parameters.

Parameter Comment

Outlet T-rise enable Enabled

Disabled

Heat exchanger Trise enable

T-rise degrees 0 °F to 234 °F (-17 °C to 112 °C)/sec

T-rise response Recycle & delay

T-rise retry limit 0 to 100

T-rise delay ___hour ___min ___sec

Enabled

Disabled

Recycle & delay with retry limit

Lockout

Heat Exchanger High Limit Configuration Parameters

Table 23 displays T-Rise limit parameters.

Table 23. Heat Exchanger High Limit

Configuration Parameters.

Parameter Comment

Heat exchanger high

limit enable

Heat exchanger high

limit setpoint

Heat exchanger high

limit response

Heat exchanger retry

limit

Heat exchanger high

limit delay

Enabled

Disabled

-40 °F to 266 °F (-40 °C to 130 °C)

Recycle & delay

Recycle & delay with retry limit

Lockout

0 to 100

___hour ___min ___sec

Anti-Condensation Configuration

Parameters (R7910A

Control Only

Table 24 displays anti-condensation parameters. Use the left

and right arrows to switch between Central Heat, Domestic Hot

Water, Frost Protection, and Priority parameters.

Fig. 50. Anti-condensation configuration.

Table 24. Anti-Condensation Configuration Parameters.

Parameter Comment

CH Enable Enabled

CH Setpoint -40 °F to 266 °F (-40 °C to 130 °C)

DHW Enable Enabled

DHW Setpoint -40 °F to 266 °F (-40 °C to 130 °C)

Frost Protection

Enable

Anticondensation

Priority

)

Disabled

Disabled

Enabled

Disabled

Anticondensation is more important

than (check those that apply):

Stack limit

Delta T limit

Slow start

Forced rate

Outlet high limit

Hydronic

29 65-0303—05

Page 30

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Frost Protection Parameters (R7910A Hydronic Control Only)

Table 25 displays frost protection parameters.

Fig. 51. Frost Protection configuration.

Table 25. Frost Protection Configuration Parameters.

Annunciation Configuration Parameters

Table 26 displays annunciation configuration parameters.

Fig. 52. Annunciation configuration example.

Table 26. Annunciation Configuration Parameters.

Parameter Comment

CH frost protection

enable

DHW frost protection

enable

Lead Lag frost

protection enable

Outdoor frost

protection setpoint

Lead Lag frost

protection rate

CH pump frost

overrun time

DHW pump frost

overrun time

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

-40 °F to 266 °F (-40 °C to 130 °C)

(applicable for CH only)

___%

___hour ___min ___sec

___hour ___min ___sec

Parameter Comment

Annunciation enable Enabled

Disabled

Annunciator (1–8)

location

Annunciator (1–8)

short name

Annunciator (1–8)

name

01 - Annunciator 1

02 - Annunciator 2

03 - Annunciator 3

04 - Annunciator 4

05 - Annunciator 5

06 - Annunciator 6

07 - Annunciator 7

08 - Annunciator 8

PII - Pre-Ignition ILK

LCI - Load Control Input

ILK - Interlock

Up to 3 characters

Up to 20 characters

Safety Configuration Parameters

Table 27 through 30 display safety parameters.

NOTE: Login is required to change Safety Parameters and

the SOLA Control will go to a Lockout 2 “waiting for

safety data verification” when a change is made.

65-0303—05 30

Page 31

S7999B, S7999C SOLA LOCAL OPERATOR INTERFACE

Fig. 53. Burner Control Interlocks control. Fig. 54. Burner Control Timings and Rates configuration.

Table 27. Burner Control

Interlocks Configuration.

Parameter Comment

PII enable Enabled

Disabled

LCI enable Enabled

Disabled

Interrupted air switch

(IAS) enable

Enable during purge and ignition

Disabled

Enable during purge

Interlock (ILK) start

check enable

ILK/IAS open

response

ILK bounce detection