7800 SERIES

S7800A1142 Keyboard Display Module

PRODUCT DATA

The S7800A1142 KDM offers the following technical

advancements to the 7800 SERIES devices:

• Compatible with installed Honeywell 7800 SERIES

systems.

• When used with the new 7800 SERIES with Valve Proving

Feature, the KDM allows for programming the Valve

Proving Control feature and timing (Pass Code protected

feature).

• Allows for naming the S7830 Expanded Annunciator

terminals to match your system drawings. (Displayed

message only.)(Pass Code protected feature.)

• A three screen two-row by twenty-column readout set of

“Call Service” (Business Card) alpha/numeric directions

can be displayed instead of the standard lockout display

message. (Pass Code protected feature). This “business

card” can be cloned to other displays to save setup time.

• Enable ModBus Communication feature.

APPLICATION

The S7800A1142 Keyboard Display Module (KDM) provides

current system status along with first-out annunciation and

system diagnosis using a two-row by twenty-column readout.

The KDM provides local or remote annunciation of operation

and fault information, remote reset, report generation, burner

control data and diagnostic information. The KDM is part of

the 7800 SERIES of microprocessor-based burner controls for

gas, oil, coal or combination fuel single burner applications.

The 7800 SERIES is programmed to provide a level of safety,

functional capabilities and features beyond the capacity of

conventional controls.

The S7800A1142 is required to program the Valve Proving

feature of select 7800 Series devices.

Contents

Application ........................................................................ 1

Features ........................................................................... 2

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

Wiring ............................................................................... 4

Troubleshooting ................................................................ 12

Hold and Fault Message Summary .................................. 16

Appendix A:Display Setup ............................................... 25

Display Setup—CLONE ............................... 25

The Business Card (Call Service) and Expanded Annunciator

can be made up using:

• Capital letters (A through Z).

• Lower case letters (a through z).

• Numbers (1 through 0).

• Symbols (!, @, #, $,%, etc.).

• Spanish symbols.

Programming can be done with the S7800 KDM mounted on a

7800 SERIES Relay Module or with a 13 Vdc power source

connected to the KDM through the 203541 5-wire connector.

Since your Business Card (Call Service) S7800A1142 will be

left at the job site, programming your personal three-number

password and personal lockout message can be set up ahead

of time without being connected to a 7800 SERIES device. A

clone function allows you to make multiple Business Cards

from the original display.

Contents

Appendix A:Display Setup—Clear All .............................. 27

Display Setup—CEA Assign ......................... 29

Display Setup—CS ON/OFF ........................ 31

Display Setup—CS EDIT .............................. 32

Appendix B:Valve Proving System ................................... 34

Setup of Valve Proving Function .................. 34

Appendix C: Setup of Post Purge ..................................... 36

Appendix D: Expanded Annunciator Tables ..................... 37

Appendix E: ModBus Function ......................................... 38

65-0288-1

7800 SERIES S7800A1142 KEYBOARD DISPLAY MODULE

WARNING

Mounting KDM on 7800 SERIES Relay Module.

1. Align the two interlocking ears of the KDM with the two

mating slots on the 7800 SERIES Relay Module. See

Fig. 2.

Fig. 2. Keyboard Display Module mounting.

2. Insert the two interlocking ears into the two mating slots

and, with a hinge action, push on the lower corners of

the KDM to secure it to the 7800 SERIES Relay Module.

3. Make sure the KDM is firmly in place.

4. Drill the pilot holes for the mounting screws.

5. Cut holes in the door panel for the interlocking ears and

the two plug-in connectors.

6. Mount the KDM, securing it with the two screws provided

in the KDM bag assembly.

Remote Display Mounting Bracket

Use the 203765 Remote Display Mounting Bracket when

mounting the KDM on a wall or remote location:

1. Use the 203765 Remote Display Mounting Bracket as a

template to mark the four screw locations.

2. Drill the pilot holes for the four mounting screws.

3. Mount the 203765 Remote Display Mounting Bracket by

securing the four no. 6 screws (M3.5 x 0.6). See Fig. 4.

4. Mount the KDM by aligning the two interlocking ears with

the two mating slots on the remote mounting bracket.

5. Insert the two interlocking ears into the two mating slots.

6. Push on the lower corners of the KDM to secure it to the

remote mounting bracket.

7. Make sure the KDM is firmly in place.

Remote Mounting KDM

The KDM can be mounted either on the face of a panel door or

on other remote locations. See Fig. 3. When mounting the

KDM on the face of a door panel, closely follow these

instructions:

Door Panel Mounting

Fig. 3. Panel mounting of a Keyboard Display Module.

1. Select the location on the door panel for flush mounting.

2. Pay attention to the insertion dimensions of the two KDM

screws, two interlocking ears, and the two plug-in connections to allow for sufficient clearance.

3.

Use the KDM or Data ControlBus Module™ as a template

(Fig. 19) and mark the two screw locations, interlocking

ear locations and the two plug-in connector locations.

Fig. 4. Remote mounting of a Keyboard Display Module

using a 203765 Remote Display Mounting Bracket.

WIRING

Electrical Shock Hazard.

Can cause severe injury or death.

To prevent electrical shock and equipment damage,

disconnect the power supply from the main disconnect

before beginning installation. More than one disconnect

can be involved.

1. Refer to Fig. 5, 6, and 7 for proper wiring.

2. Make sure all wiring complies with all applicable

electrical codes, ordinances and regulations.

3. For recommended wire size and type, see Table 1.

65-0288-1 4

7800 SERIES S7800A1142 KEYBOARD DISPLAY MODULE

M24165

PILOT IGN 00:05

Fault History

M22872

PILOT IGN 00:10 H1

Fault Cycle 174

BURNER CONTROL

BURNER CONTROL

EDIT:

BACK

- ENTER -

_

+

EDIT:

BACK

- ENTER -

_

+

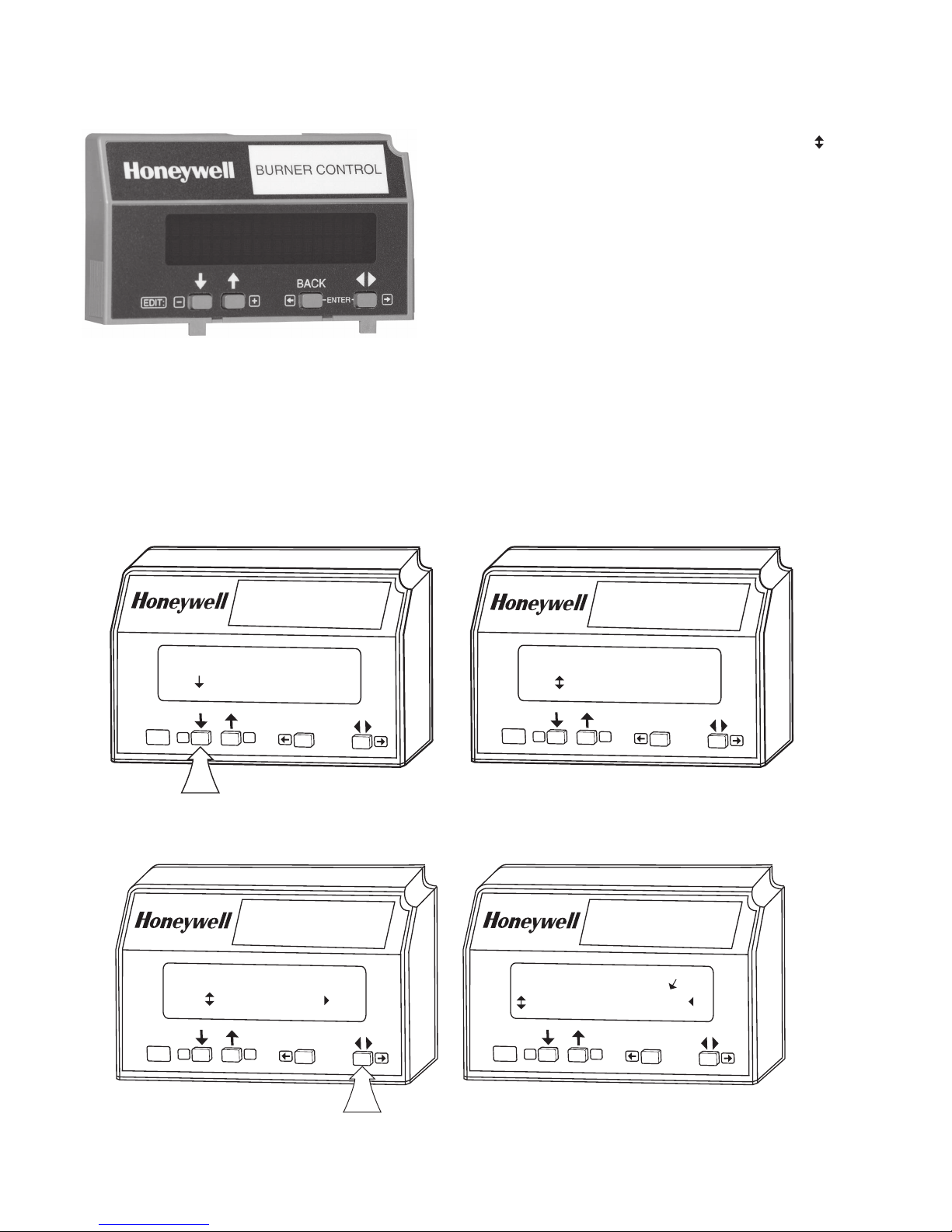

Fig. 9. S7800 Keyboard Display Module.

Keyboard Functions

The keyboard contains four push-buttons with separate

functions (SCROLL-down, SCROLL-up, MODE, and

CHANGE-LEVEL). The MODE and CHANGE-LEVEL, when

pressed together, provide a SAVE function. When in the Setup

Screen—Mode and Change Level serves as Menu or Enter.

1. Down-up arrow push-buttons. See Fig. 10. The down-up

arrow push-buttons are used to scroll through the

selectable messages. The double-headed arrow ( ),

which is located in the lower left position of the second

line of the display, represents the down-up push-buttons.

The down-up push-buttons can be pressed to display the

selectable messages one at a time or held down to scroll

through the selectable messages at the rate of two per

second. When the last item of the selectable message is

viewed, the display wraps around and displays the first

selectable message again.

2. The

push-button, see Fig. 11. The

push-button

is used to change between the first hierarchy of

selectable messages to a subset of selectable

messages. The

push-button can also be used to

change from a subset message to a first level selectable

message. The symbol located on the second line in the

lower right corner of the display, represents a subset of

selectable messages.

3. BACK push-button, see Fig. 12. Use the BACK

push-button to instantaneously switch the display from a

second-line selectable message to a second-line

preempted message. The sixty second time-out function

can also be used for this task. The BACK push-button

only works if there is a second-line preempted message

or a lockout message.

BURNER CONTROL

RUN

Total Cycles 333

_

EDIT:

BURNER CONTROL

RUN

Total Hours 1332

+

BACK

- ENTER -

EDIT:

_

+

BACK

- ENTER -

M22871

Fig. 10. Push-button function.

65-0288-1 8

Fig. 11.

push-button function.

7800 SERIES S7800A1142 KEYBOARD DISPLAY MODULE

STANDBY

Total Cycles nnn

M24043

BACK

ENTER

Edit:

- +

– Save Display

. . . Saving . . .

BURNER CONTROL

LOCKOUT 17 DI

Main Valve T9 = 0

_

EDIT:

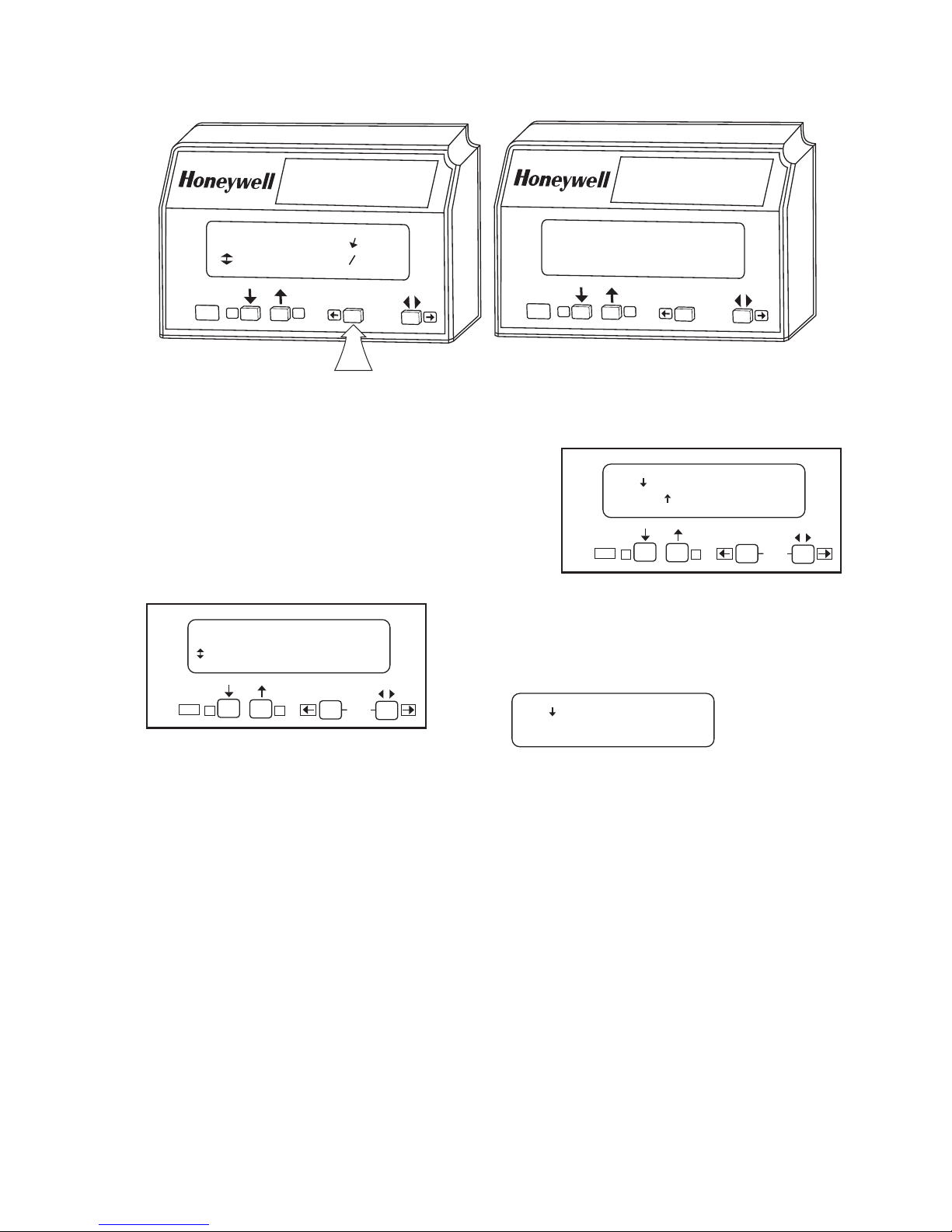

4. SAVE function, see Fig. 13, 14, and 15.

a. Enables users to identify the selectable 2nd line

message they want to view upon power restoration.

(See “Total Cycles” instead of “Flame Signal” for

example.) The second line selectable message is

restored to the most recently saved selection when

power returns.

b. Press the down-up arrows until the desired second

line is displayed. Press the ENTER function. (See

Fig. 13.)

BACK

+

- ENTER -

Fig. 12. BACK push-button function.

BURNER CONTROL

LOCKOUT 17

*Main Flame Fail*

_

E

DI

T

:

+

Edit:

-+

Fig. 14. Save Display/Exit screen

BACK

- ENTER -

M22873

– Save Display

– Exit

BACK

ENTER

M22874

Fig. 13. SAVE function.

c. The following Display will appear:

d. Press the to save the desired second line. Press-

ing the will EXIT without changing the second line.

Fig. 15. Save Display...Saving screen.

The second line of the display is now changed to the new

selected message.

9 65-0288-1

7800 SERIES S7800A1142 KEYBOARD DISPLAY MODULE

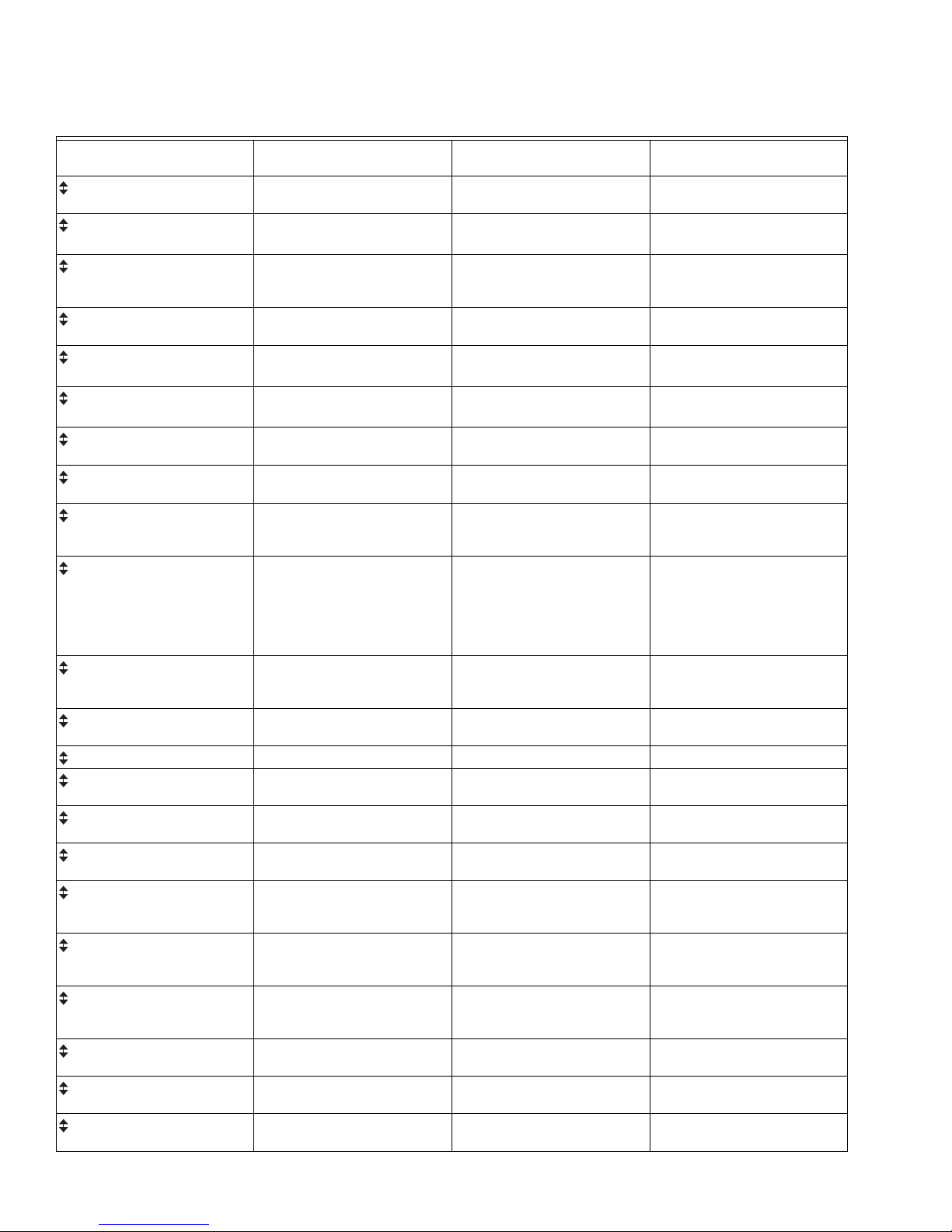

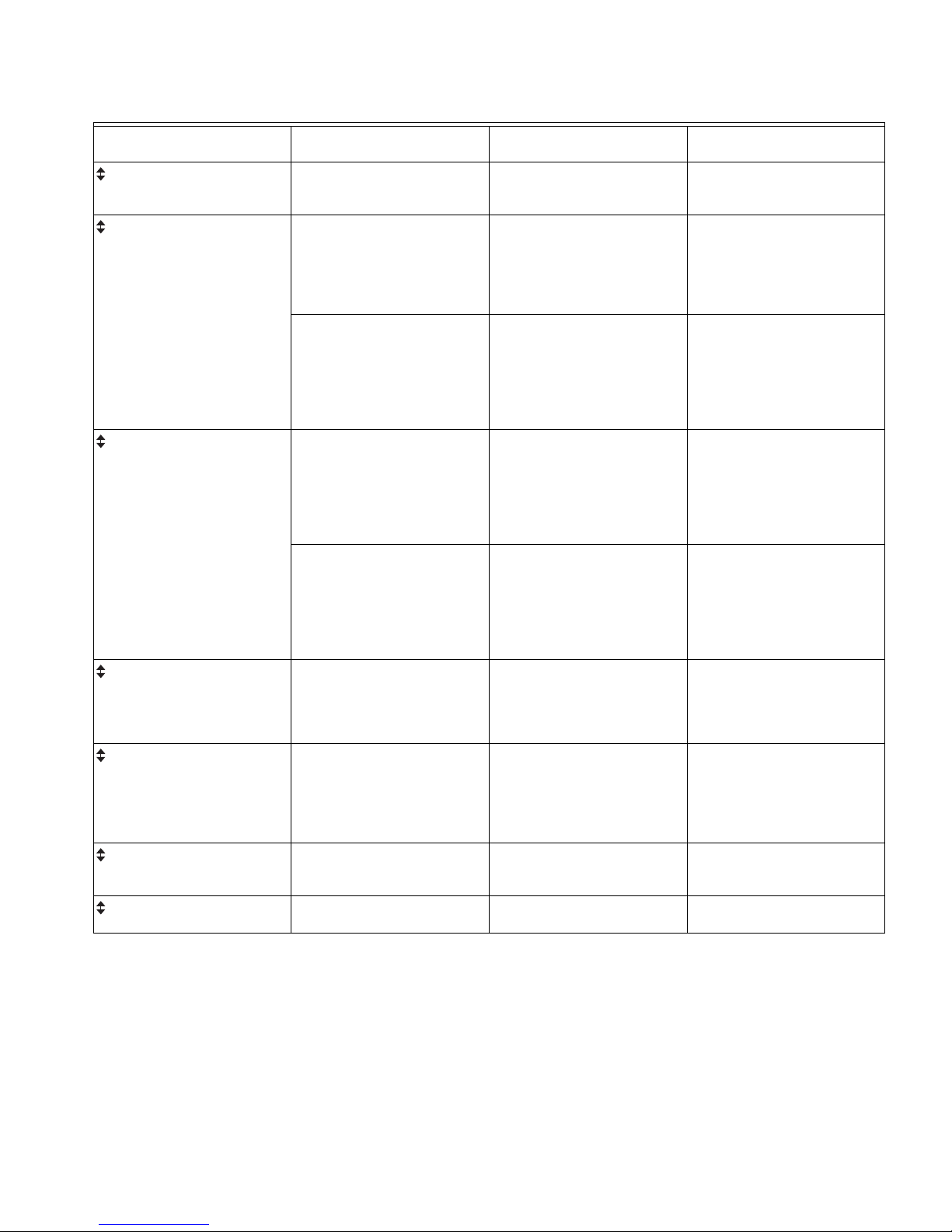

Table 3. Selectable Messages .

Selectable

Message/Display

Flame Signal

Total Cycles

Flame signal strength. 0 - 5.0 Vdc Flame Amp (+ and

Total number of equipment

Description

operating cycles.

Total Hours

Total number of equipment

operating hours.

Fault History >

(Six most recent faults)

Fault Cycle Ë

First level prompt for history

information. Has subset level.

Cycle when fault occurred. 0 - 99,999 cycles (250,000;

H1

Fault Hours Ë

Run hour when fault occurred. 0 - 99,999

H1

Fault Code Ë

H1

*Fault Message* Ë

Number that identifies the

reason for lockout.

Indicates cause of lockout. — —

H1

Sequence Message Ë

H1

Indicates where in the

sequence the lockout

occurred.

(Second Line Message) Ë

H1

Second line message explains

any further information that is

available from the 7800

SERIES or may be blank if

there is not a preemptive

second-line. H2…H6 etc.

Diagnostic Information >

First level prompt for

diagnostic information. Has

subset level.

Device

Device Suffix

Run/Test Sw.

OperControl T6

Interlock T7

Pilot Valve

Main Valve

Ignition

LowFire Sw

HighFireSw

Device type number. RM78XXX, R7140, or

Device suffix number. nnnn —

Position of Run/Test Switch. RUN or TEST Indicates if 7800 SERIES is in

Operating Control Input. = 1 or 0 Indicates if input is on or off,

Running/Lockout Interlock. = 1 or 0 Indicates if input is on (1) or off

T8 Pilot Valve. = 1 or 0 Indicates if output terminal is

T9 Main Fuel Valve. = 1 or 0 Indicates if output terminal is

T10 Ignition. = 1 or 0 Indicates if output terminal is

T18 Low Fire Switch. = 1 or 0 Indicates if input is on or off,

T19 High Fire Switch. = 1 or 0 Indicates if input is on or off,

PreIgn ILK T20 or T17b Pre-Ignition

Interlock

Possible States/ Range

(Terminals)

Comments

Flame relay pull-in and drop-

- (Com))

0 - 99,999

(250,000; 999,999c) cycles

0 - 99,999

(250,000; 999,999

c

) hours

out value 1.25 Vdc.

Cycle will be updated each

a

time main valve is energized.

Hour will be updated each time

a

main valve output is energized

for 60 minutes.

— —

—

999,999

c

) cycles

—

(250,000; 999,999

c

) hours

a

0 - 999 —

— —

— —

— —

—

EC78XXX

RUN or TEST mode.

energized or de-energized.

(0), energized or de-energized.

on or off, energized or

de-energized.

on or off, energized or

de-energized.

on or off, energized or deenergized.

energized or de-energized.

energized or de-energized.

= 1 or 0 Indicates if input is on or off,

energized or de-energized.

65-0288-1 10

Selectable

Message/Display

Val v/Start

Jumper 1

Jumper 2

Jumper 3

Amp Type

Flame Response

Purge Time

7800 SERIES S7800A1142 KEYBOARD DISPLAY MODULE

Table 3. Selectable Messages (Continued).

Possible States/ Range

Description

T21 Interrupted/Intermittent

Pilot Valve, First Stage Oil

= 1 or 0 Indicates if output is on or off,

(Terminals)

Comments

energized or de-energized.

Valve or Start Input.

Pilot Flame Establishing

Period (PFEP).

INTACT/CLIPPED Display shows state of PFEP

jumper. If jumper is intact,

7800 SERIES was 10 second

PFEP. If jumper is clipped,

7800 SERIES has 4 second

PFEP.

First Safety Time (for RM/

EC7850).

INTACT/CLIPPED Display shows state of First

Safety Time (EC7850) jumper.

If jumper is intact, EC7850 has

5 second First Safety Time. If

jumper is clipped, the EC7850

has 3 second First Safety

Time.

Pilot Valve. INTACT/CLIPPED Display shows state of Pilot

Valve (terminal no. 21). If

jumper is intact, RM7800G has

Intermittent Pilot Valve. If

jumper is clipped, RM7800G

has 15 or 30 second

Interrupted Pilot Valve.

Main Trial Time (for RM/

EC7850).

INTACT/CLIPPED Display shows state of Main

Trial Time (EC7850)Valve

(terminal no. 21). If jumper is

intact, EC7850 has 5 second

Main Trial Time. If jumper is

clipped, EC7850 has 3 second

Main Trial Time.

Start-up Airflow Switch (AFS)

check.

INTACT Disabled/CLIPPED

Enabled

Display shows state of Start-up

AFS check jumper. If jumper is

clipped, RM7800 AFS check is

enabled and if jumper is intact,

AFS check is disabled.

Defines type of amplifier

installed.

STANDARD/AMP-CHECK/

SHUTTER

Display shows type of flame

detection system installed (i.e.,

as STANDARD, AMP-CHECK/

AMPLI-CHECK™ and

SHUTTER/ Dynamic SelfChecking).

Amplifier Flame Failure

Response Time (FFRT) in

0.8 second, 1 second, 2

seconds, or 3 seconds

—

seconds.

Timing value of purge card. mm:ss Two seconds to 30 minutes.

a

European Approved Controls.

b

Pre-Ignition Interlock Terminal 17 or 20 is model dependent.

c

Valve Proving Device or RM7897.

d

The display values are as follows:

n represents a numbered value.

T represents the terminal number.

x represents the suffix letter of the Relay Module.

Expanded Annunciator Messages (Table 4)

The Expanded Annunciator (EA) may or may not be connected

because it is an optional device. If the EA is not connected, a

display message of “(EA not connected)” is shown. If the EA is

connected, display messages are shown; see Table 4 (Note

that 1 means ON and 0 means OFF). When accessing

Expanded Annunciator messages, follow the same operations

as used with the Selectable messages.

11 65-0288-1

Loading...

Loading...