S4565/S4575/S4585 SERIES

IGNITION CONTROLS FOR COMBINED VALVE AND IGNITION SYSTEM

INSTRUCTION SHEET

”Old”-- style

APPLICATION

The Combined Valve and Ignition system (CVI) has specially

been developed for application in gas fired appliances with

either intermittent pilot or direct burner ignition.

For this system, the VK41../VK81.. series gas controls have

been designed to have the S4565/S4575/S4585 series

ignition controls attached directly onto the valve.

The combined system then provides programmed safe light

up, flame supervision and regulation of gas flow to the main

burner and/or pilot burner of the appliance.

DESCRIPTION

The S4565/S4575 ignition controls provide automatic ignition

for direct gas burner applications and for intermittent pilot gas

burner applications with safety timer.

The S4565/S4575 ignition controls are not intended for direct

exposure to flame envelope.

The S4585 ignition controls provide automatic ignition for

intermittent pilot gas burner applications without safety timer.

The S4565/S4575/S4585 ignition controls are designed to

meet the european standards:

EN 298: Automatic gas burner control systems.

EN 60730--1: Automatic electrical controls for house hold

and similar use.

The S4565/S4575/S4585 ignition controls can be used in

appliances according European standard for household

electrical requirements EN 60335 series.

The S4565/S4575 ignition controls are approved on the North

American standard ANS Z21.20 Automatic Ignition Systems.

NOTE: S4565SD is not an ignition control but an ignition

circuit and rectifier only

”New”-- style

Contents

Page

Dimensional drawing 2................................

Features 3...........................................

S4565A,B,P,Q 3.......................................

S4565C,D,R,T 4.......................................

S4565AD,BD,CD,DD,PD,QD,RD,TD “1000” series 7......

S4565AD,BD,CD,DD,PD,QD,RD,SD,TD “2000” series 13..

S4565AF,BF,CF,DF,EF,PF,QF, RF, TF 18..................

S4575A,B,C,D,P,Q,R,T 23..............................

S4585D 26...........................................

General considerations 27.............................

Electrical connections 28..............................

Subject to change without notice. Printed in the Netherlands.

EN1R--9161 0006R10--NE

115

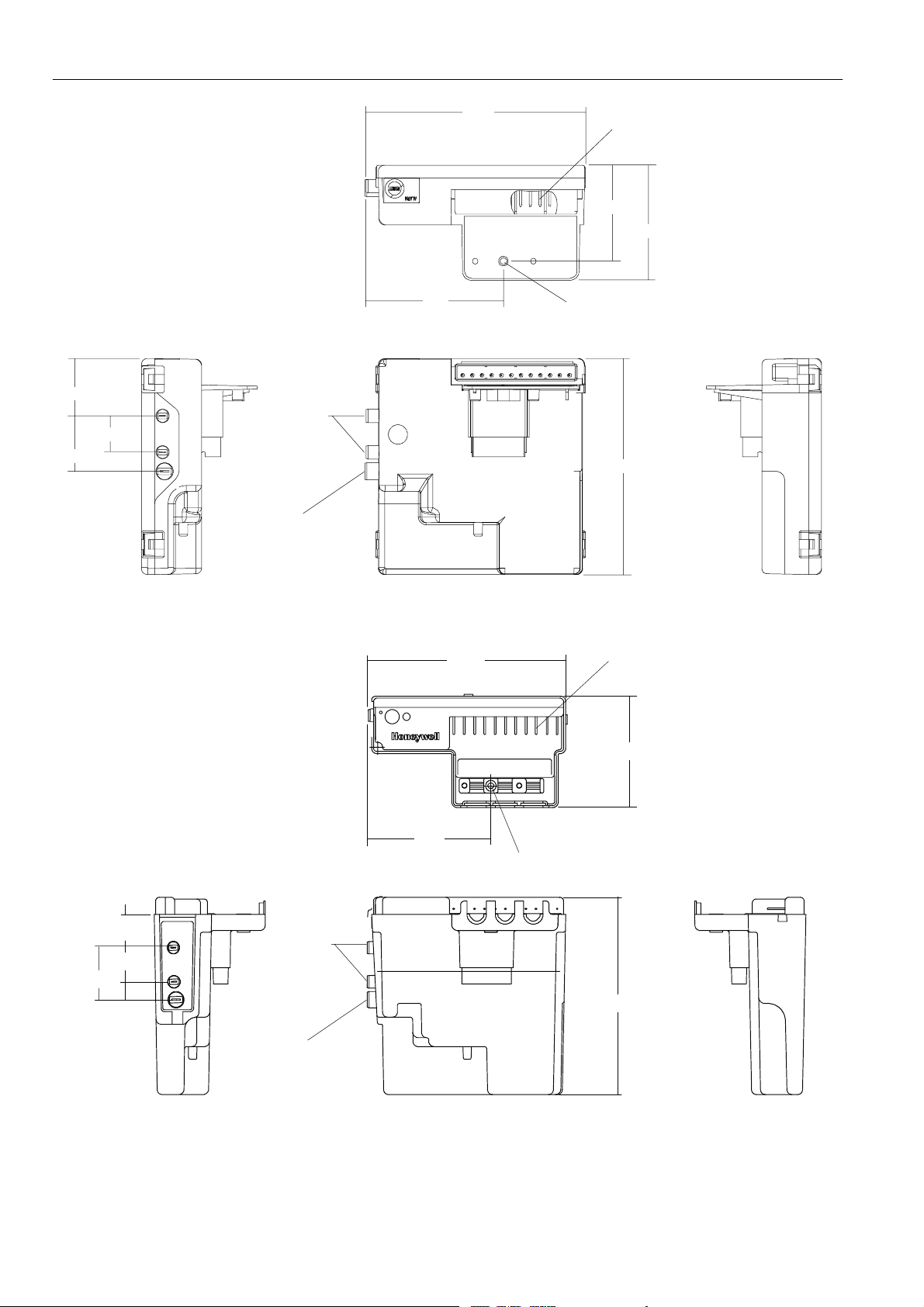

f

Connector pins suitable for

Molex 3001 female connectors

50

60

30

29

19

72

Mounting hole Ø 3.2

Ignition

113

Flame detection

Note: specific housings may deviate from drawing

Fig. 1. Dimensional drawing “new style” housing in mm

111

Connector pins suitable

Molex 3001 female connectors

or

18.5

19

29

EN1R--9161 0006R10--NE

69

69

Mounting hole Ø 3.2

Ignition

110

Flame detection

Note: specific housings may deviate from drawing

Fig. 2. Dimensional drawing “old style” housing in mm

2

62

FEATURES IGNITION CONTROLS

Flame supervision.

Built--in 2.5 ... 60 Hz ignition.

Internal or external reset and alarm.

Accurate safety timer.

Supply voltages of 220 ... 240 V in a single product.

Full operating sequence after flame loss.

Extended spark time.

Optional phase neutral independent operation, flame

sensing independent of safety ground potential for

S4565AD ... TD “2000” series and S4575.

Safety time triggered by Air Pressure Switch (APS) for

S4565AD ... TD “2000” series and S4575.

Optional safe separation flame relay output or opto

coupler.

Optional main burner interrupt for S4565 BF, DF, QF, TF.

Volatile or non volatile lock--out according EN 298.

EMC filter optional

Protective impedance flame rod

Under voltage protection

SPECIFICATIONS DIRECT BURNER IGNITION CONTROL S4565A, B, P, Q

Model

Suffix A: atmospheric, direct burner ignition

Suffix B: atmospheric, direct burner ignition, flame relay output

Suffix P: as A except volatile lock--out

Suffix Q: as B except volatile lock--out

Supply voltage

220 ... 240 Vac, 50/60 Hz

Power consumption

4VA

Humidity

90% RH max. at 40 _C

Ambient temperature

0 ... 60 _C

-- 15 ... 60 _C (optional)

Electrical rating (see also note 2.)

Alarm: 220 ... 240 Vac, 50/60 Hz, 1 A, cos ♥ > 0.6 or

1mAmax.

Flame relay contact: 220 ... 240 Vac, 50/60 Hz,

Flame opto coupler: +5 V, 10 kτ

Electrical connection

High voltage spark: 2.8 mm spade terminal

Flame sensing: 4.8 mm spade terminal

PCB connectors: Molex 3003 series suitable for Molex 3001

Housing (degree of protection)

See page 29

Timing (depending on O.S. number)

Self check time (T

1A,cos♥ > 0.6

female cable connector

): 1.5 s

c

Waiting time (T

Safety time (T

Extended spark ignition time: 0 ... T

Flame sensing

Min flame current: 0.9 ←A

Response time on: > 0.2 s

Response time off (T

Ignition

Spark voltage: > 12 kV at 40 pF load

Repetition rate: 2.5 ... 60 Hz (depending on O.S. number)

Max. spark gap: 3.5 mm

Length flame sensing cable

1mmax.

Length ignition cable

0.5 m max.

Length of wiring for external components

1mmax.

Remark

Optional integrated flame relay available with safe separation

or opto coupler with safe separation.

N.C. contact of flame relay has no safe separation.

): 0 ... 30 s

w

): 3.5 ... 55 s

s

FR

s

): < 1 s

(optionally other values available)

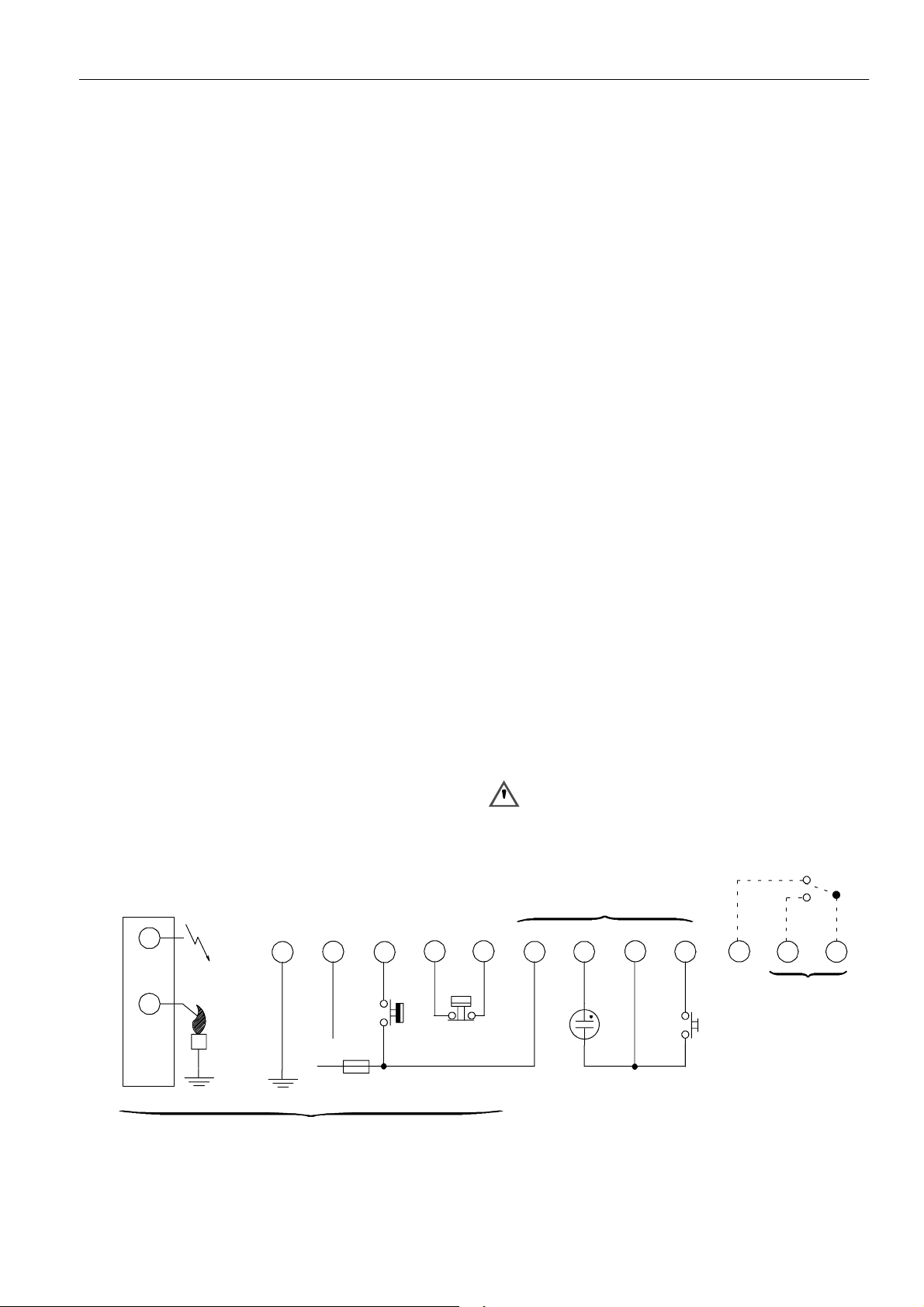

WARNING

Opto coupler interface needs a debounce time > 20

ms in order to prevent noise caused by transients on

mains.

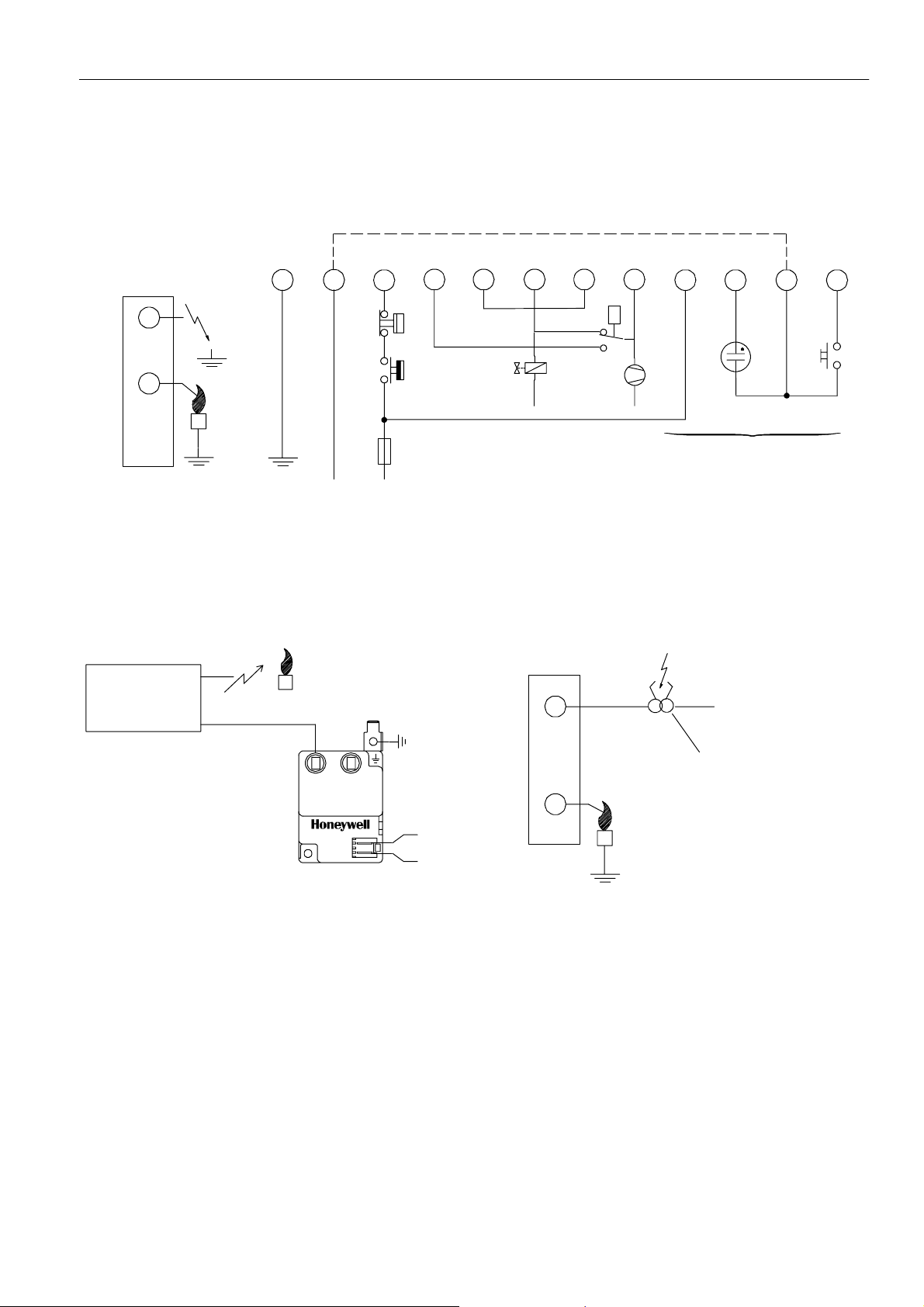

Side connections

12

N

L

All versions

Fig. 3. Connection diagram S4565A, B, P, Q

10

Optional

411

LM

8

3

7

65

*

9

3

Optional

RS

LM -- Limiter

RS -- Reset switch

* See note 2.

** See page 10 fig. 17.

EN1R--9161 0006R10--NE

Optional **

12

SYSTEM OPERATION

General

Lock- out reset

The S4565 ignition control can be reset by either depressing

the internal/external reset button (suffix A and B) or by

interrupting the permanent life (suffix P and Q).

NOTE 1.: If during normal use the reset button is pressed,

the gas valves drop out and the S4565 ignition

control starts a new sequence after releasing the

reset button.

NOTE 2.: If permanent alarm output:

neon indicator with integral resistor >150 kτ

Εmax 1 mA)

NOTE 3.: If an return high limit thermostat is used, the high

limit switch in the application needs a longer return

time than the trial for ignition time of the control.

This in order to provide non volatile lock out.

Suffix A, B, P and Q (see fig. 4.)

When there is a call for heat a self check period (T

waiting period (T

) elapse before built--in igniter and gas valve

w

)plus

c

are switched on.

The ignition spark ignites gas and resulting flame is detected

by the flame rod.

Ignition is switched off after extended ignition time and flame

establishment.

If flame is not established within the safety time (T

), the

s

S4565 ignition control locks out.

If the flame is lost during normal run, the S4565 ignition

control repeats start sequence.

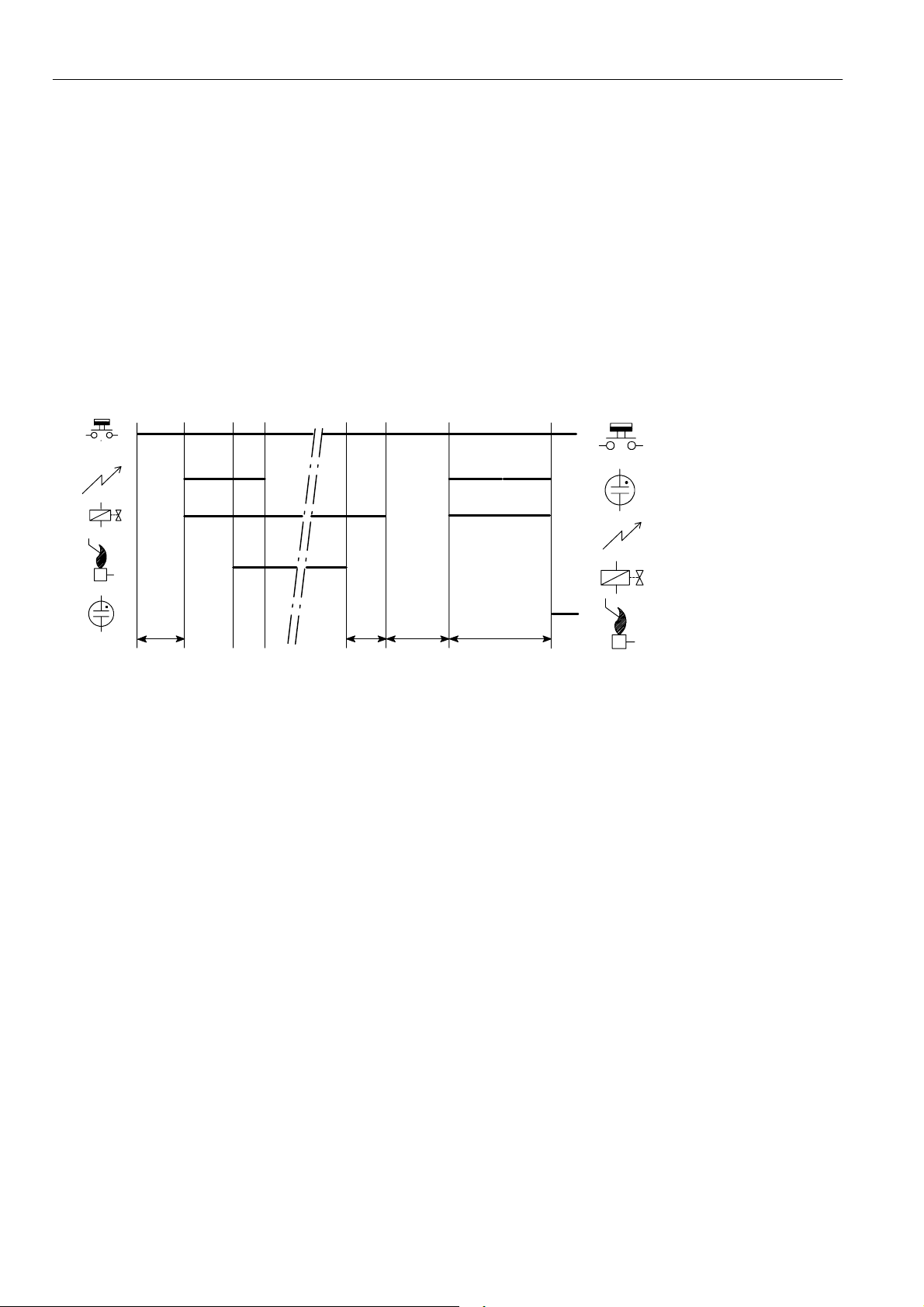

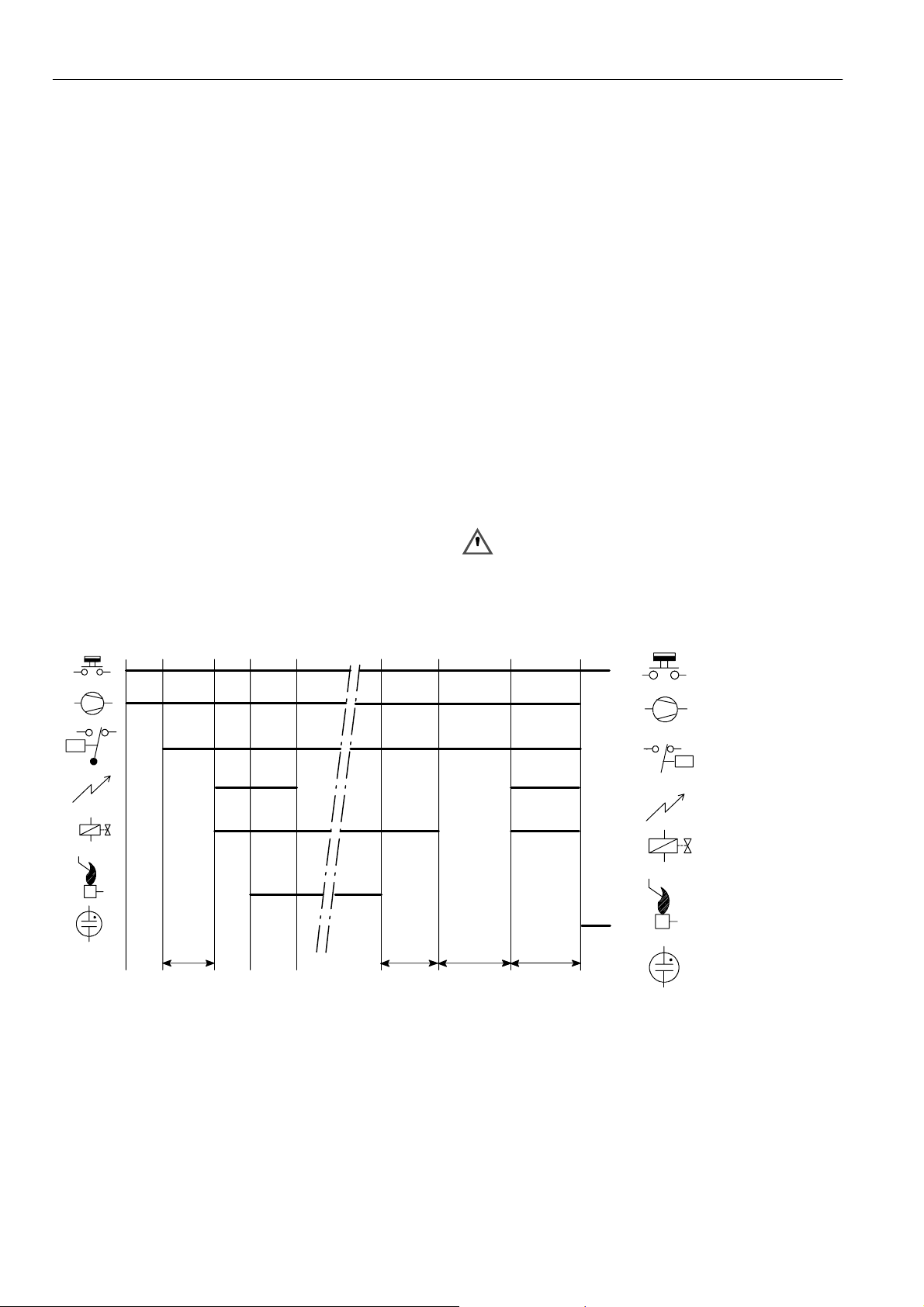

Legend

Thermostat

Alarm

Ignition

Tc+T

Tc+T

w

T

FR

w

T

s

Fig. 4. Functional diagram S4565A, B, P, Q

SPECIFICATIONS IGNITION CONTROL S4565C, D, R, T

Model

Suffix C: fan assisted, direct burner ignition

Suffix D: fan assisted, intermittent pilot burner ignition

including safety timer

Suffix R: as C except volatile lock--out

Suffix T: as D except volatile lock--out

Supply voltage

220 ... 240 Vac, 50/60 Hz

Power consumption

4VA

Humidity

90% RH max. at 40 _C

Ambient temperature

0 ... 60 _C

-- 15 ... 60 _C (optional)

Electrical rating (see also note 5.)

Alarm: 220 ... 240 Vac, 50/60 Hz, 1 A, cos ♥ > 0.6 or

max 1 mA

Fan: 220 ... 240 Vac, 50/60 Hz, 1 A, cos ♥ > 0.6

LPG outdoor valve: 220 ... 240 Vac, 50/60 Hz, 1 A,

cos ♥ > 0.6

External ignition transformer: 220 ... 240 Vac, 50/60 Hz,

1A,cos♥ > 0.6

Electrical connection

High voltage spark: 2.8 mm spade terminal

Optional:

External mains voltage ignition transformer with

2.8 mm spade terminal

Flame sensing: 4.8 mm spade terminal or 2.8 mm spade

terminal for combined high voltage

spark/flame sensing

PCB connectors:Molex 3003 series suitable for Molex 3001

female cable connector

Housing (degree of protection)

See page 29

Timing (depending on O.S. number)

Self check time (T

Prepurge time (T

Safety time (T

c

p

): 3.5 ... 55 s

s

Extended spark ignition time and stabilisation time: 0 ... T

Flame sensing

Min flame current: 0.9 ←A

Response time on: > 0.2 s

Response time off (T

): 0, 1.5 or 2 s

): 0 ... 30 s

(dependent on elaps of safety time)

): < 1 s

FR

(optionally other values available)

Gas valve

Flame rod

s

EN1R--9161 0006R10--NE

4

Ignition

Spark voltage: > 12 kV at 40 pF load

Repetition rate: 2.5 ... 60 Hz (depending on O.S. number)

Max spark gap: 3.5 mm

Length flame sensing cable

1mmax.

Length ignition cable

0.5 m max.

Length of wiring for external components

1mmax.

Side connections**

ignition control

12

Special applications

input

11

10

8

LM

7

¯

LPG

N

P -- Air proving switch

LM -- Limiter

N

L

RS -- Reset switch

* See note 5.

** Alternative side connection for models with combined flame

detection/high voltage. See page 5 fig. 6.

Fig. 5. Connection diagram S4565C, D, R, T

Side connection

230 Vac

21

569

P

3

¯

24

*¯

1

RS

N

Optional

N

Ignition transformer

AT7030

N

L

Fig. 6. Alternative side connection for models with

combined flamedetection/high voltage.

Ph1

Ph2

Fig. 7. Alternative side connection for models with flame

sense input + 230 Vac output for external ignition

transformer

5

EN1R--9161 0006R10--NE

SYSTEM OPERATION

General

Lock- out reset

The S4565 can be reset by either depressing the

internal/external reset button (suffix C and D) or by

interrupting the permanent life (suffix R and T).

NOTE 4.: If during normal use the reset button is pressed,

he gas valves close and the S4565 ignition control

starts a new sequence after releasing the reset

button.

NOTE 5.: If permanent alarm output:

neon indicator with integral resistor >150 kτ

Suffix C and R (see fig. 8.)

When there is a call for heat the fan starts running through the

no air position of the air proving switch.

If an external LPG valve is connected, this will be energized.

When sufficient air flow is proven by the air proving switch, a

self check period (T

) and prepurge period (Tp)elapse before

c

the gas valve and built--in ignition or external ignition

transformer (optional) are switched on.

The ignition spark ignites gas and resulting flame is detected

by the flame rod.

Internal or external ignition is switched off.

After flame establishment a predetermined, extended ignition

time can be included.

If flame is not established within the safety time (T

S4565 ignition control locks out.

Εmax 1 mA)

), the

s

If the flame is lost during normal run, the S4565 ignition

control repeats the start sequence with prepurge.

If no air is proven by the air proving switch within the prepurge

time (T

running.

), the ignition control stays in waiting mode with fan

p

Suffix D and T (see fig. 9.)

When there is a call for heat the fan starts running through the

no air position of the air proving switch.

If an external LPG valve is connected, this will be energized.

When sufficient air flow is proven by the air proving switch, a

self check period (T

the pilot gas valve and built-- in ignition or external ignition

) and prepurge period (Tp)elapses before

c

transformer (optional) are switched on.

The ignition spark ignites pilot gas and resulting flame is

detected by the flame rod.

Internal or external ignition is switched off.

After flame establishment a predetermined, extended ignition

time can be included and flame establishment and the main

valve is switched on.

If flame is not established within the safety time (T

), the

s

S4565 ignition control locks out.

If the flame is lost during normal run, the S4565 ignition

control repeats start sequence at prepurge.

If no air is proven by the air proving switch within the prepurge

time (T

running.

), the ignition control stays in waiting mode with fan

p

WARNING

Do not interchange air proving switch wiring in order to

prevent malfunctioning

Legend

Thermostat

Fan

P

P

¯

Air proving switch

Ignition

Main valve

Flame rod

Tc+T

p

T

FR

Tc+T

p

T

s

Alarm

Fig. 8. Functional diagram S4565C, R

EN1R--9161 0006R10--NE

6

h

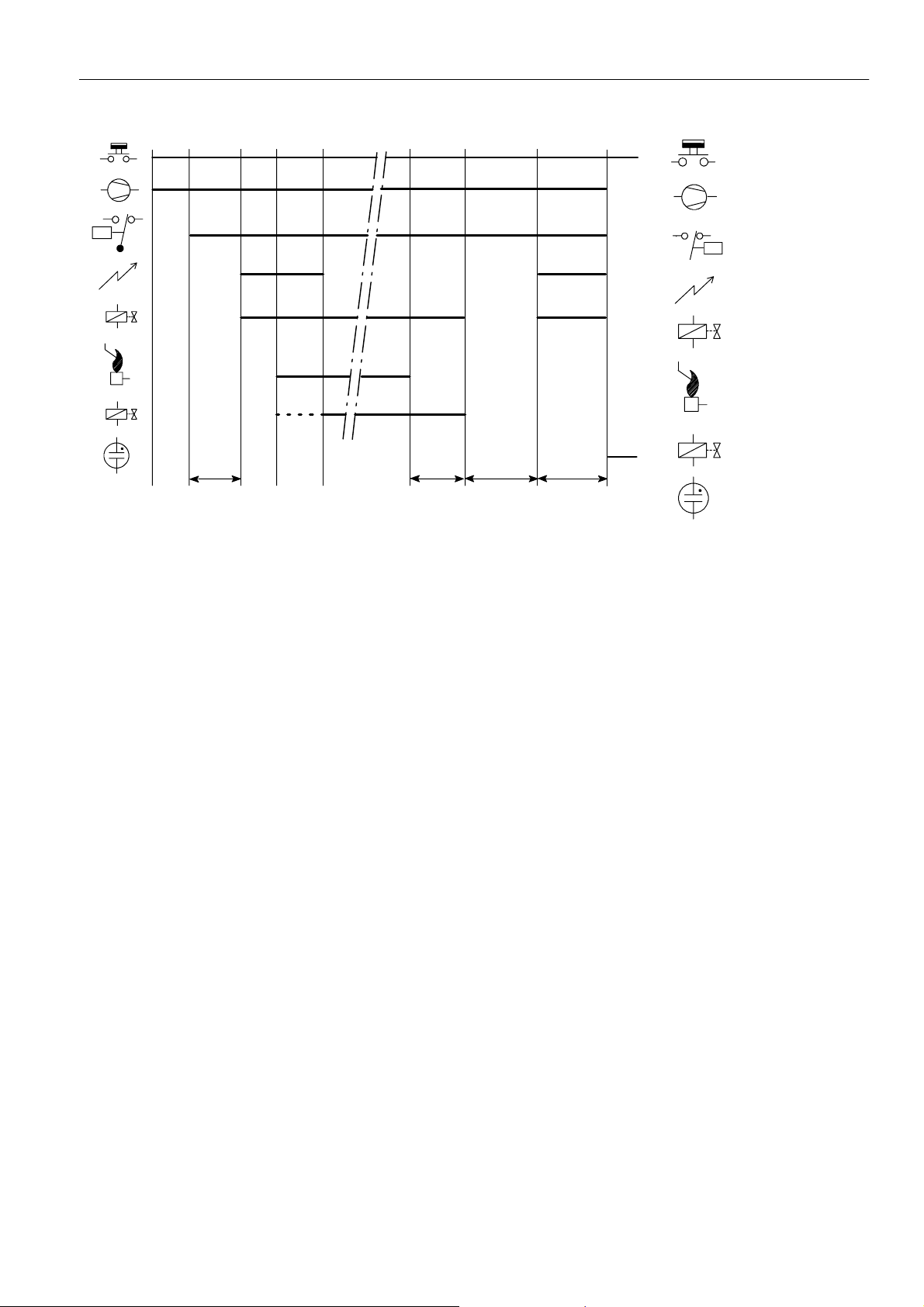

Legend

Thermostat

Fan

P

PV

MV

Tc+T

p

T

FR

T

c+Tp

T

s

Fig. 9. Functional diagram S4565D, T

SPECIFICATIONS DIRECT BURNER IGNITION CONTROL

S4565AD, BD, CD, DD, PD, QD, RD, TD “1000- SERIES”

Model

Suffix AD: atmospheric, direct burner ignition

Suffix BD: as AD but with flame relay output

Suffix CD: fan assisted, direct burner ignition

Suffix DD: as CD but with flame relay output

Suffix PD: as AD except volatile lock--out

Suffix QD: as BD except volatile lock--out

Suffix RD: as CD except volatile lock--out

Suffix TD: as DD except volatile lock--out

Supply voltage

220 ... 240 Vac, 50/60 Hz

Power consumption

4VA

Humidity

90% RH max. at 40 _C non condensing

Ambient temperature

0 ... 60 _C

-- 15 ... 60 _C (optional)

Electrical rating (see also note 8.)

Alarm: 220 ... 240 Vac, 50/60 Hz, 1 A, cos ♥ > 0.6 or max 1mA

Fan: 220 ... 240 Vac, 50/60 Hz, 1 A, cos ♥ >0.6

Flame relay contact: 220 ... 240 Vac, 50/60 Hz, 1 A,

cos ♥ >0.6

Flame opto coupler: +5 V, 10 kτ

LPG valve: 220 ... 240 Vac, 50/60 Hz,1 A max, cos ♥ >0.6

Electrical connection

High voltage spark: 2.8 x 0.5 mm spade terminal

Flame sensing: 4.8 x 0.8 mm spade terminal

PCB connectors: Molex 3003 series suitable for Molex 3001

Housing (degree of protection)

See page 29

Timing (depending on O.S. number)

Self check time (T

Waiting time (T

Safety time (T

): 1.5 s

c

): 0 ... 30 s

w

): 3.5 ... 25 s

s

Extended spark ignition time: 0 ... T

Flame sensing

Min flame current: 0.9 ←A

Response time on: > 0.2 s

Response time off (T

FR

Ignition

Spark voltage: >12 kV at 40 pF load

Repetition rate: 2.5 ... 60 Hz (depending on O.S. number)

Max. spark gap: 3.5 mm

Optional external ignition circuit: 220 ... 240 V (at no load),

Length flame sensing cable

1mmax.

Length ignition cable

0.5 m max.

Length of wiring for external components

1mmax.

P

¯

Air proving switc

Ignition

Pilot valve

PV

Flame rod

Main valve

MV

Alarm

female cable connector

(dependent on elaps of safety time)

s

): < 1 s

(depending on O.S. number)

single phase rectified, max 2 VA

7

EN1R--9161 0006R10--NE

Remark

Optional integrated flame relay available with safe separation

or opto coupler with safe separation.

N.C. contact of flame relay has no safe separation.

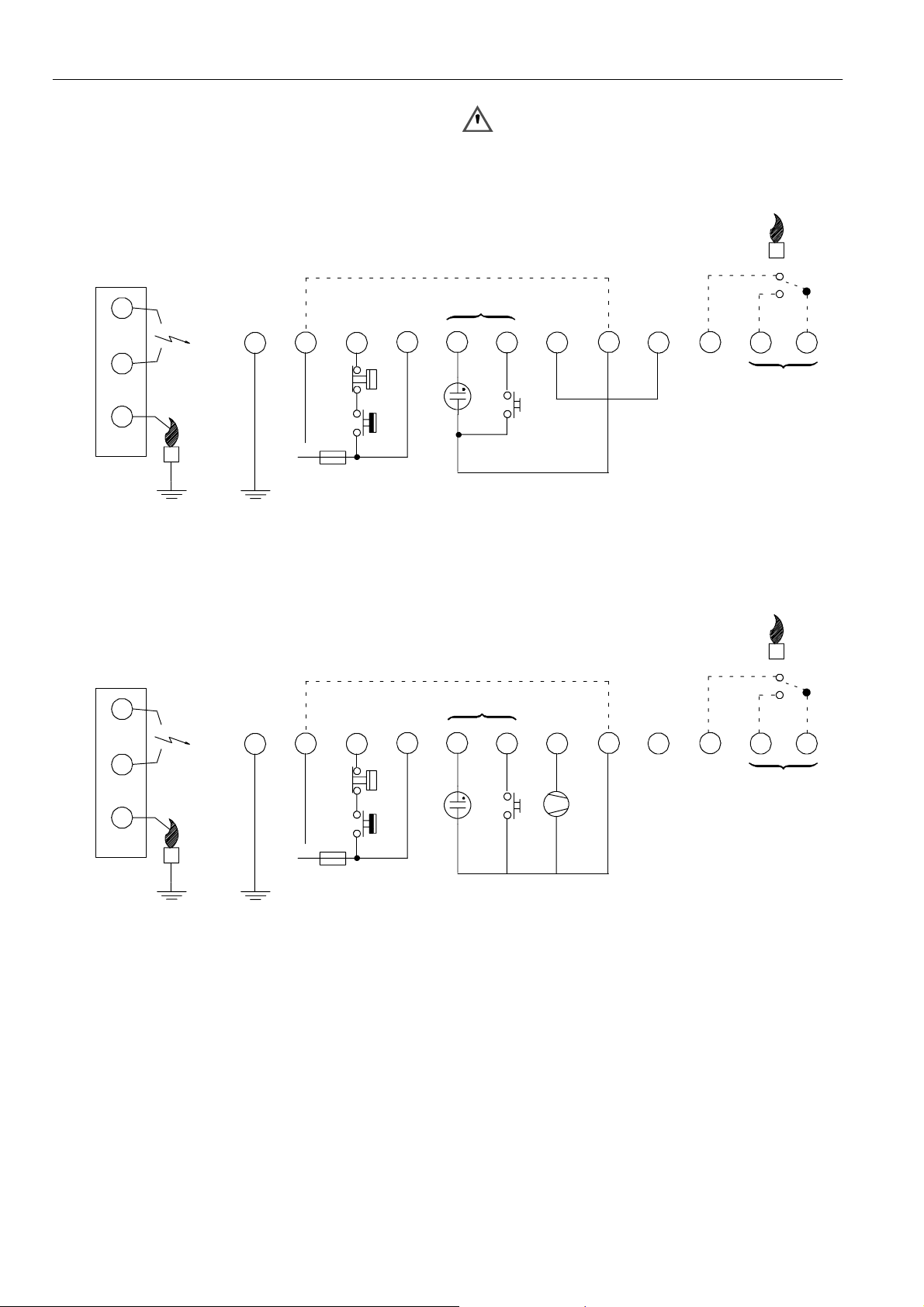

Side connections **

WARNING

Opto coupler interface needs a debounce time > 20

ms in order to prevent noise caused by transients on

mains.

Optional

Side connections **

10

9

LM

8

712

*

65

RS

N

L

Fig. 10. Connection diagram S4565AD and BD

Optional

10

9

LM

8

712

*

65

411

3

Optional ***

LM -- Limiter

RS -- Reset switch

* See note 8.

** See page 10 fig. 16.

*** See page 10 fig. 17.

411

3

Optional

Optional ***

12

12

Fig. 11. Connection diagram S4565BD and QD “1000” series for gas/air application

EN1R--9161 0006R10--NE

N

L

RS

* See note 8.

** See page 10 fig. 16.

*** See page 10 fig. 17.

8

Side connections **

Side connections

10

9

LM

8

712

*

65

RS

C

N

L

N

Fig. 12. Connection diagram S4565CD and DD

10

9

LM

8

712

*

65

+--

411

P

NC

3

Optional

Optional ***

12

¯

NO

P -- Air proving switch

LM -- Limiter

RS -- Reset switch

* See note 8.

** See page 10. fig. 16.

*** See page 10 fig. 17.

411

3

Optional ***Optional

12

Side connections **

N

L

N

Fig. 13. Connection diagram S4565QD with external ignition circuit

10

98 65

LM

712

*

N

L

Fig. 14. Connection diagram S4565PD and QD

LM -- Limiter

RS -- Reset switch

* See note 8.

*** See page 10 fig. 17.

411

3

Optional

Optional ***

LM -- Limiter

* See note 8.

** See page 10. fig. 16.

*** See page 10 fig. 17.

12

9

EN1R--9161 0006R10--NE

Loading...

Loading...