Page 1

0035

Construction

The safety valve comprises:

•Housing

• Spring bonnet

• Venting bonnet

• Rubber bellows

• Adjustment spring

Materials

• Brass housing

• Spring bonnet of cast iron, powder coated

• Venting bonnet of polyamid

• Bellows of silicon caoutchouc

• Spring steel adjustment spring

• Disc seal of Viton

S245S

Safety Valve

High performance valve for compressed air

Product specification sheet

Application

Safety valves of this type are direct loaded high performance

safety valves with lifting device. The venting bonnet discharges

the medium downwards.

Safety valves of this type protect fixed vessels containing granular

or powdered materials or silo tank vehicles containing fluids,

granular or powdered materials which are unloaded using

compressed air.

Special Features

• Sturdy metal construction

• Shakeproof lifting mechanism admitting no additional load

• Rubber bellows for protection of moving parts

• Venting bonnet for downwards discharge of fluid

• Approved to AD information sheet A 2 and to VdTÜV information sheet safety valve 100 for set relief pressure between 0.9

and 4.3 bar

• Set pressure adjustment at factory

• Set pressure settings possible between 0.5 and 30 bar in

steps of 0.1 bar

• Certified to Pressure Equipment Directive 97/23/EC, Reference No. CE 0035

Range of Application

Compressed air for discharge of granular or powdered materials

from fixed vessels and for liquid, granular or powdered materials

from silo tank vehicles.

Technical Data

Operating temperature max. 180 °C

Pressure setting between 0.9 and 4.3 bar

in steps of 0.1 bar

Approval No. TÜV · SV · ..* · 930 · 28 · F/K/S · w · p

P = set pressure

Discharge rate αw = 0.52 (0.9 -1.3 bar)

αw = 0.59 (1.4 - 2.0 bar)

αw = 0.63 (2.1 - 4.3 bar)

Connection size G 1

..* valid Approval No.

1

/4" and G 11/2"

EN0H-1310GE23 R0807 • Subject to change

www.honeywell.com 39

Page 2

S245S Safety Valve

Method of Operation

Safety valves are direct-acting. The disc seal is pushed up by the

pressure from the system against a spring which is holding the

valve closed. If the opening force exceeds the force exerted by

the spring, the valve disc is lifted off the valve seat and the valve

discharges the medium. In accordance with the requirements of

the standard, the full discharge capacity of the valve will be

achieved when the system pressure climbs to no more than 10%

above the set pressure of the valve. Full shutoff must be achieved

if the system pressure falls to below 90% of the nominal set pressure value.

The bellows protect the gliding parts inside the safety valve

against impurities.

Options

S245S- ... Z...= Special setting

Connection size

Set pressure

Ordering Example

S245B-11/4Z2.0 = Safety valve, size 1

1

/4", set pressure

2.0 bar

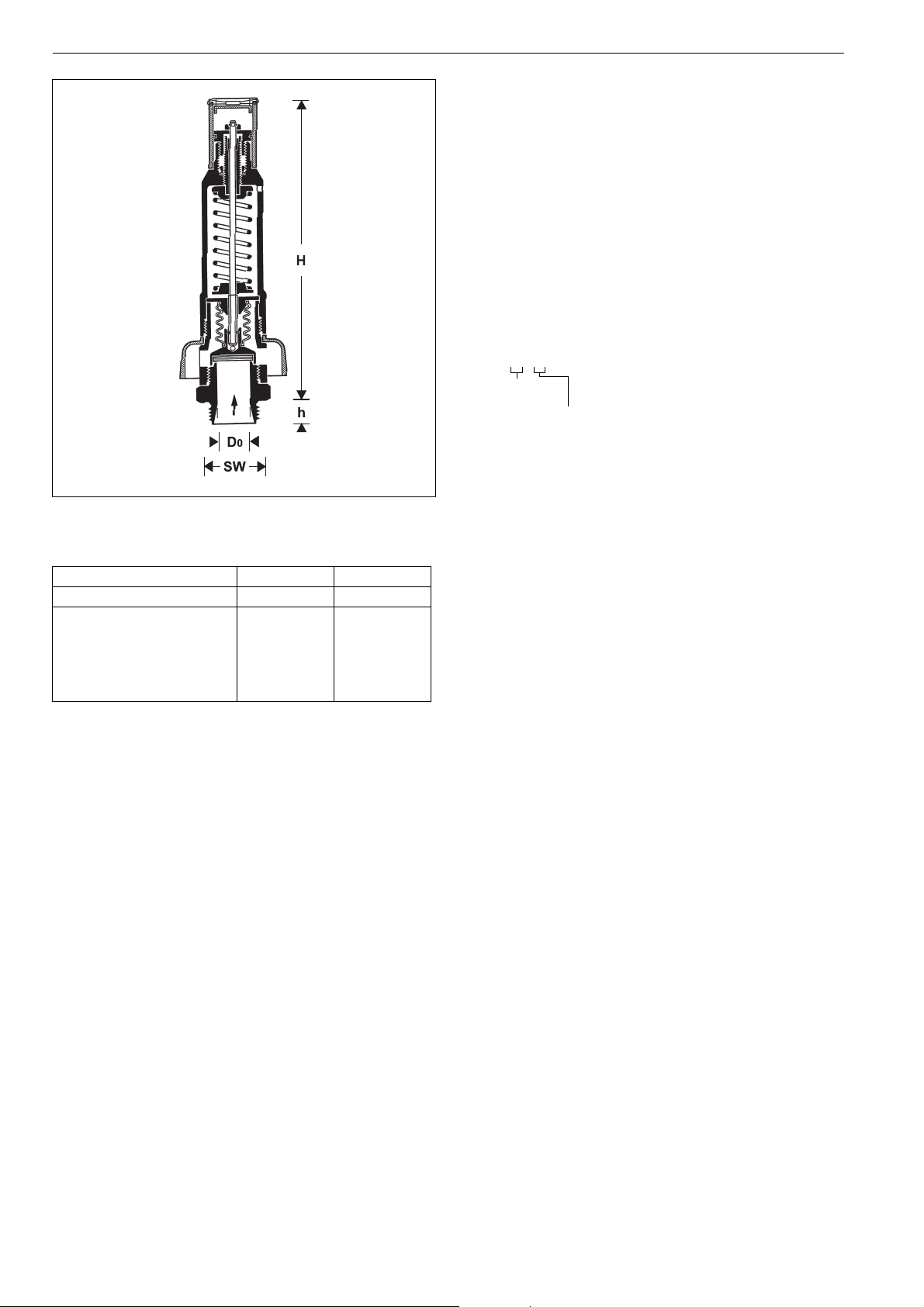

Connection size G 11/4"1

1

/2"

Weight kg 2.0 2.0

Dimensions mm

D

SW

0

h

H

28

18

258

55

28

20

258

55

40 www.honeywell.com

EN0H-1310GE23 R0807 • Subject to change

Page 3

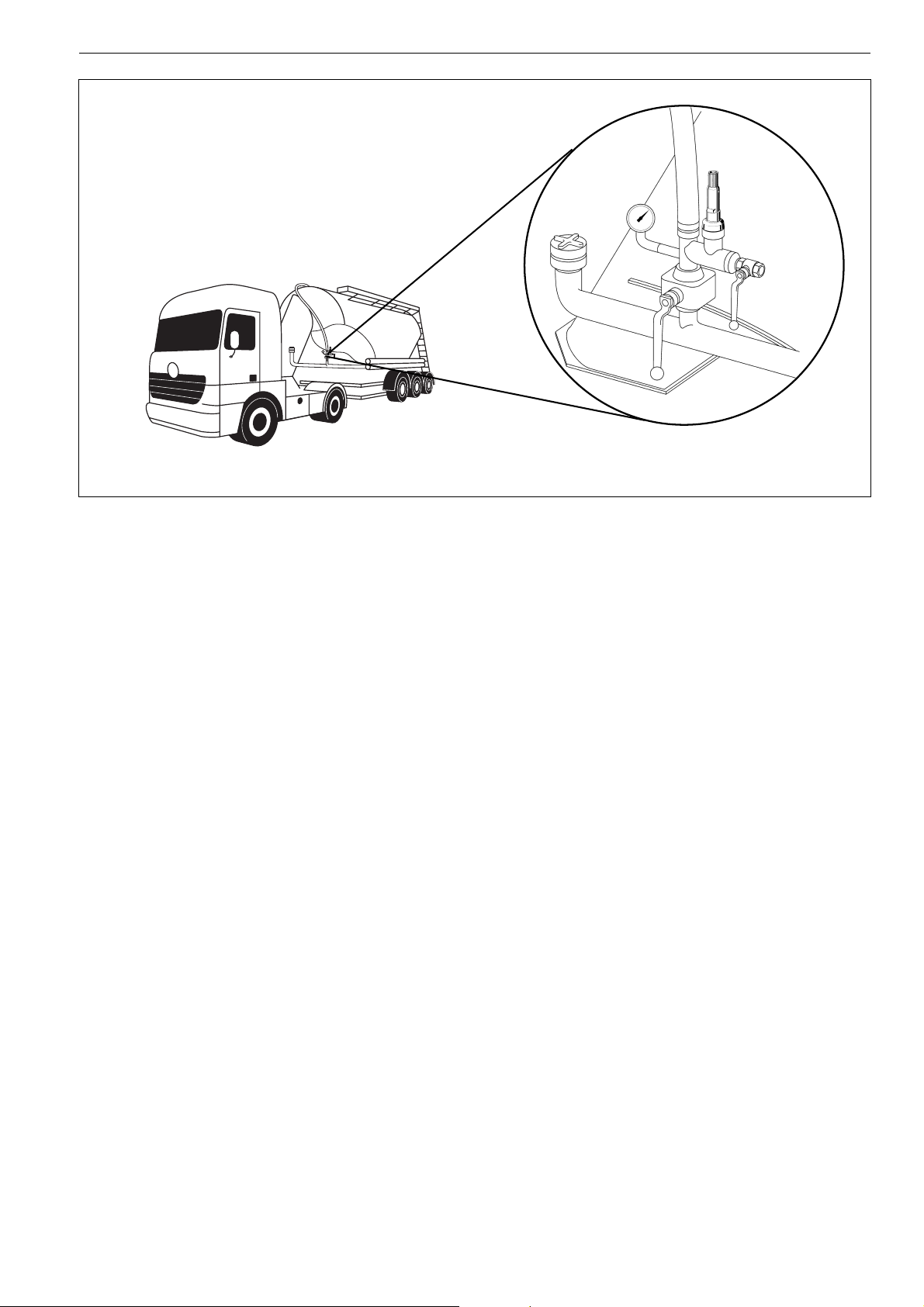

Installation Example

S245S Safety Valve

Installation Guidelines

• Install the valve vertically upwards in pipework or on a pressure vessel

o Never install in a horizontal position or vertically downwards

• Install the safety valve in such a way that during venting no

harm can occur to persons or objects adjacent to the unit

o Under some circumstances it is possible that high volumes

can discharge downwards

• Minimum clearances must be adhered to (see installation

instruction)

• No strainer or shut-off valves may be installed in the pipe

leading to the valve

• There must not be any shut-off devices in the feeding pipe.

The cross section of the feeding pipe may not be smaller than

the entrance cross section of the safety valve. The pressure

drop in the feeding pipe must not exceed 3 % of the pressure

difference between opening overpressure and superimposed

back pressure during the greatest mass flow which is to be

carried off

Typical Applications

Safety valves of this type are fitted where there is a risk of excess

pressures which may injure people or damage equipment.

The following are some typical applications:

• Silo tank vehicles

• Fixed vessels

EN0H-1310GE23 R0807 • Subject to change

www.honeywell.com 41

Page 4

S245S Safety Valve

Discharged capacity for compressed air

Opening pressure

bar 1 1/4"1

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.6

Amount of air in Nm3/h (0 °C, 1.013 bar)

1

/2"

438

462

486

510

606

462

660

688

715

742

770

797

880

909

938

967

997

1026

438

462

486

510

606

462

660

688

715

742

770

797

880

909

938

967

997

1026

Opening pres-

Amount of air in Nm3/h (0 °C, 1.013 bar)

sure

bar 1 1/4"1

2.7

2.8

2.9

3.0

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

4.0

4.1

4.2

4.3

The full discharge capacity is achieved at 10 % increase of system pressure above

set pressure.

1055

1084

1113

1142

1171

1200

1230

1259

1288

1317

1346

1375

1404

1433

1463

1492

1521

1

/2"

1055

1084

1113

1142

1171

1200

1230

1259

1288

1317

1346

1375

1404

1433

1463

1492

1521

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1310GE23 R0807

Subject to change without notice

© 2007 Honeywell GmbH

Loading...

Loading...