Page 1

S1024-2POS / S10230-2POS

S2024-2POS / S20230-2POS

SPRING RETURN DIRECT-COUPLED DAMPER ACTUATORS

10/20 Nm (88/177 lb-in) FOR 2-POSITION CONTROL

GENERAL

These direct-coupled damper actuators provide two-position

control for:

• air dampers,

• VAV units,

• air handlers,

• ventilation flaps,

• louvers, and

• reliable control for air damper applications with up to

FEATURES

• Self-centering shaft adapter

• Removable access cover

• Mechanical end limits (non-adjustable)

• Rotation direction selectable by choice of mounting

• Mountable in any orientation (IP54 only when

• Mechanical position indicator

2

1.5 m

/ 16 sq.ft (10 Nm / 88 lb-in) or 4.6 m2 / 50 sq.ft.

(20 Nm / 177 lb-in) (seal-less dampers; air frictiondependent).

orientation

mounted on a horizontal shaft with access cover

below the shaft)

PRODUCT DATA

SPECIFICATIONS

Supply voltage

Sxx24-2POS 24 Vac ±20% / 24 Vdc

50/60 Hz

Sxx230-2POS 230 Vac ±20%, 50/60 Hz

Nominal voltage

Sxx24-2POS 24 Vac / 24 Vdc, 50/60 Hz

Sxx230-2POS 230 Vac, 50/60 Hz

All values stated hereinafter apply to operation under

nominal voltage conditions.

Power consumption Holding Driving

S1024-2POS 8 VA 30 VA

S2024-2POS 8 VA 40 VA

S10230-2POS 13 VA 45 VA

S20230-2POS 13 VA 60 VA

Ambient limits

Ambient operating limits -40...+60 °C

Ambient storage limits -40...+70 °C

Relative humidity 5...95%, non-condensing

Safety

Protection standard IP54

Protection class II as per EN 60730-1

Overvoltage category III

Lifetime

Full strokes 50000

Repositions 1.5 million

Full stroke spring return 50000

Mounting

Round damper shaft 10...27 mm

Square damper shaft 13...19 mm

Shaft length 25 mm

End switch (when included)

Rating 5 A (resistive) / 3 A (ind.)

Triggering points 7° / 85°

Torque rating

S10xx-2POS 10 Nm (88 lb-in)

S20xx-2POS 20 Nm (177 lb-in)

Runtime 45 ± 5 sec (50 Hz)

Spring return timing 20 sec (50 Hz)

Rotation stroke 95° ± 3°

Dimensions see Fig. 8 on page 6

Weight 3.2 kg

Noise rating

Driving 50 dB(A)

Holding 20 dB(A) (no audible noise)

Spring return 65 dB(A)

® U.S. Registered Trademark EN0B-0462GE51 R0708

Copyright © 2008 Honeywell Inc. • All rights reserved

Page 2

SmartAct S1024-2POS / S10230-2POS, S2024-2POS / S20230-2POS

MODELS

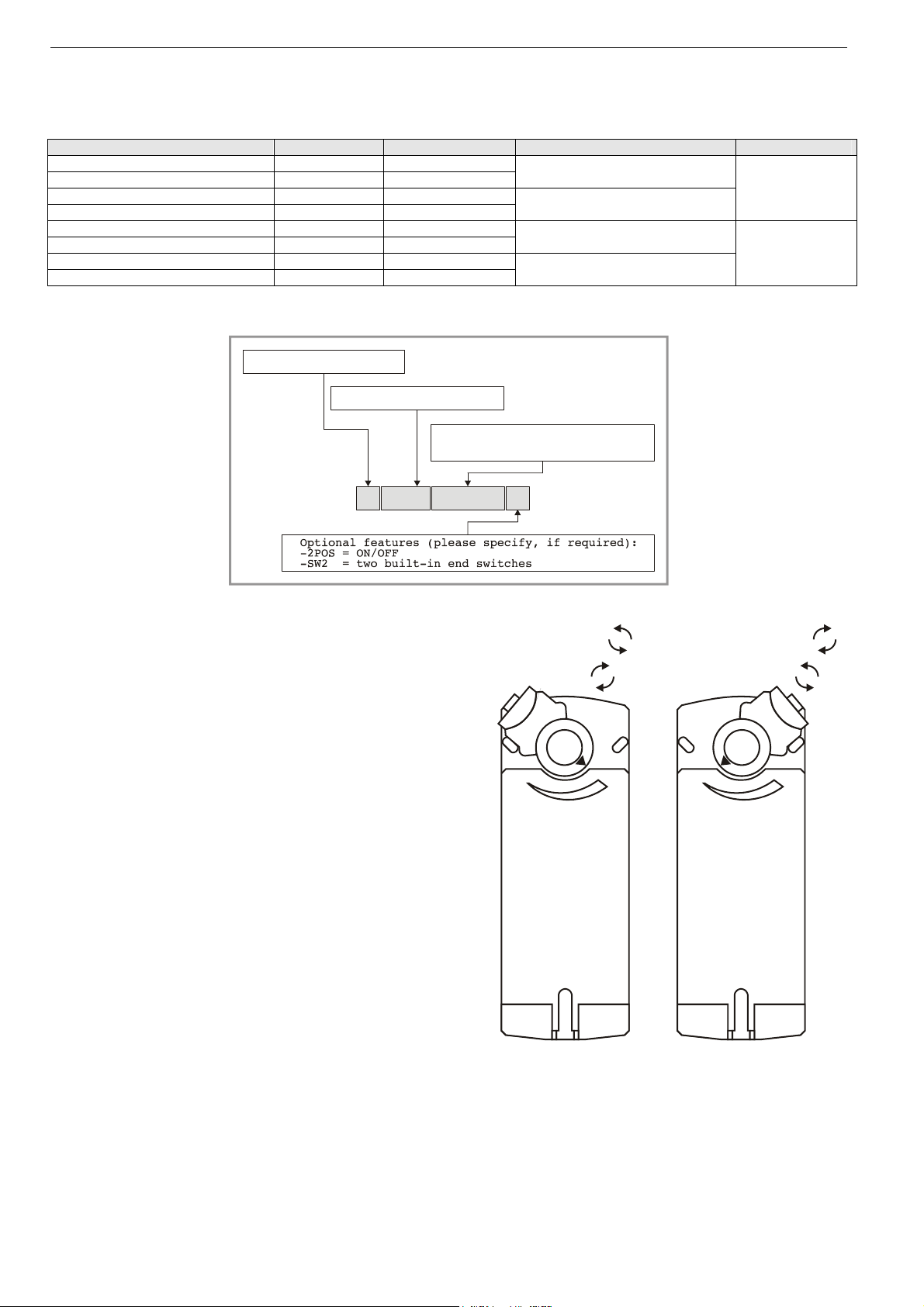

order number supply voltage end switches power consumption torque

S1024-2POS 24 Vac -S1024-2POS-SW2 24 Vac 2

S10230-2POS 230 Vac -S10230-2POS-SW2 230 Vac 2

S2024-2POS 24 Vac -S2024-2POS-SW2 24 Vac 2

S20230-2POS 230 Vac -S20230-2POS-SW2 230 Vac 2

Product Identification System

N = non-spring return

S = spring return

10 = 10 Nm (88 lb-in)

20 = 20 Nm (177 lb-in)

010 = modulating + floating

24 = 24 V

230 = 230 V

30 VA (driving) / 8 VA (holding)

45 VA (driving) / 13 VA (holding)

40 VA (driving) / 8 VA (holding)

60 VA (driving) / 13 VA (holding)

10 Nm (88 lb-in)

20 Nm (177 lb-in)

SmartAct

Fig. 1. Product Identification System

S

2

0

OPERATION / FUNCTIONS

Contents of Package

1 Self-centering shaft adapter

2 Retainer clip

3 Rotational angle scales (0...90° / 90...0°)

4 Mechanical end limits (non-adjustable)

5 Hex wrench for manual adjustment

6 Access cover

Rotary Movement

The actuators are designed to open a damper by driving the

damper shaft in either a clockwise or counterclockwise

direction.

NOTE: Actuators are shipped in the fully-closed (spring

return) position.

Two-Position Control

The two-position actuators are capable of being operated by a

two-position (open/close) controller. Refer to wiring diagrams

for correct connection.

Position Indication

An arrow molded into the hub points to tick marks on the label

to indicate the hub rotary position.

320

X

CCW to close

(failsafe position)

CW to close

(failsafe position)

CCW to openCW to open

Fig. 2. Mounting orientation

EN0B-0462GE51 R0708 2

Page 3

SmartAct S1024-2POS / S10230-2POS, S2024-2POS / S20230-2POS

Manual Adjustment

IMPORTANT

To prevent equipment damage, before manual

adjustment, you must remove power.

The actuator can be operated with no power present. Use

this feature during installation or to move and lock the damper

or valve shaft position when there is no power.

Operating the Manual Positioning

To operate the manual positioning with no power, proceed as

follows:

1. If the power is ON, turn it OFF.

2. Insert the supplied hex wrench (key) as shown in Fig. 3.

3. Rotate the key in the direction indicated on the cover.

4. Once the desired position has been reached, hold the key

to prevent the spring return from moving the actuator.

5. With the key held in place, use a screwdriver to turn the

gear train lock pin in the indicated direction until the detent

is reached.

NOTE: At the detent, the pin resists further rotation.

6. Remove the key without rotating it further.

Releasing the Manual Positioning

To release the manual positioning with no power present,

proceed as follows:

1. Insert the supplied key.

2. Turn the key ¼ of a turn in the direction indicated on the

cover.

3. Remove the key without engaging the gear train lock pin.

4. The spring will return the actuator to the failsafe position.

NOTE: Once power is restored, the actuator will return to

normal automated control.

95°

Internal End Switches

NOTE: Only those actuators for which "-SW2" has been

specified when ordering (e.g.: "S1024-2POS-SW2")

feature internal end switches.

The internal end switches are set to switch from "common" to

"normally open" at angles of 7° (±3°) and 85° (±3°),

respectively, from the totally counterclockwise position.

actuator scale: clockwise

10° 15° 92.5°0° 90°-2.5° 83°80°75°

7°

CCW internal

auxiliary switch

end switch scale

10° 15°0° 90°83°80°75°

7°

actuator scale: counterclockwise

83° 80° 75° -2.5°90° 0°92.5 ° 7°10°15°

CW internal

auxiliary switch

Fig. 4. Internal end switch triggering points

Mechanical Stroke Limit Reduction

For applications requiring a span of less than 95°, a simple

adjustment can be made. When the rotational mounting of the

shaft coupling is changed, the actuator drives less than the

full 95° stroke.

The stroke is adjustable in 5° increments. Once adjusted, the

actuator drives until the shaft coupling reaches the

mechanical stop (part of the housing). The stop causes the

motor to discontinue driving, and the shaft coupling drives no

farther. When the actuator returns, it stops at the fail-safe

position.

To set the fail-safe position, proceed as follows:

1. Remove the retainer clip from the shaft coupling and set it

aside for later use.

2. Remove the shaft coupling from the actuator.

3. Rotate the coupling to the desired fail-safe position,

aligning it based on the stroke labeling. See Fig. 5.

EXAMPLE: Setting the shaft coupling to an approx. fail-safe

position of 35° (as indicated on the housing)

limits the stroke to 60° (see Fig. 5).

4. Install the shaft coupling at this position.

5. Replace the retainer clip on the shaft coupling using the

groove of the coupling.

6. If necessary, replace the holder and position indicator on

the shaft coupling.

Fig. 3. Manual positioning

3 EN0B-0462GE51 R0708

Page 4

SmartAct S1024-2POS / S10230-2POS, S2024-2POS / S20230-2POS

Wiring

Connecting to the Power Supply

In order to comply with protection class II, the power source of

24 V actuators must be reliably separated from the network

power supply circuits as per DIN VDE 0106, part 101.

90°

45° 45°

DRIVE

SPRING RETURN

90° STROKE

0°

90°

0°

D

R

I

V

E

S

P

R

I

N

G

R

E

T

U

R

N

6

0

°

S

T

R

O

K

E

Fig. 5. Stroke reduction

Access Cover

To facilitate wiring the actuator to the controller, the access

cover can be detached from the actuator.

IMPORTANT

Remove power before detaching the access cover.

Once the access cover has been removed, please take

care to avoid damaging any of the parts now

accessible.

INSTALLATION

These actuators are designed for single-point mounting.

IMPORTANT

To prevent equipment damage, before manual

operation, you must remove power.

Mounting Instructions

All information and steps are included in the Installation

Instructions supplied with the actuator.

Mounting Position

The actuators can be mounted in any position (IP54 only

when mounted on a horizontal shaft with access cover below

the shaft). Choose a mounting position permitting easy

access to the actuator's cables and controls. When stationing

outdoors, equip with suitable cover to protect against UV and

rain.

Mounting Bracket and Screws

If the actuator is to be mounted directly on a damper shaft,

use the mounting bracket included in the delivery package.

Self-Centering Shaft Adapter

The self-centering shaft adapter can be used for shafts

having various diameters and shapes (round: 10...27 mm;

square: 13...19 mm).

In the case of short shafts, the shaft adapter may be reversed

and mounted on the duct side.

Stroke

The stroke amounts to 95° (±3°) and is mechanically limited

by end limits (non-adjustable).

S1 S2 S3 S4 S5 S6 123 4

Fig. 6. Access cover (S1024-2POS-SW2)

1234

5

5

EN0B-0462GE51 R0708 4

Fig. 7. S2024-2POS-SW2 with access cover removed

Page 5

Wiring Diagrams

S1024-2POS / S2024-2POS

SmartAct S1024-2POS / S10230-2POS, S2024-2POS / S20230-2POS

24 Vac~

24 V

TERMINAL STRIP 1

TWO-POSITION CONTROL

CW

1

100%

2

3

4

5

Connect via safety isolating transformer!

!

S1024-2POS-SW2

TERMINAL STRIP 1

END SWITCHES

24 Vac~

24 V

CW

1

100%

2

3

4

5

Connect via safety isolating transformer!

!

TWO-POSITION CONTROL

S1 black

S2 black

S3 black

S4 gray

S5 gray

S6 gray

S1

S2

S3

S4

S5

S6

END SWITCHES

NOTE: Internal end switches S1 and S4 must be connected to the same power source.

S10230-2POS / S20230-2POS

230 Vac~

230 V

TERMINAL STRIP 1

TWO-POSITION CONTROL

CW

1

100%

2

3

4

5

Connect via safety isolating transformer!

!

S10230-2POS-SW2

TERMINAL STRIP 1

END SWITCHES

230 Vac~

230 V

CW

1

100%

2

3

4

5

Connect via safety isolating transformer!

!

TWO-POSITION CONTROL

S1 black

S2 black

S3 black

S4 gray

S5 gray

S6 gray

S1

S2

S3

S4

S5

S6

END SWITCHES

NOTE: Internal end switches S1 and S4 must be connected to the same power source.

5 EN0B-0462GE51 R0708

Page 6

SmartAct S1024-2POS / S10230-2POS, S2024-2POS / S20230-2POS

DIMENSIONS

100

50 50

40

156

76 (min. from shaft end)

64 (min.)

247

6

76 (min.)

Fig. 8. Dimensions (in mm)

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich / Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0462GE51 R0708

75

Loading...

Loading...