Page 1

SIL

3

RM/EC 7800 Burner Controller

SAFETY MANUAL

Edition 11.19 · 320023101 · EN

1 Scope and Purpose of the

Document

This document provides an overview of the user responsibil-

ities for installation and operation of the Honey well 780 0

Series Relay Modules in order to maintain the designed safety

level. Items that will be addressed are proof testing, repair and

replacement of the device, reliability data, lifetime, environmental and application limits, and parameter settings.

This Safety Manual is limited to Models: RM7800, RM7823,

RM7830, RM7838, RM7840, RM7845, RM7850, RM7865,

RM7885, RM7888, RM7890, RM7895, RM7896, RM7897,

RM7898, EC7820, EC7823, EC7830, EC784 0, EC7850,

EC7890, EC7895 with one of the following Flame Detectors

and Flame Amplifiers:

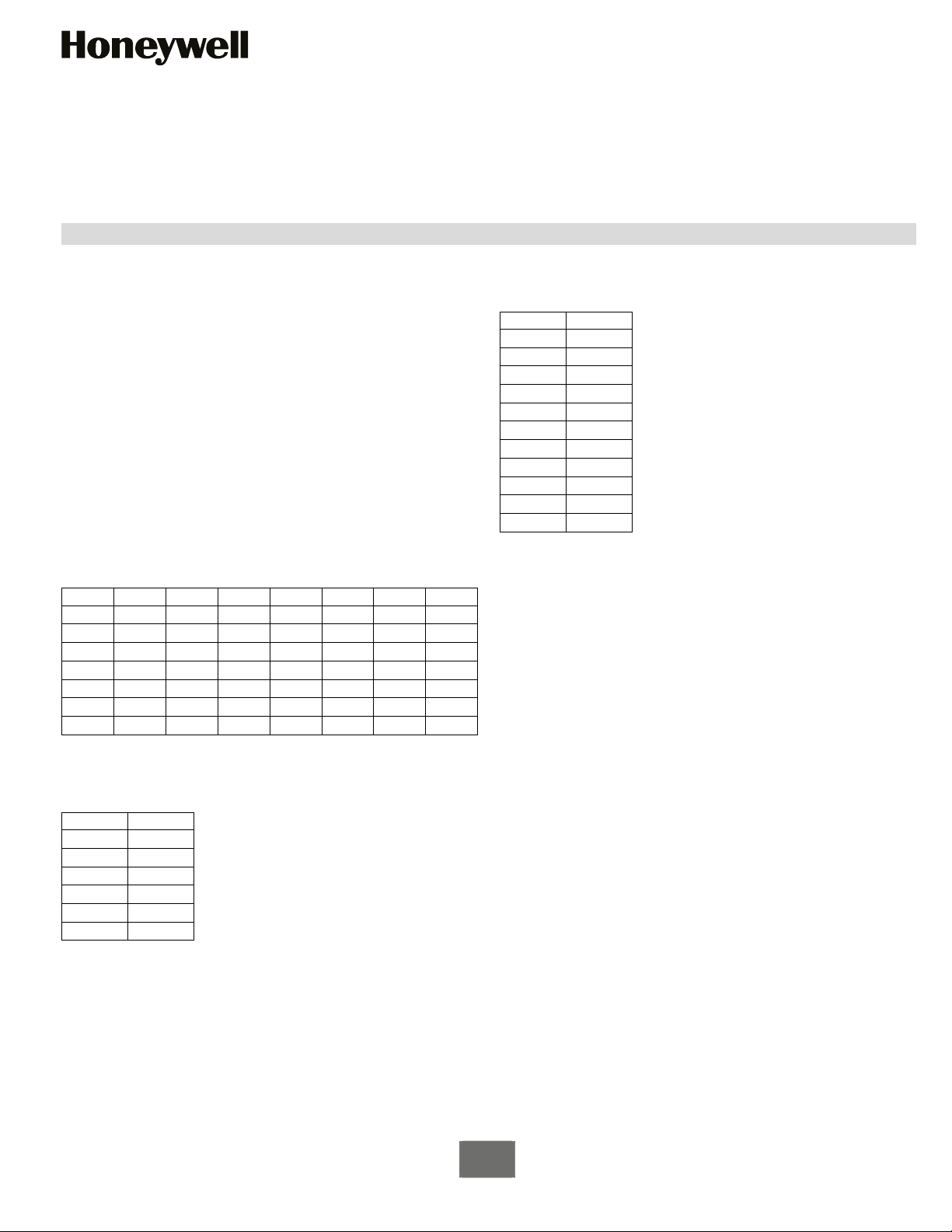

Table 1. 7800 Series Burner Controller Models and Series

MODEL SERIES MODEL SERIES MODEL SERIES MODEL SERIES

RM780 0

RM7823

RM7830

RM7838

RM784 0*

RM7845

*NOTE: RM7840E1016, RM78 40L1018 and RM7840L1026

MODEL SERIES

R78 47B 5

R7852B 1

R78 47C 5

R7851C 2

R7861A 2

R7886A 2

9

6

5

9

8

3

RM7850

RM7865

RM7885

RM7888

RM7890

5

4

5

5

9

RM7895

RM7896

RM7897

RM7898

6

EC7820

6

EC7823

6

EC7830

6

EC784 0

EC7850

EC7890

EC7895

are Series 5

Table 2. R78xx Flame Amplifier Models and Series

7

4

6

5

6

5

5

Table 3. C7xxx Flame Sensor Models and Series

MODEL SERIES

C7008A 1

C7009A 1

C7915A 1

C7012E 1

C7012F 1

C7061A 1

C7061F 1

C7076A 1

C7076D 1

C7961E 1

C7961F 1

CONTENTS

1 Scope and Purpose of the Document ....................1

2 Using the Honey well 7800 Series Relay Modules ........2

2.1 Safety Function .............................................2

2.2 Fail Safe State ...............................................2

2.3 Safety Response Time ......................................2

2.4 Diagnostic Response Time .................................2

2.5 Maximum Achievable SIL ...................................2

2.6 Model Selection and Specification of Honeywell 7800

Series Relay Modules .......................................2

2.7 Installation .................................................3

2.8 Required configuration settings........................... 3

2.9 Reliabilit y data .............................................3

2.10 Lifetime limits.............................................. 4

2.11 Proof Testing ...............................................4

2.12 Repair and replacement ................................... 4

2.13 Firmware update ........................................... 4

2.14 Environmental and EMC based limits ..................... 4

3 Definitions and Abbreviations ...........................5

3.1 Definitions ................................................. 5

3.2 Abbreviations .............................................. 5

4 Status of the document ..................................5

4.1 Releases ................................................... 5

4.2 Open issues ................................................6

4.3 Future enhancements of the document .................. 6

Capable

Page 2

RM/EC 7800 Burner Controller Safety Manual

2 Using the Honeywell 7800 Series

Relay Modules

2.1 Safety Function

The 7800 Series provides automatic burner flame sequencing

and flame supervision with protection against loss of flame.

2.2 Fail Safe State

The Safety Shutdown (Lockout) mode is the failsafe state for

the Honey well 780 0 Series Relay Modules where all safety

critical terminals (main and pilot valves, and ignition transformer) are de-energized and a manual reset is required to

return to normal operation.

2.3 Safety Response Time

The Honeywell 780 0 Series Relay Modules (all models except of EC7823 and RM7823) will respond to loss of flame

by means of shutting of f all safety outputs and transitioning

to the Safety Shutdown (Lockout) state within the published

Flame Failure Response Time (FFRT) for the selected Flame

Amplifier and Flame Sensor.

EC7823 and RM7823 will respond to loss of flame by means

of shutting off the safet y outputs and transitioning to the

Idle state within the published Flame Failure Response Time

(FFRT) for the selected Flame Amplifier and Flame Sensor.

Safety Shutdown (Lockout) state is not entered and manual

reset action is not needed in this case.

2.6 Model Selection and Specification of

Honeywell 7800 Series Relay Modules

The Honeywell 780 0 Series Relay Modules and optional components for certified SIL applications shall only be selected

and specified for applications consistent with the guidelines

presented in the Installation Instructions document and additional technical literature released for the specific model

available at web site https: //customer.honeywell.com and

further restricted to the certified Flame Amplifiers and Flame

Detectors identified in section 1 of this Safety Manual.

2.4 Diagnostic Response Time

The Honeywell 780 0 Series Relay Modules will report a detectable internal failure within 3 seconds for faults to the main

7800 Relay Module and within 15 seconds for faults to the

Flame Detector / Flame Amplifier.

2.5 Maximum Achievable SIL

The 7800 Relay Modules, Flame Amplifiers and Flame De-

tectors covered by this safety manual are suitable for use in

both high and low demand mode of operation Safety Integrity

Functions (SIF) up to SIL 3 in simplex (1oo1) configurations.

The achieved SIL for a particular SIF needs to be verified by

PFH or PFDavg calculation for the entire SIF including the

failure rates of the associated sensors and actuators that are

also part of the SIF.

Use of the Honeywell 7800 Series Relay Modules in a redundant (1ooN) configurations is not supported.

The 7800 Series Burner Controller System is classified as a

1

Type B

fault tolerance of 0.

1 Type B element: “Complex” element (using micro controllers or

element according to IEC 61508, having a hardware

programmable logic); for details see 7.4.4.1. 3 of IEC 61508-2, ed,

2010

32-00231-01 2

Page 3

RM/EC 7800 Burner Controller Safety Manual

Q7800

SELECTABLE CONFIGURATION JUMPERS

2.7 Installation

The Honeywell 780 0 Series Relay Module sub-base must be

installed, wired and the “Final Wiring Check” and “Static

Checkout” procedures successfully completed according

to the guidelines published in the Installation Instructions

document for the specific model available at web site

https://customer.honeywell.com. The Static Checkout procedure must be successfully per formed prior to installation of

the relay module on the sub-base.

For RM7823 and EC7823 models, in SIL 3 applications, both

sets of COMN.O. outputs (terminals 8, 9 and 13, 15) must

be wired in series, i.e. terminal 9 must be tied to terminal 13.

The N.C. outputs (terminals 10 and 14) can’t be used in SIL 3

applications.

G

L2

3

4

5

(L1)1314

12

15

16

COMMON

6

NORMALLY

OPEN

33

2.8 Required configuration settings

The following user settable options need to be properly configured for the individual application in order to provide the

designed safety integrity for that application. Jumpers JR1

through JR3 site-configurable jumpers come factor y installed

for one configuration and must be selectively clipped out to

select the actual desired configurations as documented on

the warning label adjacent to the jumper positions as shown

in Figure 1 below. Note that the actual jumper configuration

setting may differ by product model number.

RUNTEST SWITCH

5

3

COMMON

NORMALLY

OPEN

6

FLAME DETECTOR

4

120V, 50/60 HZ (RM7823); 220-240V, 50/60 Hz (EC 7823) POWER SUPPLY. PROVIDE

1

DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

DO NOT CONNECT ANY WIRES TO UNUSED TERMINALS

2

OUTPUTS SHOWN ARE WHEN THE DEVICE DOES NOT SEE FLAME.

3

SEE FLAME DETECTOR INSTALLATION INSTRUCTIONS FOR CORRECT WIRING.

4

TERMINALS 9 AND 13 MUST BE WIRED TOGETHER

5

(BOTH COM-N.O. RELAY OUTPUTS ARE WIRED IN SERIES)

TERMINALS 10 AND 14 MUST NOT BE USED.

6

NOTE: FOR EC7823, A 220/240V TO 120V,

10 VA, STEP-DOWN TRANSFORMER IS REQUIRED.

Fig. 1. RM7823 and EC7823 wiring for SIL 3 applications

6

7

8

9

10

F

17

2

18

19

20

21

22

L1

(HOT)

MASTER

SWITCH

L2

1

NOTE: CONFIGURATION JUMPERS SHOWN FOR RM7800G/7840G

Fig. 2. Site-configurable jumpers

Note that the cut jumper condition is the safest setting so that

failure to cut a jumper during installation can result in a configuration that does not meet the requirements for the particular application.

In addition, many models require the use of a factory preset Purge Timer Card configures the 7800 Module for the

required purge time (between 2 seconds and 30 minutes).

These cards are preset to a par ticular purge time at the factory

and must be ordered according to the needs of the particular

application.

2.9 Reliability data

A detailed Failure Mode, Effects, and Diagnostics Analysis

(FMEDA) report is available from Honeywell Thermal Solutions with all failure rates and failure modes for use in SIL verification.

Note that the failure rates of the associated sensors and actuators need to be accounted for in the SIF level PFH / PFDavg

calculation.

3 32-00231-01

Page 4

RM/EC 7800 Burner Controller Safety Manual

2.10 Lifetime limits

The expected lifetime of the Honeywell 7800 Series Relay

Modules is approximately 10 years. The reliability data listed

in the FMEDA report is only valid for this period. The failure

rates of the Honey well 7800 Series Relay Modules may increase sometime after this period. Reliability calculations

based on the data listed in the FMEDA repor t for lifetimes beyond 10 years may yield results that are too optimistic, i.e. the

calculated Safety Integrity Level may not be achieved.

2.11 Proof Testing

The objective of proof testing when used in low demand mode

of operation is to detect failures within Honeywell 7800 Series

Relay Module and its associated sensors and actuators that

may not be detected by the normal self-diagnostics. Of main

concern are undetected failures that prevent the safety instrumented function from performing its intended function.

The frequency of the proof tests (or the proof test interval ) is

to be determined in the reliability calculations for the safety

instrumented functions for which the Honeywell 7800 Series

Relay Modules is applied. The actual proof tests must be performed at least as frequently as specified in the calculation in

order to maintain required safety integrity of the safety instrumented function.

The following tools may be needed to be available to perform

proof testing

• Voltmeter (1M Ohm minimum input impedance) set on

the 0300 Vac scale.

• Two jumper wires; no. 14 wire, insulated, 12 inches

(304.8 mm) long with insulated alligator clips at both

ends.

The person(s) performing the proof test of the Honey well

7800 Series Relay Modules should be a trained, experienced,

flame safeguard service technician, trained in Honeywell

7800 Series Relay Modules maintenance and company man-

agement of change procedures.

The following tests need to be specifically executed when a

proof test is performed. The results of the proof test need to

be documented and this documentation should be part of a

plant safety management system. Failures that are detected

should be reported to Honey well Thermal Solutions.

7. Remove any remaining bypasses and restore normal operation.

8. Press reset and verify return to normal operation..

When all the tests listed above are executed a proof test coverage of 36% can be claimed.

2.11.2 Test (7823 models only)

Functional test:

1. Remove the 7823 Module from the wiring sub-base

2. Perform the “Static Checkout” procedure documented in

the Installation Instructions and verify proper response to

all test conditions

3. Reinstall the 7823 Module to the wiring sub-base.

4. While in “Run” sequence interrupt the flame signal by

either manually blocking the fuel supply or blocking the

sensor input from “seeing” the flame and verify unit goes

to Standby state and all safety critical terminals become

de-energized.

5. Restore fuel supply or visibility of flame sensor to the flame

and verify return to the normal operation.

When all the tests listed above are executed a proof test coverage of 13% can be claimed.

2.12 Repair and replacement

In the unlikely event that the Honeywell 7800 Series Relay

Modules has a failure, the failures that are detected should be

reported to Honeywell Thermal Solutions.

When replacing the Honeywell 7800 Series Relay Modules

power should be removed and the procedure in the installation manual should be followed.

The person(s) performing the repair and / or replacement of

the Honey well 780 0 Series Relay Modules should be a trained,

experienced, flame safeguard service technician.

2.13 Firmware update

In case firmware updates are required they will only be performed at factory where proper replacement procedures are

in place. The user is not permitted to perform any firmware

updates.

2.11.1 Test (except 7823 models)

Functional test:

1. Remove the 7800 Module from the wiring sub-base

2. Perform the “Static Checkout” procedure documented in

the Installation Instructions and verify proper response to

all test conditions

3. Reinstall the 7800 Module to the wiring sub-base.

4. While in “Run” sequence interrupt the flame signal by

either manually blocking the fuel supply or blocking the

sensor input from “seeing” the flame and verify unit goes

to Safety Shutdown (Lockout) state.

5. Restore fuel supply or visibility of flame sensor to the

flame.

6. Power cycle the unit and verify unit returns to Safety Shutdown (Lockout) state upon reapplication of power.

32-00231-01 4

2.14 Environmental and EMC based limits

The environmental and EMC based limits of the Honey well

7800 Series Relay Modules are specified in the user installation manual [32 00143 Rev 1217].

Page 5

RM/EC 7800 Burner Controller Safety Manual

3 Definitions and Abbreviations

3.1 Definitions

Safety Freedom from unacceptable risk of

harm

Functional Safety The abilit y of a system to carry out

the actions necessary to achieve or to

maintain a defined safe state for the

equipment / machinery / plant / apparatus under control of the system

Basic Safety The equipment must be designed and

manufactured such that it protects

against risk of damage to persons by

electrical shock and other hazards and

against resulting fire and explosion.

The protection must be effective under

all conditions of the nominal operation

and under single fault condition

Verification The demonstration for each phase of

the life-cycle that the (output) deliverables of the phase meet the objectives

and requirements specified by the

inputs to the phase. The verification is

usually executed by analysis and / or

testing

Validation The demonstration that the safety-re-

lated system(s) or the combination of

safety-related system(s) and external

risk reduction facilities meet, in all

respects, the Safety Requirements

Specification. The validation is usually

executed by testing

Safety Assessment The investigation to arrive at a judg-

ment - based on evidence - of the safety achieved by safety-related systems

Further definitions of terms used for safety techniques and

measures and the description of safety related systems are

given in IEC 615084.

3.2 Abbreviations

FMEDA Failure Mode, Effects and Diagnostic Analysis

BPCS Basic Process Control System

SIF Safety Instrumented Function

SIL Safety Integrity Level

SIS Safety Instrumented System

SLC Safety Lifecycle

4 Status of the document

4.1 Releases

Version: V3

Revision: R4

Version

History:

V3, R4 Dec 6,

V3, R3 Nov 15,

V3, R2 Oct 2,

V3, R1 Oct 2,

V3, R0 Sep 24,

V2, R0 Nov 14,

V1, R0 June 2,

V0, R3 May 28,

V0, R2 May 27,

V0, R1: April 3,

V0, R0: March 15,

Review: V0, R3 reviewed by Michael Medoff (exida)

Release status: Reviewed and released

Date Author Changes

Radomir

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

2019

V0, R1: review by client and Michael

Svoboda

Radomir

Svoboda

Radomir

Svoboda

Radomir

Svoboda

Radomir

Svoboda

John Grebe Updated OS models,

John Grebe Added Safety Func-

John Grebe Update Diagnostic

John Grebe Make client re-

John Grebe Clean up to more

John Grebe Draft

Medoff (exida)

Series numbers of

R78xx Flame Amplifier corrected

Document title updated to show 7823

Flame switch separately. Model table

split to three tables

to list modules, amplifiers and sensors

separately. Safety

function split to

address 7823 flame

switch differences.

Remaining references to 7824 system removed (not in

scope)

Added a proof test

specific to 7823

Added RM7823 and

EC7823 models

(flame switch)

company name, and

changed to released

status

tion section 2.1 and

changed to released

status

Response Time

based on Fault Injection Tests

quested changes

to product model

numbers

clearly represent

products

5 32-00231-01

Page 6

RM/EC 7800 Burner Controller Safety Manual

4.2 Open issues

None

4.3 Future enhancements of the document

None anticipated

For More Information

The Honeywell Thermal Solutions family of products includes Honeywell

Combustion Safety, Eclipse, Exothermics, Hauck, Kromschröder and

Maxon. To learn more about our products, visit ThermalSolutions.

honeywell.com or contact your Honeywell Sales Engineer.

Honeywell Process Solutions

Honeywell Thermal Solutions (HTS)

1250 West Sam Houston Parkway

South Houston, TX 77042

ThermalSolutions.honeywell.com

® U.S. Registered Trademark

© 2019 Honeywell International Inc.

32-00231-01 Edition 11.19

Printed in United States

Loading...

Loading...