Page 1

Technical Note TN-151 02/08

ELECTROCHEMICAL SENSOR REPLACEMENT &

MAINTENANCE

This technical note describes sensor replacement and maintenance

procedures for electrochemical and combustible gas (LEL/TC)

sensors used in RAE Systems instruments, including MultiRAE,

QRAE, and VRAE. For technical specifications of sensors, see

Technical Note TN-114, and for handling LEL sensor poisons,

Technical Note TN-144. For CO sensor cross-sensitivity and filters,

see Technical Note TN-121.

GENERAL

• Prepare a clean workspace and wash hands well before

installing sensors. Greases and oils can cause sensors to

perform poorly. LEL sensors are particularly sensitive to

damage from silicone lubricants, including hand lotions.

• Turn off the power to the unit and remove the instrument cover.

• Disconnect the battery before replacing a sensor.

Warning: Failure to turn off the power during

replacement can cause damage to some

sensors. Failure to disconnect the battery

can cause the non-replaceable fuse in the

battery to blow.

Sensor Replacement Procedures

Remove the gas distribution plate, if any. Carefully pull the existing

sensor straight out.

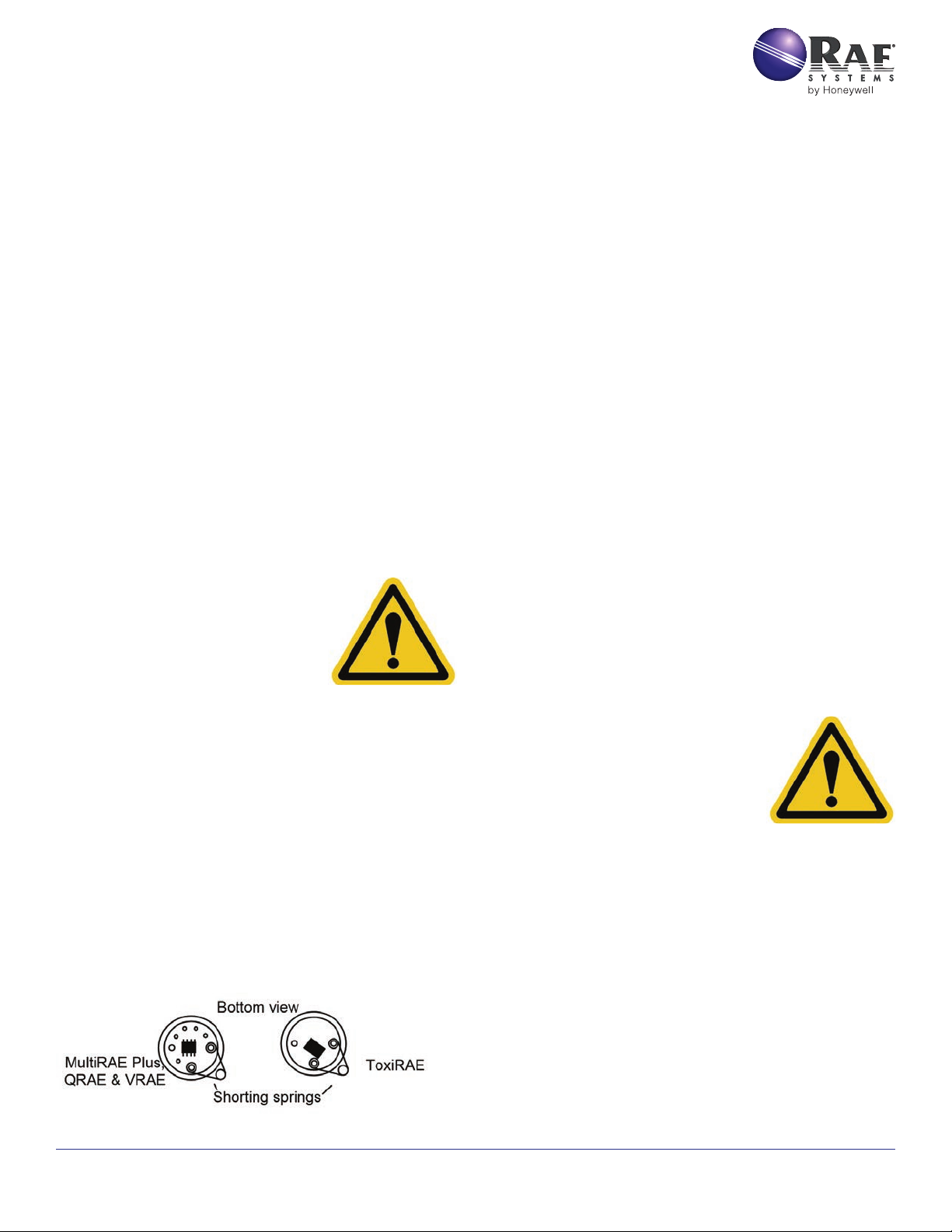

• Some electrochemical sensors are shipped with a shorting

spring connecting two of the large pins to keep the sensor

stabilized during storage. Remove any shorting spring before

installing the new sensor. Replace the spring if the sensor is

removed from the instrument for more than several minutes.

Lack of a shorting wire will not damage the sensor, but if it

is missing for more than about 10 minutes, the sensor may

require an hour or more to fully equilibrate after being installed.

Biased and LEL sensors do not have shorting springs.

• Insert the sensor by carefully lining up the sensor

pins with the sockets in the circuit board. To avoid

damaging the internal contacts, use caution and do

not bend the pins on the sensor. Bent sensor pins can

be carefully bent back using long-nose pliers.

• Do not push the sensors down too hard while

installing, as this may cause damage to the circuit

board components underneath the sensor.

• After reassembly, the unit may go into alarm if turned on

immediately. Allow about 10 minutes for the sensor to stabilize

in the unit before turning on the instrument. For maximum

accuracy, non-biased toxic sensors should be allowed to

stabilize for one hour before calibrating. Biased sensors

require a 24-hour stabilization time with batteries installed.

• Re-zero and recalibrate new sensors prior to use.

Biased Sensors (NO)

Nitric Oxide (NO) sensors require a voltage bias and must be

installed in position 1 of the MultiRAE Plus and positions 1 through

3 of the VRAE, and the bias switch must be turned on. See the

figures at the end of this Technical Note for the positions of the bias

switches and sensors.

Warning: Failure to install NO sensors in the

biased position can damage the sensors. Using

shorting springs on bias-type sensors can

damage the sensors.

Biased sensors require a 24-hour stabilization time with batteries

installed. If you receive a new unit with this sensor, install the

batteries and wait overnight before attempting to calibrate the

sensor. Units with rechargeable batteries must be kept at minimal

charge to main the bias on the sensor. If the sensors or batteries are

disconnected for more than a few seconds, it may require several

hours to again stabilize the sensor.

RAE Systems by Honeywell 877-723-2878 raesystems.com

RECALIBRATION

The MultiRAE remembers the last calibration on a given sensor

position. If a sensor is traded out, the new sensor needs about one

hour to equilibrate, and it must then be recalibrated. In the case

of a sensor with an electrical bias (NO), it must equilibrate about

1

Page 2

Technical Note TN-151 02/08

24 hours before calibrating. We recommend calibrating whenever

a sensor is removed, even if the same sensor is reinstalled in the

same location.

FILTERS

It is good practice to replace filters at the same time a sensor is

replaced. Filters may need replacement more frequently if clogged

or saturated. Filter replacement is indicated when the sensor begins

to respond slowly or take a long time to recover from an exposure. In

addition to the instrument inlet filters designed to remove particles

and water droplets, some sensors (for example, CO) need other

external filters for proper operation.

• ToxiRAE membrane filter & MultiRAE/

QRAE filter cartridges. Replace when visibly

dirty or when sensor response become slow.

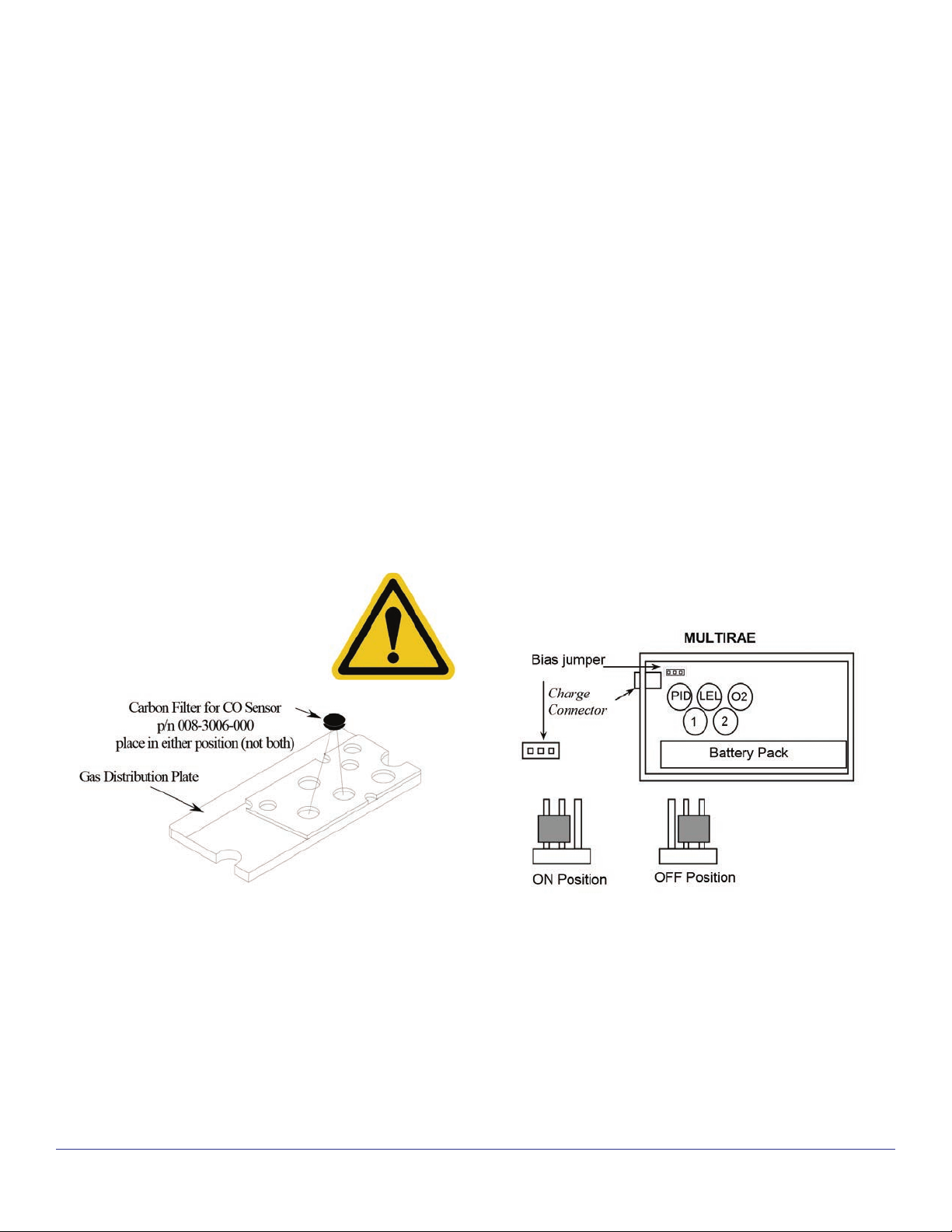

• CO sensor carbon filter. Replace when response to organic

vapors is noted or every six months, whichever comes first. This

filter is located in the MultiRAE, VRAE or QRAE cover plate.

• Remove the carbon filter if another sensor is used to

replace a CO sensor. For example, if an SO

or Cl2 sensor

2

is installed, the carbon filter removes these

gases and low readings are obtained.

Warning: Failure to remove the carbon filter

in the MultiRAE Plus cover plate for sensors

other than CO may result in low readings.

sensors are particularly sensitive to high relative

• Cl

2

humidity and may burst if stored in a refrigerator.

• Oxygen sensors are always on and are being consumed

by ambient air. These sensors are shipped in oxygenimpermeable bags. The shelf life can be extended by k

eeping the sensor in the impermeable bag until it is used.

• Replace shorting springs on non-biased sensors

for rapid start-up when reinstalled.

• Store LEL sensors away from possible catalyst poisons

such as silicone-containing greases or rubbers,

sulfur compounds, and chlorine compounds.

• The plastic containers used to ship sensors are not

air-tight and do not provide long-term protection

from humidity extremes, O

, or LEL poisons.

2

BIAS SWITCH LOCATIONS

Nitric Oxide sensors should be placed in position 1 on the MultiRAE

and positions 1 to 3 on the VRAE. The MultiRAE Plus uses a jumper

moved from the right two pins to the left two pins to turn on the

bias. The VRAE uses three switches pushed up towards the sensors

to turn on the bias. The MultiRAE can have one biased sensor and

the VRAE up to three.

STORAGE

Sensors can dry out or burst if stored at very low or very high

relative humidity, respectively. To maximize sensor life, store sensors

and instruments indoors in a climate-controlled building. Note other

special conditions:

RAE Systems by Honeywell 877-723-2878 raesystems.com

MultiRAE top view with c over plate removed showing location of

bias jumper and sensor positions.

2

Page 3

Technical Note TN-151 02/08

VRAE Internal view showing location of bias switch position and

sensor positions

Sensors PGM-7800 PGM-7840

Gas Bias

CO Off OK OK OK OK

H

S Off OK OK OK OK

2

SO

2

NO ON

NO

2

Cl

2

ClO

2

NH

3

HCN Off OK OK OK OK

PH

3

Off OK OK OK OK

Off OK

Off OK

Off OK

Off

Off OK OK OK OK

Tox1,2

Loc.

OK bias onOK bias

OK bias

off

Tox3 Loc.

on

Not

allowed

Not

allowed

Not

allowed

OK bias

off

Tox1,2,3

Loc.

OK

OK

OK

OK

OK bias

off

Tox4 Loc.

Not

allowed

Not

allowed

Not

allowed

Not

allowed

OK bias

off

INTERCHANGEABILITY

Single Sensor in Different Instruments

• Sensors for the MultiRAE, QRAE, QRAE Plus, and VRAE are

interchangeable among instruments, except for the LEL/VOL

sensor. The MultiRAE and QRAE use the 4R sensor only (p/n

008-1171-002), the VRAE uses either the 4R (p/n 017-1171-

000) or 4R/TC sensor (p/n 017-1172-000), and the QRAE Plus

uses the 3R/TC sensor (p/n 016-1171-000 or 016-1172-000).

The CO

sensor can only be used in the MultiRAE IR.

2

Different Sensors in a Single Instrument

• In the MultiRAE and VRAE, all sensors including the HCN

and PH

sensors (p/n 008-1117 and 19) are interchangeable.

3

Thus, any combination of sensors is possible, except that

the MultiRAE can have only one biased sensor (NO) because

there is only one bias position. In the VRAE, sensors with

a negative current (NO

, Cl2, and ClO2) cannot be placed in

2

position 3, and in the VRAE, sensors with a bias or negative

current cannot be placed in position 4 (see table below).

• The QRAE is limited to the four standard sensors LEL/O

/CO/H2S.

2

EXTENDED CALIBRATION TIMES

Slowly responding sensors listed in the table below may require preexposure of the sensor to the gas immediately before initiating the

calibration sequence. Some firmware versions use a fixed 60-second

calibration time; some newer versions automatically apply the full

calibration time. After completing the zero calibration, expose the

unit to the gas for the pre-exposure time listed below if a 60-second

countdown time is programmed in the unit. In many cases when a

pre-exposure is performed, the unit gives a warning message “No

gas...” when calibration is initiated. Simply push the [Y/-] button to

bypass the warning and proceed wit the calibration.

Total

Calibration

Time (sec)

2

3

Response Time

t

(sec)

90

150 150 90

60 120 60

≤40 60 0

Sensor

HCN 200 230 170

CLO

, NH3,

2

COCl

, PH

CL

2

CO, H

S, SO2,

2

NO, NO

, LEL,

2

VOL

Pre-exposure

Time for 1-min

Calibration

Time

RAE Systems by Honeywell 877-723-2878 raesystems.com

3

Loading...

Loading...