Page 1

RABO

®

Rotary Gas

Meter

Instruction

Manual

Page 2

Page 3

ELSTER

RABO® Rotary

Gas Meter

3 Honeywell

RABO® Rotary

Gas

Meter

Table of

Contents

1. General Information 3

2. Intended Use and Application 3

3. Operating Principle 3

4. Receiving, Handling and Storage 4

5. Installation 4

6. Start-up/Commissioning 6

7. Decommissioning and Removal 6

8. Inspection and Maintenance 6

9. Testing 6

10. Technical Data 8

11. Index 12

12. Pulser 14

13. Thermowell 15

14. Instrument Drive (ID) 15

15. Auxiliary Equipment Mounting 17

16. Direct mount TCI or EC350 18

17. Troubleshooting 19

1. General Inform ation

This manual covers the installation, operation

and

maintenance for the Elster Instromet RABO Rotary

Meter.

Refer

to EAM-TB

5900 for additional information.

2. Intended

Use and Application

Elster RABO meters are suitable for measur ing most types of

clean, dry, non-corrosive common gases. They are NOT

intended

for

use on biogas,

sewage

gas, oxygen, acetylene

or liquids of any kind. Product life and measurement accuracy

can be

affected

by contamination in

the gas stream. Periodic

servicing will prolong

the life and performance of

the meter.

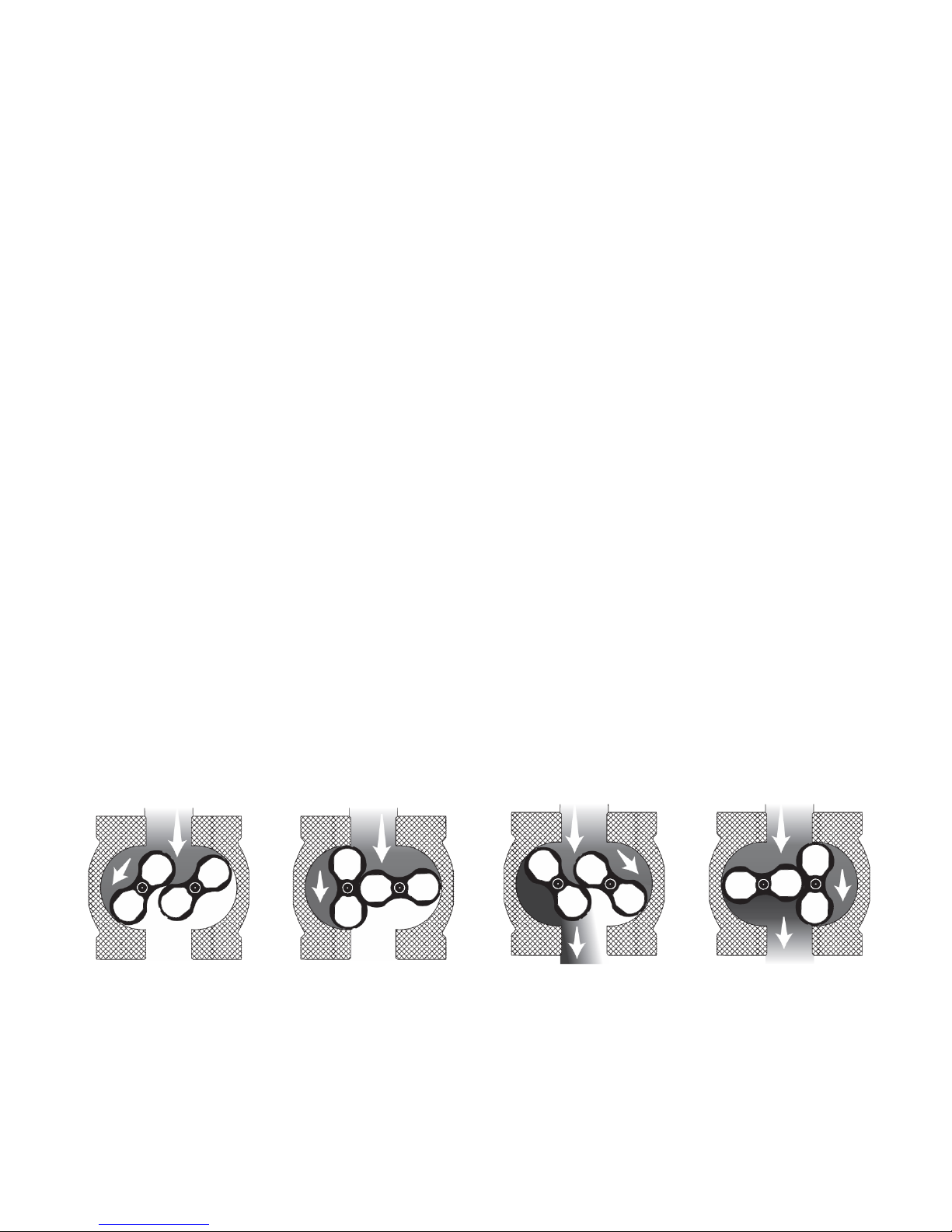

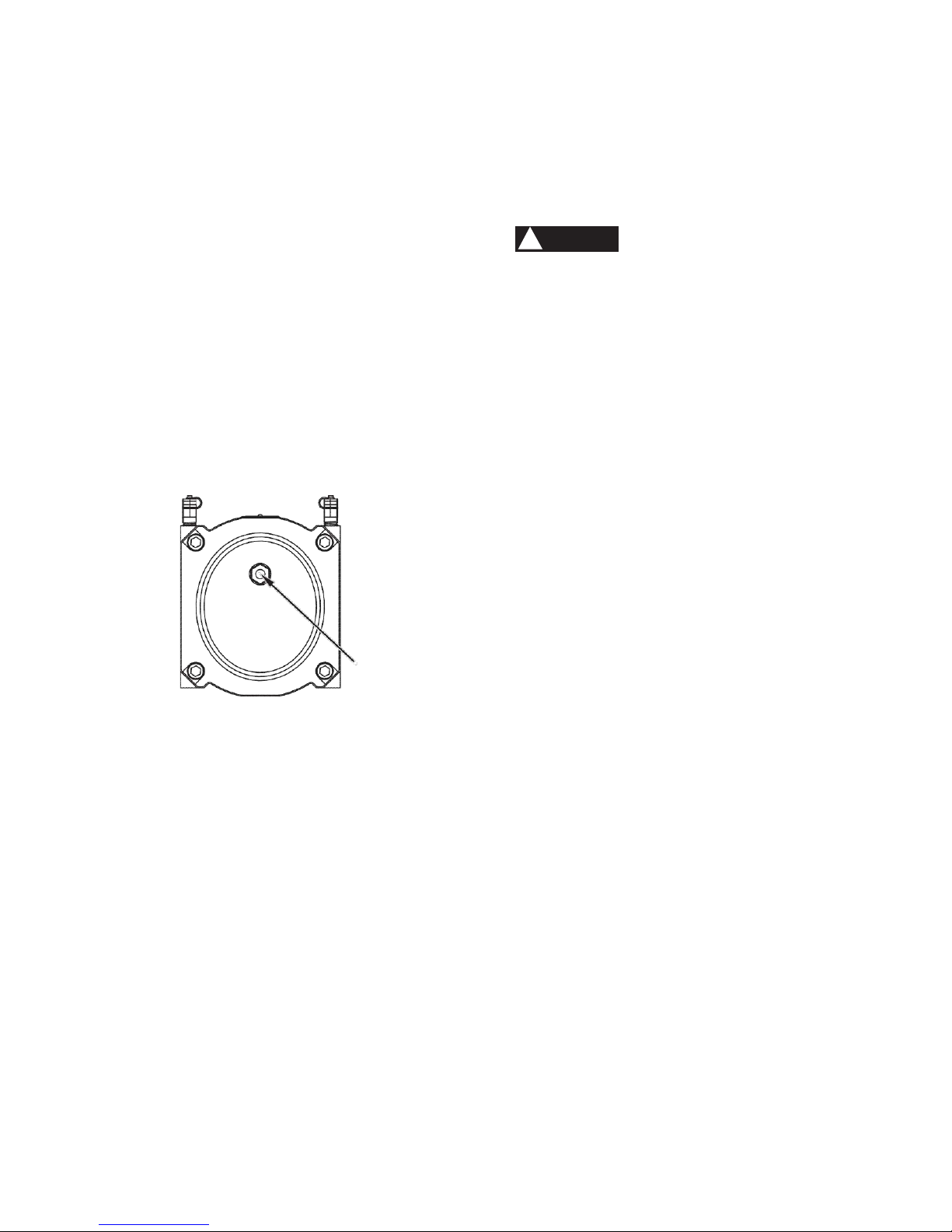

3. Operating Principle

The RABO

meter ut

ilizes positive displacement principle of

operation which

makes volumetric measurements by

displacing finite volumes of

gas. The positive displacement

occurs w

ithin a cavity formed between the meter’s internal

housing

and its rotating impellers. The counter-rotating

“figure-

8”

impellers [Figure

1]

turn as a result of

pressure

drop across

the

meter’s inlet and outlet created as downstream

gas is

consumed. The rotating

impellers

separate

the flowing gas

into small , fin ite volumes and are counted using a mechanical

index. The

RABO

meter

has no wearing parts

because

precision

clearances between

the impellers and meter body

are maintained by timing

gears,

which are

designed

to

enhance

long term accuracy. Combining

adequate

filtration

and periodic

maintenance, a RABO

meter will remain accurate

over many

years.

As the

left

impeller

rotates

toward the

vertical

position, gas enters the

cavity

created

between the

impeller and the

housing.

When the

left

impeller

reaches

the vertical

position, a

finite

volume of gas is

captured in

the

left

cavity.

As the impellers continue

to turn, the volume of gas

in the

left cavity

is

discharged.

Simultaneously, gas is

entering the space

between

the right impeller

and

housing.

After

further rotation,

the

right impeller

becomes

vertical

and a

finite

volume of gas is

captured in

the

right

cavity.

Figure 1. Operating Principle

Page 4

ELSTER

RABO® Rotary

Gas Meter

4 Honeywell

4. Receiving, Handling and Storage

Elster

RABO

meters should

be handled with care to protect

the

product from damage.

If

the package shows evidence

of damage

through mishandling in transit,

you should notify

the

shipper immediately, file

a claim with the carrier

and notify

your

Elster supplier.

Damage to internal

components may occur wit

hout

visible external

damage.

All

new meters should

be

inspected and

checked for free rotation of

the impellers

by

lightly blowing into the inlet of

the meter. This

slight

air

pressure should

cause the impellers

to rotate freely and

come to a stop

slowly.

NOTICE

DO NOT

attempt to make any repairs. Tampering with the

meter

may void warranty coverage.

If

a meter shows signs of external

damage,

or

if

the

impellers do

not rotate freely,

contact your local Elster sales

representative for return instructions.

Elster

RABO

meters are supplied

with oil in a separate

containe

r. A material safety data sheet (MSDS) is available

upon

request.DO NOT

put oil in the meter until

it is installed

and

leveled in the gas piping system. Meters containing oil

that are transported or

not installed level may lead

to

contamination of the measurement chamber, and

will impact

accuracy.

Store Elster RABO

meters in their original shipping container

in a dry location until installation.

If prolonged

storage is

experienced, RABO

meters should

be tested for accuracy

before installation.

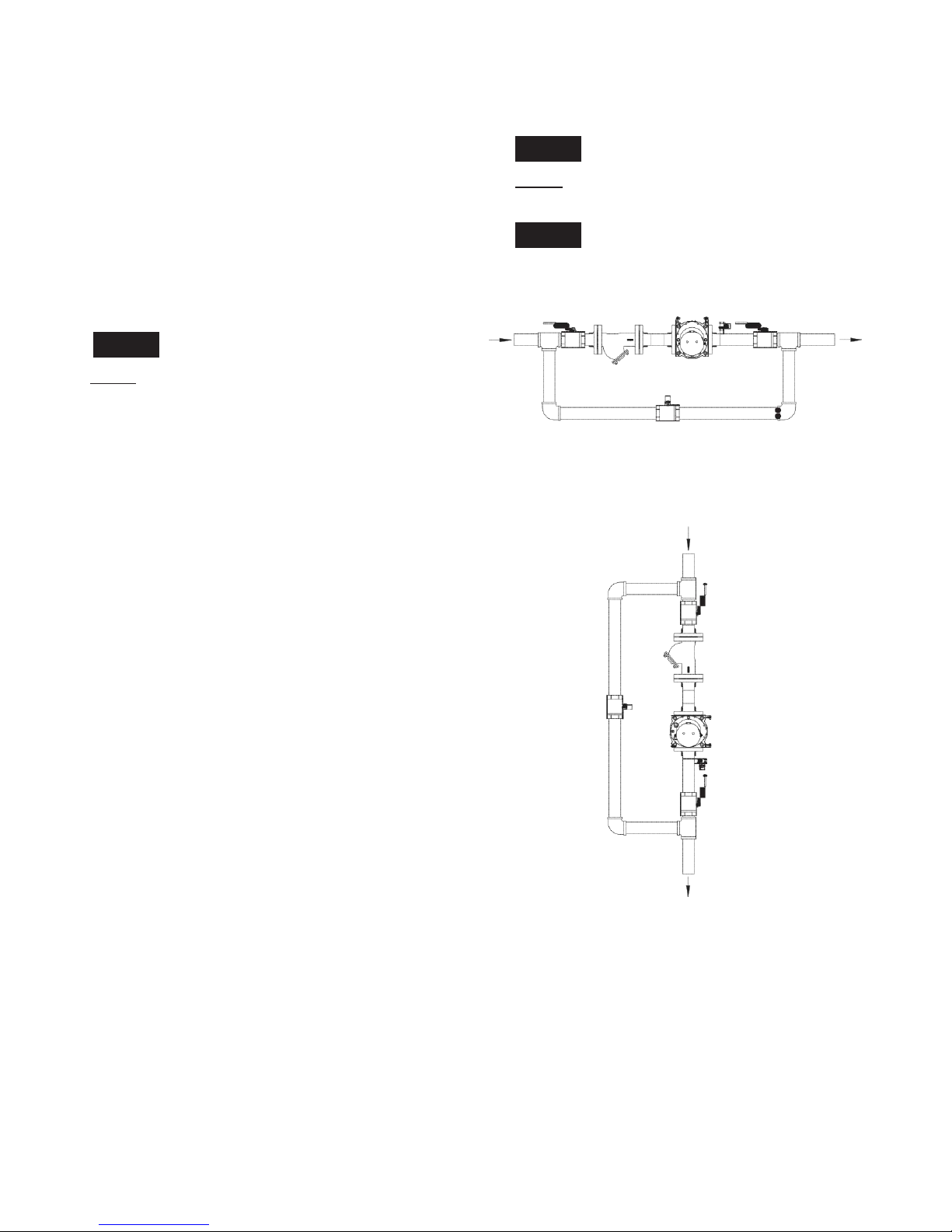

5. Installation

Elster

RABO

meters can be installed in horizontal or vertical

(top inlet) piping configurations. Vertical (top inlet) piping is

preferred

because

it

enables

the meter to pass

contaminants

more freely through the meter .

All

piping should

be properly

supported

and aligned to eliminate any strain on

the meter, which may

cau

se

the impellers to bind.

Recommended

piping practices include a

filter

or strainer on

the

inlet of the meter and non-lubricated isolation valves. A

bypass

line will facilitate

maintenance

and removal of the

meter

and provide uninterrupted gas supply.

The meter should not be installed lower than the outlet pipe

run.

If it

is

necessary

to install the meter lower than the outlet

pipe run, installation of a drip leg in the outlet piping to capture

condensate

is

recommended.

The meter should never be

located at the lowest point in the system.

A restricting

orifice

can also be installed at least 4 pipe

diameters downstream

of the outlet of the meter to prevent

the meter from flowing excess capacity. Warranty does not

cover failures due to excess

flow

conditions.

a) Piping Configurations

[Figures

2, 3 and 4]

NOTICE

DO NOT weld piping while meter is installed in

the piping system.

NOTICE

If

hydro testing, remove the meter from the piping

system.

Figure

2. Horizontal installation, side vie

w

Figure

3. Vertical installation, side view

Page 5

ELSTER

RABO® Rotary

Gas Meter

5 Honeywell

b) Mounting

1) Always follow your company’s

procedures, an

d

applicable local codes and ordinances.

2) Ensure

gas valves

are closed.

3) Ensure

the upstream piping is clean

and free of any

debris.

4) Remove protective caps from

meter inlet and outlet

prior

to installation.

5) Ensure

the impellers

turn freely.

6) Ensure

the direction of flow using the arrow on th

e

nameplate.

7) Ensure

the meter orientation is correct. Impeller

shafts must be horizontal [Figure 4].

Figure

4. Side vie

w

8) Connect the inlet and outlet pipe

flanges usin

g

appropriate bolts and gaskets. Inlet and outlet pipe

flanges s

hould

be parallel and should

not introduce

any bind

on the meter body when tightened.

9) Level meter to within 1/16“per foot in all directions an

d

tighten flange bolts evenly (maximum 80ft-lbs).

c

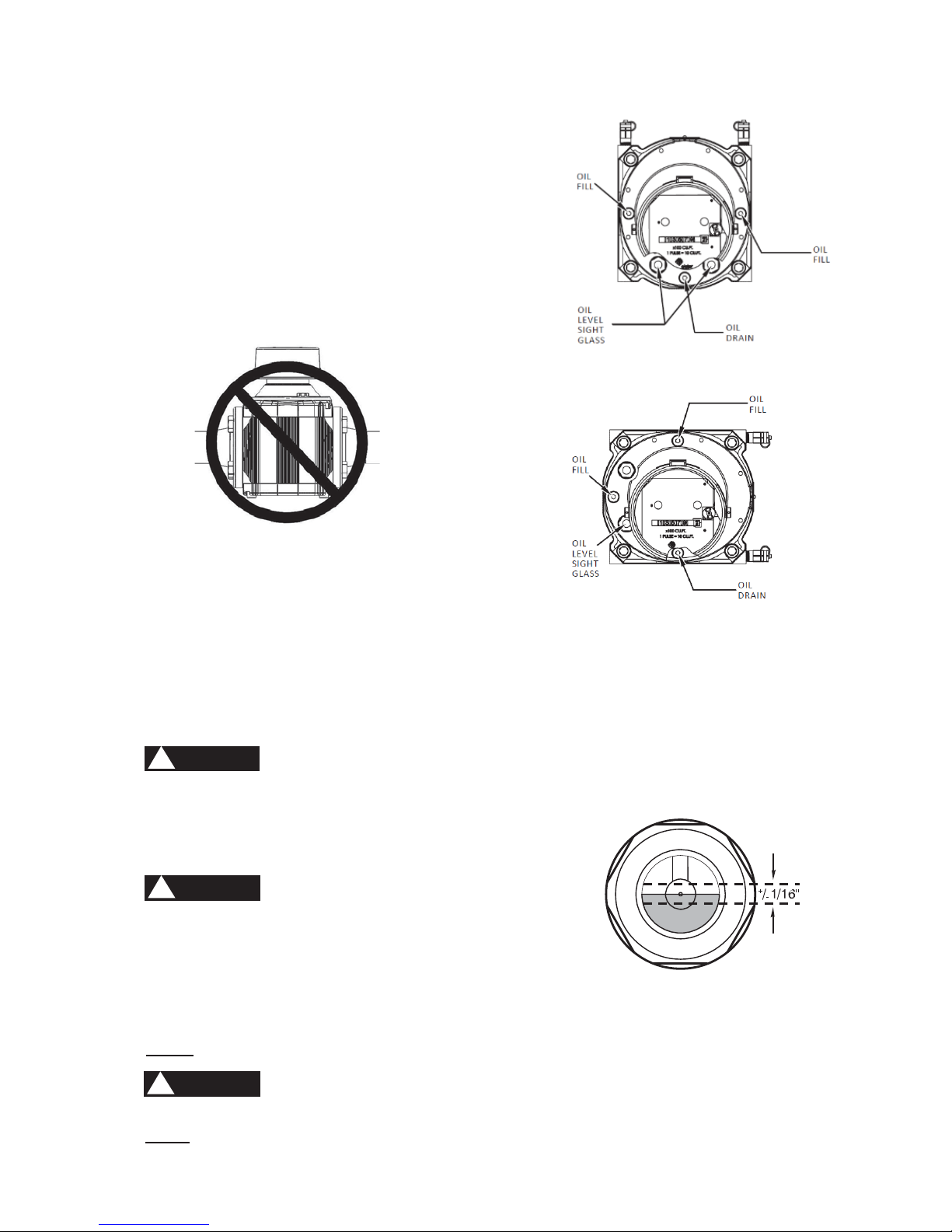

) Adding O

il

Figure

5. Horizontal installation

Figure

6. Vertical installati

on

!

WARNING

Add

oil only

to the inde

x end of the meter

.

1) Ensure gas valves

are closed

and meter and

piping are depressurized.

!

WARNING

Failure to depressurize the meter prior

to

removing meter and/or components could result

in persona

l injury and/or property damage.

2) Remove oil

fill plug in the counter end case cover

using a

5mm hex key [Figures 5 and 6].

3) Using the supplied syringe

and oil, slowly

add oil until

it is +/-1/16“of the center of

the sight glass [Figure 7]

.

DO NOT OVERFILL. Only use Shell Morlina lubricating oil.

!

WARNING

Figure

7. Sight glass

DO NOT remove any sight glasses. No maintenance

can be performed throug

h these openings.

4)

Reinstall

the

oil fill

plug.

Page 6

ELSTER

RABO® Rotary

Gas Meter

6 Honeywell

6. Start-up/Commissioning

7. Decommissioning and Removal

After

the meter has been properly installed,

it

is important to

use

extreme care during start-up to mitigate adverse

conditions

that

can

damage

the

meter.

a) Ensure

that the maximum operating

pressure of the

meter

will

not be exceeded.

b) Always follow your company’s

procedures,

and local

codes

and ordinances.

c) With

the meter run’s inlet

and outlet valves closed,

open

the

bypass valve and pressurize the piping system.

d) With

the meter outlet valve closed, slowly

open the

meter inlet valve not to exceed 5 psig

per second until

pressure is equalized throughout the meter piping

system.

Rapid pressurization can cause an over

-

speed condition and can

damage

the meter.

Damage

will

not be covered under warranty. When

the meter

piping system

pressure is stabilized,

open

the

inlet valve completely.

e) Slowly

open the meter’s outlet valve until the meter starts

to operate at

low

speed.

Meter

speed

can be seen

through

the view port located on the back of

the meter

[Figure 8].

VIEW PORT

(DO NOT REMOVE )

Figure

8. Back of meter

a) Always follow your company’s

procedures,

and local

codes

and ordinances.

b

) Slowly open bypass valve.

c) Slowly close

the meter’s outlet valve,

then the inlet valve.

d) Slowly, completely depressurize

the meter piping.

!

W

ARNING

Failure to depressurize the meter prior

to removing

m

eter and/or components could result in personal

injury and/or property damage.

e) Drain oil from the index end case cover and dispose of

the

o

il in

accordance with applicable regulations.

f) If removing

the meter from

the piping

system, loosen

flange bolts. Ensure

meter is properly supported before

removin

g bolts completely.

8. Inspecti

on

and Maintenance

It is recommended

to inspect Elster RABO

meters periodically

to h

elp

ensure accurate performance over a long period of

time. Maintenance intervals can be derived from inspection

criteria.

Routine inspections s

hould include:

a) Checking

to ensure the meter is level in all plane

s

b) Listening for abnormal sounds in

the meter

c) Checking oil level and clarity

— oil s

hould

be red and clea

r

d) Checking index

movement

if

gas is flowing

e) Checking f or le aks

f) Tes ti ng t he met er’ s differential pressure

Routine maintenance should include

:

a) Changing the oil if th e col or bec om es dark

b

) Adding oil

if

the color is

red and clear, but below the

recommended level

f)

Operate the meter at low flow for 1

to 2 minutes

to verify

proper operation.

If

the index does not start registration,

or if

you hear knocking or scraping

sounds coming from

the

meter, stop the flow and follow appropriate

decommissioning procedures before removing the

meter

from the line.

g)

If operation is satisfactory, gradually

open the meter’s

outlet valve

to the full open position.

h) Slowly close

the bypass valve.

i)

Check the meter connections for leaks using comm

on

industry practices.

j) Clock the meter (see Index section 11c)

to confirm

the flow

rate is not exceeding

the maximum capacity of

the

meter.

k) Perform and record the meter’s differential

pressure

(see Testing section 9b).

9. Testing

Elster

RABO

meters should

be tested in accordance with

applicable governing standards. The accuracy of

a meter

can

only be determined by comparing results to a traceable

reference, typically a sonic nozzle, bell, piston or transfer

prover. Accuracy may

be done on site using transfer provers,

and

typically requires removal for testing

with other

tec

hnologies.

Differential pressure testing is

a method of determining

w

hether the performance of

a rotary meter may have

changed

over time, and can be done on site while

the meter

is operating under

pressure. Baseline data must be captured

during

initial

start-up to which future data can be compared.

a) Proving

When testing a meter on a prover, the meter

temperature, pressure

and volume

are necessary

inputs for the provin

g device. The

meter temperature is

obtained by a temperature probe installed

near the inlet

of the meter. A thermowe

ll

can be installed in the meter

run

piping or on the meter itself to facilitate installation of

the

temperature probe. The

meter

pressure should

come

from the meter differential pressure taps.

Page 7

ELSTER

RABO® Rotary

Gas Meter

7 Honeywell

Pressure test ports are provided for simplified pressure

c

onnections [Figure 9].

!

W

ARNING

Below

45OF

the

neoprene

core of

the Pressure test port

s

does not recover its original shape

as rapidly as

it would

at temperatures

above

45OF. Therefore,

upon removal

of the probe used for

pressure

or temperature

readings, the valves

may not close fully

and immediately

or the

valves may remain slightly

open until the operating

temperature is

above

45OF. Duration of

probe insertion

and

pressure

are also factors in the rate of valve

closing. For this reason, plugs s

hould

not be used in

applications

where discharging gas or liquids would

create a hazard.

The gasketed cap is supplied

to

eliminate the small

amount of leakage that may occur

at

lower temperatures after probe insertion and

removal. The cap should

be left

on the plug

at all times

and tightened to deter unauthorized removal. Special

care s

hould

be taken to

assure

that readings

are taken

in the shortest space of time and that a probe is

never

left in a plug for

a period of hours or days. Severe

deformation of

the valves

may occur

if

the probe is left in

the

plug for a long period of time.

PRESSURE TEST

PORTS

Figure

9. Pressure test ports

Typically,

when proving a meter, both the meter

pressure

and

meter differential

pressure

are used and recorded.

The RABO meter differential

pressure

ports are not full

bore and

mos

t temperature

probes

will

not

fit

through

into the gas stream. Insta

lling

the temperature probe in

the

provided thermowe

ll

ports is recommended.

The

meter volume is determined

though a device

that

senses the meter revolutions. An optical pickup

can be

used on

the index proving wheel or an index pulser

may

be

used.

On-site proving, performed in-line, also requires

c

onnections

that allow air flow through the meter to the

prover.

This is accomplished

by use of pipe Tees

upstream and downstream of

the meter. A bypass loop

is

recommended for uninterrupted gas supply to the

customer.

While performing

an accuracy test, the meter is

tested fo

r

a specified volume of gas at each flow rate test point.

Poor repeatability at a given rate may be

caused

by a

test

volume that is

too small.

It

the meter does not repeat

w

ithin acceptable limits (0.1%), try increasing

the test

volume and retesting the meter. Most companies have

developed

test plans that include the volume of gas for

each

size meter at a given flo

w rate. Consult

your Elster

representative for applicable volumes.

b) Differential Pressure Testing

A differential

pressure

test is

not an accuracy test, but

it

can

be used to

gauge

the relative performance of the

meter.

Rotary meters are made from solid parts, machined

to

tight tolerances with close clearance fits, and the energy

it takes to turn the meter is generally used to overcome

the

friction of the bearings

and other rotating

parts.

If

this friction value increases,

it will

take more energy to

overcome

it. This additional

energy is measured

as an

increased pressure

drop across the meter.

The increased friction is

caused

by contamination of the

measuring

chamber and/or bearings.

Contamination in the measuring chamber can cause th

e

meter components to

wear against each other.

Contamination in

the bearings

makes them harder to

turn. Comparing

the

pressure

drop reading when the

meter

is ne

w to the reading collected after time allows

the

performance

to be monitored.

RABO

meters are supplied

with Pressure test ports

installed in the meter differential

pressure

ports [Figure

9]. This facilitates differential meter testing.

A differential

pressure

test is performed using a differential

pressure

manometer. The test is

to

measure

the

pressure

drop

across the meter at a

given flow rate, under known

operating conditions at a known date

and time.

The

meter differential curve of flo

w rate vs

pressure is

not linear. Testing

at multiple flo

w rates is suggested. It

is preferable to test at 3 rates between 25% and 100%

of flow

if possible. Differential pressure

tests at flow rates

under 25% are hard to interpret

because

the meter

differential

pressure at the lower flow rates is quite small.

The error in measurement is almost

as large as the

reading itself.

The

meter differential

pressure is also a function of lin

e

pressure

and increases as line

pressure increases.

Testing

the meter at the same conditions (line

pressure

and flow rates) yields comparable data.

A

change in

the differential

pressure indicates a

change in performance. Testing

has shown that a 50%

increase in

meter differential

pressure (at flow rates over

25%), indicates almost a 1.0% change in

meter

accuracy. Baseline data must be captured during initial

start-up to w

hich future

data can be compared.

If

the differential

pressure

test shows an increase in the

meter

pressure

drop at a given flow rate of

more than

50%

from the original value (1.5

x original value),

then

it

is recommended

that the meter be removed and

serviced.

The frequency of deferential testing is

at the discretion of

the user.

Page 8

ELSTER

RABO® Rotary

Gas Meter

8 Honeywell

10.

Technical

Data

a) Performanc

e

Units

3.5M/G65

5.5M/G100

9M/G160

14M/G

250

Rangeab

ility

90:1

160:1

160:1

160:

Start Rate

acfh [a

m3/h]

1.3 [0.04]

0.9

[0.03]

2.5 [0.07]

2.5 [0.07]

Stop Rate

acfh [a

m3/h]

1.1 [0.03]

0.8

[0.02] 1.9 [0.05]

2.3 [0.07]

Flow Rate

at ½“ w.c.

DP, Gas

acfh [a

m3/h]

2,715 [77]

4,074

[115] 5,722 [162]

6,740 [191]

Differential

Pressure at 100% Flow Rat

e

in.w.c. [mBar

]

1.46 [3.64]

1.23 [3.06] 1.70 [4.23]

2.65 [6.60]

Note: Values

are for air, except Flow Rate at ½“w.c.

DP, which are natural gas values

.

b) Sizing Chart

Using

the chart below, select the appropriate

meter by using the Maximum Instantaneous Flow Rate (scfh) and the

Minimum Operating

Pressure (psig)

at any given point in time.

Example: A flow rate of

25,000 scfh

and an operating

pressure

range of 75–100 psig would require a 5.5M meter

based

on a

75

psig minimum inlet pressure.

Model

3.5M/G65

5.5M/G100

9M/G160

14M/G

250

psig [Barg]

Corrected Capacity in scfh

[sm3/h]

0.25

[0.0]

3,500

[100

]

5,500

[160

]

9,000

[

250

]

14,

000

[

400]

2

[0.1]

3,900

[110

]

6,100

[170]

10,

000

[

280

]

15,

600

[

440]

5

[0.3]

4,600

[130

]

7,200

[

200

]

11,900

[

340

]

18,

400

[

520]

10

[0.7] 5,800

[160

]

9,100

[

260

]

14,

900

[

420

]

23,200

[

660]

20

[1.4]

8,200

[

230

]

12,

800

[

360

]

21,

000

[

590

]

32,700

[

930]

30

[2.1]

10,

500

[

300

]

16,

600

[470]

27,100

[770

]

42,200 [1,190]

40

[2.8]

12,

900

[370]

20,300

[570]

33,200

[

940

]

51,700 [1,460]

50

[3.4]

15,

300

[

430

]

24,000

[

680

]

39,300

[1,110

]

61,

200 [1,730]

60

[4.1]

1

7,700

[

500

]

27,800

[790

]

45,500

[1,

290

]

70,700 [2,000]

75

[5.2]

21,

200

[

600

]

33,400

[

950

]

54,600

[1,

550

]

85,000 [2,410]

100

[6.9]

27,200

[770

]

42,700

[1,210]

69,900

[1,

980

]

108,700 [3,080]

150

[10.3]

39,100

[1,110

]

61,

400

[1,740]

100,

400

[2,

840

]

156,

300 [4,

430]

175

[12.1] 45,000

[1,270]

70,700

[2,

000

]

115,700

[3,

280

]

180,

000 [5,100]

250

[17.2]

62,800

[1,780]

98,700

[2,790]

161,500

[4,570]

251,

300 [7,120]

290

[20.0]

72,300

[2,

050

]

113,700

[3,

220

]

186,

000

[5,270]

289,300 [8,190]

Note:

All capacities based

on 14.4 psia atmospheric pressure, 14.73 psia base pressure, and

60OF

base temperature.

Page 9

ELSTER

RABO® Rotary

Gas Meter

9 Honeywell

c) Dimensions and Weight

s

RABO standard:

Units

3.5M/G65

5.5M/G100

9M/G160

14M/G

250

A

in. [mm]

6.75

[171]

6.75 [171]

9.5 [241]

9.5

[241]

B

in. [mm]

7.56 [192]

7.56 [192]

10.08 [256]

10.08 [256]

C

in. [mm]

8.63 [219]

8.63 [219]

10.75 [273]

10.75 [273]

D

in. [mm]

3.78

[96]

5.43 [138]

5.16 [131]

6.14 [156]

E

in. [mm]

7.52 [191]

9.17 [233]

10.67 [271]

11.65 [

296]

F

in. [mm]

11.26 [

286]

14.61 [371]

15.83 [402]

1

7.76 [451]

G

in. [mm]

3.78

[96]

3.78

[96]

5.04 [128]

5.04 [128]

Nom. Pipe Size* in. [mm]

2

3

3

4

Bolt Size, H

5/8“ - 11

5/8“ - 11

5/8“ - 11

5/8“ - 11

# Bolts/Flange

4

4

4

8

Bolt Circle, J in. [mm]

4.75

[121]

6.00

[152]

6.00

[152]

7.50 [191]

Shipping Weight

Ibs. [kg]

29.8

[14]

37.7

[17]

73.9

[34]

82.3 [37]

Carton Size

in.

18.3L

x 10.6W x 12.6H

23.6L x 13.0W x 13.4H

[mm]

465L x 270W x

320H

600L x 330W x

340H

*ANSI Class 125/150 flat face flange c

onnection

Page 10

ELSTER

RABO® Rotary

Gas Meter

10 Honeywell

RABO-ID:

Units

3.5M/G65

5.5M/G100

9M/G160

14M/G250

A

in.

[mm]

6.75

[171]

6.75

[171]

9.5

[241]

9.5

[241]

B

in.

[mm]

7.56

[192]

7.56

[192]

10.08

[256]

10.08

[256]

C

in.

[mm]

8.78

[223]

8.78

[223]

11.30

[287]

11.30

[287] D in.

[mm]

3.78

[96]

5.43

[138]

5.16

[131]

6.14

[156]

E

in.

[mm]

9.53

[242]

11.23

[285]

12.72

[323]

13.67

[347]

F

in.

[mm]

13.31

[338]

16.66

[423]

17.88

[454]

19.81

[503]

Shipping Weight

lbs.

[kg]

32.3

[15]

40.2

[19]

76.4

[35]

84.8

[39]

Carton Size

[in.]

18.3L x 10.6W x 12.6H

18.3L x 10.6W x 12.6H

23.6L x 13.0W x 13.4H

23.6L x 13.0W x 13.4H

[mm]

465L x 270W x 320H

465L x 270W x 320H

600L x 330W x 340H

600L x 330W x 340H

Page 11

ELSTER

RABO® Rotary

Gas Meter

11 Honeywell

RABO-TCI:

Units

3.5M/G65

5.5M/G100

9M/G160

14M/G250

A

in.

[mm]

6.75

[171]

6.75

[171]

9.5

[241]

9.5

[241]

B

in.

[mm]

7.56

[192]

7.56

[192]

10.08

[256]

10.08

[256]

C

in.

[mm]

10.24

[260]

10.24

[260]

12.76

[324]

12.76

[324]

D

in.

[mm]

3.78

[96]

5.43

[138]

5.16

[131]

6.14

[156]

E

in.

[mm]

11.18

[284]

12.83

[326]

14.33

[364]

15.31

[389]

F

in.

[mm]

14.96

[380]

18.27

[464]

19.49

[495]

21.46

[545]

G

in.

[mm]

4.92

[125]

4.92

[125]

4.92

[125]

4.92

[125]

H

in.

[mm]

3.74

[95]

3.74

[95]

3.74

[95]

3.74

[95]

K

in.

[mm]

8.66

[220]

8.66

[220]

8.66

[220]

8.66

[220]

Shipping Weight

lbs.

[kg]

32.8

[15]

40.7

[19]

76.9

[35]

85.3

[39]

Carton Size

[in.]

22L x 12W x 16H

28L x 16W x 19H

[mm]

559L x 305W x 153H

711 x 406 x 483H

Page 12

ELSTER

RABO® Rotary

Gas Meter

12 Honeywell

RABO-EC350:

Units

3.5M/G65

5.5M/G100

9M/G160

14M/G250

C

in.

[mm]

11.42

[290]

11.42

[290]

13.00

[330]

13.00

[330]

D

in.

[mm]

3.78

[96]

5.43

[138]

5.16

[131]

6.14

[156]

E

in.

[mm]

16.22

[412]

17.87

[454]

19.37

[492]

20.35

[517] F in.

[mm]

20.00

[508]

23.31

[592]

24.53

[623]

26.50

[673]

G

in.

[mm]

3.86

[98]

3.86

[98]

5.12

[130]

5.12

[130]

H

in.

[mm]

5.12

[130]

5.12

[130]

5.12

[130]

5.12

[130]

K

in.

[mm]

8.98

[228]

8.98

[228]

10.24

[260]

10.24

[260]

R

in.

[mm]

5.71

[145]

5.71

[145]

5.71

[145]

5.71

[145]

Shipping

Weight

lbs.

[kg]

36.0

[17]

48.0

[22]

83.0

[38]

94.0

[43]

Carton

Size

[in.]

22L x 12W x 16H

28L x 16W x 19H

30L x 16W x 19H

[mm]

559L x 305W x 153H

711 x 406 x 483H

762 x 406 x 483H

11. Index

All RABO

meters are equipped with a

non-resettable

totalizing odometer-style index that displays volume in

actual cubic feet. The index is sealed by an ultravioletresistant Lexan

cover, requires no maintenance and is

completely isolated from gas pressure.

a) Rotatable

The RABO index can rotate 355

degrees

to facilitate

desired reading angle, depending

on the installation

orientation. To rotate, simply

grasp the index with both

hands and turn to

the desired position.

b) How to Read

The

odometer index is

masked to expose the desired

digits and units of

measure

to meet individual

requirements.

On all

meters, the right-most digit

will

be

highlighted with a red

square

on the index mask, and

will always increment in cubic feet. This digit is typically

not

included in

the meter read and is primarily used to

indicate flow rate.

When

reading

an odometer, record all

the digits

except

the digit

surrounded

by the red

square

on the

index

mask, and multiply

it

by the factor

shown on the

index face plate. In th

e example

on the next page,

the

reading would

be 1357900 cubic feet. [Figure 10]

.

Page 13

ELSTER

RABO® Rotary

Gas Meter

13 Honeywell

3. Pull

off

the index cover.

•

It helps to rock

it slightly.

•

Be careful not to

damage

the masking plate

and index when removing

the cover.

4.

Carefully pull

off

the index masking plate [Figure 12]

.

Figure 10. Index

Figure 12. Index masking

plate

c) How to “Clock” a Mete

r

5. Remove the three index retaining screws usi ng a

T20

driver [Figure 13]

The odometer index can be used to calculate the

instantaneous flow rate by using the right -most digit ( test

dial). Each number on this dial represents on e (1) cubic

foot, and one complete revolution of t his dial represents

ten (10) cubic feet. You will need a stop watch or a watch

with a sweep second hand to calculate flow rate.

1.

Measure the time, in

seconds, that

it

takes the test

dial to make one complete revolution (10 cubic feet).

2. Use the following formula

to calculate flow

rate: Flow Rate (acfh)

= (10 ÷ “time”) x

3600

Note that the

odometer inde

x does not

compensate

for elevated pressure or temperature. Correctio

n

factors w

ill

need to be applied to adjust

the flow rate

to

standar

d conditions (scfh).

d) Removal, Installation

and Replacement

Steps

to replace the

RABO

meter index:

SUPPORT

HOLE

INDEX

RETAINING

SCREW

Figure 13. Index retaining screws

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

1.

Cut the seal wires and remove from

the holes [Figure 11].

2.

Remove (unscrew)

the two brass screws on the

sides of the index cover [Figure 11].

SEALS

Figure 11. Index cover seals

6. Carefully remove the index

•

Pay attention to the driven

magnet —

it is

supported by the index.

• Leave the magnet on the meter.

7.

Transfer the

change

gear from

the

damaged index

to

the replacement [Figures 14

and 15].

• Remove

the

change

gear on the

damaged index.

•

Pry the locking collar

off with

a knife blade or othe

r

sharp object.

•

Unscrew the

change gear.

!

W

ARNING

Eac

h meter size uses a common inde

x that

h

as unique colored gears. Interchanging

colored gears

will result in inaccurate

readings. Ensure the replacement inde

x has

the same

color gears. [Refer to Table 1]

•

If

the replacement index has a

change

gear,

remove and discard it.

•

Attach the

change

gear from

the

damaged index

to the same

shaft

on the replacement index.

• Secure

gear on shaft.

•

Snap on the locking collar.

Page 14

ELSTER

RABO® Rotary

Gas Meter

14 Honeywell

.

Figure 14. Change gear removal Figure 16. IN-S10 pulser installed

Meter Gear Color

3.5M/G65 White

5.5M/G100 Dark Green

9M/G160 Green

14M/G250 Red

Table 1

Figure 15. Index,

change

gear and locking collar

8. Install

the replacement index.

• Orient the index so the mounting holes

line

up with the posts in

the base plate.

• Carefully

ensure the shaft on the

magnet

holder is in

the support hole

on the

index frame [Figure 13].

• Install

the three screws to retain

the index

to the

base plate. Tighten to snug.

9.

Install index masking plate.

10.

Install index cover.

11. Install security seals

.

12. Pulser (“Form A” Cont act Closure Device)

All RABO meter indexes can be easily outfitted with a pulse

output device

to interface with auxiliary equipment.

Installation of a pulser is quick and easy, and requires

no

disassembly. To install

a pulser, simply slide the pulser into

the slot on the index cover [Figure 16], an d connect the wires

to the desired auxiliary devices

[Figure 17]. The pulser

can be

secured to the

index

cover screw with a seal wire

to mitigate

and

indicate tampering.

!

W

ARNING

E

xplosion Hazard

Auxiliary equipment and interconnecting wiring must be in

accordance with local

and national codes for hazardous areas

.

Figure 17. Pulser Connections

Page 15

ELSTER

RABO® Rotary

Gas Meter

15 Honeywell

13.

Thermowell

All RABO meters come equipped with two (2) ¼“ NPT aux

iliar

y

ports on the meter body [Figure 18], which

can be used for

sensing

pressure

and temperature of

the flowing gas. A

thermowell is required when using a temperature sensing

device. Thermowells are available

as accessories to the

meter.

NPT AUXILIARY PORTS

14.

Instrument

Drive (ID)

All RABO meters can be retrofitted with

an instrument drive,

or

instrument adaptor plate. The ID provides a mounting

surface for instruments requiring mechanical rotationa

l

i

nput. The drive

rate of

the

RABO ID is 10 cubic feet

per

1

revolution in

a clockwise direction. When installing

an

instrument, orient the instrument face to the FRONT edge of

the

adaptor plate. The threads in

the adaptor plate for

instrument mounting

are 5/16” - 18.

Figure 19. RABO with Instrument Driv

e

Figure 18. Aux

iliary ports

a) Installing

a Thermowell

1. If

meter is

not installed in the gas piping, go to

Step 5.

2.

Slowly open bypass valve.

3.

Slowly close the meter’s outlet valve,

then the inlet

valve.

4.

Slowly, completely depressurize the meter piping.

5.

Remove one of

the plugs in

the meter body by

using a ¼“

hex key.

6. Apply Teflon

tape or pipe

dope to the male

threads of

the thermowell. Wipe excess pipe

dope

off

the

thermowell

probe and leading threads to ensure no

pipe dope

enters the metering chamber.

7.

Screw

the thermowell into

the meter and tighten to

18 ft-lbs.

8. Re-pressurize

the meter as instructed in Start-up

/

Commissioning (see section 6).

a

)

Retrofit

a

CTR (CTR

= Uncorrected Mechanical Totalizer)

meter with

an Instrument Drive (ID).

i) Remove index. See section 11. d) 1 to 11. d) 6

ii) Transfer the

change

gear from

the

CTR index to the ID

gearing

and index assembly [Figure 14 and 20]

.

(1)

Pry

the

change gear’s locking collar

off with

a

knife blade

or other similar object.

(2)

Unscrew the

change

gear from

the

CTR index.

(3)

Attach the

change

gear to the middle gear on the

back side of

the ID gearing

and index assembly.

(4) Reinstall locking collar to retain

the

change gear.

CHANGE

GEAR

LOCKING

COLLAR

Figure 20. Change gear ins tallation on

ID gearing and index assembly

iii)

Remove the magnet holder assembly from the meter

[Figure 21],

Magnet

holder

Figure 21. Magnet holder

Page 16

ELSTER

RABO® Rotary

Gas Meter

16 Honeywell

iv)

Unscrew the lock

nut from

the magnet holder

(THREADS

ARE LEFT HAND) [Figure 17].

LOCK

NUT

SUPPORT

HOLE

(ON

BACK SIDE)

INDEX

RETAINING

SCREW

CHANGE

GEAR

MAGNET

HOLDER

Figure

22. Magnet holder,

change

gear, and lock nut

v) Unscrew the

change

gear from

the magnet

holder

(THREADS

ARE LEFT HAND) [Figure 22].

INDEX

RETAINING

SCREW

Figure

24. ID retaining screws

INDEX

RETAINING

SCREW

vi)

Assemble the

change

gear to the ID

magnet holder

(THREADS

ARE LEFT HAND).

(1) For 3.5M meters

(a) Apply Loctit

e

®

770 primer

to the threads and mating

surfaces of

the

change

gear and the magnet holde

r

[Figure 23]. Allow to dry for 30 seconds.

(3) Tighten

the three screws until snug. Do not overtighten.

(a)

Each

screw should

have a 2mm thick retaining

washer to space the

ID gearing and index

assembly

away from

the base plate [Figure 25].

The spacers

are installed

at the factory. Verify

they have

not fallen off.

APPLY

LOCTITE

®

PRIMER. APPLY

CA

RETAINING

WASHER

APPLY

LOCTITE

®

PRIMER

Figure 25. Retaining washers

Figure 23. Magnet holder and change gear adhesive

application for 3.5M meter.

(b)

Apply Loctite

®

406, Loctit

e

®

495, or equivalent

Cyanoacrylate adhesive

to the threads and

mating surface of the magnet holder [Figure

23].

Do not get the adhesive

on the small tip

of the magnet holder.

(c)

Quickly screw the

change

gear to the magnet

holder (THREADS ARE LEFT HAND) and tighten until

gear is snugly seated against

magnet holder. Let

dry

completely

(d)

Do not reinstall

the locknut for

a 3.5M mete

r.

(2) For

5.5M, 9M and 14M meters

(a)

Screw

the

change

gear to the magnet

holder (THREADS ARE LEFT HAND) and tighten

until

gear is snugly seated against magnet

holder.

(b)

Reinstall

the lock

nut (THREADS ARE LEFT HAND)

removed

in a previous step. Tighten until snug.

vii) Install the ID

magnet holder onto the end of

the mete

r.

v

iii) Install

the ID gearing

and index assembly on meter.

(1) Orient the ID gearing

and index assembly so th

e

m

ounting

screws line up with the posts in

the

index

base plate.

(2) Ensure the shaft on the magnet holder aligns

w

ith

the support hole on the index frame [Figure 24].

ix)

Check for binds

(1) Using

compressed air blown into

the meter inlet port

,

confirm the index and ID

output shaft rotate freely.

x) Snap

the ID index masking plate

onto three posts of

the

index.

xi)

Install

the ID index cover.

(1) Lightly lubricate the blue

or purple O-ring on the inde

x

base plate with silicone O-ring grease.

(a)

Do not use petroleum

based lubricants

on this O-ring.

(2) Place

the ID index

cover onto the index base plate

w

hile aligning the holes

on the side of the index cover

w

ith the holes in the index base plate.

(3) Install the brass index cover mounting

screws which

were removed in

a previous step. Tighten the screws

just until

the screw head contacts the cover, then

back

the

screw out until the seal wire holes align.

xii)

Attach the support bracket to the accessory mount

holes in

the meter case cover [Figure 19, 26].

NOTE:

To avoid binds please pay particular attention

to the sequence given below.

(1) The ID

can be attached to a meter installed for

horizontal or vertical flow.

Use the appropriate

accessory

m

ount holes.

Page 17

ELSTER

RABO® Rotary

Gas Meter

17 Honeywell

NOTE: Regardless the meter orientation installation,

the ID adaptor plate must be mounted horizontally

during operation

so that the ID

mounted accessory

is in a vertical orientation

Figure 26. Support bracket attachment

(2) Using a 5mm Allen wrench, loosely install two M6

socket head cap screws through the support bracket

into the meter case cover [Figure 26]. The screws

will be tightened after alignment of all parts.

xiii) Install the adaptor plate assembly

(1) Lubricate the adaptor plate assembly O-ring with silicone

O-ring grease, light machine oil or petroleum jelly.

(2) Carefully align the slot of the output shaft to the flat of the

ID index output [Figure 27].

(3) Fully insert the adaptor plate assembly post into the

index cover output hole.

(4) Orient the adaptor plate to the desired direction (4

positions are possible: Fa c i ng away from the m eter,

facing the meter, facing the meter inlet, or facing the

meter outle t).

xiv) Using a 5mm Allen wrench, install two M6 socket head

cap screws through the adaptor plate into the support

bracket assembled in a previous step [Figure 28].

Tighten to 45-50 in-lbs.

xv) Using a 3mm Allen wrench, install two set screws

through the index cover neck to secure the adaptor plate

assembly [Figure 29]. Tighten snuggly.

xvi) Tighten the two M6 socket head cap screws installed

earlier (to affix the support bracket to the meter case

cover) to 45-50 in-lbs.

xvii) Check for binds: Using compressed air blown into the

meter inlet port, confirm the index and the instrument

drive rotate freely

xviii) Install security seals as required

(1) Security wires are included to secure the index cover

mounting screws and the support bracket lower mounting

screws.

(a) To install, feed the security wire through the holes in

the drilled head screws, thread the free end of the

wire through the hole in the center of the seal, pull

tight, and snap the seal together.

(2) Red Security seals (plugs) are included to seal the support

bracket upper mounting screws.

(a) To install, press the seals in the adaptor plate holes

over the screws until they are fully seated.

b) Changing the meter from horizontal to vertical flow and

vice versa

i) Remove instrument from instrument drive if applicable

(refer to instrument manual for detailed information).

ii) Using a 3mm Allen wrench, remove the two set

screws from the index head.

iii) Using a 5mm Allen wrench, remove the two M6 socket

head cap screws from the adaptor plate.

iv) Pull the adaptor plate assembly off the index head with

a smooth rectangular movement.

v) Using a 5mm Allen wrench, remove the two M6 socket

head cap screws that affix the support bracket to the

case cover.

vi) Rotate the complete index assembly into the desi red

position depending on the meter orientation.

vii) Re-Assemble the instrument drive using the steps

described in a) xii) to xviii).

(1) for 3.5M and 5.5M meters use the support bracket

that you removed before.

(2) for 9M and 14M meters use the additional support

bracket that was supplied with the instrument drive kit

or with your meter.

15. Auxiliary Equ i pm ent Mo unt in g

All RABO meters are equipped with threaded holes for mounting

compact, lightweight auxiliary equipment [Figures 30 and 31].

All holes are M6 x 1 by 10mm deep. Heavier equipment should

be pipe or wall mounted adjacent to the meter. Elster provides

customized brackets for commonly used equipment [Figure 32].

Please contact your local Elster representative for details.

Page 18

ELSTER

RABO® Rotary

Gas Meter

18 Honeywell

16. Direct mount TCI or EC350

The RABO meter can be shipped by the factory with either a Honeywell Mercury Instruments Temperature Compensation

Index (TCI) or an Electronic Volume Corrector (EC350) directly mounted to it, with or without an Autom ated Meter Reading

(AMR) device attached to it. The TCI is an advanced, yet simple to use, electronic temperature compensating index available

for natural gas rotary meters. The TCI is an ideal replacement for mechanical TC indexes.

For higher volume application and greater accuracy, the RABO meter can be fitted with the EC350. The EC350 is Honeywell’s

latest Gas Volume Corrector pla tform. It features new high accuracy/stability digital pressure transducer, Cellular 4G/LTE

communication, advanced audit trail capability and lowers ownership and operating costs

Detailed assembly instructions can be found in the manual delivered with the co rrector or temperature compensation index.

Page 19

ELSTER

RABO® Rotary

Gas Meter

19 Honeywell

17.

Troubleshooting

Problem Probable

Cause

Suggested Action

Excessive

vibration Build-up of foreign material on impellers

Misalignment

Clean by flushing, or replace worn

parts

Level

meter in piping

Worn

bearings

Replace

bearings

Worn timing

gears

Replace timing

gears

Impellers contacting

body

Rotate manually to

verify

impellers spin freely

High differential

pressure Heavyweight or too much oil

Dirt

deposits on impellers

Check

oil

level and condition

Remove dirt by flushing

Impellers out of time Retime impellers

Impellers contacting

body

Rotate manually to

verify

impellers spin freely

Low

registration Upstream or bypass

leak

Check all valves for

leakage

Non-registration Broken or binding index

odometer

Obstruction in

meter

Replace

odometer

Remove meter, remove obstructions, flush

meter

Page 20

ELSTER

RABO® Rotary

Gas Meter

20 Honeywell

About

Elster

Gas

Elster provides best-in-class measurement

and regulation products, systems an

d

solutions for the safe control

and delivery of natural

gas across the globe.

Trusted Brands

• Elster American

Meter Company, LLC

• Elster Perfection Corporation

• Elster Instromet

• Elster Canadian

Meter Company, LLC

• Elster Gas Depot

• Elster Meter Services

Elster American Meter Company, LLC

2221 Industrial Road

Nebraska

City, NE

68410

USA

T +1

402 873

8200

F +1

402 873 7616

www.elster.com/gas

Elster is now part of Honeywell.

© 2017 by Elster. All rights

reserved. Information contained herein is subject

to

change without notice.

Contact your Elste

r representative for the most current

product information.

Elster

and Elster Logo

are trademarks of Elster American Meter

Company

LLC.

7

3023895d/07.2018/NZ

Loading...

Loading...