Page 1

TRADELINE

RA89A, RA832A, R845A

Switching Relays

Application

These relays can be used for a variety of switching

applications. Typically they provide control of line- or lowvoltage devices by a low voltage controller.

The RA89A is a pdst relay. A parallel, double pole relay

provides one line voltage connection with increased current

capacity. A removable jumper allows line voltage to be selected

from the transformer input or through a separate connection.

The RA832A is a tpst relay. One relay pole is designed

for low voltage or millivoltage (Powerpile) auxiliary load.

Two other relay poles are for line voltage loads.

The R845A is a dpst relay. One relay pole can switch

line voltage while the other pole is used for line- or lowvoltage switching. All relays have an internal transformer

to provide low voltage power for the controller.

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

instructions can damage product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Make sure installer is a trained, experienced service

technician.

4. After completing installation, use these instructions

to check out product operation.

WARNING

!

ELECTROCUTION HAZARD CAN

CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH.

Transformer core not bonded.

Disconnect power supply before wiring to pre-

vent electrical shock or equipment damage.

MOUNTING

For replacement, mount the relay in the same location

as the old relay. If this is a new installation, locate the relay

vertically on a solid wall or partition as near as possible to

the device to be controlled. Select a location that is easily

accessible for installation and service.

NOTE: To reduce the possible transformer hum and relay

noise that is sometimes amplified by mounting surfaces

such as sheetmetal, plasterboard, and similar materials,

place rubber or felt washers between the case and the

mounting surface.

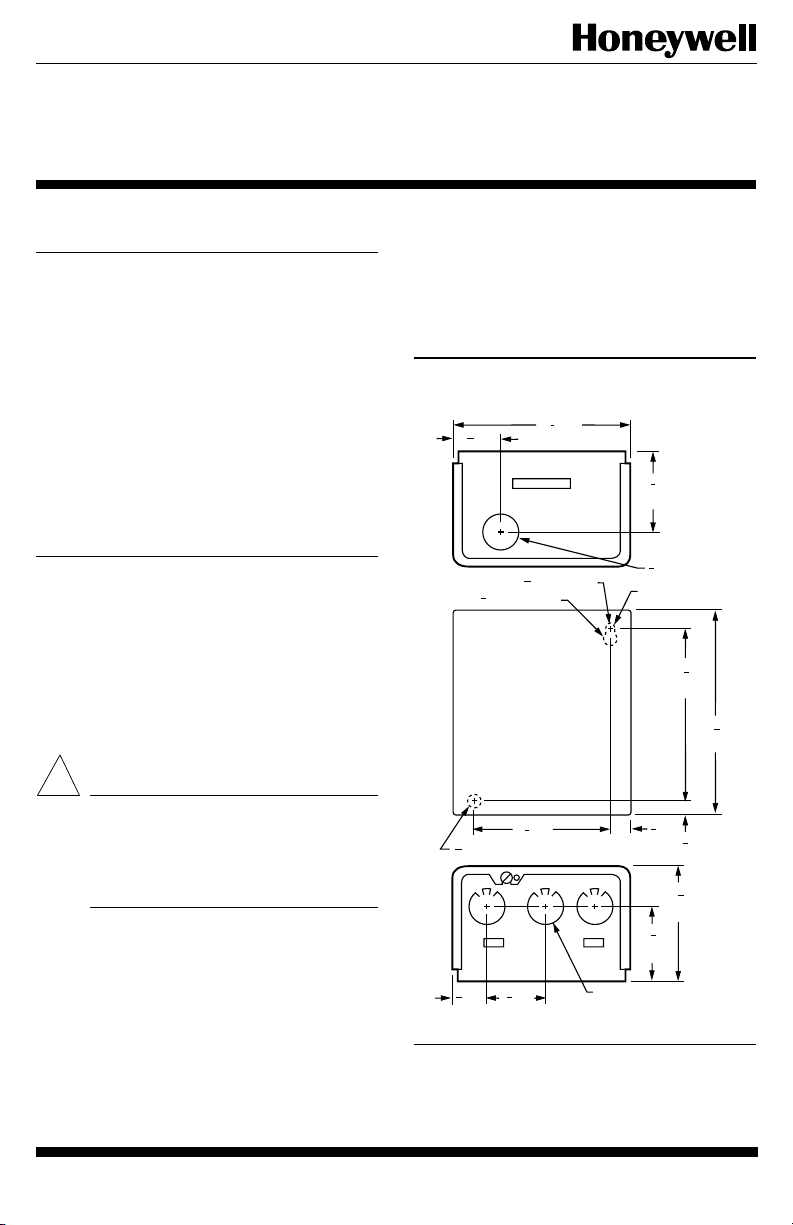

1. Position the relay and mark the mounting holes (Fig. 1).

2. Start a screw for the keyhole type mounting hole in

the upper right corner. Screw it down within about 1/8 in.

[3 mm] of the surface.

3. Hang the relay on the screw, position the case, and

start the bottom screw.

4. Tighten both screws.

Fig. 1—Approximate mounting dimensions in

in. [mm].

1

4 [108]

3

[2] DIAMETER

32

[13] DIAMETER

1

3 [89]

2

3

1 [35]

8

4

7

1

8

[48]

7

[22] DIAMETER

8

KEYHOLE TYPE

MOUNTING HOLE

3

[10]

8

2

[75]

7

1

8

[48]

KNOCKOUT FOR

1/2 (13) CONDUIT (3)

4

[114]

15

16

1

2

1

5

4

[133]

3

[10]

8

M3823

5

1 [29]

32

1

2

7

[6] DIAMETER MOUNTING HOLE

32

25

[20]

32

WIRING

All wiring must comply with all applicable electrical

codes, ordinances, and regulations. Follow any instructions

furnished with the controlled equipment.

1 69-0791BG. H. • 10-93 • ©Honeywell Inc. 1993 • Printed in U. S. A. • Form Number 69-0791B

Page 2

IMPORTANT: The switching relay terminals are ap-

L1

HOT

L2

2

1

3

4

1

1

RA845A RELAY

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

AND DISCONNECT MEANS AS REQUIRED.

IF CONTROLLING TWO LOADS, USE:

3 AND 4 FOR LINE VOLTAGE LOAD

5 AND 6 FOR LINE OR LOW VOLTAGE LOAD

IF USING LOW VOLTAGE, USE A SEPARATE TRANSFORMER.

M3822

T

T

THERMOSTAT

ZONE 1

ZC

ZP

B1

B2

C1

C2

1

2

BURNER

CIRC.

LINE

THERM.

BURNER

CONTROL

CIRCULATOR

ZONE 1

2

3

THERMOSTAT

ZONE 2

CIRCULATOR

ZONE 2

TO ADDITIONAL R845A

RELAYS FOR OTHER ZONES

HYDRONIC HEATING

CONTROL TERMINALS

2

3

5

6

proved for use with copper wires only.

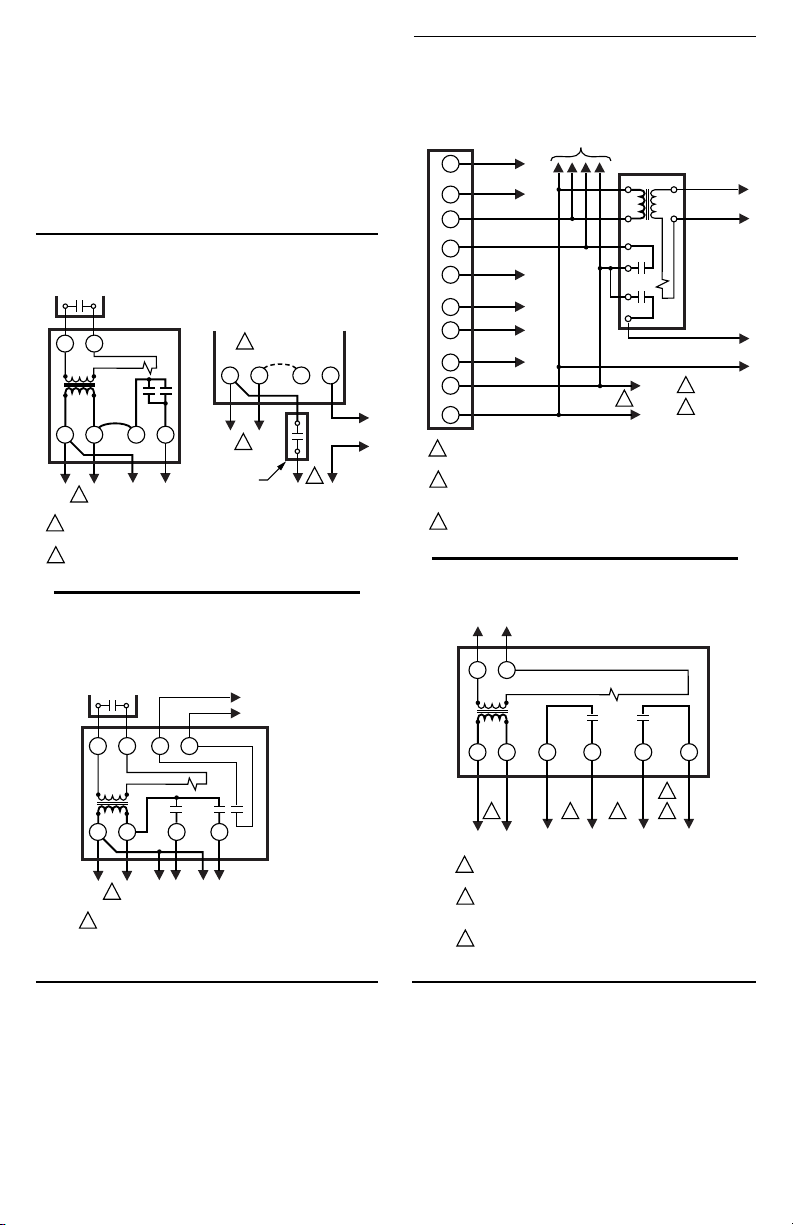

See Figs. 2-5 for hookup diagrams for these relays.

When two or more devices are to be controlled in parallel, the total current must not exceed the relay load rating.

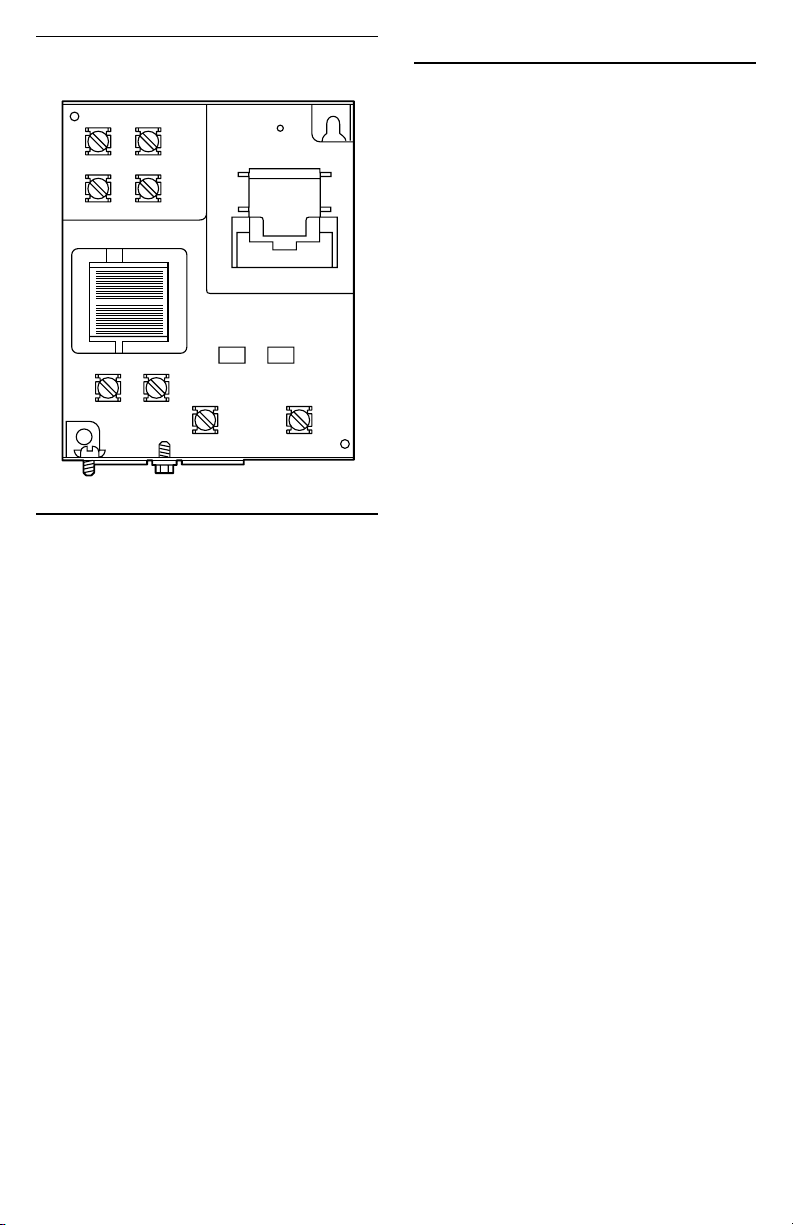

Fig. 6 is an internal view of the RA832A showing terminal locations and barriers.

Never connect load terminals to a load that takes more

current than the amount listed in the electrical ratings on

the relay.

Fig. 2—Internal schematic and typical hookup

for RA89A.

LOW VOLTAGE (CLASS 2)

2-WIRE THERMOSTAT

TT

RA89A (SPST)

2

21 34

RA89A

JUMPER REMOVED

Fig. 4—Schematic diagram showing R845A in

multizone, forced hydronic heating system.

This arrangement is suitable for any number of

additional zones.

JUMPER

21 34

L2

1

2

Fig. 3—Internal schematic and typical hookup

for RA832A.

TO LOAD

L1

1

HOT

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

AND DISCONNECT MEANS AS REQUIRED.

COMPLETE WIRING AS SHOWN ABOVE.

LOW VOLTAGE (CLASS 2)

2-WIRE THERMOSTAT

TT

21 34

L2

1

XX

LOAD 1

L1

1

HOT

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

AND DISCONNECT MEANS AS REQUIRED.

L2

CONTROLLER

(IF USED)

RA832A

LOAD 2

(OPTIONAL)

1

AUXILIARY TO LOW

OR MILLIVOLTAGE

(POWERPILE) LOAD

L1

HOT

1

M3821

TO LOAD

M3819

Fig. 5—R845A hookup for controlling two loads.

LOW VOLTAGE (CLASS 2)

2-WIRE THERMOSTAT

2

TO

POWER

R845A

65

3

LOAD 2

M3820

TT

21 34

1

L1

HOTL2

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

1

AND DISCONNECT MEANS AS REQUIRED.

WHEN CONTROLLING TWO LOADS, USE 3 AND 4

2

FOR LINE VOLTAGE LOAD AND 5 AND 6 FOR LINE

OR LOW VOLTAGE LOAD.

IF USING LOW VOLTAGE, USE A SEPARATE

3

TRANSFORMER.

1 1

TO

POWER

LOAD 1

2

Page 3

Fig. 6—Internal view of RA832A Switching

Relay.

T

X

T

X

24V TRANSFORMER

12

34

RELAY

Service and Checkout

1. Never use oil on any part of the relay coil or contacts.

2. Keep the cover on the relay during normal operation

and remove only for service and checkout.

3. Relay contacts require no cleaning. They are arranged

so they close with a wiping action and are self-cleaning. The

contacts may turn black after being in service for some time.

This discoloration does not prevent proper operation.

4. After installation is complete, operate system through

at least one cycle from the controller to make certain the

relay controls the equipment as intended.

M3824

3 69-0791B

Page 4

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

M1P 2V9

QUALITY IS KEY

4

Page 5

TRADELINE

Relais de Commutation

RA89A, RA832A, RA845A

Application

Ces relais peuvent être utilisés dans de nombreuses

applications de commutation. Ils assurent une régulation

des appareils tension secteur ou basse tension à partir d’

un régulateur basse tension.

Le RA89A est un relais de commutation parallèle

bipolaire unidirectionnel. Il assure la commutation d’une

charge tension secteur avec une capacité de courant

augmentée. Un cavalier amovible permet de choisir la

tension secteur à partir du transformateur ou d’une

connexion distincte.

Le RA832A est un relais de commutation tripolaire

unidirectionnel. L’un des pôles est utilisé pour une charge

auxiliaire à basse tension ou à tension mV (Powerpile) et

les deux autres pôles sont utilisés pour les charges tension

secteur.

Le R845A est un relais de commutation bipolaire

unidirectionnel. L’un des pôles sert à la commutation

d’une charge tension secteur et l’autre pôle sert à la

commutation d’une charge tension secteur ou basse

tension. Tous les relais ont un transformateur intégré qui

alimente le régulateur en basse secteur.

Installation

AVANT D’INSTALLER CE PRODUIT…

1. Lire les instructions attentivement. Le fait de ne pas

les suivre pourrait endommager le produit ou causer un

danger.

2. Vérifier les caractéristiques électriques dans les

instructions et sur le produit afin de s’assurer que le

produit convient à l’application.

3. L’installateur doit être un technicien d’expérience

ayant reçu une formation pertinente.

4. Effectuer une vérification complète après

l’installation.

AVERTISSEMENT

!

Un danger d’électrocution peut causer des

dommages matériels, entraîner des blessures

ou la mort.

Couper le courant avant d’effectuer les

raccordements pour éviter tout choc ou tout

dommage à l’équipement.

MONTAGE

Installer le relais à l’emplacement de l’ancien relais. Si

un autre emplacement convient mieux, monter le relais à

la verticale sur un mur ou une cloison solide près de

l’appareil à asservir. Choisir un endroit facile d’accès

pour l’installation et la maintenance.

REMARQUE: Le bruit du relais et du transformateur est

parfois amplifié lorsque ces appareils sont montés sur

des surfaces en tôle, en placoplâtre ou en matériau de

même type. Pour réduire le bruit, placer des rondelles

en caoutchouc ou en feutre entre le boîtier et la surface

de montage.

1. Positionner le relais et marquer les trous de vis

(Fig. 1).

2. Commencer à visser dans le trou de fixation évasé

du coin supérieur droit. Visser jusqu’à 3 mm [1/8 po] de

la surface de montage.

3. Suspendre le relais à la vis, placer le boîtier et

commencer à serrer la vis du coin inférieur.

4. Bien serrer les deux vis.

Fig. 1—Encombrement approximatif en mm [po].

1

108 [4 ]

1

13 [ ] DIAM.

2

1

89 [3 ]

2

3

35 [1 ]

8

4

48

[1 ]

3

2 [ ] DIAM.

32

7

32

OUVERTURE DÉFONÇABLE POUR

CONDUIT DE 13 (1/2 po) (3)

22 [ ] DIAM.

TROU DE

FIXATION ÉVASÉ

48

[1 ]

7

8

10 [ ]

7

8

7

8

3

8

75

[2 ]

114

[4 ]

10 [ ]

15

16

1

2

133

1

[5 ]

4

3

8

MF3823

5

29 [1 ]

32

TROU DE FIXATION 6 [ ] DIAM.

25

20 [ ]

32

G.H. • 10-93 • ©Honeywell Inc. 1993 • Imprimé aux États-Unis • Numéro de publication 69-0791B

1 69-0791B

Page 6

CÂBLAGE

Tout le câblage doit être conforme aux codes et

règlements locaux. Suivre les instructions accompagnant

l’appareil asservi.

IMPORTANT: Les bornes des relais de commutation

sont approuvés lorsqu’ils sont utilisés avec des fils

de cuivre seulement.

Les Figures 2 à 5 montrent des schémas de

raccordement types. Lorsque deux appareils ou plus

doivent être asservis en parallèle, le courant total ne doit

pas dépasser la charge nominale du relais. La Figure 6

montre l’emplacement des bornes et des guide-fils à

l’intérieur du RA832A.

Ne jamais raccorder des bornes de sortie à une charge

prélevant plus de courant que la valeur nominale indiquée

sur le relais.

Fig. 2—Schéma de raccordement interne type

du RA89A.

THERMOSTAT BIFILAIRE

BASSE TENSION (CLASSE 2)

RA89A (BIPOL.,

TT

UNDIDIR.)

CAVALIER

21 34

L1

(SOUS

TENSION)

VERS

CHARGE

L2

1

ALIMENTATION. AU BESOIN, FOURNIR DES DISPOSITIFS DE

1

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

PROCÉDER AU RACCORDEMENT TEL QU'INDIQUÉ CI-DESSUS.

2

2

SANS CAVALIER

21 34

L1

L2

(SOUS

1

TENSION)

RÉGULATEUR

(S'IL Y A LIEU)

RA89A

VERS

CHARGE

1

MF3819

Fig. 4—Schéma montrant un R845A dans un

un système de chauffage à eau forcée. Cette

configuration convient à toute zone

additionnelle.

BORNES DU

RÉGULATEUR

DE CHAUFFAGE

T

THERM.

T

ZC

ZP

B1

BRÛLEUR

B2

C1

CIRC.

C2

1

SECTEUR

2

ALIMENTATION. AU BESOIN, FOURNIR DES DISPOSITIFS DE

1

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

2

S'IL Y A 2 CHARGES À ASSERVIR, UTILISER:

3 ET 4 POUR UNE CHARGE TENSION SECTEUR

5 ET 6 POUR UNE CHARGE TENSION SECTEUR OU BASSE TENSION.

3

S'IL S'AGIT D'UNE CHARGE BASSE TENSION, UTILISER UN

TRANSFORMATEUR DISTINCT.

Fig. 5 —Schéma de raccordement du R845A

pour l’asservissement de deux charges.

TT

VERS LES R845A ADDITIONNELS

POUR LES AUTRES ZONES

THERMOSTAT

ZONE 1

RÉGULATEUR

DU BRÛLEUR

CIRCULATEUR

ZONE 1

THERMOSTAT BIFILAIRE

BASSE TENSION(CLASS 2)

RELAIS R845A

2

1

4

3

5

6

L1

(SOUS

1

TENSION)

L2

THERMOSTAT

ZONE 2

CIRCULATEUR

ZONE 2

2

3

MF3822

R845A

Fig. 3—Schéma de raccordement interne du

RA832A.

THERMOSTAT BIFILAIRE

BASSE TENSION (CLASSE 2)

TT

21 34

L2

1

XX

CHARGE 1

L1

1

(SOUS

TENSION)

ALIMENTATION. AU BESOIN, FOURNIR DES DISPOSITIFS DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

AUXILIAIRE VERS CHARGE

BASSE TENSION OU

MILLIVOLT (POWERPILE)

RA832A

CHARGE 2

(OPTIONNELLE)

MF3821

21 34

1

L2

L1

(SOUS

TENSION)

ALIMENTATION. AU BESOIN, FOURNIR DES DISPOSITIFS DE

1

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

S'IL Y A 2 CHARGES À ASSERVIR, UTILISER:

2

3 ET 4 POUR UNE CHARGE TENSION SECTEUR

5 ET 6 POUR UNE CHARGE TENSION SECTEUR OU BASSE TENSION.

S'IL S'AGIT D'UNE CHARGE BASSE TENSION, UTILISER UN

3

TRANSFORMATEUR DISTINCT.

1

VERS

ALIMENTATION

CHARGE 1

2

VERS

ALIMENTATION

2

1

65

3

CHARGE 2

MF3820

Page 7

Fig. 6—Vue interne du relais de commutation

RA832A

T

X

T

X

24V TRANSFORMATEUR

12

34

RELAIS

MF3824

Maintenance et Vérification

1. Ne jamais appliquer d’huile sur les parties du relais

ou sur les contacts.

2. Laisser le couvercle sur le relais durant le

fonctionnement normal et le retirer seulement pour la

vérification et la maintenance.

3. En frottant l’un sur l’autre, les plots de contact du

relais se nettoient d’eux-mêmes. Après un certain temps,

ils peuvent devenir noirs, mais cela ne nuit aucunement à

leur bon fonctionnement.

4. Après avoir installé le relais, rétablir le courant et

vérifier au moins un cycle complet pour s’assurer que le

relais manoeuvre bien.

3 69-0791B

Page 8

Régulation résidentielle et commerciale Pour la maîtrise de votre univers

Honeywell Limitée Honeywell Inc.

740 Ellesmere Road 1985 Douglas Drive North

Scarborough, Ontario Golden Valley, MN 55422

M1P 2V9

La qualité, la clé

du succés

4

Loading...

Loading...