Page 1

Honeywell

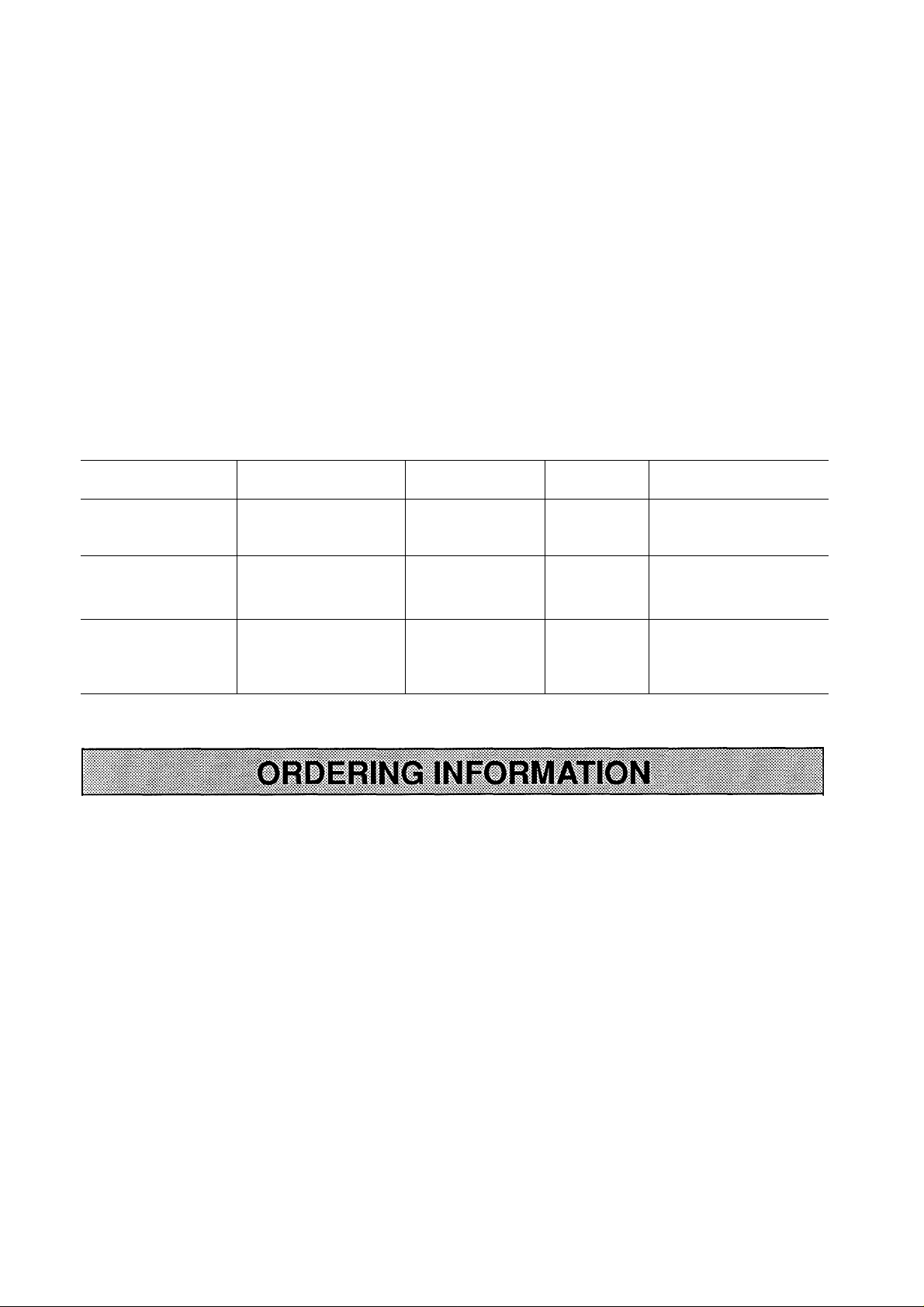

THESEONE-PIECE.STACK-MOUNTEDOIL BURNER

PRIMARY CONTROLS CYCLE THE BURNER ON

THERMOSTAT DEMAND AND SHUT DOWN THE

BURNER ON FLAME LOSS OR SYSTEM MALFUNC

TION.

□ Combine a Protectorelay unit for cyciing the burner

and a Pyrostat flame detector for sensing temperature

changes of fiue gases up to 1000° F [556° C].

□ RA116A is used with intermittent ignition burners

(formerly called constant ignition burners).

□ RA117A and RA817A are used with interrupted

ignition burners (formeriy cailed intermittent ignition

burners).

PROTECTORELAY

OIL BURNER

CONTROLS

□ Used with line voltage or 24V controllers.

□ Safety switch may be manually tripped on all models.

□ On RA116A, lockout occurs if fiame is not re-es-

tabiished during safety switch timing.

□ On RA117A and RA817A, flame or power failure is

followed by a one minute (approximate) scavenging

period and one attempt to re-establish flame. Lockout

occurs if flame is not re-established.

□ Manual resetof safety switch is required after ignition

failure completely shuts off main burner.

RA116A

RA117A

RA817A

D.T.

3-91

Form Number 68-0119

©Honeywell Inc. 1991

Page 2

IMPORTANT

THE SPECIFICATIONS GIVEN IN THIS PUBLICATION DO NOT INCLUDE NORMAL MANUFACTURING

TOLERANCES. THEREFORE, UNITS MAY NOT MATCH THE LISTED SPECIFICATIONS EXACTLY. ALSO,

PRODUCTS ARE TESTED AND CALIBRATED UNDER CLOSELY CONTROLLED CONDITIONS, AND SOME

MINOR DIFFERENCES IN PERFORMANCE CAN BE EXPECTED IF THOSE CONDITIONS ARE CHANGED.

SUPER TRADEUNE MODELS

SUPER TRADELINE controls offer features not

available on TRADELINE or standard models, and

are designed to replace a wide range of Honeywell

and competitive controls.

SUPER TRADELINE MODELS AVAILABLE:

RA117A Stack Mounted Protectorelay

Special SUPER TRADELINE packaging with

cross reference label and SUPER TRADELINE in

struction sheet.

TRADELINE MODELS

TRADELINE controls offer features not available

on standard models and are designed to replace a wide

range of Honeywell and competitive controls.

TRADELINE MODELS:

RA116A Stack Mounted Protectorelay

Special TRADELINE packaging with cross refer

ence label and TRADELINE instruction sheet.

STANDARD MODELS

MODEL

NUMBER TYPE OF IGNITION

RA116A

RA117A Interrupted ignition^

RA817A Interrupted ignition'^

» Lockout occurs if flame is not re-established during the safety switch timing.

^ Flame or power failure is followed by a one minute (approximate) scavenging period and one attempt to re-establish the

flame. Lockout occurs if flame is not re-established.

Intermittent ignition^

(formerly called

constant ignition)

(formerly called

intermittent ignition)

(formerly called

intermittent ignition)

24V

THERMOSTAT

2- wire

3- wire

series 10

2- wire

3- wire

series 10

2-wire 550 VA

IGNITION

RATING

360 VA 120V/60HZ

550 VA

INPUT

VOLTAGE

120V/60 Hz

110V/50 Hz

120V/60 Hz

220V/50 Hz

240V/60 Hz

FOR ORDERING INFORMATION WHEN PURCHASING REPLACEMENT AND MODERNIZATION PRODUCTS FROM YOUR

TRADEUNE WHOLESALER OR YOUR DISTRIBUTOR, REFER TO THE TRADEUNE CATALOG OR PRICE SHEETS FOR

COMPLETE ORDERING NUMBER, OR SPECIFY:

1. Order number. TRADEUNE or SUPER TRADEUNE.

2. Input voltage and frequency.

IF YOU HAVE ADDITIONAL QUESTIONS, NEED FURTHER INFORMATION, OR WANT TO COMMENT ON OUR PRODUCTS

OR SERVICES, PLEASE WRITE OR PHONE:

1. YOUR LOCAL HONEYWELL RESIDENTIAL AND BUILDING CONTROLS DIVISION SALES OFFICE (CHECK

WHITE PAGES OF PHONE DIRECTORY).

2. RESIDENTIAL AND BUILDING CONTROLS CUSTOMER SATISFACTION

HONEYWELL INC., 1885 DOUGLAS DRIVE NORTH

MINNEAPOLIS, MINNESOTA 55422-4386

(612) 542-7500

IN CANADA: HONEYWELL CONTROLS LIMITED

740 ELLESMERE ROAD

SCARBOROUGH, ONTARIO M1P 2V9

INTERNATIONAL SALES AND SERVICE OFFICES IN ALL PRINCIPAL CITIES OF THE WORLD.

Page 3

AMBIENT TEMPERATURE:

Operating: 0° F to 104” F [-18“ C to 40° C].

Shipping: -40° F to 150° F [-40° C to 66° C],

DIMENSIONS: Referto Fig. 1.

ELECTRICAL RATINGS (amperes):

Motor Ratings

110V/50 Hz

120V/60 Hz

Full Load

Locked Rotor

ELEMENT INSERTION LENGTH:

Adjustable from 3-1 /2 to 5-1 /2 inches [89 to 140 millime

ters].

7.4 3.7

44.4

220V/50 Hz

240V/60 Hz

22.2

COMPETITIVE CROSS-REFERENCE

The RA116A replaces the following competitive devices:

MOUNTING FLANGE:

Available for 6 inch [152 millimeter] diameter pipe (refer

to Fig. 2). Can also be flattened for flat-mounting applica

tions.

24V THERMOSTAT HEAT ANTICIPATOR CURRENT:

0.4A.

LINE VOLTAGE THERMOSTAT OR CONTROLLER

(RA116A, RA117A):2wire, 8A. Requires jumper across

W and B terminals. Refer to Fig. 5 or 7.

SAFETY SWITCH TIMING: 75 Seconds (nominal).

APPROVALS:

UNDERWRITERS LABORATORIES INCORPORATED

LISTED (RA116A, RA117A ONLY): File Number

MP268, Guide Number MCCZ.

HONEYWELL WHITE RODGERS GENERAL ELECTRIC

R116A,B

R124A,B 611-1

R134A 611-31

R168A 611-33

R494A 615

RA116A,B 6L18

RA416A

RA816A,Db

PENN ITT GENERAL

664

670

680 R96G102DC

3 A Detroit 3-wire thermostat must be replaced by a 2-wire thermostat with a suitable heat anticipator.

^ When replacing a model having an F or O terminal to power a clogged filter indicator light, provide a separate transformer

for the light.

The RA117A replaces the following competitive devices:

HONEYWELL WHITE RODGERS

R116A,B

R117A 603 A101B2

R123A,B 610-2 CR7856

R124A,B 610-32

R134A 611-1

R168A 611-31

R494A

RA116A,B

RA117A

RA416A

RA816A

RA817A,C

RA817A,C°-C

603

5200 JM

R96A102A

602

615

6L18

A101B2

CR7865

MERCOID

GENERAL ELECTRIC

A101A2

GENERAL PERFEX

5200

5300

DETROIT

CA7013

CA702°

GENERAL PERFEX

5200

5230

5520

5525^

DELCO PENN ITT GENERAL

COA 664 5200

COA-1

® A Detroit 3-wire thermostat must be replaced by a 2-wire thermostat with a suitable heat anticipator.

When replacing a model having an F or O terminal to power a clogged filter indicator light, provide a separate transformer

for the light.

^ Do not use RA117A to replace this control where timed ignition is required for a wall-flame burner.

670 R96A102A

672 R96G102DC

680

682

MERCOID DETROIT

JM

JM1

CA70ia

CA702^

68-0119

■■ ■' 1', , . I' 'i "

]■

Page 4

WHEN INSTALLING THIS PRODUCT...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause hazardous

condition.

2. Check the ratings given in these instructions and on

the product to ensure the product is suitable for your

application.

3. Ensure the installer is a trained, experienced service

technician.

4. After completing installation, use these instructions

to check product operation.

CAUTION

1.

Do not bend contact arms or stops on the Py rostat

detector mechanism or make any adjustments

other than those given in the instructions.

Remove the cardboard packing behind the drive

2.

shaft lever by pushing the packing up and pulling

it straight, out over the top of the lever. Do not

remove packing by pulling sideways.

3. Ensure all wiring complies with applicable codes

and ordinances.

MOUNTING (Refer to Fig. 2)

Followthe mounting instructionssuppliedbythe furnace,

boiler, or burner manufacturer, if available. Otherwise, use

the instructions provided below.

When replacing one of the controls listed on page 3,

identify each leadwire as it is removed from the old control

by marking the wire with the number of the RA116A or

RA117A terminal to which it will be connected. Refer to

Table 1 and 2 to translate the old terminal identifications to

the new RA116A or RA117A terminal identifications.

TABLE 1—IDENTIFYING TERMINALS FOR RA116A

TERMINAL TERMINAL

IDENTIFICATION

ON OLD CONTROL

1, LH,or HOTLINE

2, LG, or LINE

3, 4, M, or MOTOR

TABLE 2—IDENTIFYING TERMINALS FOR RA117A

TERMINAL

IDENTIFICATION

ON OLD CONTROL

1, LH, or HOTLINE

2, LG, or LINE

3, M, or MOTOR

4, 1, or IGNITION

If the position of the old control was satisfactory, install

the new RA116Aor RA117A in the same location as the old

one, making sure to insert the bimetal element the same

distance into the stack as the old element. If the old

element was inserted more than 5-1 /2 inches [140 millime

ters], insert the new control 5-1/2 inches [140 millimeters]

into the stack.

If the position of the old control was not satisfactory,

close the old holes tightly with a metal plate and follow

these instructions.

1. Follow these location considerations.

REPLACEMENT.

IDENTIFICATION ON

NEW RA116A

1

2

3

REPLACEMENT.

TERMINAL

IDENTIFICATION ON

NEW RA117A

1

2

3

4

■ ■■■■•. '

I

Page 5

A DO NOT FORCE THE COLLAR OF THE MOUNTING FLANGE PAST THE STOP.

FIG. 2—MOUNTING AND LOCATION CONSIDERATIONS.

• Locate the control between the boiler or furnace and

draft regulator.

• Locate the control as near as possible to the boiler

or furnace.

• If mounting in an elbow, locate the element near the

outer curve where the hottest gases flow.

• Do not locate the element where the temperature

may exceed 1000° C [556° С].

2. Cut a 1 -3/8 inch [35 millimeter] hole in the stack at the

location desired.

3. Drill two holes and fasten the mountihg flange using

the screws provided. The flange should fit the mounting

surface snugly, but it may be bent to fit a different radius

stack or flattened to fit aflat surface. Do not force the collar

or mounting flange past the stop.

4. Insert the bimetal element at the center of the stack

in direct path of the hottest flue gasses.

5. Tighten the lockscrew.

WIRING

Follow the appliance manufacturer’s instructions, if

available. Otherwise, follow the wiring diagrams shown in

Fig. 3 through 7.

FIG. 3—RA116A WIRING DIAGRAM WITH A 24V, 3-

WIRE THERMOSTAT.

68-0119

Page 6

^{HOT)

OIL VALVE I

BURNER

RA117A

MOTOR

IGNITION

HIGH

LIMIT

<3) © (3)

2K3 i

;1K3

2X2

1K1

№

__

(COLD) ^

.SAFETY

■ SWITCH

■HEATER

PYROSTAT

J CONTACTS

SERIES 10

THERMO

STAT ^

SAFETY,

SWITCH I

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

A USE GREEN TERMINAL TO CONNECT CONTROL CASE TO GROUND.

A IF USING A TWO-WIRE THERMOSTAT, TAPE LOOSE ENDS OF RED

WIRE (IF NECESSARY).

A CONTACTS BREAK IN SEQUENCE ON TERMPERATURE RISE.

A TO REPLACE AN INTERMITTENT IGNITION DEVICE (FORMERLY

CALLED CONSTANT IGNITION), CONNECT IGNITION LEADWIRE TO

TERMINAL 3, INSTEAD OF TERMINAL4.

Mt)

©7?T] 1K

^(T)

Hh

1K2

■wi

-V

Ar

2K1 i (HOT)

4JÍ4-

2K

1

________

LI

FIG. 4—RA116A WIRING DIAGRAM WITH A LINE

VOLTAGE THERMOSTATOR CONTROLLER.

FIG. 5—RA117A WIRING DIAGRAM WITH A 24V, 3-

WIRE THERMOSTAT.

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

A USE GREEN TERMINAL TO CONNECT CONTROL CASE TO GROUND.

A CONTACTS BREAK IN SEQUENCE ON TERMPERATURE RISE.

FIG. 6—RA117A WIRING DIAGRAM WITH A LINE VOLTAGE THERMOSTAT OR CONTROLLER.

: f: ;

I',

y

Page 7

A POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

A USE GREEN TERMINAL TO CONNECT CASE TO GROUND.

A CONTACTS BREAK IN SEQUENCE ON TERMPERATURE RISE.

FIG. 7—RA817A WIRING DIAGRAM.

OPERATION

The schematic diagrams show all systems in the idle

condition:

• Burner off, no call for heat.

• Pyrostat contacts closed (RA116A).

• "Cold”contactsclosed, “hof’contacts open (RA117A,

RA817A).

• Safety switches closed.

• All relays de-energized.

NORMAL OPERATING SEQUENCE

On a thermostat (or line voltage controller) call for heat,

the ignition, oil valve, and burner motor start. The safety

switch begins heating. Afterthe burner flame is established,

the stack temperature rises and expands the bimetal

detector element. The Pyrostat contacts open (RA116A) or

the "hot” contacts close and the “cold” contacts open

(RA117A, RA817A), de- energizing the safety switch heater.

The ignition circuit de-energizes (RA117A, RA817A only).

When the call for heat is satisfied, the system returns to

the idle condition.

IGNITION FAILURE

Iftheburnerflameis not established within approximately

75 seconds (nominal) of a thermostat (or line voltage

controller) call for heat, the Pyrostat contacts (RA116A) or

“cold” contacts (RA117A, RA817A) remain closed. During

that time, the safety switch is heated. If the burner flame is

not established after 75 seconds (nominal), the system

locks out and cannot be started again until the safety switch

is manually reset.

BURNER FLAME FAILURE DURING THE RUNNING

CYCLE

RA116A

The loss of burner flame reducesthe stacktemperature,

closes the Pyrostat contacts, and energizes the safety

switch. If the burner flame is not re-established within the

75 second (nominal) safety switch timing, the system locks

out and cannot be started again until the safety switch is

manually reset.

RA117A, RA817A

The loss of burner flame reducesthe stacktemperature,

opens the "hot” contacts, and shuts the system down by

de-energizing the 2K burner motor relay. After a one

minute (approximate) scavenging period, the "cold” con

tacts close and energize the safety switch heater. If the

thermostat (or line voltage controller) is still calling for heat,

the Protectorelay control makes one attempt to restart the

system. If the burner flame is not re-established in 75

seconds (nominal), the system locks out and cannot be

started again until the safety switch is manually reset.

POWER FAILURE DURING THE RUNNING CYCLE

A power failure shuts off the ignition and burner motor.

If the thermostat is still calling for heat when power is

restored, the stack temperature must cool and return the

system to the idle position. Once the system returns to the

idle condition, it begins the normal operating sequence.

'■ fVv'':'

Ikv '

''i'' 'i'

V

-i'-'

■1'.

68-0119

.i'L';:

Page 8

STARTUP AND CHECKOUT

WARNING

FIRE HAZARD

CAN CAUSE SEVERE BURNS

START THE SYSTEM

1. Ensure the Pyrostat detectors are in step.

2. Push in and release the safety switch reset button.

3. Open the hand valve in the oil supply line.

4. Set the limit control and thermostat to call for heat.

5. Close the line switch. The burner should start.

Ensure the combustion chamber is free of oil or

oil vapor before starting system.

STEP THE PYROSTAT DETECTOR CONTACTS

The detector contacts are actuated by a friction clutch

that is mounted on a rod connected directly to the heatactuated element. Occasionally, this clutch gets "out of

step” after a long period of idleness. To place the clutch and

the contacts “in step,”

1. Remove the cover.

2. Pull the lever forward 1/4 inch (Fig. 8).

3. Slowly release the lever.

4. Replace the cover.

CHECK THE SAFETY FEATURES

Simulate Flame Failure:

1. Follow the starting procedure to turn on the burner.

2. Close the hand valve in the oil supply line.

3. The RA116A locks out after 75 second (nominal)

safety switch timing. The RA117A and RA817A lock out

after one minute (approximate) scavenging period and 75

second (nominal) safety switch timing.

4. Reset the safety switch and open the hand valve in

the oil supply line.

Simulate Ignition Failure:

1. Follow the starting procedure to turn on the burner,

except do not open the oil supply hand valve.

2. Safety switch locks out after 75 second (nominal)

safety switch timing. Ignition and burner motor stops and

oil valve closes.

3. Reset the safety switch and open the hand valve in

the oil supply line.

Simulate Power Failure:

1. Follow the starting procedure to turn on the burner.

2. With the burner running, trip the circuit breaker or

remove the fuse to turn off power to the system. The burner

should stop.

3. Restore power. The burner should restart.

FIG. 8—STEPPING THE PYROSTAT DETECTOR CON

TACTS.

Check the Scavenger Timing:

1. Follow the starting procedure to turn on the burner.

2. With the burner operating normally, open and im

mediately close the line switch. The burner should stop

immediately.

3. After recycle timing (one minute approximately), the

burner should restart automatically.

If the system does not operate as described, proceed to

Troubleshooting.

Page 9

TROUBLESHOOTING AND MAINTENANCE

To cxsmpletely troubleshoot an oil burner installation,

check the burner, ignition transformer, and oil primary

control for proper operation and condition.

TRIP SAFETY SWITCH BEFORE OPERATING BURNER

MAINTENANCE

CAUTION

Tripping the safety switch shuts down the burner but

does not disconnect the power supply. Turn off the

power at the system switch or the circuit breaker

before servicing the control system, burner motor, oil

valve, or ignition to avoid electrical shock.

To trifithe safety switch, move the safety switch lever

down until the red reset button pops out. Refer to Fig. 9.

The burner wiil not operate until the safety switch is reset

by pushing the red reset button.

PRELIMINARY STEPS

Before checking the oil primary and cad cell, check out

the following parts of the burner and ignition systems.

Repair or replace controls as indicated.

1. Wiring connections, power supply, and burner motor

fuse. Ensure power is on to the controls, burner motor, and

ignition transformer.

2. Limit switch.

3. Ignition transformer.

4. Electrode gap and position.

5. Contacts between ignition transformer and electrode.

6. Oil pump pressure.

7. Oil tubing to tank.

8. Oil nozzle.

9. Oil supply.

10. Oil filter.

If the system is still not operating properly, check the oil

primary control as instructed below.

FIG. 9—TRIPPING AND RESETTING THE SAFETY

SWITCH.

CHECK THE OIL PRIMARY CONTROL

CAUTION

Since troubleshooting is done with the system pow

ered, observe all necessary precautions to prevent

electrical shock or equipment damage.

Equipment Required:

1. Screwdriver

2.0 to 300 Vac Voltmeter

3. Insulated Jumper Wires

4. Hard Surface Card (such as a business card) for

cleaning contacts

68-0119

Page 10

Burner Does Not Start When Thermostat Calls For Heat

PRELIMINARY CHECKS

1. Ensure all limit switches are closed.

2. Ensure safety switch is reset.

3. Check for the proper line voltage at the oil primary.

Proceed as follows after completing the preliminary checks.

PROCEDURE

1. Jumper the thermostat

terminals:

• Low voltage thermostat

at oil primary

• Line voltage thermostat

at thermostat

BURNER STARTS

Trouble in the thermostat circuit.

Check the thermostat and

wiring connections.

CORRECTIVE ACTION

BURNER DOES NOT START

Trouble is in the bimetal detector or

the oil primary. Put contacts in step

by pulling drive shaft lever out 1/4

inch and releasing. Refer to Fig. 8.

2. Jumper thermostat terminals

to start burner.

3. Jumper thermostat terminals

to start burner.

4. Jumper the thermostat

terminals and jumper the

normally closed contacts.

5. Jumper the thermostat

terminals and jumper the

R and B terminals on the

oil primary.

Burner Starts, Flame Is Established. Then Safety Switch Locks Out on Safety.

PRELIMINARY STEPS;

1. Reset the safety switch.

2. Clean bimetal detector contacts.

Proceed as follows after completing the preliminary checks.

Bimetal detector and oil primary

are OK.

Bimetal detector and oil primary

are OK.

Reclean the bimetal detector

contacts again and recheck

by jumpering the thermostat

terminals. If the burner starts,

bimetal detector and oil primary

are OK.

Check for broken wires, loose

connections between the bimetal

detector and the control.

Repair and recheck by jumpering

the thermostat terminals. Replace

the bimetal detector if necessary.

Clean the bimetal detector contacts

and timer contacts (if provided).

Go to step 3.

Go to step 4.

Go to step 5.

Replace the oil primary and perform

Startup and Checkout procedures.

PROCEDURE

1. Jumper thermostat

terminals to start burner.

• Low voltage thermostat

at oil primary

• Line voltage thermostat

at thermostat

2. Reset the safety switch

and jumper the thermostat

terminals to start the burner.

Honeywell Inc.

U.S.A.: 1885 Douglas Drive N.

Golden Valley, MN 55422-4386

CANADA: 740 Ellesmere Road

Scarborough, Ontario M1P 2V9

CORRECTIVE ACTION

BURNER KEEPS RUNNING

Bimetal detector and oil primary

are OK.

Bimetal detector and oil primary

are OK.

BURNER LOCKS OUT

• Clean the drive shaft, remove

the detector and clean bimetal

element. Replace the detector.

• Check the detector location. If

the stack temperature is below

300° F [149° C], replace the bimetal

detector.

Replace the oil primary and perform

Startup and Checkout procedures.

International Sales Offices in all principal cities of the world. Manufacturing in

Australia, Canada, Finland, France, Germany, Japan, Mexico, Netherlands,

Spain, Taiwan, United Kingdom, U.S.A.

PRINTED IN U.S.A.

QUALITY IS KEY

Loading...

Loading...