Page 1

R182J, R482J, R845A, R847A, R882J,

RA89A, RA832A Switching Relays

Application

These relays can be used for a variety of switching applications to provide control of line- or low-voltage devices by a low

voltage controller. See Table 1.

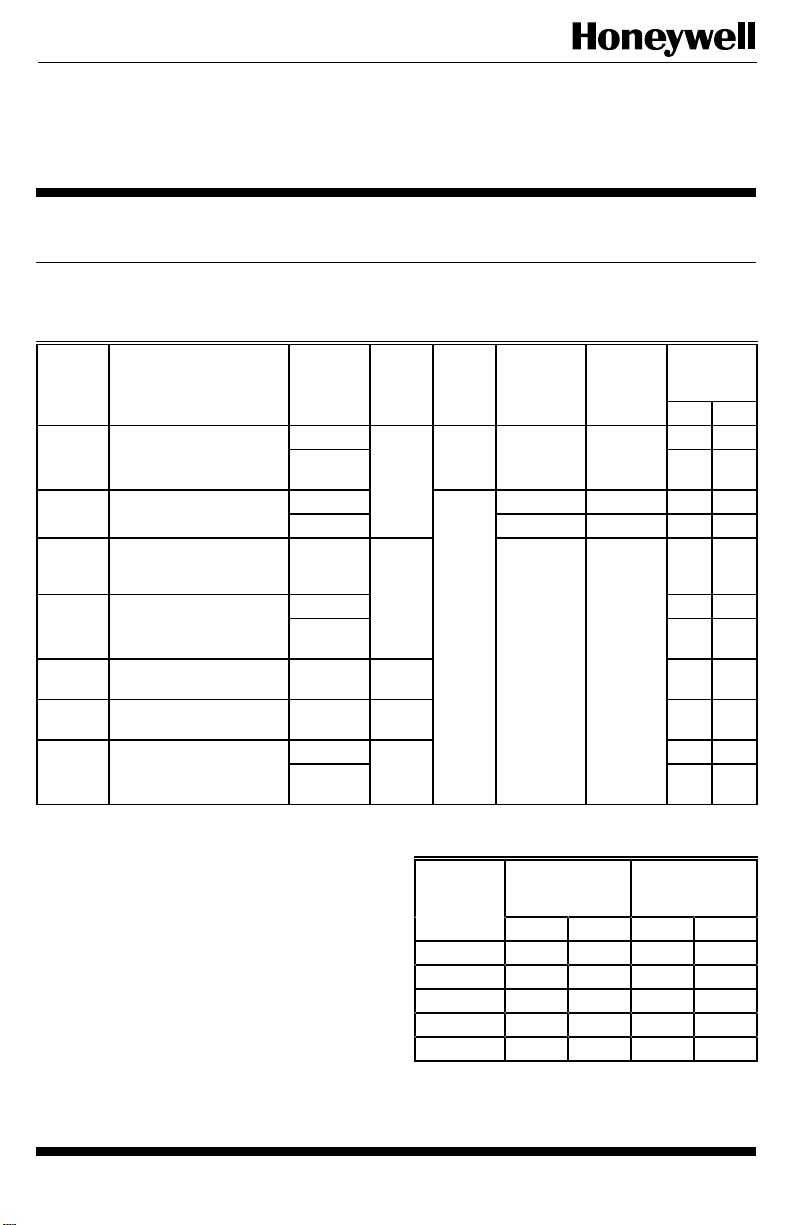

TABLE 1—SWITCHING RELAY SPECIFICATIONS.

Models Application

R182J

R482J

R845A For hot water zone control

R847A

R882J For use with separate low

RA89A For switching one line

RA832A

For 24V thermostat

control of line voltage

devices.

Controlled by a line

voltage controller

systems or spst control of

two separate loads.

Provides switching for

high-current loads such as

cooling compressors.

voltage power source.

voltage load.

For switching two line

voltage loads with a

common power source.

Coil

Voltage Switch Control

(50/60 Hz) Action Circuit 50/60 Hz) (A)

120 Dpdt 3-wire 24 0.40

240 3.7 22.2

120 2-wire 120 0.08 7.4 44.4

208/240 208/240 0.04 3.7 22.2

120 Dpst 24 0.40 7.4 44.4

120 22 100

240 10 50

24 Dpdt 7.4 44.4

120 Spst 10.2 61.2

120 Dpst 7.4 44.4

240 3.7 22.2

Voltage

(Vac at

Relay Coil

Current

a

Contact

Ratings (A)

AFL ALR

7.4 44.4

a

IMPORTANT: The transformer on the R182 can over-

heat when used with a series 20 thermostat if the

total resistance of the thermostat circuit exceeds

2.5 ohms. If the measured resistance of the thermostat (including thermostat wire and thermostat contact resistance) exceeds 2.5 ohms, add a 100 ohm,

10 watt resistor between the W and R terminals.

Table 2 gives maximum thermostat wire runs; if

longer runs are necessary, measure the resistance or

add a 100 ohm, 10 watt resistor across terminals W

and R.

TABLE 2—LENGTH OF WIRE.

AWG

Wire

Size

(Number)

22 120 38.0 60 18.0

20 200 61.0 100 30.5

18 300 91.5 150 45.5

16 500 152.5 250 76.0

14 800 244.0 400 122.0

1 69-0790—3J.H. • Rev. 10-94 • ©Honeywell Inc. 1994 • Form Number 69-0790—3

Total Wire

Length

Feet Meters Feet Meters

Length of Run

to Thermostat

(Wires)

Page 2

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

instructions can damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Make sure installer is a trained, experienced service

technician.

4. After completing installation, use these instructions

to check out product operation.

W ARNING

ELECTROCUTION HAZARD CAN

CAUSE PROPERTY DAMAGE, SEVERE

INJURY, OR DEATH.

Transformer core not bonded.

Disconnect power supply before wiring to pre-

vent electrical shock or equipment damage.

MOUNTING

For replacement, mount the relay in the same location as

the old relay. If this is a new installation, locate the relay

vertically on a solid wall or partition as close as possible to

the device to be controlled. Select a location that is easily

accessible for installation and service.

NOTE: To reduce the possible transformer hum and relay

noise that is sometimes amplified by mounting surfaces

such as sheetmetal, plasterboard, and similar materials,

place rubber or felt washers between the case and the

mounting surface.

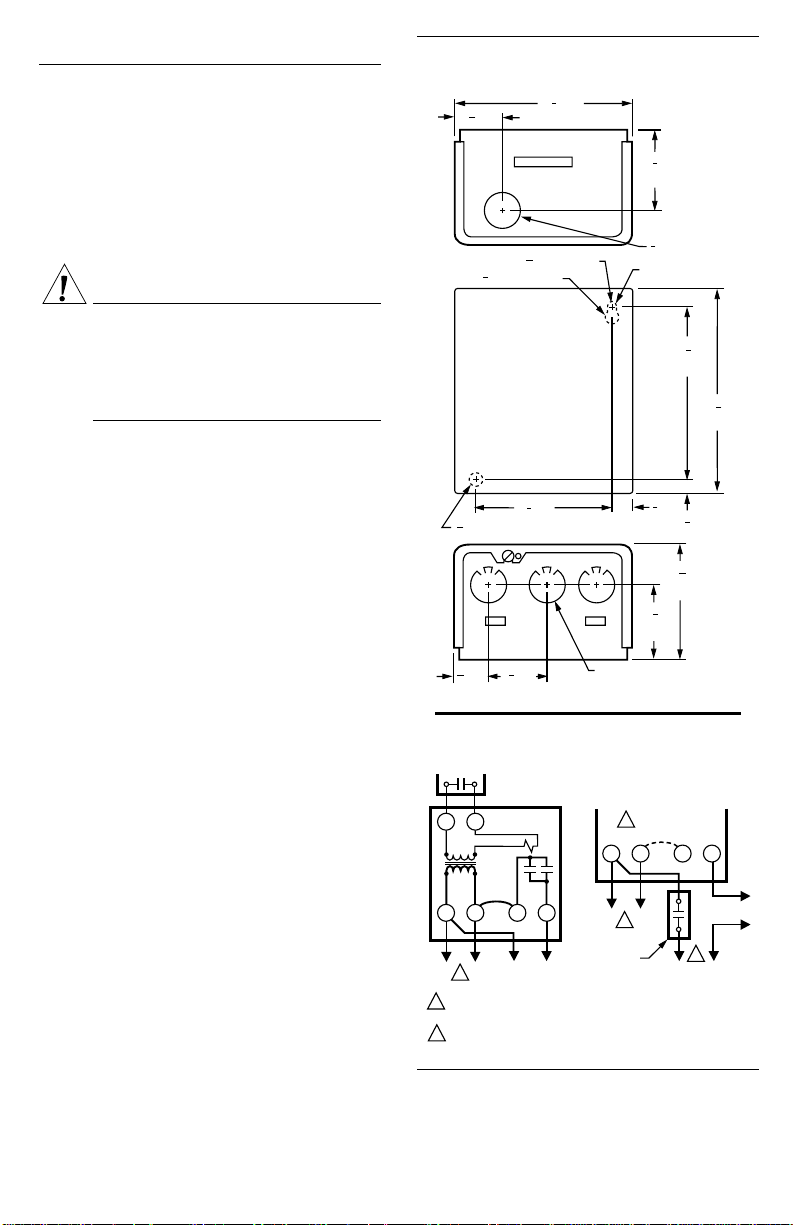

1. Position the relay and mark the mounting holes. See

Fig. 1.

2. Start a screw for the keyhole type mounting hole in

the upper right corner. Screw it down within about 1/8 in.

[3 mm] of the surface.

3. Hang the relay on the screw, position the case, and

start the bottom screw.

4. Tighten both screws.

WIRING

All wiring must comply with all applicable electrical

codes, ordinances, and regulations. Follow any instructions

furnished with the controlled equipment.

IMPORTANT: The switching relay terminals are ap-

proved for use with copper wires only.

See Figs. 2 through 10 for hookup diagrams for these

relays. When two or more devices are to be controlled in

parallel, the total current must not exceed the relay load

rating. Fig. 11 is an internal view of the RA832A and

shows terminal locations and barriers.

Never connect load terminals to a load that takes more

current than the amount listed in the electrical ratings on the

relay.

Fig. 1—Approximate mounting dimensions in

in. [mm].

1

4 [108]

3

[2] DIAMETER

32

[13] DIAMETER

1

3 [89]

2

3

1 [35]

8

RA89A (SPST)

TO LOAD

4

KNOCKOUT FOR

1/2 (13) CONDUIT (3)

L2

CONTROLLER

(IF USED)

7

1

8

[48]

7

[22] DIAMETER

8

KEYHOLE TYPE

MOUNTING HOLE

1

4

2

[114]

1

5

4

[133]

3

[10]

8

3

[10]

8

15

2

16

[75]

7

1

8

[48]

M3823

2

21 34

1

RA89A

JUMPER REMOVED

L1

HOT

1

TO LOAD

5

1 [29]

32

1

2

7

[6] DIAMETER MOUNTING HOLE

32

25

[20]

32

Fig. 2—Internal schematic and typical hookup

for RA89A.

LOW VOLTAGE (CLASS 2)

2-WIRE THERMOSTAT

TT

JUMPER

21 34

L2

L1

1

HOT

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

1

AND DISCONNECT MEANS AS REQUIRED.

COMPLETE WIRING AS SHOWN ABOVE.

2

M3819

69-0790—32

Page 3

Fig. 3—Internal schematic and typical hookup

for RA832A.

LOW VOLTAGE (CLASS 2)

2-WIRE THERMOSTAT

TT

XX

AUXILIARY TO LOW

OR MILLIVOLTAGE

(POWERPILE) LOAD

RA832A

Fig. 6—Internal schematic and typical hookup

for R482J.

R482J

21 34

L2

L1

1

HOT

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

1

AND DISCONNECT MEANS AS REQUIRED.

Fig. 4—Internal schematic and typical hookup

for R182J.

WX RB

3

OHMS

L1

L2

1

L1

L2

(HOT)

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION AND

1

DISCONNECT MEANS AS REQUIRED.

N.O. CONTACTS MAKE BEFORE N.C CONTACTS BREAK,

2

AND N.C. CONTACTS MAKE BEFORE N.O. CONTACTS BREAK.

LOAD 1

K1

LOAD 2

(OPTIONAL)

K1

4

LOAD

N.O.

R182J

K1

K2

37

LOAD

N.C.

N.O.

M3821

2

K2

6

N.C.

M8232

Fig. 5—Thermostat connections for R182J.

THREE-WIRE

LOW VOLTAGE

(SERIES 10)

THERMOSTAT

RRB

W

1

THREE-WIRE

LOW VOLTAGE

(SERIES 20)

THERMOSTAT

W

RB

2

TWO-WIRE

LOW VOLTAGE

(SERIES 80)

THERMOSTAT

3

5

421

37

CONTROLLER

HYDRONIC HEATING

CONTROL TERMINALS

2

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

1

AND DISCONNECT MEANS AS REQUIRED.

CONTROLLER (IF USED) MUST BE SNAP ACTION OR

2

MERCURY SWITCH TYPE.

N.O. CONTACTS MAKE BEFORE N.C CONTACTS BREAK,

3

AND N.C. CONTACTS MAKE BEFORE N.O. CONTACTS BREAK.

Fig. 7—Schematic diagram showing R845A in

multizone, forced hydronic heating system.

This arrangement is suitable for any number

of additional zones.

T

THERMOSTAT

THERM.

ZONE 1

T

ZC

ZP

B1

BURNER

BURNER

CONTROL

B2

C1

CIRC.

CIRCULATOR

ZONE 1

C2

1

LINE

2

N.O.

TO LOAD

TO ADDITIONAL R845A

RELAYS FOR OTHER ZONES

8

N.O.

N.C.

COM. COM.

RA845A RELAY

2

1

4

3

5

6

L1

2

HOT

1

3

L2

N.C.

TO LOAD

THERMOSTAT

ZONE 2

CIRCULATOR

ZONE 2

3

6

M8234

W

MAKES CONTACT ON TEMPERATURE FALL ONLY.

1

MAKES CONTACT ON BOTH A TEMPERATURE RISE AND FALL.

2

BX

R182J

R

W

BX

R182J

JUMPER

W

R182J

M8233A

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

1

AND DISCONNECT MEANS AS REQUIRED.

2

R

BX

IF CONTROLLING TWO LOADS, USE:

3 AND 4 FOR LINE VOLTAGE LOAD

5 AND 6 FOR LINE OR LOW VOLTAGE LOAD

3

IF USING LOW VOLTAGE, USE A SEPARATE TRANSFORMER.

3 69-0790—3

M3822

Page 4

Fig. 8—R845A hookup for controlling two

loads.

LOW VOLTAGE (CLASS 2)

2-WIRE THERMOSTAT

TT

R845A

Fig. 10—Internal schematic and hookup for

R882J.

LOW VOLTAGE

SOURCE

2

CONTROLLER

R882J

1

21 34

1

TO

L1

POWER

HOTL2

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

1

AND DISCONNECT MEANS AS REQUIRED.

WHEN CONTROLLING TWO LOADS, USE 3 AND 4

2

FOR LINE VOLTAGE LOAD AND 5 AND 6 FOR LINE

OR LOW VOLTAGE LOAD.

IF USING LOW VOLTAGE, USE A SEPARATE

3

TRANSFORMER.

Fig. 9—Internal schematic and hookup for

R847A.

LOW VOLTAGE (CLASS 2)

2-WIRE THERMOSTAT

TT

L2 L1 34

1

TO

L1

L2

POWER

(HOT)

POWER SUPPLY. PROVIDE OVERLOAD PROTECTION

1

AND DISCONNECT MEANS AS REQUIRED.

WHEN CONTROLLING TWO LOADS, USE 3 AND 4

2

FOR LINE VOLTAGE LOAD AND 5 AND 6 FOR LINE

OR LOW VOLTAGE LOAD.

IF USING LOW VOLTAGE, USE A SEPARATE

3

TRANSFORMER.

4

10 AMP CONTACT RATING OR 20 AMP WHEN POLES

ARE CONNECTED IN PARALLEL.

2

1 1

LOAD 1

2

1 1

LOAD 1

TO

POWER

TO

POWER

3

44

3

65

LOAD 2

M3820

R847A

67

LOAD 2

M8231B

3

5

4

37

N.O.

N.C.

COM. COM.

LOAD

Fig. 11—Internal view of RA832A Switching

Relay.

TTX

X

24V TRANSFORMER

12

34

N.O.

3

6

8

N.C.

LOAD

M8235

RELAY

M3824

Service and Checkout

1. Never use oil on any part of the relay coil or contacts.

2. Keep the cover on the relay during normal operation

and remove only for service and checkout.

contacts may turn black after being in service for some

time; this discoloration does not prevent proper operation.

4. After installation is complete, operate system through

at least one cycle from the controller to make certain the

relay controls the equipment as intended.

3. Relay contacts require no cleaning; they are arranged

so they close with a wiping action and are self-cleaning. The

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

69-0790—34

Printed in U.S.A.

M1P 2V9

Loading...

Loading...