Page 1

Honeywell

THE R841 ELECTRIC HEATING RELAY IS

USED WITH A 2-WIRE, 24V THERMOSTAT

TO PROVIDE CONTROL OF ELECTRIC

HEATING EQUIPMENT. IT IS A DIRECTFOLLOWING RELAY WHICH OPERATES

WITH EACH CYCLE OF THE THERMOSTAT (4 TO 6 CYCLES PER HOUR).

❑

R841C,D

load.

❑ R841E is used either with one thermostat

to control two loads simultaneously, or with

two thermostats to control two independent

loads.

❑

R841C

transformer; R841 D model must be powered

from a remote 24V transformer.

models are used to control one

and E models include an integral

❑

R841C

and D models have a 1/2 inch male

conduit bushing.

❑ The

R841C ,D

and E models are for instal-

lation on a wireway or J-box.

❑ R841 E has a 1/2 inch male conduit bushing

and includes an enclosure with a low voltage

wiring compartment.

❑ Special R841E with 10 second minimum

timing between stages is available.

❑ Each relay switches up to a 5,000 watt load.

❑ Spst MICRO SWITCH snap switches are

actuated by ambient-compensated

bimetal

strips.

❑ Leadwires are provided for both line voltage

and low voltage connections.

❑ Small size and silent operation allow instal-

lation in living area, utility room, or basement,

❑

May be mounted in any convenient position.

R.E.

REV. 10-79 (.11)

Page 2

THE SPECIFICATIONS GIVEN IN THIS PUBLICATION DO NOT INCLUDE NORMAL MANUFACTURING TOLERANCES.

THEREFORE, THIS UNIT MAY NOT MATCH THE LISTED SPECIFICATIONS EXACTLY .ALSO, THIS PRODUCT IS TESTED

AND CALIBRATED UNDER CLOSELY CONTROLLED CONDITIONS, AND SOME MINOR DIFFERENCES IN PERFORMANCE CAN BE EXPECTED IF THOSE CONDITIONS ARE CHANGED.

IMPORTANT

TRADELINE MODELS

TRADELINE models are selected and packaged to provide ease of stocking, ease of handling, and maximum

replacement value. TRADELINE model specifications are the same as those of standard models except as noted

below.

TRADELINE MODELS A VA ILABLE:

R841C, D, and E Electric Heating Relays.

VOLTAGE AND FREQUENCY:

R841C–240 Vat, 60 Hz.

R841D–24

R841E–120, 208, 240, 277 Vat; 50/60 Hz.

ADDITIONAL FEATURES: TRADELINE pack with

cross reference label and special instruction sheet.

Vat, 60 Hz.

STANDARD MODELS

MODELS: R841 Electric Heating Relay.

R841 C Electric Heating Relay –with integral trans-

former, with conduit bushing; includes one spst

snap switch.

R841 D Electric Heating Relay –without transformer,

with conduit bushing; includes one spst snap switch.

R841 E Electric Heating Relay–with integral trans-

former, with conduit bushing; includes two spst

switches.

VOLTAGE AND FREQUENCY:

R841C (with transformer)– 120, 208, or 277 Vac at

60 Hz; 240 Vac at 50/60 Hz.

R841 D (without transformer)–24 Vat, 60 Hz.

R841E

(with transformer)–1 20, 208, 240, or 277

Vac at 50/60 Hz,

bimetal

SWITCH: MICRO SWITCH snap switch,

operated. Makes contact about 75 seconds (cold) after

thermostat calls for heat. (Top stitch on R841 E

with optional specification makes at about 55 seconds,

bottom switch at about 75 seconds. ) Breaks contact

about 65 seconds (hot) after thermostat shuts off,

ELECTRICAL RATINGS (A per switch, 60 Hz current):

Noninductive Rating: 22 A at 120, 208 and 24(I Vac;

19 A at 277 Vat.

THERMOSTAT HEAT ANTICIPATOR CURRENT:

R841C,D–O.2 A.

R841 E –0.4 A (one thermostat controlling both loads);

0.2 A (one thermostat controlling each load).

AMBIENT TEMPERATURE RANGE: Minus 20 F to

plus 150 F [minus 29 C to 66 C].

UNDERWRITERS LABORATORIES INC. LISTED

(R841C,D

and E): File No. E4436, Guide XAPX.

CANADIAN STANDARDS ASSOCIATION CERTI-

FIED:

R841C,D–File No. LR1620 and LR1322.

R841E–File No.

LR1620.

(continued on page 3)

WHEN PURCHASING REPLACEMENT AND MODERNIZATION PRODUCTS FROM YOUR TRADELINE

WHOLESALER OR YOUR DISTRIBUTOR, REFER TO THE TRADELINE CATALOG OR PRICE SHEETS FOR

COMPLETE ORDERING NUMBER, OR

1. Order number; specify TRADE LINE, 2. Voltage and frequency.

if desired.

IF YOU HAVE ADDITIONAL QUESTIONS, NEED FURTHER INFORMATION, OR WOULD LIKE TO COMMENT ON OUR

PRODUCTS OR SERVICES, PLEASE WRITE OR PHONE:

I. YOUR LOCAL HONEywELL Residential DIVISION SALES OFFiCE

2. RESIDENTIAL DIVISION CUSTOMER SERVICE

HONEYWELL INC., 1885 DOUGLAS DRIVE NORTH

NNEAPOLIS,

Ml

(IN CANADA–HONEYWELL

INTERNATIONAL SALES AND SERVICE OFFICES IN ALL PRINCIPAL CITIES OF THE WORLD.

MINNESOTA 55422 (612) 542-7500

CONTROLS LIMITED, 740 ELLESMERE ROAD, SCARBOROUGH, ONTARIO MIP 2V9)

SPECIFY–

3. Optional specification, if desired.

(CHECK

WHITE

PAGES

OF

PHONE

DIREcToRY).

2

Page 3

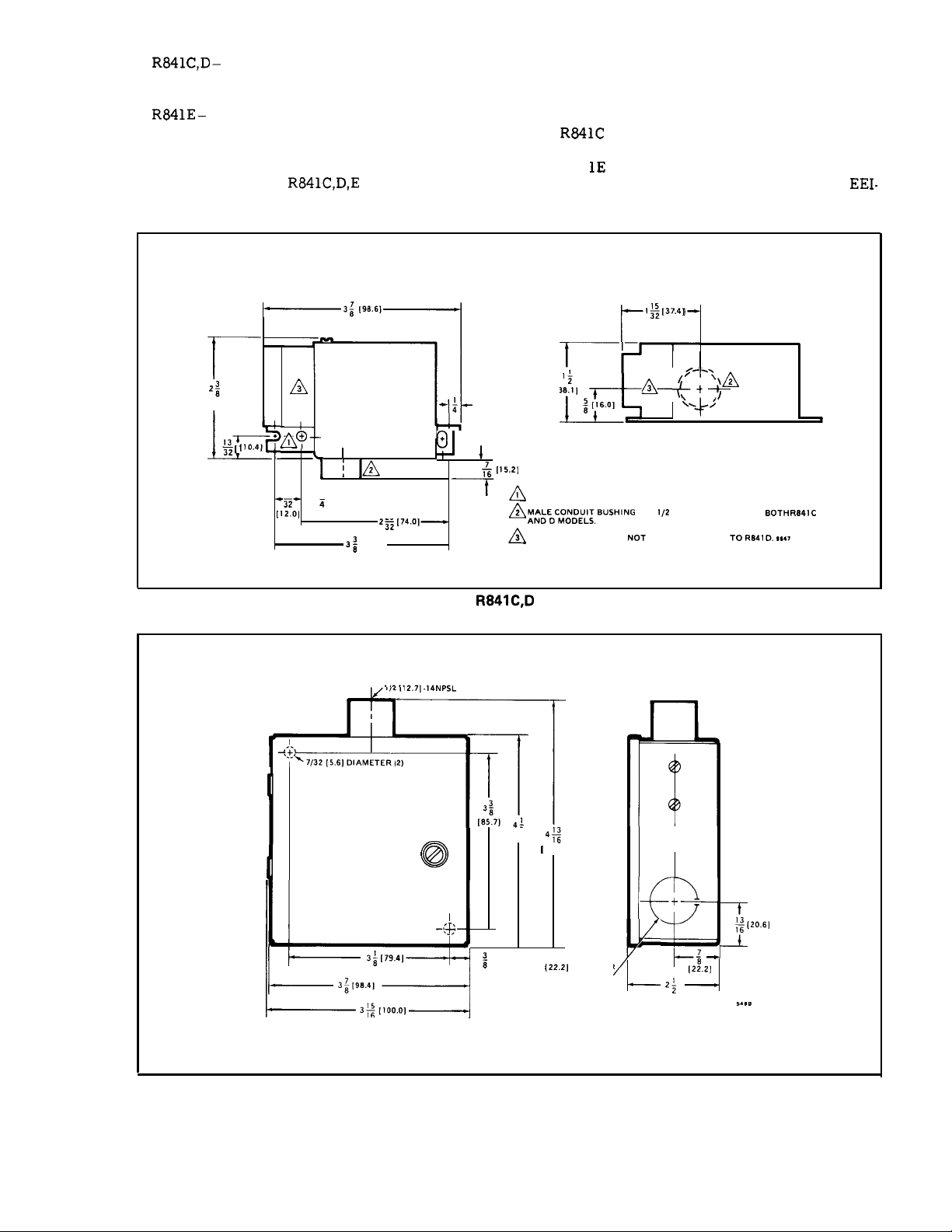

LEADWIRE LENGTH (NOMINAL):

R841C,D–

Line voltage–18 in. [457.2 mm].

Low voltage–7-l/2 in. [ 190.5 mm].

R841E–

Line voltage–8 in. [203.2 mm].

Low voltage–4 in. [ 101.6 mm].

CASE FINISH: Zinc bichromate.

CONDUIT BUSHING:

R841C,D,E

have a 1/2 in. [12.7

mm] male conduit bushing; R841 E also has three

7/8 in. [22. 2 mm] knockouts in back and sides of

case for 1/2 in. [ 12.7 mm] conduit.

DIMENSIONS: See Figs. 1 and 2.

OPTIONAL SPECIFICATIONS:

1.

R841C

with special leadwires (277 Vat, 60 Hz

only ).

2. R84 lE with 10 second minimum timing between

stages on both make and break operation. Meets

NE-MA requirement.

EEI-

T

2;

[60,4]

!__?

,3r-+~@

~

II 0.41

—3;

A

-7

, ,

15

-Z”

“

[12.01 [19.1]

1, ~

3

i

[98.6]

1 1A

3;

2s2

[65.8]

FIG. 1-DIMENSIONS OF

29

[74’01—

112[12.71.14NPSL

*;

0+

7A

1;[37

.4]

r

~’

[6.4]

15.21

&l

R841C,D

[3821 ]

;

[16.0]

I_&

I MOUNTING HOLE AND TWO MOUNTING SLOTS FOR NO. 8 SCREW.

~ ~4/&:C:::#fl,6USHlNG

~

TRANSFORMER NOT APPLICABLE TO R841D. ,**T

IN in. [mm IN BRACKETS].

A–

(t

-y

“+’

FOR

l,,

INCH KNOCKOUT ON BOTH F(84,C

F

4:2)

-=J

[101.8 I

4;

[

122.7]

@

-(4

3;

[79.41

3;

[96.4]

b

~

3: [100.0]

FIG. 2–DIMENSIONS OF R841E IN in. [mm IN BRACKETS].

;

[9.5]

718 [22.21 DIAMETER

KNOC

“ ‘

KOUT (3)

<

J1~

+

:[20.61

7

—-

[2:.2}

2; —

[63.5]

‘G

‘v

,...

‘

60-2004– 1

Page 4

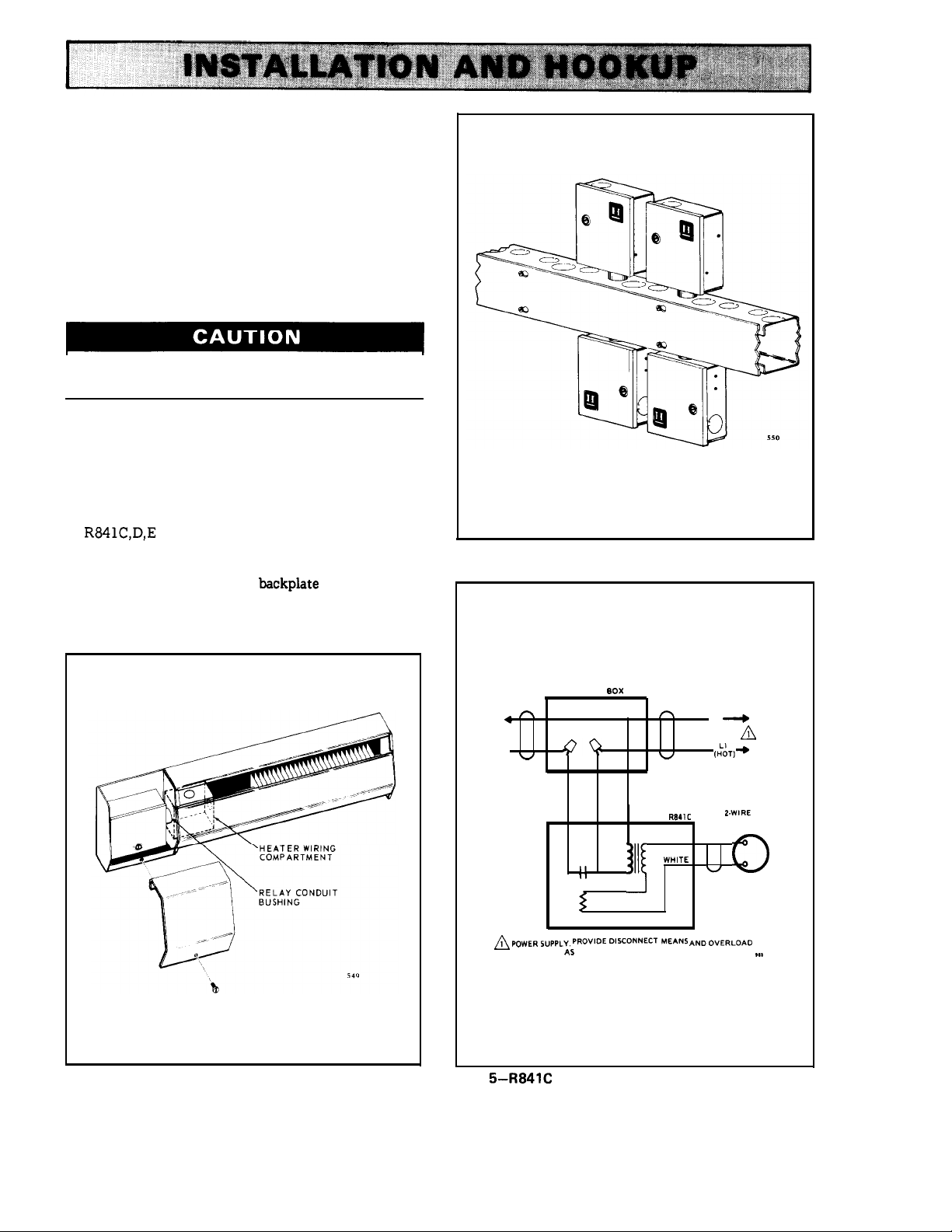

WHEN INSTALLING THIS PRODUCT . . .

1. Read these instructions carefully. Failure to

follow them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

I

I

All wiring must comply with applicable codes and

ordinances. Be sure the power supply voltage agrees with

the rating on the relay label.

Fig. 3 shows a typical installation within a compartment enclosure on the end of a baseboard heater. The

back of the compartment enclosure should be equipped

with embossing to clear mounting screws.

R841C,D,E

also may be mounted on a wireway

(Fig. 4) or junction box.

1. Fasten relay securely to mounting surface using

the 2 mounting holes in the

backplate or the conduit

bushing.

2. Disconnect the power supply.

FIG. 4–FOUR RELAYS MOUNTED ON WIREWAY.

FIG. 3–TYPICAL INSTALLATION ON BASEBOARD

HEATER.

JUNCTION

BOX

II

II

RESISTANCE

HEATER

n

n

w

R841C

RED

WHITE

111~

ME&N,

ANDovERLoAo

L2

~

(;:T]~

2.WIRE

LOW VOLTAGE

THERMOSTAT

n

u

n

4

4

~

PIYUER5”PPLY. PRovlDEDl,coNNEcT

PROTECTION

FIG.

5–R841C INTERNAL SCHEMATIC AND CON-

f?Q

w

RED BLACK BLUE

AS

REQUIRED.

NECTION DIAGRAM FOR ONE RELAY.

A

(~

,.,

!

Page 5

fAf

Ll (HOT) L2

@

ELEcTRIc

HEATER

NO.

1

e

J’J

PC3WERS”PPLY. PROVIDEA DI*CONNECTMEANS

DE-ENERGIZE ALL VOLTAGE S

AS REQUIRED,

o

~~

BLUE

BLACK

RED

OURCES. PROVIDE OVERLOAD PROTECTION

*

\

J

\ll

1

R841C 24 V

TO S,

2THERMOSTAT

RED

RE515TANCE

HEATER

M”LTANEO”,LY

WIRE

TRANSFORMER

..

r

R841D RELAV

ACK

LOAD

-%

. . . .

A

LOAD

4

A

~

,,.,

BLACK RED

—

—

LOAD

POWER

S”PPL”.

TECTION AS REQuIRED,

R841D RELAY

~

RED

1+

R841D RELAY Low VOLTAGE

●

1

qED

PROVIDE DISCONNECT MEANSANI)OVERLOAD

RED

WHITE

.

---

WHITE

b

I

(

)

W,FI.

LOW VOLTAGE

RMOSTAT

THE

2.WIRE

LOW VOLTAGE

THERMOSTAT

m

(>

2.WIRE

THERMOSTAT

“,,0.

,

PRO.

,,,.

FIG. 6–TWO OR MORE

ED TO ONE THERMOSTAT SO THEY OPERATE IN SEQUENCE ABOUT ONE MINUTE

APART. THIS REDUCES THE INITIAL LINE

LOAD ON LARGE KILOWATT

LATIONS. SET THE THERMOSTAT HEAT

ANTICIPATOR AT 0.2A.

IUNCTION BOX

4~

>AO

4“

J?%

(

z

RED

-1+

D

)

BLACK

I

~

Pow,,

5LIW’L”

PROTECTION AS REQUIRED.

PROV,CIEC)ISCONNECT

R841C

RELAYS CONNECT-

n

L2

~

A

(H:T)~

w

LJ

=24V

R841

RED

WHITE

DROPPING

RE515ToR

D

~

n

u

J

MEANS AND OV,I?LCIAD

iNSTAL-

REMOTE

TRANSFORMER

2.WIRE

LOW VOLTAGE

THERMOSTAT

..,,

.

FIG. 8–CONNECTIONS FOR FOUR

AND THERMOSTATS USED WITH ONE

TRANSFORMER. SET EACH THERMOSTAT

HEAT ANTICIPATOR AT 0.2 A.

A

POWER S”PPLY, PROVIDE DISCONNECT MEAN, AND OVERLOAD ,,a,

PROTECTION

AS

REQuIRED.

R841D

RELAYS

E

FIG.

7–R841D INTERNAL SCHEMATIC AND CON-

NECTION DIAGRAM FOR ONE RELAY.

FIG. 9–CONNECTIONS FOR TWO R841D RELAYS

USED WITH ONE TRANSFORMER AND

THERMOSTAT. SET THERMOSTAT HEAT

ANTICIPATOR AT 0.4 A.

5

60-2004–1

Page 6

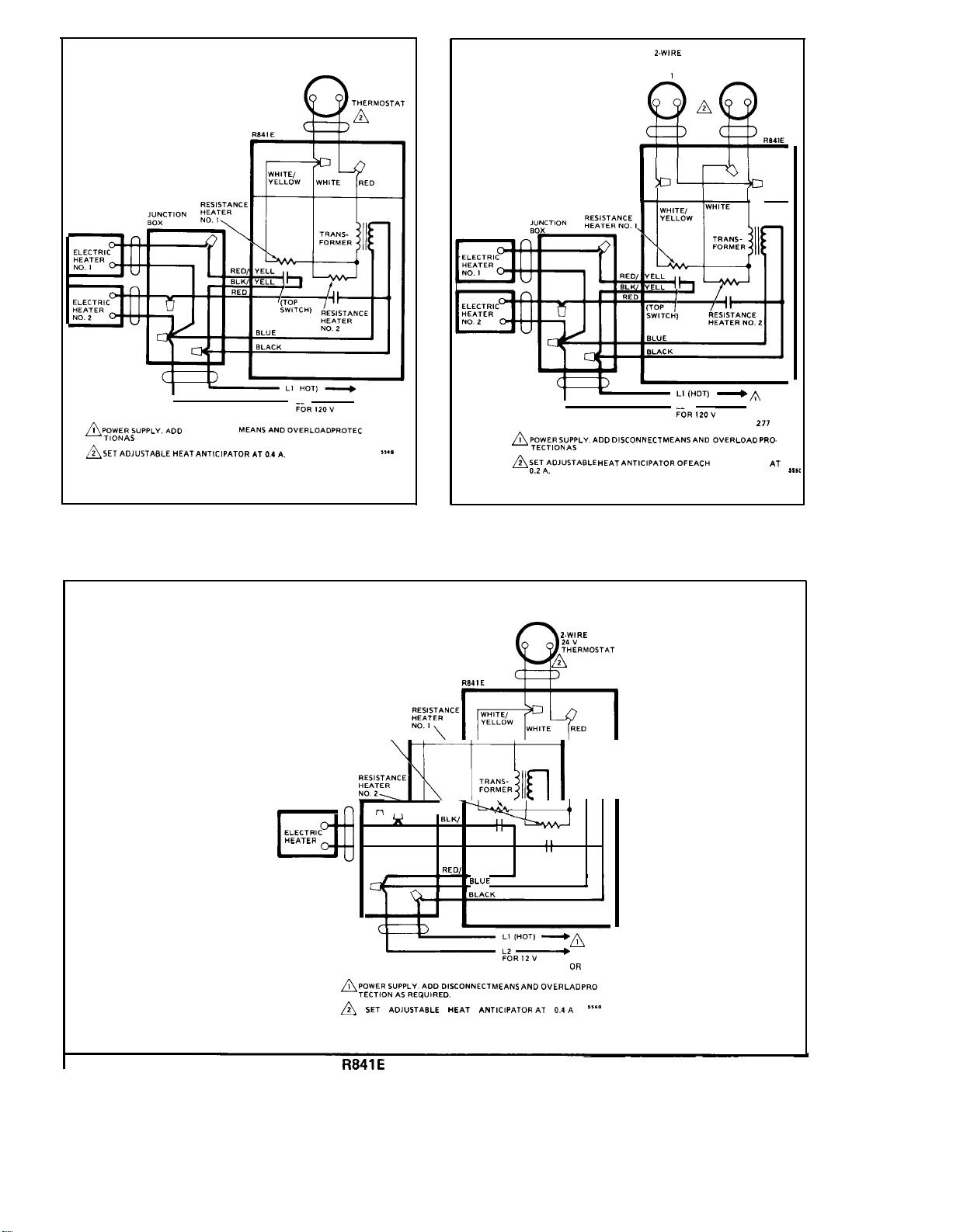

Q

2-WIRE

24 V

THERM05TA7

A

2.WIRE

24 V

THERMOSTAT THERMOSTAT

1

NO

@@

2-WIRE

24 V

NO. 2

—

~6R120V

~

PowERs”PPLY.ADcl

TION AS REQUIRED

A

5ETAD,”sTABLEHEAT

DISCONNECT

ANT!clPAToRATo.4A.

MEAN5ANDOVERLOACI

(L3 FOR 208, 240, OR 277 V]

,,0,.,

,,..

FIG. IO–TYPICAL WIRING HOOKUP FOR R841E

WITH ONE THERMOSTAT OPERATING

TWO LOADS SIMULTANEOUSLY.

~

POWER SUPPLY.

TECTION AS REQUIRED.

~

:~:DJLISTABLE

I !iJ-L$L

%R120V

(L3 FOR 208,240, OR

ADD

DISCONNECT MEANS AND

HEAT AP4TICIPATOP.OF EACH THERMOSTAT

RED

-

2?7

OVERLOAD

PRo.

V)

A,

FIG. II–TYPICAL WIRING HOOKUP FOR R841E

WITH TWO THERMOSTATS, EACH WITH

ITS OWN LOAD.

2.WIRE

24 V

THERMOSTAT

A

R841

E

A

,,s,

JUNCTION HEATER

00x

b

ELECTRIC

HEATER

M

::rm

nl

n

1

9

Q

BLK/ YELL

RED

REDI YELLOW

BLUE

~

~

p##&wLYPLYyxwEcT

~

SET

AOJLISTABLE HEAT ANT,CIPATIJRAT

I. 12–TYPICAL WIRING HOOKUP FOR

THAT BOTH SIDES OF THE SINGLE PHASE LINE ARE SWITCHED.

R841E

WITH ONE THERMOSTAT CONNECTED TO ONE LOAD SO

6

11

II

:(-n~

FOR12V

(L3 FOR 208, 240,

MEANS AND

11

II

OR

OV,RLAD

04A

277 V)

,.0

‘s”

Page 7

The cycling pattern of the R841 is determined by the

thermostat(s). On a call for heat, the thermostat(s)

activates the low voltage resistance heater(s) in the

R841.

The heater(s) drives the

the

spst,

MICRO SWITCH snap-acting switch or switches.

bimetal strip is ambient temperature compensated

The

bimetal

strip(s) to actuate

within the specified ambient range. At rated voltage and

frequency, the R841 switch contacts make

approxi-

mately 75 seconds (from cold start) after the thermostat

calls for heat. (The top switch on the special R841 E

with optional specification is adjusted to approximately

55 seconds; the bottom switch to approximately 75

seconds. This allows, at the very minimum, 10 seconds

between stages in both make and break sequence.)

After mounting and wiring have been completed, turn heating equipment functions properly. Return the

on the power supply. Set the thermostat above room

perature until the electric heating equipment starts.

tem-

mostat to the desired room temperature before leaving

the installation.

Permit the system to operate long enough to prove the

ther-

Dear Customer,

We welcome your comments and suggestions for improving this

cation. Your assistance is greatly appreciated and will

better

tachnical information for ye”.

HONEYWELL MINNEAPOLIS, MN 5540S INTERNATIONAL Salas Offices in all principal cltias of tha world. Manufacturing in

Australia, Canada, Finland, France,

Germeny, Japan, Mexico, Natharlands, Spain, Taiwen, United Kingdom, U.S.A.

eneble us to provide

publi-

Please send your

Honaywell Inc.

Honeywell Plaza

Minneapolis, Minnesota 55408

ATTN: Publications Supervisor MN 12-3247

commanta and suggestions to:

PRINTED IN U.S.A.

Loading...

Loading...