Page 1

Honewvell

-u

R8330 ELECTRIC FURNACE SEQUENCERS SWITCH A FAN AND ELECTRIC

HEATING ELEMENTS ON AND OFF IN

SEQUENCE.

q Single unit control of heating elements and

fan reduces control space .requirements and

wiring in furnace.

q Elements sequence on within 2 minutes and

off within 4 minutes.

q Meet latest EEI-NEMA standards.

o Multipoise mounting of control.

q All models are same size.

q Designed for easy mounting with tab and

single screw.

q Devices are ambient compensated for minus

20 to plus 162 F [ minus29toplus71C].

q Models available with low VA pilot duty

rating for remote fan operation.

EI Isolated fan or combination rated models

available.

q Quick-connect terminals for easy wiring.

q Designed for quiet, reliable operation.

q .Thermostat current draw is constant (0.4

amp).

q Model line offers complete range of control

choice to meet all application requirements.

ii

L.H.

REV. 7-75 l.086)

Page 2

Tradeline models are selected and packaged for ease of handling, ease of stocking, and maximum replacement

TRADELINE MODELS

value. Tradeline model specifications are the same as those of standard models except as noted below.

MODEL: R8330D1039 Electric Furnace Sequencer.

This single model replaces all 10 of the other

models in our line.

ADDITIONAL FEATURES:

0 Includes special Tradeline accessories.

I

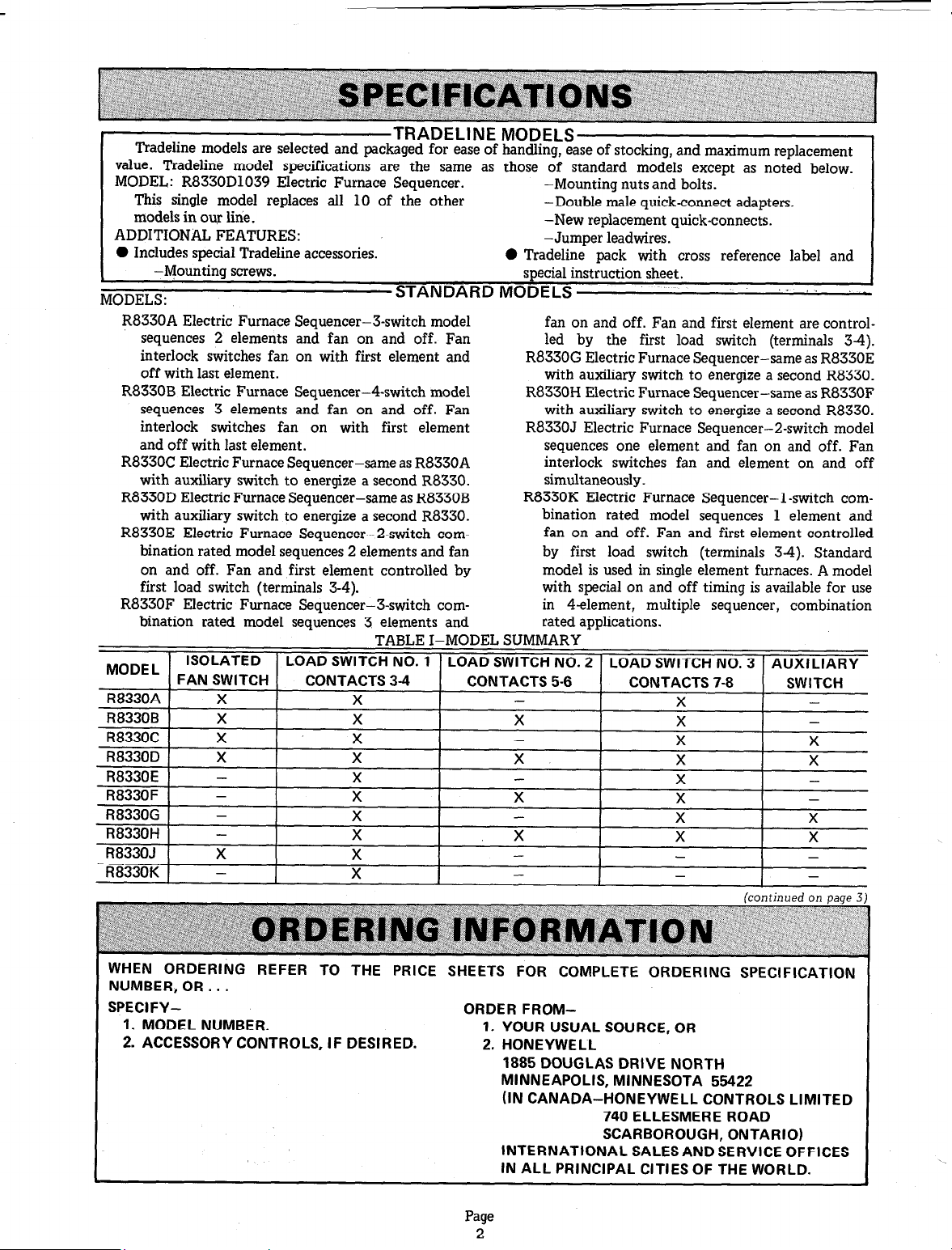

MODELS:

-Mounting screws.

STANDARD MODELS

R8330A Electric Furnace Sequencer-3-switch model

sequences 2 elements and fan on and off. Fan

interlock switches fan on with first element and

off with last element.

R8330B Electric Furnace Sequencer-4-switch model

sequences 3 elements and fan on and off. Fan

interlock switches fan on with first element

and off with last element.

R8330C Electric Furnace Sequencer-same as R8330A

with auxiliary switch to energize a second R8330.

R8330D Electric Furnace Sequencer-same as R8330B

with auxiliary switch to energize a second R8330.

R8330E Electric Furnace Sequencer-2-switch com-

bination rated model sequences 2 elements and fan

on and off. Fan and first element controlled by

first load switch (terminals 3-4).

R8330F Electric Furnace Sequencer-J-switch com-

bination rated model sequences 3 elements and

TABLE I-MODEL SUMMARY

-Mounting nuts and bolts.

-Double male quick-connect adapters.

-New replacement quick-connects.

-Jumper leadwires.

0 Tradeline nack with cross reference label and

special instruction sheet.

._

fan on and off. Fan and first element are controlled by the first load switch (terminals 34).

R8330G Electric Furnace Sequencer-same as R8330E

with auxiliary switch to energize a second R8330.

R8330H Electric Furnace Sequencer-same as R8330F

with auxiliary switch to energize a second R8330.

R8330J Electric Furnace Sequencer-2-switch model

sequences one element and fan on and off. Fan

interlock switches fan and element on and off

simultaneously.

R8330K Electric Furnace Sequencer- 1 -switch com-

bination rated model sequences 1 element and

fan on and off. Fan and first element controlled

by first load switch (terminals 34). Standard

model is used in single element furnaces. A model

with special on and off timing is available for use

in 4element, multiple sequencer, combination

rated applications.

I

WHEN ORDERING REFER TO THE PRICE SHEETS FOR COMPLETE ORDERING SPECIFICATION

NUMBER, OR.. .

SPECIFY- ORDER FROM-

1. MODEL NUMBER.

2. ACCESSORY CONTROLS, IF DESIRED.

1. YOUR USUAL SOURCE, OR

2. HONEYWELL

1885 DOUGLAS DRIVE NORTH

MINNEAPOLIS, MINNESOTA 55422

(IN CANADA-HONEYWELL CONTROLS LIMITED

740 ELLESMERE ROAD

SCARBOROUGH, ONTARIO)

INTERNATIONAL SALES AND SERVICE OFFICES

IN ALL PRINCIPAL CITIES OF THE WORLD.

Page

2

Page 3

ELECTRICAL RATINGS:

Load Contact Rating (all models)-

CONTACT RATINGS

VOLTS AC

b

208 25.0 5.2 20.8 4.3 5.5 15.0

240 25.0 6.0 20.8 5.0 5.5 15.0

277 21.7 6.0 18.0 5.0 3.6 8.6

(3-4, 5-6, AND 7-8)

RESISTIVE

AMP

KW AMP

Fan contacts (Fl, F2)-R8330A,B,C,D, and J7

COMBINED RESISTIVE AND INDUCTIVE

CONTACT RATINGS (3-4 ONLY) (UL)

RESISTIVE

KW

INDUCTIVE

AFL ALR

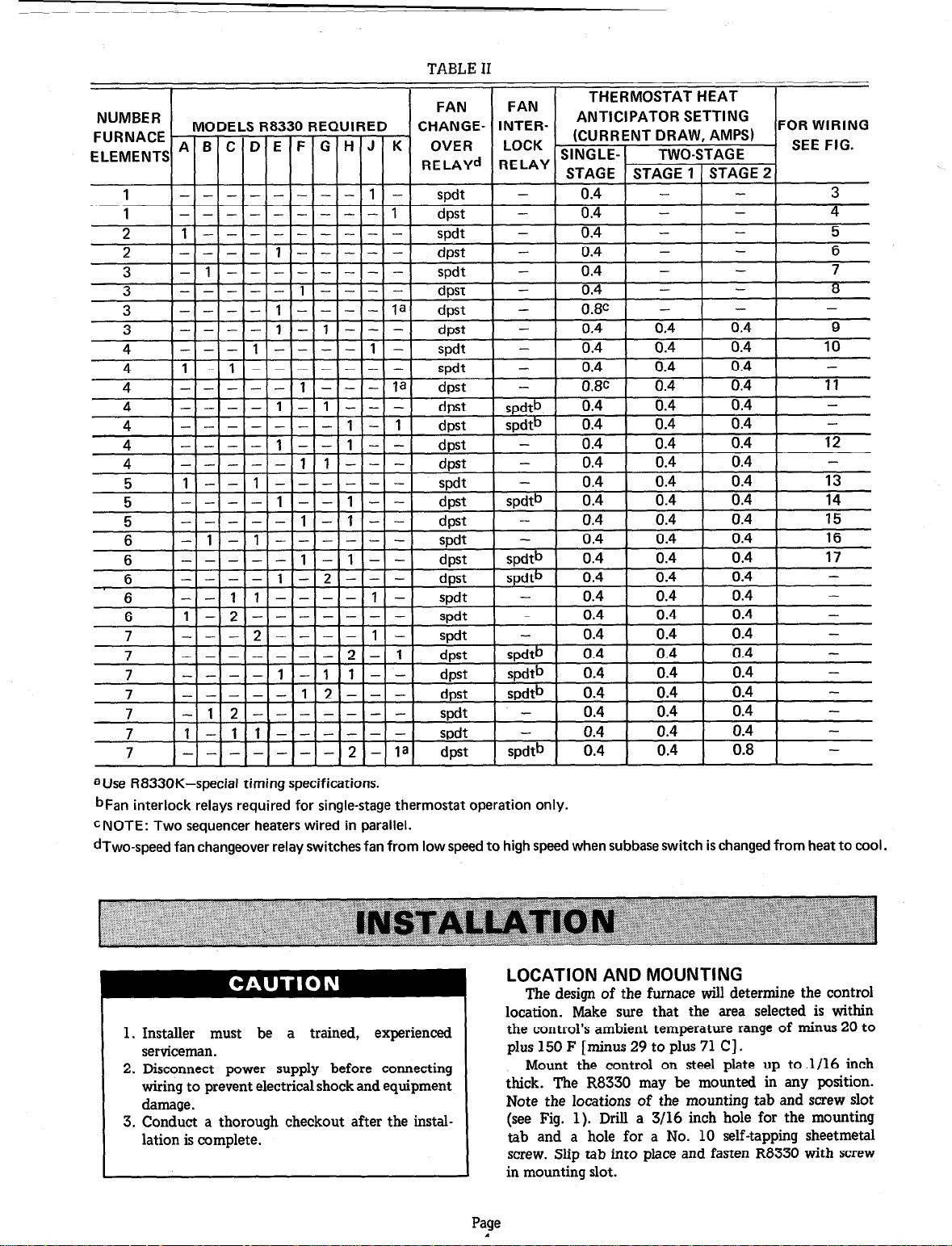

THERMOSTAT HEAT ANTICIPATOR SETTING: 0.4

amp. If combination hookups are used (see wiring

diagrams), set heat anticipator to the values given

in Table II.

I

\-J

ai/3 hp.

b314 hp.

Pilot Duty Rating-62.5 VA at 24V ac; special models

available with pilot duty rating of 3.5-62.5 VA on

fan contacts at 24V ac.

AUXILIARY SWITCH (R8330C,D,G, and H only): 3.6

‘-

amp full load; 21.6 amp locked rotor at 240V ac;

5 amp resistive at 24, 120, 208, and 240V ac; 35

VA pilot duty at 24V ac.

CONTROL VOLTAGE: 24V ac; 0.40 amp.

MINIMUM AMBIENT TEMPERATURE: Minus 20 F

[minus 29 C].

MAXIMUM AMBIENT TEMPERATURE: Plus 162 F

[plus 71 C] (Underwriters Laboratories Inc.).

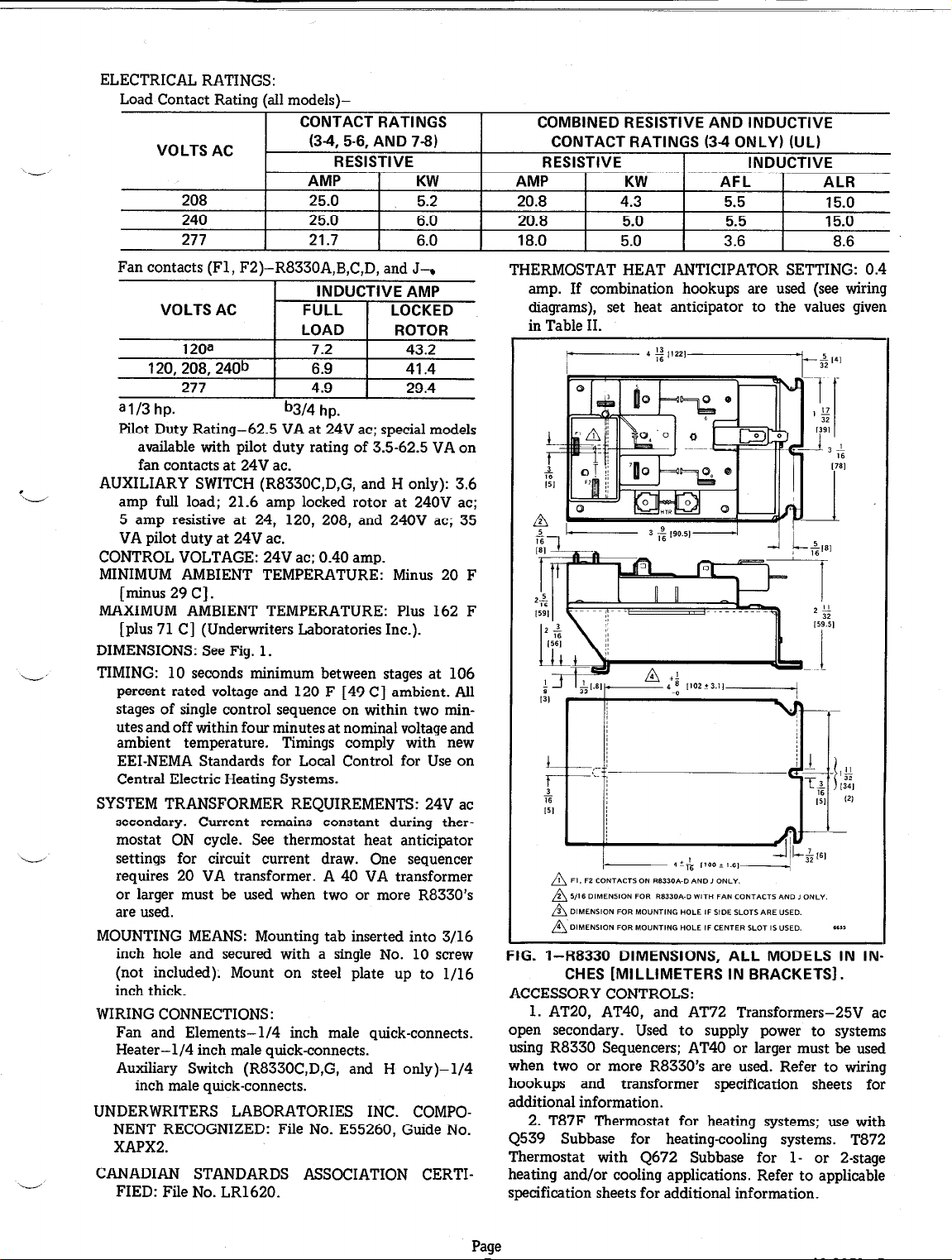

DIMENSIONS: See Fig. 1.

TIMING: 10 seconds minimum between stages at 106

percent rated voltage and 120 F [49 C] ambient. All

stages of single control sequence on within two minutes and off within four minutes at nominal voltage and

ambient temperature. Timings comply with new

EEI-NEMA Standards for Local Control for Use on

Central Electric Heating Systems.

SYSTEM TRANSFORMER REQUIREMENTS: 24V ac

secondary. Current remains constant during thermostat ON cycle. See thermostat heat anticipator

settings for circuit current draw. One sequencer

requires 20 VA transformer. A 40 VA transformer

or larger must be used when two or more R8330’s

are used.

MOUNTING MEANS: Mounting tab inserted into 3/16

inch hole and secured with a single No. 10 screw

(not included): Mount on steel plate up to l/16

inch thick.

WIRING CONNECTIONS:

Fan and Elements-l/4 inch male quick-connects.

Heater-l/4 inch male quick-connects.

Auxiliary Switch (R8330C,D,G, and H only)-l/4

inch male quick-connects.

UNDERWRITERS LABORATORIES INC. COMPO-

NENT RECOGNIZED: File No. E55260, Guide No.

XAPXZ.

CANADIAN STANDARDS ASSOCIATION CERTI-

FIED: File No. LR1620.

FIG. l-R8330 DIMENSIONS, ALL MODELS IN IN-

CHES [MILLIMETERS IN BRACKETS].

ACCESSORY CONTROLS:

1. AT20, AT40, and AT72 Transformers-25V ac

open secondary. Used to supply power to systems

using R8330 Sequencers; AT40 or larger must be used

when two or more R8330’s are used. Refer to wiring

hookups and transformer specification sheets for

additional information.

2. T87F Thermostat for heating systems; use with

Q539 Subbase for heating-cooling systems. T872

Thermostat with 4672 Subbase for l- or 2-stage

heating and/or cooling applications. Refer to applicable

specification sheets for additional information.

Page

Page 4

4 --

4 --

5 1 5 -5 -6 - 1

6 -6 --

TABLE II

FOR WIRING

7 1

7 -

aUse R8330K-special timing specifications.

bFan interlock relays required for single-stage thermostat operation only.

cNOTE: Two sequencer heaters wired in parallel.

dTwo-speed fan changeover relay switches fan from low speed to high speed when subbase switch is changed from heat to cool.

. _

_ 1 ll- __I- - -

- - -I- -I- 2 -

I

I -r--

_I spdt Ial dpst spdtb

0.4 0.4 0.4 1

0.4 0.4 0.8 1

-

-

LOCATION AND MOUNTING

The design of the furnace will determine the control

location. Make sure that the area selected is within

1. Installer must be a trained, experienced

serviceman.

2. Disconnect power supply before connecting

wiring to prevent electrical shock and equipment

damage.

3. Conduct a thorough checkout after the installation is complete.

the control’s ambient temperature range of minus 20 to

plus 150 F [minus 29 to plus 71 C] .

Mount the control on steel plate up to .1/16 inch

thick. The R8330 may be mounted in any position.

Note the locations of the mounting tab and screw slot

(see Fig. 1). Drill a 3/16 inch hole for the mounting

tab and a hole for a No. 10 self-tapping sheetmetal

screw. Slip tab into place and fasten R8330 with screw

in mounting slot.

?age

1

Page 5

L’

c

rxl9nEl

E

Disconnect power supply to prevent electrical

shock and equipment damage.

I

IMPORTANT

The terminals on these controls are approved for

use with copper wire only.

All wiring must comply with applicable codes and

ordinances. Refer to manufacturer’s wiring information

if available. Terminal identifications are molded in

the R8330 base for wiring convenience. Adjust the

thermostat heat anticipator to match the circuit current

draw (see SPECIFICATIONS).

Figs. 3-17 show typical hookups using the R8330 in

systems with up to six elements. Optional methods of

wiring the fan to provide delayed on and/or off are

shown in Figs. 18-19.

ONE-ELEMENT FURNACES WIRING

R8330A

R8330C

A

AUXILIARY SWITCH

c

QQOQ

660%

R8330E

R8330G R8330H

W-2

AUXILIARY SWITCH

R8330B

R8330D

R8330F

AUXILIARY SWITCH

I PROWDE DlSCONNECT MEANS AND OVERLOAD PROTECTION AS

a

REQUIRED.

2 HEAT ANTlClPATOR SETTING 0.4 AMPS.

n

3 FAN MAY BE WIRED FOR DELAYED ON AND/OR OFF. REFER TO FAN

n

WIRING HOOKUPS. .,a.

FIG. 3-WIRING SCHEMATIC FOR A SINGLE

ELEMENT SYSTEM-ISOLATED FAN.

T87F

ELEMENT 1 :.

POWER + L1

1 SVPPLY + L2

n

PGWER

SUPPLY

A

c L2 -

20 “A

24” TRANSFORMER

f DPST

CHANGEOVER

R8330K 1

ii

R8330J

R8330K

HTR

FIG. P-INTERNAL SCHEMATICS OF R8330 FUR-

NACE SEQUENCERS.

SPEED FAN

I PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS

n

REQVtRED.

HEAT ANTlClPATOR SETTING 0.4 AMP.

FAN MAY GE WlREO FOR DELAYED ON AND/OR OFF. REFER TO FAN

WlRlNG HOOKUPS.

FIG. 4-WIRING SCHEMATIC FOR A SINGLE-ELE-

MENT SYSTEM-COMBINATION RATED.

Page

.los

Page 6

A

eLI

eL2

TWO-ELEMENT FURNACES

T87F THERMOSTAT

.- - _ _.

\

HTR

Q_P 0-p

Fl

SEQUENCE ON

THERMOSTATCALLS FOR HEAT THERMOSTAT SATISFIED

THERMOSTAT CONTACTS MAKE THERMOSTAT CONTACTS BREAK

I PROVlDE DSCONNECT MEANS AND OVERLOAD PROTECTION AS

A

REQVIREO.

HEAT ANTKIPATOR SETTING 0.4 AMPS.

FAN MAY BE WIRED FOR DELAYED ON AND/OR OFF. REFER TO FAN

OPERATIONAL SEGUENCE

EL%. I ELTT. 2

FAN

w

ELMT. 2

SEQUENCE OFF

EL%. 1

FAN

I

FIG. 5-WIRING SCHEMATIC FOR A TWO-ELEMENT SYSTEM-ISOLATED FAN.

20 “A

24 VOLT

TRANSFORMER

- L1

1

n

FIG. 6-WIRING SCHEMATIC

20 “A

24 VOLT

TRANSFORMER

4

nn

J ~87~ THERMOSTAT

1 PROWOE DISCONNECT MEANS AN0 OVERLOAD PROTEcTION AS

n

REWIRED.

HEAT ANTICIPATOR SETTING 0.4 AMP.

FAN MAY BE WREO FOR OELAYEO ON AND/OR OFF. REFER To FAN

WlRlNG HOOKUPS.

: FOR A TWO-ELEMENT SYSTEM-COMBINATION RATED.

.1,14\

FIG. 7-WIRING SCHEMATIC

1 POWER SUPPLY. PROWOE DISCONNECT MEANS AN0 OVERLOAD

n

PROTECTION AS REQUIRED.

2 FAN MAY BE WREO FOR DELAYED ON AND/OR OFF. REFER TO FAN

a

WlRlNG HOOK”PS.

3 HEAT ANTICIPATOR SETTING 0.4 AMP.

n

4 FOR HEATINO,CO~LING *-SPEED FAN CHANGEOVER, USE SPOT RELAY.

n

FOR HooKuP SEE FIG. 3.

FOR A THREE-ELEMENT SYSTEM-ISOLATED FAN.

Page

A

11158

Page 7

FIG. 8-WIRING SCHEMATIC FOR A THREE-ELEMENT SYSTEM-COMBINATION RATED.

MAKE CONNECTlONS AS SHOWN

FOR IlNcxE STAGE THERMOSTAT;

REMOVE JVMPER FOR &STAGE

THERYOSTAT APPLKATIONS.

40 “A

24 VOLT

LOW VOLTAGE

FURNACE TERMINAL

FURNACE

SEP”ENCER THERMOSTAT SATISFIED SEQUENCER

CwERATlONAL SEwENtE

SEQuErKE on

THEy~;~~;ALLs

THERMOSTAT

CONTACTS MAKE CONTACTS BREAK

SEQUENCEOFF FVRNACE

THERMOSTAT

A”XlLlARY OPENS

FIG. 9-WIRING SCHEMATIC FOR A THREE-ELEMENT SYSTEM-COMBINATION RATED.

Page

7

60-2051-5

Page 8

FOUR-ELEMENT FURNACES

FIG. II-WIRING SCHEMATIC FOR A FOUR-ELEMENT SYSTEM-COMBINATION RATED.

Page

8

Page 9

FIG. 13-WIRING SCHEMATIC FOR A FIVE-ELEMENT SYSTEM-ISOLATED FAN.

Page

9 60-2051

Page 10

FIG. 15-WIRING SCHEMATIC FOR A FIVE-ELEMENT FURNACE-COMBINATION RATED.

Page

10

Page 11

SIX-ELEMENT FURNACES

-

AUXILIARY CLOSES

t

ELMT. 4

R83308 ELMT. 5

{

t

t

ELMT. 6

t

EMT. 6

t

ELMT. 5

t

ELMT. 4

FAN

R83308

)

FIG. 1%WIRING SCHEMATIC FOR A SIX-ELEMENT SYSTEM-ISOLATED FAN.

i

MAKE CONNECTION5 A5 SHOWN FOR

SINGLE STAGE THERMOSTAT APPLICATIONS;

REMOVE JVMPER FOR Z-STAG

THERMOSTAT APP!-ICATIONS.

LOW VOLTAGE FURNACE

TERMINAL BLOCK FOR

THERMOSTAT

OPERATIONAL SEQUENCE

FURNACE

SEPVENCER

R8330H

RBJSOF ELMT. 5 t

SEQUENCE ON

THERMOSTAT CALLS

FOR HEAT

THERMOSTAT

CONTACTS CLOSE

v

ELMT. I

FAN w

FAN INTERLOCK RELAY

w

ELMT. 2

t

ELMT. 3

A”XlLlARY CLOSES

i

{

v

ELMT. 4

w

T

ELMT. 6

THERMOSTAT SATtSFtED SEQUENCER

cotmcx$ BREAK

FAN INTERLOCK RELAY

AUXIUARY OPENS

SEQUENCE OFF FURNACE

THERMOSTAT

ELMT. 3

ELMT. 2

v

ELMT. 1

t

ELMT. 6

w

ELMT. 5

ELMT. 4

FAN

R8330H

>

R8330F

>

\i/

HEAT ANTlClPATOR SETTING 0.4 AMPS.

FIG. 17-WIRING SCHEMATIC FOR A SIX-ELEMENT SYSTEM-COMBINATION RATED.

Page

11

60-2051-5

Page 12

DELAYEI

1 PROWOE ol*CONNECT MEANS AND OVERLOAD PROTECTION

n

AS REQUIRED.

2 FAN ON WlT” FIRST ELEMENT AND REMAINS ON “NT,L FVRNACE

n

COOLS TO FAN CONTROL SET POINT (DELAYED FAN OFF).

IG. l&WIRING SCHEMATIC FOR FAN DELAYED OF

FAN COMES ON WITH FIRST ELEMENT AND

REMAINS ON UNTIL FURNACE COOLS TO FAN

CONTROL SET POINT.

1’11,8

FAI WIRING

T87F

THERMOSTAT

40 “A

24 VOLT

TRANSFORMER

CONTROL

A - I I I

1 PROVlOE DISCONNECT MEANS AND OVERLOAD PROTECTION

n

AS REQUIRED.

2 FAN ON WHEN FURNACE WARMS TO FAN CONTROL SET POINT AND

n

OPERATES UNTIL FURNACE COOLS TO SET POINT (DELAYED FAN ON

AND OFF,.

IG. 19-WIRING SCHEMATIC FOR FAN DELAYED ON AND

OFF. FAN COMES ON WHEN FURNACE WARMS

TO FAN CONTROL SET POINT AND OPERATES

UNTIL FURNACE COOLS TO SET POINT.

-.

*,21m

CHECKOUT

Set the system thermostat to call for heat and make sure that

all elements sequence on and off properly and that fan starts with

first element on and stays on until all elements are off.

NOTE: This is a time delay device; allow time for elements to

sequence on and off.

SERVICE

The R8330 is not field repairable. If any component fails, it

should be replaced. No adjustment or periodic service is required

on these controls. Since all R8330’s are very similar, the R8330D

may be used to replace the R8330A-H or .I.

TROUBLESHOOTING

PRELIMINARY SYSTEM CHECKOUT

1. Check system wiring for any loose or broken connections.

2. Make sure that fan and all heating elements operate

properly.

TRANSFORMER CHECKOUT

1. Use an ac voltmeter to measure the voltage across the

secondary terminals. If voltage is 24V ac 5~ 10 percent, proceed

to check the R8330. If incorrect, proceed to step 2.

2. Check that voltage across transformer primary is within

,+ 10 percent of rated voltage. If correct, replace the transformer.

If the primary voltage is incorrect, correct source problems.

R8330 SYSTEM CHECKOUT

Refer to wiring diagrams. Note that if R8330 Sequencers are

used in combination, the troubleshooting procedure must be

adapted for the individual system.

1. Move the thermostat set point above the room temperature

so that thermostat calls for heat-

a. If system does not start (after time delay), proceed to

step 2.

b. If fan and/or some heating elements start (but not all),

proceed to step 3.

c. If fan and heating elements all sequence on properly,

proceed to step 4.

2. Jumper RH to Wl at the thermostat-

a. If fan and heating elements now begin operating (after

time delay), check thermostat and wiring and replace

thermostat if necessary. Proceed to step 4.

b. If neither fan nor heating elements operate (and system

wiring has been checked), replace the R8330.

3. Jumper across the terminals of the Inoperative fan or

heating element. If the fan or element now starts, the contacts

are not conducting; replace the R8330.

The R8330 contacts carry line voltage.

4. When all elements and fan are on, break the power supply

to the R8330 by lowering the thermostat set point (or removing

jumper RH-Wl) so that switch breaks. Check to make sure that

all heating stages sequence off, beginning with the last element on.

The fan should operate until all stages are off, turning off with the

last stage.

NOTE: This is a time delay device; allow time for all elements

to sequence off.

HONEYWELL MINNEAPbIS, MINN. 55408 INTERNATIONAL Sales Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

PRINTED IN U.S.A.

Loading...

Loading...