Honeywell Q682B, Q682D, Q682L Application Manual

Q682B,D,L Switching Subbases

Application

Switching

Subbase Use with Thermostat System Fan Application LED Options

Q682B T8082A; T8085A,B,C;

T8090A, T8095, T8190

Q682D T8082A; T8085A,B,C;

T8090A, T8095, T8190

Q682L T8085R EM.HT.-HEAT-

HEAT-OFF-

COOL

ON-OFF or

AUTO-OFF

OFF-COOL

AUTO-ON Heating/Cooling Clogged Filter LED

AUTO-ON Heating-only or

None

Cooling-only

AUTO-ON Heat pump EM.HT. and AUX.

HT. LEDs

Installation

WHEN INSTALLING THIS PRODUCT

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

1. Disconnect power supply to prevent electrical

shock or equipment damage.

2. On systems using a low-voltage gas valve,

never apply a jumper across valve coil terminals.

This may burn out thermostat heat anticipator.

IMPORTANT:

1. T8082, T8085, T8090, T8190 and T8095 Fuel Saver

Thermostats are mounted at true level when calibrated at the factory. An inaccurately leveled subbase will cause the temperature control to deviate

from set point.

2. Refer to thermostat Owner Manual for complete

installation instructions.

LOCATION

Locate the subbase about 5 ft. [1.5m] above the floor in

an area with good air circulation at average temperature.

Do not mount the subbase where the thermostat may be

affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from the sun, appliances or fireplace.

— concealed pipes and chimneys.

— unheated (uncooled) areas, such as an outside wall

behind the thermostat.

MOUNTING

1. If replacing an existing thermostat, remove thermostat and wallplate or subbase. To avoid miswiring, label

wires with the letter or number of each terminal as it is

disconnected. Be sure insulation on thermostat wires is in

good condition (not cracked, worn or frayed). Replace

wires if necessary.

If a new installation, prepare an opening for the thermostat wires, run wires and pull about 3 in. [76 mm] through

the opening.

NOTE: Color-coded, 18-gauge thermostat cable (Under-

writers Laboratories Inc., approved limited energy safety

control wire) with one conductor to each wiring terminal

is recommended.

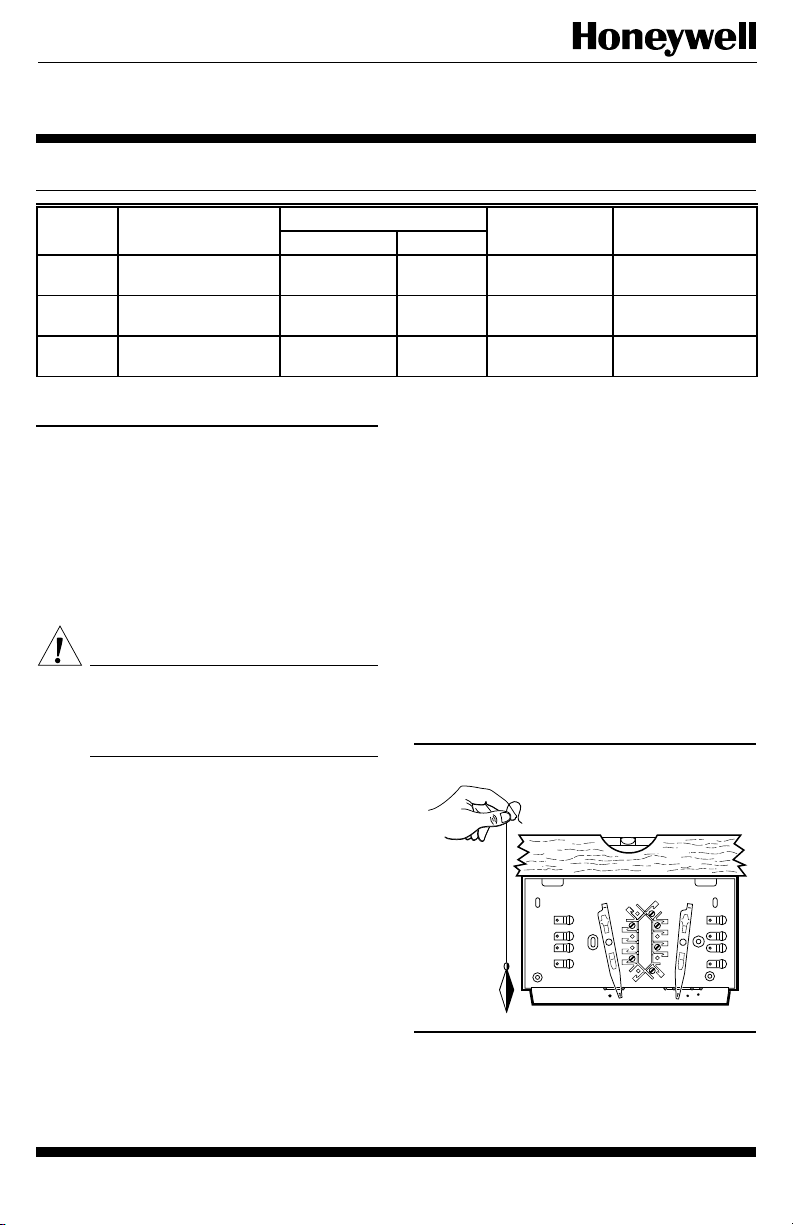

2. Use a spirit level for leveling the Q682 Switching

Subbase (Fig. 1) and mount to the wall with the three

screws provided. If mounting to a horizontal outlet box, use

the two machine screws furnished.

Fig. 1—Leveling the Q682 Switching Subbase.

SPIRIT LEVEL

PLUMB

LINE

PLUMB

BOB OR

WEIGHT

FAN

O

B

R

W

G

Y

AUTO OFF

HEATON

COOL

M1555

WIRING

Disconnect power supply before making wiring connec-

tions to prevent electrical shock or equipment damage.

All wiring must comply with local electrical codes and

ordinances.

J. H. • Rev. 4-94 • ©Honeywell Inc. 1994 • Form Number 60-1179—7

1 60-1179—7

A letter code is located near each terminal for easy

identification.

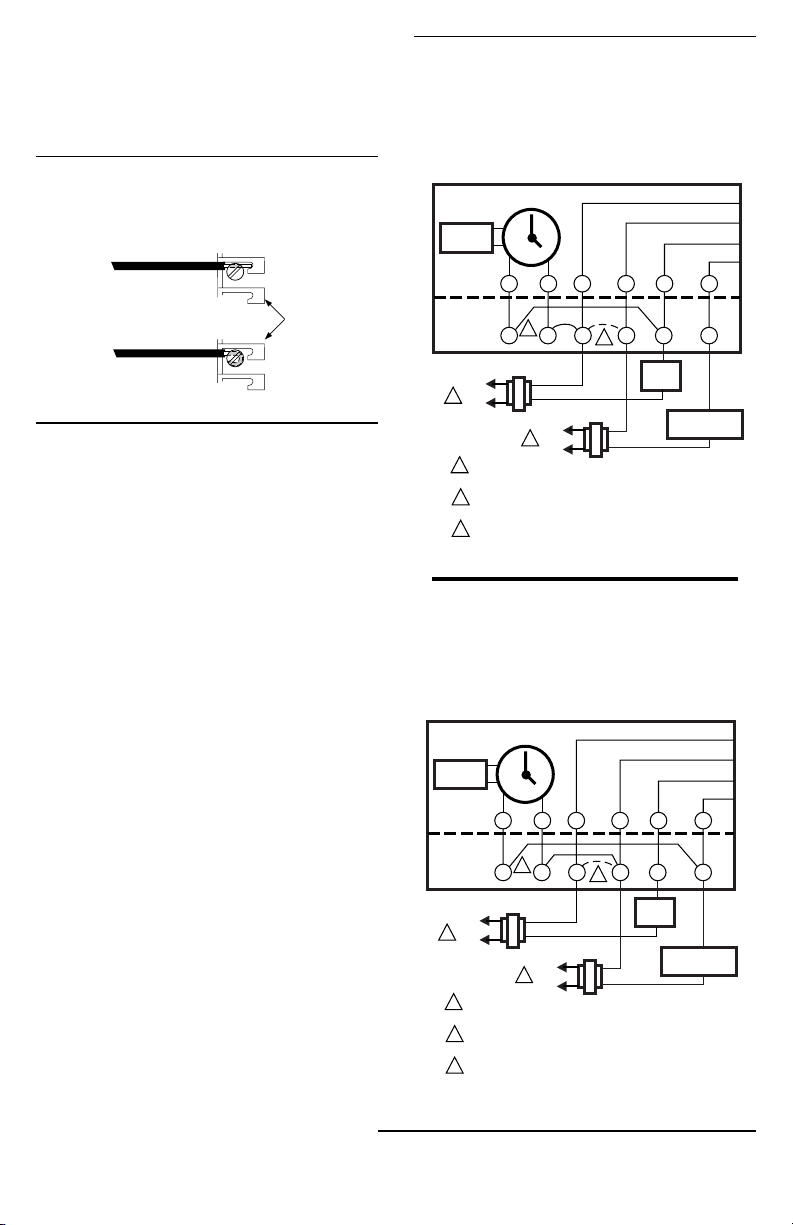

The shape of the terminal barrier permits insertion of

straight or conventional wraparound wiring connections.

Either method is acceptable. When making wiring connections, strip wire to length specified in Fig. 2.

Fig. 3—Typical hookup for T8090A Thermostat clock powered through the control

system. Clock powered by battery when

heating or cooling equipment is on; clock

steals power from system when heating

equipment is off.

Fig. 2—Barrier configuration.

FOR STRAIGHT

CONNECTION—

STRIP 5/16 in. [8 mm]

FOR WRAPAROUND

CONNECTION—

STRIP 7/16 in. [11 mm]

BARRIER

M1556B

The Q682B or D Subbase allows the T8082A or

T8085A,B,C Thermostat clock to be powered by the system transformer or separate 24 Vac transformer. The Q682B

also allows the T8090A Thermostat clock to be powered by

the system transformer, separate 24 Vac transformer, batteries, or through the control system. Refer to Figs. 3 and 4

for hookup diagrams of a T8090A powered through the

control system.

The Q682L Subbase uses a separate clock transformer.

Ensure 24V exists between the R and X terminals. Wire the

X terminal to transformer common to operate the LEDs and

24V clock.

Follow the equipment manufacturer wiring instructions,

if available. If not available, refer to typical system hookups in Figs. 5 through 12.

Push any excess wire back into wall and plug the hole

carefully to prevent drafts from affecting the thermostat. To

mount and adjust thermostat, see the instructions included

with the thermostat.

THERMOSTAT

CLOCK

BATTERY

3

C C RH RC

SUBBASE

L1

(HOT)

1

L2

L1

(HOT)

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

JUMPER RH-RC TERMINALS WHEN ONE TRANSFORMER

2

POWERS BOTH HEATING AND COOLING.

FOR POWER STEALING ON HEATING, JUMPER

3

C-RH AND C-W TERMINALS.

Fig. 4—Typical hookup for T8090A Thermostat clock powered through the control

system. Clock powered by battery when

heating or cooling equipment is on; clock

steals power from system when cooling

equipment is off.

THERMOSTAT

BATTERY

L2

CLOCK

2

WY

HEAT

RELAY

COMPRESSOR

CONTACTOR

M1514B

3

C C RH RC

SUBBASE

L1

(HOT)

1

L2

L1

(HOT)

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

JUMPER R H-RC TERMINALS WHEN ONE TRANSFORMER

2

POWERS BOTH HEATING AND COOLING.

FOR POWER STEALING ON HEATING, JUMPER

3

C-RC AND C-Y TERMINALS.

L2

2

WY

HEAT

RELAY

COMPRESSOR

CONTACTOR

60-1179—72

M720

Fig. 5—Q682A Subbase with Fuel Saver Thermostat (T8195 shown) in an electric heat system with auto

fan.

COOL

ANTICIPATORS

BIMETAL

H

HEAT

ANTICIPATOR

W1

C

FALL

Y1

T8095A

THERMOSTAT

CLOCK

C1 C2

RED

BLUE

BIMETAL

HEAT

ANTICIPATOR

R1

C

H

FALL

OFF

COOL

O

COOLING

CHANGEOVER

HEAT

ANTICIPATOR

SYSTEM SWITCH

OFF

COOL

O

SYSTEM SWITCH

FAN

SWITCH

H

FAN

SWITCH

FALL

ON

G

FAN

ON

G

AUTO

AUTO

1

C

2

2

HEAT

ANTICIPATOR

OFF

HEAT

W

HEAT

COOL

Y

H

C

FALL

OFF

COOL

Y

3

HEATING COOLING

COOL

ANTICIPATORS

W

M7185

FILTER

LIGHT

2

SWITCH

Q682B

SUBBASE

HEAT

C

L1

(HOT)

1

L2

Fig. 6—Q682B Subbase with Fuel Saver Thermostat (T8195 shown) in a heating-cooling system with O

and B terminals for damper motors or changeover valve, and optional filter indicator LED.

CLOCK

T8095A

THERMOSTAT

Q682B

SUBBASE

C

R

B

R

HEATING

CHANGEOVER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

JUMPER 1-2 FOR AUTO FAN IN HEAT AND COOL MODE; I.E. HEAT PUMP AND

2

ELECTRIC HEAT APPLICATIONS.

3

JUMPER 1-Y FOR AUTO FAN WITH COOLING MODE ONLY.

HEAT

B

L1

(HOT)

1

L2

HEAT

DAMPER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

2

REMOTE INDICATION FOR FILTER (OPTIONAL).

COOL

DAMPER

FAN

RELAY

HEAT

RELAY

COMPRESSOR

CONTACTOR

M2496A

3 60-1179—7

Loading...

Loading...