Page 1

Q345A, Q348A, Q348B, Q362A,Q373A

and Q381A Pilot Burner/Igniter-Sensors

Application

These pilot burner/igniter-sensors provide pilot flame

ignition and sensing in intermittent pilot systems. They

consist of a target type pilot burner with a combination

spark igniter and flame sensor mounted in place of the

thermocouple.

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to

follow instructions can damage product or cause a

hazardous condition.

2. Check ratings given in instructions and on

product to make sure product is suitable for your

application.

3. Make sure installer is a trained, experienced

service technician.

4. After completing installation, use these

instructions to check out product operation.

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH.

Follow these warnings exactly:

1. Disconnect power supply before wiring

to prevent electrical shock or equipment

damage.

2. To avoid dangerous accumulation of fuel

gas, turn off gas supply at appliance service

valve before starting installation and

perform Gas Leak Test after completion of

installation.

3. Do not bend pilot tubing at the control or

pilot after compression nut has been

tightened. Gas leakage at the connection may

result.

Follow appliance manufacturer instructions if avail-

able; otherwise, use instructions provided below.

LOCATION

1. Position pilot burner/igniter-sensor for easy

access and observation. In replacement applications,

replace pilot burner/igniter-sensor with an identical unit

and position new pilot burner/igniter-sensor in the same

location and orientation as the original one.

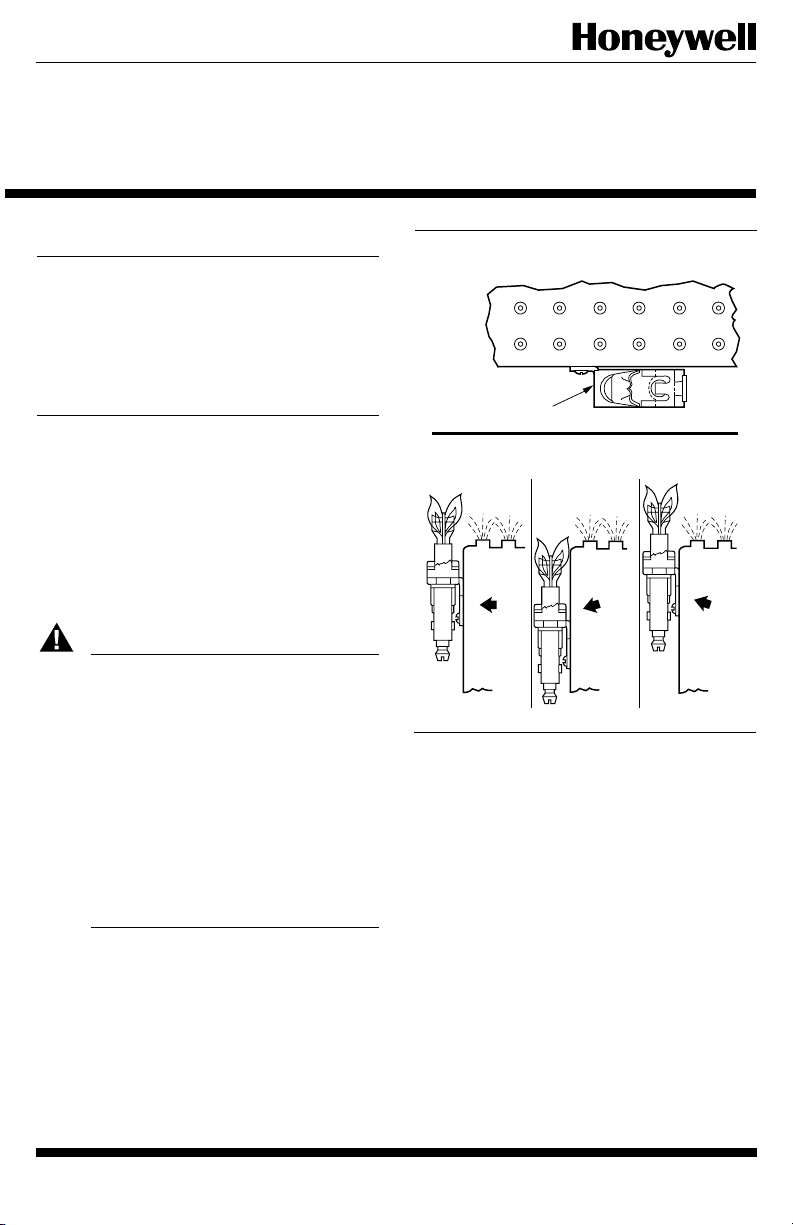

Fig. 1—Mount pilot burner/igniter-sensor on

main burner.

PILOT BURNER/IGNITER-SENSOR

MUST BE RIGIDLY POSITIONED

RELATIVE TO MAIN BURNER

Fig. 2—Location of pilot burner/igniter-sensor.

PILOT BURNER/

IGNITER-

SENSOR

JUST RIGHT

IGNITION FLAME

JUST MISSES

MAIN BURNER

PILOT BURNER/

IGNITER-

SENSOR

TOO LOW

IGNITION

FLAME WILL

IMPINGE ON

MAIN BURNER

M3271

PILOT BURNER/

IGNITER-

SENSOR

TOO HIGH

MAIN BURNER

FLAME WILL

IMPINGE ON

IGNITION-

SENSOR

M3273

2. Mount pilot burner/igniter-sensor on main burner.

Mounting surfaces other than the main burner may shift,

bend, or warp as furnace expands and contracts while

operating. See Fig. 1.

3. Mount pilot burner/igniter-sensor so the pilot flame

remains properly positioned with respect to the main

burner flame. See Fig. 2.

4. Supply pilot flame with ample air free of

combustion products.

5. Do not impinge pilot flame on adjacent parts.

Do not impinge main burner flame on pilot burner/

igniter-sensor.

6. Do not expose pilot flame to falling scale, which

could impair main burner ignition.

7. Do not expose pilot burner/igniter-sensor to main

burner rollout while igniting or extinguishing.

8. Do not expose pilot flame to drafts that push or

pull pilot flame away from the igniter-sensor.

NOTE: The Q381A Pilot Burner/Igniter-Sensor is for

horizontal mounting only. Mounting bracket must

remain vertical.

G. S. • Rev. 7-93 • ©Honeywell Inc. 1993 • Form Number 60-0653—8

Page 2

CONNECT PILOT GAS TUBING

1. Cut tubing to desired length and bend as necessary

for routing to pilot burner/igniter-sensor. Do not make

sharp bends or deform tubing. Do not bend tubing at

control after compression nut has been tightened

because this can result in gas leakage at connection.

2. Square off and remove burrs from end of tubing.

3. Push tubing into compression nut clearance hole

until tubing bottoms.

NOTE: When replacing a control, cut off old

compression fitting and replace with new

compression fitting provided with new pilot

burner. Never use old compression fitting because it

may not provide a gas-tight seal. See Fig. 3.

2. Connect one end of the ignition cable to stud

terminal on igniter-sensor using 1/4 in. [6 mm] diameter snap-spring or cage-clips on cable ends.

3. Connect the other end of the ignition cable to the

igniter terminal on ignition module.

4. Use ceramic or plastic standoff insulators as necessary to prevent cable from contacting metal surfaces.

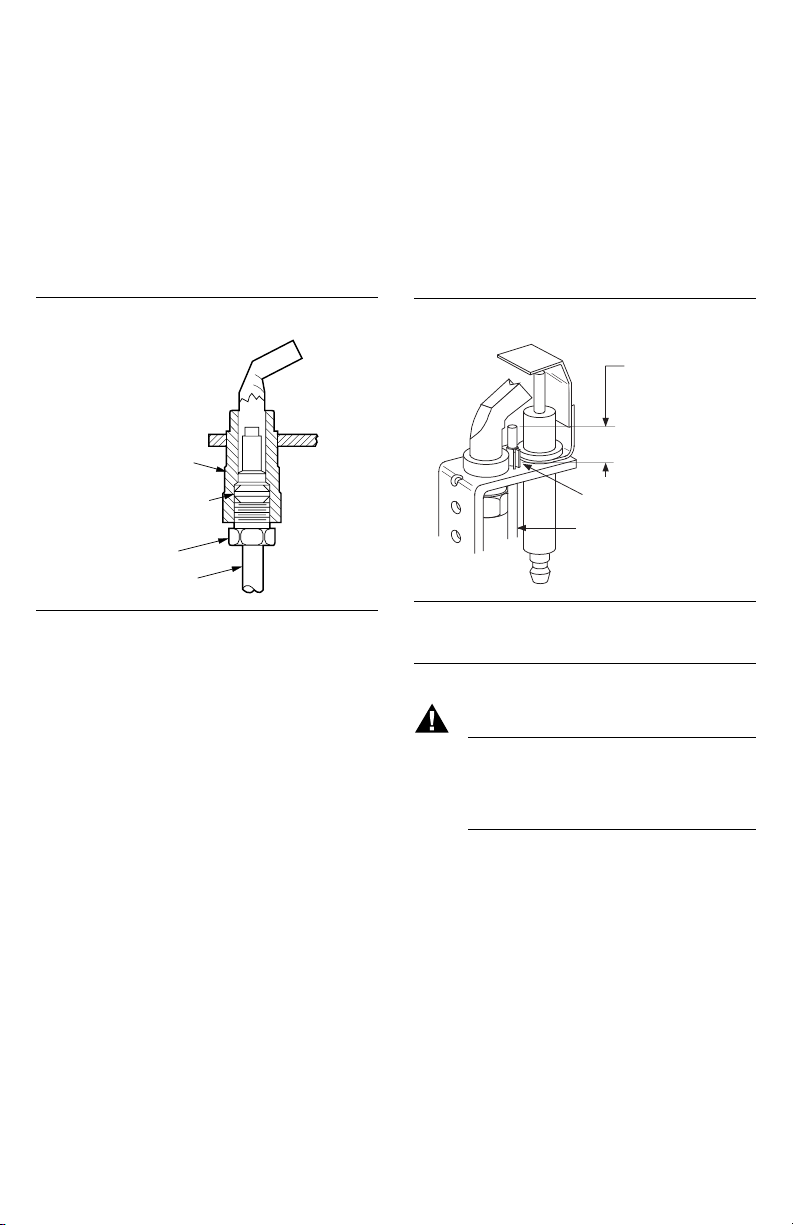

INSTALL BLEED GAS TUBE (optional)

1. Route bleed tube from bleed tap on gas control to

the pilot burner/igniter-sensor.

2. Push clip into place. See Fig. 4.

3. Insert bleed gas tube until 3/8 in. [10 mm] to

tubing is above pilot burner/igniter-sensor bracket. Tip

of bleed gas tube must not extend into pilot flame.

Fig. 3—Always use new compression fitting.

PILOT BURNER BODY

ON BRACKET OF PILOT

BURNER/IGNITER-SENSOR

COMPRESSION FITTING

BREAKS OFF AND CLINCHES

TUBING AS NUT IS TIGHTENED

TIGHTEN NUT ONE TURN

BEYOND FINGER TIGHT

TO GAS CONTROL

M3296

4. While holding tubing all the way in, engage threads

and turn until finger tight.

5. Using a wrench, turn compression nut one turn

beyond finger tight. Do not overtighten.

6. Connect other end of tubing to gas control

according to gas control manufacturer instructions.

WIRE IGNITER-SENSOR

The igniter-sensor must be mounted on the burner.

Connect the control module ground wire to one of the

igniter-sensor mounting screws to complete the system

grounding.

Connect ground wire as follows:

1. Use 221° F [105° C] minimum thermoplastic-

insulated wire for the ground leadwire (asbestos

insulation is not acceptable).

2. A male 1/4 in. [6 mm] quick-connect terminal is

provided on Honeywell ignition modules. Fasten female

quick-connect to wire end at ignition module.

3. Strip other end and fasten under igniter-sensor

mounting screw.

4. If necessary, use shield to protect lead from radiant heat of burner.

5. The pilot burner serves as the grounding area for

the flame signal. Run lead from pilot burner to the

common ground selected.

Connect the ignition cable as follows:

1. The high tension ignition cable must conform to

applicable local or national standards.

Fig. 4—Install bleed gas tube.

THIS DIMENSION SHOULD

BE MAXIMUM OF 3/8 INCH

[9.5 mm] WHEN BLEED

TUBE IS IN FINAL

POSITION.

BLEED TUBE CLIP

1/8 IN. STEEL TUBING

M1261

Startup and Checkout

PERFORM GAS LEAK TEST

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH.

Check for gas leaks with soap and water solution any time work is done on a gas system.

Gas Leak Test:

1. Ensure that gas supply is turned on at the appliance

service valve.

2. Paint pipe connections upstream of pilot burner

with rich soap and water solution. Bubbles indicate gas

leak.

3. If leak is detected, tighten pipe connections.

4. Set thermostat to call for heat to light main burner.

5. With main burner in operation, paint pipe joints

(including adapters) and gas control inlet and outlet with

rich soap and water solution.

6. If another leak is detected, tighten adapter screws,

joints, and pipe connections.

7. Replace part if leak cannot be stopped.

2

Page 3

Fig. 5—Igniter-sensor tip must be in pilot flame. Fig. 6—Proper shielding of pilot flame.

3/8 TO 1/2 INCH

[10 TO 13 mm]

PROPER FLAME

ADJUSTMENT

IGNITER-SENSOR

Q373A

PROPER FLAME

ADJUSTMENT

Q345A, Q348A-B, Q362A AND Q 381A

3/8 TO 1/2 INCH

[10 TO 13 mm]

IGNITER-SENSOR

M3777

ADJUST PILOT FLAME

The pilot flame should envelop 3/8 to 1/2 in.

[10 to 13 mm] of the igniter-sensor tip. See Fig. 5. To

adjust pilot flame:

1. Turn off system by setting thermostat below

temperature to call for heat.

2. Disconnect lead to MV terminal on gas control.

3. Light pilot by setting thermostat to call for heat.

4. Remove pilot adjustment cover screw from gas

control.

5. Turn inner pilot adjustment screw clockwise to

decrease or counterclockwise to increase pilot flame.

6. Always replace pilot adjustment cover screw and

tighten firmly after completing adjustment to assure

pro-per operation.

Service

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH.

Perform Gas Leak Test anytime work is done to

the system.

PILOT OUTAGE

1. If pilot flame goes out during ignition, but is

pro-perly adjusted, recheck mounting and location

instructions in Location section.

2. Refer to ignition module instructions to check

wiring between igniter-sensor and ignition module or

between gas control and ignition module.

3. If all mounting and location instructions are followed but pilot continues to go out, construct shielding

to protect pilot flame from main burner ignition and

extinction and drafts. See Fig. 6.

4. Check pilot and main burner lightoff.

TYPICAL

SHIELD

M1273

J Set the thermostat to call for heat.

J Watch the pilot burner during the ignition sequence.

See if:

• Ignition spark continues after the pilot is lit.

• The pilot lights and the spark stops, but main

burner does not light.

• S8600B,H; S86H only: The pilot lights, the spark

stops and main burner lights, but the system locks

out.

J If so, assure adequate flame current as follows:

• Turn off furnace at circuit breaker or fuse box.

• Clean the flame rod with emery cloth.

• Make sure electrical connections are clean and tight.

Replace damaged wire with moisture-resistant

no. 18 wire rated for continuous duty up to

221° F [105° C].

• Check for cracked ceramic insulator, which can

cause short to ground, and replace pilot burner/

igniter-sensor if necessary.

• At the gas control, disconnect main valve wire

from the TH or MV terminal.

• Turn on power and set thermostat to call for heat.

The pilot should light but the main burner will

remain off because the main valve actuator is disconnected.

• Check the pilot flame. Make sure it is blue, steady

and envelops 3/8 to 1/2 in. [10 to 13 mm] of the

flame rod. See Fig. 7 for possible flame problems

and their causes.

• If necessary, adjust pilot flame by turning the pilot

adjustment screw on the gas control clockwise to

decrease or counterclockwise to increase pilot

flame. After adjustment, always replace pilot

adjustment cover screw and tighten firmly to

assure proper gas control operation.

• Set thermostat below room temperature to end call

for heat.

J Recheck ignition sequence as follows:

• Reconnect main valve wire.

• Set thermostat to call for heat.

• Watch ignition sequence at burner.

• If spark still does not stop after pilot lights, replace

ignition module.

• If main burner does not light or if main burner

lights but system locks out, check module, ground

wire, and gas control as described in control

module instructions.

3 60-0653—8

Page 4

Fig. 7—Example of unsatisfactory pilot flames.

APPEARANCE

SMALL BLUE FLAME

LAZY YELLOW FLAME

WAVING BLUE FLAME

NOISY LIFTING BLOWING FLAME

HARD SHARP FLAME

APPEARANCE

SMALL BLUE FLAME

LAZY YELLOW FLAME

WAVING BLUE FLAME

NOISY LIFTING BLOWING FLAME

HARD SHARP FLAME

CHECK IGNITION CABLE

1. Assure that ignition cable is not in contact with

metal surfaces.

2. Assure that ignition cable is not more than

3 feet [1 m] long.

3. Assure connections to the ignition module stud

terminal and the igniter-sensor are clean and tight.

4. Check electrical continuity of ignition cable.

CHECK GROUNDING

1. If ground is poor or erratic, safety shutdown will

occur. Therefore, if nuisance shutdowns are reported,

check the ground precautions in Wire Igniter-Sensor

section.

CAUSE

CHECK FOR LACK OF GAS FROM:

• CLOGGED ORIFICE FILTER

• CLOGGED PILOT FILTER

• LOW GAS SUPPLY PRESSURE

• PILOT ADJUSTMENT AT MINIMUM

CHECK FOR LACK OF AIR FROM:

• DIRTY ORIFICE

• DIRTY LINT SCREEN, IF USED

• DIRTY PRIMARY AIR OPENING,

IF THERE IS ONE

• PILOT ADJUSTMENT AT MINIMUM

CHECK FOR:

• EXCESSIVE DRAFT AT PILOT

LOCATION

• RECIRCULATING PRODUCTS

OF COMBUSTION

CHECK FOR:

• HIGH GAS PRESSURE

THIS FLAME IS CHARACTERISTIC

OF MANUFACTURED GAS

CHECK FOR:

• HIGH GAS PRESSURE

• ORIFICE TOO SMALL

M3778

2. If leadwire is damaged or deteriorated, use

no. 14 to 18 gauge, moisture-resistant, thermoplastic,

insulated wire with 221° F [105° C] minimum rating as

replacement.

3. Excessive temperature at the ceramic flame rod

insulator will permit electrical leakage to ground.

a. If bracket is bent, bend it back to correct

position.

b. If insulator is cracked, replace pilot burner/

igniter-sensor.

TEST SAFETY LOCKOUT

Refer to appliance manufacturer instructions to test

for proper safety lockout times.

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, Minnesota 55422 Scarborough, Ontario

M1P 2V9

Printed in U.S.A.

QUALITY IS KEY

Loading...

Loading...