Page 1

62-0210-07

P7640A,B

Differential Pressure Sensors

INSTALLATION INSTRUCTIONS

APPLICATION

The P7640A Panel Mount and P7640B Duct Mount

Differential Pressure Sensors provide reliable, accurate

measurement and control. Proper applications include

measurement of extremely low pressure applications such

as: building/room pressure, air flow, variable air volume,

filter status, and duct pressure. They are ideal for clean

rooms, hospitals, fume hoods, and computer rooms.

The P7640 Pressure Sensors are designed with fieldselectable 4-20 mA, 0-5 Vdc, or 0-10 Vdc output. The four

pressure ranges fall between 0–1 in. w.c./0–250 Pa or 0–

10 in. w.c./0–2500 Pa, depending on the model.

Accessory

32003169-001 Duct Pressure Pick-up Probe, 4 in.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check ratings given in instructions and on the

product to ensure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

Mounting

Screw holes are accessed inside the enclosure (with the

cover removed) and are located in the upper left and

lower right corners.

Panel Mount

Run tubing from one (static) or both (differential) barb

fittings, making sure the typically higher pressure source

is connected to the port labeled HI, and the typically

lower pressure source is connected to the port labeled

LO.

Duct Mount

The units with the integral probe should typically be

mounted at the high pressure location when used for

differential control.

CONFIGURATION

Select the proper output, mode, and pressure range

using the switches and jumpers:

1. Select output using the output switch:

a. Current: mA (then skip to step 3), or

b. Voltage: Volt.

2. Select 0-10 Vdc or 0-5 Vdc using jumper J4.

3. Select bi- or uni-directional mode using jumper J5.

NOTE: Setting for 0 to 1 in. w.c. and bi-directional

4. Select inches w.c. or Pascal scale using jumper J7.

5. Select fast or standard response time using jumper

J8.

6. Select appropriate full-scale pressure range using

the rotary switch. Align arrow (not the slot) to the

desired range. See Table 2 for the range selection

guide.

NOTE: Note that either the 1 in. w.c. or 10 in. w.c.

7. Set output according to Table 1.

Controller

W7750, W7760, W7761 4-20 mA FilterPress or

W7750B, W7760C,

W7753, W7760

Non-Honeywell 0-5 Vdc n/a

will give output from -1.0 to 1.0 in. w.c.

scale is marked. This is the available

scale for that given model. When the

range is changed, the LCD models

momentarily indicate selected range.

Table 1. Controller Compatibility

and Output Settings.

Required Sensor

Output Setting

0-10 Vdc (default) FilterPress or

L

P7610B

P7610F, or voltage

ONSPEC™

Setting

Page 2

P7640A,B DIFFERENTIAL PRESSURE SENSORS

CAUTION

CAUTION

12 TO 30 Vdc

POWER SUPPLY

CONTROLLER,

METER OR

RECORDER

INPUT SIGNAL

COMMON

+

+

–

–

M27292

ZERO

PWR OUT COM ZERO

RESPONSE

FAST/STD

mA

VOLT

1

DRY CONTACT TO AUTOMATICALLY ZERO THE SENSOR

UPON CLOSURE. (OPTIONAL)

1

OUTPUT

JP8

UNITS

IN. W.C./PA

JP7

MODE

BI/UNI

JP5

VOLT

SV/10V

JP4

7

1

2

3

4

5

6

E

GND

OUT1OUT2OUT3OUT4OUT5OUT6OUT7OUT8DI1DI2DI3DI4GND GND

24

VAC

COM

24

VAC

COM

24

VAC24VAC24VAC24VAC24VAC

OUT

COM

21

VDC

OUT

GND E-BUS E-BUS

AI1AI

2

AI3AI

4

AI5AI

6

AI7AI

8

ANALOG

OUT

AO1AO

2

17 18 19 20 21 22 23 24 25 26 27 28 29

L1

(HOT)

L2

31 32 33 34 35 36 37 38 39 40 41 42 43

44

12345 678 9101112 14 1615

13

W7760A

AI

GND

AI

GND

AI

GND

AI

GND

AO

GND

+

–

O

P7640

+

–

O

P7640

+

–

O

H76XX

+

–

M18302B

Vin (Vac)

Gnd

Vo (0-10 Vdc)

PWR

COM

OUT

PWR

COM

OUT

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

TEMPERATURE SIGNAL CONNECTIONS ARE NOT POLARITY SENSITIVE.

1

1

2

2

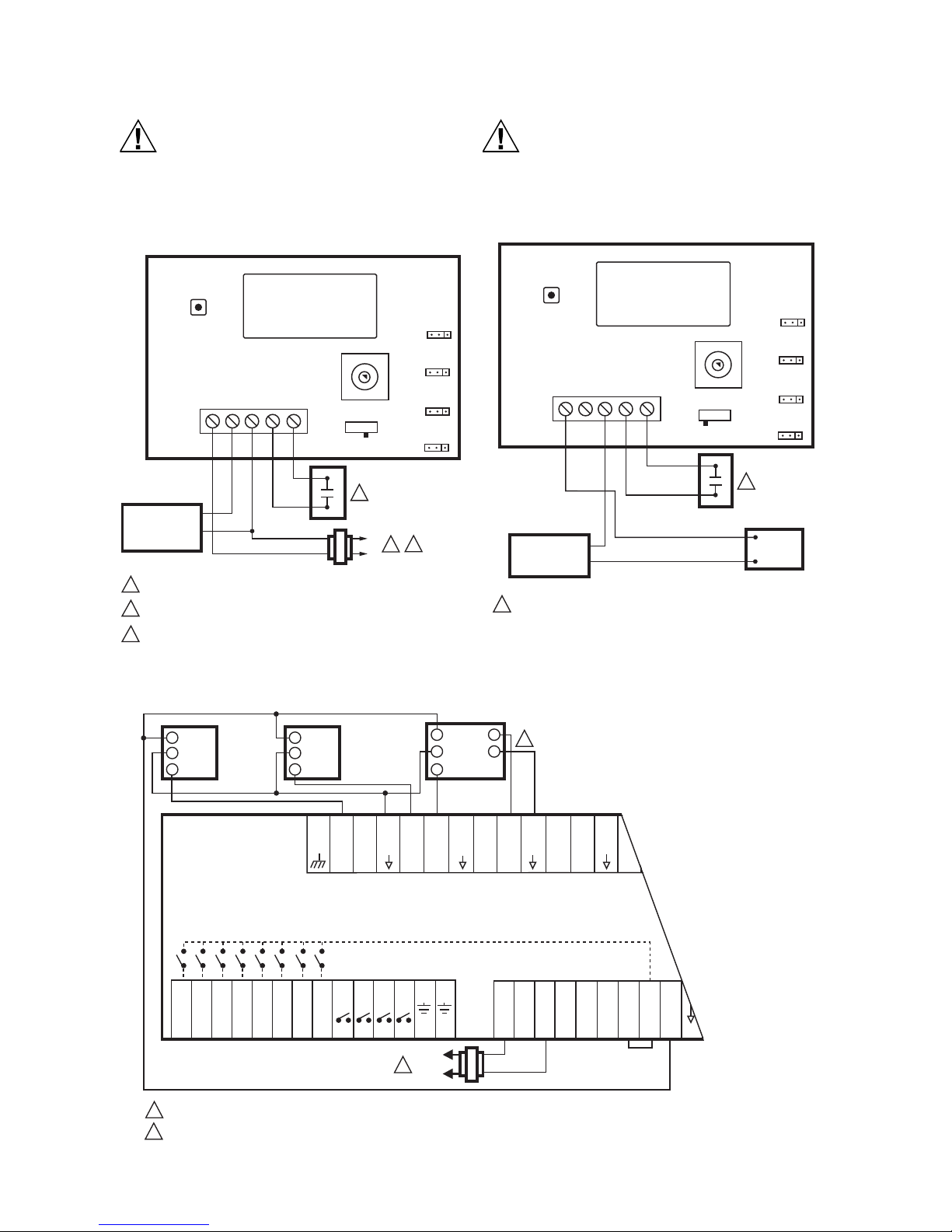

WIRING (FIG. 1 THROUGH 3)

Equipment Damage Hazard.

Can damage the device beyond repair.

Disconnect power supply before installation.

NOTE: Wiring to the ZERO terminals is optional.

ZERO

RESPONSE

FAST/STD

JP8

1

2

VOLT

IN. W.C./PA

JP7

JP5

JP4

1

M27291

UNITS

SV/10V

2

MODE

BI/UNI

7

6

5

3

4

–

+

mA

OUTPUT

+

–

3

L1

L2

PWR OUT COM ZERO

CONTROLLER,

METER OR

RECORDER

INPUT SIGNAL

+

COMMON

–

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

POLARIZED SECONDARY INDICATIONS FOR USE WITH DC POWER

2

SUPPLY ONLY.

DRY CONTACT TO AUTOMATICALLY ZERO THE SENSOR UPON

3

CLOSURE. (OPTIONAL)

Fig. 1. Wiring for voltage (Vdc) output.

Equipment Damage Hazard.

Can damage the device beyond repair.

Do not apply power to output terminal. Permanent

equipment damage will result.

VOLT

Fig. 2. Wiring for current (mA) output.

62-0210—07 2

Fig. 3. Typical wiring for three-wire pressure sensor with Vdc output (used with the XL15A Controller).

Page 3

P7640A,B DIFFERENTIAL PRESSURE SENSORS

Table 2. Range Selection Guide.

Rotary

Switch

Position

00.1251250

10.25501250

2 0.5 100 1 250

3 1 250 1 250

4 1 250 2.5 500

5 1 250 5 1000

61250102500

71250102500

1-in. Models 10-in. Models

0–1

in. w.c.

0–250

Pascal

0–10

in. w.c.

0–2500

Pascal

OPERATION

IMPORTANT

During the first few minutes of operation, readings at zero pressure and lowest pressure

ranges appear erroneous. Following this initial

warm-up period, the P7640 maintains specified

accuracy and stability.

The display momentarily indicates “SET” when a selection

is made. In normal operation, pressure indications are in.

w.c.

Zeroing

IMPORTANT

Perform zeroing only when both Zero ports are

exposed to the same pressure.

Zeroing the device automatically resets the output and

displays zero pressure. To do this either:

— Press and hold the ZERO pushbutton for 2 seconds, or

— Provide contact closure on the ZERO terminals. To

ensure this, place a piece of jumper tubing between HI

and LO.

NOTE: To avoid accidental zero, this feature is

enabled only while detected pressure is

within 5% of factory calibration.

3 62-0210—07

Page 4

P7640A,B DIFFERENTIAL PRESSURE SENSORS

CAUTION

APPENDIX

IMPORTANT

Pre 0816 Date Code Configuration

Select the proper output, mode, and pressure range using the switches and jumpers:

NOTE: Setting for 0 to 1 in. w.c. and bi-directional will give output from -1.0 to 1.0 in. w.c.

NOTE: Note that either the 1 in. w.c. or 10 in. w.c. scale is marked. This is the available scale for that given

This page is only for models with date code prior to 0816.

1. Select output using the output switch:

a. Current: mA (then skip to step 3), or

b. Voltage: Volt.

2. Select 0-10 Vdc or 0-5 Vdc using jumper J4.

3. Select bi- or uni-directional mode using jumper J5.

4. Select appropriate full-scale pressure range using the slide switch.

model. When the range is changed, the LCD models momentarily indicate selected range.

WIRING (FIG. 4 THROUGH 5)

Equipment Damage Hazard. Can damage the device beyond repair.

Disconnect power supply before installation.

NOTE: Wiring to the ZERO terminals is optional.

ZERO

PWR OUT COM

CONTROLLER,

METER OR

RECORDER

INPUT SIGNAL

+

COMMON

–

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

POLARIZED SECONDARY INDICATIONS FOR USE WITH DC POWER

2

SUPPLY ONLY.

DRY CONTACT TO AUTOMATICALLY ZERO THE SENSOR UPON

3

CLOSURE. (OPTIONAL)

ZERO

mA

VOLT

3

–

+

L1

L2

–

+

Fig. 4. Wiring for voltage (Vdc) output.

RANGE

10" 1"

1.0

10

.5

5

.25

2.5

.1

1.0

MODE

BI/UNI

VOLT

5V/10V

1

M22554A

ZERO

RANGE

10" 1"

1.0

10

.5

5

.25

2.5

.1

1.0

PWR OUT COM

CONTROLLER,

METER OR

2

RECORDER

INPUT SIGNAL

+

COMMON

–

DRY CONTACT TO AUTOMATICALLY ZERO THE SENSOR

1

UPON CLOSURE. (OPTIONAL)

ZERO

mA

MODE

BI/UNI

VOLT

VOLT

5V/10V

1

12 TO 40 Vdc

POWER SUPPLY

+

–

M22555A

Fig. 5. Wiring for current (mA) output.

LonSpec™ is a trademark of Echelon® Corporation.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

By using this Honeywell literature, you agree that Honeywell will have no liability for any

damages arising out of your use or modification to, the literature. You will defend and indemnify

Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages,

including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

® U.S. Registered Trademark

© 2014 Honeywell International Inc.

62-0210—07 M.S. Rev. 07-14

Printed in United States

Loading...

Loading...