Honeywell Notifier 002-467 User Manual

by Honeywell

Installing the Network Gateway Unit (NGU)Installing the Network Gateway Unit (NGU)

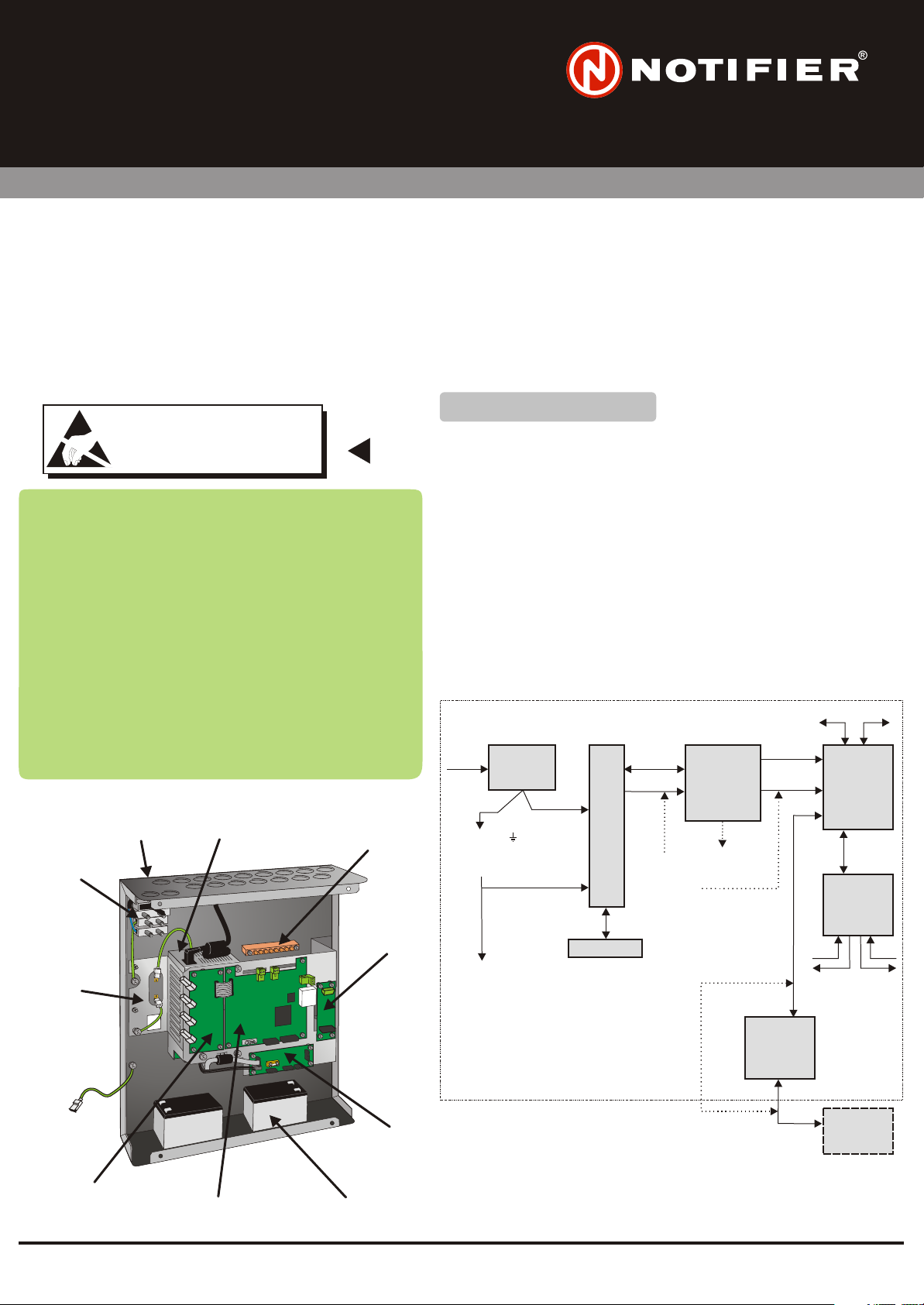

The Network Gateway Unit (PN: 002-467) consists of a Back Box (with cover) with the following fitted on a chassis: a PSU3A

The Network Gateway Unit (PN: 002-467) consists of a Back Box (with cover) with the following fitted on a chassis: a PSU3A

to Network Interface PCB and a Network Gateway Module (NGM) PCB. There is space for a PSU3A and two 12Ah batteries.

to Network Interface PCB and a Network Gateway Module (NGM) PCB. There is space for a PSU3A and two 12Ah batteries.

This basic configuration is used as an ID net Network Booster. The chassis allows a Fibre-optic PCB and RS232 PCB (for

This basic configuration is used as an ID net Network Booster. The chassis allows a Fibre-optic PCB and RS232 PCB (for

connection of a network repeater) to be fitted.

connection of a network repeater) to be fitted.

The PSU3A provides a 28V output and a battery charger. The PSU3A to Network Interface PCB provides battery and PSU

The PSU3A provides a 28V output and a battery charger. The PSU3A to Network Interface PCB provides battery and PSU

fault monitoring, controls the battery charger and converts 28V dc to 5V dc (for the Network PCB). Alternatively, the NGU can

fault monitoring, controls the battery charger and converts 28V dc to 5V dc (for the Network PCB). Alternatively, the NGU can

be powered by an external 28V supply connected at the PSU3A to Network Interface PCB.

be powered by an external 28V supply connected at the PSU3A to Network Interface PCB.

ATTENTIONATTENTION

OBSERVE PRECAUTIONS FOR HANDLING

OBSERVE PRECAUTIONS FOR HANDLING

ELECTROSTATIC SENSITIVE DEVICES

ELECTROSTATIC SENSITIVE DEVICES

Your Network Gateway Unit, PN: 002-467 should contain:

Your Network Gateway Unit, PN: 002-467 should contain:

Back box, NGU, with electronics and cover.

Back box, NGU, with electronics and cover.

Anti-static Warning Instructions PN: 997-180

Anti-static Warning Instructions PN: 997-180

Accessory kit, NGU PN: 020-685

Accessory kit, NGU PN: 020-685

The Accessory kit should contain:

The Accessory kit should contain:

Battery interlink assembly PN: 082-082-002

Battery interlink assembly PN: 082-082-002

Screw M3 x 6mm button head (8 off) PN: 775-059

Screw M3 x 6mm button head (8 off) PN: 775-059

Hex key 2mm PN: 334-051

Hex key 2mm PN: 334-051

Fuse T 2A H 250V (2 off) PN: 570-106

Fuse T 2A H 250V (2 off) PN: 570-106

Fuse T 500mA 250V PN: 570-105

Fuse T 500mA 250V PN: 570-105

Ferrite (5 off) PN: 670-068

Ferrite (5 off) PN: 670-068

Cable tie (1 off) PN: 233-144

Cable tie (1 off) PN: 233-144

NGU EN54-compliant label PN: 345-497 or

NGU EN54-compliant label PN: 345-497 or

Cable Assembly (PSU3A dc power) PN: 082-244

Cable Assembly (PSU3A dc power) PN: 082-244

Cable Assembly (short: NGM/RS232) PN: 082-177-001

Cable Assembly (short: NGM/RS232) PN: 082-177-001

Cable Assembly (x-over: NGM/repeater) PN: 082-255

Cable Assembly (x-over: NGM/repeater) PN: 082-255

PSU3A

PSU3A

(OPTIONAL)

(OPTIONAL)

MAINS

MAINS

TERMINATION

TERMINATION

BLOCK

BLOCK

CHASSISCHASSIS

BACK

BACK

BOX

BOX

2

2

PN: 345-499

PN: 345-499

EARTH

EARTH

TERMINATION

TERMINATION

KIT (OPTIONAL)

KIT (OPTIONAL)

ISOLATED

ISOLATED

RS232 PCB

RS232 PCB

(OPTIONAL)

(OPTIONAL)

Check your equipment....Check your equipment....

Take suitable anti-static precautions, such as wearing a grounded

Take suitable anti-static precautions, such as wearing a grounded

wrist strap, when following ALL instructions. Remove all packaging

wrist strap, when following ALL instructions. Remove all packaging

from the kit and ensure that it has not been damaged in transit (and

from the kit and ensure that it has not been damaged in transit (and

that no items are missing - see checklist on the left) before proceeding

that no items are missing - see checklist on the left) before proceeding

any further. If no damage is evident, proceed using the instructions

any further. If no damage is evident, proceed using the instructions

below. In the unlikely event that damage has occurred or items are

below. In the unlikely event that damage has occurred or items are

missing, DO NOT PROCEED, contact your supplier and refer to the

missing, DO NOT PROCEED, contact your supplier and refer to the

panel’s .

panel’s Installation & Commissioning Manual.

To install the Network Gateway Unit it is necessary to remove the

To install the Network Gateway Unit it is necessary to remove the

supplied electronics chassis (to prevent damage), fit the back box to

supplied electronics chassis (to prevent damage), fit the back box to

the wall, re-install the supplied electronics chassis, and fit any

the wall, re-install the supplied electronics chassis, and fit any

required options. Instructions are given on the following pages.

required options. Instructions are given on the following pages.

Installation & Commissioning Manual

(OPTION)

L, N, E

EARTH TO

BACK BOX

EARTH TO

UNIT COVER,

& EARTH TO

Note:

See Section ‘PSU3A to Network

Interface PCB - if using PSU3A’

for 28V supplies to external

equipment.

MAINS

TERMINAL

BLOCK

SAFETY

EARTH TO

PSU

CHASSIS

L, N

BATTERIES

(OPTION)

PSU

3A

RIBBON

28V DC

28V DC

FROM

EXTERNAL

SOURCE

(OPTION)

PCB -

PSU3A

TO

NETWORK

INTERFACE

28V

5V DC

PSU

FAULT

PCB -

ISOLATED

RS232

(OPTION)

2

ID NET

CH1 CH2

PCB -

NETWORK

(NGM)

RIBBON

PCB -

FIBRE-

OPTIC

(OPTION)

CH2

CH1

RX/TX

RX/TX

2

ID NET

FIBRE-OPTIC

FIBRE-OPTIC

PCB

PCB

(OPTIONAL)

(OPTIONAL)

NETWORK

NETWORK

PCB (NGM)

PCB (NGM)

PSU3A TO

PSU3A TO

NETWORK

NETWORK

INTERFACE

INTERFACE

PCB

PCB

BATTERIES

BATTERIES

(NOT SUPPLIED)

(NOT SUPPLIED)

CROSS-

OVER

RIBBON

(OPTION)

1

997-451, Issue 6 July 2006

REPEATER

RS232

FOR CLARITY, INTERNAL EQUIPMENT IS NOT

FOR CLARITY, INTERNAL EQUIPMENT IS NOT

SHOWN.

SHOWN.

33

33

22

33

33

11

Installing the Network Gateway Unit (Continued)

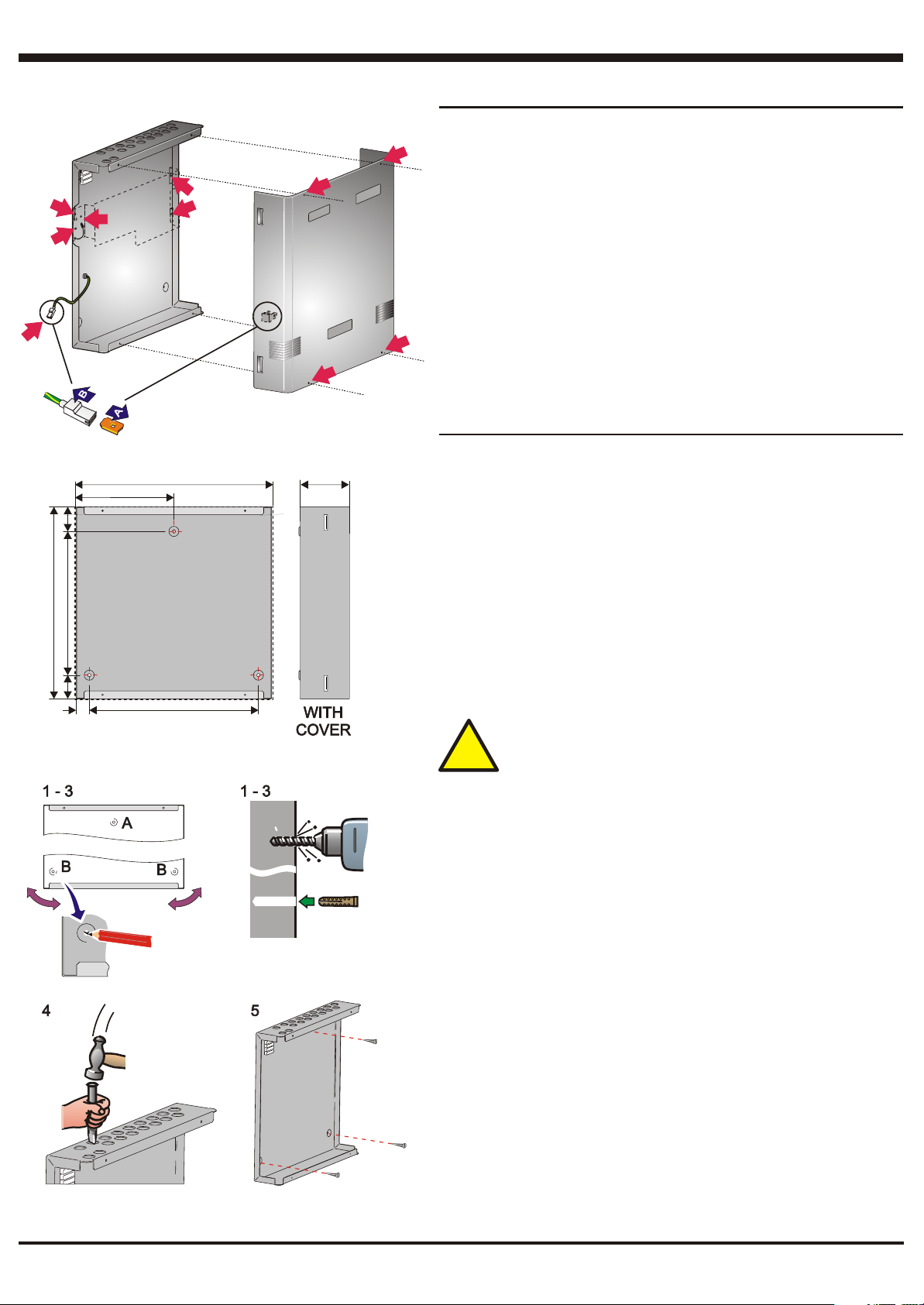

Preparing the Back Box

1 Remove and retain the four screws that secure the front cover. Disconnect

1 Remove and retain the four screws that secure the front cover. Disconnect

the cover earth lead from the blade on the cover. Place the cover in a

11

the cover earth lead from the blade on the cover. Place the cover in a

protective bag and store safely.

protective bag and store safely.

2 At the back box, disconnect the chassis earth lead from the blade terminal.

2 At the back box, disconnect the chassis earth lead from the blade terminal.

3 Remove and retain the 4 nuts and washers that secure the chassis to the

3 Remove and retain the 4 nuts and washers that secure the chassis to the

back box, and remove the chassis together with the electronics mounted

back box, and remove the chassis together with the electronics mounted

on it. Place in anti-static bag and store safely.

on it. Place in anti-static bag and store safely.

11

11

11

Note: All blade connections to earth incorporate a locking barb. To make a

Note: All blade connections to earth incorporate a locking barb. To make a

connection push the shrouded receptacle on to the earth blade (A). To

connection push the shrouded receptacle on to the earth blade (A). To

remove this connection, pull the shroud (B), NOT the earth wire.

remove this connection, pull the shroud (B), NOT the earth wire.

Fitting the Back Box to the Wall

Wall Flatness

Wall Flatness

105.00

To prevent distortion, the back box MUST be installed on the wall as flat as

To prevent distortion, the back box MUST be installed on the wall as flat as

possible, i.e. with a maximum flatness deviation between any two points of

possible, i.e. with a maximum flatness deviation between any two points of

3mm. Where the wall is out of tolerance, use appropriate packing pieces when

3mm. Where the wall is out of tolerance, use appropriate packing pieces when

installing the back box to meet the above requirements.

installing the back box to meet the above requirements.

Failure to comply with this requirement will result in the misalignment of

Failure to comply with this requirement will result in the misalignment of

the cover’s securing screws, which may cause difficulties in fitting the

the cover’s securing screws, which may cause difficulties in fitting the

cover.

cover.

All dimensions are in millimeters. Fixing hole diameters are 6mm.

All dimensions are in millimeters. Fixing hole diameters are 6mm.

Procedure

Procedure

When a suitable location has been found for installing the back box, and the

When a suitable location has been found for installing the back box, and the

Network Gateway Module electronics have been removed, fix the back box to

Network Gateway Module electronics have been removed, fix the back box to

the wall as follows:

the wall as follows:

365.00

37.50

190.00

45.00

275.00

45.00

380.00

301.00

DO NOT use the back box as a guide when drilling.DO NOT use the back box as a guide when drilling.

!!

1 Using a suitable-sized drilling bit - for holes to take up to 6mm (No. 12-

1 Using a suitable-sized drilling bit - for holes to take up to 6mm (No. 12-

sized) wood screws - drill a hole at position A in the wall. Fit a suitable-

sized) wood screws - drill a hole at position A in the wall. Fit a suitable-

sized wall-plug, or equivalent.

sized wall-plug, or equivalent.

2 Hold the back box in position at hole A (ensure the panel is level) and mark

2 Hold the back box in position at hole A (ensure the panel is level) and mark

the position of the remaining fixing holes (B). Remove the back box and

the position of the remaining fixing holes (B). Remove the back box and

store safely.

store safely.

3 Drill two holes at positions B in the wall, and fit suitable-sized wall-plugs, or

3 Drill two holes at positions B in the wall, and fit suitable-sized wall-plugs, or

equivalent.

equivalent.

4 Prepare apertures (20mm knockouts) required for cable access. Make

4 Prepare apertures (20mm knockouts) required for cable access. Make

sure paint is scraped from the area surrounding the knockouts, to ensure

sure paint is scraped from the area surrounding the knockouts, to ensure

good earthing for glands, or use earth termination kit 020-453 (see

good earthing for glands, or use earth termination kit 020-453 (see

previous page for mounting position). Use the 2 top front knockouts for

previous page for mounting position). Use the 2 top front knockouts for

fibre-optic cables.

fibre-optic cables.

5 Secure the back box to the wall using all three fixing holes and

5 Secure the back box to the wall using all three fixing holes and

appropriate-sized screws (up to 6mm [No. 12-sized] round or pan-head

appropriate-sized screws (up to 6mm [No. 12-sized] round or pan-head

screws - do not use countersunk screws).

screws - do not use countersunk screws).

6 If a PSU3A is to be fitted, follow the procedure given on the next page.

6 If a PSU3A is to be fitted, follow the procedure given on the next page.

7 Reverse the ‘Preparing the Back Box’ procedure to refit all items except

7 Reverse the ‘Preparing the Back Box’ procedure to refit all items except

the cover. Ensure chassis earth connections are made correctly.

the cover. Ensure chassis earth connections are made correctly.

8 If an RS232 or Fibre-optic PCB is to be fitted, follow the appropriate ‘Fitting

8 If an RS232 or Fibre-optic PCB is to be fitted, follow the appropriate ‘Fitting

Optional PCBs’ procedure given on following pages.

Optional PCBs’ procedure given on following pages.

9 Refit the cover (ensure earth lead is connected).

9 Refit the cover (ensure earth lead is connected).

2

997-451, Issue 6 July 2006

GG

HH

XX

(typical 4

(typical 4

locations)

locations)

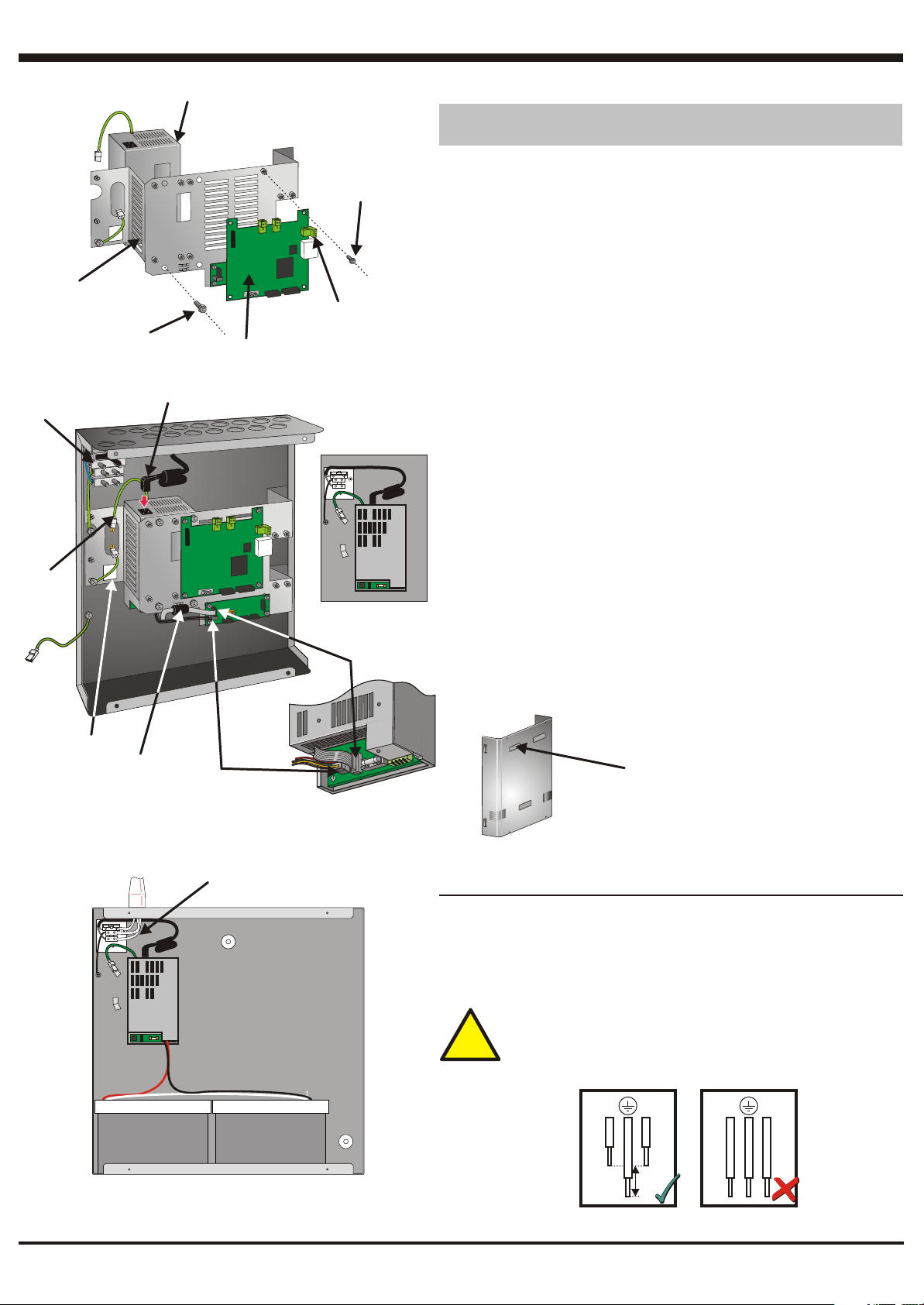

Installing the Network Gateway Unit (Continued)

Fitting a PSU3A (Kit PN: 020-648) - Optional

DD

C

C

(typical 4

(typical 4

locations)

locations)

E

E

AA

BB

FF

LL

NN

F - in detailF - in detail

JJ

Fitting a PSU3A (Kit PN: 020-648) - Optional

TRANSIT CABLE CLIP: Before proceeding, CAREFULLY cut the cable

TRANSIT CABLE CLIP: Before proceeding, CAREFULLY cut the cable

clip that secures the ferrite cable loop to the chassis (at 'X' on drawing).

clip that secures the ferrite cable loop to the chassis (at 'X' on drawing).

This procedure assumes that the chassis has been removed from the back

This procedure assumes that the chassis has been removed from the back

box - see ‘Preparing the Back Box’.

box - see ‘Preparing the Back Box’.

1

Disconnect the dc connector (A) from the Network Gateway Module

1 Disconnect the dc connector (A) from the Network Gateway Module

(NGM) - (B).

(NGM) - (B).

2

Remove and retain the four M3 X 8 SEM screws (C) that secure the NGM

2 Remove and retain the four M3 X 8 SEM screws (C) that secure the NGM

to the chassis, then remove the NGM and store it safely (take anti-static

to the chassis, then remove the NGM and store it safely (take anti-static

precautions).

precautions).

3

Orientate the PSU3A (D) as shown and secure it to the chassis using the

3 Orientate the PSU3A (D) as shown and secure it to the chassis using the

M4 x 8 SEM screws (E) supplied with the PSU3A.

M4 x 8 SEM screws (E) supplied with the PSU3A.

4

Replace the NGM onto the chassis (by reversing steps 2 and 1 above),

4 Replace the NGM onto the chassis (by reversing steps 2 and 1 above),

then replace the chassis in the back box.

then replace the chassis in the back box. Ensure the chassis earth

connection is remade.

connection is remade.

5

Push the connector of the PSU3A mains cable (F) into the socket on the

5 Push the connector of the PSU3A mains cable (F) into the socket on the

PSU3A [the other end of the mains cable is factory-fitted to the mains

PSU3A [the other end of the mains cable is factory-fitted to the mains

terminal block (G)]. Ensure the mains cable is routed as shown in the

terminal block (G)]. Ensure the mains cable is routed as shown in the

illustration. Pull tight the cable clip at the side of the back box.

illustration. Pull tight the cable clip at the side of the back box.

6

Connect the PSU earth lead (H) to the upper blade on the back box.

6 Connect the PSU earth lead (H) to the upper blade on the back box.

7

Connect the 4-way power cable (I) and 10-way ribbon cable (J) (supplied

7 Connect the 4-way power cable (I) and 10-way ribbon cable (J) (supplied

with the NGU) between the PSU3A and the PSU3A to Network Interface

with the NGU) between the PSU3A and the PSU3A to Network Interface

PCB.

PCB.

8

Use the supplied cable tie to secure the ribbon cable’s ferrite (K) to the tie

8 Use the supplied cable tie to secure the ribbon cable’s ferrite (K) to the tie

point on the chassis.

point on the chassis.

9

Remove and discard the PSU rating label (L) from the chassis.

9 Remove and discard the PSU rating label (L) from the chassis.

10

Remove and discard the NGU product label (M) from the cover. Peel off

10 Remove and discard the NGU product label (M) from the cover. Peel off

the backing from the NGU EN54-compliant label supplied in the NGU

the backing from the NGU EN54-compliant label supplied in the NGU

accessory kit, and attach the label to the cover in place of the removed

accessory kit, and attach the label to the cover in place of the removed

label.

label.

Ensure the chassis earth

LL

KK

II

MAINS

MAINS

WIRES

WIRES

LL

NN

FOR CLARITY, SHOWN WITH

FOR CLARITY, SHOWN WITH

CHASSIS REMOVED

CHASSIS REMOVED

PSU3APSU3A

MM

Wiring Connections - Mains and Safety Earth

Live and Neutral must only be connected if the PSU3A is fitted. The earth

Live and Neutral must only be connected if the PSU3A is fitted. The earth

connection must always be connected. Cables are to be brought into the

connection must always be connected. Cables are to be brought into the

back box using 20mm knockouts and appropriate glands - (refer to the panel’s

back box using 20mm knockouts and appropriate glands - (refer to the panel’s

Installation & Commissioning manual) in accordance with local standards.

Installation & Commissioning manual) in accordance with local standards.

Terminate the mains/earth at the terminal block; connections are labelled.

Terminate the mains/earth at the terminal block; connections are labelled.

Segregate mains wiring from all other wiring.

Segregate mains wiring from all other wiring.

When terminating mains leads, ensure that the earth lead is

When terminating mains leads, ensure that the earth lead is

!!

longer than L and N.

longer than L and N.

L N L N

>25mm

3

997-451, Issue 6 July 2006

Loading...

Loading...