Page 1

Construction

The refilling combination with softening unit consists of:

• integrated ball valve, inlet and outlet side

• Backflow preventer type BA with discharge valve, cartridge

insert, integrated dirt trap on the inlet side, backflow preventer

outlet side and three measuring points with sealing plugs

• Pressure reducing valve with pressure gauge

• Blending unit, consisting of water flow meter, outlet-sided

blocking capability and bleeder valve

• 3.5l cartridge with ionic exchange resin

• Total hardness test-kit to determine water hardness

Materials

• Dezincification-resistant brass housing

• Discharge valve, cartridge insert, valve insert, mechanical

components of the blending unit and spring bonnet made of

high-quality plastic

• Fibre-reinforced NBR diaphragm

• Seals in NBR and EPDM

EN0H-1546GE23 R0908 • Subject to change

• Spring steel adjustment spring

• Stainless steel fine filter mesh

• Polypropylene cartridge

NK300soft

Refilling combination with softening unit

for heating systems

Product specification sheet

Application

The softening unit of the Honeywell NK300soft facilitates the

softening of heating water according to VDI-guideleine 2035/I.

Limescale and thereby caused damages and malfunction in hot

water heating system (DIN EN 12828) are avoided efficiently.

The refilling combination fitted on the inlet and based on a

BA-type backflow preventer protects the potable water supply

against back flow of heating water according to DIN EN 1717.

Special Features

• Intergrated water meter simplify the determination of cartridge

exchange

• Easy exchange of cartridge without tools

• Constant connection with the drinking water supply in accordance with EN1717 by hose line or piping is possible

• Optimal protection of the drinking water supply system

• Backflow preventer approved for noise level protection,

class 2

• Pressure reducing valve approved for noise level protection,

class 1

• Pressure reducing valve with inlet pressure balancing - inlet

pressure fluctuation does not influence the outlet pressure

• Outlet pressure adjustable and directly at the pressure gauge

readable

Range of Application

Medium Water

Inlet pressure max. 10.0 bar

Outlet pressure 1.5-4 bar adjustable, preset to

1.5 bar

Liquid category Backflow

preventer BA

Suitable for heating systems with the following materials: steel,

copper, copper alloys and plastics.

Treated water has modified corrosive chemical parameters.

Conditioning by means of inhibitors is to be provided for separately.

Technical Data

Installation position horizontal pipework with discharge

Operating temperature max. 30 °C

k

-value 0.45 m3/h

vs

Connection ball valve

Backflow preventer

Connection size

Discharge

Connection size

4 (toxic, highly toxic, tumourigenic, radioactive materials)

connection directed downwards

1

/4"

G

HT 50

1

/2" External thread

www.honeywell.com 1

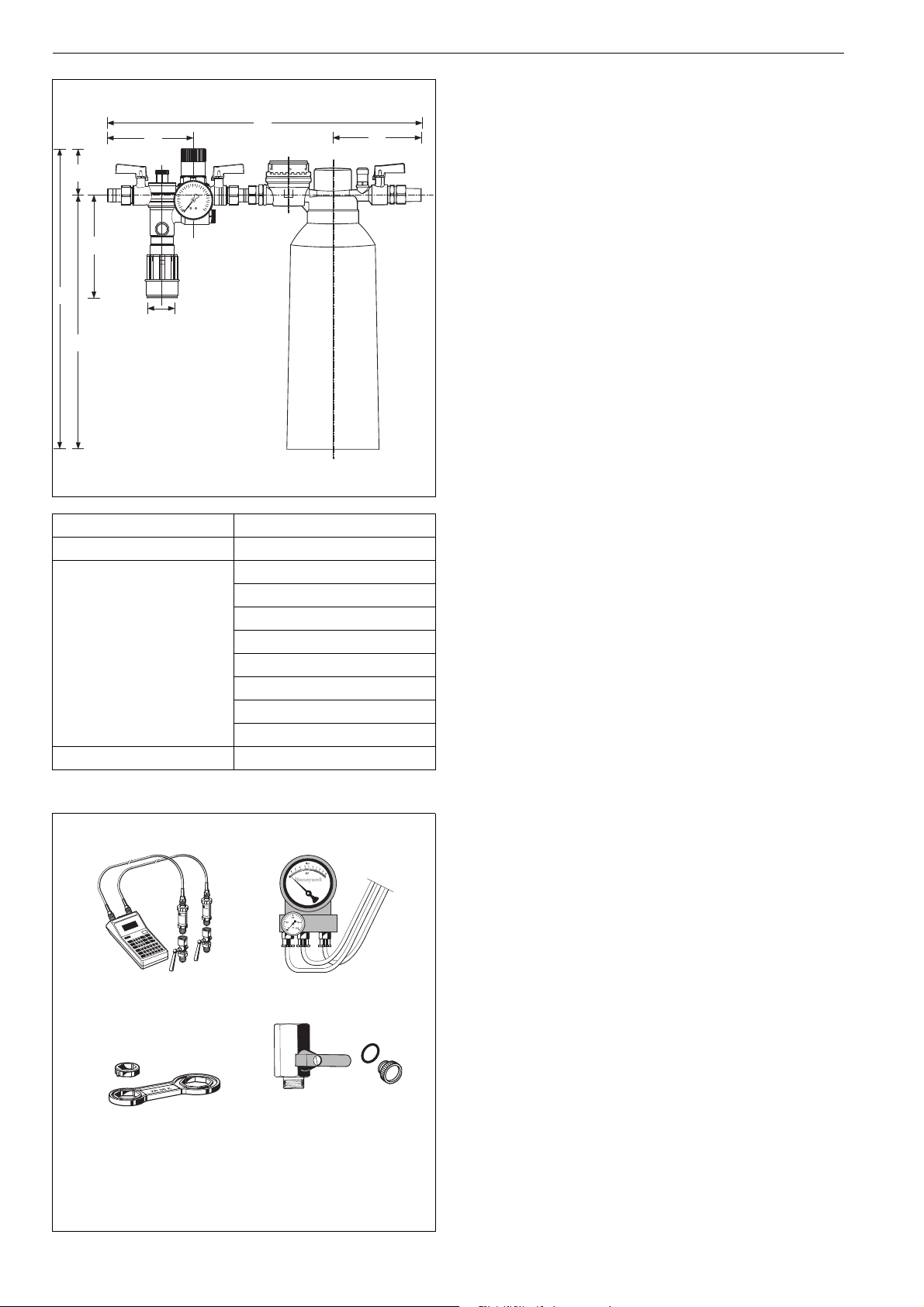

Page 2

NK300soft Refilling combination with softening unit for heating systems

Method of Operation

In the first instance the water passes through the refilling combi-

L

l

1

h

1

h

3

H

Ø50mm

h

2

Connection size R

1

Weight kg 6

Dimensions mm

H524

h

1

h

2

h

3

450

162

L495

l

1

l

2

-value m3/h 0,45

k

vs

137,5

138

/2"

74

l

2

nation which protects the system against back flow of heating

water. It combines backflow preventer, pressure reducing valve

and ball valves in one appliance.

The backflow preventer changes to shut-off position (back pressure) if the differential pressure between middle- and inlet

chamber falls under 0.14 bar. The check valves are closed and

the discharge valve is opened.

The pressure reducing valve reduces the pressure on the inlet

side (admission pressure) to the level of the desired pressure on

the outlet side (outlet pressure) in individual cases.

Inlet pressure fluctuation does not influence the outlet pressure,

because the pressure reducing valves operate by means of a

force equalising system (inlet pressure balancing).

The softening unit, installed directly after the refilling combination,

works according to the ionic exchange principle and replaces the

alkaloids of soil such as calcium and magnesium with sodium

ions.

Dependant on the regional water hardness, the water is either

partially softened (<8°dH) or completely softened (<0,11°dH) by

adjusting the blending unit.

Options

NK300soft-1/2A = Standard version with threaded connec-

NK300soft-1/2AZ25 = Version with threaded connection R1/2"

1

tion R

/2" and 600µm filter in the refilling

combination

and 25µm filter in the refilling combination

TK295

ZR06K

2 www.honeywell.com

TKA295

3x

WS300NK

3x

Accessories

TK295 Test kit

Electronic pressure measuring device with digital indicator, battery-operated.

With case and accessories, ideal for inspection and

maintenance of backflow preventer type BA.

TKA295 Test kit

Analogue pressure measuring device with differential

pressure display.

With case and accessories, ideal for inspection and

maintenance of backflow preventer type BA.

ZR06K Double ring spanner

For removal of spring hood and filter bowl

WS300NK Maintenance set

Maintenance set for refilling combination NK300 for

use with TK295 resp. TKA295

EN0H-1546GE23 R0908 • Subject to change

Page 3

Installation Example

NK300soft Refilling combination with softening unit for heating systems

Installation Guidelines

• Installation in inlet of the heating system, fasten softening unit

on the wall

• Install in horizontal pipework with discharge connection

directed downwards

• The installation may not take place in areas or ducts where

poisonous gases or vapours may be present or where flooding can occur

• The installation environment should be protected against

frost and ventilated well

• The installation location has to be easily accessible

o Simplified maintenance and cleaning

o Pressure gauge at the pressure reducing valve can be read

off easily

• First install the refilling combination in the flow direction, then

immediately thereafter install the softening unit

• The national installation regulations must be observed during

the assembly.

Typical Applications

The refilling combination serves filling and refilling of closed heating systems with softened water to DIN EN 12828:2003. The

included backflow preventer BA protects the potable water

supply against back flow of heating water of liquid category 4

(with inhibitors) into service pipe.

EN0H-1546GE23 R0908 • Subject to change

www.honeywell.com 3

Page 4

NK300soft Refilling combination with softening unit for heating systems

Spare Parts

Refilling combination NK300soft (from 2008 onwards)

No. Description Part No.

1

3

1 Cartridge insert

complete

2 Check valve

1

/2" 0903733

1

/2" 2166200

4

5

4

5

5

4

2

6

3 Valve insert complete1/2"D06FA-1/2

(not incl. filter)

4 Blanking plug

with O-ring R

1

/4"

S06K-1/4

(5 pcs.)

5 Sealing ring set (10

1

/2" 0901443

piece)

6 Pressure gauge 0 - 4 bar M07M-A4

7 Water flow meter WZ300

8

8 Air bleed valve 2421100

9 Cartridge 0.75 l P300-S

3.5 l P300-L

7

9

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1546GE23 R0908

Subject to change without notice

© 2008 Honeywell GmbH

Loading...

Loading...