Honeywell MP Nova Mark II, MP Nova6 TT, MP Nova4 DT, MP Nova4 TT, MP Nova6 DT & User Manual

Page 1

MP Nova Mark II

MP Nova4 DT, MP Nova4 TT, MP Nova6 DT &

MP Nova6 TT

User Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other

information contained in this document without prior notice, and the reader should in all cases consult HII to

determine whether any such changes have been made. The information in this publication does not

represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or

consequential damages resulting from the furnishing, performance, or use of this material. HII disclaims all

responsibility for the selection and use of software and/or hardware to achieve intended results.

This document contains proprietary information that is protected by copyright. All rights are reserved. No

part of this document may be photocopied, reproduced, or translated into another language without the

prior written consent of HII.

Firmware (Software) Agreement

The enclosed firmware (software) resident in the printer is owned by licensor or its suppliers and is licensed

for use only on a single printer in the user’s Trade or Business. The User agrees not to, and not to authorize

or permit any other person or party to, duplicate or copy the firmware or the information contained in the

non-volatile or programmable memory. The firmware (software) is protected by applicable copyright laws

and Licensor retains all rights not expressly granted. In no event will licensor or its suppliers be liable for

any damages or loss, including direct, incidental, economic, special, or consequential damages, arising out

of the use or inability to use the firmware (software).

Information in this document is subject to change without notice and does not represent a commitment on

the part of Honeywell. No part of this manual may be reproduced or transmitted in any form or by any

means, for any purpose other than the purchaser's personal use, without the expressed written permission

of Honeywell.

Trademarks

Wi-Fi is a registered certification mark of the Wi-Fi Alliance.

Microsoft, Windows, and the Windows logo are either registered trademarks or registered trademarks of

Microsoft Corporation in the United States and/or other countries.

Bluetooth is a trademark of Bluetooth SIG, Inc., U.S.A.

All other brand and product names are trademarks, service marks, registered trademarks, or registered

service marks of their respective companies.

Patents

For patent information, please refer to www.hsmpats.com.

Copyright © 2016 Honeywell International Inc. All rights reserved.

ii MP Nova Mark II User Guide

Page 3

MP Nova Mark II User Guide iii

Page 4

Contents

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Product Service and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Send Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Agency Compliance and Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1

Important Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Printer Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About the Printer Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2

Learn About the Printer Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Identify the Printer Box Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MP Nova4 DT & MP Nova6 DT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MP Nova4 TT & MP Nova6 TT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Identify the Parts of the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MP Nova4 & 6 DT – Printer Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MP Nova4 & 6 TT – Printer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

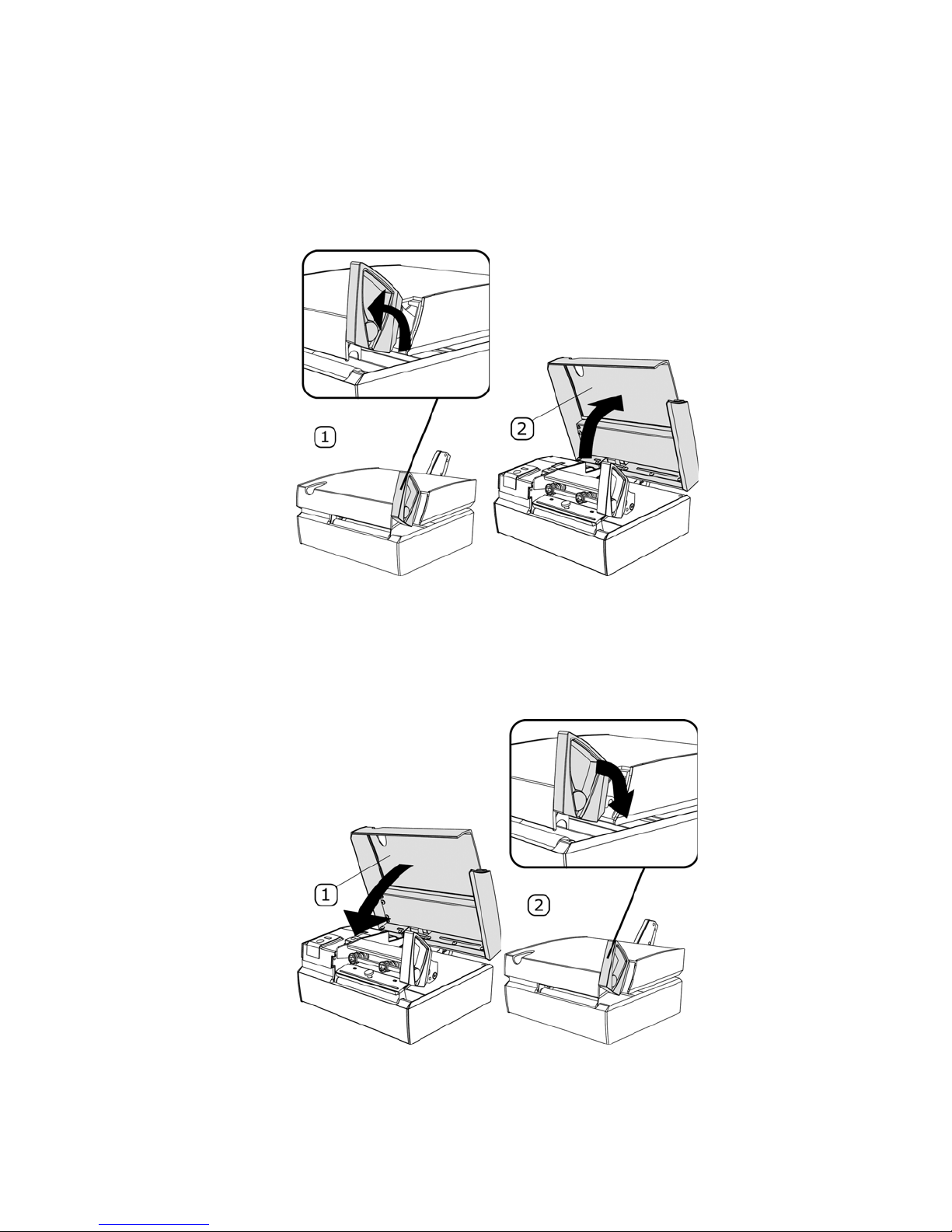

Open and Close the Printer Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Open the MP Nova4 & 6 DT Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Close the MP Nova4 & 6 DT Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

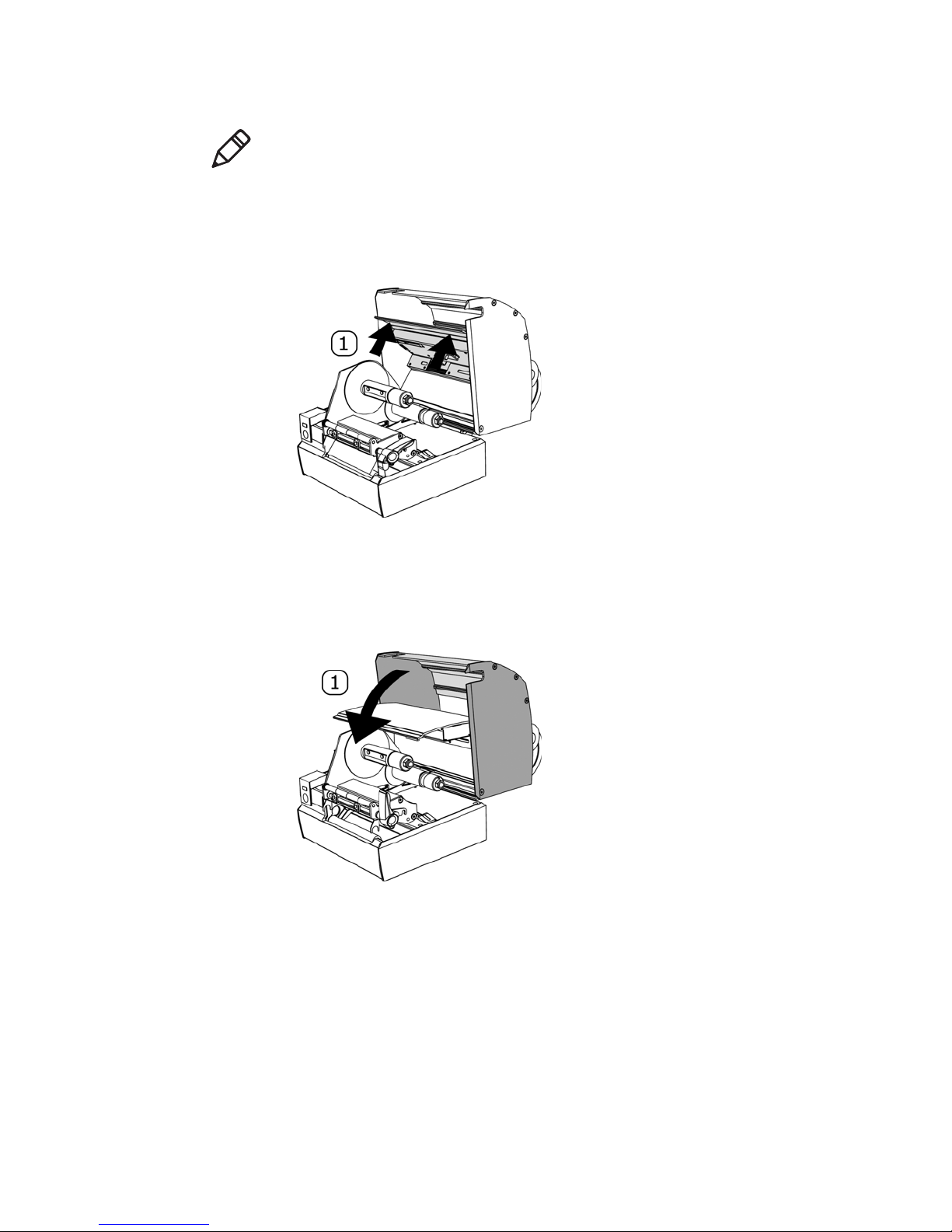

Open the MP Nova4 & 6 TT Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Close the MP Nova4 & 6 TT Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

How to Set Up Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3

Printer Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MP Nova4 & 6 DT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MP Nova4 & 6 TT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Peel-Off Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MP Nova4 & 6 DT Peel-Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MP Nova4 & 6 TT Peel-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Insert Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MP Nova4 & 6 DT/TT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Peel-Off Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Insert Ink Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MP Nova4 & 6 TT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Printer Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4

Printer Configuration Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

iv MP Nova Mark II User Guide

Page 5

Printer Configuration Utility (NETira CT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

USB Connection Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

How to Use NETira CT Configuration Utility. . . . . . . . . . . . . . . . . . . . . . . . 33

Windows Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Printer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Media Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Quick Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Manual Media Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Internal Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Database Configuration Label and HEX-Dump Mode . . . . . . . . . . . . . . . . . . . . . . 45

Media Positioning Sensor Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Printhead Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Printhead Position Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Printhead Pressure Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6

Printhead and Roller Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Changeable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Roller Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Printhead Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Troubleshoot Your Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Printer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

A

MP Nova4 DT & TT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

MP Nova6 DT & TT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Kits, Parts & Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

B

Printer Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Peel-Off Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

LTS – Label-Taken Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

215-mm Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

MP Nova Mark II User Guide v

Page 6

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

General Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

vi MP Nova Mark II User Guide

Page 7

Customer Support

If you need assistance installing or troubleshooting your product, contact us by

using one of these methods:

Knowledge Base: www.hsmknowledgebase.com

Our Knowledge Base provides thousands of immediate solutions. If the

Knowledge Base does not help you solve your problem, log into the Technical

Support Portal to submit your problem or ask your question.

Technical Support Portal: www.hsmsupportportal.com

Log into the Technical Support Portal to search our Knowledge Base, submit

your problem or question, request a call back, or provide feedback. When filling

out one of the forms, provide as much detail as possible. You can even include

attachments.

Telephone: www.honeywellaidc.com/locations

For our latest contact information, please check our website.

Product Service and Repair

Honeywell International Inc. provides service for all of its products through

service centers throughout the world. To find your service center, go to

www.honeywellaidc.com and select Support > Contact Support > Service

and Repair. Contact your service center to obtain a Return Material

Authorization number (RMA #) before you return the product.

To obtain warranty or non-warranty service, return your product to Honeywell

(postage paid) with a copy of the dated purchase record.

Limited Warranty

For warranty information, go to www.honeywellaidc.com and click Resources

> Warranty.

Send Feedback

Your feedback is crucial to the continual improvement of our documentation. To

provide feedback about this manual, please contact the Technical

Communications department directly at

ACSHSMTechnicalCommunications@honeywell.com.

MP Nova Mark II User Guide vii

Page 8

Agency Compliance and Approvals

Certification and Compliance Marks and Descriptions

UL = Underwriters Laboratories USA

UL60950-1 2nd Edition

CSA C22.2 No. 60950-1-07 2nd Edition

The manufacturer declares under sole responsibility that this

product conforms to the following standards or other normative

documents:

•

CFR47 FCC part is subpart B:2014

• ICES-003-2012

• EMC: EN 55022: 2010 + AC:2011, Class A

• EMC: EN 50024 (2010)

CE = European Commission

• Safety: This product complies with the requirements of IEC 60950-1:

2005 2nd Edition; AM1: 2009 + AM2: 2013

• ROHS: 2011/65/EC

• LVD: 2006/95/EC

• EMC: 2004/108/EC

• RTT&E: 1995/5/EC

Warning:

product may cause radio interference in which case the use may

be required to take adequate measures.

This is a class A product. In a domestic environment this

FCC = Federal Communications Commission

This equipment has been tested and found to comply with the limits for

a Class B digital device, pursuant to part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful

interference with radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

viii MP Nova Mark II User Guide

Page 9

Certification and Compliance Marks and Descriptions

VCCI = Voluntary Control Council for Interference

Japan

MP Nova Mark II User Guide ix

Page 10

1

Safety Information

Please read the following safety information prior to setting up or

operating your printer.

1

Page 11

Chapter 1 — Safety Information

Important Safety Requirements

Honeywell disclaims all responsibility regarding the CE directive if the printer is

used, altered or installed in any way other than described in this manual.

This symbol is used to indicate circumstances that may be dangerous to the user

or that cause damage to the equipment.

• Never use sharp or pointed tools when cleaning or replacing the printhead.

• Remember to handle the printhead with care.

• Don't use any sharp objects to remove labels from the print roller.

• The MP Nova Mark II printers have double fuses. The fuses are rated at 250

V, 4.0 A, AT-type. Fuses must be UL-approved.

• The circuit board contains a battery. Used batteries should be disposed of in

accordance with the manufacturer’s instructions.

• Please read all instructions before using the printer for the first time.

• The printer should be connected to the power supply indicated on the voltage

plate. If you are unsure of the type of power supply available, please contact

Honeywell service personnel.

• The printer is equipped with a plug suitable for grounded sockets. This is a

safety measure. If the plug does not fit the power socket, a qualified

electrician must replace it.

• We do not recommend the use of extension cables.

• The power cable must not be subjected to pressure. Ensure that the printer is

not placed anywhere where a person could stand on the power cable.

• Check that the power switch is off (in the ‘0’ position) before connecting the

power cable.

• Do not use liquids or aerosols when cleaning this printer. Always use

Honeywell’s special cleaning cloths.

• Do not attempt to open the electronic unit or other sealed parts! The user

cannot service these parts.

• Do not use cables that exceed 5 m (16.5 in.) in length for RS-232

communication. Signals may be corrupted or lost as a result. This is

particularly important in environments where there are high levels of electrical

interference.

• Disconnect the power to the printer and call in qualified personnel under the

following conditions:

• The power cable or plug is damaged or worn.

• Liquid has been spilled on the printer.

2 MP Nova Mark II User Guide

Page 12

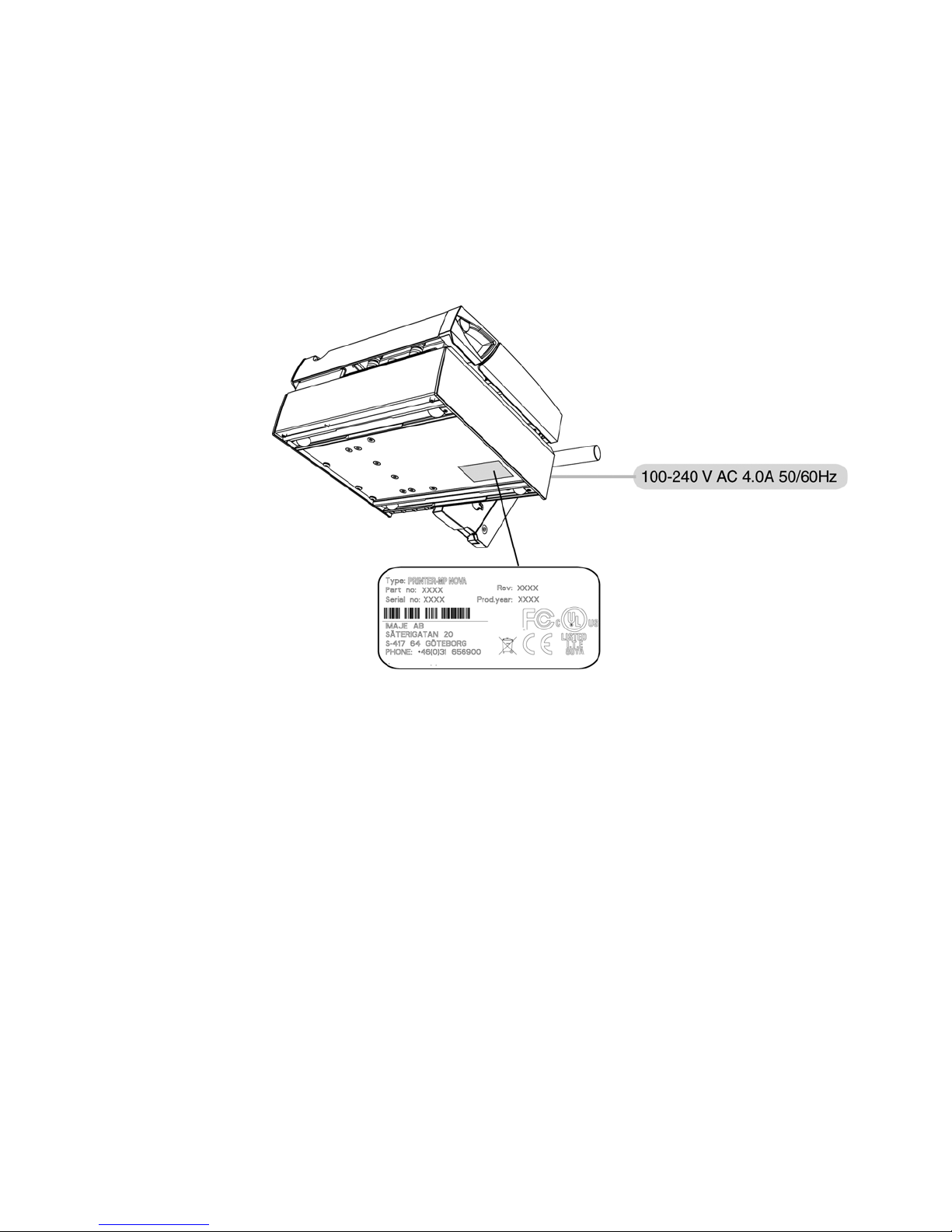

Printer Label

Chapter 1 — Safety Information

• Rain or water has got into the printer.

• The printer is not functioning correctly despite the user has followed the

instructions for use.

• You have dropped the printer or the casing has been damaged.

• The printer is not functioning correctly and requires service.

Printer Sign: Use this illustration to identify printer information.

MP Nova Mark II User Guide 3

Page 13

Chapter 1 — Safety Information

4 MP Nova Mark II User Guide

Page 14

2

About the Printer Basics

Use this chapter to learn about the MP Nova Mark II printer basic

information, including available models, parts and open/close

functionality.

5

Page 15

Chapter 2 — About the Printer Basics

Learn About the Printer Models

The MP Nova Mark II printers, with their unique technology, have been

developed to offer a range of different applications. Thank you for choosing a

Honeywell printer for your business needs. The high quality, user-friendliness

and simple maintenance procedures of the MP Nova Mark II direct thermal (DT)

and thermal transfer (TT) printers make them the perfect choice.

They are built on a platform with advanced software, offering wide possibilities

from simple local solutions to integrated solutions working over the Internet.

Applications include:

• Manufacturing

• Warehousing

• Healthcare

• Transport

• Ticketing

MP Nova Mark II Printer Models

MP Nova4 Mark II DT, 203-dpi

Item number: 53-2211-01

MP Nova4 Mark II DT, 300-dpi

Item number: 53-2211-02

MP Nova4 Mark II TT, 203-dpi

Item number: 53-2213-01

MP Nova4 Mark II TT, 300-dpi

Item number: 53-2212-02

MP Nova6 Mark II DT, 203-dpi

Item number: 53-2213-01

MP Nova6 Mark II TT, 203-dpi

Item number: 53-2214-01

6 MP Nova Mark II User Guide

Page 16

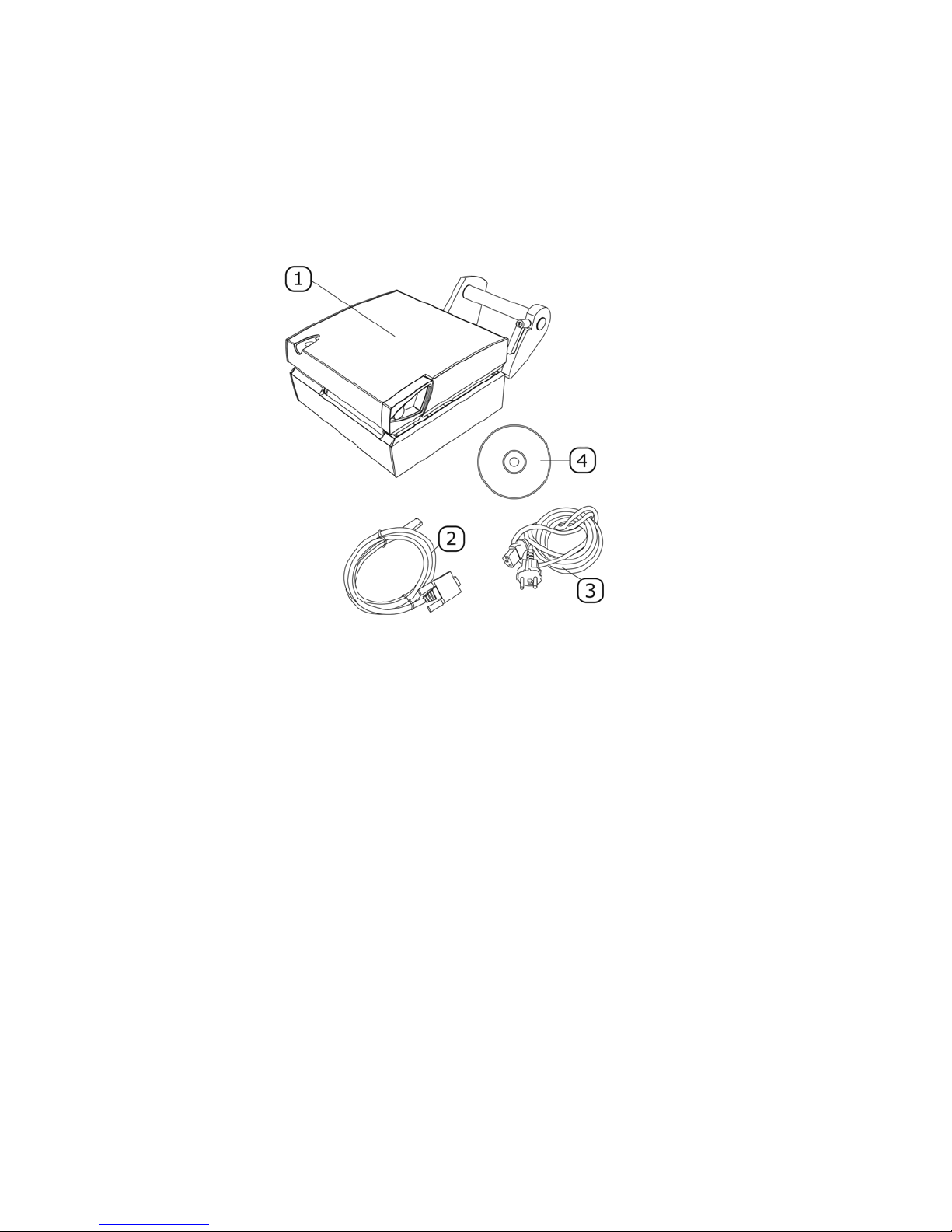

Identify the Printer Box Contents

MP Nova4 DT & MP Nova6 DT

The following items should be included in the box when you receive your new

MP Nova4 DT or MP Nova6 DT printer:

Chapter 2 — About the Printer Basics

1 1 x MP Nova4 DT or MP Nova6 DT

2 1 x Communication cable (Serial RS-232)

3 1 x Power cable

4 1 x Accessories CD

MP Nova Mark II User Guide 7

Page 17

Chapter 2 — About the Printer Basics

MP Nova4 TT & MP Nova6 TT

The following items should be included in the box when you receive your new

MP Nova4 TT or MP Nova6 TT printer:

1 1 x MP Nova4 TT or MP Nova6 TT

2 1 x Communication cable (Serial RS-232)

3 1 x Power cable

4 1 x Accessories CD

8 MP Nova Mark II User Guide

Page 18

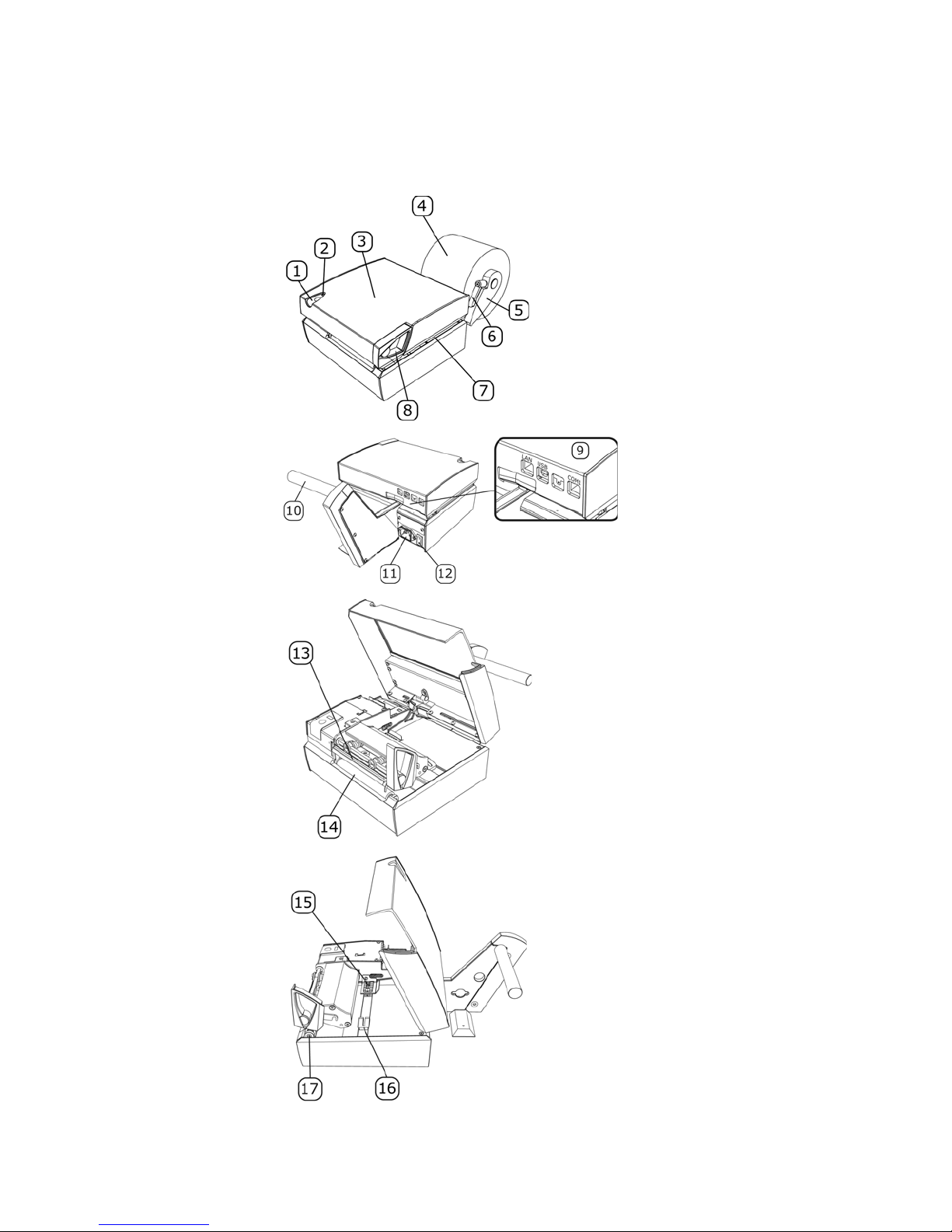

Identify the Parts of the Printer

MP Nova4 & 6 DT – Printer Parts

Chapter 2 — About the Printer Basics

1 Print button

2 Status lamp (LED)

3 Cover

4 Media roll

5 Roll steering

6 Roll-guide lock

7 Media track

8 Handle

9 Communication ports

10 Unroll shaft

11 Power connection

12 Power switch

13 Printhead

14 Print roll

15 Media Positioning Sensor

(MPS)

16 Paper guide

17 Outer plate holder

m p

MP Nova Mark II User Guide 9

Page 19

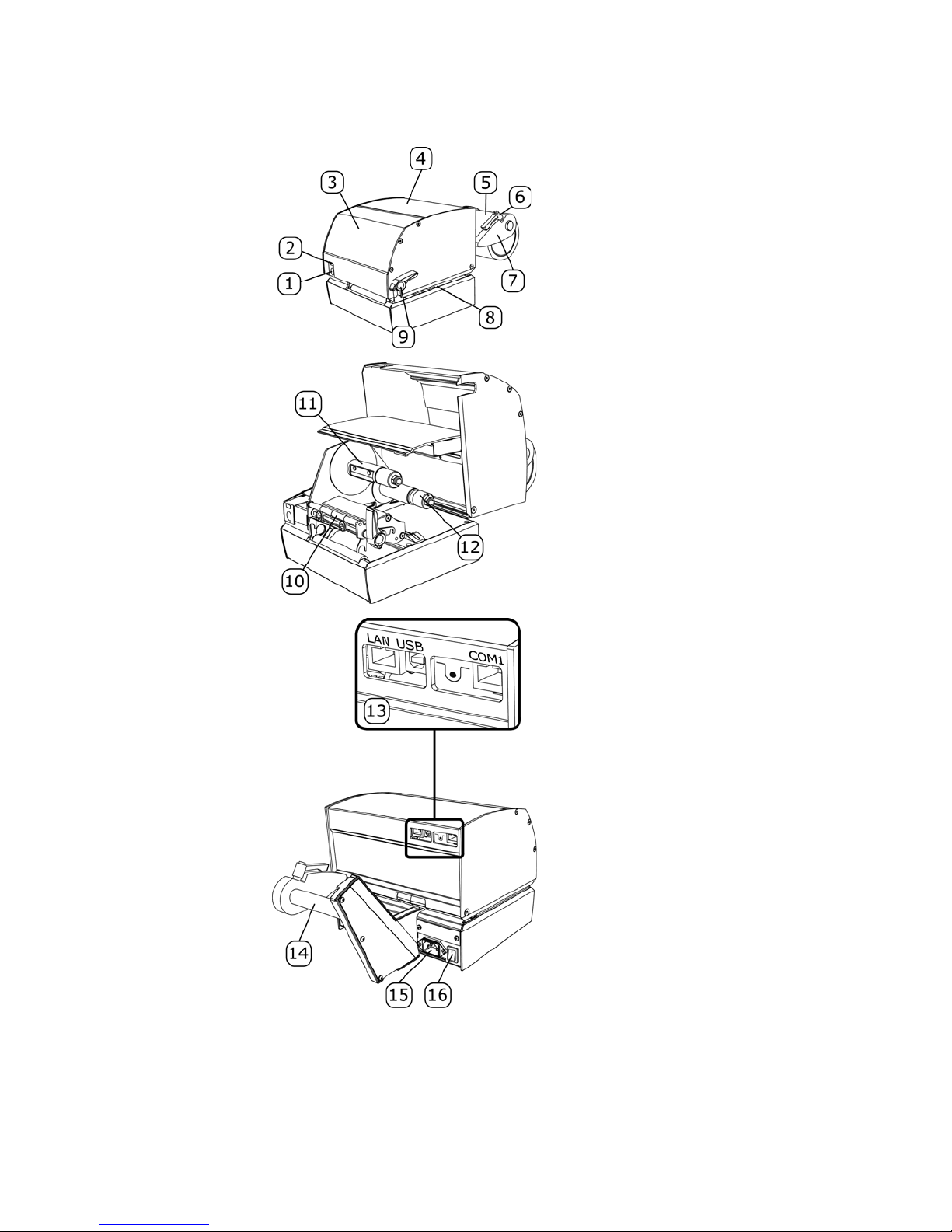

Chapter 2 — About the Printer Basics

MP Nova4 & 6 TT – Printer Parts

1 Print button

2 Status lamp (LED)

3 Front cover

4 Rear cover

5 Media roll

6 Roll-guide lock

7 Roll steering

8 Media track

9 Handle

10 Ink-ribbon guide

11 Rewind spool

12 Unwind spool

13 Communication ports

14 Unroll shaft

15 Power connection

16 Power switch

10 MP Nova Mark II User Guide

Page 20

Open and Close the Printer Cover

Open the MP Nova4 & 6 DT Cover

1 Pull the handle.

Chapter 2 — About the Printer Basics

2 Open the cover.

Close the MP Nova4 & 6 DT Cover

1 Push down to close the cover.

2 Fold the handle. (Printhead will be engaged.)

MP Nova Mark II User Guide 11

Page 21

Chapter 2 — About the Printer Basics

Note: Make sure the handle is folded all the way down.

Open the MP Nova4 & 6 TT Cover

1 Open cover. The inner cover slides automatically up together with the cover.

Close the MP Nova4 & 6 TT Cover

1 Close cover. The inner cover slides automatically down together with the

cover.

12 MP Nova Mark II User Guide

Page 22

3

How to Set Up Your Printer

Learn to use the printer features, including how to insert the media and

ink ribbon, and connect to a power source.

13

Page 23

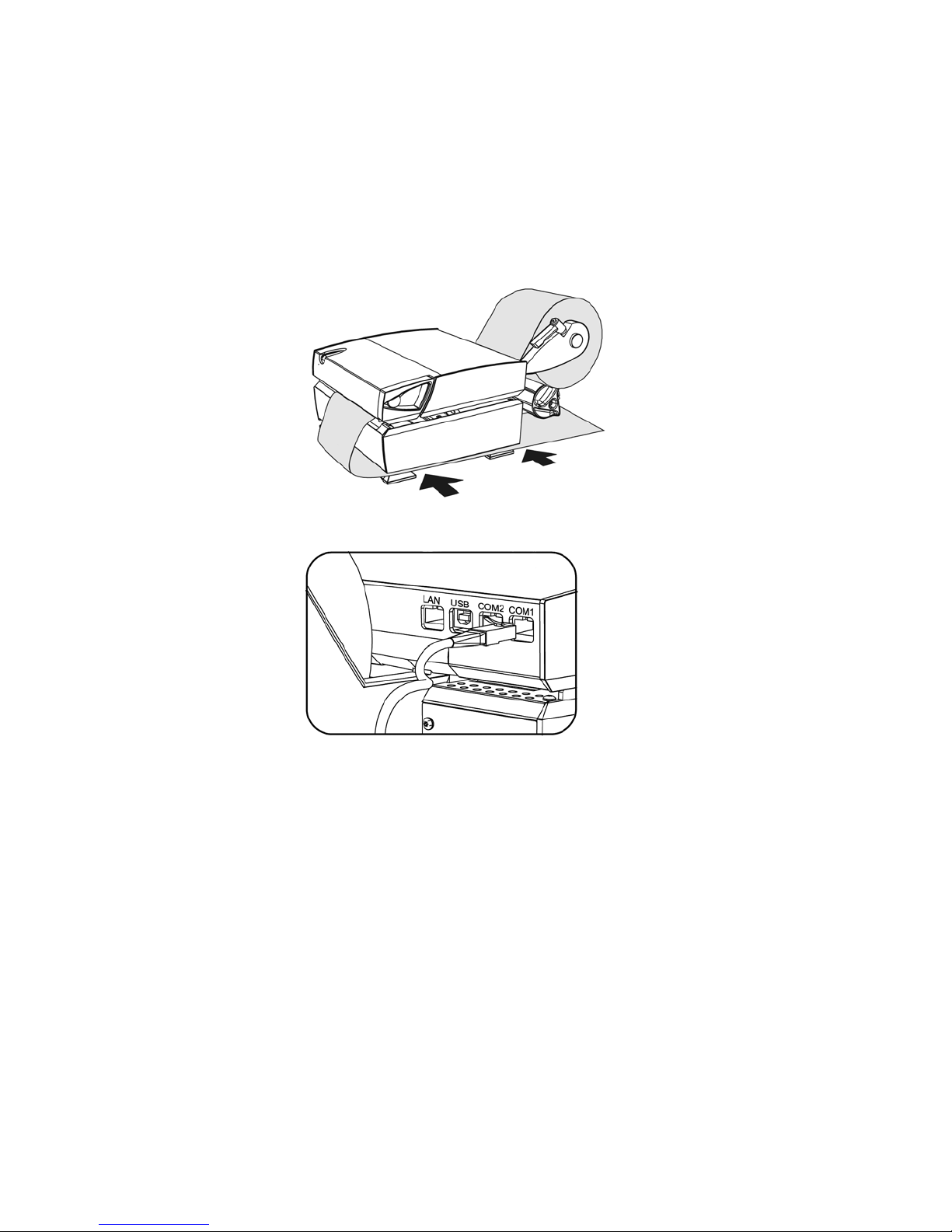

Chapter 3 — How to Set Up Your Printer

Printer Overview

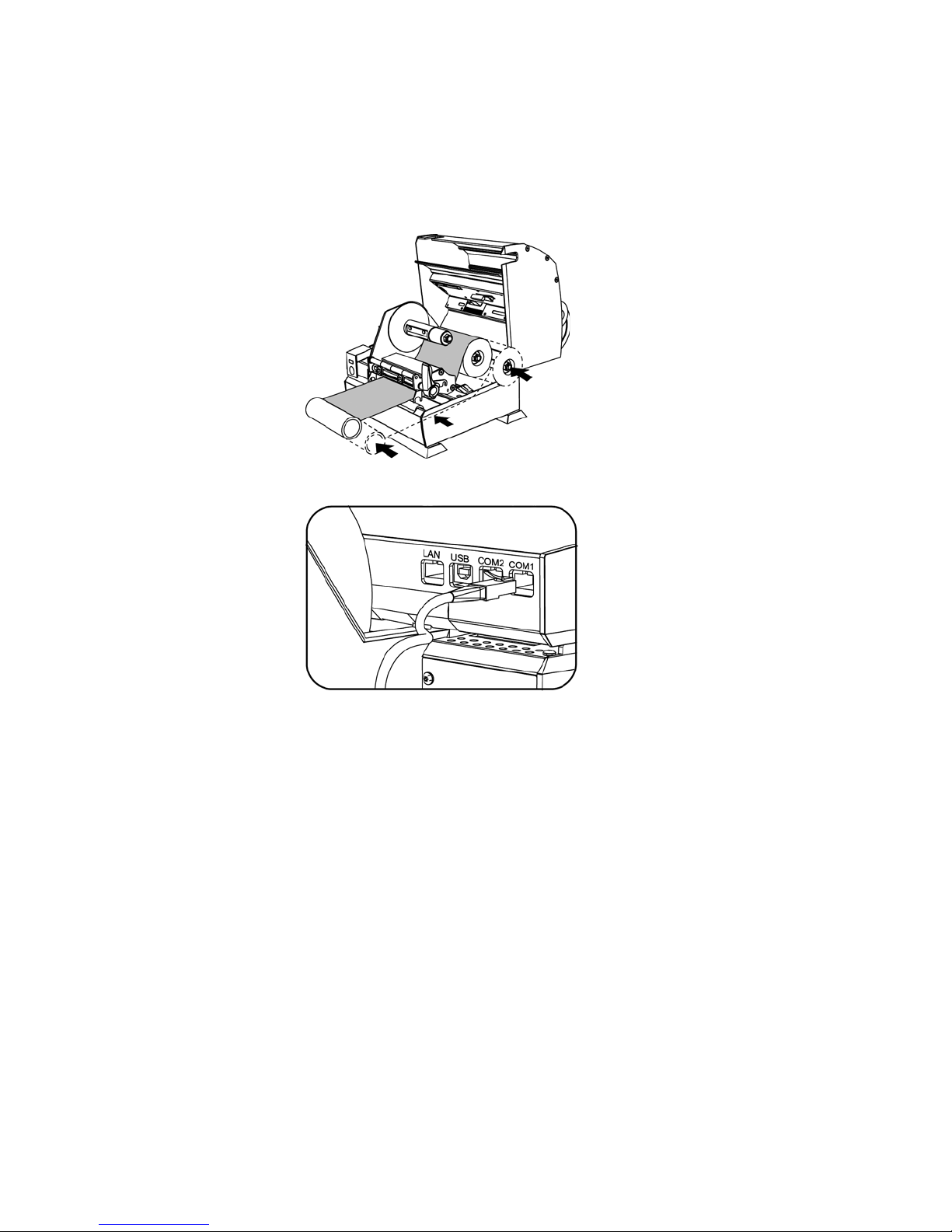

MP Nova4 & 6 DT

1 Insert media, MP Nova4 & 6 DT. Refer to “Insert Media” on page 18 for

detailed instructions.

2 Connect the printer to a PC.

14 MP Nova Mark II User Guide

Page 24

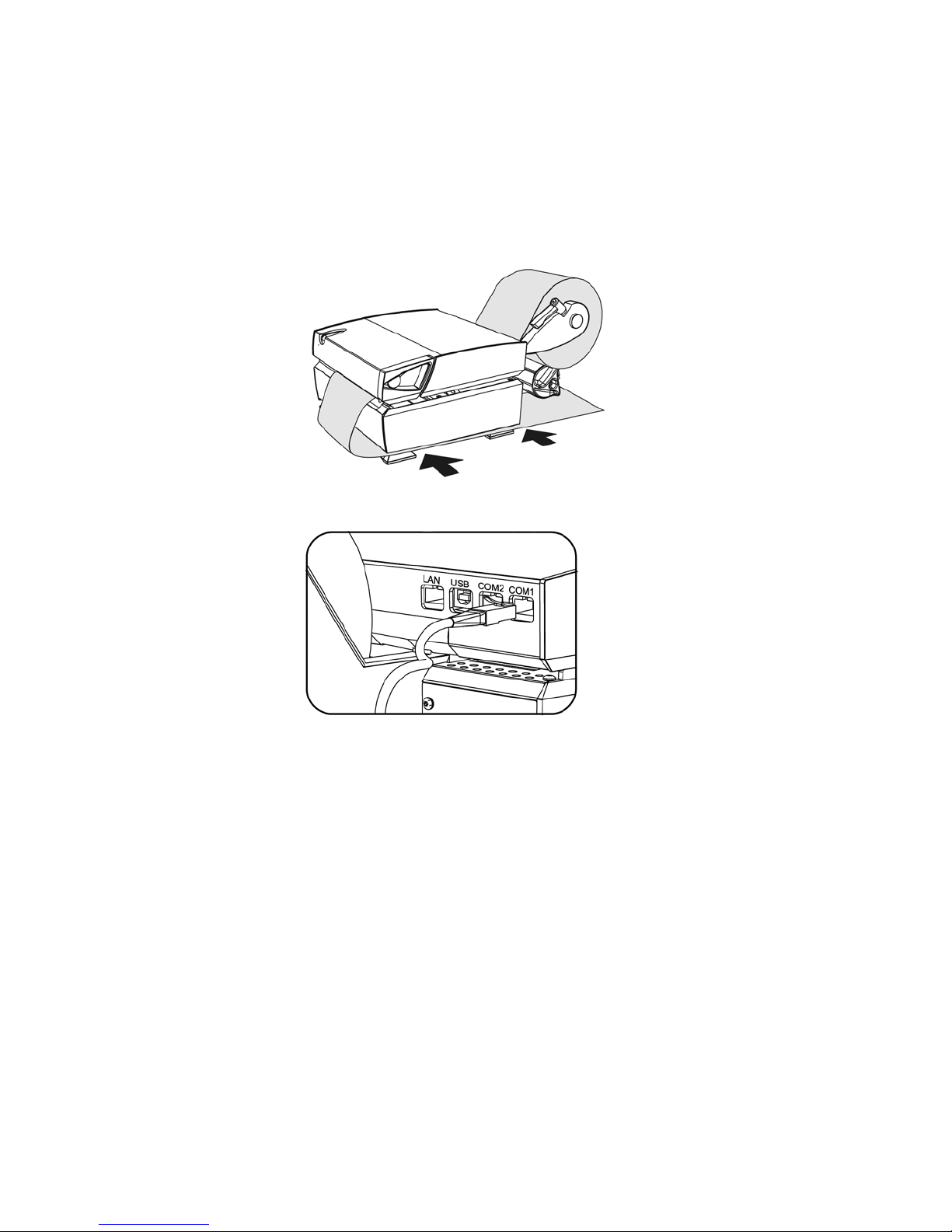

MP Nova4 & 6 TT

1 Insert media. Refer to “Insert Media” on page 18 for detailed instructions.

2 Insert ink ribbon.

3 Connect the printer to a PC.

Chapter 3 — How to Set Up Your Printer

MP Nova Mark II User Guide 15

Page 25

Chapter 3 — How to Set Up Your Printer

Peel-Off Overview

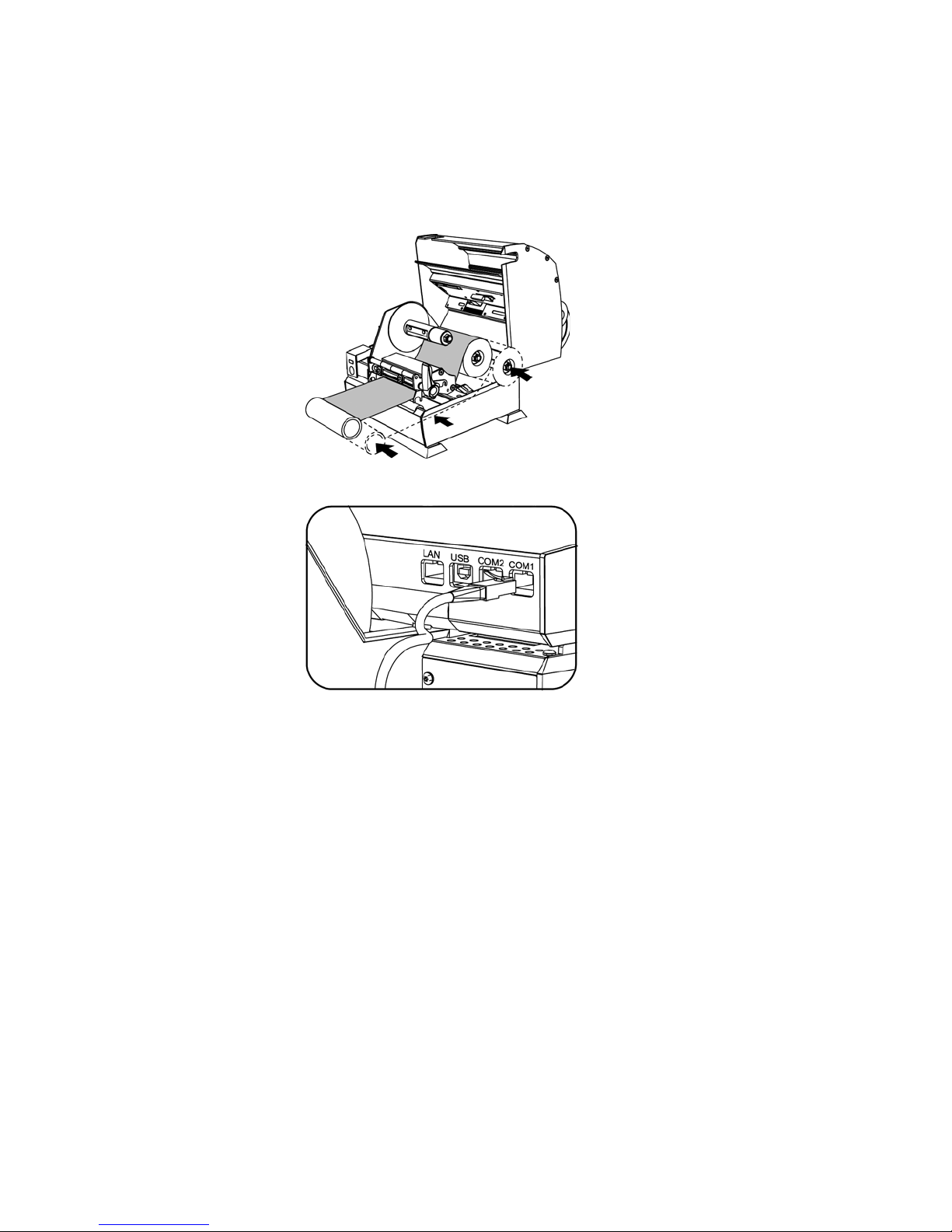

MP Nova4 & 6 DT Peel-Off

1 Insert peel-off media. See “Peel-Off Kit” on page 22.

2 Connect the printer to a PC.

16 MP Nova Mark II User Guide

Page 26

MP Nova4 & 6 TT Peel-Off

1 Insert peel-off media. See “Peel-Off Kit” on page 22.

2 Insert ink ribbon.

3 Connect the printer to a PC.

Chapter 3 — How to Set Up Your Printer

MP Nova Mark II User Guide 17

Page 27

Chapter 3 — How to Set Up Your Printer

Insert Media

MP Nova4 & 6 DT/TT

Note: The pictures shown describe an MP Nova4 DT. The process works just

the same for the MP Nova6 DT and MP Nova4 & 6 TT.

1 Undo the roll-guide lock.

2 Remove the roll guide from the media shaft.

3 Pull handle to lift the printhead from the roller.

18 MP Nova Mark II User Guide

Page 28

Chapter 3 — How to Set Up Your Printer

4 Position a new media roll onto the spool and insert the media from the side

into the printer’s media track.

5 Check that the media is aligned with the internal printer wall.

Note: Make sure the outer-roll guide suits the width of the media. If necessary,

open the cover and adjust the outer-roll guide. (Only necessary when changing

media type.)

6 Put the roll guide on the unroll shaft. Push it against the roll for optimum

control.

MP Nova Mark II User Guide 19

Page 29

Chapter 3 — How to Set Up Your Printer

7 Lock the roll-guide lock (turn the handle clockwise). The roll steering should

guide the roll, but not be tight.

Note: If the roll-guide lock cannot be properly tightened (but not too tight), lift

the lock upwards, rotate it back half a turn, lower it and retighten.

8 Fold the handle (the printhead folds automatically onto the roller).

20 MP Nova Mark II User Guide

Page 30

Chapter 3 — How to Set Up Your Printer

9 Press the print button a few times until the printer automatically finds the

correct position of the media.

.

Note: If necessary, make a test printout and auto adjust the media positioning

sensor.

MP Nova Mark II User Guide 21

Page 31

Chapter 3 — How to Set Up Your Printer

Peel-Off Kit

Note: The pictures shown describe an MP Nova4 DT Peel-Off. The process

works just the same for the MP Nova4 & 6 TT Peel-Off and MP Nova6 DT

Peel-Off.

First insert the media. The peel-off media inserts in the same way as the media.

1 Lift the handle and then pull 40 cm (15.8 in.) of the label roll out of the

printer.

2 Fold the handle.

3 Remove all of the labels on the exposed section.

22 MP Nova Mark II User Guide

Page 32

Chapter 3 — How to Set Up Your Printer

4 Pull the backing paper under the printer.

5 Fold 2 cm (0.79 in.) of the backing paper to make it slide more easily into the

rewind-unit slot.

6 Open the rewind-unit slot by turning the knob clockwise while holding the

cylinder firmly.

MP Nova Mark II User Guide 23

Page 33

Chapter 3 — How to Set Up Your Printer

7 Slide the backing paper into the rewind-unit slot.

8 Close the rewind-unit slot by turning the knob counter-clockwise while

holding the cylinder and backing paper firmly.

9 Roll the backing paper around the rewind unit by turning the knob counter-

clockwise. This increases the tension of the backing paper.

24 MP Nova Mark II User Guide

Page 34

Chapter 3 — How to Set Up Your Printer

10 Press the print button a few times until the printer automatically finds the

correct position of the media.

Note: If necessary, make a test printout and auto adjust the Media Positioning

Sensor (MPS).

MP Nova Mark II User Guide 25

Page 35

Chapter 3 — How to Set Up Your Printer

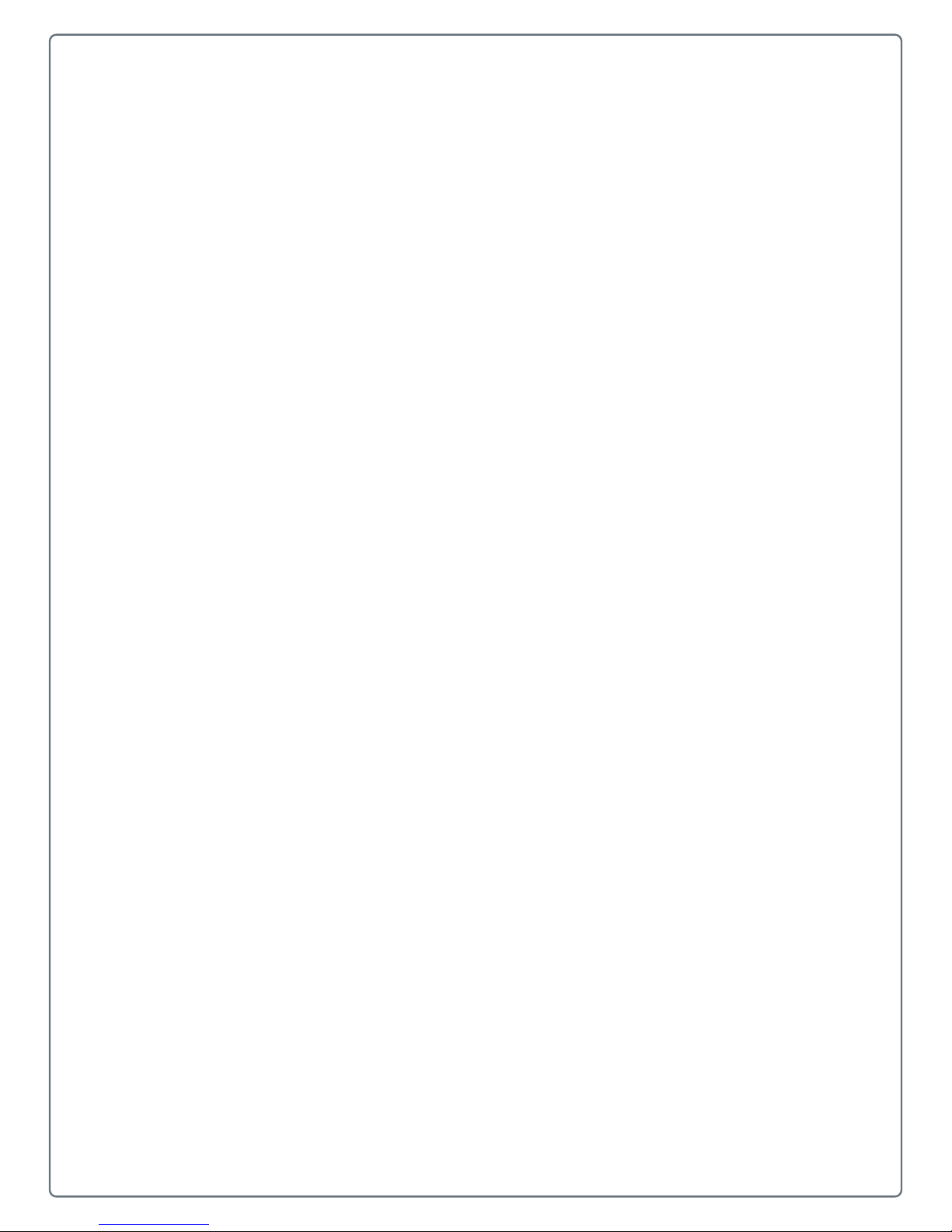

Insert Ink Ribbon

MP Nova4 & 6 TT

1 Undo the handle and open the cover.

2 Remove the old ink ribbon.

3 Slide the new ink ribbon onto the spool.

4 Feed the ink ribbon under the printhead.

Note: Check that the inked side of the ribbon is facing downward.

26 MP Nova Mark II User Guide

Page 36

Chapter 3 — How to Set Up Your Printer

5 The ink ribbon must not pass under the MPS (Media Positioning Sensor).

6 Move the empty roll, which will collect the used ink ribbon, up and around

the printhead.

7 Slide the roll onto the takeup spool.

8 Fold the handle.

MP Nova Mark II User Guide 27

Page 37

Chapter 3 — How to Set Up Your Printer

9 Press the print button. The ink ribbon will automatically wind around the

rewind spool, thus tensioning the ink ribbon.

10 Close the cover.

28 MP Nova Mark II User Guide

Page 38

4

Printer Configuration

Please read the following chapter to learn about the available

configuration tools for your printer.

29

Page 39

Chapter 4 — Printer Configuration

Printer Configuration Tools

The printer contains many user-adjustable parameters. These parameters are

configurable using a few methods. The table below lists the most popular ways of

configuring the printer and the advantages of each. Choose the method that best

addresses your application.

Printer Configuration Methods

Method Description Pros Cons

NETira CT

program*

Internal web

pages

Windows driver The Windows printer driver (located on

DPL

programming

commands

* Recommended method.

NETira CT (located on the

Accessories CD or available on

website at

www.honeywellaidc.com for

download) is a Windows

configuration utility that allows the user

to make changes to the existing printer

set up via a direct connection to the

host computer’s serial, USB or LAN

connection.

Internal web pages are simple HTML

pages that can be accessed with any

web browser via the Ethernet port.

the Accessories CD).

DPL Programming Language

commands can be built into custom

label formats or sent individually to the

printer.

See the DPL Programmer Manual.

®

-based

Easy to use, gives the user the

most control of the printer.

Easy to use. Printer can be

configured from any host

connected to the network

regardless of physical location

or host operating system.

No additional software

required.

Many applications require use

of driver for printing from thirdparty applications. This can be

an all-in-one solution for some

users that do not require

advanced set up.

DPL commands can be built

directly into label formats that

can configure the printer on the

fly.

Software must be

installed on a Windowsbased host computer.

Printer must be

connected via Ethernet.

Depending on the

complexity of the

network, initial

connection may not be

possible until network

parameters are set via

another method.

Requires installation of a

driver on a Windowsbased host.

Only basic parameters

can be configured.

DPL programming

knowledge needed.

30 MP Nova Mark II User Guide

Page 40

Printer Configuration Utility (NETira CT)

NETira CT (located on the Accessories CD) is a Windows-based configuration

utility that allows the user to make changes to the existing printer set up via a

direct connection to the host computer’s serial, USB or Ethernet port.

NETira CT features include the following:

• Allows real-time control/query of printer configuration

• Define and save optimal configurations for applications

• Saved configurations can be shared with other printers and sent via email

• Download files, formats and fonts

• Query memory modules

Note: Be sure to use the NETira CT utility located on the Accessories CD that is

included with your printer. Older versions might not operate correctly with some

printers. For the latest version please visit our web site at

www.honeywellaidc.com.

Note: Be sure your printer’s firmware version is 15.04_0001 or greater.

Firmware is available from our website, for the latest version please visit our

website at www.honeywellaidc.com.

Chapter 4 — Printer Configuration

MP Nova Mark II User Guide 31

Page 41

Chapter 4 — Printer Configuration

USB Connection Requirements

Using NETira CT with a USB connection requires a Windows driver to be

installed and the driver to be set to “Print directly to the printer.” Other

connections (e.g., serial and LAN) do not require the Windows driver or this

setting. Install the Windows driver as described in on “Windows Driver” on

page 36. Then follow the steps below to set the driver settings:

1 Open the list of installed printers on your PC.

• Windows XP: Click the Start button > Settings > Printer and Faxes.

• Windows 7: Click the Start button > Devices and Printers.

2 Right-click on the printer and select Properties from the drop-down menu.

3 In the driver Properties window, click on the Advanced tab.

4 Click the “Printer directly to the printer” radio button. Then, click OK. USB

connections will now be available for NETira CT.

32 MP Nova Mark II User Guide

Page 42

Chapter 4 — Printer Configuration

How to Use NETira CT Configuration Utility

1 Once installed, launch the NETira CT configuration utility.

2 Be sure the printer is turned on. Connect the host to the printer.

a For serial connections: Query the printer by using the Auto Detect button.

This will connect the printer and retrieve the setting currently stored in the

printer.

b For USB connections: Close the Open a configuration file... dialogue

box.

• In the toolbar from the drop-down menu, select the appropriate port.

Next, click on the Query Printer Icon.

MP Nova Mark II User Guide 33

Page 43

Chapter 4 — Printer Configuration

c For Ethernet connections: Close the Open a configuration file...

dialogue box.

• In the toolbar, click on the TCP/IP Configuration icon.

• In the TCP/IP Configuration dialogue box, enter the IP address of the

printer, port: 9100, and click OK.

The IP address is displayed on the printer’s Network Report and

Configuration labels.

• In the toolbar from the drop-down menu, select TCP_IP. Next, click on

the Query Printer icon.

34 MP Nova Mark II User Guide

Page 44

Chapter 4 — Printer Configuration

3 At this point, you may browse the Printer Component categories and make

any changes necessary to the printer configuration.

4 Once complete, send the new settings to the printer using the Send button.

Note: When sending the changes to the printer, only the changes displayed on

the current page will be sent. You must click the Send button for each page that

has been modified.

MP Nova Mark II User Guide 35

Page 45

Chapter 4 — Printer Configuration

Windows Driver

The Windows driver is located on the Accessories CD included with your printer.

For the latest version please visit our website at www.honeywellaidc.com.

Note: Be sure your printer’s firmware version is 15.04_0001 or greater.

Firmware is available from our website. For the latest version please visit our

website at www.honeywellaidc.com.

Note: Be sure your printer’s USB Mode is set to “Printer.” This mode can be

viewed/changed via the printer’s front panel menu under: Communications >

USB Port > USB Device Class.

1 Place the Accessories CD included with your pinter into your computer’s CD

drive.

2 Once the CD starts, select your printer model and click Install Driver from the

menu. Follow the instructions on the screen to install.

3 When prompted, select your printer from the list. Continue to follow the on-

screen instructions to install the driver.

36 MP Nova Mark II User Guide

Page 46

Chapter 4 — Printer Configuration

Important Notes

The Windows driver functions the same as any other Windows printer. While

built-in help files provide information on all settings, there are some important

setting parameters that should be observed for trouble-free printing.

Page Set Up Tab: Stock

It is important that the Stock setting matches the size of the label you are using.

If you cannot find a match for your label, click New, and enter the dimensions for

your label.

Stock settings

Options Tab: Printer Speed and Printhead Temperature

These two settings will have the greatest effect on print quality. Some labels

stocks will require more heat and slower print speeds to generate a quality

image.

Optional printing preferences

• The Windows application software used to create the label format will likely

have a Page Set Up screen. This will also need to match the size of the label

that you are using.

MP Nova Mark II User Guide 37

Page 47

Chapter 4 — Printer Configuration

38 MP Nova Mark II User Guide

Page 48

5

Printer Operation

Use this chapter to learn the functions on the front panel, how to calibrate the

media, how the Media Position Sensor is set, and how to adjust the printhead

position and pressure.

39

Page 49

Chapter 5 — Printer Operation

Front Panel

The front panel consists of two indicator lights and one control button, as

detailed in the following sections.

Front panel button and LEDs

1 Green/Orange/Red Status LED

2 Control Button

LED Indicators

An LED indicator light provides a quick visual reference of printer operations

and conditions, as defined below:

LED Reference Table

LEDs

Color Green Orange Red

Solid Ready to print Paused or present sensor is blocked TOF sensing error; next TOF not found

Flashing Processing/busy Paused/busy Out of stock/labels, or printer jam

Off No power No power No error

40 MP Nova Mark II User Guide

Page 50

Control Button

Using the Control Button

Chapter 5 — Printer Operation

The control button performs different functions depending upon the mode of the

printer.

Ready

Button Action

Momentary Press Feeds label Pauses printer Resumes printing Clears fault

Press and hold for 5

seconds (release when

LED blinks orange)

Press and hold for 10

seconds (release when

LED blinks green)

Press and hold for 15

seconds (release when

LED blinks red)

Press and hold for 20

seconds (release when

LED blinks orange)

Press and hold for 25

seconds

(LED – Green)

Prints network

report

Performs the quick media calibration

Resets the printer’s parameters to the stored dealer settings. Resetting the printer will clear

the RAM of downloaded images, fonts and label formats, and remove temporary printer

configuration changes.

Resets parameters to factory defaults

Resets the printer

Busy/Printing

(LED – Green Flashing)

Cancels batch

Paused

(LED – Orange)

Faulted

(LED – Red)

MP Nova Mark II User Guide 41

Page 51

Chapter 5 — Printer Operation

Media Calibration

The printer is factory-calibrated for operation with most media types (both gap

and black mark). Try your media without performing any calibration adjustments

first; this will determine if the factory settings are compatible. Only perform the

calibration adjustments if you are experiencing media-registration issues.

The Quick Media Calibration should be performed first, if it fails to detect your

label media proceed to the “Manual Media Calibration” on page 43

procedure.

Quick Calibration

The Quick Media Calibration can be performed using the NETira CT

configuration utility, (see “Printer Configuration Utility (NETira CT)” on

page 31 for more information).

1 Launch the NETira CT configuration utility and query (connect) to the printer.

2 Click on the Sensor Calibration printer component.

3 Install your media in the printer and click the Quick Media button.

4 The printer will feed the media while the sensor is being calibrated. At the

end of the process, a message will be shown, indicating a successful

calibration. Values displayed in the “New Value” column may change after a

calibration.

42 MP Nova Mark II User Guide

Page 52

If the calibration is not successful, repeat the procedure. If the Quick Media

calibration continues to fail, proceed to “Manual Media Calibration” on

page 43.

Manual Media Calibration

The Manual Media Calibration is intended for use when Quick Media

Calibration printer has failed to detect the start of each label. This procedure

performs a complete recalibration of the sensors and will optimize the printer to

your media. In some instances you may need to perform a Quick Media

Calibration after the Manual Media Calibration to further optimize the printer’s

sensor.

Sensor calibration is needed to set either the black mark or the gap value of the

media sensor on the printer. The Manual Media Calibration can be performed

using the NETira CT configuration utility, proceed to “Printer Configuration

Utility (NETira CT)” on page 31.

1 Launch the NETira CT configuration utility and query (connect) to the printer.

2 Click the Manual Media button to start the manual calibration process.

Follow the on-screen instructions.

Chapter 5 — Printer Operation

3 Select the Interlabel/Gap radio button, then click OK.

4 Load the Stock by placing the face of the media over the sensor. Lower the

cover and click OK.

MP Nova Mark II User Guide 43

Page 53

Chapter 5 — Printer Operation

5 Load the Special Backing Media for Gap Media Type by peeling the labels

off the backing and place back over the sensor. Lower the cover and click

OK.

6 Remove the Stock by removing all media from the printer. Lower the cover

and click OK.

7 NETira CT will display a message indicating the process has finished.

In case of any error, a FAILED CALIBRATION message will be displayed

and you must repeat the process.

44 MP Nova Mark II User Guide

Page 54

Chapter 5 — Printer Operation

Internal Labels

Database Configuration Label and HEX-Dump Mode

The Database Configuration Label provides information including the printer

firmware version, memory allocations, enabled options and label-counter data.

1 Load the media [10.16 cm (4 in.) wide] and ribbon (if printing with a thermal

transfer media).

2 Turn the printer on.

3 When the LED is solid red, press and hold the control button until the LED

turns solid green (up to 60 seconds) and then release. The Database

Configuration Label will then print.

Note: Printed label may not match the label shown above.

4 After the printer finishes printing the Database Configuration Labels, the

printer is in HEX-Dump Mode. Cycle printer power to exit the HEX-Dump

Mode.

MP Nova Mark II User Guide 45

Page 55

Chapter 5 — Printer Operation

Media Positioning Sensor Settings

The MP Nova Mark II printers are equipped with Media Positioning Sensors

(MPS). The MPS detects the media and can be set to three (3) different modes,

depending on how and where gaps and marks are positioned on the media:

Media Positioning Sensor Specifications

Approximate Sensor Reading Point

Sensor Mode

(from Edge of Media)

DPL

1 Outer (default) 16 mm (0.63 in.) <STX>KcG0;

2 Inner 5 mm (0.2 in.) <STX>KcG1;

3 Black mark 5 mm (0.2 in,)

1 Outer sensor mode – detects label gaps about 16 mm (0.63 in.) from the

edge of the media.

Note: This is the default setting.

2 Inner sensor mode – detects label gaps about 5 mm (0.2 in.) from the edge

of the media.

3 Black-mark sensor – detects black marks on the reverse side of the media,

about 5 mm (0.2 in.) from the edge of the media.

4 To change the settings, proceed to the NETira CT menu.

Note: Changes in the printer settings should be made by qualified personnel.

46 MP Nova Mark II User Guide

Page 56

Printhead Adjustments

Printhead Position Adjustment

Note: These adjustments are only necessary when changing to media with a

different thickness or width. The pictures shown describe an MP Nova4 DT. The

process works the same for all MP Nova Mark II printers.

Changing the position of the adjustment screws may be necessary if the labels

are very narrow.

1 Check that the printer is turned off. Open the cover and fold the handle.

2 Loosen the upper nut of the adjustment screw that is to be moved by turning

it counter-clockwise.

Chapter 5 — Printer Operation

3 Slide the adjustment screw into a new position and tighten the upper nut.

Pull the handle if sliding the adjustment screw past the finger nut.

MP Nova Mark II User Guide 47

Page 57

Chapter 5 — Printer Operation

4 When tightening the upper nut, make sure it is pressing the sliding rail

against the bottom of the notch and not against the lower nut.

5 The adjustment screws should make the printhead press evenly onto the

media. Make test prints to find the correct positions.

6 For MP Nova4 DT only. On the MP Nova4 DT, the position of the printhead

itself can be changed. As default there is a 3 mm (0.12 in.) non-printable

area on the left side. To be able to print all the way to the edge of the label

the margin has to be set to 0 mm. Pull the handle. Loosen the finger nut and

slide the printhead into position. Tighten the finger nut.

48 MP Nova Mark II User Guide

Page 58

Printhead Pressure Adjustment

1 To increase the pressure on the printhead, turn the lower nuts downwards

(clockwise). This will tighten the spring.

2 To decrease the pressure on the printhead, turn the lower nuts upwards

(counter-clockwise).

Chapter 5 — Printer Operation

MP Nova Mark II User Guide 49

Page 59

Chapter 5 — Printer Operation

50 MP Nova Mark II User Guide

Page 60

6

Printer Maintenance

This chapter describes how to preform routine maintenance on your

printer, including printer adjustments and replacements for the

printhead and roller.

51

Page 61

Chapter 6 — Printer Maintenance

Printhead and Roller Cleaning

Only use cleaning cloths from Honeywell. These are specifically designed

for cleaning Honeywell thermal printers. Proceed to “Spare Parts” on

page 73 for correct type.

Note: Frequent cleaning prevents printhead and roller damage, and is

especially important in demanding environments.

• Do not use liquids or aerosols when cleaning this printer.

• Never use sharp or pointed tools when cleaning or replacing the printhead.

• Don't use any sharp object to remove labels from the print roller.

• Remove all media before starting.

1 Tear the bag.

2 Pull out the cleaning cloth.

52 MP Nova Mark II User Guide

Page 62

Chapter 6 — Printer Maintenance

3 Pull the handle and feed the cloth into the printer in the same way as

inserting the media (described in “Insert Media” on page 18). Fold the

handle and press the print key.

4 Keep the print key pressed and let the cloth pass through the printer. (This

cleans the printhead.)

Note: If the roller is clogged with labels it can easily be removed for cleaning,

see “Changeable Parts” on page 54.

MP Nova Mark II User Guide 53

Page 63

Chapter 6 — Printer Maintenance

Changeable Parts

Roller Replacement

s

Note: The pictures shown describe an MP Nova4 DT. The process is the same

for all MP Nova Mark II printers.

1 Check that the printer is turned off and open the cover (see“Open and

Close the Printer Cover” on page 11).

2 Pull the roller and the roller bearing support to the right (use the rubber

surface when pulling right).

3 Lift the left-hand end of the roller toward the interior of the printer.

4 Lift out the right-hand end of the roller.

54 MP Nova Mark II User Guide

Page 64

Chapter 6 — Printer Maintenance

5 Remove the entire roller from the printer.

6 Pay careful attention to the drive belt when removing the left-hand end of the

roller from the printer.

7 Unpack the new roller.

MP Nova Mark II User Guide 55

Page 65

Chapter 6 — Printer Maintenance

8 Insert the left-hand end of the roller (the end with the cog wheel). Check that

it fits inside the drive belt.

9 Insert the right-hand end of the roller into position.

56 MP Nova Mark II User Guide

Page 66

Chapter 6 — Printer Maintenance

10 Push the left-hand end of the roller downward into the notch until the roller is

parallel with the edge of the printer.

11 Push the roller slightly to the left.

12 Ensure that the left-hand end slots are in the groove.

13 Close the cover (see “Open and Close the Printer Cover” on page 11).

14 Turn on the printer.

MP Nova Mark II User Guide 57

Page 67

Chapter 6 — Printer Maintenance

Printhead Replacement

Note: The pictures shown describe an MP Nova4 DT. The process is the same

for all MP Nova printers.

1 Make sure the printer is turned off and open the cover.

2 Check and remember the current lateral position of the printhead; 3 mm

(0.12 in.) is the default position.

Note: Only adjustable on the MP Nova4 DT printer.

3 Carefully push the printhead downward until the finger nut becomes visible.

Unscrew the finger nut.

Note: Take care not to lose the finger nut.

58 MP Nova Mark II User Guide

Page 68

Chapter 6 — Printer Maintenance

4 Carefully remove the printhead.

5 Carefully remove the cables from the back of the printhead.

Note: There is a latch on top of the right cable. Push the latch before removing

the cable.

6 Unpack the new printhead and attach the cables to the new printhead.

Remember to handle the printhead with care!

MP Nova Mark II User Guide 59

Page 69

Chapter 6 — Printer Maintenance

7 Carefully insert the printhead into position.

8 Check that the lateral position has not changed; 3 mm (0.12 in.) is the

default position.

Note: Only adjustable on MP Nova4 DT.

60 MP Nova Mark II User Guide

Page 70

Chapter 6 — Printer Maintenance

9 Hold the printhead in place and tighten the finger nut.

10 Close the cover (see “Open and Close the Printer Cover” on page 11).

11 Turn on the printer.

MP Nova Mark II User Guide 61

Page 71

Chapter 6 — Printer Maintenance

62 MP Nova Mark II User Guide

Page 72

7

Troubleshoot Your Printer

Use this chapter to find answers to any problem situations you may

encounter while using the printer. Contact a qualified technician for

problems that persist or problems not covered in this chapter.

63

Page 73

Chapter 7 — Troubleshoot Your Printer

Troubleshooting Tips

The following section lists the symptoms and the associated sections of the

topics covered. While not every situation is addressed, you may find some tips

helpful. After a corrective action is taken, press the FEED button to clear the

alarm.

Unacceptable print quality:

• Dirty printhead: Clean the printhead (see “Printhead and Roller

Cleaning” on page 52).

• The temperature setting may be incorrect for the media being used:

Use the software program or DPL commands adjust the Heat Setting

and Print Speed

• A mismatched incorrect ribbon/media combination is being used:

Check the types being used.

• Faulty printhead: Replace it (see “Printhead and Roller Cleaning”

on page 52) or call for service.

The printer does not print or prints several labels at once:

• The labels are incorrectly loaded: See the loading instructions on the

inside cover of the printer.

• The media is not calibrated: Calibrate it (see “Media Calibration” on

page 42).

• The media sensor or sensor circuitry may be defective: Call for

service.

The ribbon does not advance (the paper advances, but ribbon does

not):

• The ribbon may be installed incorrectly: Ensure that the inked side of

the ribbon faces the labels. With most ribbons this can be verified by

rubbing paper against the ribbon; the ink should smudge the paper.

Or, if using label stock, the sticky side of a label will pull off the ink.

• A mismatched ribbon/paper combination is resulting in an insufficient

amount of friction between paper and ribbon: Ensure that the correct

type of ribbon is being used with the media.

Skipping every other label (print quality is good, but every other label

is skipped):

• The label is formatted too close to the top edge of the label: Leave

white space equal to 8-dot rows [about 0.5 mm (0.02 in.)] at the top of

the label.

64 MP Nova Mark II User Guide

• The media is not calibrated: Calibrate it (see “Media Calibration” on

page 42).

• The media sensor or media sensor circuitry may be defective: Call for

service.

Page 74

Chapter 7 — Troubleshoot Your Printer

Unable to print rotations:

• The characters are formatted outside the dimensions of the label:

Check that the row/column values provide enough room for the height

of the image being printed.

Light print on the right side of the label:

• The printer’s cover is not latched down: Latch it.

• The printhead is not properly aligned: Call for service.

Printer fails to power ON:

• The AC wall outlet may be faulty: Try another outlet.

• The power supply may be faulty: Call for service.

• Possible defective power switch: Call for service.

Label advances 2.5-5.1 cm (1-2 in.) before a fault indication:

• The ribbon may be incorrectly installed. Ensure that the inked side of

the ribbon faces the labels. With most ribbons this can be verified by

rubbing paper against the ribbon; the ink should smudge the paper.

Or, if using label stock, the sticky side of a label will pull off the ink.

• A mismatched ribbon/paper combination is resulting in an insufficient

amount of friction between paper and ribbon: Ensure that the correct

type of ribbon is being used with the media.

Label advances 30.5 cm (12 in.) before a fault indication:

• The media may not be properly loaded: Reload it (see “Insert Media”

on page 18). When loading media ensure that the media hangers

and media guides are against the media and that gaps or marks in the

labels are in line with the media sensor.

• The media sensor or media-sensor circuitry may be defective: Call for

service.

Labels move excessively from side to side during printing:

• The media may not be properly loaded: Reload it (see “Insert Media”

on page 18). When loading media ensure that the media hangers

and media guides are against the media and that gaps or marks in the

labels are in line with the media sensor.

MP Nova Mark II User Guide 65

Page 75

Chapter 7 — Troubleshoot Your Printer

66 MP Nova Mark II User Guide

Page 76

A

Printer Specifications

67

Page 77

Appendix A — Printer Specifications

MP Nova4 DT & TT

Technical Specifications: MP Nova4 DT & TT

Dimensions (H x W x L) DT: 150 x 232 x 360 mm (6” x 9-1/8” x 14-1/8”)

TT: 210 x 250 x 360 mm (8-1/4” x 9-1/2” x 14-1/8”)

Weight DT: 5.8 kg (12 lbs), TT: 7.2 kg (15 lbs)

Power pack 100/240 VAC 50-60 Hz, 325 VA

Printer technology Direct thermal and thermal transfer

Printing width 104 mm (4-1/8”)

Printing speed DT: 80 – 250 mm/second, TT: 80 – 250 mm/second

Printing resolution 203 dpi/300 dpi

Media specifications Width: 40 mm – 115 mm (1-1/2” – 4-1/2”)

Length: 10 mm (3/8”) – unlimited

Thickness: 58 µm – 180 µm

Media types Roll or fan-folded paper

External diameter of roll: maximum 215 mm (8-1/2”)

Inner core of roll: minimum 37 mm (1-1/2”) in diameter

Ink ribbon, TT Maximum width of roll: 110 mm (4-1/3”)

Inner core diameter of roll: 25 mm (1”)

Maximum length: 300 m (328 yards)

CSI/CSO maximum outer diameter of ribbon roll: 300 mm (11-4/5”)

Connections 1 x RS-232 port (up to 115 kBps)

USB port

Ethernet port [TCP/IP (LPD)]

Typefaces 10 scalable typefaces

13 scalable, emulated typefaces

Supports true type typefaces

Bar codes Most common bar codes including two-dimensional.

Examples: EAN128, Interleaved 2 of 5, Code 39 and PDF417

Graphics Supports several file types

Settings program Internal program using Web browser or NETira CT

Counters Two internal counters

Memory 32 Mb standard RAM

Time and date Internal clock, real-time

Printhead diagnostic PHD (Printhead Diagnostic)

68 MP Nova Mark II User Guide

Page 78

Appendix A — Printer Specifications

MP Nova6 DT & TT

Technical Specifications: MP Nova6 DT & TT

Dimensions (H x W x L) DT: 150 x 292 x 360 mm (6” x 11-1/2” x 14-1/8”)

TT: 210 x 310 x 360 mm (8-1/4” x 11-7/8” x 14-1/8”)

Weight DT: 6.8 kg (15 lbs), TT: 8.2 kg (16.5 lbs)

Power pack 100/240 VAC 50-60 Hz, 325 VA

Printer technology Direct thermal and thermal transfer

Printing width 168 mm (6-5/8”)

Printing speed DT: 80 – 200 mm/second, TT: 80 – 200 mm/second

Printing resolution 203 dpi

Media specifications Width: 40 mm – 175 mm (1-1/2” – 6-7/8”)

Length: 10 mm (3/8”) – unlimited

Thickness: 58 µm – 180 µm

Media types Roll or fan-folded paper

External diameter of roll: maximum 215 mm (8-1/2”)

Inner core of roll: minimum 37 mm (1-1/2”) in diameter

Ink ribbon, TT Maximum width of roll: 174 mm (6-7/8”)

Inner core diameter of roll: 25 mm (1”)

Maximum length: 300 m (328 yards)

CSI/CSO maximum outer diameter of ribbon roll: 300 mm (11-4/5”)

Connections 1 x RS-232 port (up to 115 kBps)

USB port

Ethernet port [TCP/IP (LPD)]

Typefaces 10 scalable typefaces

13 scalable, emulated typefaces

Supports true type typefaces

Bar codes Most common bar codes including two-dimensional.

Examples: EAN128, Interleaved 2 of 5, Code 39 and PDF417

Graphics Supports several file types

Settings program Internal program using Web browser or NETira CT

Counters Two internal counters

Memory 32 Mb standard RAM

Time and date Internal clock, real-time

Printhead diagnostic PHD (Printhead Diagnostic)

MP Nova Mark II User Guide 69

Page 79

Appendix A — Printer Specifications

70 MP Nova Mark II User Guide

Page 80

B

Kits, Parts & Consumables

71

Page 81

Appendix B — Kits, Parts & Consumables

Printer Options

The following printer kits are available for all MP Nova Mark II printer models.

Peel-Off Kit

The peel-off device separates the labels from the backing paper, which is rolled

up behind the printer.

Item number:

• 533541 Nova4

• 533542 Nova6

LTS – Label-Taken Sensor

The Label-Taken Sensor (LTS) enables A new label is only printed once the

previous label has been removed from the sensor. Printing is controlled by a

photocell. It is often used in association with the Peel-Off Kit.

Item number: 533625-01

215-mm Kit

The 215-mm Kit makes it possible to use media rolls with diameters up to 215

mm (8.5 in.).

Item number: 533615

72 MP Nova Mark II User Guide

Page 82

Spare Parts

Spare Parts List: MP Nova Mark II

Consumables Part Number Description

Appendix B — Kits, Parts & Consumables

501933

501934

501935

501936

533529

533667

533529

533667

533640

533640

533530

533636

533616

532089

Cables 502542

000554

001464

001463

502543

Optional 533625-01

533541

533542

533615

10 x Cleaning cloths (4")

50 x Cleaning cloths (4")

10 x Cleaning cloths (6")

50 x Cleaning cloths (6")

Printhead – 203 dpi – MP Nova4 DT

Printhead – 300 dpi – MP Nova4 DT

Printhead – 203 dpi – MP Nova4 TT

Printhead – 300 dpi – MP Nova4 TT

Printhead – 203 dpi – MP Nova6 DT

Printhead – 203 dpi – MP Nova6 TT

Print roll – MP Nova4

Print roll – MP Nova6

MPS - Media Positioning Sensor

Media guide – Lockable

Cable – Serial - (RJ-45)

Power cable - Europe

Power cable - UK

Power cable – USA & Canada

USB cable

LTS Kit (Label-Taken Sensor)

Peel-Off Kit – Nova4

Peel-Off Kit – Nova6

215-mm Kit

MP Nova Mark II User Guide 73

Page 83

Appendix B — Kits, Parts & Consumables

Consumables

General Media

Self-adhesive labels are backed with silicon-coated backing paper, from which

the label is removed. There are different types of adhesive:

• Tickets are printed on non-adhesive paper, which means there is no need

for backing paper.

• Both labels and tickets are available as rolls or as fan-folded continuous

paper tracks. Fan-folded labels and tickets are supplied in boxes, in which

labels are stored before passing through the printer.

• Perforations are used to divide labels and tickets. This makes them easier to

tear after printing.

• In order to start and stop the media during the print process, the printer is

equipped with a detector that senses any gaps or black marks.

For more detailed information about media and consumables, we recommend

you read Honeywell’s Consumables document (currently only available in

English).

MP Nova4 DT & Nova6 DT

The MP Nova DT printers use direct-thermal media, such as labels, paper and

tickets.

Direct-thermal media is made of special paper that reacts to heat and printouts

are often black. Different paper qualities are available.

MP Nova4 TT, Nova6 TT

The MP Nova TT uses a special ink ribbon, which transfers ink to media

(receiver) when subjected to heat. Labels printed using the thermal-transfer

method show a greater resistance to heat and UV-light.

74 MP Nova Mark II User Guide

Page 84

Page 85

Honeywell

www.honeywellaidc.com

MP Nova Mark II User Guide

P/N *92-2744-01*

P/N: 92-2744-01

Loading...

Loading...