Page 1

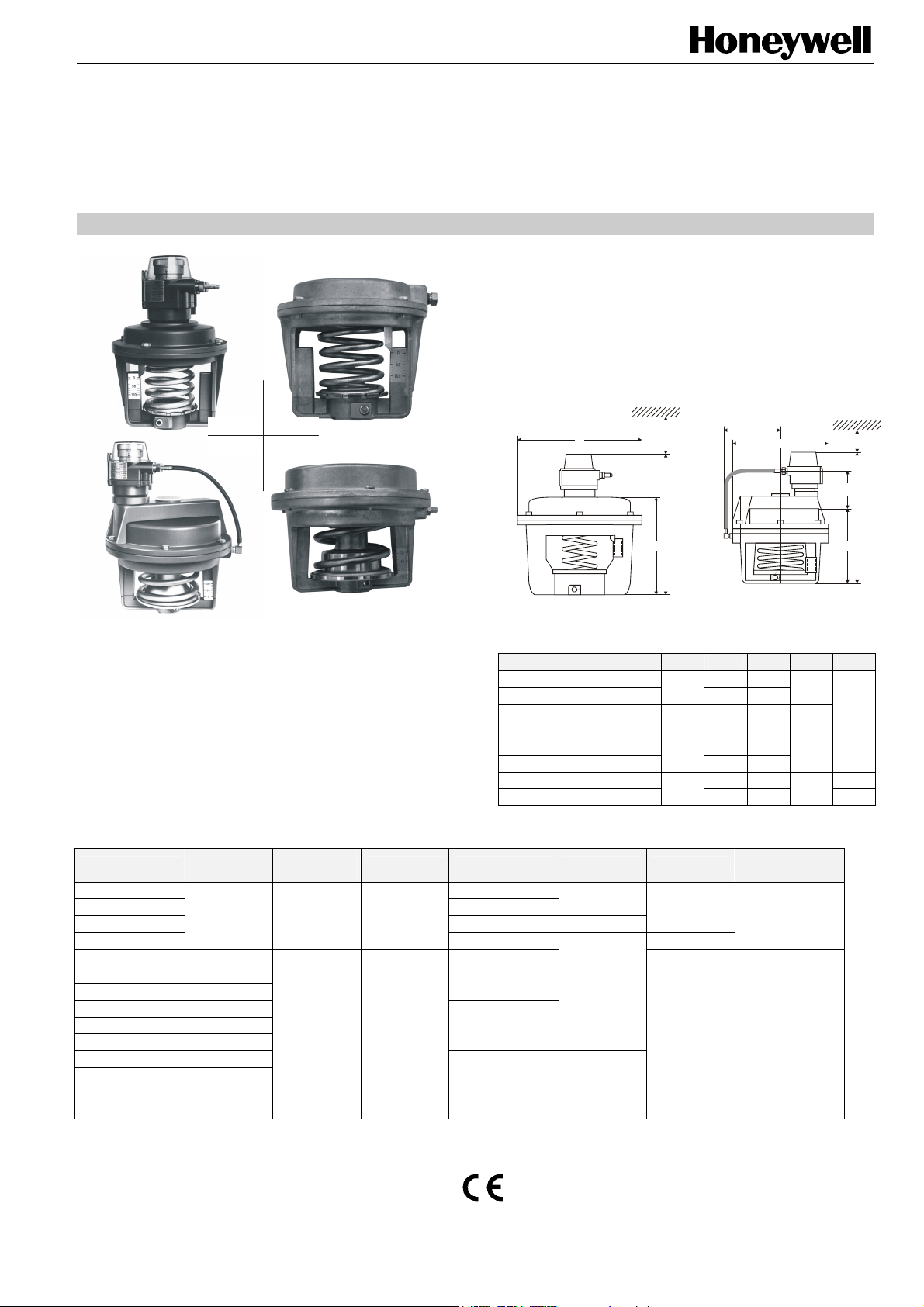

MP953A,B,C,D

PNEUMATIC VALVE ACTUATORS

PRODUCT DATA

SPECIFICATIONS

Max. operating pressure 140 kPa

Max. safe air pressure 210 kPa

Air connection barb fitting for PE tube 6x1 or

¼ " outer diameter

See also Table 2.

DIMENSIONS

MP953A

MP953C

MP953DMP953B

E

Fig. 1. MP953A,C (left) and MP953B,D

GENERAL

MP953 Pneumatic Valve Actuators are suitable for use in

conjunction with Honeywell valves V5011, V5013, V5015,

V5016, V5025, V5049, V5050, V5328, and V5329 to

provide proportional control of steam or hot and cold water

in HVAC systems.

Table 2. Specifications

order no.

MP953A5005 125 mm (5")

MP953A5039 200 mm (8")

MP953A5054 330 mm (13") 38

MP953B5003

MP953C5001 13.8 to 48.3

MP953C5019 55.2 to 82.8

MP953C5027 27.6 to 75.9

MP953C5068 13.8 to 48.3

MP953C5076 55.2 to 82.8

MP953C5084 27.6 to 75.9

MP953C5142 13.8 to 48.3

MP953C5159 27.6 to 75.9

MP953D5009 55.2 to 82.8

MP953D5025 27.6 to 75.9

pressure

range (kPa)

34.5 or 69 20.7 to 69 yes

adjustable

start point

-- no

positioner diaphragm Ø stroke stem action

MP953A, 125 (5") 192 -MP953C, 125 (5")

MP953A, 200 (8") 237 -MP953C, 200 (8")

MP953A, 330 (13") 327 -MP953C, 330 (13")

MP953B, 180 (7") 242 -- 107

MP953D, 180 (7")

180 mm (7") retracts

125 mm (5")

200 mm (8")

330 mm (13") 38

180 mm (7") 20 retracts

Model EØ F G H K

H

F

G

Table 1. Dimensions

130

210

343

180

20

20

extends

extends

K

E

-- 120

-- 165

-- 255

-- 137

max. operating

temperature

70 °C

120 °C

120

140

200

120

H

70

F

G

--

--

® U.S. Registered Trademark EN0B-0552GE51 R1009

Copyright © 2009 Honeywell Inc. • All rights reserved

Page 2

MP953A,B,C,D PNEUMATIC ACTUATORS

FEATURES

• Rolling diaphragm for long life and low hysteresis

• Easily attached to valve assembly

• May be installed after valve piping

• Slide lock feature permits simple engagement to valve

stem

• Models with positive-positioning relay available

ACCESSORIES

Extension Yokes

The extension yoke (see also Fig. 7) provides for extra air

circulation and less conduction of heat from the valve body to

the pneumatic actuator.

Recommended if the medium temperature in the valve body

is in the range of from 150 to 220 °C.

Table 3. Extension yokes

part no. applied to valves

43161276-001

43297431-001

V5049A DN 15…65

V5050A DN 15…80

V5025A DN 15…80 PN 25

V5016A DN 15…80

V5328A

V5329A

V5329C DN 40…80 PN 6

V5011R,S

V5013R,E

V5328A

V5329A

V5329C DN 15…32 PN 6

DN 40…80

DN 15…32 PN 16

PN 25/40

PN 16

Repair Kit Diaphragm

Table 4. Repair kit diaphragms

part no. model

R43312760-001 MP953A,C 125 (5")

R43161319-001 MP953A,C 200 (8")

R43161320-001 MP953A,C 330 (13")

R43180626-001 (diaphragm. a. sleeve MP953B,D 180 (7")

R43161322-001 (sleeve) MP953B,D 180 (7")

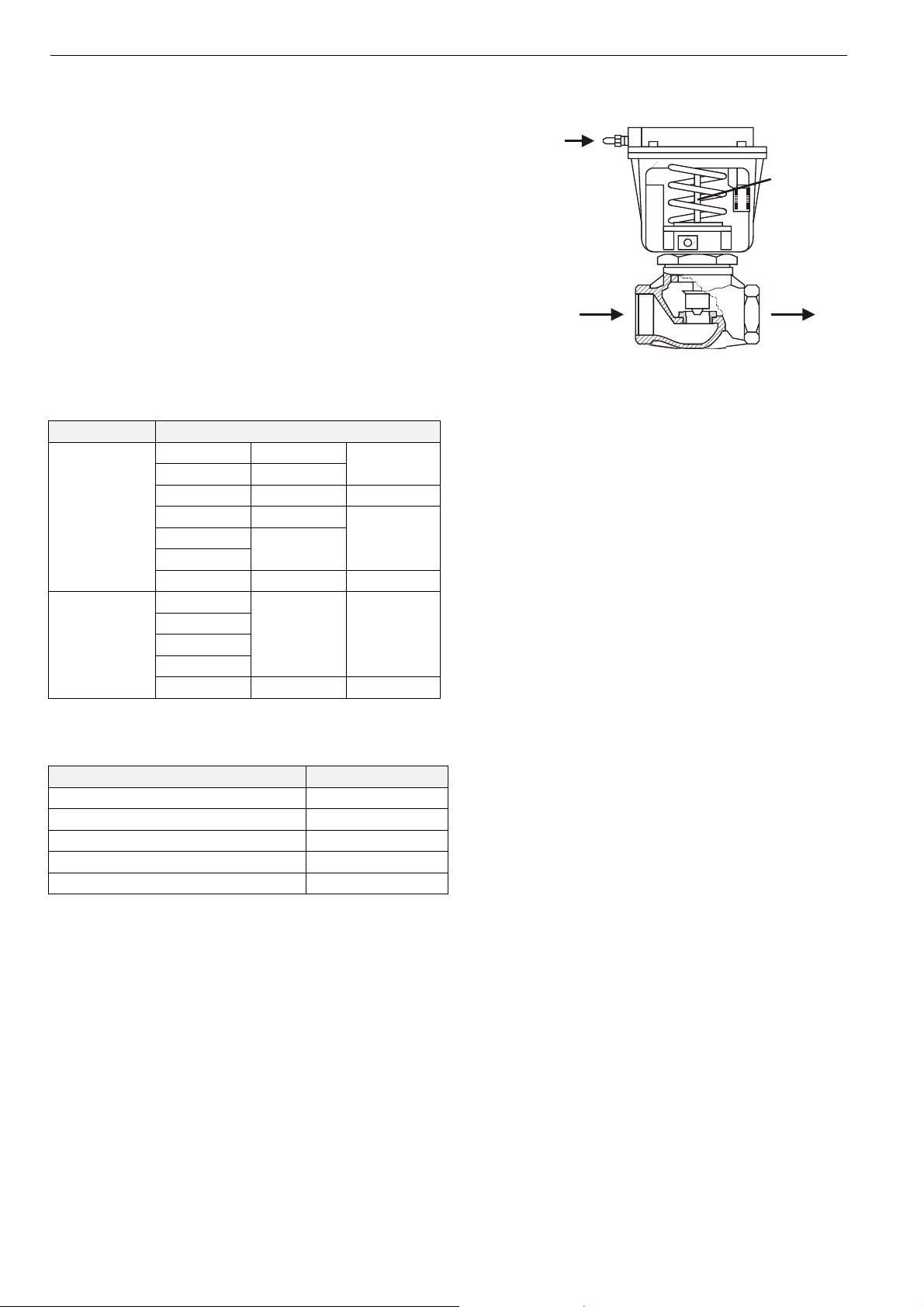

TYPICAL OPERATION

In a direct-acting (normally-open valve) system, an increase

in control air pressure will force the actuator diaphragm and

cup downward, forcing the valve stem down to proportionally

close off the flow through the valve.

Operators without the positive positioner have branch line

pressure applied to the diaphragm. Operators with positive

positioners have up to full main air pressure applied to the

diaphragm to ensure that the valve is positioned

proportionally to the branch line pressure.

control air

valve

stem

flow

Fig. 2. Typical operation

INSTALLATION

General

Ensure that the actuator has the correct size and travel to

match the valve body. Refer to the corresponding valve

product literature.

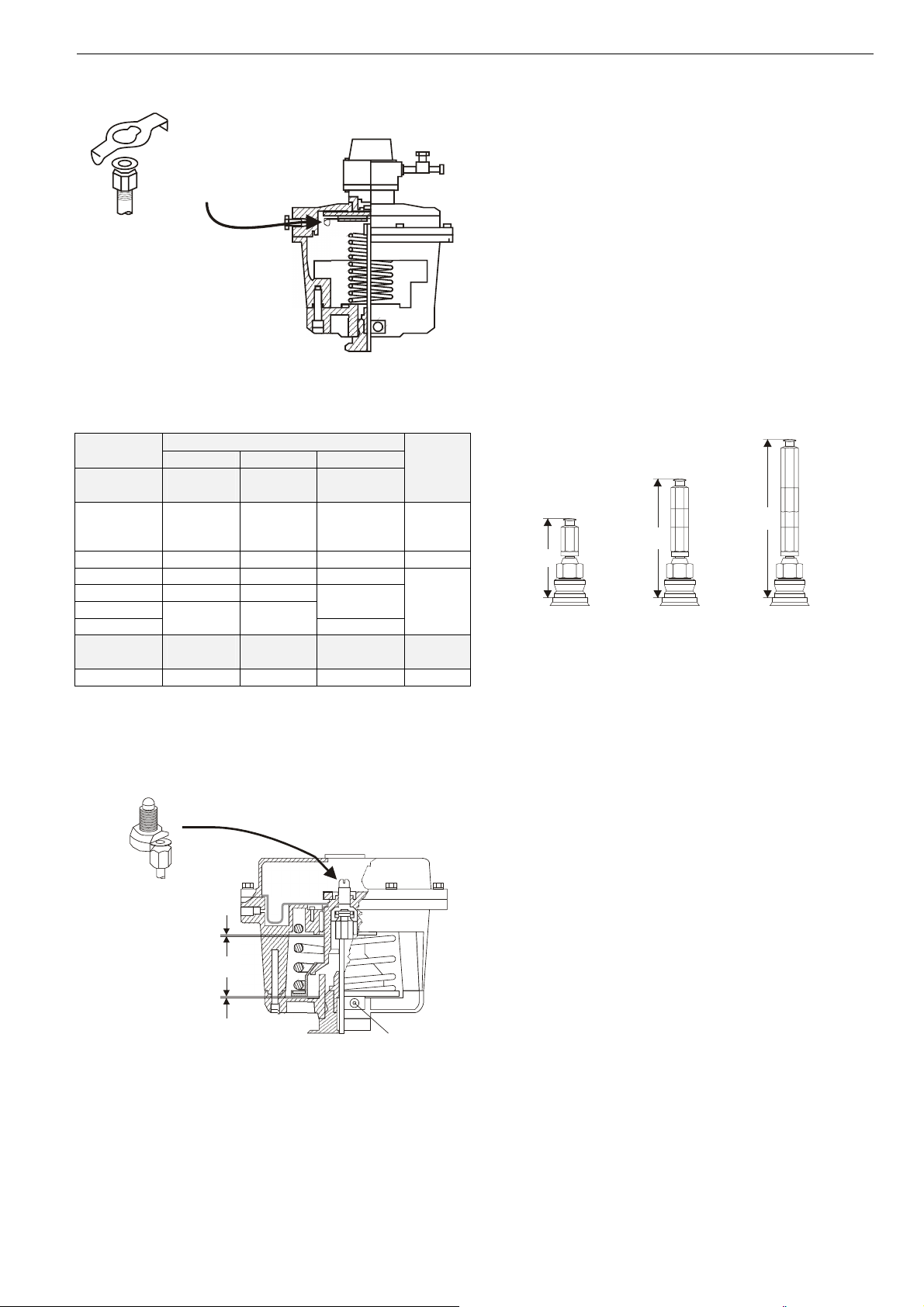

Mounting the MP953A,C (Size 5")

1. Pull the valve stem up.

2. Position the stem-locking slide so that the large hole is in

view (see also Fig. 3).

3. Set the actuator on the valve bonnet. Ensure that the stem

button passes through the hole in the stem-locking slide

and that the actuator is down flush on the shoulder of the

valve bonnet.

4. Rotate the actuator on the valve bonnet to the desired

position and tighten both actuator set screws.

5. Apply air pressure until the diaphragm cup contacts the

stem button and secure the stem button with the stemlocking slide.

Mounting the MP953A,C (Size 8" and 13")

1. If converting from smaller-size actuator, remove the

actuator by following, in reverse order, the steps outlined

in section "Mounting the MP953A,C (Size 5")".

2. Remove the stem button (see also Fig. 5).

3. Screw the stem button on the (single or double) stem

extension until it bottoms.

4. Screw the stem extension on the stem until it bottoms

(flats or locking-pin hole provided).

5. Rotate the stem extension as required to adjust dimension

"Y" as per Table 5 to the value listed, then lock the stem

extension in place by tightening the hex nut.

EN0B-0552GE51 R1009

2

Page 3

stem-locking slide

stem button

Fig. 3. Stem-locking slide

Table 5. Dimensions Y, in mm

valve size

valve series

5", 7" 8" 13"

DN

15…80 Y1

actuator size

DN

15…80 Y2

DN

100…150 Y

action

to open

3

V5016A

V5025A

89 133 190 ↑

V5328A

V5011R,S 89 133 -- ↑

V5013R,E 107 151 -V5015A -- -V5050A

V5329A,C

valve size

valve series

107 151

DN

15…65

DN

15…65

80…100

227

--

DN

↓

action

to open

V5049A 89 133 190 ↑

Mounting the MP953B,D

1. Pull the valve stem up.

2. Attach the stem connector screw to stem button (Fig. 4).

3. Place the actuator on the valve without pushing the stem

down.

stem button connector

clearance “B”

(measured when

spring is

compressed)

clearance “A”

MP953A,B,C,D PNEUMATIC ACTUATORS

4. Turn the stem connector screw by its screw-slot

counterclockwise to back out the stem button until the

actuator is in contact with the shoulder of the stem button.

5. Push the actuator onto the valve bonnet and hold it firmly

in place; tighten the two set screws

6. Load the stem by turning the stem connector screw

clockwise by its screw slot.

a) On a straight-through valve (position 1), turn the stem

connector screw until a clearance A of approx. 3 mm

(1/8") exists between the spring and the actuator

spider.

b) On a three-way valve, a clearance A and B of approx.

1.5 mm each is required at both ends of the stroke to

permit proper close-off. If there is no air on the

actuator, adjust the A clearance approx. 1.5 mm and

recheck the B clearance when air is available.

7. If clearances A and B cannot be adjusted following the

procedure outlined above, check the stem height "y" and

adjust, if necessary.

Y3

Y2

Y1

without stem

extension for

MP953A,C 5”

MP953B,D7”

Fig. 5. Stem extensions

with stem

extension for

MP953A,C 8”

with stem

extension for

MP953A,C 13”

ADJUSTMENTS

NOTE: Adjustments are necessary only for the

GRADUTROL-Relay used with the MP953A, B.

The range is adjusted using six adjustment screws (see also

Fig. 6). Note label on body of GRADUTROL-Relay. All

devices are factory-set for 35 kPa range. This point is adjusted by turning the adjustment knob. The graduations of the

external calibration scale on the knob present various values

within the different ranges. All devices are factory-set for

35 kPa start point. After completing the adjustment procedure, do not change the position of GRADUTROL-Relay

(with respect to the actuator).

set screw

Fig. 4. Attaching the stem connector screw

3

EN0B-0552GE51 R1009

Page 4

MP953A,B,C,D PNEUMATIC ACTUATORS

set screw

operating

range

70 kPa

(10 psi)

35 kPa

adjustment screw

(5 psi)

21 kPa

(3 psi)

Fig. 6. Adjustments of ranges and start points

Adjustment Check

1. Install a gauge in the pilot air line (P).

2. Adjust the set screw (see Fig. 6) so that travel just begins.

3. Increase pilot pressure (P) until travel is complete. If the

adjustment is correct, the gauge should read this pressure

within ±5 kPa of the start point pressure plus the range

setting.

EXAMPLE: Range setting 35 kPa start point setting 21 kPa.

The gauge should then read 56±5 kPa after the travel is

completed.

4. If the measured pressure should not be within the

permissible variation, fine adjustments must be done (if

necessary) using the start point adjustment knob.

MOUNTING WITH EXTENSION YOKE

For working temperatures of 150 to 220 °C (300 to 425 °F),

use of an extension yoke is mandatory for the MP953A,C (5"

and 8") and the MP953B,D actuators to protect the diaphragm

against excessive heat. Screw the stem extension (for the 5"

size) onto the stem, with the stem either pulled out or pushed

in (see Fig. 7), and adjust dimension "y" to the value listed in

Table 6. Lock stem extension into place by tightening the hex

nut, and attach the yoke.

Table 6. Mounting actuators with extension yoke

actuator "y" (mm) valve

MP953A,C, 5" 89

MP953B,D 107 V5013R,E, V5329A,C, V5050A

MP953A,C, 8"

133

151 V5013R,E, V5329A,C, V5050A

V5011R,S, V5328A, V5016A,

V5025A, V5049A

V5011R,S, V5328A, V5016A,

V5025A, V5049A

range adjustment start point adjustment

1

2

ALL screws “1” and “2”

tightened.

Three screws “1”

backed off to friction stop.

ALL screws “1” and “2”

backed off to friction stop.

1

1

MP953A + C5’’

MP953B + D

One graduation of scale on the start point adjustment knob represents a

start point change of 7 kPa. One complete turn of the start point

adjustment knob represents a start point change of 7 kPa.

2

One graduation of scale on the start point adjustment knob represents a

start point change of 3.5 kPa. Two complete turns of the start point

adjustment knob represent a start point change of 70 kPa.

One graduation of scale on the start point adjustment knob represents a

2

start point change of 2 kPa. Three complete turns of the start point

adjustment knob represent a start point change of 62 kPa

(note auxiliary scale).

MP953A + C8’’

V5011A

V5049A

V5328A

travel

travel

V5013A

V5049B

V5050A

V5329A,C

y

70 mm

Fig. 7. Extension yoke

y

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0552GE51 R1009

Loading...

Loading...