Page 1

Falcon™ Edge Self-Retracting Lifelines

USER INSTRUCTION MANUAL

I361 Rev. C / MFP9720228

May 2018

Page 2

TABLE OF CONTENTS

SOMMAIRE / ÍNDICE

Product Identication and Specications ................................3

Identication du produit et spécications / Identicación y especicaciones

del producto

English ....................................................................... 4-10

EN

Français ....................................................................11-17

FR

Español .................................................................... 18-24

ES

Appendix A: Referenced Pictures ...........................................25

Annexe A: Images référencés / Apéndice A: Imágenes referenciados

Appendix B: Fall Clearance Tables

for LEADING EDGE APPLICATIONS ................................. 26-27

Annexe B: Tableaux sur la distance de chute libre pour les tâches à

proximité de bordure /

Apéndice B: Tablas de espacio libre de caída para aplicaciones de borde

avanzado

Appendix C: Fall Clearance Diagrams

for OVERHEAD APPLICATIONS ..............................................28

Annexe C: Schémas sur la distance de chute libre pour les tâches

en hauteur / Apéndice C: Diagramas de espacio libre de caída para

aplicaciones elevadas

Appendix D: Product Labels Specications .................... 29-30

Annexe D: Étiquettes sur les Produits / Apéndice D: Etiquetas de los

Productos

Appendix E: Inspection and Maintenance Log ......................31

Annexe E: Registre D’inspection et D’entretien / Apéndice E: Registro de

Inspección y Mantenimiento

Download this manual and product specication sheets at: www.millerfallprotection.com

Descargue este manual y las hojas de especicaciones del producto en: www.millerfallprotection.com

2

Téléchargez ce manuel et les ches techniques sur: www.millerfallprotection.com

Page 3

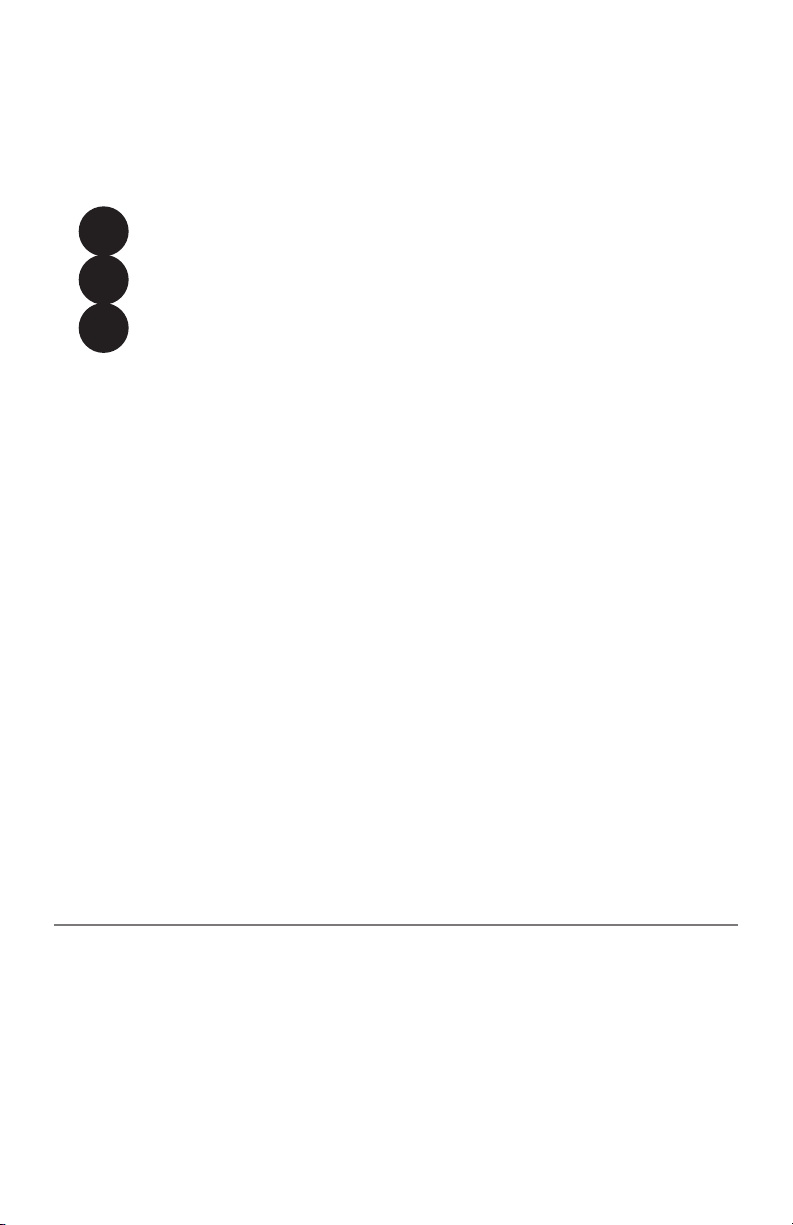

PRODUCT IDENTIFICATION

AND SPECIFICATIONS

IDENTIFICATION DU PRODUIT ET SPÉCIFICATIONS

IDENTIFICACIÓN Y ESPECIFICACIONES DEL PRODUCTO

Working

Models

Modèles

Modelos

MP30G-LE

MP50G-LE

MP20G-LE

MP20G-LEK

MP30G-LE

MP30G-LEK

MP50G-LE

MP50G-LEK

Ballistic Nylon

Nylon Ballistic / Nylon Ballistic

CarbonX Flame Retardant Fabric

CarbonX Tissu ignifugé / CarbonX

Tela de retardante de llama

FALCON EDGE

MP20G-LE

Galvanized Steel

Acier galvanisé

Acero galvanizado

Performance Specications

Spécications de performance

Especicaciones de rendimiento

Capacity*

Capacité

Capacidad

Approved for Sharp Edge

Approuvé pour bordure à angle vif

Aprobado para borde alado

Max Arrest Distance**

Distance D’Arret Max

Distancia De Detención Máx

Max Arrest Force

Force D’Arret De Chute Max

*Includes body weight, clothing and tools; if the system is used by an employee having a combined tool and body weight greater than 310 lbs. (140.6

kg), then the employer must appropriately modify the criteria and protocols to provide proper protection for such heavier weights, or the system will

not be deemed to be in compliance with the requirements of OSHA 1926.502(d)(16). [ANSI capacity range is 130 lbs.- 310 lbs. (59kg-140.6kg)].

**Overhead use / Usage aérien / Aplicaciones elevadas. ***For a 170 kg (375 lb) user, deployment is equal to 1.25 times free fall distance, h, or 1.2 m

(47 in), whichever is greater.

Refer to variable label for unit compliances. / Prière de se reporter à l’étiquette variable pour les conformités d’unités. / Consulte la etiqueta variable

para ver el cumplimiento de normas de la unidad.

Fuerza De Frenado Máx

Length

Longueur

de travail

Longitud

de trabajo

20 ft.

(6m)

30 ft.

(9m)

50 ft.

(15m)

OSHA

1926.502

& 1910.66

90-420 lbs

(40.8-190.5kg)

R ≥ 0.005 in

(0.13mm)

42 in (1.1m) for 20 ft and 30 ft models;

42 po (1,1m) pour les modèles de 20 pi et de 30 pi;

42 pulgadas (1,1m) para modelos de 20 pies y 30 pies;

54 in (1.4m) for 50 ft models

54 po (1,4m) pour les modèles de 50 pi

54 pulgadas (1,4m) para modelos de 50 pies

1,800 lbf

(8kN)

Material

Matériel

de lin de

sécurité

Material de

cuerda de

seguridad

ANSI Z359.14

Class B & LE

[Average / Moyenne /

Promedio 900 lbf (4kN)]

Lifeline

Shock

Absorber

Cover

Boîtier de

l’amortisseur

Funda del

absorbedor de

impacto

Steel Snap Hook

Crochet mousqueton

en acier / Gancho de

cierre rápido de acero

130-310 lbs

(59-140.6kg)

R ≥ 0.005 in

(0.13mm)

1,800 lbf (8kN)

Lifeline

Connector

Connecteur

de lin de

sécurité

Conector de

cuerda de

seguridad

CSA

Z259.2.2-17

Class SRL-LE

90-375 lbs

(41-170kg)

R ≥ 0.010 in

(0.25mm)

***

1,800 lbf

(8kN)

3

Page 4

EN

INSTRUCTIONS FOR USE

Personal Protective Equipment

LEADING EDGE

SELF-RETRACTING

LIFELINES

Thank you for your purchase of Honeywell

Miller fall protection equipment manufactured

by Honeywell Industrial Safety.

WARNING

All persons using this equipment

must read, understand and follow all

instructions. Failure to do so may result

in serious injury or death. Do not use

this equipment unless you are properly

trained.

It is crucial that the authorized person/user

of this equipment read and understand these

instructions. In addition, federal law requires

employers to ensure that all users are trained

in the proper installation, use, inspection, and

maintenance of fall protection equipment. Fall

protection training should be an integral part

of a comprehensive safety program.

Proper use of fall arrest systems can save

lives and reduce the potential of serious

injuries from a fall. The user must be aware

that forces experienced during the arrest of a

fall or prolonged suspension may cause bodily

injury. Consult a physician if there is any

question about the user’s ability to use this

product. Pregnant women and minor children

must not use this product.

1.0 Purpose

Self-retracting lifelines are self-contained

retractable devices designed to be used

by personnel in applications where fall

protection in combination with unrestricted

worker mobility is needed. Honeywell Miller

Falcon Edge Self-Retracting Lifelines are

specially-engineered retractable units with

unique features designed for leading edge

applications as well as overhead applications.

4

2.0 General Fall Protection

Requirements

2.1 General Requirements

All warnings and instructions shall be provided

to authorized persons/users.

All authorized persons/users must

reference the regulations governing

occupational safety, as well as applicable

ANSI or CSA standards. Please refer

to product labeling for information on

specic OSHA regulations, and ANSI and

CSA standards met by product.

Proper precautions should always be taken to

remove any obstructions, debris, material, or

other recognized hazards from the work area

that could cause injuries or interfere with the

operation of the system.

Always check for obstructions below the work

area to make sure potential fall path is clear.

Allow adequate fall clearance below the work

surface.

To minimize the potential for accidental

disengagement, a competent person must

ensure system compatibility.

All equipment must be inspected before

each use according to the manufacturer’s

instructions. Additionally, equipment must be

inspected by a competent person, other than

the user, on a regular basis, at least annually.

Any product exhibiting deformities, unusual

wear, or deterioration must be immediately

discarded in such a manner as to prevent

inadvertent further use.

Any equipment subject to a fall must be

removed from service.

The authorized person/user shall have

a rescue plan and the means at hand to

implement it when using this equipment.

Equipment must not be altered in any way.

Do not lubricate or attempt to repair this

device. Repairs must be performed only

by the manufacturer, or persons or entities

authorized in writing by the manufacturer.

Never use fall protection equipment for

purposes other than those for which it was

designed. Fall protection equipment should

never be used for towing or hoisting.

Page 5

Environmental hazards should be considered

when selecting fall protection equipment.

Equipment must not be exposed to chemicals,

heat, ames, or other environmental conditions

which may produce a harmful effect. Use in

a corrosive or caustic environment dictates

a more frequent inspection and servicing

program to ensure the integrity of the device

is maintained.

All synthetic material must be protected from

slag, hot sparks, open ames, or other heat

sources. The use of heat resistant materials is

recommended in these applications.

Do not allow equipment to come in contact

with anything that will damage it including,

but not limited to, abrasive, rough or hightemperature surfaces, heat sources, electrical

hazards, or moving machinery.

Do not expose the equipment to any hazard

which it is not designed to withstand. Consult

the manufacturer in cases of doubt.

Never remove product labels, which include

important warnings and information for the

authorized person/user.

2.2 Warnings and Limitations

Capacity

For use by ONE person only. Refer to the

product labels and to Product Identication

and Specications in this manual for the

minimum and maximum weight capacities.

Anchorage Requirements

Honeywell recommends that all anchorages

be:

• Capable of supporting 5,000 lbs (22.2 kN)

per worker attached; OR

• Designed, installed, and used, under the

supervision of a qualied person, as part of

a complete personal fall protection system

that maintains a safety factor of at least two.

Always refer to applicable national and

regional fall protection regulations and

standards to ensure compliance.

Limits of Use

Self-retracting lifelines (SRLs) are designed

for fall arrest applications only. Never use

an SRL as a restraint or positioning device.

IMPORTANT!

A fall restraint scenario could occur

anytime:

• the user fully extends the lifeline and

applies weight or stress to that lifeline;

• the user intentionally or unintentionally

locks up the lifeline, without the lifeline

fully extended, and applies weight or

stress to that lifeline.

The correct application for using an

SRL allows the user to be connected

and move freely to perform the required

work tasks without locking the lifeline

or applying tension on the lifeline at full

extension.

System Compatibility

Honeywell Miller fall protection products are

designed for use with Honeywell-approved

components only. Substitution or replacement

with non-approved component combinations or

subsystems or both may affect or interfere with

the safe function of each other and endanger

the compatibility within the system. This

incompatibility may affect the reliability and

safety of the total system.

WARNING

Always refer to the regulations and

standards regarding personal fall

arrest system component requirements

and the instructions provided with each

component being used as part of the

personal fall arrest system.

Falcon Edge Self-Retracting Lifelines

are approved for overhead and leading

edge applications. For the purposes of

this instruction manual, a leading edge

application is one whereby the user may

be anchored at foot level/working surface

or higher and the lifeline has the potential

to come in contact with an edge if the user

falls. It is recommended to anchor device

vertically overhead whenever possible. For

the purposes of this instruction manual,

an overhead application implies that there

is no slack in the lifeline when the unit is

mounted above the user and connected to

the user’s back D-ring.

5

Page 6

Falcon Edge Self-Retracting Lifelines

may be used with Honeywell-approved

horizontal lifeline systems with special

considerations. The retractable must

be capable of traveling well along the

length of the lifeline and should remain

perpedicular to the worker throughout the

course of work. It is recommended that

an on-site qualied person evaluate the

conditions before installation and use of

the retractable with the horizontal lifeline

system. In addition, always refer to the

instructions provided with the horizontal

lifeline system to ensure compatibility of

the self-retracting lifeline with the system.

This device shall be installed and used in

such a manner as to minimize the potential

for a swing fall. User must never be

exposed to a swing fall hazard.

Do not allow lifeline to become slack.

3.0 Installation/Use

WARNING

All Honeywell Miller Self-Retracting

Lifelines must be inspected and tested

for locking and retraction before each

use (see 6.0 Inspection & Maintenance).

Special Requirements, Warnings &

Limitations pertaining to All Leading

Edge Applications

• The anchor point must be at the same

height or higher than the edge at which a

fall might occur.

• The allowable angle of redirection of

the lifeline portion of the device at the

edge over which a fall might occur (as

measured between the two sides formed

by the redirected lanyard) shall be at

least 90 degrees.

• The potential for a swing fall must

be minimized for worker and lifeline

protection. The worker must never work

on the far side of an opening, opposite

the anchor point.

• Falcon Edge Self-Retracting Lifelines are

specically designed to reduce forces to

both the worker and lifeline connection

that extends beyond a leading edge.

• Applications for leading edge retractables

include steel decking, concrete and

wood surfaces. Despite the wide range of

applications for these units, surfaces in

contact with the equipment must still be

evaluated by a qualied person in regards

to creating premature wear and/or failure

due to excessive abrasion or cutting of

materials.

The installer of the SRL must not be

exposed to a fall hazard while mounting

the unit.

IMPORTANT!

Overhead mounting of a self-retracting

lifeline is typically recommended.

However, Falcon Edge Self-Retracting

Lifelines have been specically designed

and successfully tested in accordance

with the standards for

falls over a sharp edge (radius ≥ .005 in

(.13mm)).

6

horizontal use and

Special Anchorage Requirements for

Leading Edge Applications

Honeywell Industrial Safety approves a

connection height at foot level/working surface

or higher for Falcon Edge Self-Retracting

Lifelines. Minimum set-back distance is

18 in. (0.5m). Lateral edge distance (work

zone) from perpendicular to the anchor

point is dependent on set-back distance of

anchor point (see DIAGRAMS A & B and Fall

Clearance Tables in APPENDIX B).

IMPORTANT!

A Falcon Edge unit anchored at a setback distance of 25 ft. (7.62m) with a

user working at the maximum permitted

lateral edge distance (work zone) of 25

ft. (7.62m) will experience the greatest

swing fall allowed for a Falcon leading

edge application. It is imperative that

swing fall be limited as much as possible.

This can be accomplished by increasing

the set-back distance and/or limiting the

work zone. A swing fall hazard must not

exist in the path of the potential swing

fall.

Page 7

3.1 Falcon Edge

Connecon Height

Edge SetbackDistance

VercalSwing Fall

Lateral Swing Fall

30˚

30˚

30˚

30˚

Self-Retracting Lifelines

REFERENCED PICTURES ARE

LOCATED IN APPENDIX A ON

PAGE 25.

3.1.2 Connection to Harness

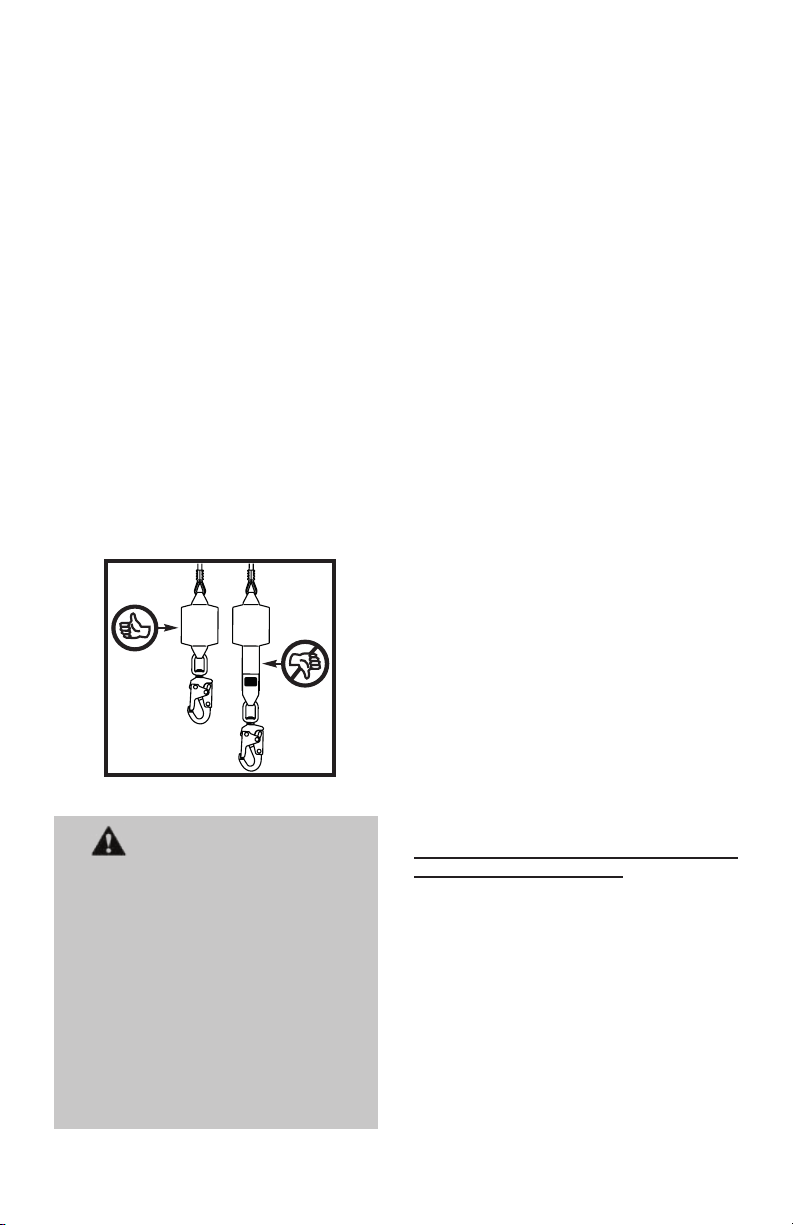

1) Connect the lifeline end connector to the

harness back D-ring (see Fig. 2). Make sure

that the connector is completely closed and

locked.

4.0 Fall Clearance

3.1.1 Installation to Anchorage

1) Locate an approved anchorage following

all general anchorage requirements as well as

the additional requirements for leading edge

applications found in 3.0. If an anchorage

connector is used, make sure it is compatible

with the anchorage and the device connector

(carabiner) in regards to strength, size, and

shape. Follow all instructions provided with the

anchorage connector.

2) Connect the body of the self-retracting

lifeline to the anchorage (or anchorage

connector, if applicable) using the device

connector (carabiner) (see Fig. 1). Make sure

that the connector is completely closed and

locked and that its gate is not in a position to

be load-bearing.

DIAGRAM A - LEADING EDGE APPLICATION

Connection

Height

Set-Back

Edge

Distance

Max Fall Arrest

Distance

+ Swing Fall

4.1 Calculating Fall

Clearance Required for

LEADING EDGE APPLICATIONS

When a Falcon Edge Self-Retracting

Lifeline is used in a leading edge

application, use the Fall Clearance

Tables in APPENDIX B on pages 2627 to determine minimum required fall

clearance.

Anchor Point

Work Radius

Lateral Edge

Distance

Swing Fall

IMPORTANT!

Max

DIAGRAM B - OVERHEAD VIEW OF LEADING EDGE APPLICATION

≤25 ft.

(7.62m)

Anchor Point

≤25 ft.

(7.62m)

Edge

Refer to Fall Clearance Tables

in APPENDIX B for lateral edge distance

(work zone) limitations with regard to

specied set-back distances of anchor point.

7

Page 8

4.2 Calculating Fall

Clearance Required for

OVERHEAD APPLICATIONS

STOP!

This section only applies when using

a Falcon Edge Self-Retracting Lifeline

in an overhead application. For leading

edge applications, refer to Fall Clearance

Tables in APPENDIX B.

It is essential to understand how to

calculate the fall clearance distance

required for each work application to avoid

contact with a lower level.

The basic calculation shown below and the

related diagrams in Appendix C on page

28 may be used to determine Required

Fall Clearance when using a self-retracting

lifeline in an overhead application. For a

more automated approach to calculating

Required Fall Clearance, access the Miller

Fall Clearance Calculator online:

www.millerfallprotection.com/fallclearance.

SELF-RETRACTING LIFELINE

FALL CLEARANCE CALCULATION

FOR OVERHEAD APPLICATIONS

(see Appendix C: Diagram 1)

[Calculation taken from work level]

Maximum Arrest Distance (MAD)

+ [Non-Standing Work Position Factor (NSF)]

+ [Swing Fall Factor (SFF)]

+ 2.5 ft. (0.8m) Safety Factor (SF)

= Required Fall Clearance (RFC)

CAUTION: Read all notes and refer to all

self-retracting lifeline fall clearance diagrams

and labels to determine exact required fall

clearance for your application.

IMPORTANT NOTES:

Self-retracting lifelines must be anchored

overhead to ensure the accuracy of the fall

clearance calculation and related information.

It is important to understand that other factors,

such as whether the user is performing work

in a standing, crouched or lying down position

and/or whether the user is working directly

below the anchor point or at an angle, can affect

fall distance when using a retractable device.

The self-retracting lifeline fall clearance

calculation assumes the user is standing. If

the user will be performing work in a crouched

or kneeling position, an additional 3 ft. (0.9m)

of fall clearance is required (see Diagram 2).

If the user will be performing work in a lying

down position, an additional 5 ft. (1.5m) of fall

clearance is required.

The self-retracting lifeline fall clearance

calculation also assumes the user is working

directly below the anchor point, minimizing

any possibility for a swing fall. In a swing

fall situation, the total fall distance will be

greater than if the user were working directly

below the anchor point (see Diagram 3). In

some applications, it may not be possible

to work directly below the anchor point. In

such a case, the worker must increase the fall

clearance distance to account for the swing

fall factor. In any case, the worker must not

be exposed to a potential swing fall where

contact with another object may occur (see

Diagram 4).

The maximum arrest distance [free fall (FF) +

deceleration (D)] varies by retractable. Always

refer to the labels on the specic unit to

determine the maximum arrest distance.

If there is any question about

calculating fall clearance distance,

please contact Honeywell Technical Service:

1-800-873-5242 (press 4)

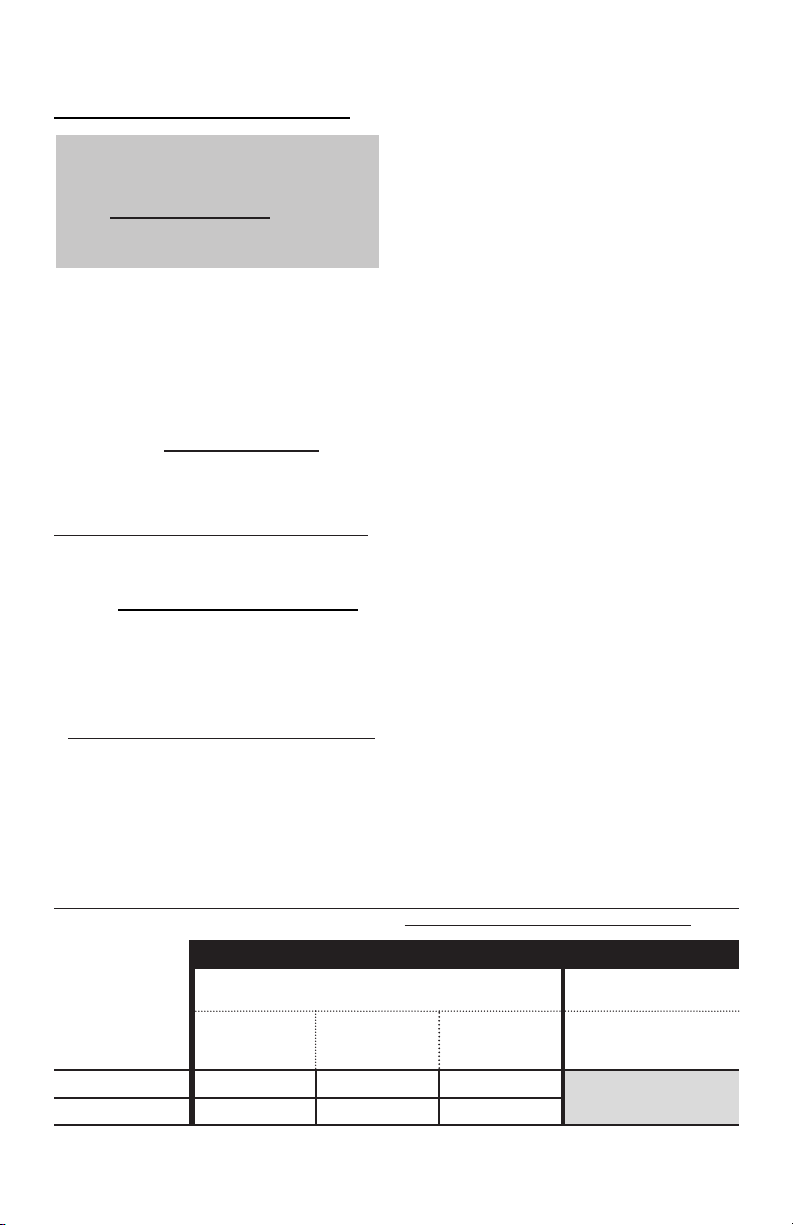

TABLE 1: Minimum Required Fall Clearances - OVERHEAD APPLICATIONS ONLY

Minimum Required Fall Clearance from Work Level to Lower Level*

Working Directly

Below Anchor Point

Maximum

Arrest Distance

of SRL

42 in (1.1m)

54 in (1.4m)

*This chart shows general minimum fall clearances required for an overhead application. An exact calculation, based on the SRL

to be used and an assessment of the work site and conditions that may affect the worker’s fall clearance, must be performed.

In Standing

Position

6 ft (1.8m) 9 ft (2.7m) 11 ft (3.4m)

7 ft (2.1m) 10 ft (3m) 12 ft (3.7m)

In Kneeling/

Crouched

Position

In Lying Down

Position

NOT Working Directly

Below Anchor Point

In Potential

Swing Fall Position

Varies - Additional Fall

Clearance Required

8

Page 9

5.0 Inspection and

Maintenance

5.1 Inspection and Operation

Testing

Honeywell’s inspection requirements incorporate

the criteria established by current safety

standards. The inspection criteria for the

equipment shall be set by the user’s organization,

such that it equals or exceeds the criteria

required by the manufacturer and the standards

with which the organization elects to comply.

Equipment shall be thoroughly inspected

and operationally tested by the user before

each use, and additionally, by a competent

person, other than the user, at least annually

(or semi-annually per ANSI A10.32) for:

[*ANSI Z359.14 and CSA Z259.2.2-17 provide

additional inspection requirements based on type

of use and conditions of use. Refer to Table 2 for

compliance with these standards. (*See note in 6.2

Maintenance.)]

Absence or illegibility of markings/labels.

Absence of any elements affecting the

equipment form, t or function.

Evidence of defects in or damage to the

cable lifeline including cuts, broken strands,

corrosion, kinks, chemical attack, abrasion,

alteration, excessive aging, and excessive wear.

CAUTION: Always wear gloves when

inspecting cable lifelines; broken strands

can cause injury!

Operational damage to the lifeline.

Retraction - With the device in a mounted

position, test the lifeline retraction and tension

by pulling out several feet of the lifeline and allow

to retract back into the unit. Always maintain

a light tension on the lifeline as it retracts. The

lifeline should pull out freely and retract all the

way back into the unit. If the lifeline does not

pull out smoothly or sticks when retracting, pull

all the lifeline out of the housing and allow it to

retract slowly under tension. Do not use the unit

if the lifeline does not retract properly.

CAUTION: Do not let go of the lifeline and

let it retract on its own; always maintain

tension while it retracts!

Lockup Mechanism - The braking mechanism

can be tested by grasping the lifeline and

applying a sharp steady pull downward which

will engage the brakes. There should be no

slippage of the lifeline while the brakes are

engaged. Once tension is released, the brakes

will disengage and the unit will return to the

retractable mode.

Evidence of defects in or damage to

hardware elements including cracks, breaks,

rough or sharp edges, deformation, corrosion,

chemical attack, excessive heating, pitted

surfaces, alteration, and excessive wear.

TABLE 2: ANSI Z359.14 and CSA Z259.2.2-17: Inspection Requirements

Type of

Use

Infrequent

to Light

Moderate

to Heavy

Severe to

Continuous

Notes:

1) Failure of a worker to perform “before each use” inspection or failure of an inspection by a worker shall

initiate the requirement for inspection by a competent person.

2) Failure of a competent person to perform inspections as specied in this Table, or failure of an inspection by

the competent person shall initiate product revalidation or disposal.

3) Determination of the type of use category shall be determined by a competent person.

4) A SRD that is considered non-repairable, or not designed for disassembly such that internal inspection is not

possible without rendering it unserviceable, is not subject to revalidation inspection. These SRD’s shall have

service life and other inspection requirements as provided by the manufacturer’s instructions.

Application

Examples

Rescue & conned space,

factory

maintenance

Transportation,

residential

construction,

utilities, ware-

house

Commercial

construction,

oil & gas,

mining

Conditions of Use

Good storage conditions,

indoor or infrequent outdoor

use, room temperature,

clean environments

Fair storage conditions, indoor and extended outdoor

use, all temperatures, clean

or dusty environments

Harsh storage conditions,

prolonged or continuous out-

door use, all temperatures,

dirty environment

Worker

Inspection

Frequency

Before each

use

Before each

use

Before each

use

Competent

Person

Inspection

Frequency

Annually At least every 5

Semi-

annually to

annually

Quarterly

to semiannually

APPLIES TO CSA

ONLY

Product Revalida-

tion Frequency

years but not more

than intervals

required by the

manufacturer

At least every 2

years but not more

than intervals

required by the

manufacturer

At least annually

but not more than

intervals required by

the manufacturer

9

Page 10

Operational damage to the hardware.

Snap Hook/Carabiner - The connector

gate (keeper) should seat into the nose

without binding and should not be distorted

or obstructed. The gate spring should exert

sufcient force to rmly close the gate. The

gate locking mechanism must prevent the gate

from opening when closed. It is permissable to

lubricate snap hooks and carabiners if needed.

Evidence of defects in or damage to the

housing and/or loose/missing fasteners.

Evidence of defects in or damage to

shock absorber pack including holes, tears,

deterioration, loose or broken stitching.

Evidence of deployed or activated fall load

indicators.

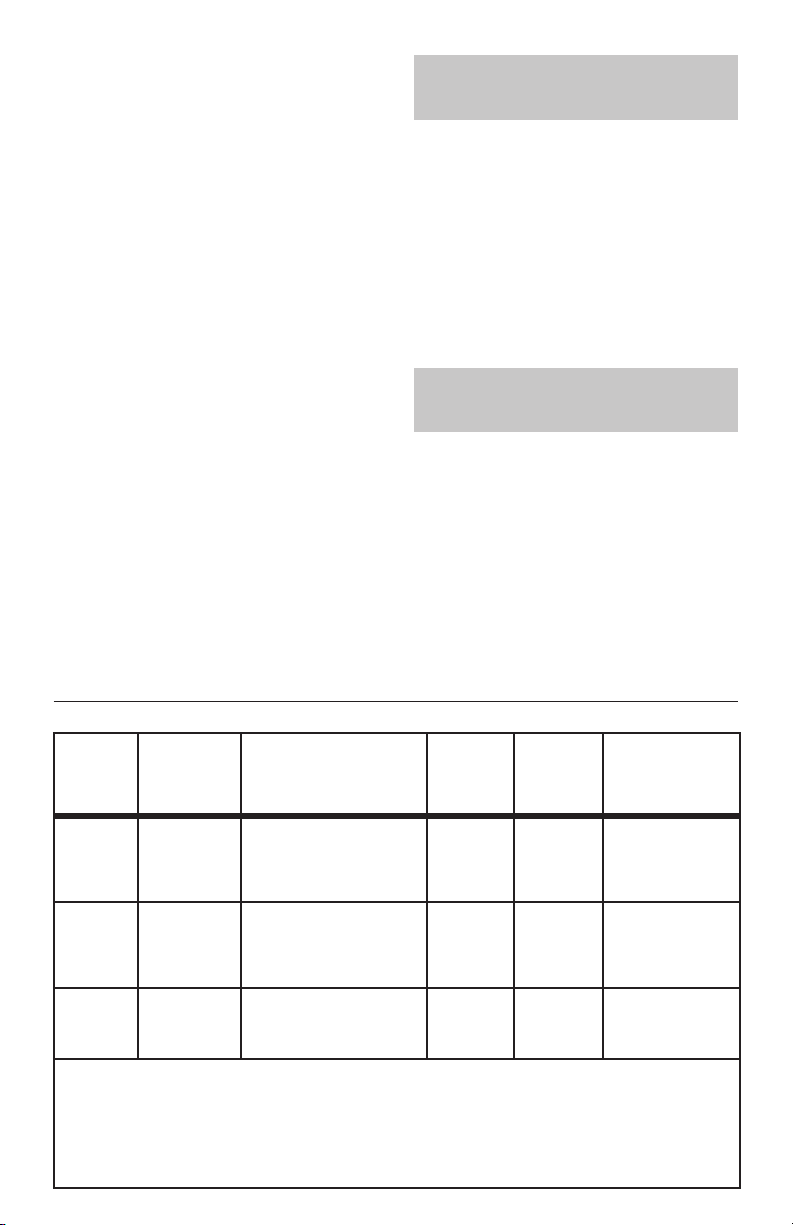

Falcon Edge Self-Retracting Lifelines are

equipped with a load indicator built into the

shock absorber pack. When subjected to

fall arrest forces the internal white energy

absorber will become exposed or deploy as

shown.

5.2 Maintenance

Basic care of all fall protection equipment

will prolong its service life and will contribute

toward the performance of its vital safety

function.

Servicing

Servicing of Honeywell Miller self-retracting

lifelines must only be carried out by Honeywell

Industrial Safety or persons or entities

authorized in writing by Honeywell. A record

log of all servicing and inspection dates for

this device must be maintained. Only original

Honeywell replacement parts are approved

for use in this device. Contact your Honeywell

distributor or call Honeywell Technical Service

at 1-800-873-5242 for a return authorization

number.

Honeywell Miller self-retracting lifelines

require no annual factory recertication.*

*Honeywell, as the manufacturer, does not

require annual factory recertication for

Honeywell Miller self-retracting lifelines.

Ultimately, however, the end-user/company

must ensure compliance with applicable

national and regional fall protection

regulations and may elect to follow additional

voluntary standards with regard to inspection

and recertication requirements.

WARNING

When inspection and operational

testing reveals defects in or damage to

equipment, inadequate maintenance of

equipment, or evidence of equipment

having been exposed to fall arrest forces

or loading, the equipment shall be

immediately removed from service.

Falcon Edge Self-Retracting Lifelines

are repairable devices. Units removed

from service, shall be marked and

tagged “UNUSABLE” and returned

for service in accordance with the

manufacturer’s instructions.

10

Cleaning and Storage

This device must be kept clean and free of

contaminants. Periodically clean the exterior

of the device and wipe the lifeline using a

damp cloth and mild detergent.

When not in use, equipment shall be stored

in a manner as to preclude damage from

environmental factors, such as temperature,

light, UV, excessive moisture, oil, chemicals

and their vapors, or other degrading elements.

The lifeline should be fully retracted into

the device when not in use.

Page 11

FR

MODE D’EMPLOI

Équipements de protection

individuelle

LEADING EDGE

SELF-RETRACTING

LIFELINES

Nous vous remercions pour votre achat

d’équipement de protection contre les chutes

Honeywell Miller fabriqué par Honeywell

Industrial Safety.

AVERTISSEMENT

Toutes les personnes utilisant cet

équipement doivent lire, comprendre et

observer l’intégralité des instructions.

Le non-respect de cette consigne peut

entraîner des blessures, ou même le

décès. N’utilisez cet équipement que si

vous avez été correctement formé.

Il est essentiel que la personne autorisée à

utiliser cet équipement de protection contre

les chutes lise et comprenne ces instructions.

De plus, la loi fédérale oblige les employeurs

à s’assurer que tous les utilisateurs ont reçu

une formation sur la manière appropriée

d’installer, d’utiliser, d’inspecter et d’entretenir

les équipements antichute. La formation sur la

protection contre les chutes devrait faire partie

intégrante d’un programme global de sécurité.

L’utilisation adéquate de systèmes d’arrêt

de chute peut épargner des vies et réduire

le risque de blessures graves consécutives

à une chute. L’utilisateur doit être sensibilisé

au fait que les forces subies lors d’un arrêt de

chute ou d’une suspension prolongée peuvent

causer des blessures corporelles. Dans

l’incertitude sur la capacité de la personne à

utiliser ce produit, consulter un médecin. Les

femmes enceintes et les mineurs ne doivent

pas utiliser ce produit.

1.0 Objet

Les lins de sécurité autorétractables sont

des dispositifs rétractables conçus pour être

utilisés par le personnel lorsqu’une protection

antichute n’entravant pas la mobilité de

l’ouvrier est nécessaire pour réaliser leur

travail. Les lins de sécurité autorétractables

à proximité de bordure Falcon de Honeywell

Miller sont des dispositifs rétractables de

conception spéciale qui présentent des

caractéristiques uniques destinées aux

tâches près des bordures ainsi que pour des

utilisation suspendues.

2.0 Exigences générales de

protection contre les chutes

2.1 Exigences Générales

Les avertissements et instructions devront

être mis à la disposition des personnes/

utilisateurs autorisés.

Les personnes/utilisateurs autorisés doivent

se reporter à la réglementation applicable en

matière de sécurité en milieu de travail, ainsi

qu’aux normes ANSI ou CSA pertinentes.

Veuillez vous reporter aux étiquettes apposées

sur les produits pour des informations plus

détaillées sur les règlements OSHA, ainsi

que les normes ANSI et CSA auxquelles ces

produits sont conformes.

Des précautions doivent être prises an

d’éliminer de la zone de travail les obstacles,

débris, matériaux ou autres éléments

présentant un danger et qui pourraient causer

des blessures ou nuire au bon fonctionnement

du système.

Toujours vérier qu’il n’y a pas d’obstacles en

dessous de la zone de travail et que le trajet

en cas de chute est dégagé.

Prévoir une distance de dégagement

sufsante en dessous de la surface de travail.

Pour minimiser le risque de décrochage

accidentel, une personne compétente doit

s’assurer de la compatibilité du système.

L’ensemble de l’équipement doit être inspecté

avant chaque utilisation conformément aux

instructions du fabricant. En outre, l’équipement

doit être inspecté par une personne

compétente, autre que l’utilisateur, sur une

base régulière, au moins annuellement.

Tout produit présentant des déformations,

usure inhabituelle ou détérioration doit être

immédiatement jeté dans une telle manière à

empêcher l’utilisation par inadvertance.

Tout équipement soumis à une chute doit être

mis hors service.

L’utilisateur doit posséder un plan de

sauvetage et avoir les moyens de le mettre en

œuvre lorsqu’il utilise cet équipement.

Il est interdit de modier l’équipement, de

quelque façon que ce soit. Ne lubriez ou tenter

de réparer ce dispositif. Les réparations doivent

être effectuées uniquement par le fabricant de

l’équipement, ou par des personnes ou entités

autorisées par écrit par le fabricant.

11

Page 12

Ne jamais utiliser un équipement de protection

contre les chutes dans un but autre que celui

pour lequel il a été prévu. Ne jamais utiliser un

tel équipement pour remorquer ou lever une

charge.

Dans la sélection d’équipement de protection

contre les chutes, on doit tenir compte des

risques environnementaux. Les équipements

ne doivent pas être exposés aux dangers

environnementaux ni aux produits chimiques

qui peuvent produire un effet nocif. Pour

utiliser l’équipement dans des environnements

hautement corrosifs ou caustiques, il faut

mettre en place un programme d’inspection

et d’entretien à intervalles rapprochés pour

maintenir l’intégrité du dispositif.

Les matériaux synthétiques doivent être

protégés contre le laitier (de soudure), les

étincelles chaudes, les ammes nues ou

autres sources de chaleur. Dans de tels cas,

on recommande d’utiliser des matériaux

résistant à la chaleur.

Ne pas laisser l’équipement venir en

contact avec quoi que ce soit qui pourrait

l’endommager, comprenant (sans y être

limité) : les surfaces rugueuses, abrasives ou

chaudes, les sources de chaleur, les dangers

électriques ou les pièces mobiles.

Ne pas exposer les équipements aux dangers

pour lesquels ils n’ont pas été conçus. En cas

de doute, consulter le fabricant.

Ne jamais ôter une étiquette apposée sur un

produit; des informations et avertissements

importants y sont en effet inscrits à l’intention de

la personne/de l’utilisateur autorisé.

2.2 Avertissements et Limitations

Capacité

Pour utilisation par UNE seule personne.

Pour connaître la capacité de charge

minimale et la capacité de charge

maximale, se reporter aux étiquettes de

produit et à la section « Identication du

produit et spécications » du présent

manuel.

Compatibilité du Système

Honeywell Miller produits de protection

contre les chutes sont conçus pour être

utilisés avec des composants approuvés par

Honeywell seulement. Les substitutions ou

les remplacements par des combinaisons

de composants ou de sous-systèmes non

approuvés peuvent nuire à leur sécurité de

fonctionnement réciproque et ainsi remettre en

cause la compatibilité des éléments du système.

Cette incompatibilité peut nuire à la sécurité et à

la abilité de l’ensemble du système.

12

AVERTISSEMENT

Toujours se référer aux normes et

règlements relatifs aux composants

formant le système d’arrêt de chute,

ainsi qu’aux instructions fournies

avec chaque composant utilisé dans le

système d’arrêt de chute individuel.

Exigences relatives aux

ancrages

Honeywell recommande que tous les ancrages

soient:

• Capable de supporter 5 000 lb (22,2 kN) par

travailleur attaché; OU

• Conçu, installé et utilisé, sous la supervision

d’une personne qualiée, dans le cadre d’un

système complet de protection contre les

chutes qui maintient un facteur de sécurité

d’au moins deux.

Toujours se référer aux réglementations et aux

normes nationales et régionales en matière de

protection contre les chutes applicables pour

assurer la conformité.

Limites d’utilisation

Les câbles de sécurité autorétractables

sont conçus pour arrêter les chutes

seulement. N’utilisez jamais un câble de

sécurité autorétractable comme dispositif

de retenue ou de positionnement.

REMARQUE IMPORTANTE!

Un scénario de retenue antichute peut se

produire à tout moment :

• l’utilisateur déploie complètement

le câble de sécurité et applique un

poids ou une contrainte à ce câble de

sécurité;

• l’utilisateur, intentionnellement ou

non, bloque le câble de sécurité sans

que celui-ci soit entièrement déployé

et applique un poids ou une contrainte

à ce câble de sécurité.

L’usage correct d’un câble de sécurité

autorétractable permet à l’utilisateur

d’être rattaché et de se déplacer

librement pour exécuter des tâches

de travail sans verrouiller le câble de

sécurité ni appliquer de la tension sur le

câble de sécurité pleinement déployé.

Les lins de sécurité autorétractables

à proximité de bordure Falcon sont

approuvés pour les tâches en hauteur et

près des bordures. Aux ns du présent

manuel d’instructions, une tâche à

proximité de bordure est une tâche lors de

Page 13

laquelle l’utilisateur peut être amarré à

hauteur des pieds ou de la surface de

travail minimum et que le lin de sécurité

risque d’entrer en contact avec une

bordure en cas de chute de l’utilisateur.

Il est recommandé dexer le dispositif à

la verticale en hauteur dès que possible.

Dans le cadre de ce manuel d’instructions,

une application avec ancrage en hauteur

implique que le cordage de sécurité ne

comporte aucun jeu lorsque l’unité est

montée au-dessus de l’utilisateur et

connectée à l’amarrage métallique dorsal

de l’utilisateur.

Les lins de sécurité autorétractables à

proximité de bordure Falcon peuvent être

associés, avec précaution particulière, à

des systèmes à lin de sécurité horizontaux

approuvés par Honeywell. Le dispositif

rétractable doit pouvoir se déplacer sur

toute la longueur du lin de sécurité et

rester perpendiculaire à l’ouvrier pendant

sa tâche. Avant d’installer et d’utiliser le

dispositif rétractable avec le système à lin

de sécurité horizontal, il est recommandé

de faire évaluer les conditions par une

personne qualiée sur place. En outre,

toujours se reporter aux instructions

fournies avec le système à lin de sécurité

horizontal pour s’assurer de sa compatibilité

avec le lin de sécurité autorétractable.

Ce dispositif doit être installé et utilisé de

manière à minimiser le risque de chute en

balancier. L’utilisateur ne doit jamais être

exposé à une chute en balancier.

Faire en sorte que le câble de sécurité ne

devienne pas lâche.

Exigences particulières,

avertissements et limitations

concernant les applications à

proximité de bordure

• Le point d’ancrage doit être à la même

hauteur ou plus haut que le bord où une

chute peut se produire.

• L’angle admissible de redirection doit

être d’au moins 90 degrés pour la partie

de la ligne de vie du dispositif au bord

d’attaque duquel une chute pourrait

se produire (telle que mesurée entre

les deux parties formées par la longe

redirigée).

• Le risque d’un effet pendulaire doit être

réduit pour la protection du travailleur

et de la ligne de vie. Le travailleur ne

doit jamais travailler sur la face cachée

de l’ouverture, à l’opposé du point

d’ancraget.

• Les lins de sécurité autorétractables

à proximité de bordure Falcon sont

spécialement conçus pour réduire les

contraintes sur l’ouvrier et le cordage du

lin de sécurité qui s’étend au-delà d’une

bordure.

• Les applications destinées aux dispositifs

rétractables à proximité de bordure

comprennent le platelage en tôle et les

surfaces en béton et en bois. Malgré le

large éventail d’applications pour ces

dispositifs, les surfaces en contact avec

l’équipement doivent être évaluées par

une personne qualiée pour vérier qu’il

n’ y aura aucune usure prématurée et/

ou défaillance due à une abrasion ou

découpe excessive des matériaux

3.0 Installation/Utilisation

AVERTISSEMENT

Tous les lins de sécurité autorétractables

de Honeywell Miller doivent être inspectés

et testés pour vérier leur verrouillage et

rétraction avant chaque utilisation (voir

6.0 Inspection et entretien).

L’installateur du lin de sécurité

autorétractable ne doit pas être exposé

à un risque de chute lorsqu’il installe le

dispositif.

REMARQUE IMPORTANTE!

Il est généralement recommandé d’installer

un lin de sécurité autorétractable en hauteur.

Cependant, les lignes de vie rétractables

de bordure Falcon ont été spécialement

conçues et éprouvées avec succès pour

répondre aux normes pour utilisation

horizontale et pour les chutes avec arêtes

vives (rayon de ≥ 0,005 po [0,13 mm]).

Exigences d’ancrage spéciales pour

les tâches à proximité de bordure

Honeywell Industrial Safety autorise une

hauteur d’amarrage au niveau des pieds ou

de la surface de travail minimum pour les

lignes de vie rétractables Falcon. Distance

de recul minimale de 18 po (0,5 m). La

distance latérale par rapport à la bordure

(zone de travail) du point perpendiculaire à

l’ancrage dépend de la distance de recul du

point d’ancrage (voir SCHÉMAS A et B, et les

tableaux sur la distance de chute libre dans

l’ANNEXE B).

13

Page 14

REMARQUE IMPORTANTE!

Connecon Height

Edge SetbackDistance

VercalSwing Fall

Lateral Swing Fall

30˚

30˚

30˚

30˚

Si un dispositif de bordure Falcon est

ancré à une distance de recul de 25 pi

(7,62 m) et que l’utilisateur travaille à une

distance latérale par rapport à la bordure

(zone de travail) de 25 pi (7,62 m),

celui-ci connaîtra la chute en balancier

maximale autorisée pour un limiteur

de chute personnel à proximité de la

bordure Falcon. Il est impératif de limiter

le plus possible la chute en balancier.

Pour cela, il faut augmenter la distance

de recul et/ou limiter la zone de travail.

Aucun danger ne doit se trouver sur la

trajectoire de l’ouvrier victime d’une

chute en balancier.

3.1 Les lins de sécurité autorétractables à proximité de

bordure Falcon

LES IMAGES RÉFÉRENCÉES

SE TROUVENT À L’ANNEXE A,

PAGE 25.

3.1.1 Fixation à un ancrage

1) Trouver un ancrage approuvé qui

est conforme à toutes les exigences

d’ancrage générales ainsi qu’aux exigences

supplémentaires relatives aux tâches à

proximité de bordure présentées à la section

3.0. Si un connecteur d’ancrage est utilisé,

s’assurer qu’il est compatible avec l’ancrage et

le dispositif de raccordement (mousqueton) sur

le plan de la résistance, des dimensions et de la

forme. Respecter l’ensemble des instructions

fournies avec le connecteur d’ancrage.

2)

Raccorder le corps de la ligne de vie

rétractable à l’ancrage (ou au connecteur

d’ancrage, le cas échéant) à l’aide du

connecteur (mousqueton) (voir g. 1). S’assurer

que le connecteur est complètement fermé et

verrouillé, et que son doigt n’est pas en position

de charge.

3.1.2 Raccordement au harnais

1) Raccorder le connecteur d’extrémité du lin

de sécurité à l’anneau en D arrière du harnais

(voir g. 2). S’assurer que le connecteur est

entièrement fermé et verrouillé.

4.0 Distance de chute libre

4.1 Calcul de la distance de

chute libre requise pour les

TÂCHES À PROXIMITÉ DE

BORDURE

REMARQUE IMPORTANTE!

Lorsqu’un lin de sécurité autorétractable

de bordure Falcon est utilisé dans une

tâche à proximité de bordure, se servir des

tableaux sur la distance de chute libre qui

gurent dans l’ANNEXE B aux pages 26 et

27 pour déterminer la distance de chute

libre minimale requise.

4.2 Calcul de la distance de

chute libre requise pour les

TÂCHES EN HAUTEUR

SCHÉMA A - APPLICATION À PROXIMITÉ DE BORDURE

Hauteur

d’amarrage

Distance

Bordure

Distance d’arrêt de

+ chute en balancier

de recul

chute max.

Point d’ancrage

Rayon de travail

max.

Distance latérale

par rapport à la

bordure

Chute en balancier

SCHÉMA B - VUE AÉRIENNE DE L’APPLICATION À PROXIMITÉ DE BORDURE

14

≤25 pi

(7,62 m)

Point d’ancrage

≤25 pi

(7,62 m)

Se reporter aux tableaux sur la distance de chute libre

de l’ANNEXE B pour connaître les limitations relatives

à la distance latérale (zone de travail) par rapport aux

distances de recul du point d’ancrage précisé.

Bordure

Page 15

Cette section s’applique seulement

à l’utilisation du lin de sécurité

autorétractable de bordure Falcon dans

des utilisations suspendues. Pour les

tâches à proximité d’une bordure, se

reporter aux tableaux sur la distance de

chute libre dans l’ANNEXE B.

Pour ne pas heurter le niveau inférieur, il

est essentiel de savoir calculer la distance

de chute libre requise pour chaque tâche.

Le calcul de base indiqué ci-dessous et les

schémas associés qui gurent en Annexe

C à la page 28 peuvent être utilisés pour

déterminer la distance de chute libre requise

lorsqu’un lin de sécurité autorétractable est

utilisé dans une tâche en hauteur. Pour une

approche plus automatisée du calcul de la

distance de chute libre requise, consulter la

page Internet du calculateur de distance de

chute libre de Miller :

www.millerfallprotection.com/fallclearance

CALCUL DE LA DISTANCE DE CHUTE

LIBRE DES FILINS DE SÉCURITÉ

AUTORÉTRACTABLES POUR LES

TÂCHES EN HAUTEUR

(voir Annexe C : Schéma 1)

[Calcul réalisé depuis le niveau de travail]

Distance maximale d’arrêt (MAD)

+

[Facteur de position de travail non debout (NSF)]

+ [Facteur de chute en balancier (SFF)]

+ 2,5 pi (0,8 m) [facteur de sécurité (SF)]

= Distance de chute libre requise (RFC)

ATTENTION!

ATTENTION :

et se reporter à l’ensemble des schémas

et étiquettes portant sur la distance de

chute libre associée au lin de sécurité

autorétractable pour déterminer avec

exactitude la distance de chute libre

requise pour votre tâche.

Lire toutes les remarques

REMARQUES IMPORTANTES :

Les lins de sécurités autorétractables

doivent être ancrés en hauteur an de

s’assurer de l’exactitude de la distance de

chute libre calculée et des informations

associées.

Lorsqu’un dispositif rétractable est utilisé,

il est important de savoir que la distance

de chute peut être inuencée par d’autres

facteurs, par ex. si l’utilisateur travaille en

position debout, accroupie ou allongée et/

ou s’il travaille juste en dessous du point

d’ancrage ou à un angle donné.

Le calcul de la distance de chute libre

associée au lin de sécurité autorétractable

part du principe que l’utilisateur est en

position debout. Si l’utilisateur travaille

en position accroupie ou agenouillée, il

est nécessaire d’ajouter 3 pi (0,9 m) à la

distance de chute libre (voir Schéma 2). Si

l’utilisateur travaille en position allongée,

il est nécessaire d’ajouter 5 pi (1,5 m) à la

distance de chute libre.

Le calcul de la distance de chute libre

associée au lin de sécurité autorétractable

part également du principe que l’utilisateur

travaille juste en dessous du point

d’ancrage, ce qui limite le risque de chute

en balancier. Dans une situation de chute

en balancier, la distance de chute totale

sera plus élevée si l’utilisateur travaille

juste en dessous du point d’ancrage

(voir Schéma 3). Dans certaines tâches,

il peut être impossible de travailler juste

en dessous du point d’ancrage. Dans ce

cas, l’ouvrier doit augmenter la distance

soit, l’ouvrier ne doit pas être exposé à un

risque de chute en balancier, qui pourrait

le conduire à heurter un autre objet (voir

Schéma 4).

TABLEAU 1 : Distances de chute libre minimales requises - POUR UTILISATION

SUSPENDUE SEULEMENT

Distance de chute libre minimale requise entre la hauteur de travail et

le niveau inférieur*

Ouvrier travaillant juste

en dessous du point d’ancrage

Distance d’arrêt

maximale

du lin

42 po (1,1 m)

54 po (1,4 m)

*Ce tableau montre les distances de chute libre minimales générales requises. Il faut établir un calcul exact basé sur le

lin de sécurité autorétractable utilisé et une évaluation du site et des conditions de travail susceptibles de jouer sur la

distance de chute libre de l’ouvrier.

En position

debout

6 pi (1,8 m) 9 pi (2,7 m) 11 pi (3,4 m)

7 pi (2,1 m) 10 pi (3 m) 12 pi (3,7 m)

En position

agenouillée ou

accroupie

En position

allongée

Ouvrier ne travaillant

PAS juste en dessous

du point d’ancrage

En position

de chute en balancier

potentielle

Variable - Augmentation

nécessaire de la

distance de chute libre

15

Page 16

La distance d’arrêt maximale [chute libre

(FF) + décélération (D)] varie en fonction du

dispositif rétractable. Toujours se reporter

aux étiquettes apposées sur le dispositif

en question pour déterminer la distance

d’arrêt maximale.

Pour toute question sur le calcul de la

distance de chute libre, contacter le

Service technique Honeywell :

1-800-873-5242 (option 4)

5.0 Inspection et entretien

5.1 Inspection et test de

fonctionnement

Les exigences d’inspection de Honeywell

comprennent les critères établis par les normes

de sécurité actuelles. Les critères d’inspection

de l’équipement doivent être déterminés par

l’entreprise l’utilisant, comme par exemple

critères équivalents ou plus sévères que les

critères requis par le fabricant et les normes

auxquelles l’entreprise décide de se conformer.

L’équipement devra être inspecté méticuleusement

par l’utilisateur avant chaque utilisation et aussi par

une personne compétente autre que l’utilisateur

au moins annuellement (ou semi-annuellement en

vertu de la norme ANSI A10.32) pour ce qui suit :

[*ANSI Z359.14 et CSA Z259.2.2-17 fournit d’autres

exigences d’inspection en fonction du type d’utilisation

et des conditions d’utilisation.

Se reporter au Tableau 2 pour les exigences relatives

à l’inspection pour la conformité à ces normes. (*Voir

remarque à la section 6.2 Entretien.)]

Absence des étiquettes ou illisibilité des

instructions imprimées.

Absence d’un élément quelconque

affectant la forme, l’ajustage ou la fonction de

l’équipement.

Signes de défectuosités ou de dommages

au filin de sécurité à câbles, y compris des

entailles, brins cassés, nœuds, attaque

chimique, abrasion, altération, vieillissement

excessif ou usure excessive.

ATTENTION : Toujours porter des gants

pour inspecter les lins de sécurité à câbles,

car les brins cassés peuvent vous blesser.

Dommages empêchant l’utilisation du lin

de sécurité.

Rétraction - Avec le dispositif en position

montée, tester la rétraction et la tension du

lin de sécurité en déroulant une bonne partie

du lin de sécurité et en le laissant se rétracter

dans le dispositif. Toujours maintenir le lin de

sécurité légèrement tendu lorsqu’il se rétracte.

Le lin de sécurité doit pouvoir être déroulé

librement et se rétracter entièrement dans le

dispositif. Si le lin de sécurité ne se déroule

pas facilement ou se bloque lorsqu’il se

TABLEAU 2 : ANSI Z359.14 and CSA Z259.2.2-17: Exigences relatives à l’inspection

Type

d’utilité

Rare

à peu

fréquent

Modéré à

souvent

Très souvent

à continuelle-

ment

Notes:

1) La non conformité d’un utilisateur d’effectuer l’inspection “Avant chaque utilisation” initiera l’exigence d’inspection par une personne qualiée.

2) La non conformité d’une personne qualiée d’effectuer inspections comme specié dans cette table, ou la non conformité d’une inspection par la

personne qualiée initiera la revalidation ou élimination du produit.

3)La détermination du type de catégorie d’usage sera établi par une personne qualiée.

4)Un SRD consideré non réparable ou s’il n’est pas conçu pour le démontage de sorte que l’inspection interne n’est pas possible sans le rendant

inutilisable, n’est pas sujet d’inspection de revalidation. Ces SRDs aurant durée de vie et autres éxigences d’inspection conforme aux instructions du

fabricant.

Exemples

d’application

Sauvetage et

espace con-

né, entretien

d’usine

Transport,

construction

résidentielle,

services d’utilité

publique,

entrepôt

Construction

commerciale,

pétrole et gaz,

mines

Conditions d’utilisation

Bonnes conditions ’entrepo-

sage, usage intérieur ou

peu fréquent à l’extérieur,

température ambiante,

environnements propres

Conditions d’entreposage

acceptables, utilité intérieure et

extérieure fréquente, toutes les

températures, environnements

propres ou poussiéreux

Conditions d’entreposage

difciles, usage extérieur

prolongé ou continu,

toutes les températures,

environnement sale

Fréquence

d’inspection

utilisateur

Avant chaque

utilisation.

Avant chaque

utilisation.

Avant chaque

utilisation.

Fréquence

d’inspection

personne

qualiée

Annuelle Au moins tous

Semiannuelle à

annuelle

Trimestrielle

à annuelle

APPLICABLE

SEULEMENT POUR

CSA Fréquance

de revalidation du

produit

les 5 ans mais

n’excédant pas

les intervalles

requises par le

fabricant.

Au moins tous

les 2 ans mais

n’excédant pas

les intervalles

requises par le

fabricant.

Au moins annuellement mais

n’excédant pas

les intervalles

requises par le

fabricant.

16

Page 17

rétracte, sortir l’intégralité du lin de sécurité et

le laisser se rétracter lentement sous tension.

Ne pas utiliser le dispositif si le lin de sécurité

ne se rétracte pas correctement.

ATTENTION : Ne pas lâcher le lin

de sécurité et le laisser se rétracter

automatiquement. Toujours le maintenir

tendu lorsqu’il se rétracte!

Mécanisme de verrouillage - Il est possible

de tester le mécanisme de freinage en attrapant

le lin de sécurité et en tirant brusquement

dessus vers le bas, ce qui enclenche les freins.

Le lin de sécurité ne doit pas pouvoir glisser

lorsque les freins sont enclenchés. Une fois la

tension relâchée, les freins se desserreront et

le dispositif sera de nouveau rétractable.

Les preuves de défaut ou de dommage

au matériel, incluant les ssures, bris, arêtes

rugueuses ou acérées, déformation, corrosion,

attaque chimique, surchauffe, modication et

l’usure excessive.

Les dommages opérationnels au matériel.

Crochet mousqueton/Mousqueton - Le doigt du

connecteur (gâche) doit reposer sur le bec sans

contrainte et ne doit pas être déformé ou entravé.

Le ressort du doigt doit exercer une force sufsante

pour le maintenir solidement fermé. Le mécanisme

de verrouillage du doigt doit empêcher l’ouverture

de ce dernier lorsqu’il est fermé.

de lubrier les crochets instantanés et les

mousquetons si nécessaire.

Il est permis

Signes de défectuosités ou de dommages

causés au logement et/ou éléments de xation

desserrés ou manquants.

Signes de défectuosités ou de dommages

aux amortisseurs, y compris des trous,

déchirures, détérioration, coutures affaiblies

ou brisées.

Signes d’indicateurs de charge de chute

déployés ou activés.

Les lignes de vie rétractables de bordure

Falcon sont équipées d’un indicateur de

charge intégré à l’amortisseur. En cas de

chute, le dispositif d’arrêt force l’absorbeur

d’énergie blanc à s’ouvrir, comme illustré.

AVERTISSEMENT

Lorsqu’une inspection ou un test de fonctionnement

révèle des défauts ou un endommagement de

l’équipement, un entretien inapproprié ou des

signes montrant que l’équipement a été exposé

à des contraintes d’arrêt de chute ou une charge,

il faut immédiatement mettre l’équipement hors

service.

Les lins de sécurité autorétractables à proximité

de bordure Falcon Edge sont des dispositifs

qui peuvent être réparés.

hors service doivent avoir le mot « UNUSABLE »

(INUTILISABLE) inscrit au marqueur dessus ou

sur une étiquette apposée dessus et doivent être

remis en service conformément aux instructions

du fabricant.

5.2 Entretien

Un entretien de base de l’équipement

antichute prolongera sa vie utile et contribuera

à la bonne performance de sa fonction vitale

de sécurité.

Entretien et réparation

Les opérations d’entretien et de réparation des

lins de sécurité de Honeywell Miller doivent

être effectuées uniquement par Honeywell

Industrial Safety ou des personnes ou entités

autorisées par écrit par Honeywell. Il faut tenir

un registre de toutes les dates d’entretien et

d’inspection du système. Seules les pièces

de rechange Honeywell sont approuvées pour

être utilisées dans ce dispositif. Contacter votre

distributeur Honeywell ou appeler le Service

technique Honeywell au 1-800-873-5242 pour

obtenir un numéro d’autorisation de retour.

Les lins de sécurité autorétractables de

Honeywell Miller n’exigent aucune recertication

d’usine annuelle.*

*Honeywell, le fabricant, n’exige aucune

recertication d’usine annuelle pour les lins

de sécurité autorétractables Honeywell Miller.

Toutefois, la société ou l’utilisateur nal doit

s’assurer de respecter les réglementations

nationales et régionales sur la protection

contre les chutes. Des normes additionnelles

peuvent également être suivies en matière

d’inspection et de recertication.

Nettoyage et remisage

Ce dispositif doit rester propre et exempt

de contaminants. Nettoyer périodiquement

l’extérieur du dispositif et essuyer le lin

de sécurité avec un chiffon humide et un

détergent doux.

Lorsque non utilisé, l’équipement devra être

entreposé de sorte à prévenir les facteurs

d’endommagement tels qu’une température

élevée, la lumière vive, les rayons ultraviolets,

l’humidité excessive, l’huile, les émanations

chimiques ou autres éléments de détérioration.

Le lin de sécurité doit être entièrement

rétracté dans le dispositif lorsqu’il n’est

pas utilisé.

Les dispositifs mis

17

Page 18

ES

INSTRUCCIONES DE USO

Equipos de protección personal

LEADING EDGE

SELF-RETRACTING

LIFELINES

Gracias por comprar el equipo de protección

contra caídas Honeywell Miller fabricado por

Honeywell Industrial Safety.

ADVERTENCIA

Todas las personas que usen este

equipo deben leer, entender y seguir

las instrucciones. Su incumplimiento

puede causar lesiones graves o incluso

la muerte. No utilice este equipo si no

se ha capacitado debidamente.

Es muy importante que la persona o el usuario

autorizados de este equipo lean y entiendan

estas instrucciones. Además, la ley federal

exige que los empleadores garanticen que

todos los usuarios estén capacitados en la

correcta instalación, el uso, la inspección y el

mantenimiento de los equipos de protección

contra caídas. La capacitación en la protección

contra caídas debería ser una parte esencial

de un programa de seguridad integral.

El uso adecuado de los sistemas de detención

de caídas puede salvar vidas y reducir la

posibilidad de lesiones graves causadas por

una caída. El usuario debe saber que las

fuerzas experimentadas durante la detención

de una caída o la suspensión prolongada

pueden causar lesiones corporales. Consulte

con un médico si tiene alguna pregunta acerca

de la capacidad del usuario para utilizar este

producto. Las mujeres embarazadas y los

niños menores de edad no deben usar este

producto.

1.0 Objetivo

Las cuerdas de seguridad autorretráctiles

son dispositivos retráctiles autocontenidos

diseñados para ser usados por el personal

en aquellas aplicaciones donde se necesite

una protección contra caídas combinada

con movilidad irrestricta del trabajador. Las

cuerdas de seguridad autorretráctiles Falcon

Edge de Honeywell Miller son unidades

retráctiles especialmente diseñadas con

características únicas y creadas para las

aplicaciones de borde avanzado como así

también para las aplicaciones elevadas.

18

2.0 Requisitos generales de

protección contra caídas

2.1 Requisitos generales

Deben suministrarse a las personas y

usuarios autorizados todas las advertencias e

instrucciones.

Todas las personas y usuarios autorizados

deben consultar los reglamentos de

seguridad laboral y las normas ANSI o

CSA que correspondan. Las etiquetas del

producto contienen información sobre los

reglamentos OSHA y las normas ANSI y

CSA que cumple el producto.

Siempre deben tomarse las debidas

precauciones al retirar del área de trabajo

obstrucciones, basura, material y otros

peligros reconocidos que pudieran causar

lesiones o interferir en el funcionamiento del

sistema.

Siempre revise para ver si hay obstrucciones

abajo del área de trabajo con el n de

asegurarse de que esté despejada la

trayectoria de una posible caída.

Deje una distancia segura de caída adecuada

abajo de la supercie de trabajo.

A n de reducir al mínimo las posibilidades

de un desenganche accidental, una persona

competente debe garantizar la compatibilidad

del sistema.

Todo el equipo debe ser inspeccionado

visualmente antes de cada uso de conformidad

con las instrucciones del fabricante. Además,

el equipo debe ser inspeccionado por una

persona competente, que no sea el usuario, de

forma regular, al menos una vez al año.

Cualquier producto que presente

deformaciones, desgaste inusual o deterioro

debe ser descartado inmediatamente de

manera que se evite su uso posterior accidental.

Todo equipo sometido a una caída debe ser

puesto fuera de servicio.

La persona autorizada/usuario debe contar

con un plan y medios de rescate a mano para

poder aplicarlos al usar este equipo..

El equipo no debe ser alterado de ninguna

forma. Las reparaciones deben ser efectuadas

exclusivamente por el fabricante del equipo o

bien por personas o entidades autorizadas por

escrito por el fabricante.

Jamás lo utilice par nes distintos al

Page 19

proyectado. No use jamás el equipo para

remolcar o izar objetos.

Los peligros ambientales deberían ser

considerados al seleccionar el equipo de

protección contra caídas. El equipo no

debe exponerse a condiciones ambientales

peligrosas ni a sustancias químicas que

podrían causar un efecto nocivo. El uso en un

ambiente corrosivo o cáustico requiere de un

programa de inspección y mantenimiento más

frecuentes para garantizar que se mantenga la

integridad del producto.

Debe protegerse todo el material sintético con

el objeto de mantenerlo alejado de escorias,

chispas calientes, llamas y otras fuentes de

calor. Para tales usos se recomienda el uso

de materiales resistentes al calor.

No permita que el equipo entre en contacto con

cualquier cosa que pueda dañarlo, incluyendo,

entre otras, supercies abrasivas, ásperas o

de alta temperatura, fuentes de calor, peligros

eléctricos o maquinaria en movimiento.

No exponga el equipo a peligros que no pueda

soportar de acuerdo a su diseño. Consulte

con el fabricante en caso de dudas.

No quite nunca del producto las etiquetas que

incluyan advertencias e información importante

para la persona o el usuario autorizados.

2.2 Advertencias y limitaciones

Capacidad

Para uso de UNA sola persona.

Consulte las etiquetas de los productos y la

sección Identicación y especicaciones

del producto de este manual para las

capacidades de peso mínima y máxima.

Compatibilidad del sistema

Productos anticaídas Honeywell Miller

están diseñadas para utilizarse solo con los

componentes aprobados por Honeywell.

sustitución o el reemplazo por combinaciones

o subsistemas de componentes no aprobados

o ambos puede afectar o interferir en el

funcionamiento seguro entre ellos y poner en

peligro la compatibilidad dentro del sistema.

Esta incompatibilidad puede afectar la

abilidad y seguridad de todo el sistema.

La

ADVERTENCIA

Consulte siempre las regulaciones y las

normas relativas a los requisitos de los

componentes del sistema personal de

detención de caídas y las instrucciones

proporcionadas con cada componente

que se utiliza como parte del sistema

personal de detención de caídas.

Requisitos de anclaje

Honeywell recomienda que todos los anclajes

sean:

• Capaz de soportar 5,000 libras (22,2 kN) por

trabajador unido; O

• Diseñado, instalado y utilizado, bajo la

supervisión de una persona cualicada,

como parte de un sistema personal completo

de protección contra caídas que mantiene un

factor de seguridad de al menos dos.

Siempre reérase a los reglamentos y normas

de protección contra caídas nacionales

y regionales aplicables para asegurar el

cumplimiento.

Límites de uso

Las cuerdas de seguridad autorretráctiles

están diseñadas únicamente para

aplicaciones de detención de caídas.

Nunca utilice las cuerdas de seguridad

autorretráctiles (SRL) como dispositivo de

contención o posicionamiento.

¡IMPORTANTE!

Un escenario de restricción de caída

podría suceder en cualquier momento:

• el usuario extiende la cuerda de

seguridad por completo y le aplica

peso o tensión;

• el usuario, intencionalmente o por

accidente, traba la cuerda sin que esté

completamente extendida, y le aplica

peso o tensión.

La correcta aplicación para el uso de

SRL permite al usuario estar conectado

y moverse sin restricciones para realizar

las tareas requeridas, sin trabar la

cuerda ni aplicarle tensión cuando está

completamente extendida.

Cuerdas de seguridad autorretráctiles

Falcon Edge están aprobados para

aplicaciones elevadas y de borde avanzado.

A los nes de este manual de instrucciones,

una aplicación de borde avanzado es aquella

en la que el usuario puede estar anclado al

nivel del piso o a la supercie de trabajo o

a más altura y la cuerda de seguridad tiene

el potencial de entrar en contacto con un

borde si el usuario se cae. Se recomienda

anclarel dispositivo verticalmente y elevado

siempre que sea posible A los nes de este

manual de instrucciones, una aplicación

elevada implica que no hay ojedad en la

cuerda de seguridad cuando la unidad está

montada arriba del usuario y conectada al

anillo en D posterior del usuario.

Cuerdas de seguridad autorretráctiles Falcon

Edge pueden usarse con sistemas de cuerdas

de seguridad horizontales aprobados por

Honeywell con consideraciones especiales.

19

Page 20

El retráctil debe ser capaz de desplazarse

bien a lo largo del tramo de la cuerda de

seguridad y debe permanecer perpendicular

al trabajador durante toda la duración del

trabajo. Se recomienda que una persona

calicada evalúe in-situ las condiciones antes

de la instalación y uso del retráctil con el

sistema de cuerda de seguridad horizontal.

Además, siempre deben consultarse las

instrucciones provistas con el sistema

de cuerda de seguridad horizontal para

asegurarse de la compatibilidad de la cuerda

de seguridad autorretráctil con el sistema.

Este dispositivo debe estar instalado y

utilizarse de manera tal que minimice

la posibilidad de una caída oscilante. El

usuario nunca debe estar expuesto a un

riesgo de caída oscilante.

No permita que se ponga holgada la

cuerda salvavidas.

3.0 Instalación / Uso

ADVERTENCIA

Todas las Cuerdas de seguridad

autorretráctiles Honeywell Miller deben

ser inspeccionadas y probadas en lo

que respecta a bloqueo y retracción

antes de cada uso (ver 6.0 Inspección y

mantenimiento).

El instalador de la cuerda de seguridad

autorretráctil no debe ser expuesto a

un riesgo de caída mientras monta la

unidad.

Típicamente, se recomienda el montaje

elevado de una cuerda de seguridad

autorretráctil. Sin embargo, las cuerdas

de seguridad autorretráctiles Falcon Edge

han sido especícamente diseñadas y

exitosamente testeadas de acuerdo con

los estándares para el uso horizontal y las

caídas sobre borde loso (radio ≥ 0,005

pulg ([0,13 mm])).

Requisitos especiales, Advertencias

y Limitaciones pertinentes a las

aplicaciones de borde avanzado

• El punto de anclaje debe estar a la

misma altura o más alto que el borde

sobre el cual podría ocurrir una caída.

• El ángulo permitido para el

redireccionamiento de la porción de la

cuerda de rescate del dispositivo en

el borde sobre el cual podría ocurrir

una caída (según la medida entre los

dos lados formados por el acollador de

20

¡IMPORTANTE!

sujeción) debe ser por lo menos de 90°.

• El potencial de que ocurra una caída

colgante debe ser minimizado para la

protección del trabajador y de la cuerda

de rescate. El trabajador nunca debe

trabajar en la parte extrema de una

apertura, del lado opuesto del punto de

anclaje.

• Cuerdas de seguridad autorretráctiles

Falcon Edge están especícamente

diseñados para reducir las fuerzas

aplicadas tanto al trabajador como a la

conexión de la cuerda de seguridad que se

extienda más allá de un borde avanzado.

• Las aplicaciones para retráctiles de borde

avanzado incluyen planchas de acero,

concreto y supercies de madera. A pesar

del amplio rango de aplicaciones de estas

unidades, las supercies en contacto con

el equipo deben ser evaluadas por una

persona calicada para determinar si las

mismas pueden crear desgaste prematuro

y/o fallas debido a la excesiva abrasión o

cortes de los materiales.

Requisitos de anclaje especiales

para aplicaciones de borde avanzado

Honeywell Industrial Safety aprueba una altura

de conexión a nivel del pie o de la supercie

de trabajo o más alta para las cuerdas de

seguridad autorretráctiles de Falcon Edge.

La distancia de alejamiento mínima es de 18

pulg (0,5 m). La distancia del borde lateral

(zona de trabajo) desde la perpendicular al

punto de anclaje depende de la distancia de

alejamiento del punto de anclaje (consulte los

DIAGRAMAS A & B y las tablas de espacio

libre de caída en el APÉNDICE B).

¡IMPORTANTE!

Una unidad Falcon Edge anclada a una

distancia de alejamiento de 25 pies

(7,62 m) con un usuario que trabaja a

una distancia de borde lateral máxima

permitida de 25 pies (7,62 m) (zona

de trabajo) experimentará la mayor

caída oscilante permitida para una

aplicación de borde avanzado Falcon.

Es imperativo limitar tanto como sea

posible la caída oscilante. Esto se puede

lograr incrementando la distancia de

alejamiento y/o limitando la zona de

trabajo. No debe existir un riesgo de

caída oscilante en el trayecto de la caída

oscilante potencial.

Page 21

3.1 Cuerdas de seguridad au-

30˚

30˚

30˚

30˚

Connecon Height

Edge SetbackDistance

VercalSwing Fall

Lateral Swing Fall

torretráctiles Falcon Edge

LAS IMÁGENES REFERENCIADAS