Page 1

Put Bar Code Here

Q7130A, Q7230A, Q7330A

Q7130A Q7230A

Q7330A

Modutrol IV Interface Modules

INSTALLATION INSTRUCTIONS

FEATURES

• Mounts inside the wiring box of any Series 90 Modutrol

IV Motor (M91XX models). Module protected from

weather by the Modutrol IV NEMA 3 wiring box.

• Mates to quick-connect terminals in motor wiring box

and provides screw terminals for control wiring

connections.

• Features solid state circuitry with surface mount

components.

• Plastic enclosure provides easy handling and

protection for circuitry.

• Q7130A provides selectable voltage range (4-7, 6-9, or

10.5-13.5 Vdc). Adapts M91XX Modtrol IV Motor to

function as M71XX model for M734H,J, M744D,

M745G,P replacements. Includes reversing switch to

allow replacement of electrically normally open or

electrically normally closed motors.

APPLICATION

The Q7130, Q7230, and Q7330 Modutrol IV Interface

Modules are used with Series 90 Modutrol IV Motors (M91XX)

for conversion to electronic (Series 70) control.

• Q7230A provides current or voltage control (4-20 mA

and 2-10 Vdc) with adjustable zero and span. Adapts

the M91XX Modutrol IV Motor to function as M72XX

model for M744S,T,Y or M745S,T,Y replacements.

Includes reversing switch to allow replacement of

electrically normally open or electrically normally

closed motors.

• Q7330A is an interface to W936 and W945 controls.

Adapts the M91XX Modutrol IV Motor to function as

M73XX model for M734D, M744A, M745A replacements.

63-2235-07

Page 2

Q7130A, Q7230A, Q7330A MODUTROL IV INTERFACE MODULES

SPECIFICATIONS

IMPORTANT:

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed specifications. Also, this product is tested and calibrated

under closely controlled conditions and some minor

differences in performance can be expected if those

conditions are changed.

Models:

Q7130A Modutrol IV Interface Module:

Used with M91XX Modutrol IV Motor to replace M71XX

Motor applications. Module controls only one motor.

See Table 1.

Q7230A Modutrol IV Interface Module:

Used with M91XX Modutrol IV Motor to replace M72XX

Motor applications. Module controls only one motor.

See Table 1.

Q7330A Modutrol IV Interface Module:

Used with M91XX Modutrol IV Motor to replace M73XX

Motor applications. Module controls only one motor.

See Table 1.

Electrical Ratings:

Input Voltage: 24 Vac, 50/60 Hz.

Power Consumption: 2 VA.

Input Impedance:

Q7130A: >100k ohms.

Q7230A: voltage input >100k ohms; current input 67 ohms.

Temperature Rating: -40° F to +150° F [-40° C to + 66° C].

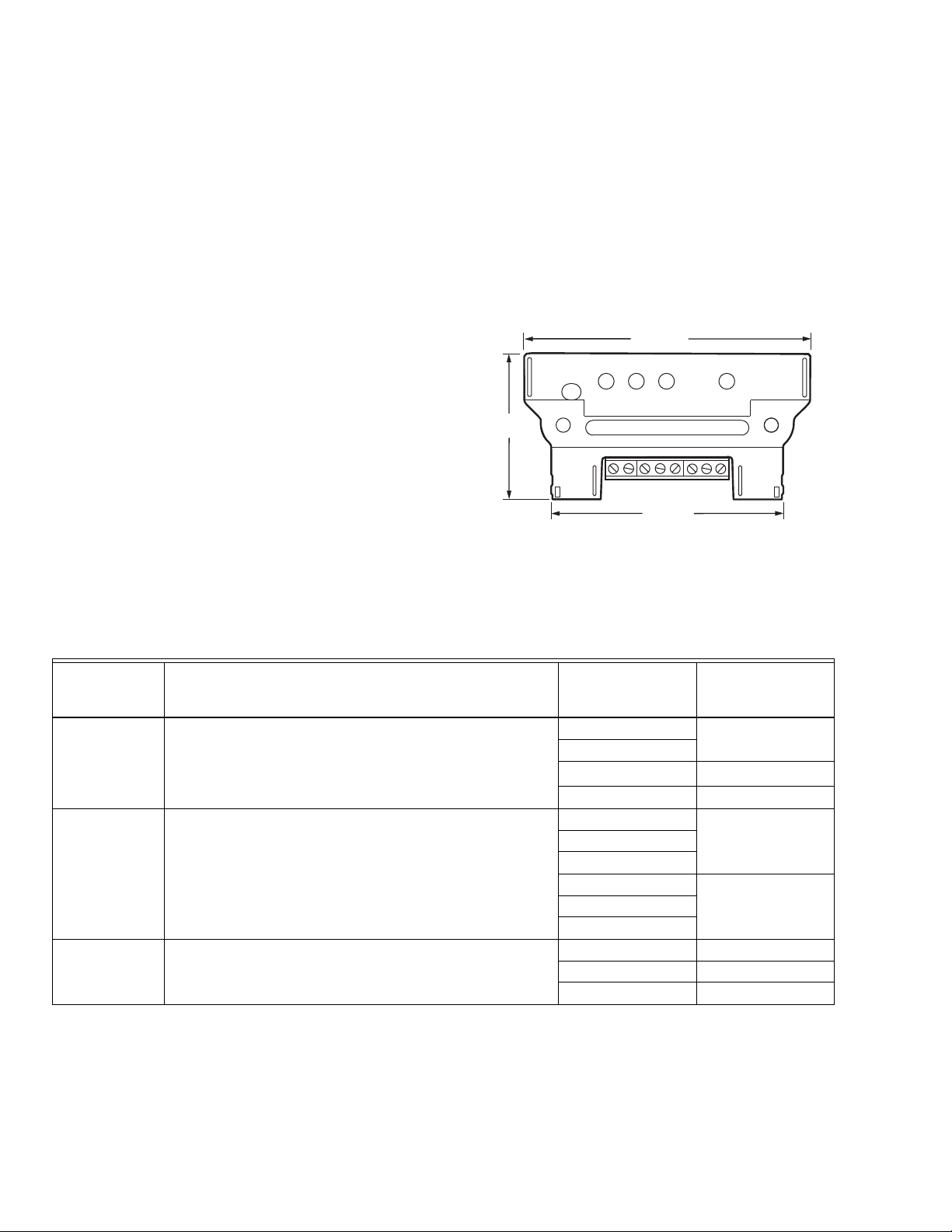

Dimensions: See Fig. 1.

3-25/32 (96)

1-59/64

(49)

3-5/64 (78)

M27211

Fig. 1. Q7130,Q7230,Q7330 Modutrol IV Interface Module

dimensions in in. (mm).

Table 1. Interface Module Function/Application Chart.

And Replaces

This Model Provides Interface For

These Old Style

a

Motors

When Used with

Series 90 Models:

Q7130A Selectable voltage ranges: 4-7, 6-9, or 10.5 to 13.5 Vdc M734H M9164D1009

M734J

M744D

b

M9184D1021

M745G M9185A1018

Q7230A Adjustable zero and span, voltage or current M9184D1021

control (includes 4-20 mA and 2-10 Vdc).

M744S M9184D1021

M744T

M744Y

M745S M9185D1004

M745T

M745Y

Q7330A W936 or W945 control interface. M734D M9164D1009

M744A M9184D1021

M745A M9185D1004

a

Refer to customer.honeywell.com for cross-reference details.

b

M744D1037 and M744D1045 do not apply.

63-2235—07 2

Page 3

Q7130A, Q7230A, Q7330A MODUTROL IV INTERFACE MODULES

CAUTION

CAUTION

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous condition.

2. Check the ratings and description given in this specification to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

5. Excessive force can damage potentiometer controls.

Use a small screwdriver when adjusting all potentiometers located on the unit.

Disconnect power before installation to prevent

electrical shock or equipment damage.

IMPORTANT:

For ease of adjustment, make all stroke and auxiliary

switch adjustments before installing the interface

module. After installation, access to the stroke adjust

cams and auxiliary switches inside the motor is

restricted. For complete details on performing these

adjustments, refer to the specification sheet packed

with the Modutrol Motor.

Installing Terminal Block

When installing the terminal block on the motor

quick connects, push the board straight down.

Rocking or tilting of the board can damage the

electrical connectors and result in an inoperative

wiring module.

1. Disconnect power from the M91XX Modutrol IV Motor to

prevent electrical shock or equipment damage.

2. Remove wiring box cover from the motor by removing

four screws.

3. Disconnect all field wiring from the motor.

4. If motor has an internal transformer, make sure trans-

former is not powered and disconnect secondary wires

from T1 and T2 terminals. Clip quick-connect termina-

tions from transformer secondary (brown) wires. Trim

1/8 to 1/4 in. (3 to 6 mm) of insulation from the ends of

the wire. Tin wire ends with solder.

5. Plug terminal block onto quick-connect terminals inside

wiring box.

6. Connect field wiring to screw terminals on terminal

block. See Fig. 3, 5, and 9 for terminal designations.

Trim wire ends neatly and tin with solder.

7. Position circuit module and secure.

SETTINGS AND ADJUSTMENTS

Module Adjustments

Q7130A Adjustments (Fig. 3)

The Q7130A provides selectable range, two-wire voltage

control (4-7, 6-9 or 10.5-13.5 Vdc). It includes a clockwise/

counterclockwise (cw/ccw) switch for replacing electrically

normally open or electrically normally closed motors. Please

remove film from CW/CCW switch before use.

1. Set Mod IV motor pots—both CW or both CCW for your

application. Use the checkout procedure in Table 2 to

ensure proper motor function.

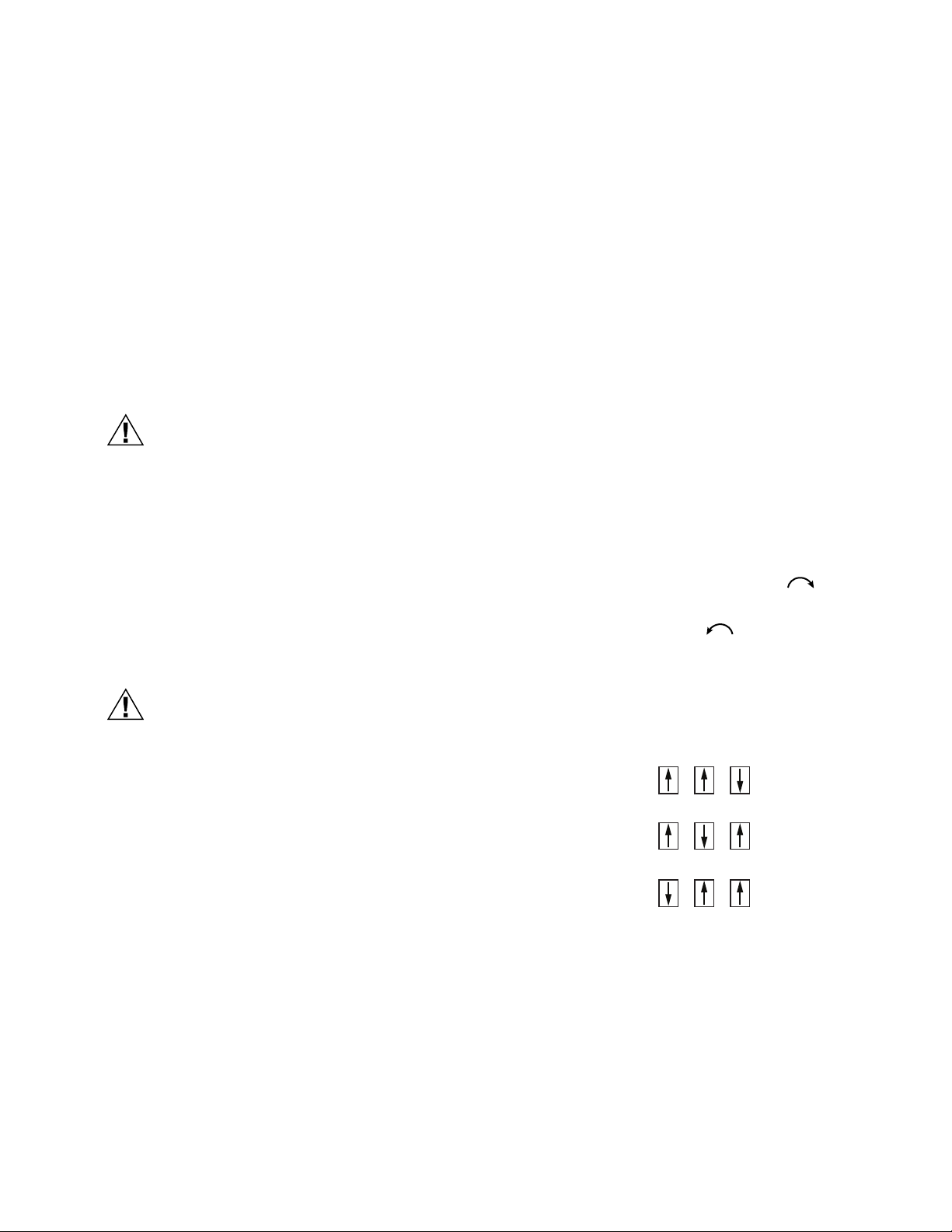

2. Select desired voltage range using the three-position

switch reference chart for dip switch settings (see Fig.

2).

3. Select desired rotation. Select cw for electrically normally closed (motor drives clockwise , as viewed

from power end, to open with an increase in control signal). Select ccw for electrically normally open (motor

drives counterclockwise , as viewed from power

end, to close with an increase in control signal) (default

switch position is clockwise).

4. See Fig. 4 for typical system wiring.

5. Set controller to drive motor to fully open position and

then to fully closed position to check for proper operation.

Q7130

4-7

6-9

10.5-13.5

M29165

Fig. 2. DIP switch reference.

3 63-2235—07

Page 4

Q7130A, Q7230A, Q7330A MODUTROL IV INTERFACE MODULES

M27212

T1

T2

F

C+

A–

10.5-13.5

CCW

CW

6.9

4.7

Fig. 3. Q7130A terminals and adjustments.

MOTOR

+

3

3

MODULATING

DC VOLTAGE

SOURCE

–

C

2

24V

T1

R

T2

F

L1

(HOT)

1

L2

TRANSFORMER

1

POWER SUPPLY. ADD DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

OPTIONAL NORMALLY OPEN SWITCH. WITH CCW SELECTION,

MOTOR WILL RUN TO FULLY CLOSED; WITH CW SELECTION

MOTOR WILL RUN TO FULLY OPEN WHEN THIS SWITCH CLOSES

(AS LONG AS POWER IS APPLIED TO T1, T2 TERMINALS).

3

OPTIONAL NORMALLY CLOSED SWITCHES. FINE SILVER OR

DRY CONTACTS REQUIRED. WITH CCW SELECTION, MOTOR

WILL RUN TO FULLY OPEN; WITH CW SELECTION, MOTOR WILL

RUN TO FULLY CLOSED WHEN SWITCH IN EITHER C OR R

LEAD IS OPENED.

M505C

Fig. 4. Typical system wiring for Q7130A Interface Module

and M91XX Modutrol Motor.

Table 2. Q7130A/M91XX Checkout Procedure.

Proper Motor Response Switch in

Step

Clockwise Position Switch in Counterclockwise Position

1. Open terminal C or R. Motor runs closed (fully ccw). Motor runs open (fully cw).

2. Jumper terminals C and F. Motor runs fully open (fully cw). Motor runs fully closed (fully ccw).

3. Remove either T terminal or disconnect

power supply.

Spring return motors return to normal spring position (fully ccw for

mechanically normally closed motors; fully cw for mechanically normally

open motors).

Q7230 Adjustments (Fig. 5 and Table 3)

The Q7230A provides adjustable range (zero and span) for

two-wire current or voltage control. Separate potentiometers

are provided on the circuit module for adjusting the zero point

and the span. It includes a cw/ccw switch for configuring the

motor to rotate clockwise or counterclockwise with an

increase in control signal.

1. Set Mod IV motor pots—both CW or both CCW for your

application. Use the checkout procedure in Table 3 to

ensure proper motor function.

2. Verify that the zero potentiometer is fully clockwise and

that the span potentiometer is fully counterclockwise.

(Do not exceed the stop point of the potentiometer.)

3. Select desired rotation direction [cw (electrically normally closed) is the most common]. The following directions apply for the clockwise setting. For

counterclockwise setting, reverse open and closed, and

reverse clockwise and counterclockwise. Remove film

on switch before use. (Default switch position is CW.)

4. See Fig. 7 and 8 for typical system wiring.

5. For current control, connect the current input signal to I+

(screw terminal 3) and COM (screw terminal 5). For

voltage control, connect the voltage input signal to V+

(screw terminal 1) and COM (screw terminal 5).

6. Set the controller to output the signal required to drive

the motor to the closed position. Wait for the motor to

stop driving closed.

7. Turn the zero potentiometer slowly counterclockwise

until the motor starts to open.

8. Turn the zero potentiometer slowly clockwise

until the motor is fully closed. This is defined as the zero

setting.

9. Set the controller to output the signal required to drive

the motor to the fully open position. Wait for the motor to

stop driving open.

10. Turn the span potentiometer slowly clockwise

until the motor starts to drive closed. The difference

between the fully open position signal and the fully

closed position signal is defined as the operating span.

11. Recheck the fully closed position and readjust the zero

potentiometer, if necessary. (Turn the zero potentiometer clockwise to close the motor and counterclockwise to open the motor.)

63-2235—07 4

Page 5

Q7130A, Q7230A, Q7330A MODUTROL IV INTERFACE MODULES

12. Recheck the fully open position and readjust the span

potentiometer, if necessary. (Turn the span potentiometer clockwise to close the motor, counterclockwise to

open the motor.) Verify the mid point of your stroke.

T1

Com

F

T2

1+

V+

ZEROSPAN

CCW

CW

M27213

Fig. 5. Q7230A terminals and adjustments.

FOR ADJUSTABLE ZERO AND SPAN MODELS

20

(10)

16

(8)

12

(6)

8

(4)

CONTROL OUTPUT

mA CURRENT (OR VOLTS DC)

4

(2)

SEQUENTIAL OPERATION

13. For sequential operation at two or more motors (as

shown in Fig. 6), repeat the above steps for each motor,

individually adjusting each for the desired response to

the input signal.

L1

L2

1

2

3

4

5

1

(HOT)

4

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQURED.

CONNECTING TO EITHER (+) OR (-) WILL DRIVE THE

MOTOR TO FULLY OPEN.

DRIVE UP TO SIX MOTORS IN UNISON.

EACH MOTOR MUST HAVE SEPARATE TRANSFORMER.

IF COMMON LINE VOLTAGE SUPPLY MUST BE USED,

ADD ISOLATION TRANSFORMER TO EACH M91XX MOTOR.

INTERNAL MODUTROL IV CONNECTION.

MOTOR

T1

T2

MOTOR

T1

T2

MOTOR

T1

T2

5

COM

+

I

F

2

5

COM

+

I

F

2

5

COM

+

I

F

2

4-20 mA

CONTROLLER

–

+

3

M506H

Fig. 7. Typical wiring diagram for Q7230A Interface

Module and M91XXX Modutrol IV Motor with 4-20 mA

controller.

0

CLOSED

MOTOR 1 PROPORTIONS BETWEEN 4 AND 12 mA; FULLY

1

CLOSED AT 4 mA, FULLY OPENED AT 12 mA.

MOTOR 2 PROPORTIONS BETWEEN 8 AND 16 mA; FULLY

CLOSED AT 8 mA, FULLY OPENED AT 16 mA.

MOTOR 3 PROPORTIONS BETWEEN 12 AND 20 mA SIGNAL;

FULLY CLOSED AT 12 mA, FULLY OPENED AT 20 mA.

2

UP TO 6 MOTORS CAN BE DRIVEN SEQUENTIALY OR IN

UNISON FROM ONE CONTROLLER.

3

ADJUST ZERO ADJUST AND SPAN ADJUST POTENTIOMETERS

TO ACHIEVE DESIRED SEQUENCE.

OPEN

MOTOR 1 MOTOR 2 MOTOR 3

1 3 3 3

CLOSED

OPEN

CLOSED OPEN

M2893A

2

Fig. 6. Sequential operation of three motors with Q7230A

Interface Module.

MOTOR

L1

(HOT)

1

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION AS REQURED.

2

CONNECTING TO EITHER (+) OR (-) WILL DRIVE THE

MOTOR TO FULLY OPEN.

3

INTERNAL MODUTROL IV CONNECTION.

3

T1

T2

COM

V+

F

2

2-10 Vdc

CONTROLLER

–

+

M29166

Fig. 8. Typical wiring diagram for Q7230A Interface

Module and M91XXX Modutrol IV Motor with 2-10 Vdc

controller.

5 63-2235—07

Page 6

Q7130A, Q7230A, Q7330A MODUTROL IV INTERFACE MODULES

M27214

T1

T2

4

3

1

2

Table 3. Q7230/M91XX Checkout Procedure.

Proper Motor Response Switch in

Step

Clockwise Position Switch in Counterclockwise Position

1. Open terminals (+), (-), F Motor closes fully ccw Motor opens fully cw

2. Jumper F to (-) Motor opens fully cw Motor closes fully ccw

3. Remove either T terminal

Spring return motors return to normal spring position (fully ccw for

mechanically normally closed motors, fully cw for mechanically normally

open motors).

(+) and (-) denotes terminals on the controller

Q7330A Adjustments (Fig. 9 and Table 4)

The Q7330A provides control interface for W936 and W945

controllers. This module consists only of the terminal block

and does not require any adjustments. See Fig. 9 for

terminals.

After the motor stroke is adjusted (if necessary), simply plug

the module onto the motor quick-connect terminals and

secure to the motor. See Fig. 10 for typical system wiring.

To check proper motor operation:

1. Provide power to the motor.

2. Jumper terminals 1 and 2 to drive motor open (clock-

wise as viewed from power end).

3. Jumper terminals 1 and 3 to drive motor closed. Connect field wiring to appropriate screw terminals.

Fig. 9. Q7330A terminals.

ELECTRONIC

2

CENTRAL PROCESSOR

ELECTRONIC

L1

(HOT)

1

2

3

4

5

MODULATING

DAMPER MOTORS

L2

1

T1

T2

T1

T2

T1

T2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQURED.

SEE APPROPRIATE SYSTEM CONTROL INSTRUCTIONS

FOR CONNECTIONS TO CENTRAL PROCESSOR.

(LABELED E1 ON W936 OR T1 ON W945).

FIVE PERCENT CARBON RESISTOR. VALUE VARIES WITH

NUMBER OF MOTORS PARALLELED (1000 OHMSÐ2 MOTORS,

820 OHMSÐ3 MOTORS.

AUTHORITY OF MINIMUM POSITION POTENTIOMETER IF USED,

INCREASES WITH NUMBER OF MOTORS PARALLELLED (135

OHMS ON MOTORÐ50 PERCENT STROKE, ON 2 MOTORSÐ

100 PERCENT STROKE, ON 3 MOTORSÐ150 PERCENT STROKE).

USE AUXILIARY END OF M9185 TO REPLACE M945B; M745D

MOTORS TO SPRING RETURM TO THE NORMALLY OPEN

POSITION.

5

1

2

3

4

1

2

3

4

1

2

3

4

3

12

OPTIONAL

MINIMUM

POSITION

POTENTIOMETER

4

3

CHANGEOVER

CONTROLLER

M487C

63-2235—07 6

Fig. 10. Typical wiring diagram for Q7330A Interface

Module and M91XX Modutrol IV Motor.

Page 7

Q7130A, Q7230A, Q7330A MODUTROL IV INTERFACE MODULES

Table 4. Q7330/M91XX Checkout Procedure.

Step

1. Disconnect leads from terminals

1,2,3,4.

2. With motor powered jumper terminals 1

and 2.

3. Remove either T terminal or disconnect

power supply.

Proper Motor Response for Normally

Closed Motor

Motor closes. (Fully ccw as

viewed from power end).

Motor drives open (clockwise as

viewed from powered end).

Proper Motor Response for Normally

Open Motor

Motor opens. (Fully cw as viewed

from the power end)

Motor drives closed (counterclockwise

as viewed from the power end).

Spring return motors return to normal spring position (fully ccw for

mechanically normally closed motors, fully cw for mechanically normally

open motors.

7 63-2235—07

Page 8

Q7130A, Q7230A, Q7330A MODUTROL IV INTERFACE MODULES

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

63-2235—07 T.D. Rev. 01-11

Printed in U.S.A.

Loading...

Loading...