Page 1

Page 2

Page 3

GENERAL

DESCRIPTION

The MO953 and MP953 Pneumatic

(“Actuators”) are used with

V5011

and

Valve

V5013

Actuators

Valves and

can control older steam and water valves via adapters. The

M0953A-D

MP953A-D

Actuators are functionally identical to the

Actuators. Therefore, most of this sheet is

directed to the MP953 Actuators.

MP953A

positioning, and the

and B Actuators use a Gradutrol Relay for

MP953E

and

MP953F

Actuators use a

positive positioner. The relay and the positioner function in

essentially the same way. Positivepositionerretrofitkitsare

available for

MP953A

and B Actuators (see

ACCESSORIES).

APPLICATION

These Actuators operate the

and certain other coil, line, and zone valves that

Device Type Active Inactive Active Inactive In. (mm)

Direct

acting

with Gradutrol

Relay

-

-

A

-

-

V5011

and

V5013

Table 1.

MP953

A1087 A1004 A1210

Al095 A1012 Al228

All78 A1053

A1202 All86 A1061

Valves

MO953/MP953

I

MO953

-

Al 5 (127)

A2

-

-

A7

A8

-

I

I

proportionally control steam or hot and cold liquids in

HVAC systems.

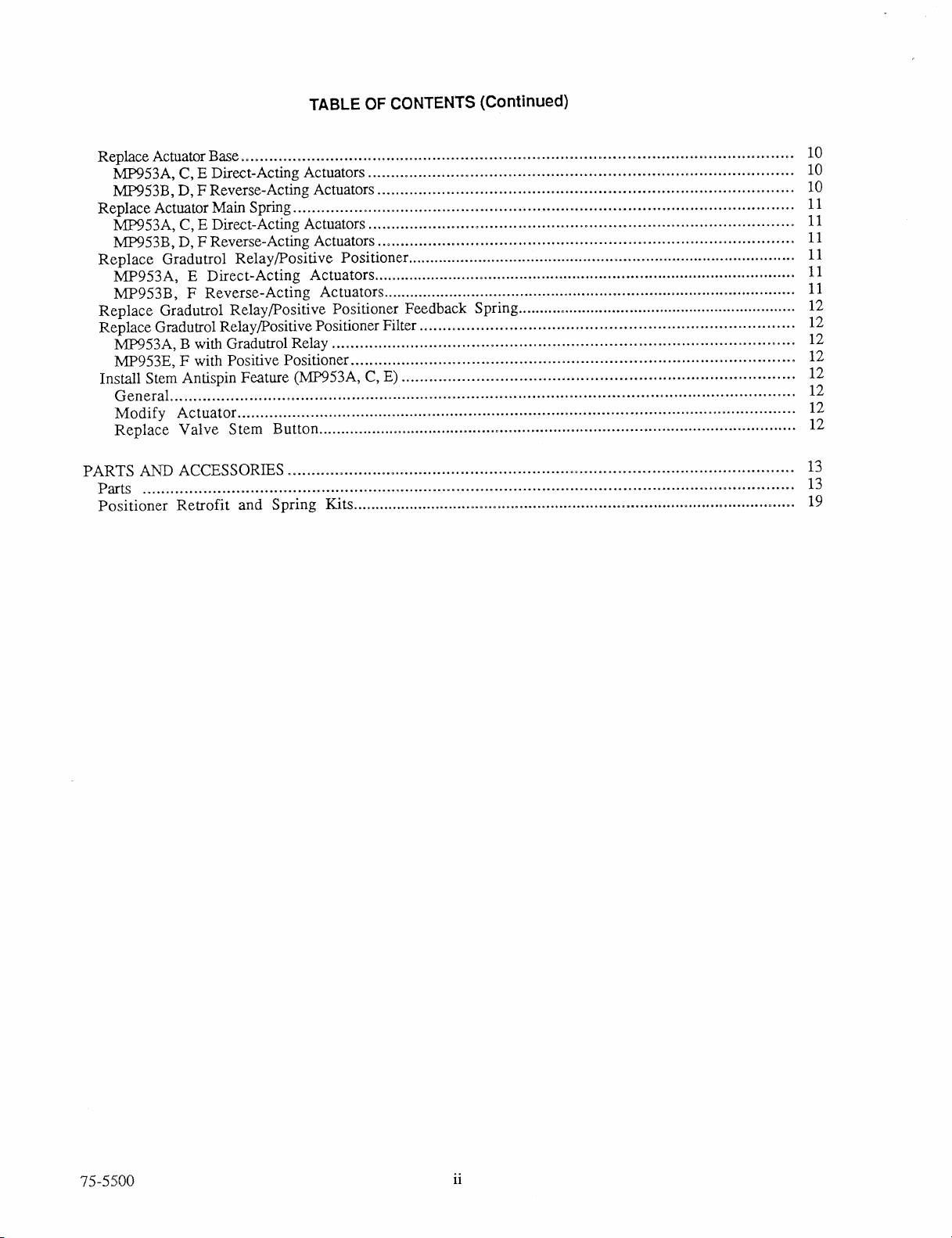

SPECIFICATIONS

MODELS:

MP953A-Direct-acting with Gradutrol Relay

MP953B-Reverse-acting with Gradutrol Relay

MP953C-Direct-acting without positioner

MP953D-Reverse-acting without positioner

MP953E-Direct-acting with positive positioner

MP953F-Reverse-acting with positive positioner

MAXIMUM SAFE AIR PRESSURE

25 psi (172

See Table 1 for additional specifications.

Specifications.

Size in

13 (330)

kPa)

112

(13) 160 (71)

314 (19)

314

(19)

l-1/2

(38)

314

(19)

l-1/2

(38)

with Gradutrol

i

Cl067 I-

Cl075

I

-

-

Cl141

-

Cl158

Cl067 C3XH

Cl075

C3XK

-

C9XH

-

C9XK

1

8 (203)

5 (127)

314 (19)

l/2

(13)

103)

2-7 (14-48) No

8-l 2 (55-83)

3-91 75-5500

Page 4

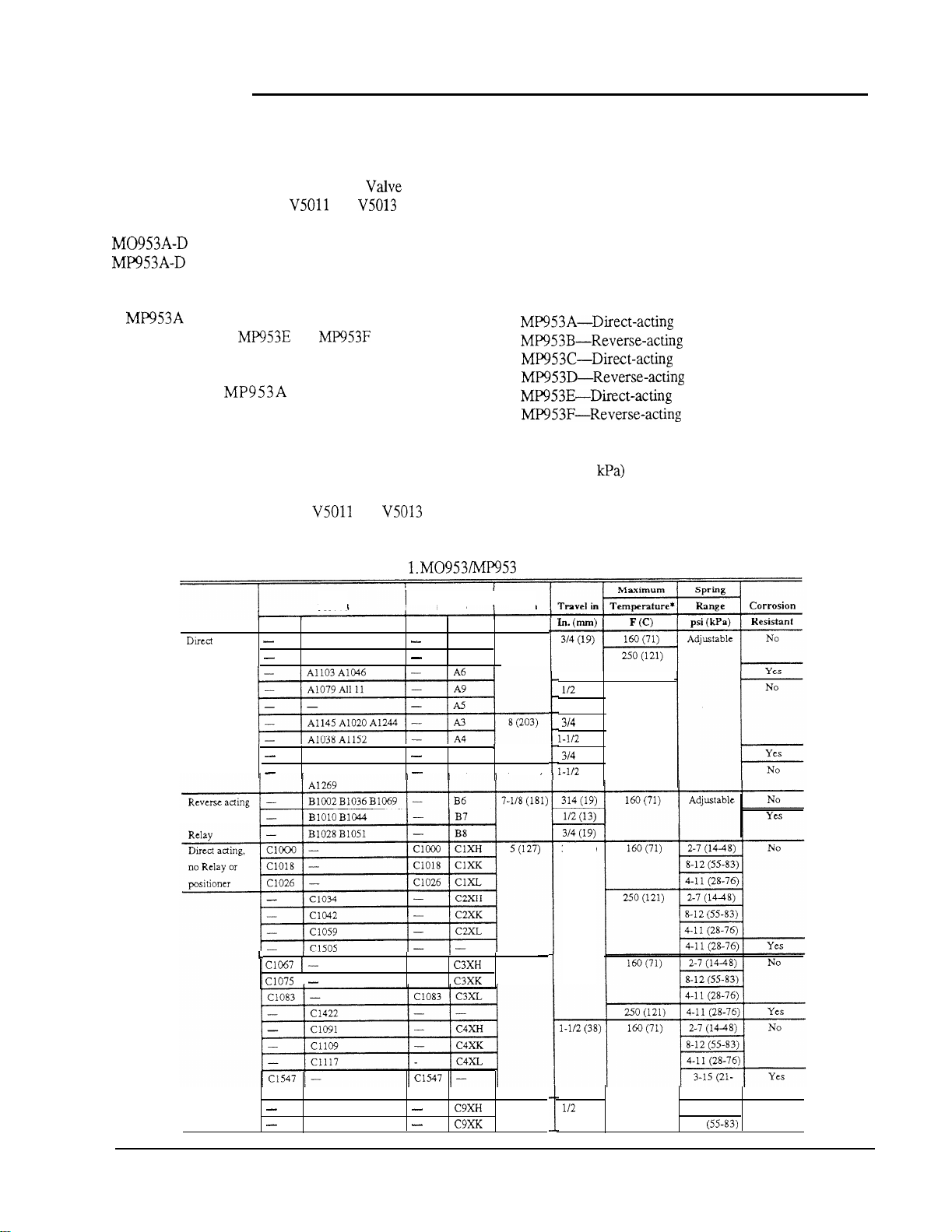

Table 1.

MO953hW53

Specifications (Continued).

MP953

Device Type

Direct acting

no Relay or

positioner

(Cant)

Direct acting

with positive

positioner

Reverse acting

with positive

wsitioner

*Diaphragm color indicates maximum temperature:

Black

Black with White Dot (Ethylene Propylene-250F

Active

1

-

-

Cl471 Cl125

I

Cl489 Cl133 Cl489

Cl554

Cl562

-

-

D1222

D1230

D1248

D1255

El301

El319

El327

El277

El285

El293

El368

El376

El384

Inactive

I

Cl166

Cl414

-

-

D1206 D1206t -

D1214

-

-

- -

-

-

El400

- -

El418

-

El427

El435

-

El443

F1119

-

FllOl

-

F1093

-

(Neoprenetl6OF

(71C)

Active

-

-

Cl471

D1214t -

D1222

-

-

-

I-

I-

-

-

-

(121C)

MO953

1

Inactive In (mm)

I

c9xL5

C8XH

C8XL

Cl554

Cl562

-

-

-

-

-

-

-

-

-

!

I

I

I-

I-

Sh?In

(127)

8 (203)

13 (330)

-

7-118

(181)

8 (203)

13 (330)

3 (330)

7

(180)

Travel

In (mm)

1n

(13)

314

(19)

l-l/2

(38)

314

(19)

l-112

(38)

1-K

(38)El392

in

250

(121) 3-7 (21-48)

160

(71) 3-7 (21-48)

160 (71)

8-12

(55-83)

4-l 1 (28-76)

8-12 (55-83)

1(28-76)

4-l

(55-83)

8-12

4-l 1

(28-76)

10 (69)

10 (69)

No

,

75-5500

Page 5

OPERATION

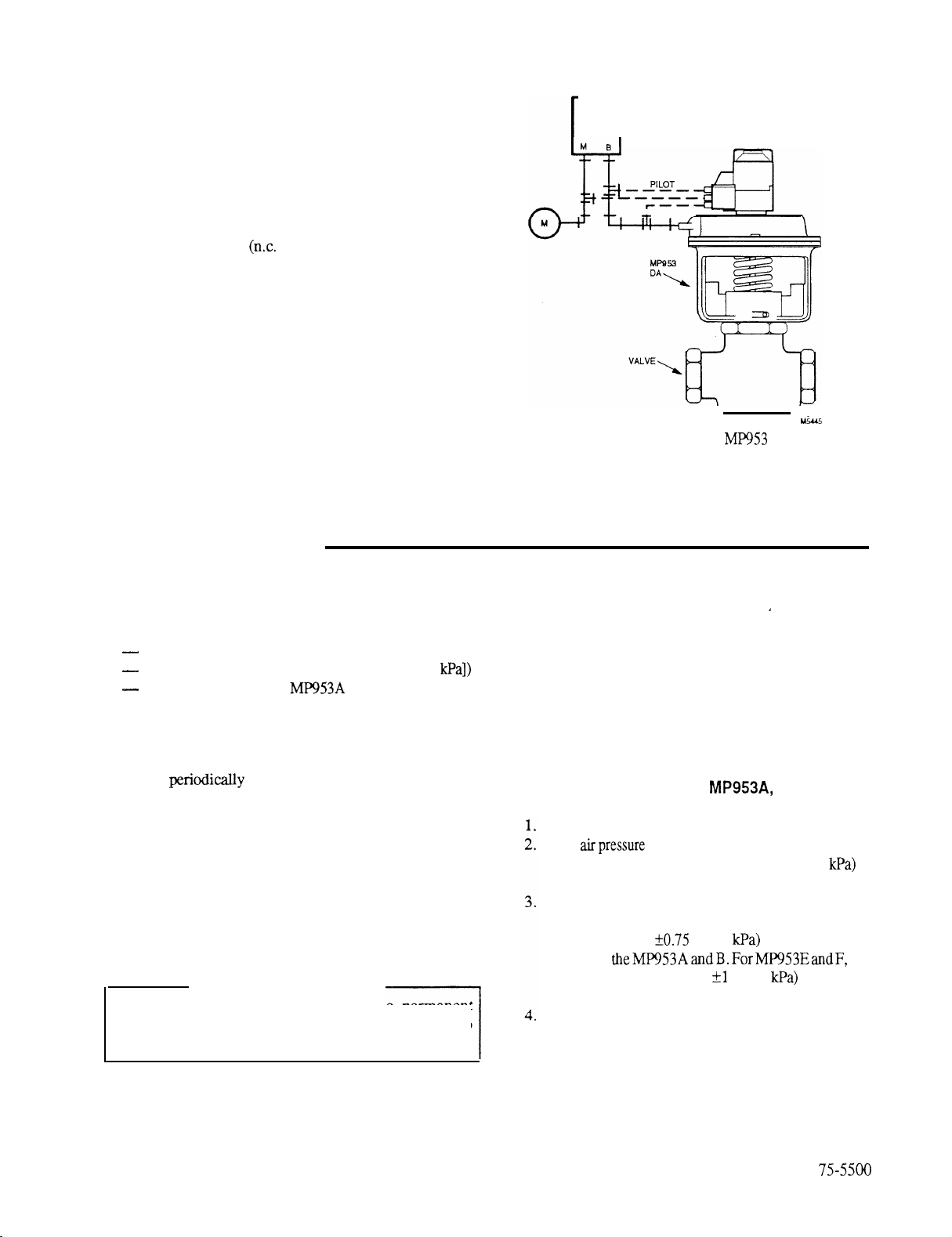

In a direct-acting (n.o. valve) system, an increase in

control (branch/pilot) air pressure forces the Actuator

diaphragm and cup assembly downward, forcing the valve

stem down to proportionally close off the flow through the

valve (Fig. 1).

1

THERMOSTAT

POSITIONER

In a reverse-acting

control (branch/pilot) air pressure forces the Actuator

diaphragm and cup assembly upwards, forcing the valve

stem up to proportionally increase the flow through the

valve.

In Actuators without Gradutrol Relays or positive

positioners, branchline pressure is applied to the

diaphragm. In Actuators with Gradutrol Relays or positive

positioners, up to full main air pressure is applied to the

diaphragm to ensure the valve is positioned proportionally

to the pilot pressure (the branchline pressure output from

the controlling device).

(nc.

valve) system, an increase in

MAINTENANCE

EQUIPMENT NEEDED

-

Commercial cleaning solvent or degreaser

-

Pressure Gage 14003519 (0 to 30 psi [0 to 207

-

Wrench 301572A for

MP953A

and B

kPa])

Mius

Fig. 1. Typical Direct-Acting

OPERATIONAL CHECK

Vary the branchline (pilot) pressure through the

operational range of the Actuator in both directions. The

valve should open and close smoothly.

MP953

Operation.

2

VISUAL INSPECTION

Check

periodically

visible problems.

for leaks, loose fittings, and other

CLEANING

Clean the Actuator with a commercial cleaning solvent or

degreaser.

A

WARNING

Careless handling of solvents can cause permanent

respiratory or skin damage. Avoid prolonged exposure to

solvents.

A

ADJUSTMENTS

CHECK ADJUSTMENT ON

Install gages in the main and pilot air lines.

Main

air

pressure

should be greater than or equal to the

top of the sequencing range (span): 13 psi (90

the minimum main pressure for the device to function.

Slowly increase

which the valve stem begins to travel. This pressure

should be within

setting

pressure should be within +l psi (7

point.

Continue increasing the pilot pressure until the valve

stem stops traveling. This pressure should be the start

point pressure plus the range (span) setting.

of

pilot

kO.75

theMP953AandB‘ForMP953EandF, the

MP953A,

pressure and note

psi (5

kPa)

of the start point

kPa)

B, E, F

the

pressure at

of the start

75-5500

kPa)

is

Page 6

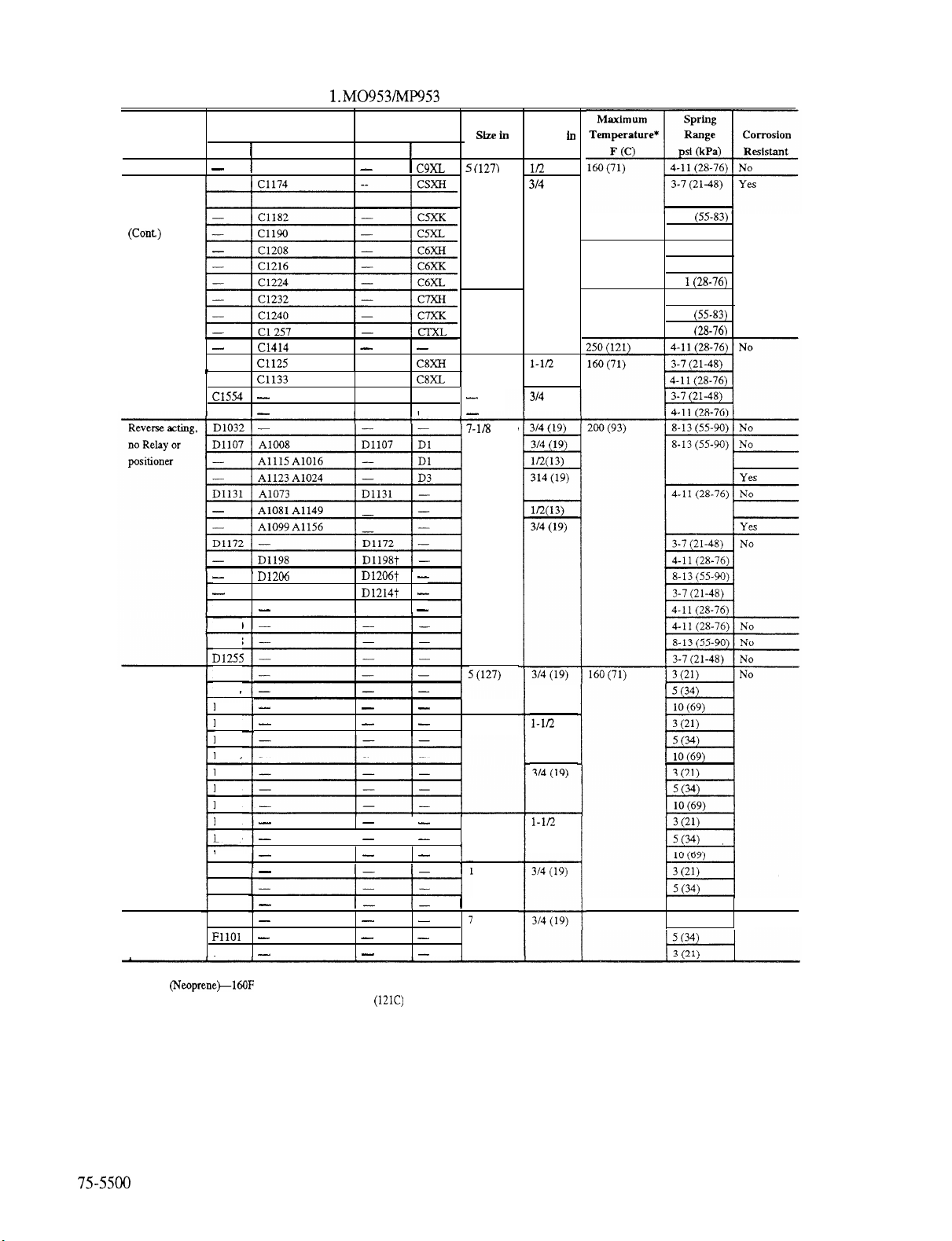

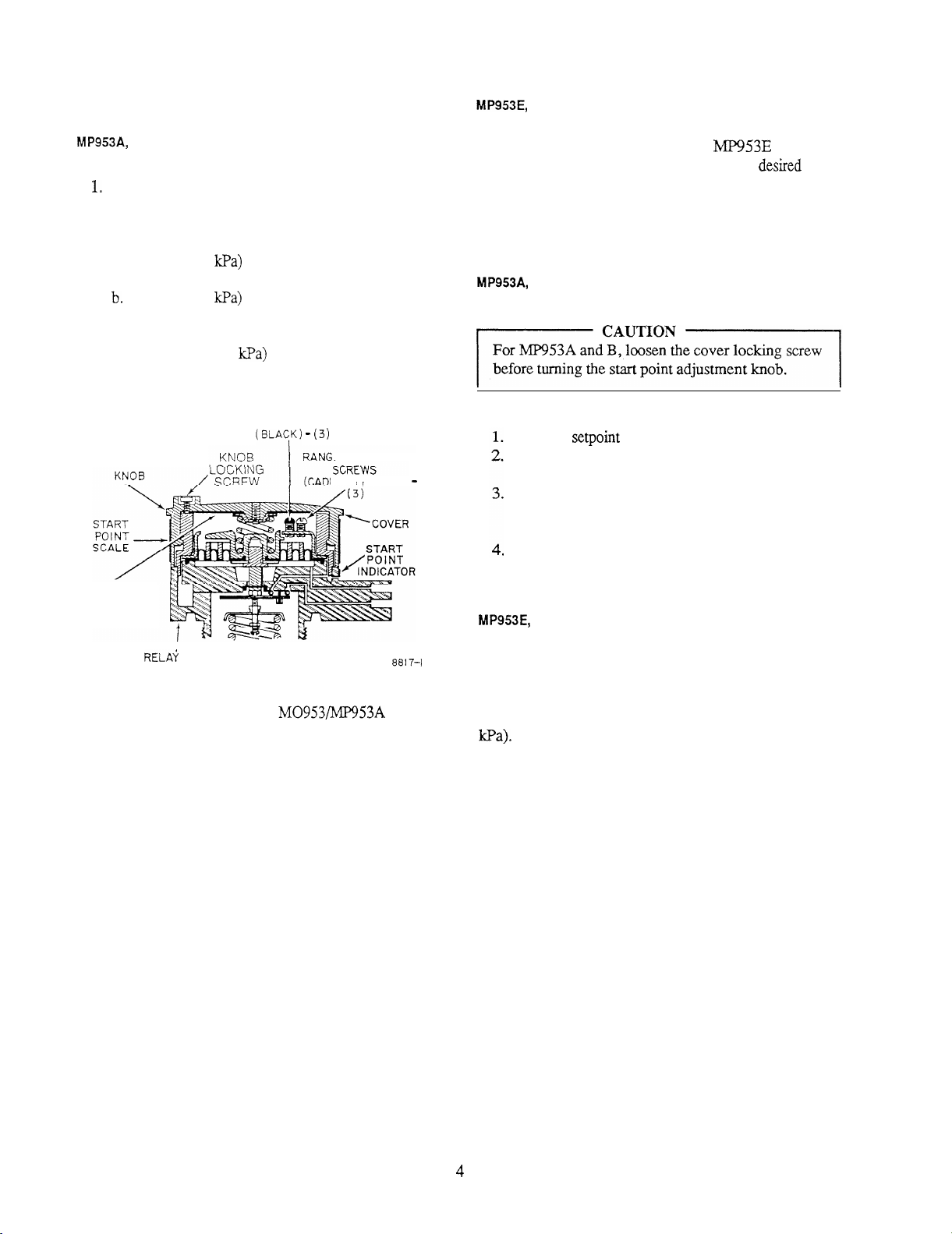

SET OPERATING RANGE

MP953E,

F

MP953A,

B

1,2.Use Wrench 301572A to loosen the cover locking

screw (Fig. 2).

Unscrew the start point adjustment knob until thread

is disengaged. Remove knob.

a.

For 3 psi (21

kPa)

range, back all range adjustment

screws off to friction stop.

b.

For 5 psi (34

kPa)

range, back only the black range

adjustment screws to stop and tighten the outer,

cadmium-plated range adjustment screws.

c. For 10 psi (69

kPa)

range, tighten all range

adjustment screws.

RANGE ADJUSTMENT SCREWS

START POINT

ADJUSTMENT

RANGE

ADJUSTMENT

INSTRUCTIONS

SHOWN HERE

(BLANK) -

(3)

E ADJUSTMENT

M IUM

PLATED)

-

Change the operating range of

replacing the feedback spring with one for the

MP953E

desired

and F by

(see REPAIR).

ADJUST START POINT

MP953A, B

Reinstall

setpoint

knob.

Tighten knob by turning it until it is seated on relay

body (Fig.

2).

Loosen knob (maximum of one turn) until start point

of correct scale range lines up with start point

indicator.

Tighten knob locking screw until it engages relay

body. Do not overtighten.

MP953E, F

range

RELA‘i BODY

Fig. 2. Adjustment Points of

Gradutrol Relay.

M0953/MP953A

8817-I

and B

Set the start point on the positioner to the value shown on

the job drawings. Critical applications and feedback spring

changes mightrequire fine-tuning the

of the start point knob will adjust the start

start

point. Each click

point

0.25 psi (1.7

kPa).

75-5500

4

Page 7

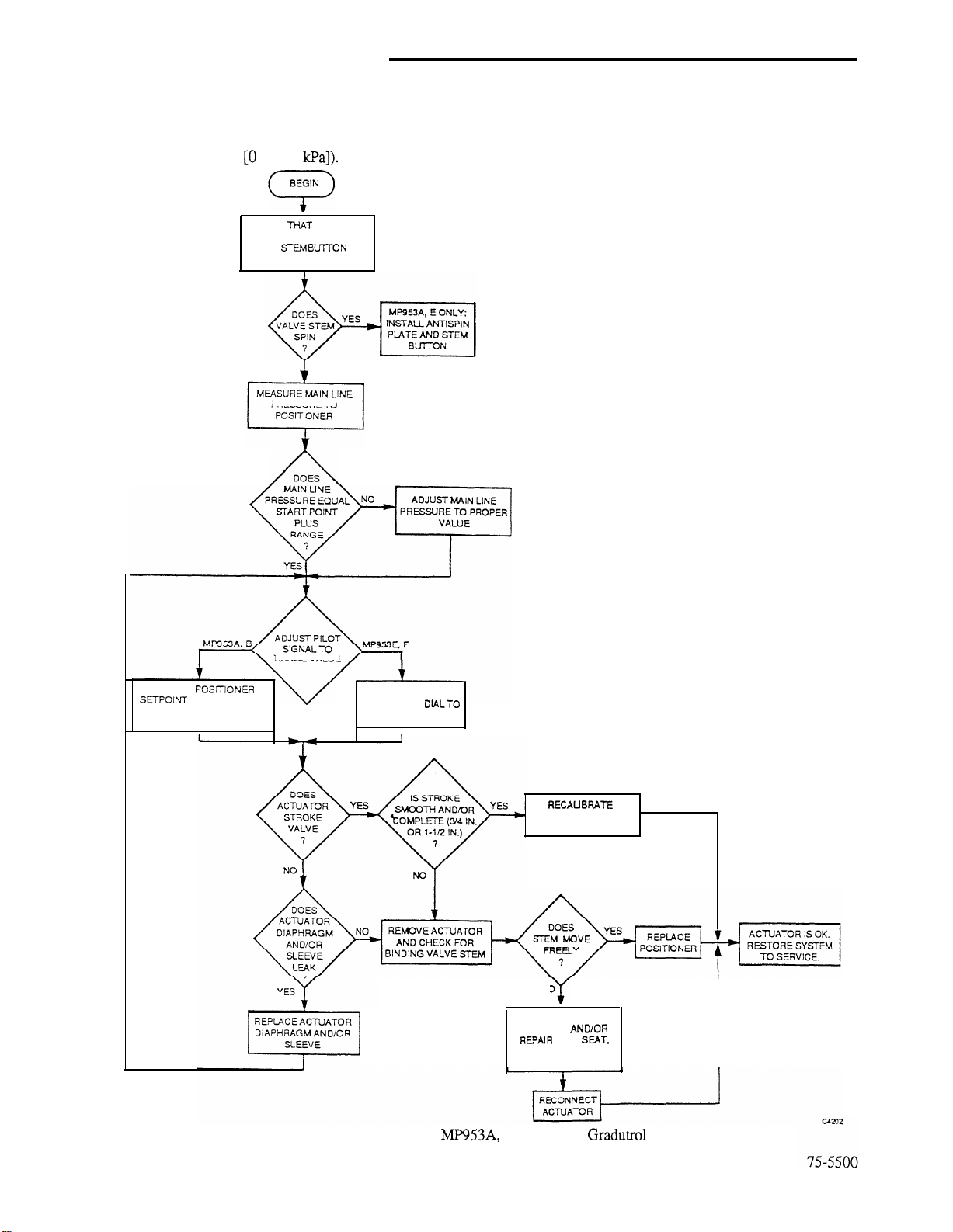

TROUBLESHOOTING

EQUIPMENT NEEDED

Troubleshooting procedures require Pressure Gage

14003519 (0 to 30 psi [O to 207

CHECK

IS SECURELY MOUNTED

kPa]).

THAT

ACTUATOR

STEM EU-lTON IS

AND

PROPERLY LATCHED

NO

f

PRESSURETO

DOES

A

SYMPTOMS AND CORRECTIVE

ACTION

Figures 3 and 4 show troubleshooting flowcharts.

LOOSEN

SETPOINT COVER. SLOWLY

TURN COVER SCALE TO

BELOWZERO START POINT.

POSiTlONER

RANGE VALUE

ADJUST POSITIONER

START POINT

MINIMUM VALUE

DIALTO

I

RECAUBRATE

POSITIONER START

POINT IF NECESSARY

NO

Y

REMOVE ANY FOREIGN

MATERIAL;

REPAIR

AND STEM; AND/OR

AND/OR

DISC, SEAT.

REPACK VALVE

Fig. 3. Troubleshooting Flowchart for

MP953A,

B, E, F (with

5

Gradutrol

Relay/Positioner).

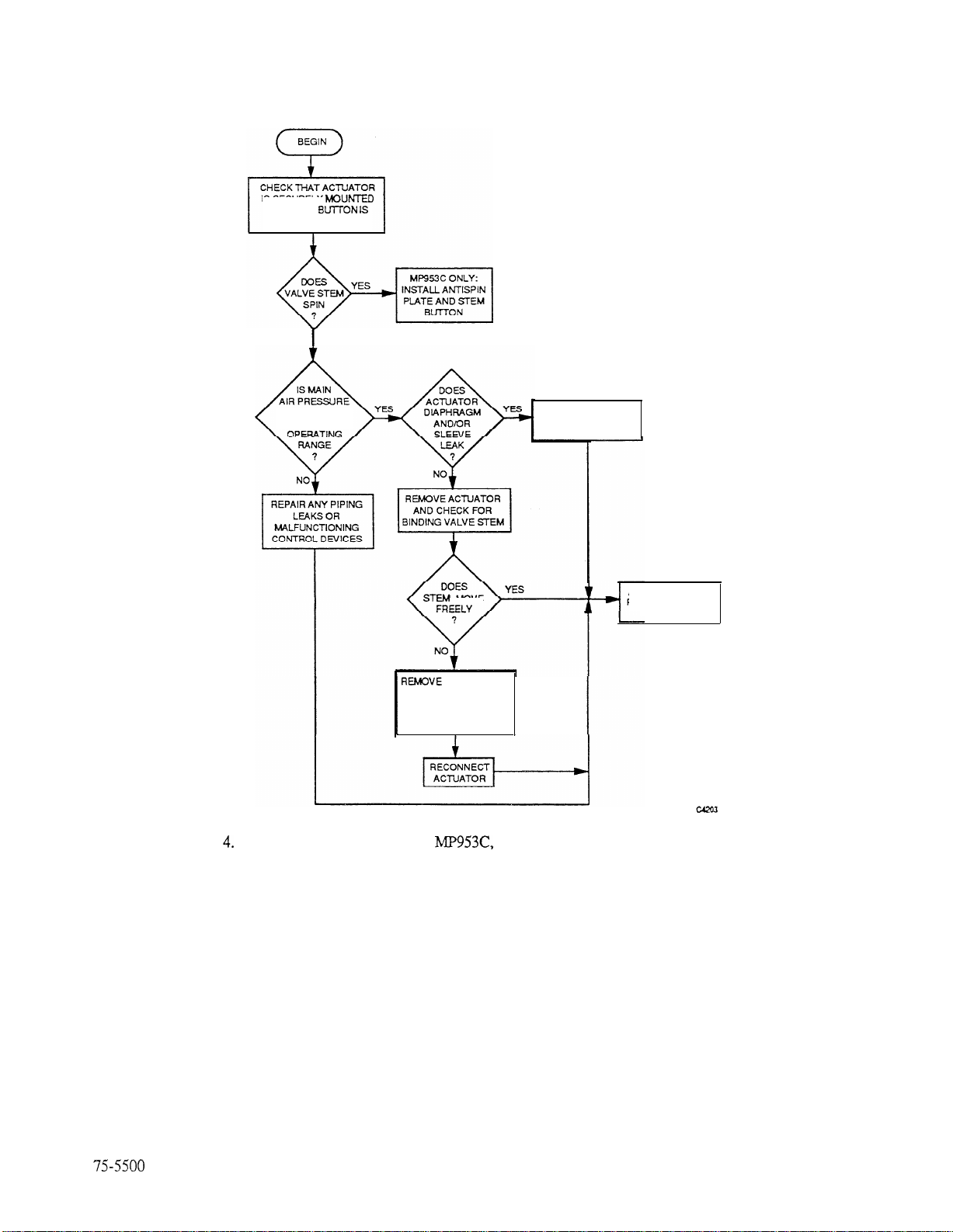

Page 8

IS SECURELY h4OUNTED

AND STEM

PROPERLY LATCHED

NO

6UlTON Is

I

ADEQUATE FOR

COMPLETE

S-EM MOVE

REMOVE ANY FOREIGN

MATERIAL; AND/OR

REPAIR DISC, SEAT,

AND STEM; AND/OR

REPACK VALVE

Fig. 4. Troubleshooting Flowchart for

MP953C,

REPLACE ACTUATOR

DIAPHRAGM AND/OR

SLEEVE

ACTUATOR IS OK.

RESTORE SYSTEM

TO SERVICE.

D (without Gradutrol Relay/Positioner).

75-5500

Page 9

REPAIR

GENERAL

This section lists tools needed to disassemble and

reassemble Actuators and gives procedures for replacing

parts of actuators. See PARTS AND ACCESSORIES for

parts diagrams and lists.

Table 4. Loosening and Removing Actuator Bases from

Valve Bonnets.

Device

Model

MP953A

MP953c

MP953E

Series Dia (In.)

Actuator

Tools Required

3/16-in hex

or T-25 Torx bit

NOTE Series number does not

allen

wrench (bit)

EQUIPMENT NEEDED

Tables 2 through 5 list basic repair tasks and the tools

required for each.

Table 2. Removing and Replacing Actuator Covers.

‘~

Model

1/4-h

MP953A

MF953c

h4P953E

MP953B

MIY53D

MP953F

Au

All

5

8

13

7

hex socket

- 3/8-in

hex socket

-

Two l/4-20 x 3 in. hex-head

bolts, threaded to within

l/%-in.

of bolt head

- 3/8-in.

-Four

5/16-in.

hex socket

5/16-18

x 3 in. hex-head

bolts, threaded to within

l/2-+1.

of bolt head

hex socket

Table 3. Removing and Replacing Actuator Bases.

De vice

Model

MP953A

MP953c 2

MP953E

MP953F 1

Series Dia (In.)

2

1

Actuator

5

Tools Required

5/16-in.

hex socket

5/16-in.

hex socket or T-25

Torx bit

NOTE: Series number does not

indicate type of

fastener.

9/16-m.,

six-point, deep socket

(3/8-in.

drive preferable)

3/8-in. hex

3/16-m. hex

3/16-in. hex

or T-25 Torx bit

NOTE: Series number does not

allen

wrench (bit)

allen

wrench (bit)

allen

wrench (bit)

indicate type of

fastener.

Mp953c

MP953E

MP953A

MP953c

MP953E

MP953B

MP953D

MP953F

Table 5. Miscellaneous Tasks.

Task

Removing

Gradutrol Relay positioner

Removing

positioner

Removing

Gradutrol Relay positioner

bracket assembly

Removing

positioner bracket assembly

Removing and replacing

MP953B,

diaphragm

Replacing feedback-spring

cup on

diaphragm

Unlatching actuator from

valve stem button

Lubricating

Gradutrol Relay positioner

O-ring

Lubricating

positive positionerO-ring

MP953A

MP953E

hJP953B

MP953F

D, F sleeve

MP953A,

MP953A

MP953E

positive

positive

E main

NOTE:Used only

1989

or later date

actuatorsregardlessof date

umber does not

Tools Required

Crescent wrench with jaw

opening to at least

mm). Narrow-jaw pipe wrench or

large adjustable pliers may be

substituted as long as they do not

the setpoint knob.

distort

Adjustable crescent wrench with

jaw opening to at least

(67 mm).

5/16-in. hex socket

-

Small-blade screwdriver

-3/16-m

-

l-3/8-in. adjustable hex socket

(crescent wrench is acceptable

substitute)

Pliobond glue or equivalent

Medium- to large-blade

screwdriver

Lubricant or silicone grease

obtained locally

2-5/8

hex socket

in. (67

2-5/8

in.

75-5500

Page 10

GRA

DUTRO

‘ELAY

ASSEMBLIES

313695 J

SPRING

31371

(MP953B) ’

-@

I

A

/--_315178

PARTS BELOW COMMON TO AU RELAYS

CUP

SCREW

NUT OS0 X

CUP ASSY

0-80X

.05

5/16 ROUND

IN.

THICK

HD

6-32 X

l/4

ROUND H

PARTS BELOW COMMON TO ALL RELAYS

VALVE UNIT

75-5500

Fig. 5.

START

POlNT

SPRING

Gradutrol

1

A

THE 313711A AND D MODELS HAVE

DUAL BARBED CONNECTORS; THE

3137118 AND C MODELS USE

THREAD CONNECTION. THE

AND 8 MODELS HAVE DUAL SCALE,

ENGLISH AND METRIC; THE 313711C

AND D MODELS HAVE ENGLISH

Relay Assemblies Exploded View.

8

PlPt=

. .

-

313711A

5!32c-2

Page 11

MO953

JO CONVFRT A4

8

IN. (203 MM)

RELAY ASSY 313695J

FEEDBACK SPRING

3 13696-00063

CUP 315178-00062

DIAPHRAGM 311750 OR

314153

31174O-OO602

CUP

CONVERSION

DFVICF-

YOKE ASSEMBLY

TO CONVFRT A8

13 IN. (330 MM)

RELAY ASSY

FEEDBACK SPRING

313814-00605

CUP 315178-00062

DIAPHRAGM 312505

CUP 315020-00124

-DIAPHRAGM

@

-SCREW

72

Q-WASHER

-

PLATE

Fig. 6. MO953 Conversion.

DWICF-

313695J

-

Black with white spot: Ethylene Propylene

(EPR)

Maximum temperature 250F (121C)

Used on

-

White: Silicone

Maximum temperature 250F (12

Used on

MP953B,

MP953A

D and F

1C)

and C and may be installed on

MP953E

Flat diaphragms and beaded-roll diaphragms are not

interchangeable. Neoprene and EPR diaphragms are

interchangeable but must meet maximum temperature

requirements.

MP953A, C, E DIRECT-ACTING ACTUATORS

Direct-acting Actuators are subject to extremely high

internal spring loads. Therefore, Actuator covers must be

removed very carefully before the the main diaphragm can

be replaced.

When using the following procedures, see Figures 8 and

10 for exploded diagrams and Tables 6 and 8 for parts.

SPRING

314652

YOKE

314651 (314651A)

316059 (316059A)

ASSEMBLY

HELICOIL INSERT

ASSEMBLY

NYLON INSERT

316059A-FOR

314651A-FOR

SUPPORT WITH

SUPPORT WITH

314653

14732-l

Fig. 7. Yoke Assembly.

REPLACE MAIN DIAPHRAGM

GENERAL

Before replacing the diaphragm, determine the type and

material of the existing diaphragm according to its color:

-

Black: Neoprene

Maximum temperature 160F (71C)

Used on

MP953A, 6,

and E

REMOVE ACTUATOR COVER

WARNING

A

A

Use extreme caution when disassembling Actuators.

Actuator assemblies are under spring load which can reach

1.

Disconnect all air lines, including any connected to

Gradutrol Relay or positive positioner, if present.

2.

MP953A

and E only: Remove Relay/positioner from

Actuator cover by turning counterclockwise.

Remove exposed feedback spring.

3.

See WARNING in this section. Loosen cover

4.

setscrews sequentially

Check whether cover can be squeezed back to

5.

l-1/2

turns each.

frame

by hand. If so, continue sequentially loosening screws

until cover is free. Remove cover, diaphragm, and go

to REPLACE DIAPHRAGM.

If cover cannot be squeezed back to frame, use the

6.

following guides according to Actuator size.

NOTES:

a. Bolts should be threaded to within

approximately

b.

In each case, turn the long bolt in until its head

l/2

in. of their heads.

contacts the cover flange.

-

8-m Actuator: Remove two cover screws

that are directly opposite each other. Replace

cover screws with

l/4-20

x 3 in. bolts.

75-5500

Page 12

-

13-in. Actuator: Sequentially remove and

replace every second cover screw with a

16-18 x 3 in. bolt.

7.

Continue sequentially loosening all bolts/screws until

all original (short) bolts/screws are disengaged.

8,

Continue to loosen remaining long bolts alternately

until no more spring load exists. Remove bolts, cover,

and diaphragm.

REPLACE DIAPHRAGM

Fit new diaphragm over Actuator cup. Position cover

1.

over diaphragm,

2.

Reinstall Actuator cover following procedure in

REMOVE ACTUATOR COVER in reverse order.

NOTE: In some cases, cup and diaphragm will be

forced above top of frame. As cover is

tightened, check that diaphragm bead is

properly positioned in its retention groove.

MP953A

3‘

spring cup to new diaphragm. Cup must be centered

in hole of Actuator cover.

4.

Reassemble feedback spring and Relay/positioner.

Make certain that each end of spring is located in a

spring cup (one end on diaphragm and the other end

in Relay/positioner) before screwing Relay/

positioner back into position.

Reinstall air lines and restore system to service.

5,

MP953B,

Reverse-acting Actuators are not subject to high internal

spring loads. Therefore, the Actuator cover can be removed

routinely.

and E only: Cement positioner feedback

D, F REVERSE-ACTING ACTUATORS

5/

Reinstall small sleeve cup, ring, and screws.

5.

6.

Install new main diaphragm, checking that it is

properly located.

Reinstall cup, lockwasher, and nut. Tighten nut

7.

enough to seal diaphragm against cup.

8.

Reinstall feedback spring. Check that spring is

securely seated in grooves on lever and cup support.

9.

Reinstall cover and cover screws.

Reinstall air lines and restore system to service,

10.

REPLACE ACTUATOR BASE

MP953A, C, E DIRECT-ACTING ACTUATORS

When using the following procedure, see Figures 8 and

10 for exploded diagrams and Tables 6 and 8 for parts.

WARNING

A

Use extreme caution when disassembling Actuators.

Actuator assemblies are under spring load which can reach

550 pounds.

1.

To eliminate internal forces in Actuator assembly and

remove Actuator cover, refer to REMOVE

ACTUATOR COVER under

DIRECT-ACTING ACTUATORS in REPLACE

MAIN

DIAPHRAGM section.

2.

Remove Actuator cup, spring, retainer, plate,

mainspring, and ring

3.

Remove fasteners securing base to frame.

4

Install new base assembly and reinstall fasteners.

5.

Reassemble Actuator assembly by following

procedure in Steps 1 and 2 in reverse order.

6.

Reinstall air lines and restore system to service.

(5-in.

A

MP953A,

models only).

C, E

Replace diaphragm and sleeve (inner seal) together. Use

SERVICELINE Kit 14003

are rated at 250F

When using the following procedure, see Figures 9 and

11 for exploded diagrams and Tables 7 and 9 for parts.

Disconnect all air lines, including any connected to

Gradutrol Relay or positive positioner, if present.

Remove cover screws, cover (on

Relay/positioner remains attached to cover),

feedback spring

lockwasher, cup, and diaphragm.

Remove small sleeve cup, screws, ring, and sleeve

diaphragm.

Install new sleeve diaphragm, checking for proper

seating in its locating groove.

75-5500

(121C).

124-002

(MP953B,

for all Actuators. Parts

MP953B

F), large nut,

and F,

10

MP953B,

When using the following procedure, see Figures 9 and

11

for exploded diagrams and Tables 7 and 9 for parts.

To safely disassemble and reassemble reverse-acting

Actuators with 8 psi start point, a mechanical advantage is

required due to the high compression of the main spring

(200 pounds). For safety, use a large bench vise or C-clamp

and two blocks of wood.

1.

D, F REVERSE-ACTING ACTUATORS

WARNING

A

To release support assembly from Actuator cup, refer

to Steps 1 through 3 in

ACTING ACTUATORS under REPLACE MAIN

DIAPHRAGM.

A

MP953B,

D, F

REVERSE-

Page 13

2.

See WARNING in this section. Sequentially loosen

fasteners securing base to frame. Base pops

frame when fasteners disengage.

When tension is relieved, remove fasteners and base.

3.

Install new base assembly.

4.

Reinstall fasteners.

5.

Reassemble Actuator assembly by following

6.

procedure in Steps 1 and 2 in reverse order.

Reinstall air lines and restore system to service.

7.

up from

REPLACE ACTUATOR MAIN

SPRING

MP953A, C, E DIRECT-ACTING ACTUATORS

Remove the main

by following the procedure in REMOVE ACTUATOR

COVER under

ACTUATORS in REPLACE MAIN DIAPHRAGM

section. This procedure relieves all internal spring force and

makes the spring fully accessible.

See PARTS for the proper replacement spring.

spring

on direct-acting Actuators

MP953A, C, E DIRECT-ACTING

safely

NOTE:

3. Remove feedback spring. Retain old spring for

MP953A.

4. Install original feedback spring in diaphragm cup

when Relay/positioner is being replaced with an

identical device.

5. When replacing Gradutrol Relay with a new-style

positive positioner, discard original spring and install

feedback spring with proper range from appropriate

retrofit kit. For part number, see POSITIONER

RETROFIT AND SPRING KITS in PARTS AND

ACCESSORIES.

6. Position new O-ring in groove of Relay/positioner

base and install new Relay/positioner in Actuator

cover.

NOTE: Compress feedback spring as the Relay/

Tighten Relay/positioner only enough to seat large

7.

Considerable force may be required before

the positioner begins to turn because of the

large O-ring that seals the Relay/positioner

to the Actuator cover.

positioner is screwed in place. Check that

both ends of the feedback spring are located

in the spring cups, one in the Relay/

positioner and one cemented to the Actuator

diaphragm.

O-

MP953B, D, F REVERSE-ACTING ACTUATORS

Remove the main spring on reverse-acting Actuators

safely by following the procedure in

DIRECT-ACTING ACTUATORS in REPLACE MAIN

DIAPHRAGM section. This procedure relieves all internal

spring force and makes the spring fully accessible.

See PARTS for the proper replacement spring.

MP953B,

D, F

REPLACE GRADUTROL RELAY/

POSITIVE POSITIONER

MP953A, E DIRECT-ACTING ACTUATORS

When using the following procedure, see Figure 8 for an

exploded diagram and Table 6 for parts.

To prevent damage to the

1.2.Disconnect all air lines.

Unscrew Relay/positioner counterclockwise from

Actuator cover and remove.

MP953E,

wrench force must only

of position and damage Actuator diaphragm and

feedback spring when unit is destroked.

8. Reinstall air lines and restore system to service.

9. Adjust range

MAINTENANCE.

MP953B,

When using the following procedure, see Figure 9 for an

exploded diagram and Table 7 for parts

F REVERSE-ACTING ACTUATORS

Disconnect all air lines, including short tube from

Relay/positioner to side of Actuator cover.

Remove three screws that locate the Relay/positioner

bracket assembly on the Actuator cover.

Remove bracket assembly. Retain original bias and

feedback springs when Relay/positioner is being

replaced with an identical device,

When replacing Gradutrol Relay assembly with

style positive positioner assembly, discard original

bias and feedback springs and install springs with

proper range from appropriate retrofit kit. For part

number, see POSITIONER RETROFIT AND

SPRING KITS in PARTS AND ACCESSORIES.

(MP953A only) and/or start point. See

new-

.l

75-5500

Page 14

Check that ends of bias and feedback springs are

properly located. Install new Relay/positioner

bracket assembly on Actuator cover.

Replace short tube from Relay/positioner branch port

to fitting on side of Actuator cover.

Reinstall remaining air lines and return system to

service.

Adjust range

MAINTENANCE.

(MP953B

only) and/or start point. See

5.

Replace service plate and reinstall positioner.

6. Reconnect tubing and restore system to service.

INSTALL STEM

FEATURE

GENERAL

(MP953A,

ANTISPIN

C, E)

REPLACE GRADUTROL RELAY/

POSITIVE POSITIONER

FEEDBACK SPRING

See

appropriate part of REPLACE GRADUTROL

RELAY/POSITIVE POSITIONER for correct feedback

spring replacement procedures.

REPLACE GRADUTROL RELAY/

POSITIVE POSITIONER FILTER

MP953A, B WITH GRADUTROL RELAY

When using the following procedure, see Figures 5, 8,

and 9 for exploded diagrams and Tables 6 and 7 for parts.

Remove tubing.

1.

Remove

2.

Remove filters from Relay ports with pointed tool

3.

such as an awl.

Install foam filters, taking care not to fold

4.

bunch them together.

Reinstall fittings and tubing. Restore system to

5.

service.

Gradutrol

Relay air fittings.

filters

or

A valve

Actuator. The

MP953A,

MP953A,

modifying the latching mechanism in the Actuator then

replacing the stem button on top of the valve.

‘when

10 for exploded diagrams and Tables 6 and 8 for parts.

MODIFY ACTUATOR

1.

2.

3.

4.

5.

6.

7.

stem

will not spin when it is locked to the

antispin

C, and E and can be added to the 5- and

C, and E. Adding the

using the following procedures, see Figures 8 and

Disconnect air lines.

Loosen

release stem button latch located on underside of

Actuator cup.

Remove Actuator from valve.

On Relay/positioner equipped Actuators

and E), refer to appropriate procedures under

REPLACE GRADUTROL RELAY/POSITIVE

POSITIONER. Remove feedback spring.

Remove Actuator cover, diaphragm, cup, spring,

retainer, and plate. Refer to appropriate procedures

under REPLACE MAIN DIAPHRAGM for

disassembly.

Replace plate with

Reassemble retainer, spring, cup, diaphragm, cover,

two

and positioner.

feature is built into 13-inch

8inch

antispin

Actuator base/valvebonnet setscrews and

Antispin

feature involves

Plate 3

11975A.

(MP953A

MP953E,

When using the following procedure, see Figures 8 and 9

for exploded diagrams and Tables 6 and 7 for parts.

75-5500

F

WITH

POSITIVE POSITIONER

Remove tubing.

To remove positioner from Actuator cover, follow

appropriate procedures under REPLACE

GRADUTROL RELAY/POSITIVE POSITIONER.

Remove service plate (Fig. 12 through 14) from

positioner.

Replace filter assembly with Filter Assembly

14001865-001.

12

REPLACE VALVE STEM BUTTON

Use the following procedure to replace the stem button on

lf2-

to 3-inch

Valves. The procedure requires Stem Button 3 12495.

Remove existing stem button.

Replace old button with new button, checking that the

new button is installed at the same height as the old

button.

Reinstall Actuator on valve.

Reconnect air lines and restore system to service,

V5011

Valves and l/2- to 2-inch

V5013A

Page 15

PARTSANDACCESSORIES

PARTS

Figures 8 through 11 show exploded diagrams of

M0953A-D

11 list parts shown in the figures.

and

MP953A-F

Actuators. Tables 6 through

Fig. 8.

MO/MP953A

and

MP953E

24076

Exploded View.

13

Fig. 9.

MO/MP953B

and

MP953F

Exploded View.

75-5500

Page 16

Table 6.

MOLMP953A

and

MP953E

Parts.

313814~OGO65

313696-00063

Feedback spring for l-l/2-in. stroke

Feedback spring for

MP953A

(see NOTE 2)

3/4-in. stroke MP953A (see NOTE 2)

t

14004698-001

1

312099

21 1 14004298-005

14003034-261

14003034-264

Frame for

Frame for

Base for 5-in. models, includes screws

Base for

Base for

Base for

Replace with l/4-20 x

Replace

Replace with

Rentace

Base screw

Basescrew

Basescrew

g-in.

models, includes screws

13-in.

models

g-in.

models

13-in.

models,

3/4-in.

stroke

13-in.

models,

l-l/2-in.

stroke

5/8

in. can-head machine screw (2) for 5-in. models

with 5/16-18

with

x I-

l/4

in. cap-head machine screw (2) for

5/16-18

x l-314 in. cap-head machine screw (2) for 13-in. models,

3/8-16

x

I-112

in. can-head machine screw

(2),

l/4-20 x 314 in. for 5-m. models

(2), l/2-13

(2),

x i-1/2 in. for

ID-13 x 2 in. for

13-in.

NOTES:

I.

For metric conversion: Model sizes- 5 in. (127

in. (203 mm) 13

in. (330 mm)

2.

For

MP953E

feedback spring, see Table 13.

75-5500

mm)8

Stroke- l/2 in. ( 13

mm)3/4 in. (19

mm)l-l/2

14

g-in.

models

models

in. (38

(2)

g-in.

models

for

13-in.

models. I-l/2-in. stroke

3/4-in.

stroke

Page 17

Kev

NO:

1

2

8

9

10-

11

12

13

14

Table 7. MO/MP953B and MP953F Parts.

1

Part Number

-

Obtain locally

3 16579

Obtain locally

14004080-00 1

Obtain locally

314420-01508 Bias spring for Gradutrol Relay

140040 15-00 1

I

Obtain locally Hex-head screw (6),

14004665-00 1

313918-00064

313919-00063

3 12205

304733

312199

1400204@002

I

Gradutrol Relay assembly for MP953B, use 14004138-001 Positive Positioning Retrofit Kit.

(2),

lo-24

x

Hex-head screw

Filters (3)

Tubing connector,

l/8

Positive positioner and bracket assembly

Copper or plastic tubing,

Bias spring for positive positioner

I Y L

I

Cover (casting stamped 14004660-001)

Feedback spring for

Feedback spring for all other

.

l/2-in.

v

Nut

Lockwasher

CUP

Diaphragm for alltemperature ranges

506

NPT, for MP953B

l/4

in.

L

10-24

x 3/4 in.

stroke MP953B (see NOTE 1)

MP953Bs (see NOTE 1)

in.

(see NOTE 2)

Description

MP953F,includes

for

filter

14001865-001

1

1

314524

Washer for 3/4-in. stroke models

NOTES:

1. For

MP953F

feedback spring, see Table 13.

2. Diaphragm and Sleeve (Seal) available in Kit 14003 124-002.

15

75-5500

Page 18

Fig.

10. MOjMP953C

24078

Exploded View.

Fig. 11.

Y

MO/MP9531>

Exploded

24079

View_

75-5500 PUC

9-90

16

Page 19

Table 8.

MO/MP953C

Parts.

Key

No.

1

2

3

7

8

9

10

11

12

13

NOTE:

Part Number

312817

311748

312103

Obtain locally

Obtain locally

Obtain locally

Obtain locally

310673

312760

3 10668

3 13745

3 14683-00062

310501-00021

31197514

3 14646-00062

See Table 10

3 10665-00062

14004613-001

14004611-001

312101

14004577-001

311744

14004698-001

312099

Obtain locally

Obtain locally Replace with

Obtain locally

Obtain locally

14004298-003

14004383-562

30462 I-00605

For metric conversion: Model sizes- 5 in. (127 mm)

Cover for 5-in. Series 2 model

Cover for 8-in. model

Cover for 13-m. model

Fillister-head screw, 6-32 x

Fillister-head screw, 8-32 x

Filhster-head screw,

Fillister-head screw,

Main diaphragm for old

Main diaphragm for 5-in. models neoprene black

Main diaphragm for old

Main diaphragm for 5-in. models,

Retainerfor

Plate for5- and S-in. models,

Plate for 8-in. model,

Plate for

Mainspring

Ring for 5-in.model

Frame for 5-in. model, includes screws

Frame for 8-in. model, includes screws

Frame for

Base for 5-in. model, includes screws

Base for 8-in. model

1

Base for

Base for

Replace with

Replace with

Replace with

Base screw

Base screw

Base screw

13-in.

13-in.

13-in.

13-in.

13-in.

(2), l/4-20

(2), l/2-13

(2),

Stroke-112 in. (13 mm)

Description

l/2

in. for early models (8)

l/2

in. for

5-in.

model (4)

l/4-20

x

3/4

in. for

8-in.

model (6)

5/l

6-18 x

7/8

in. for

13-in.

model (4)

5-in.

models Al,

5-in.

models A2 and A6; 250F

model

3/4-in.stroke

l-l/2-in.

stroke, with antispin

model

model

model, 3/4-in. stroke

model,

l/4-20

5/l

5/16-18 x

3/8-16 x l-1/2 in. cap-head machine screw (2) for

l-l/2-in.

x

5/8

in. cap-head machine screw (2) for

6-l 8 x

l-1/4

in. cap-head machine screw (2) for 8-in. model

l-3/4

in. cap-head machine screw (2) for

x

3/4

in. for

x l-1/2 in. for

l/2-13 x 2 in. for

8 in. (203 mm)

13 in. (330 mm)

314

in. (19 mm)

l-1/2

in. (38 mm)

stroke

(121C),

5-in.

8-in.

13-in.

A5, A9;

160F

silicone white

model

model

model

(71C),

(121C),

neoprene black

silicone white

5-in.

model

13-in.

model,

13-in.

model, I-l/2-in. stroke

3/4-in.

stroke

17

75-5500

Page 20

Table 9.

MO/MP953D Parts.

2

3 I 14004660-001

4

5

6

15 I 3 12200-00767

16

17

18

19

20 1 Obtain locally

NOTE 1. Diaphragm and Sleeve (Seal) available in Kit 14003124-002.

Obtain locally Hex-head screw with lockwasher

I

Cover

3 1220.5

304733-00021 Lockwasher

1

312199

1

314524

3 14650A

I

14004578-001 I Base. includes set screw

3

1605914

3 1465

1A

14004298-003

Nut

I CUD

I Washer for 3/4-in. stroke model

I CUD

Support Assembly with helicoil insert for Series 2 models only. Convert MOIMP953D

Series 1 to Series 2 with this Support Assemblv and 3 16059A Yoke Assemblv.

Yoke Assembly for Support Assembly with helicoil insert (see detail in Fig. 7)

Yoke Assembly for Support Assembly with nylon insert (see detail in Fig. 7)

Socket-cap base screw (2).

1

Replace with

l/4-20

x

l/4-20

5/8

in. cap-head machine screw

(6), lo-24

x

l-3/4

x 3/4 in.

in.

B

Actuator

Diameter In.

Table 10.

Stroke

In. b-m m-4

5

(127)

*Used on MP953A and E models.

l/2 (13) Brown

MP953C

Color

Gray

Mainsprings.

Pressure Range

psi &Pa)

2-7 (14-48)

8-12

-

(55-83)

Part Number

-

-

3/4

(19) 1 White

*

Used on

Table 11. MP953D Mainsprings.

1

1

Black I

8-13

I Silver I

MP953B

4-11 (28-76)1

(55-90) I

3-7

(21-48)

and F models.

314313-00123

312203-00017*

I

314963-0060~

Tbl II

75-5500

8

Page 21

POSITIONER RETROFIT AND

SPRING KITS

Table 12.

Part No.

14004138-001 For RA valve actuators (Fig 12)

14004139-001 For 8- and 13-in.

14004140-001 For 8- and 13-in.

14004214-001 For 5-in.

*

Includes corresponding feedback spring kit listed in

Table 13.

MP953

Positive Positioner Retrofit Kits.

1

1 3/4-in. (19-mm)

actuators (Fig. 13)

1 l-1/2

actuators (Fig. 14)

stroke valve actuators (Fig. 13).

(Positioner has cream-colored lower

plate.)

I

Description*

(203-

and 330-mm),

stroke valve

(203-

and 330-mm),

in. (38-mm) stroke valve

(127-mm), 3/4-in. (19-mm)

Table 13. MP953 Feedback Spring Kits.

Part No.

1400421 l-001 For

14004212-001~

14004213-001

* All kits include springs with 3-, 5, and lo-psi

34-, and

For

For RA valve actuators (includes bias

I

spfiw~

69-kPa)

range.

Description*

3/4-in. (19-mm)

l-l/&in.

(38-mm) stroke DA

stroke DA

vahs

(21-,

Fig. 12. Positive Positioner Retrofit Kit 14004138-001.

19

PUC

9-90 75-5500

Page 22

BLUE

10 PSI (69 KPA)

YELLOW

5 PSI (34 KPA)

BLACK

3 PSI

D-RING

312602

.

(21 KPA)

FEEDBACK SPRING K

14004211-001

R2719-1

Fig. 13. Positive Positioner Retrofit Kits 14004139-001

and 14004214-001

(3/4

in. stroke):).

GREEN

10

PSI (69 KPA)

GRAY

5 PSI (34 KPA)

O-RING

312602

RED

(21 KPA)

3 PSI

FEEDBACK SPRING KIT

14004212-001

_

Fig. 14. Positive Positioner Retrofit Kit

14QO4

(l-1/2 in. stroke).

R27151

140-001

75-5500

20

Page 23

E

i

0

1

ACTUATOR STEM EXTENSION

311851-00062 - 8 IN. MODEL

12

3

ACTUATOR STEM AND SETSCREW

13 IN. MODEL.

EXTENSION

312518-00062

l-1/2

IN. STROKE

Cb

Q

I I

-

SETSCREW

l/4-28 X

114

BUTTON

.0503-00062

31

IN.

POSITION INDICATOR FOR.

5IN.

(127 MM)

7-IN

(178 MM)

8-IN

(203 MM) DIA-316037A

13-IN

(330 MM) DIA,

13-IN

(330 MM) DIA,

CORRCSION RESISTANT SPRAY

MSC 3858

DIA-316028A

DIA-316035A

314

IN (19 MM) STROKE-1400d722-001

l-112

IN (38 MM) STROKE-316036A

314 IN. STROKE

Fig. 15.

MP953

Accessories.

ADAPTER

14001162-001, -002. -003, -004

ADAPTS MP953C TO

VO55 OR V056 FOR COMPLETE CROSS-

REFERENCE iNFORMATION ON VALVES,

SEE 95-5579

V053,

8825.2

21

7545500

Page 24

Honeywell

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN

75-5.500

7-89

55408-0524

Home and Building Control

Honeywell Limited-Honeywell

740

Ellesmere Road

Scarborough, Ontario

MlP 2V9

Limit&z

Helping You Control Your World

Loading...

Loading...