Page 1

N20, N34 Series MN7220, MN7234

NON-SPRING RETURN DAMPER ACTUATOR

20/34 Nm (175/300 lb-in) FOR MODULATING CONTROL

SPECIFICATIONS

Supply voltage 24 Vac ±20%, 50/60 Hz;

24 Vdc -10...+20%

Nominal voltage 24 Vac, 50/60 Hz; 24 Vdc

All values stated hereinafter apply to operation under

nominal voltage conditions.

Power consumption

MN7220 6 VA / 6 W

MN7234 8 VA / 6 W

Ambient limits

Ambient operating limits -5...+140 °F (-20...+60 °C)

Ambient storage limits -40...+175 °F (-40...+80 °C)

Relative humidity 5...95%, non-condensing

Safety

Protection standard IP54 (non-USA models)

NEMA2 (USA models)

Protection class II as per EN 60730-1

Overvoltage category II

Lifetime

GENERAL

These direct-coupled damper actuators provide modulating

control for:

• rotary valves,

• air handling units,

• ventilation flaps,

• louvers, and

• reliable control for air damper applications with up to 50

sq.ft. (20 Nm / 175 lb-in) or 85 sq. ft. (34 Nm / 300 lb-in)

(seal-less damper blades; air friction-dependent).

FEATURES

• New self-centering shaft adapter

• Access cover to facilitate connectivity

• Declutch for manual adjustment

• Mechanical end limits (MN7220 only)

• Field-installable auxiliary switches

• Rotation direction selectable by switch

• Mountable in any orientation (no IP54 if upside down)

• Mechanical position indicator

Full strokes 60000

Repositions 1.5 million

Mounting

Round damper shaft 3/8...1-1/16” (10...27 mm)

Square damper shaft 3/8...11/16” (10...18 mm);

45° steps

Shaft length min. 7/8” (22 mm)

Control signal 0(2)...10 Vdc

0(4)...20 mA

Input impedance 100 kΩ [0...10 V]

500 Ωm [0...20 mA]

Feedback signal

Limits ± 1 mA at 0...10 V

Auxiliary switch (when included)

Rating 5 A (resistive) / 3 A (inductive)

Triggering points 5° / 85°

Torque rating

MN7220 175 lb-in (20 Nm)

MN7234 300 lb-in (34 Nm)

Runtime 95 sec (60 Hz) / 110 sec (50 Hz)

Rotation stroke 95° ± 3°

Dimensions see “Dimensions” on page 8

Weight 3 lbs. (1.35 kg)

Noise rating 40 dB(A) max. at 1 m

PRODUCT DATA

63-2587-1

Page 2

N20, N34 SERIES MN7220, MN7234

MODELS

M – Electrical motor

N – Fail Safe Function (Non-Spring Return)

61 – 24V Floating Control

72 – 24V Modulating Control

MN7220A20XX

20 – 20 Nm (175 lb-in)

34 – 34 Nm (300 lb-in)

A – Standard Model

1 – No Feedback

2 – Voltage Feedback Signal

0 – No Internal Auxiliary Switches

2 – Two Internal Auxiliary Switches

XX – System Controlled Numbers

Fig. 1. Product Identification System

OPERATION/FUNCTIONS

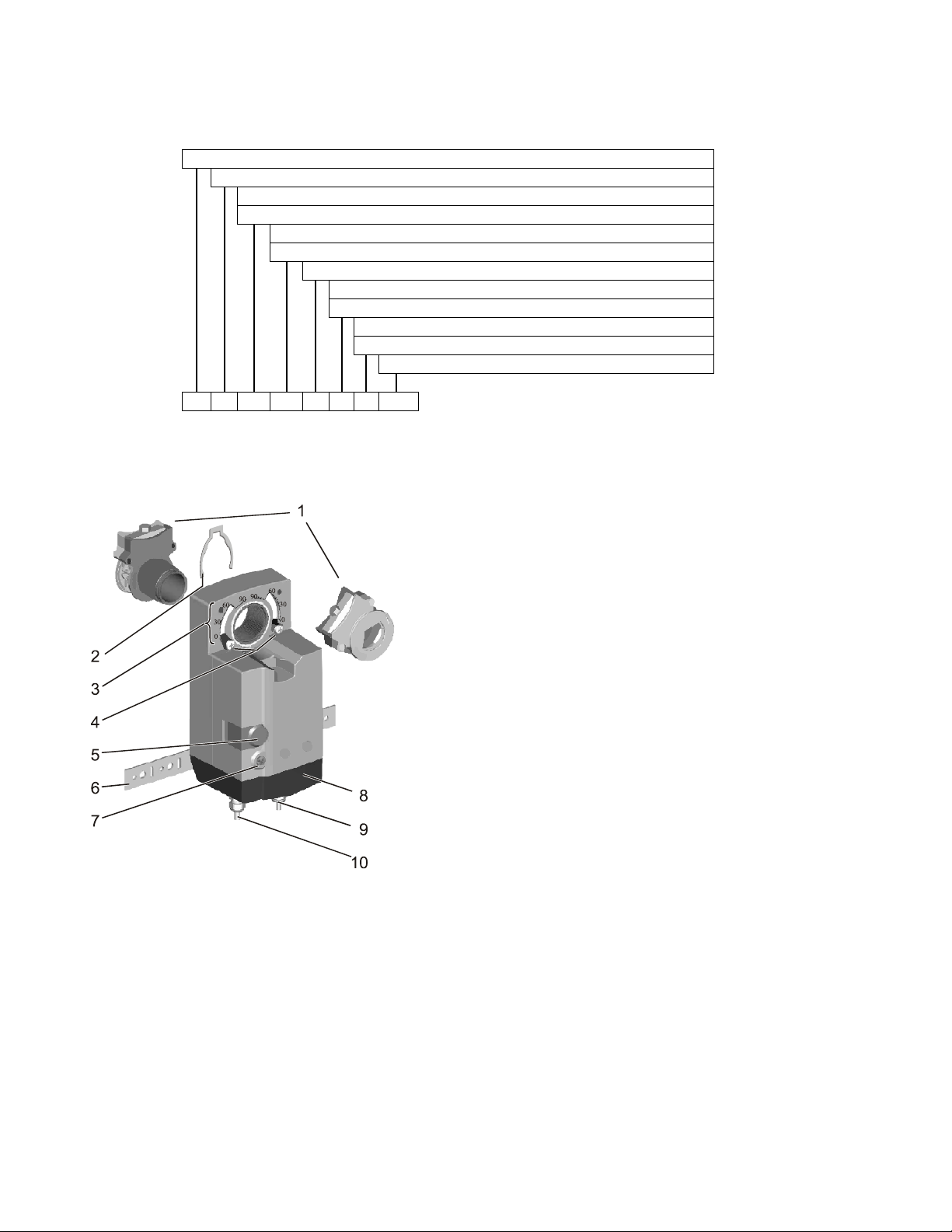

Fig. 2. Setting units and control elements

Legend for Fig. 2. Setting units and control elements:

1. Self-centering shaft adapter

2. Retainer clip

3. Rotational angle scales (0...90° / 90...0°)

4. Mechanical end limits (20 Nm [175 lb-in] models, only)

5. Declutch button

6. Anti-rotation bracket

7. Rotation direction switch

8. Access cover

9. Internal auxiliary switch wire

10. Power and control wire

Contents of Package

The delivery package includes the actuator itself, parts 1

through 10 (see Fig. 2; in the case of U.S. models – e.g.

MN7220 – parts 1 through 8), the anti-rotation bracket screws,

and the SM mounting plate and screws.

Modulating Control

The actuator is capable of being operated by several

controllers providing Vdc or mA output.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2587—1 2

Page 3

Rotary Movement

The control signal and the corresponding rotation direction

(clockwise or counterclockwise) can be selected using the

rotation direction switch (see part Rotation direction switch in

Fig. 2), thus eliminating the need to re-wire. To ensure tight

closing of the dampers, the actuator has a total rotation stroke

of 95°.

N20, N34 SERIES MN7220, MN7234

As soon as operating power is applied, the actuator may start

to run. When power is removed, the actuator remains in

position. For actuator-controller wiring instructions, see section

“Wiring” on page 5.

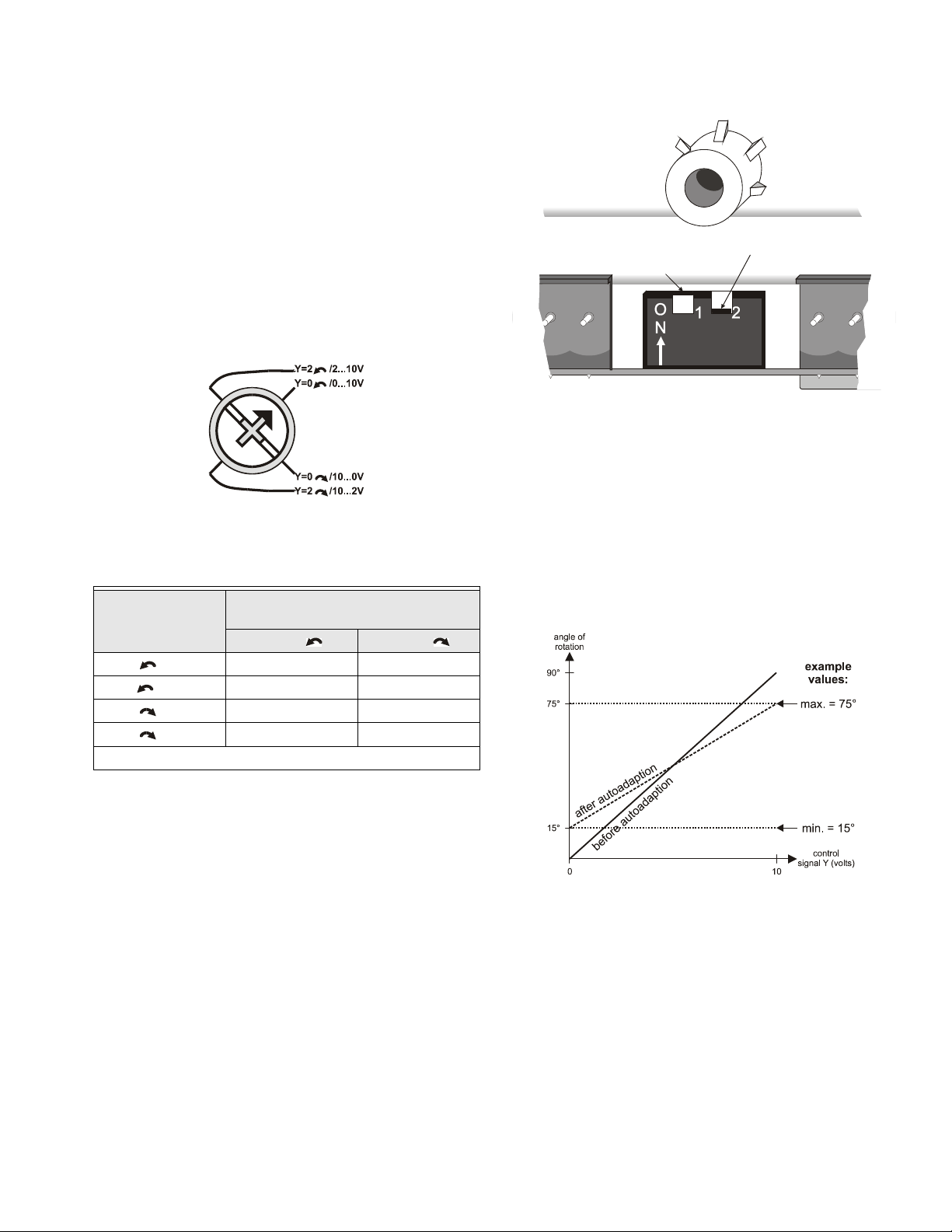

Rotation Direction Switch

Fig. 3. Rotation Direction Switch

Table 1. Feedback/control signal values

Rotation direction

switch position

Y=2 /2...10V U = 2 V U = 10 V

Y=0 /0...10V* U = 0 V U = 10 V

Y=0 /10...0V U = 10 V U = 0 V

Y=2 /10...2V U = 10 V U = 2 V

* Default shipping position.

Feedback/control signal when

actuator is

totally totally

voltage/current control signal

autoadapt dip switch for

normal operation ( )

Fig. 4. Dip switches (view with PCB at bottom)

dip switch ( )

ON

OFF

Autoadapt Dip Switch for Normal Operation

In its default shipping position, the autoadapt dip switch for

normal operation is set to ON as shown in Fig. 4. Dip switches

(view with PCB at bottom)4. If it is set to OFF, no autoadapting

is performed, and the control signal map remains constant.

The autoadapt functionality does not have to be triggered.

Rather, the SmartAct actuator does this automatically when the

min. and max. control signals are provided (see Fig. 5); the

feedback signal is likewise autoadapted.

Feedback Signal and Manual Adjustment

If, while the actuator is not rotating, the user declutches it and

manually repositions the shaft adapter, the feedback signal will

then follow the new position at which the shaft adapter has

been left.

Power Off/On Behavior

In case the power to the actuator fails, after re-applying power,

the actuator acknowledges its present position and follows the

signal from the controller. This makes it unnecessary for the

actuator to employ autoadaption in order to re-map the control

signal settings.

Dip Switches

The actuators are equipped with two dip switches accessible

after removing the access cover (see Fig. 4).

3 63-2587—1

Fig. 5. Actuator positioning curve

In order to make use of the autoadapt functionality, proceed as

follows:

1. Set the autoadapt dip switch to the ON position.

2. If necessary, limit the stroke to the desired range using

the mechanical end limits.

3. Drive the actuator to the left end limit (totally counter-

clockwise) by setting the control signal as specified in

Table 1. Feedback/control signal values1.

4. Drive the actuator to the right end limit (totally clockwise)

by setting the control signal as specified in Table 1.

Feedback/control signal values1. The stroke has now

been limited to 0...100% of the control signal range.

Page 4

N20, N34 SERIES MN7220, MN7234

°

Voltage/Current Control Signal Selection Dip Switch

In its default shipping position, the voltage/current control

signal dip switch (see Fig. 4) is set to OFF (= voltage control).

as shown in Fig. 4. Setting it to ON results in current control.

Position Indication

The hub adapter indicates the rotation angle position by means

of the rotational angle scales (0...90° / 90...0°).

90 90

60

30

60

30

00

Fig. 6. Position indication

Manual Adjustment

IMPORTANT

In order to prevent equipment damage, you must

remove power before manual adjustment.

After removing power, the gear train can be disengaged using

the declutch button, permitting the actuator shaft to be

manually rotated to any position. The feedback signal will then

follow the new position.

Limitation of Rotation Stroke

Two mechanical end limits (adjustable in 3° increments) are

provided (20 Nm [175 lb-in] models, only) to limit the angle of

rotation as desired (see Fig. 7).

The mechanical end limits must be securely fastened in place

as shown in Fig. 8. Correct / incorrect tightening of end limits8.

Specifically, it is important that they properly mesh with the

rotational angle scales when the screws are tightened.

Fig. 8. Correct/incorrect tightening of end limits

Internal Auxiliary Switches

The internal auxiliary switches are set to change from

“common” to “normally open” at angles of 5° and 85°,

respectively, from the totally counterclockwise position.

actuator scale: clockwise

5° 10° 15° 92.5

0° 90°-2.5° 85°80°75°

CCW internal

auxiliary switch

auxiliary switch scale

5° 10° 15°0° 90°85°80°75°

actuator scale: counterclockwise

85° 80° 75° -2.5°90° 0°92.5° 5°10°15°

CW internal

auxiliary switch

Fig. 9. Internal auxiliary switches

Override

If terminal 3 of the terminal strip (see section “Wiring

Diagrams” on page 6) is unplugged, the stroke will be 0%;

reversing the rotation direction using the rotation direction

switch will result in a max. stroke of 100%. If terminal 3 is

jumped with terminal 1 (24 V), the stroke will be 50%.

Fig. 7. Mechanical end limits

63-2587—1 4

INSTALLATION

These actuators are designed for single-point mounting.

IMPORTANT

In order to prevent equipment damage, you must

remove power or set the rotation direction switch to

the “Service/Off” position before manual operation.

Mounting Instructions

All information and steps are included in the Installation

Instructions supplied with the actuator.

Page 5

N20, N34 SERIES MN7220, MN7234

Mounting Position

The actuators can be mounted in any desired orientation (no

NEMA2 or IP54 if mounted upside down; see Fig. 10). Choose

an orientation permitting easy access to the actuator's cables

and controls.

NEMA2

IP54

NEMA2

IP54

Fig. 10. Mounting for IP54/NEMA2

NEMA2

IP54

NEMA2

IP54

Mounting Bracket and Screws

If the actuator is to be mounted directly on a damper shaft, use

the mounting bracket and screws included in the delivery

package.

IMPORTANT

Remove power before detaching the access cover.

Once the access cover has been removed, please

take care to avoid damaging any of the parts now

accessible.

Fig. 11. Access cover

Depending upon the model, the access cover may have one or

two terminal strips, including a layout with a description for

each of the terminals.

Self-Centering Shaft Adapter

The self-centering shaft adapter can be used for shafts having

various diameters (3/8...1-1/16” [10...27 mm]) and shapes

(square or round).

In the case of short shafts, the shaft adapter may be reversed

and mounted on the duct side.

Stroke Limitation with Mechanical End Limits

The mechanical end limits (20 Nm [175 lb-in] models, only)

enable the stroke to be limited from 0...90° in increments of 3°.

Wiring

Access cover

To facilitate wiring the actuator to the controller, the access

cover can be detached from the actuator.

Fig. 12. Actuator with access cover removed

5 63-2587—1

Page 6

N20, N34 SERIES MN7220, MN7234

A

A

Wiring Diagrams

MN7220/MN7234

TERMINAL STRIP 1

MN7220 WITH SWITCHES

TERMINAL STRIP

UXILIARY

24 Vac 24 Vdc

~

0(2)...10 Vdc

0(4)...20 mA

0(2)...10 Vdc

!

Connect via safety

isolating transformer!

1

2

3Y

5U

1~

2

3Y

5U

MODULATING CONTROL

24 Vac 24 Vdc

~

0(2)...10 Vdc

0(4)...20 mA

0(2)...10 Vdc

!

Connect via

isolating

1

2

3Y

5U

1~

2

3Y

5U

MODULATING

S1

S2

S3

S4

S5

S6

UXILIARY

S1

S2

S3

S4

S5

S6

NOTE: Internal auxiliary switches S1 and S4 must be connected to the same power source.

connecting cable terminal name

supply and signal lines

1~

2⊥ 24 Vac⊥ / 24 Vdc-

24 Vac∼ / 24 Vdc+

3Y 0(2)...10 Vdc / 0(4)...20 mA control signal

5U 0(2)...10 V feedback signal

S1 Common

CCW (left)

5°

auxiliary switched

(when included)

CW (right)

85°

S2 normally closed

S3 normally open

S4 Common

S5 normally closed

S6 normally open

63-2587—1 6

Page 7

N20, N34 SERIES MN7220, MN7234

7 63-2587—1

Page 8

N20, N34 SERIES MN7220, MN7234

DIMENSIONS

100 mm (3-15/16”)

shaft

adapter

min. 60 mm (2-3/8”)

adapter (reverse)

20.6 mm

(1-3/16”)

shaft

95°

60

90

48 mm

(1-7/8”)

223 mm (8-25/32”)

30

0

92 mm (3-5/8”)

1000 mm (39”)

132 mm (5-3/16”)

230 mm [+/- 0.5 mm] (9-1/16” [+/-1/64”])

20 mm (25/32”)

7 mm (9/32”)

2 mm (5/64”)

13 mm (1/2”)

5 mm (+0.05, -0.10 mm)

25/128” (+0.002, -0.004”)

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2005 Honeywell International Inc.

63-2587—1 M.S. Rev. 10-05

anti-rotation bracket

Loading...

Loading...