Page 1

ML4125, ML4135, ML8125, ML8135

Fast-Acting, Two-Position Actuators

FOR HEATING, VENTILATION AND

AIR-CONDITIONING APPLICATIONS

PRODUCT DATA

FEATURES

• Integral spring return.

• -40 to 130°F (-40 to 54°C) operating temperature range.

• No audible noise during holding.

• Electronic circuitry provides efficient operation while

eliminating the need for limit switches.

• Ninety-five degree angle of rotation.

• Die-cast aluminum housing.

• Housing design allows flush mounting to damper.

• Integral junction box with three conduit openings

eliminates need for separate wiring box.

• Direct mounting to 3/8 or 1/2 in. round or square shaft.

APPLICATION

The ML4125, ML4135, ML8125 and ML8135 Fast-Acting,

Two-Position Actuators are spri ng return direct coupled

actuators (DCA) with an integral junction box for on/off

damper control. The actuator accepts an on/off signal from

a single-pole, single-throw (spst) controller. Models are

available with clockwis e (cw) or counterclockwise (ccw)

spring return and are designed for heating, ventilation, and

air-conditioning (HVAC) applications.

IMPORTANT

This actuator is not to be used in fire/smoke

applications requiring UL555/555S approval.

ML4125, ML8125

• 100 lb-in. (11.3 N•m) minimum driving torque.

• 25 to 40 second drive timing (load dependant).

• Models available for 24, 120, and 230 Vac.

ML4135, ML8135

• 40 lb-in. (4.5 N•m) minimum driving torque.

• 20 to 25 second drive timing (load dependant).

• Models available for 24 and 120 Vac.

APPLICABLE LITERATURE

— Motor/Actuator Selection Guide

for Damper Applications 63-8419

— Engineering Manual of Automatic Control

(also called The Gray Manual) 77-1100

— Direct Coupled Actuator

Quick Selection Guide 63-8553

— Damper Torque Calculator 63-8437

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 4

Operation .......................................................................... 6

Checkout .......................................................................... 6

® U.S. Registered Trademark

Copyright © 2000 Honeywell • All Rights Reserved

N314

63- 2567-3

Page 2

ML4125, ML4135, ML8125, ML8135 FAST-ACTING, TWO-POSITION ACTUATORS

SPECIFICATIONS

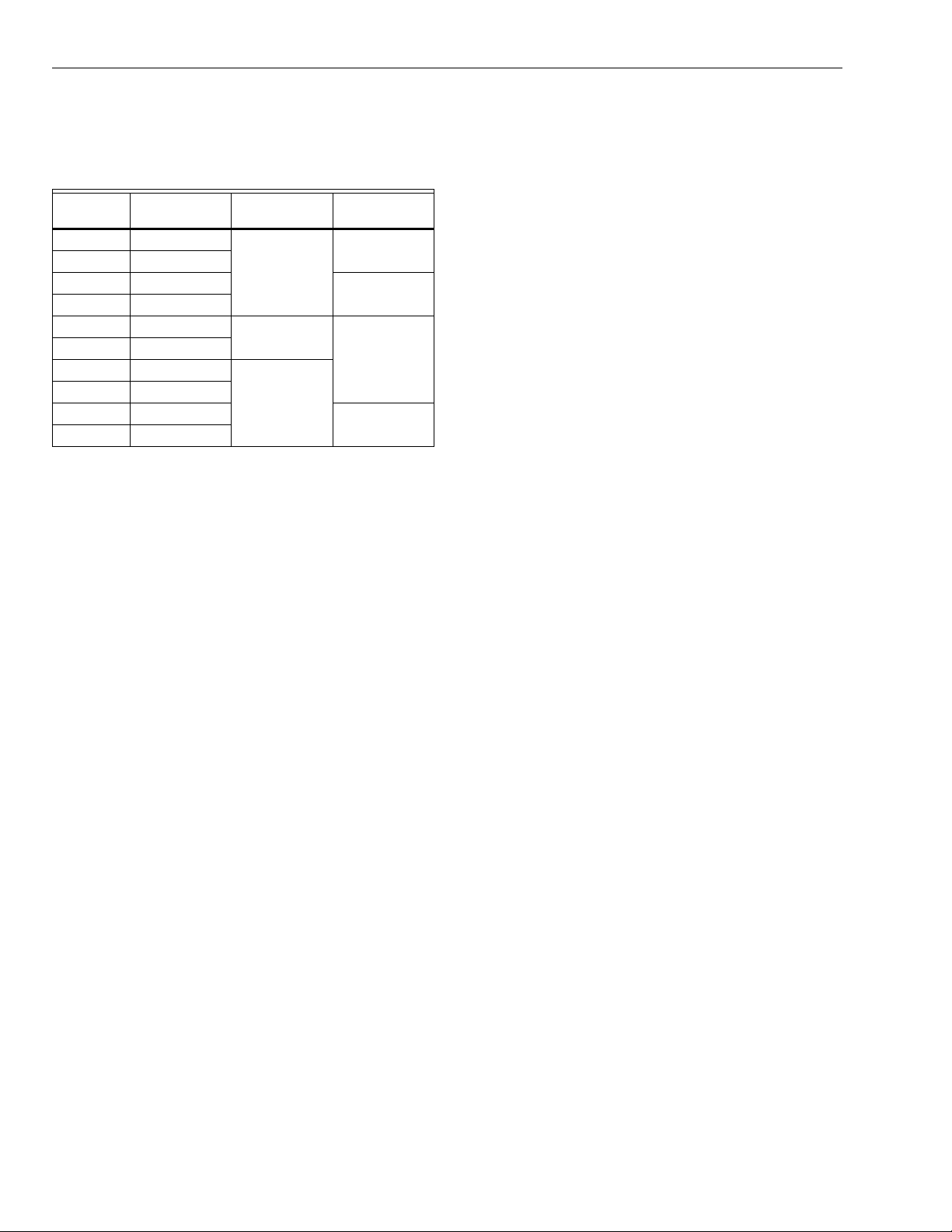

Models:

ML4125A ccw 120 100 (11.3)

ML4125B cw

ML4135A ccw 40 (4.5)

ML4135B cw

ML4125C ccw 230 100 (11.3)

ML4125D cw

ML8125A ccw 24

ML8125B cw

ML8135A ccw 40 (4.5)

ML8135B cw

Dimensions:

Electrical Ratings:

Power Input:

Power Consumption (at Nominal Voltage):

Temperature Ratings:

Ambient: -40°F to 130°F (-40°C to 55°C).

Shipping and Storage: -40°F to 140°F (-40°C to 60°C).

Humidity Ratings:

See Table 1.

Table 1. ML4125/4135, ML8125/8135 DCA Models.

Model

ML4125A,B: 120 Vac +10%, -15%, 60 Hz.

ML4125C,D: 230 Vac ±10%, 50 Hz.

ML4135: 120 Vac ±10%, 60 Hz.

ML8125, ML8135: 24 Vac +20%, -10%, 50/60 Hz.

ML4125A,B: Running: 0.16A, 15W.

ML4125C,D: Running: 0.12A, 18.6W.

ML4135: Running: 0.18A, 18W.

ML8125: Running: 15.6 VA.

ML8135: Running: 18 VA.

Spring Return

Direction

See Fig. 1.

Holding: 0.10A, 5W.

Holding: 0.10A, 7W.

Holding: 0.11A, 9W.

Holding: 4 VA.

Holding: 8.5 VA.

5% to 95% RH noncondensing.

Voltage

in Vac

Torque

in lb-in. (N•m)

Electrical Connections:

ML4125A,B, ML4135, ML8125, ML8135: Two color coded

16 in. leads; includes ground screw.

ML4125C,D: 1m appliance cable.

Three 7/8 in. holes for conduit connections (fittings not

included).

Controller Type:

ML4125A,B, ML4135: Line voltage (120 Vac), two-position,

spst (Series 40).

ML4125C,D: Line voltage (230 Vac), two-position, spst

(Series 40).

ML8125, ML8135: Low voltage (24 Vac), two-position, spst

(Series 80).

Device Weight:

Stroke:

To rque Rating s:

Driving:

Spring Return:

Holding (minimum): 100 lb-in. (11.3 N•m).

Stall Maximum:

Noise Rating (Maximum):

Driving/Spring Return: 65 dBA at 1m.

Holding: 20 dBA at 1m (no audible noise).

95° ± 3°, mechanically limited.

Minimum:

ML4125, ML8125: 100 lb-in. (11.3 N•m).

ML4135, ML8135: 40 lb-in. (4.5 N•m).

Typical:

ML4125, ML8125: 170 lb-in. (19.2 N•m).

ML4135, ML8135: 100 lb-in. (11.3 N•m).

Minimum:

ML4125, ML8125: 80 lb-in. (9 N•m).

ML4135, ML8135: 40 lb-in. (4.5 N•m).

Typical:

ML4125, ML8125: 100 lb-in. (11.3 N•m).

ML4135, ML8135: 50 lb-in. (5.7 N•m).

Derated (from -40°F to 0°F [-40°C to -18°C]):

ML4135, ML8135: 30 lb-in. (3.4 N•m).

ML4125, ML8125: 240 lb-in. (27.1 N•m).

ML4135, ML8135: 150 lb-in. (17 N•m).

5 lb (2.3 kg).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Home and Building Control Sales Office (check white pages of your phone directory).

2.

Home and Building Control Customer Logistics

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitée, 155 Gordon Baker Road, North York, Ontario M2H 3N7.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2567—32

Page 3

ML4125, ML4135, ML8125, ML8135 FAST-ACTING, TWO-POSITION ACTUATORS

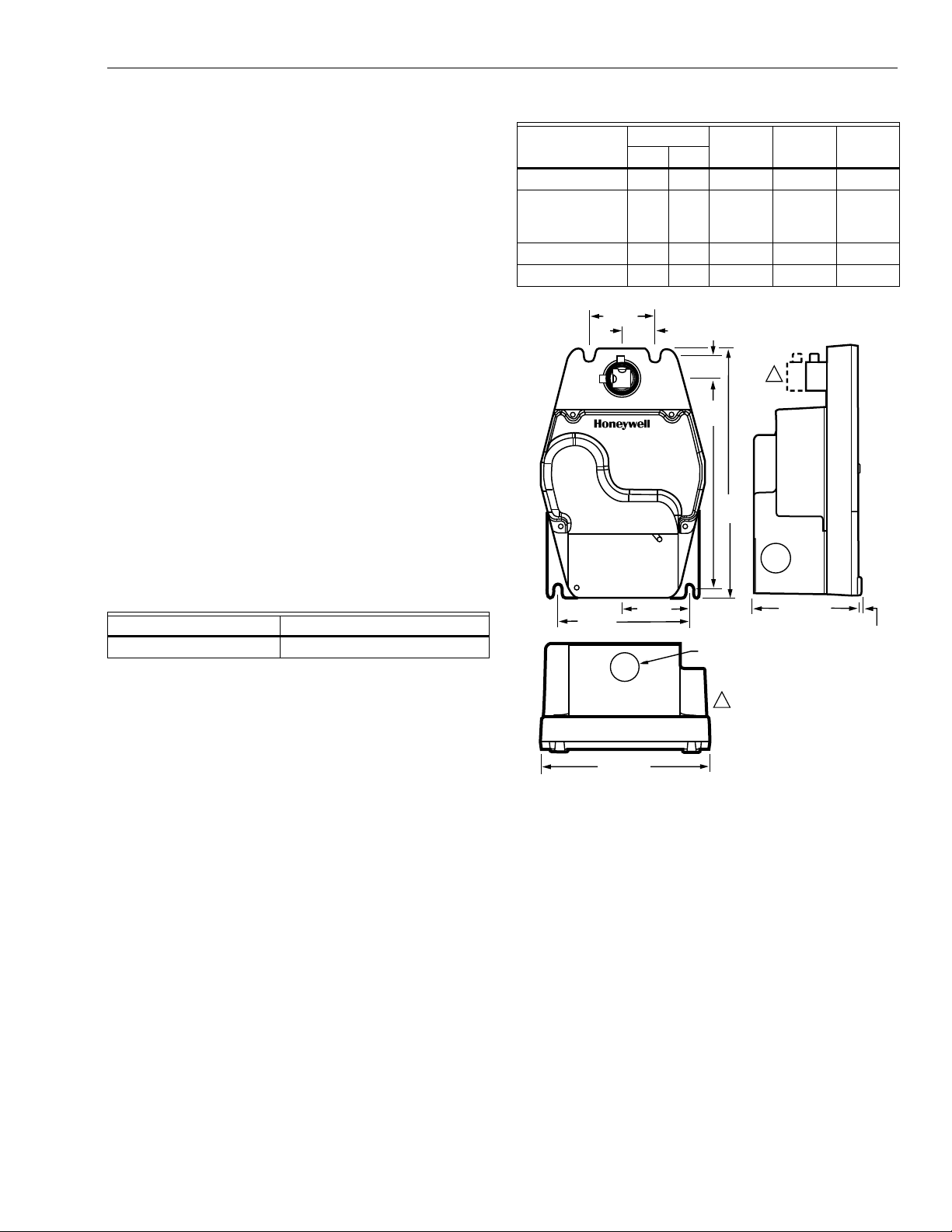

2 (51)

1 (25)

5/8

(17)

6 3/8

(161)

7 1/2

(192)

4 (102)

7/8 (22)

5 1/8 (129)

2 (51) 3 5/16 (84)

1/16 (2)

M17538

ML4135/ML8135 HAVE SHORTER

HUB WITH TWO SET SCREWS.

ML4125/ML8125 HAVE LONGER

HUB WITH FOUR SET SCREWS.

1

1

Mounting:

3/8 in. (10 mm) to 1/2 in. (13 mm) square or round damper

shafts. Actuator ca n b e m ounted with shaft in any pos iti on.

Secure hub to shaft with:

ML8125, ML4125A,B: Four 1/4-28 UNF set screws. Use

1/8 in. Allen wrench to tighten set screws.

ML8135, ML4135: Two 1/4-28 UNF set screws. Use 1/8 in.

Allen wrench to tighten set screws.

ML4125C,D: Four 3 mm set screws. Use 3 mm Allen wrench

to tighten set screws.

IMPORTANT

Honeywell does not recommend using linkages with

these actuators because side-loading of the output

hub reduces actuator life.

Minimum Damper Shaft Length:

1-3/4 in. (45 mm).

Timing:

Drive Open:

ML4125, ML8125: 25 to 40 seconds (load dependant).

ML4135, ML8135: 20 to 25 seconds (load dependant).

Spring Close:

ML4125, ML8125: 20 to 25 seconds.

ML4135, ML8135: 15 seconds.

Design Life (at Rated Voltage):

ML4125, ML8125: 80,000 full-stroke cycles.

ML4135, ML8135: 60,000 full-stroke cycles.

T a ble 3. App rovals.

ML4125

ML4135 ML8125 ML8135A,B C,D

UL/cUL X X X X X

UL873

XXX X X

Plenum Rating,

File No. E4436

CE X X X

C-TICK X X

Environmental Protection Ratings:

See Table 2.

Table 2. Environmental Ratings.

All Devices ML4125C,D, ML8125, ML8135

NEMA1 IP54

Approvals:

See Table 3.

Accessories:

201391 Shaft Adapter for 3/8 in. (10 mm) shafts.

205649 Mounting Bracket (included with the actuator).

32003532-001 Adjustable Switch Package, two 10A

externally-mount ed full y-a dj ust abl e sw itc he s.

Fig. 1. ML4125/4135, ML8125/8135

dimensiona drawing in in. (mm).

3 63-2567—3

Page 4

ML4125, ML4135, ML8125, ML8135 FAST-ACTING, TWO-POSITION ACTUATORS

INSTALLATION

When Installing this Product...

1.

Read these instructio ns c aref ull y. Failure to foll ow them

could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

WARNING

Electrical Power Hazard.

Line voltage can cause death or serious injury

and short equipment circuitry.

Disconnect power supply before installation.

1

CAUTION

Electrical Shock or Equipment Damage Hazard.

Low voltage can shock individuals or short

equipment circuitry.

Disconnect power supply before installation.

Location and Mounting

CAUTION

Equipment Damage Hazard.

Tightly securing actuator to damper housing can

damage actuator.

Mount actuator t o all ow i t t o f loa t along its vertical ax is.

The actuators are designed to open a damper by driving the

damper shaft in either clockwise or counterclockwise

direction. The actuator housing has two slots on the

bottom that, with a 205649 Mounting Bracket, secure it flush

to a damper box (see Fig. 2). When mounted correctly, these

slots allow the actuato r to

damper shaft.

NOTE: ML4125, ML4135, ML8125 and ML8135 Actuators

are shipped in the fully closed position.

float

without rotating relative to the

ENSURE THAT MOUNTING ASSEMBLY PREVENTS ACTUATOR

1

ROTATION AND ALLOWS ACTUATOR TO FLOAT ALONG INDICATED

AXIS. WHEN TOO TIGHT, THE RESULTING BINDING CAN DAMAGE

THE ACTUATOR OR REDUCE TORQUE OUTPUT.

Fig. 2. Mounting actuator to damper housing.

NOTE: The actuator mounts flush with the damper box.

M17519

Preparation

Before mounting the actuator onto the damper shaft, determine

the damper shaft size (3/8 in. to 1/2 in. [10 mm to 13 mm]).

If damper shaft is 3/8 in. (10 mm) round or square, use part

number 201391 Shaft Adapter. Place adapter opposite

set screws (see Fig. 3).

NOTE: The damper shaft adapter centers a 3/8 in. (10 mm)

damper shaft in the hub. Failure to use adapter can

cause mounting screws to loosen. A 1/2 in. (13 mm)

damper shaft does not require an adapte r.

SHAFT ADAPTER

Fig. 3. Using damper shaft adapter for

3/8 in. (10 mm) damper shafts.

63-2567—34

M2064

Page 5

ML4125, ML4135, ML8125, ML8135 FAST-ACTING, TWO-POSITION ACTUATORS

L1

24 VAC

L2

RED

BLACK

R

W

M17585

( )

( )

L1

120

VAC

L2

WHITE

BLACK

R

W

M17589

( )

( )

L1

230

VAC

L2

BLUE

BROWN

R

W

M17588

( )

( )

Installation

CAUTION

Device Malfunction Hazard.

Improper set screw tightening causes device

malfunction.

Tighten set screws with proper torque to prevent

damper shaft slippage.

CAUTION

Actuator Damage Hazard.

Using actuator as shaft bearing causes device

damage.

Use actuator only to supply rotational torque. Avoid

any side loads to actuator output coupling bearings.

To install actuator, proceed as follows:

1.

Place actuator over damper shaft; and hold mounting

bracket in place. See Fig. 2.

2.

Mark screw holes on damper housing.

3.

Remove actuator and mounting bracket.

4.

Drill or center-punch holes for mounting screws (or use

no.10 self-tapping sheet metal screws).

5.

Turn damp er b lad es to d esired normal (closed) position.

6.

Place actuator and mounting bracket back into position

and secure bracket to damper box with sheet metal

screws.

7.

Tighten set screws securely into damper shaft using

minimum 30 lb-in., maximum 60 lb-in. torque. Use

1/8 in. or 3 mm Allen wrench (see Specifications for

details) to tighten set screws.

Wiring

IMPORTANT

1. All wiring must comply with local electrical codes,

ordinances and regulations.

2. Voltage and frequency of transformer used with

ML8125 or ML8135 must correspond with the

characteristics of power supply and actuator.

3. Use wires rated for at least 75°C (167°F).

See Fig. 4 through 6 for typical wiring diagrams.

Fig. 4. Typical 24 Vac wiring.

Fig. 5. Typical 120 Vac wiring.

WARNING

Electrical Power Hazard.

Line voltage can cause death or serious injury

and short equipment circuitry.

Disconnect power supply before installation.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Low voltage can shock individuals or short

equipment circuitry.

Disconnect power supply before installation.

BROWN

BLUE

BLACK

WHITE

RED

5 63-2567—3

Fig. 6. Typical 230 Vac wiring.

Table 4. Color Translations.

GFIE

BRAUN BRUN BRUNO CAFE

BLAU BLEU AZZURRO AZUL

SCHWARZ NOIR NERO NEGRO

WEISS BLANC BIANCO BLANCO

ROT ROUGE ROSSO ROJO

Page 6

ML4125, ML4135, ML8125, ML8135 FAST-ACTING, TWO-POSITION ACTUATORS

OPERATION

The actuators are operated by an s ps t tw o-po si tio n co ntrol le r.

When using an spst tw o-position c ontroller , the ac tuator drives

to the damper fully open position when controller contact

makes and spring returns to the damper fully closed po sition

when controller contac t bre ak s. Th e ac tuat or dro ps to hol din g

power level on detection of stall, indepe nd ent of hub pos iti on.

If power fails, the actuator spring returns to the 0° pos iti on.

CHECKOUT

ML4125A,B, ML4135 (120 Vac model)

1.

Check damper position.

2.

Connect 120 Vac to the black and white leadwires to

drive the damper to the open position. The actuat or

should drive the damper.

3.

If the actuator does not run, remove power for at least

two seconds.

4.

If the actuator spring returns, allow it to close entirely,

then return to step 2.

5.

If the actuator does not spring return, verify that the

actuator is properly installed. See Installation section.

6. I

f the actuator is correctly installed but neither runs nor

spring returns, replace the actuator.

ML4125C,D (230 Vac model)

1.

Check damper position.

2.

Connect 230 Vac to the blue and brown leadwires to

drive the damper to the open position. The actuat or

should drive the damper.

3.

If the actuator does not run, remove power for at least

two seconds.

4.

If the actuator spring returns, allow it to close entirely,

then return to step 2.

5.

If the actuator does not spring return, verify that the

actuator is properly installed. See Installation section.

6. I

f the actuator is correctly installed but neither runs nor

spring returns, replace the actuator.

ML8125, ML8135 (24 Vac model)

1.

Check damper position.

2.

Connect 24 Vac to the red and black leadwires to drive

the damper to the open position. The actuator should

drive the damper.

3.

If the actuator does not run, remove power for at least

two seconds.

4.

If the actuator spring returns, allow it to close entirely,

then return to step 2.

5.

If the actuator does not spring return, verify that the

actuator is properly installed. See Installation section.

6.

If the actuator is correctly installed but neither runs nor

spring returns, replace the actuator.

63-2567—36

Page 7

D Montageanweisung

M11882

a

b

c

HEX

4mm

MIN: 45 lb-in. (5.1 Nm)

MAX: 60lb-in. (6.8 Nm)

F Instru ctions d’Installation

I Istruzioni per I’Installazione

NL Installatievoorschrift

DK Installasjonsinstruks

N Installationsinstrukioner

SF Asennusohje

S Installations Instrukioner

E Instrucciones de montaje

ML4125, ML4135, ML8125, ML8135 FAST-ACTING, TWO-POSITION ACTUATORS

M11875

A2

a

c

M11876

A6

AA1, A4

24 VAC

!

230 VAC

ASSEMBLY

EINBAU

D

MONTAGE

F

MONTAGGIO

I

NL

DK

N

FIN

S

E

A3

MONTAGE

MONTERE

MONTERING

ASENTAMINEN

MONTERA

MONTAJE

M11874

M11876

A5

a

b

d

b

a

b

M12030

b

M11881

7 63-2567—3

a

Page 8

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

ML4125, ML4135, ML8125, ML8135 FAST-ACTING, TWO-POSITION ACTUATORS

M11886

BB1B2

24 VAC

!

230 VAC

a

DISASSEMBLY

AUSBAU

D

DÉMONTAGE

F

SMONTAGGIO

I

DEMONTAGE

NL

AFMONTERE

DK

DEMONTERE

N

PURKAMINEN

FIN

NEDMONTERA

S

DESMONTAJE

E

M11884

M11887

M11888

a

b

b

HEX

4mm

B4B3

M11885

Home and Building Control Home and Building Control Honeywell Asia Pacific Inc. Honeywell Europe S.A. Honeywell Latin American

Honeywell Honeywell Limited-Honeywell Limitée Room 3213-3225 3 Avenue du Bourget

1985 Douglas Drive North 35 Dynamic Drive Sun Hung Kai Centre 1140 Brussels 480 Sawgrass Corporate Parkway

Golden Valley, MN 55422 Scarborough, Ontario No. 30 Harbour Road Belgium Suite 200

63-2567—3 B.B. Rev. 7-00 www.honeywell.com

M1V 4Z9 Wanchai Sunrise FL 33325

Hong Kong

Region

Loading...

Loading...