Page 1

ML7430E/ML7435E

ELECTRIC LINEAR ACTUATORS

FOR MODULATING CONTROL

SPECIFICATION DATA

FEATURES

• 0...10 Vdc / 2...10 Vdc signal input

• Fast run-time

• Low power consumption

• Quick and easy installation

• No separate linkage required

• No calibration

• Force-limiting end switches

• Spring return (ML7435E)

• Manual operator

• Synchronous motor

• Direct / reverse action adjustable

• Maintenance-free

GENERAL

The ML7430E and ML7435E Electric Linear Actuators are

designed to provide modulating control in closed control loops

together with the small linear valves V5832B/V5833A

(DN25...DN40) and V5825B/V5872B for high-differential

pressure.

These valve-actuator combinations are suitable especially for

integration into compact or conventional stations for direct or

indirect district heating connections, air handling units and

roof top units for zone control, and domestic hot water

applications.

The actuators are microprocessor-controlled for exact

positioning. The direction of movement is reversible. The

V5825B or V5872B valve and ML7435E actuator combination

provides safe close-off function and is approved according to

DIN EN 14597.

SPECIFICATIONS

Temperature Limits

Ambient operating limits 0...+50 °C at 5 to 95% rh

Ambient storage limits -40...+70 °C at 5 to 95% rh

Medium valve temperature max. +130 °C

Signals

Input voltage range Y = 0...10 Vdc or 2...10 Vdc

Input resistor R

Signal source output register Max. 1 kΩ

Safety

Protection standard IP54 as per EN60529

Protection class II as per EN60730-1

Flame retardant V0 as per UL94 (optional

with metal cable gland)

Software class A as per EN 60730-1

Operating mode See Table 1 on pg. 2

Wiring

Terminals 1.5 mm

Cable entry M20x1.5

Weight 0.37 kg / 0.5 kg

Dimensions See Fig. 2 and Fig. 3

Material

Cover ABS-FR

Base Glass fiber reinforced plastic

= 100 kΩ

i

2

® U.S Registered Trademark

Copyright © 2009 Honeywell Inc. • All Rights Reserved EN0B-0260GE51 R0209

Page 2

ML7430E/ML7435E Electric Linear Valve Actuator

Table 1. Specifications, by model

OS-number ML7430E1005 ML7435E1004

supply voltage

power consumption

signal input 0(2) Vdc (factory setting)

signal input 10 Vdc (factory setting)

nominal stroke

run-time at 50 Hz

nominal stem force

spring return time (6.5 mm stroke)

spring return direction

operating mode (as per EN 60730-1, 6.4)

OPERATION

General

The drive of a synchronous motor is converted into linear

motion of the actuator stem by using a spur gear transmission. Actuator and valve are directly connected by a nut.

An integrated mechanism limits the stem force. Installed

microswitches switch off the actuator precisely when the

specified stem force is reached.

The close-off position is self-adjusting by means of an automatic synchronization function. Synchronization is performed

when the applied control signal is 0 V or 10 V. The actuator

then checks its end position every 20 minutes. Any manual

operation will be detected within 20 minutes, at the latest, and

the actuator will return to its end position after that control

cycle.

4 VA 4 VA

15 s 60 s

type 1B type 2B

Input Signal Range

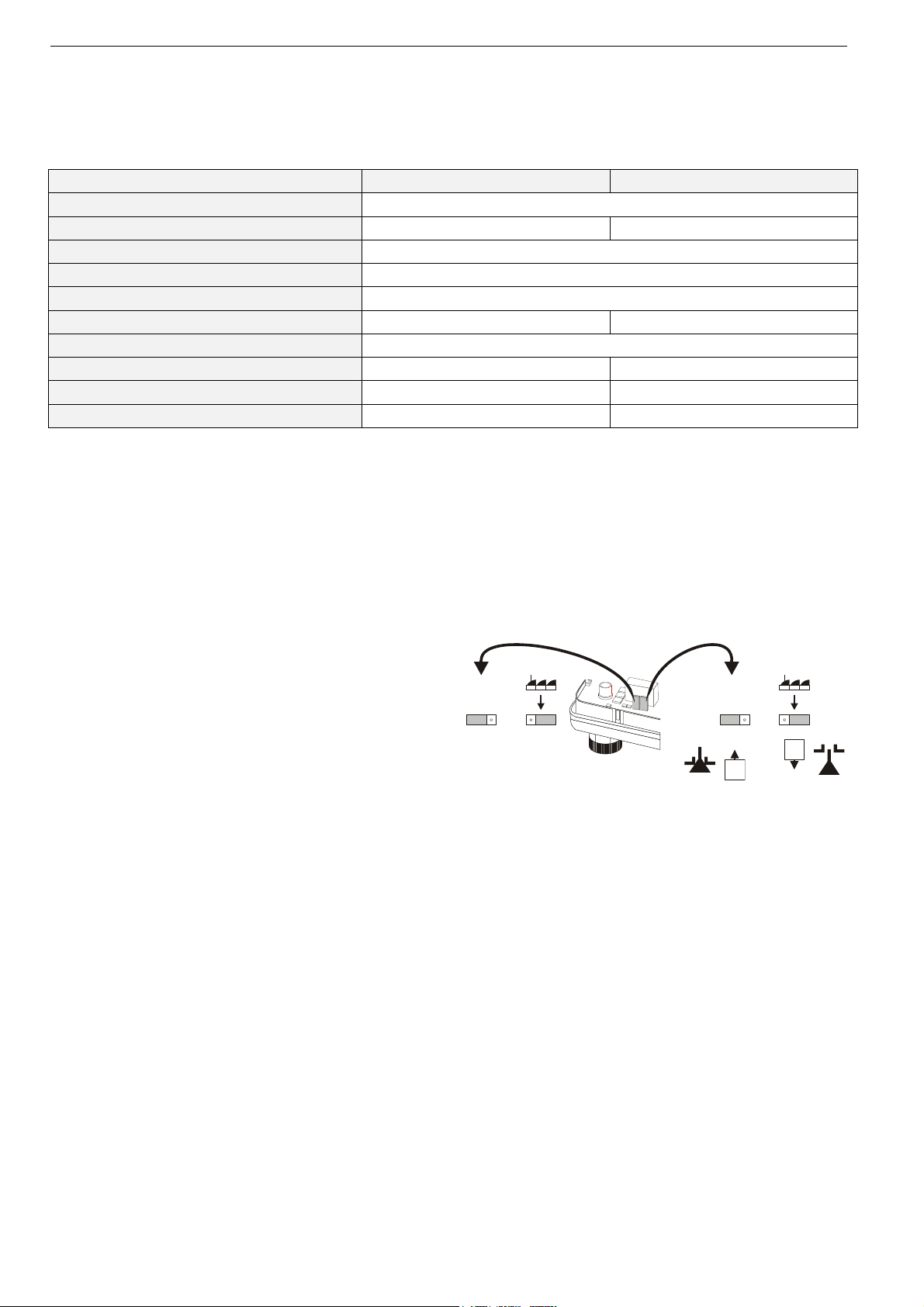

The range of the analog input signal Y (0...10 Vdc or

2...10 Vdc) can be selected by changing the position of

jumper plug W2 (see Fig. 1). The factory set is at 0...10 Vdc.

Direction of Action

The direction of action (direct or reverse) can be selected by

changing the position of jumper plug W1 (see Fig. 1). It is set

by the factory such that the stem extends at increasing signal

and retracts at decreasing signal (direct action).

W2

24 Vac -15/+20%, 50/60 Hz

actuator stem retracts

actuator stem extends

6.5 mm

400 N

-- max. 20 s

-- actuator stem retracts at power failure

W1

0...10 V2...10 V

10 V

Manual Operation for ML7430E

The actuators are equipped with a manual operator. Manual

operation is possible only after the power supply has been

switched off or disconnected. It should be used only to check

the valve operation. To operate, turn the manual operator

knob clockwise to move the stem downward and counterclockwise to move the stem upward.

NOTE: Jumper plugs W1 and W2 are accessible after the

Fig. 1. Jumper plugs W1 and W2

cover has been removed (see Fig. 1).

Manual Operation for ML7435E

The actuators are equipped with a manual operator (for 8 mm

Hex Key). Manual operation is possible only after the power

supply has been switched off or disconnected. It disables the

actuators safety function and should be used only to check

the valve operation. The manual operator is located under the

cover.

Electrical Installation

To avoid the voltage drop influence of the cabling, it is

recommended that you wire control signal Y and 24 V⊥

separately from power supply wiring.

10 V

EN0B-0260GE51 R0209 2

Page 3

ML7430E/ML7435E ELECTRIC LINEAR ACTUATORS

Y-Signal Override

To override the Y-signal and force the actuator in 0% or

100% stroke position, inputs 1 and 2 (see Fig. 4) must be

connected as follows:

• 0% stroke position (stem fully retracted):

24 V⊥ applied to input Y

• 100% stroke position (stem fully extended):

24 V

∼ applied to input Y

• or vice versa if reverse action is selected

Y-Signal break

In the event of a wire break at the Y-signal input, the

actuator is moved into the 0 V signal position (safety

position).

Spring Return (ML7435E1004, only)

The ML7435E1004 spring return actuator provides a

defined safety position of the valve in case of power failure.

DIMENSIONS

126 108

In the event of a power failure, the actuator retracts its

stem.

Suitable Valves

DN15 DN20 DN25 DN32 DN40 order no.

close-

off pres-

sure in

kPa

1600 -- 1600 -- -- V5872B

-

-

2500 2500 2500 2500 -- V5825B

-- 1600 1200 1000 V5832B

-- 1600 1200 1000 V5833A

Approvals

NOTE: Actuator ML7435E1004 in combination with the

following valves is approved according to DIN EN

14597:

valve OS-no. DIN registration no.

V5825B 1F152/08

97

33 33

Fig. 2. ML7430E (dimensions in mm)

126 108

81

33 33

Fig. 3. ML7435E (dimensions in mm)

3

EN0B-0260GE51 R0209

Page 4

WIRING

ML7430E/ML7435E ELECTRIC LINEAR ACTUATORS

0(2)...10 Vdc

W2

M

W1

10 V 10 V

0(2)...10 Vdc

Y

3

Y

0%

2

24 V 24 V

1

24 V ~ 24 V ~

Fig. 4. Wiring

100%

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0260GE51 R0209

Loading...

Loading...