Page 1

63-2516-07

ML6425, ML7425 Spring Return

Electric Linear Valve Actuators

PRODUCT DATA

FEATURES

ML6425 and ML7425

• Accurate valve positioning.

• Quick and easy installation.

• No separate linkage required.

• On power failure:

ML6425A and ML7425A drive valve stem down.

ML6425B and ML7425B draw valve stem up.

• Conduit connector is standard.

• No adjustments required.

• True spring return on power failure.

• Low power consumption.

• High close-off ratings.

• Force-limiting end switches.

APPLICATION

The ML6425 Spring Return Electric Linear Valve Actuators are

floating control actuators used with controllers that provide a

switched or floating single-pole double-throw (spdt) output.

These actuators operate standard Honeywell valves in

heating, ventilating, and air conditioning (HVAC) applications.

The ML7425 Spring Return Electric Linear Valve Actuators are

modulating control actuators used with controllers that provide

an analog output of 0 to 10 Vdc or 2 to 10 Vdc. These

actuators operate standard Honeywell valves in heating,

ventilating, and air conditioning (HVAC) applications. An

internal selector plug can be used to reverse the direction of

action.

• Direct/reverse action.

• Synchronous motor.

• Corrosion resistant design.

• Maintenance free.

ML7425

• Position Feedback signal.

• Fail-safe position selection for control signal loss.

Contents

Application ........................................................................ 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

WIring ............................................................................... 4

Operation .......................................................................... 7

Checkout .......................................................................... 8

Page 2

ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

SPECIFICATIONS

Models:

Model Spring Return Action Description

ML6425A Drive valve stem down on power

ML7425A

ML6425B Draw valve stem up on power

ML7425B

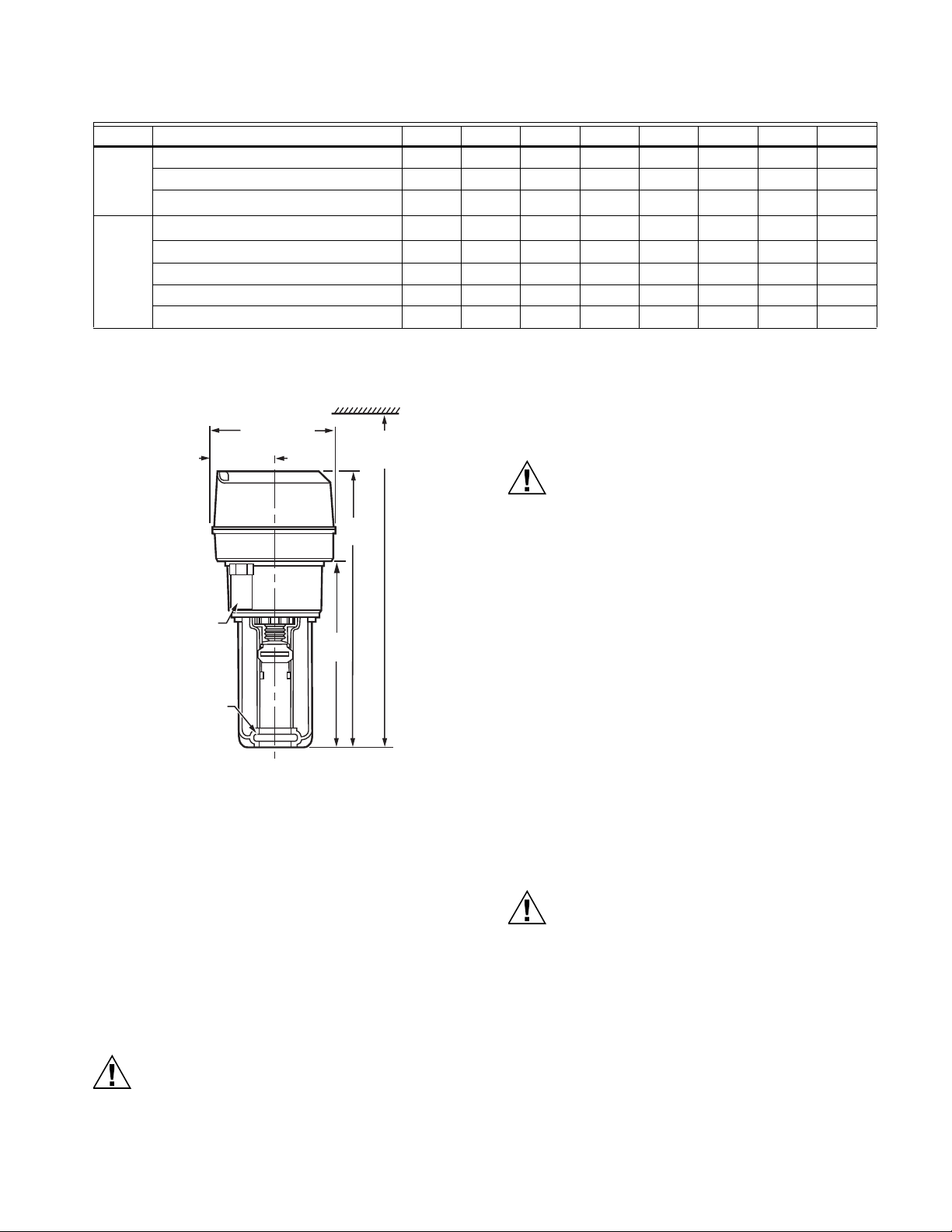

Dimensions: Refer to Fig. 1.

Weight: 5.1 lb (2.3 kg).

Electrical Ratings:

Power Input: 24 Vac ±15%, 60 Hz.

Power Consumption:

ML6425: 11 VA maximum at 24 Vac.

ML7425: 12 VA maximum at 24 Vac.

Signal Source Output Resistance: 1 kOhm maximum.

Signal Load: 1 mA maximum.

Signal Inputs (Supply Voltage Between Terminals):

ML6425:

B and 24 Vac: Drive valve stem down.

W and 24 Vac: Draw valve stem up.

ML7425: 0 to 10 Vdc or 2 to 10 Vdc.

Stem Force: 135 lbf (600 N).

Actuator Stroke: 3/4 in. (19 mm).

Actuator Run Time at 60 Hz: 90 seconds.

Spring Return Time: 12 seconds.

Temperature Ranges:

Ambient: 14° to 122° F (-10° to +50° C).

failure

failure

Electric

Linear Valve

Actuator

Storage: -40° to +158° F (-40° to +70° C).

Maximum Valve Medium: 300° F (149° C).

Humidity: 5 to 95 percent relative humidity, noncondensing.

Close-off Pressure Ratings: Refer to Table 1.

Protection Standard: IP54.

Approvals:

Underwriter’s Laboratories, Inc. UL94-5V Flame Retardant.

Meets CE requirements.

Cable entry: Conduit connector and one knockout on case.

Actuator Material:

Cover: ABS-FR plastic.

Base: PBTP-FR plastic.

Yoke: Diecast aluminum.

Accessories:

43196000-001 High Temperature Kit (for actuators with

3/4 in. stroke). Increases the maximum temperature to

428°F (220°C).

43196000-102 High Temperature Kit (for actuators with

1-1/2 in. stroke). Increases the maximum temperature to

428°F (220°C).

43191679-111 Single Auxiliary Potentiometer (10K ohm).

43191679-112 Single Auxiliary Potentiometer (220 ohm).

43191680-102 Dual Auxiliary Switch (24 Vac use only).

ML6420/ML6425 Only

43191679-101 Single Auxiliary Potentiometer.

43191679-102 Single Auxiliary Potentiometer.

43191679-103 Dual Auxiliary Potentiometer.

43191679-104 Dual Auxiliary Potentiometer.

43191680-105 Dual Auxiliary Switch (24 Vac use only).

ML7420/ML7425 Only

43191680-205 Dual Auxiliary Switch (24 Vac use only).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

63-2516—07 2

Page 3

ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

CAUTION

CAUTION

CAUTION

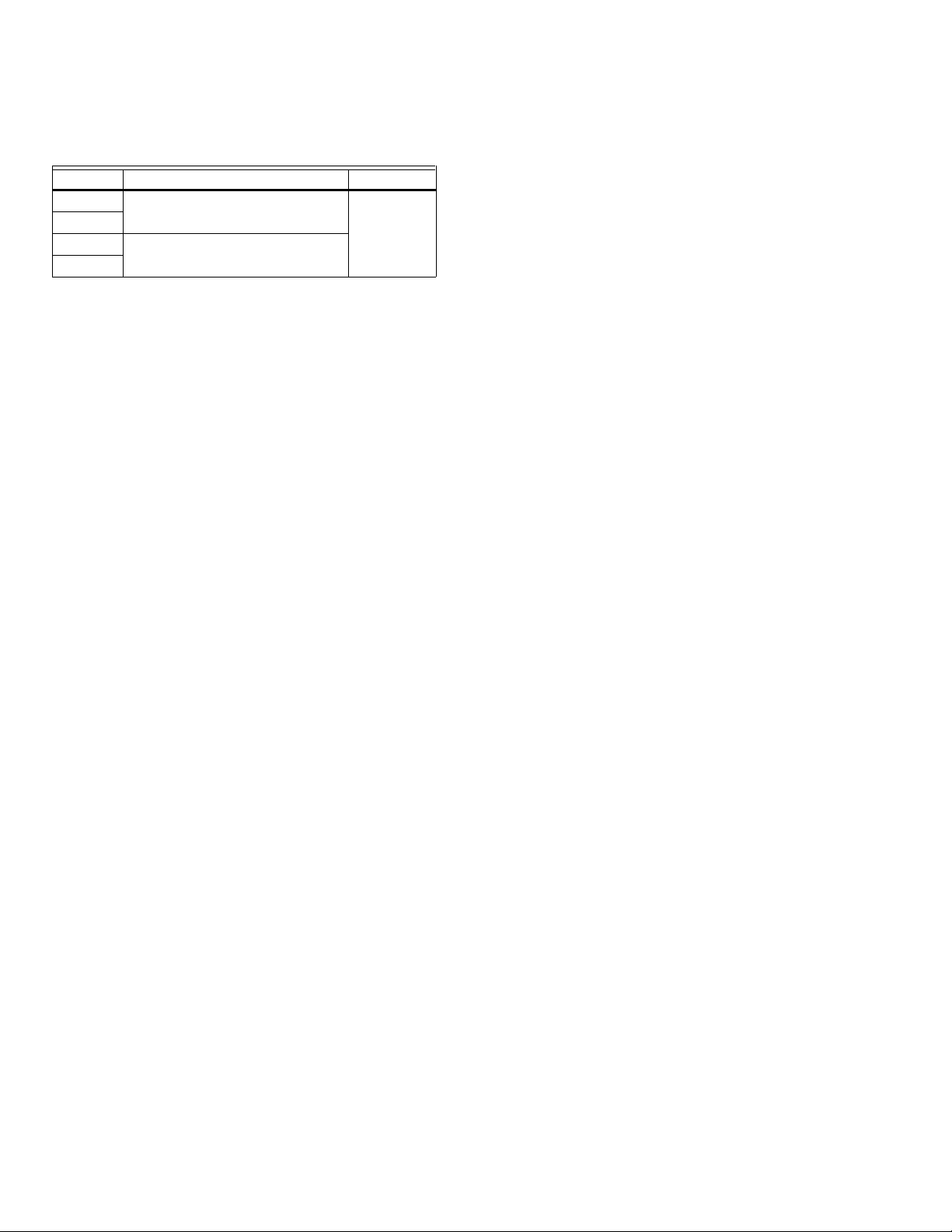

Table 1. Close-off Ratings for ML6425, ML7425 Electric Linear Valve Actuators and Honeywell Valves (psi).

Type Valve 1/2 in. 3/4 in. 1 in. 1-1/4 in. 1-1/2 in. 2 in. 2-1/2 in. 3 in.

FlangeV5011A ——————2816

V3350/ 3351/ 3450/ 3451 — —————2114

V5013B, C; V3360/ 3361/ 3460/ 3461 — —————

NPT V5011F, G

150

a

21

b

150

b

150

b

134

b

77 49 28 16

14

a

V5011H, J 150 150 150 145 — — — —

V5011N1xxx, V5011N3xxx, V5013N 230 230 163 104 67 37 — —

V5011N2xxx 100 100 100 100 67 37 — —

V5013F 150 150 150 126 77 49 — —

a

Represents maximum pressure difference between the outlet and either of the two inlets.

b

Do not exceed 100 psi with V5011G valves used in steam applications.

Location

5-5/15

(135)

2-11/16 (67)

6-5/16

x

(161)

14-5/16 (364)

MINIMUM

CLEARANCE

11-1/4

(284)

Install the actuator in a location that allows enough clearance

for mounting accessories and for servicing.

Equipment Damage Hazard.

Can damage actuator due to condensation or a

valve gland leak.

Install the actuator in a position above horizontal.

1/2 (13) FPT

7-5/8

(192)

YOKE

DIAMETER

1-3/8 (35)

M7892A

Fig. 1. Approximate Dimensions of ML6425, ML7425

Electric Linear Valve Actuator in in. (mm).

INSTALLATION

When Installing this Product...

1. Read instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

2. Check ratings and description given in the specifications

to make sure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect power supply before installation.

Mounting

1. Place the actuator on the valve with the U-bolt around

the valve collar (Refer to Fig. 2).

2. Place the U-bolt against the valve collar and secure the

actuator to the valve by turning each U-bolt nut

clockwise. To assure even pressure on the collar, first

tighten the nuts finger-tight and then alternate turning

each U-bolt nut until both are snug.

3. Push aside the stem button retaining clip and hold

(Refer to Fig. 3).

4. Lift valve stem until the head of the valve stem button is

inside the large slot of the stem button retaining clip on

the actuator.

5. Release the stem button retaining clip to secure the stem

button. Check to make certain the stem button is secured

by the retaining clip.

6. Remove the cover from the actuator using a Phillips or

crosspoint screwdriver (Refer to Fig. 4).

Personal Injury Hazard.

Manual spring handle under tension can turn

quickly when lifted, pinching fingers between

handle and plastic casing.

Use a screwdriver to lift and release manual spring

handle (Refer to Fig. 5).

7. Remove the manual spring handle retaining clip, and lift

and release the handle (Refer to Fig. 5). The easiest way

to perform this operation safely is to:

a. Remove the retaining clip.

b. Wedge a small, flat-bladed screwdriver under the

manual spring handle and pry up the handle

(Refer to Fig. 5).

3 63-2516—07

Page 4

ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

CAUTION

CAUTION

M6632

M6633

M6630

Fig. 5. Removing Spring Retaining Clip and Releasing

M6629

Manual Spring Handle.

Fig. 2. Attaching Actuator to Valve Collar.

Fig. 3. Securing Actuator to Valve.

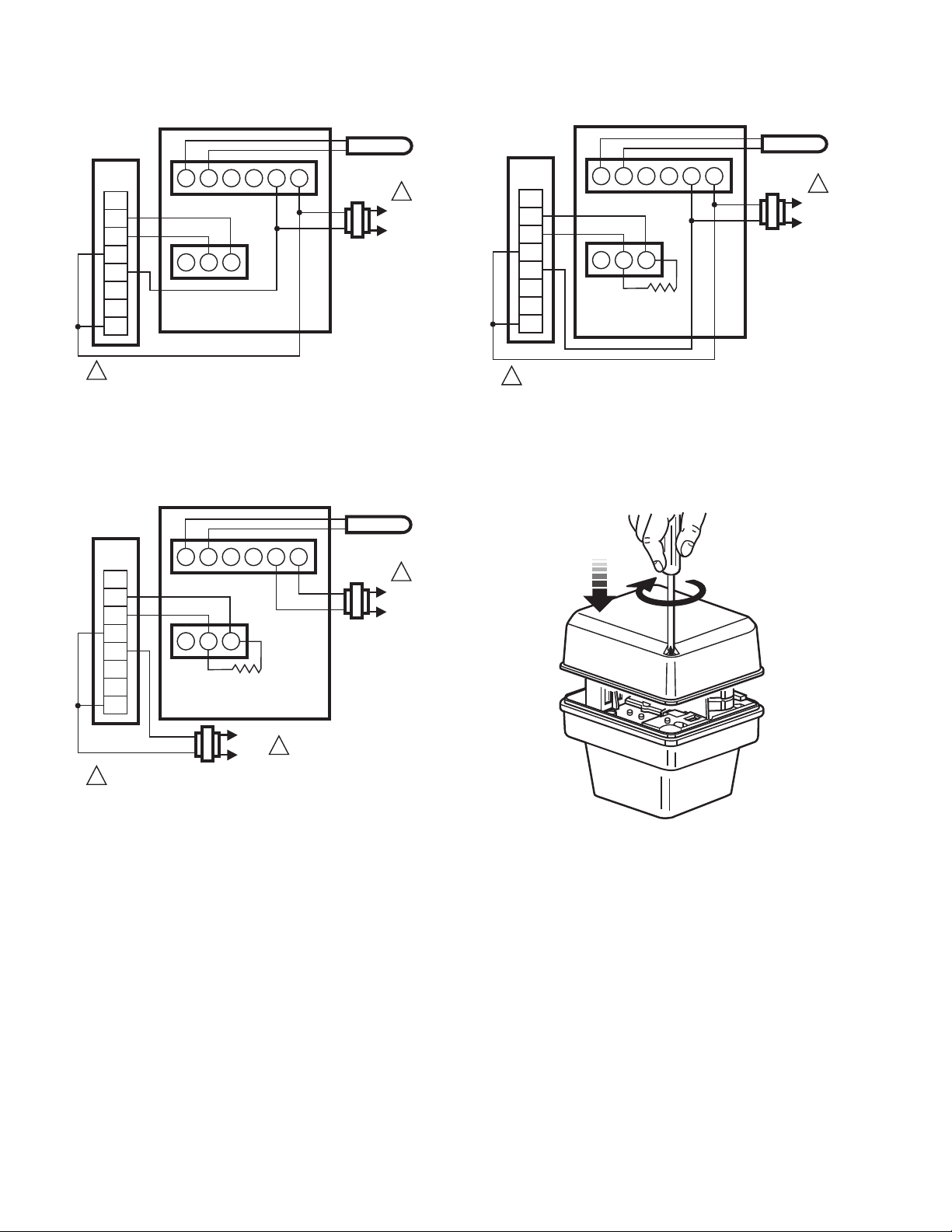

WIRING

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect power supply before installation.

All wiring must comply with local electrical codes, ordinances

and regulations. Voltage and frequency of the transformer

used with the actuator must correspond with the power supply

and actuator characteristics. Refer to Figures 6 through 13 for

connection information and typical wiring hookups.

1. Feed power and control wires through the conduit

connector located on the bottom of the actuator case

(See Fig. 6).

Equipment Damage Hazard.

Conduit connection or removal can break an

unsupported connector.

When removing or attaching conduit, use a wrench to

support the motor connector.

2. Using the wiring diagram in Fig. 7, connect power and

control wires. Make sure that all wiring is correct.

3. When wiring is complete, replace the cover on the

actuator (Refer to Fig. 14).

4. Apply power and control signals to the actuator.

M6627

Fig. 4. Removing Actuator Cover.

63-2516—07 4

Fig. 6. Connecting Power and Control Wiring.

Page 5

ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

WIRING

STRIP

T5

T1

W

B

1

L1

(HOT)

L2

T

Y

G

ML6425A,B

2

4

3

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

ALL WIRING BLOCKS HAVE THE SAME

NUMBER OF TERMINALS (8), BUT THE ONLY

TERMINALS THAT ARE ACTIVE ON THIS

BLOCK ARE T1, T5, W, AND B.

THE T-Y-G TERMINALS ARE A THREE TERMINAL

WIRING BLOCK SEPARATE FROM THE MAIN

BLOCK. THEY DO NOT APPEAR ON ALL MODELS

BECAUSE THEY ARE FOR A SINGLE FEEDBACK

POTENTIOMETER (10K OR 220 OHMS). THE

REQUIRED WIRING BLOCKS ARE PART OF

THE POTENTIOMETER ACCESSORY KITS.

MOTOR OPEN SIGNAL DRAWS VALVE STEM

UPWARDS. MOTOR CLOSE SIGNAL DRIVES

VALVE STEM DOWNWARDS.

1

2

3

4

T6984 (FLOATING CONTROLLER)

M25446

MOTOR OPEN

MOTOR CLOSE

COMMON

24 Vac

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

TS MUST BE POWERED, OR THE ACTUATOR WILL

SPRING RETURN.

ML7425A,B

WIRING

STRIP

F

+

Ð

T2

T1

O1

O2

TS

1

2

2-10 Vdc OUTPUT

T7984

(2-10 Vdc

CONTROLLER)

24 VAC

COMMON

2

1

L1

(HOT)

L2

M17394

L1

(HOT)

L2

1

1

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

1

2

2

3

3

4

5

6

L1

(HOT)

L2

1

ML7425

T775

(WITH 2-10 VDC OUTPUT)

DUAL

TRANSFORMERS

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M7894

SENSOR

ML7425

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

2-10 Vdc FEEDBACK SIGNAL. SEE OUTPUT SIGNAL

FEEDBACK SECTION.

3

0-10 Vdc OR 2-10 Vdc CONTROL SIGNAL. SEE SIGNAL

INPUT (+) SECTION.

2

F

+

–

INPUT

(FEEDBACK)

OUTPUT

3

1

L1

(HOT)

L2

C8286B

Fig. 7. ML6425 Wiring.

Fig. 8. ML7425 Wiring.

Fig. 9. ML7425 Wiring using Controller Feedback Output

and a Common Transformer.

Fig. 10. ML7425 Wiring using 2 to 10 Vdc Control Signal

and Separate Transformers.

5 63-2516—07

Page 6

ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

L1

(HOT)

L2

1

1

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

1

2

2

3

3

4

5

6

ML7425

T775

(WITH 2-10 VDC OUTPUT)

SINGLE

TRANSFORMER

40 VA 24 VAC

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M7895

SENSOR

L1

(HOT)

L2

1

1

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

1

2

2

3

3

4

5

6

L1

(HOT)

L2

1

ML7425

T775

(WITH 4-20 MA OUTPUT)

DUAL

TRANSFORMERS

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

M7896

500 OHM

RESISTOR

SENSOR

L1

(HOT)

L2

1

1

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

1

2

2

3

3

4

5

6

ML7425

SENSOR

T775

(WITH 4-20 MA OUTPUT)

SINGLE

TRANSFORMER

40 VA 24 VAC

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M7897

500 OHM

RESISTOR

Fig. 11. ML7425 Wiring using 2 to 10 Vdc Control Signal

and a Common Transformer.

Fig. 12. ML7425 Wiring using 4 to 20 mA Control Signal

and Separate Transformers.

Fig. 13. ML7425 Wiring using 4 to 20 mA Control Signal

and a Common Transformer.

NOTE: 500 ohm resistor not shipped with product.

M6628

Fig. 14. Replacing Actuator Cover.

NOTE: 500 ohm resistor not shipped with product.

63-2516—07 6

Page 7

ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

CAUTION

W3

0%

W1

100%50%

W2

M33047

Fig. 15. Location of W1, W2, and W3 Selector Plugs.

Auxiliary Potentiometers

The 43191679 Auxiliary Potentiometers can be used as

feedback potentiometers and to provide remote indication of

the valve position. Refer to the Installation Instructions packed

with the potentiometers.

Auxiliary Switches

Equipment Damage Hazard.

Improper voltage will damage the auxiliary switch

beyond repair.

Use the 43191680 Dual Auxiliary Switch only with 24

Vac applications.

ML7425

Signal Input (+)

The analog input signal (+) range is set at the factory to 0 to 10

Vdc. Changing the position of the W2 selector plug sets the

range to 2 through 10 Vdc. Selector plugs W1, W2, and W3 are

positioned on the back side of the printed circuit board. Refer

to Fig. 15 for location of the selector plugs.

Signal Input Failure

Using the potentiometer, the actuator can be set to run to any

position in event of a signal failure (ML7420/ML7425 only).

ML6420 does not have any input signal failure jumpers or

potentiometers.

Output Signal Feedback (F)

An analog output signal (2 to 10 Vdc) that represents the actual

actuator stem position is available at terminal F. It can be used

for remote indication of the stem position. When the valve stem

is fully downward, the output signal is 10 Vdc.

When the valve stem is up, the output signal is 0 or 2 Vdc. The

output of the signal does not change when the action of the

actuator is reversed using W3. See Direction of Action.

Actuator Override

To override the control signal (for freeze protection or similar

applications), connect the 24 Vac common (T2) to either

terminal O1 or O2. Connecting to terminal O1 fully extends the

actuator stem. Connecting to O2 fully retracts the actuator

stem.

The control signal (+) is ignored when the override signal is

applied to Terminal O1 or O2. This override can be achieved

with a switch or a relay (See Fig. 16).

The 43191680 Dual Auxiliary Switch can be used on both the

ML6425 and ML7425 Electric Linear Valve Actuators.

Switching points are adjustable over the full length of actuator

stroke; for example, the switch can be used to switch pumps or

provide remote indication of any stroke position. Refer to the

Installation Instructions packed with the auxiliary switch.

OPERATION

In the actuator, the drive of a synchronous motor is converted

into the linear motion of the actuator stem by using a spur gear

transmission. A button retainer clip connects the actuator stem

to the valve stem.

An integrated spring package limits the stem force to a factory

adjusted value in either direction. Installed microswitches turn

off the actuator when the specified stem force is reached.

The ML6425, ML7425 Spring Return Valve Actuators provide a

safety valve position in the event of power failure. On power

failure, the ML6425A and ML7425A extend the actuator stem;

the ML6425B and ML7425B retract the actuator stem.

The actuators are shipped from the factory with a spring

handle retaining clip installed, so the actuator can be

connected to the valve without applying power. Remove this

clip after the actuator is installed. (Refer to the Installation

section.)

ML7425

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

2-10 Vdc FEEDBACK SIGNAL. SEE OUTPUT SIGNAL

FEEDBACK SECTION.

3

0-10Vdc OR 2-10 Vdc CONTROL SIGNAL. SEE SIGNAL

INPUT (+) SECTION.

SEE OVERRIDE SECTION FOR DETAILS ON

4

OVERRIDE OPERATION.

2

F

+

–

INPUT

(FEEDBACK)

OUTPUT

3

SP3T

OVERRIDE

SWITCH

4

1

L1

(HOT)

L2

M7906A

Fig. 16. Connections for Overriding Control Signal to Drive

ML7425 to a Specific Position.

7 63-2516—07

Page 8

ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

Direction of Action (ML7420/ML7425 only)

The direction of actuator action can be changed using the

pushbutton and LED, which is factory set so that the actuator

drives the valve stem down on increasing signal and draws it

CHECKOUT

The actuator can be checked out either directly or by using a

controller.

Direct Checkout

1. Mount the actuator for the required application; see

Installation section.

2. Check the valve position and make sure that 24 Vac is

correctly applied to the actuator.

3. Apply the power to the appropriate leadwires to move

the valve.

4. If the actuator does not move, make sure the actuator is

properly installed/wired.

5. If the actuator installation and wiring are both correct

and the actuator does not run, replace the actuator.

up on decreasing signal. When the valve stem is up, the

output signal from the feedback (F) function is 0 or 2 Vdc. The

output of the signal does not change when W3 is used to

reverse the action of the actuator (see Fig. 15).

Controller Checkout

1. Adjust the setpoint of the controller to call for opening

the valve. Observe the actuator.

2. If the valve is closed, it should begin to open.

3. If the valve remains closed, move the setpoint further

toward the open setting.

4. If the valve does not move, check for 24 Vac in the

actuator power input.

5. If 24 Vac is present and the actuator does not operate,

check the voltage across the controller leadwires to

determine if the device is miswired.

6. If the wiring is correct, 24 Vac is present on the power

input terminals, and the actuator does not run, replace

the actuator.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 211 Honeywell International Inc.

63-2516—07 M.S. Rev. 07-11

Printed in United States

Loading...

Loading...