Page 1

63-1146-1

35 and 70 lb-in. Non-Spring Return

ISO 9001

®

The 35 and 70 lb-in. Non-Spring Return Direct Coupled

Actuators (DCA) are control motors that provide floating or

proportioning control for valves and dampers. The proportioning

motors accept a current or voltage signal from a controller to

position the damper or valve at any chosen point between fully

open and fully closed.

®

SPECIFICATIONS

Electrical Ratings:

Power Input: 24 Vac ±20%, 50/60 Hz.

Model Power Consumption

q ML6161A,B,C,D 1.8 VA

q ML7161A 4.8 VA

q ML6174A,B 2.4 VA

q ML7174A 5.4 VA

Auxiliary Switch Ratings:

q Electrical selective NO or NC, not simultaneous.

q Pilot Duty: 50 VA, 24 Vac.

q Switch Differential: Three angular degree maximum.

Direct Coupled Actuators

ML6161, ML7161

ML6174, ML7174

SPECIFICATION DATA

FEATURES

•45°, 60°, and 90° selectable stroke in either clockwise

(cw) or counterclockwise (ccw) directions.

• Magnetic coupling eliminates the need for mechanical

stops.

• Two field-addable auxiliary switches.

• Auxiliary feedback potentiometer field-addable on

select models.

•0

° to 30° minimum position adjustment (cw or ccw

direction) on all models.

• Manual declutch on select models.

• W7620 Terminal Unit Controller compatibility.

• Commercial Zone Damper in W7600 Commercial Zone

System compatibility.

Actuator Timing for 90

q 90 Second Models 108 sec 90 sec

q Three-Minute Models 216 sec 180 sec

q Seven-Minute Models 504 sec 420 sec

° Stroke:

At 50 Hz At 60 Hz

Torque Ratings (at Rated Voltages):

35 lb-in. DCA 70 lb-in. DCA

lb-in. (Nm)

q Running 35 (4) 70 (8)

q Breakaway 35 (4) 70 (8)

q Stall Minimum 45 (5) 70 (8)

q Stall Maximum 70 (8) 130 (14)

Actuator Stroke:

q Selectable: 45°, 60°, and 90°.

q Rotation: Clockwise (CW) and counter clockwise (CCW).

Device Weight:

q 1.3 lb (0.58 kg).

Environmental Protection Ratings:

q NEMA1.

q IP54 (ML6161E, ML7161E, ML6174E, ML7174E only).

® U.S. Registered Trademark

Copyright © 1998 Honeywell Inc., Mpls. MN • All Rights Reserved

Mounting:

q Mounts directly on 3/8 in. to 1/2 in. (10 to 13 mm) round or

square shaft.

q Minimum Shaft Length Required: 1-3/4 in. (45 mm).

q Actuator can be mounted with shaft in any position.

q Secured Using: Two 1/4 in. (6 mm) 28 NF Allen screws.

Actuator Minimum Design Life:

35 lb-in. DCA 70 lb-in. DCA

q Cycles 50,000 40,000

q Repositions 1,500,000 1,500,000

Temperature Ratings:

q Ambient: 20°to 125°F (-18° to 50°C).

q Derated Timing to: -20°F (-29°C).

q Shipping and Storage: -20° to 130°F (-29° to 54°C).

Humidity Ratings:

q 5% to 95% RH noncondensing.

Noise Output:

q 45 dBA at 1 meter maximum.

Page 2

35 AND 70 LB-IN NON-SPRING RETURN DIRECT COUPLED ACTUATORS

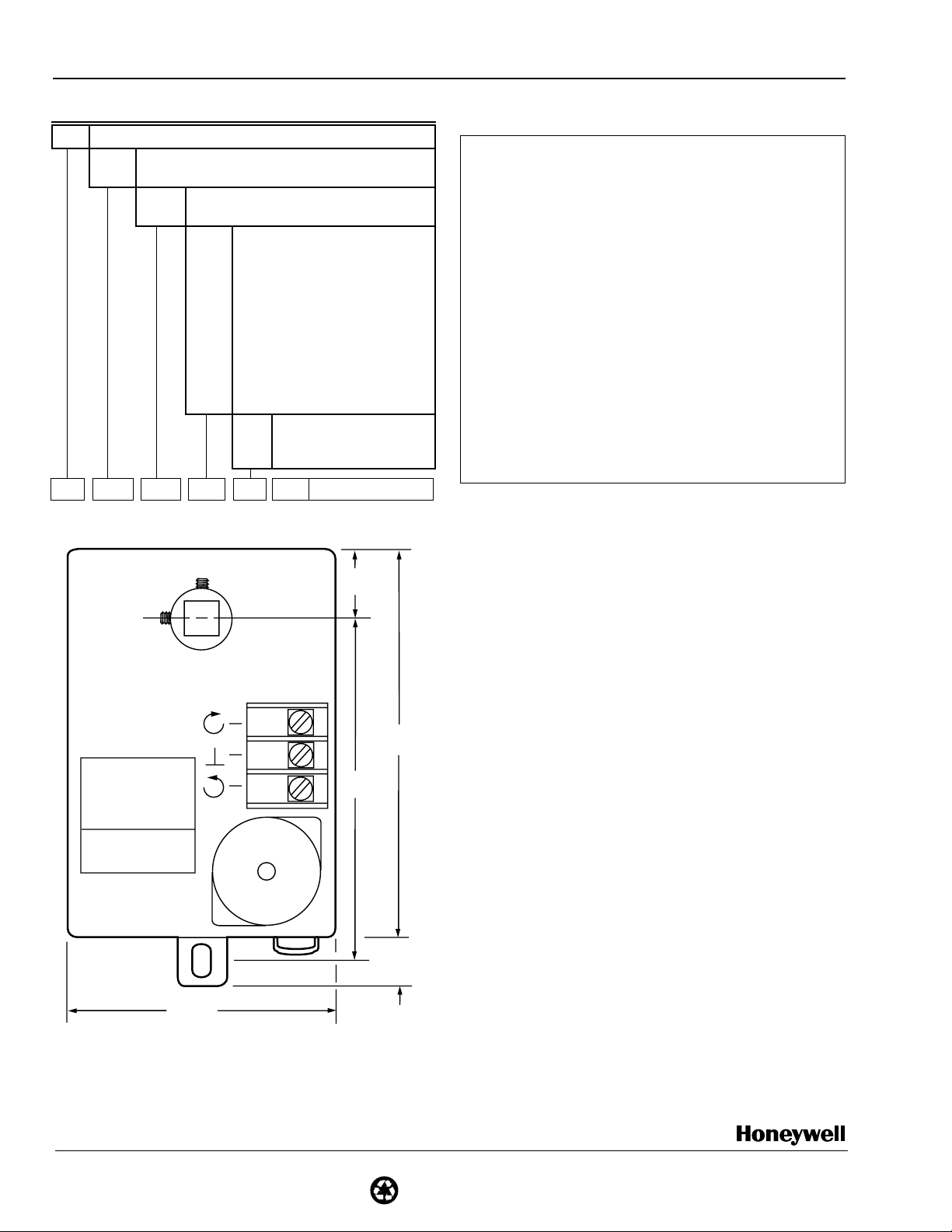

Models:

ML Motor Linkage

q 61

q 71

Floating Control

4-20 mA/2-10 Vdc Control

q 61

q 71

35 lb-in. (4 Nm), Non-Spring Return

70 lb-in. (8 Nm), Non-Spring Return

74

q A

Includes output for feedback

potentiometer.

q B

Standard (includes minimum

position setscrews)

q C

Includes output for feedback

potentiometer and cover w/

conduit connections.

q D

Includes cover w/ conduit

connections.

q E

Standard with European

ratings.

q 1

Standard

q 2

Includes declutch

function

ML XXX Varies by Model

Dimensions:

1

(25)

TYPICAL SPECIFICATION

Non-spring return actuator shall be direct coupled type

that requires neither crankarm nor linkage and be capable

of direct mounting to a 3/8 inch or 1/2 inch diameter

jackshaft. The actuator shall connect to the shaft using

set screws. The actuator must provide floating or

proportional control.

The actuator design must be for use in either clockwise

or counterclockwise operation.

Actuators shall use a true synchronous ac stepper motor

to drive the output hub. Run time shall be constant and

independent of load, temperature and supply voltage

(within product-family specifications). Overload

protection shall be provided at all angles of rotation by a

magnetic clutch mechanism that provides an absolute

limit to the output torque without a physical link between

the motor and the gear train.

Actuators shall have a minimum performance of 40,000

full-stroke powered cycles, and 1,500,000 repositions

documented in the product data literature. Actuators shall

be UL and CSA listed, manufactured under ISO 9001

International Quality Control Standards.

Feedback Potentiometer Ratings:

q Electrical Rating (200976A,C Potentiometer): 24 Vac,

50/60 Hz, 2.25W.

q Resistance Output (Resistance Linear as Measured

Between Terminals R-B):

q 0 ohms (at 0°, cw stroke).

q 250 ohms (at 45°, cw stroke).

q 333 ohms (at 60°, cw stroke).

q 500 ohms (at 90°, cw stroke).

Approvals:

q Underwriter’s Laboratories Inc. Component Recognized:

File No. E4436; Guide No. XAPX2.

CW

COM

CCW

4-1/4

(108)

4-7/8

(123)

q Meets UL94-5V plenum requirements.

q Canadian Standards Association Certified (includes

auxiliary switch).

Accessories:

q 200976A Auxiliary Potentiometer (0 to 500 ohm).

q 200976C Auxiliary Potentiometer (0 to 2000 ohm).

q 201052A Auxiliary Switch (one).

q 201052B Auxiliary Switch (two).

q 4074ENJ Bag Assembly—includes stop pin, shaft adapter,

and two minimum position screws.

q 4074ENY Bag Assembly—includes stop pin and shaft

adapter.

q 4074EVK Short Shaft Extender.

q 7640QW Metal Enclosure—for attaching conduit to

11/16

(18)

actuator.

q T641 Floating Thermostat—for use with seven-minute

models.

3-3/8 (86)

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your

use or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and

against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to

the literature by you.

M14227

q T6984 Floating Thermostat—for use with 90-second and

seven-minute models.

q T7984 Modulating Thermostat—for use with ML7174.

Printed in U.S.A. on recycled

63-1146—1 B.B. Rev. 5-98

XX-XXXX 2

paper containing at least 10%

post-consumer paper fibers.

www.honeywell.com

/building/components/

Loading...

Loading...