Page 1

35 and 70 lb-in.

Non-Spring Return

Direct Coupled Actuators

ML6161, ML7161, ML6174, ML7174

PRODUCT DATA

FEATURES

• Selectable 45°, 60°, or 90° stroke in both clockwise

(cw) or counterclockwise (ccw) directions.

• 0° to 30° minimum position adjustment (cw or ccw

direction) on all models.

• Magnetic coupling eliminates the need for mechanical

stops.

• Two field-addable auxiliary switches.

• Auxiliary feedback potentiometer field-addable on

select models.

• Manual declutch on all models.

• ML7161 and ML7174 models include standard reverse/

direct acting rotation switch on outside cover.

• W7620 Terminal Unit Controller compatibility.

• Commercial zone damper in W7600 Commercial Zone

System compatibility.

APPLICATION

The 35 and 70 lb-in. Non-Spring Return Direct Coupled

Actuators (DCA) are control actuators that provide floating or

proportioning control for valves and dampers. The

proportioning actuators accept a current or voltage signal from

a controller to position the damper or valve at any chosen

point between fully open and fully closed. Floating actuators

are suitable for use with single pole double throw (spdt)

floating thermostats or two-position control systems.

Two-position control requires installation of the 201052B

Auxiliary Switch.

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 5

Operation .......................................................................... 10

Checkout .......................................................................... 12

® U.S. Registered Trademark

Copyright © 2003 Honeywell International Inc.

All Rights Reserved

Þ

63-2209-8

Page 2

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

SPECIFICATIONS

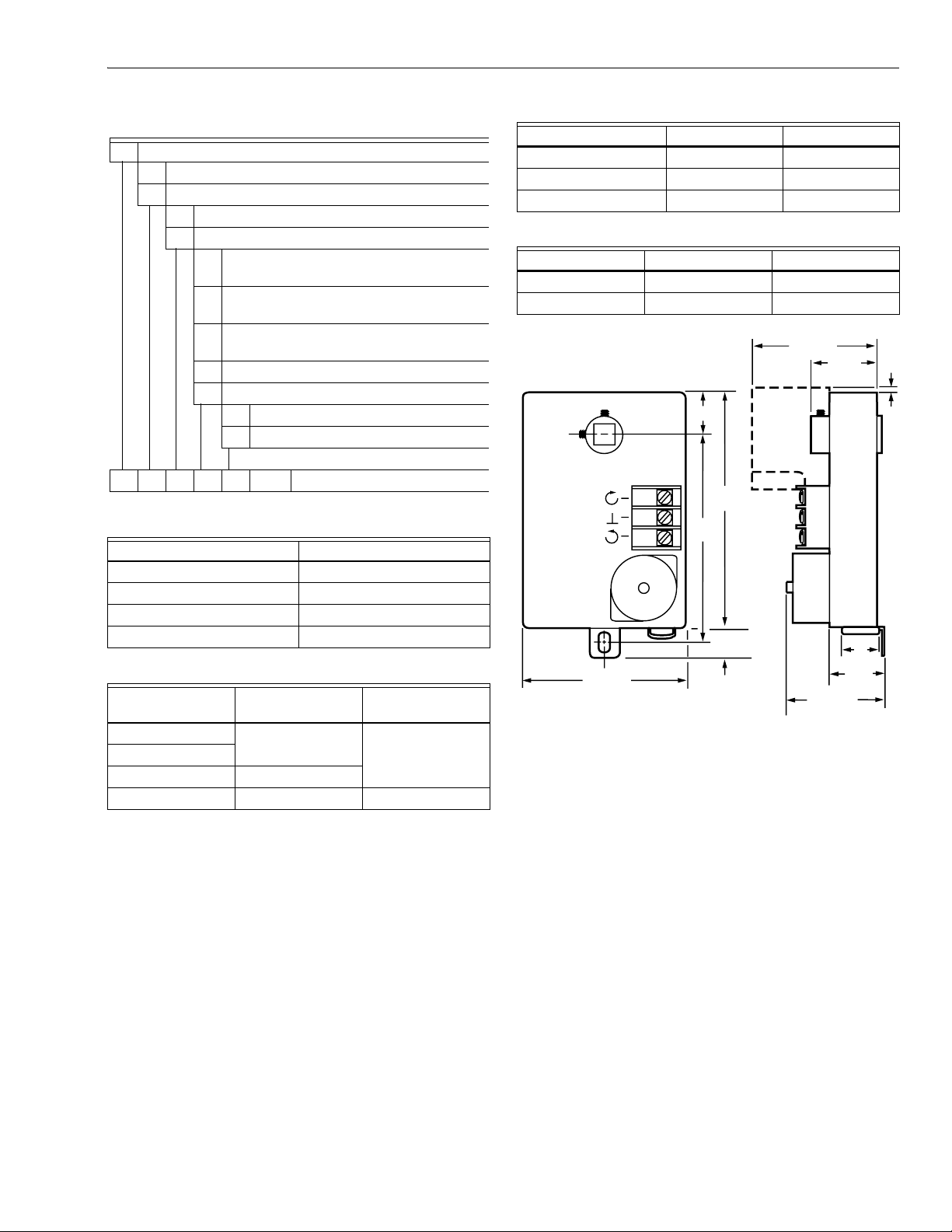

Models: See Table 1.

Dimensions: See Fig. 1, 1A, and 1B.

Electrical Ratings:

Power Input: 24 Vac ±20%, 50/60 Hz.

Impedance:

2-10 Vdc: 45k ohms.

4-20 mA: 536 ohms.

Power Consumption: See Table 2.

Auxiliary Switch Ratings:

Electrical: Selective NO or NC, not simultaneous.

Pilot Duty: 50 VA, 24 Vac.

Switch Differential: Three angular degree maximum.

Torque Ratings (at Rated Voltages): See Table 3.

Actuator Stroke:

Selectable: 45°, 60°, and 90°.

Rotation: Clockwise (cw) and counterclockwise (ccw).

NOTE: Reversing drive rotation of the ML7161 and ML7174

requires changing the control signal from 2-10 Vdc to

10-2 Vdc.

Device Weight: 1.3 lb (0.58 kg).

Actuator Timing for 90° Stroke: See Table 4.

Mounting: Mounts directly on 3/8 in. to 1/2 in. (10 to 13 mm)

round or square shaft. Can be mounted with shaft in any

position with two 1/4 in. (6 mm) 28 NF Allen screws. Mini-

mum Shaft Length Required: 1-3/4 in. (45 mm).

Temperature Ratings:

Ambient: 20°F to 125°F (-18°C to 50°C).

Derated Timing to: -20°F (-29°C).

Shipping and Storage: -20°F to 130°F (-29°C to 54°C).

Humidity Ratings: 5% to 95% RH noncondensing.

Actuator Minimum Design Life: See Table 5.

Noise Output: 45 dBA at 1 meter maximum.

Feedback Potentiometer Ratings:

Electrical Rating (200976A,C Potentiometer): 24 Vac, 50/60 Hz,

2.25W.

Resistance Output (Resistance Linear as Measured Between

Terminals R-B):

0 ohms (at 0°, cw stroke).

250 ohms (at 45°, cw stroke).

333 ohms (at 60°, cw stroke).

500 ohms (at 90°, cw stroke).

Environmental Protection Ratings:

NEMA1.

IP54 (ML6161E, ML7161E, ML6174E, ML7174E only).

Approvals:

Underwriter’s Laboratories Inc. Component Recognized: File

No. E4436; Guide No. XAPX2.

UL94-5V: Meets plenum requirements.

Canadian Standards Association Certified (includes Auxiliary

Switch).

ML6161E, ML6174E, ML7161E, ML7174E only: CE.

Accessories:

200976A Auxiliary Potentiometer (0 to 500 ohm).

200976C Auxiliary Potentiometer (0 to 2000 ohm).

201052A Auxiliary Switch (one).

201052B Auxiliary Switch (two).

201391 Shaft Adapter (included).

4074ENJ Bag Assembly—includes stop pin, shaft adapter,

and two minimum-position screws.

4074ENY Bag Assembly—includes stop pin and shaft

adapter.

4074EVK Short Shaft Extender.

7640QW Metal Enclosure—for attaching conduit to actuator.

T641 Floating Thermostat—for use with seven-minute

models.

T6984 Floating Thermostat—for use with 90-second and

seven-minute models.

T7984 Modulating Thermostat—for use with ML7161 or

ML7174.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2209—8 2

Page 3

Table 1. 35 lb-in. and 75 lb-in. DCA models.

ML Motor Linkage

61 Floating Control

71 4-20 mA/2-10 Vdc Control

61 35 lb-in. (4 Nm), Non-Spring Return

74 70 lb-in. (8 Nm), Non-Spring Return

A Includes output for feedback

potentiometer.

B Standard (includes minimum-position

setscrews).

C Includes output for feedback potentiometer

and cover with conduit connections.

D Includes cover with conduit connections.

E Standard with European ratings.

1 Standard.

2 Includes declutch function.

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

Table 4. Actuator 90° Stroke Timing.

At 50 Hz At 60 Hz

90 Second Models 108 sec 90 sec

Three-Minute Models 216 sec 180 sec

Seven-Minute Models 504 sec 420 sec

Table 5. Actuator Minimum Design Life.

35 lb-in. DCA 70 lb-in. DCA

Cycles 50,000 40,000

Repositions 1,500,000 1,500,000

2-7/8 (73)

1-11/16

(42)

1 (25)

OPTIONAL

AUXILIARY

SWITCH

1/8

(3)

ML 61 61 B 1 XXX Varies by model

Table 2. Power Consumption.

Model Power Consumption

ML6161A,B,C,D 1.8 VA

ML7161A 4.8 VA

ML6174A,B 2.4 VA

ML7174A 5.4 VA

Table 3. Torque Ratings.

35 lb-in. DCA

lb-in. (Nm)

70 lb-in. DCA

lb-in. (Nm)

Running 35 (4) 70 (8)

Breakaway

Stall Minimum 45 (5)

Stall Maximum 70 (8) 130 (14)

Fig. 1A. Approximate dimensions of ML7161, ML7174 DCA in in. (mm).

4-1/4

(108)

4-7/8

(123)

11/16

(18)

2-1/2 (64)

7/8

(22)

1-5/16

(33)

CW

COM

CCW

3-3/8 (86)

Fig. 1. Approximate dimensions of ML6161A,B,E

and ML6174A,B,E DCA in in. (mm).

M18016

3 63-2209—8

Page 4

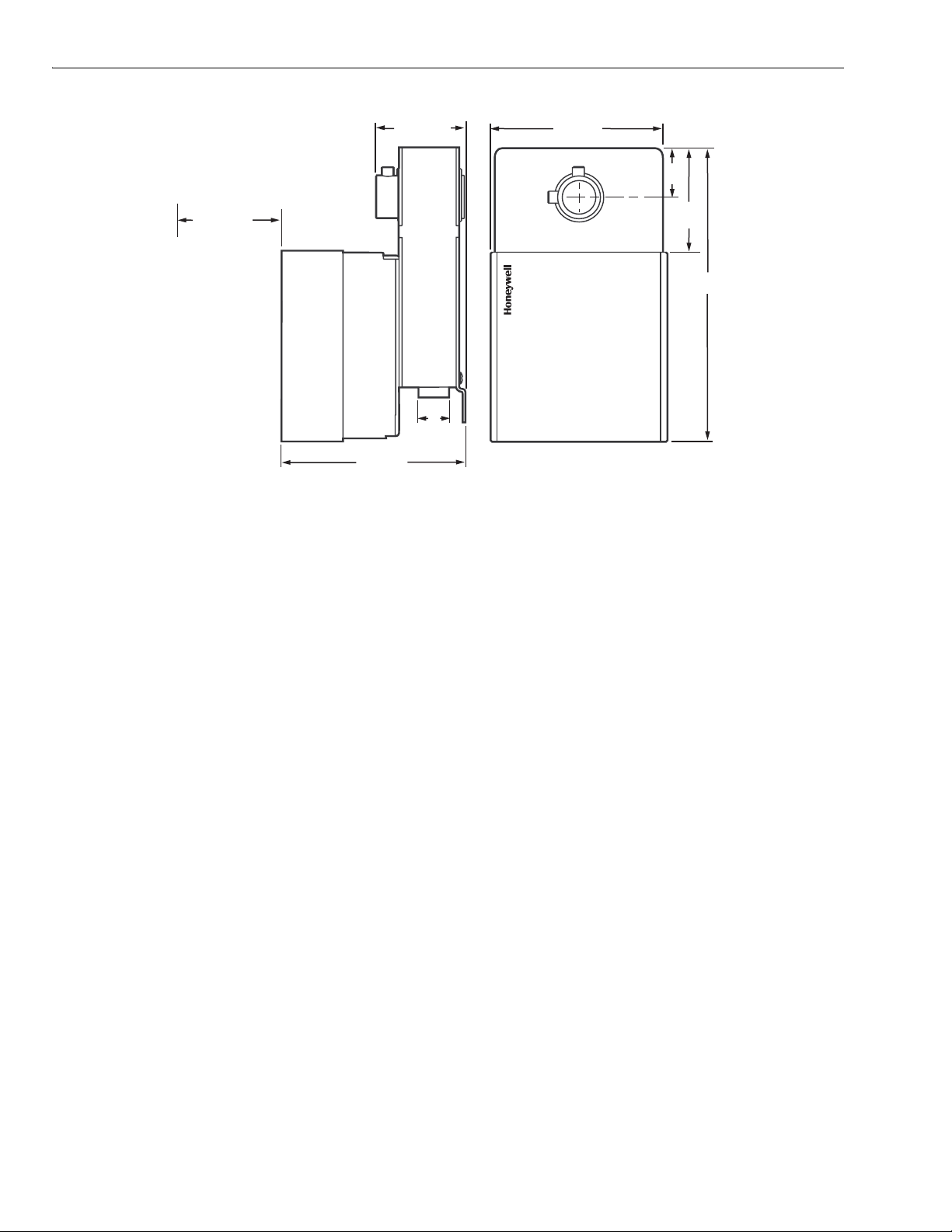

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

3 IN. (76 MM)

MINIMUM SPACING

REQUIRED

FOR REMOVING

CONDUIT COVER

3-3/4 (95)

1-13/16 (46)

7/8

(22)

3-5/8 (92)

1

(25)

1-13/16

M18018

(46)

5-7/8

(149)

Fig. 1B. Approximate dimensions of ML6161C,D and ML6174C,D DCA in in. (mm).

63-2209—8 4

Page 5

INSTALLATION

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

WARNING

Explosion Hazard.

A spark from the actuator or attached accessories

can result in serious injury or death.

Install the actuator in areas free of escaping gas and

other explosive vapors.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Actuators with auxiliary switches can have more than

one disconnect.

These actuators are shipped in the fully clockwise 90° position

as viewed from the end of the damper shaft.

CAUTION

Equipment Damage Hazard.

Mounting actuator unevenly with damper housing

can damage actuator.

Mount actuator flush with damper housing or add

spacer between mounting tab and damper box

housing (see Fig. 2).

DAMPER

SHAFT

ADD SPACER BETWEEN

DAMPER BOX AND TAB

VAV BOX HOUSING

Fig. 2. Mounting actuator to VAV box when

actuator is not flush with box.

ML6161

ML6174

M11624A

CAUTION

Actuator Damage Hazard.

Deteriorating vapors and acid fumes can damage

the actuator metal parts.

Install actuator in areas free of acid fumes and

deteriorating vapors.

Location

Choose a location for the actuator that allows enough

clearance for mounting accessories and for servicing.

Mounting

These actuators are designed to open a damper or valve by

driving the shaft in either the clockwise (cw) or

counterclockwise (ccw) direction. The actuator has a

mounting tab on the bottom that secures it to a damper box

or valve linkage. When mounted correctly, this tab allows the

actuator to float without rotating relative to the shaft. The tab

is sized for 1/4 in. screw or pin (not included).

CAUTION

Equipment Damage Hazard.

Tightly securing mounting tab to damper housing

can damage actuator.

Once mounted, the actuator must be allowed to float;

do not fully tighten the screw.

Preparation

Before mounting the actuator onto the shaft, determine the

following:

1. Size of the shaft (3/8 in. to 1/2 in.).

2. Direction the shaft rotates to open the device (cw or

ccw). See Fig. 4.

3. Degrees of actuator stroke for opening device (45°, 60°,

or 90°).

If the shaft is 3/8 in. round or square, use part number 201391

Shaft Adapter provided inside the bag assembly shipped with

the actuator. Place the adapter opposite the setscrews (see

Fig. 3).

SHAFT ADAPTER

M2064

Fig. 3. Using shaft adapter for 3/8 in. shafts.

5 63-2209—8

Page 6

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

A

A

Installation

IR

FLOW

IR

FLOW

TYPE A DAMPER

CW TO OPEN, CCW TO CLOSE

TYPE B DAMPER

After determining the direction of the shaft rotation (cw or

ccw), install the device. For valve linkage mounting, refer to

the instructions shipped with the linkage. For damper

mounting, proceed as follows:

1. Place the actuator onto the damper shaft.

CAUTION

Equipment Damage Hazard.

Improper range stop selection can damage

light-duty dampers.

Be sure to select the proper range stop.

M2067BB

CCW TO OPEN, CW TO CLOSE

Fig. 4. Determining direction damper

shaft rotates when opening.

Manual Operation (Declutch)

CAUTION

Product Damage Hazard.

Do not use manual declutch without supporting

the load.

Support actuator load independently immediately

before and during use of manual declutch lever.

Manual declutch capability is available on some actuators.

Use the manual declutch lever to manually adjust the actuator

setting. Fig. 5 shows the location of the manual declutch lever.

To operate, push the lever in the direction of the arrow on the

lever cover.

60

2. If the angle of the damper opening is either 45° or 60°,

close the actuator using the manual declutch:

a. Disengage the hub using the declutch lever; see

Manual Operation (Declutch) section.

b. Rotate the hub until the actuator gear train passes

the proper 45° or 60° setting. (Do not insert the pin

until after the actuator passes this point.)

c. Release the declutch lever.

NOTE: Dampers with 90° stroke do not require the

range stop pin.

3. Insert the range stop pin into the appropriate (cw or

ccw) 45° or 60° slot. The range stop pin clips into its

final position only after the pin passes through both

actuator plates (see Fig. 7). The range stop pin should

snap into position and not be removable manually

(see Fig. 8).

IMPORTANT

Do not fully tighten the mounting screw; the actuator

must be allowed to float.

4. With the actuator placed in its final position, fix the

mounting tab in position with a 1/4 in. screw or pin. See

Fig. 6.

5. Position the damper in the open position and securely

tighten the Allen screws into the damper shaft.

60

MANUAL

DECLUTCH

ROTATION

REVERSAL SWITCH

LEVER

Fig. 5. Location of manual declutch lever.

M10076B

1MM (1/32 IN.)

1MM

(1/32 IN.)

M20884

Fig. 6. Proper actuator mounting to prevent rotation.

63-2209—8 6

Page 7

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

1. Determine the direction of the desired closing rotation.

RANGE STOP PIN

2. Move the actuator to the position fully opposite the

desired closing rotation (if cw closing rotation is desired,

move the actuator to the full ccw position).

3. Determine the correct hole for the setscrew using Fig. 9

ACTUATOR PLATES

and the results of step 1.

CAUTION

Equipment Damage Hazard.

Improper hub positioning or hole selection can

permanently damage the device.

Avoid backdriving the actuator with the setscrew.

60

45

60

45

CW

COM

CCW

M10246A

4. Remove the red cap from the desired hole. Leave the

other cap in position. The caps ensure that dust and

other impurities do not enter the gear train through

unused holes.

5. Thread the locknut fully onto the 1/4 in. setscrew.

6. Insert the setscrew into the desired hole, turning

clockwise until resistance is encountered or the locknut

contacts the housing.

7. If resistance is met before the setscrew is fully inserted,

stop and review the initial setup procedures as detailed

in steps 1 through 3.

8. Determine the angle of minimum position required for

the application. With the setscrew fully inserted, the

minimum position is 30°. With the setscrew fully out, the

minimum position is 0°.

9. Using the conversion of approximately 1.7 angular

degrees per turn of the setscrew, back the screw out of

the housing and stop slightly short of the calculated

position. This allows the setscrew to be set accurately

while taking air flow measurements.

Fig. 7. Range stop pin properly inserted.

SCREWDRIVER

M2065

Fig. 8. Lifting range stop pin out of its slot.

Minimum Position Setscrew

Certain ML6161, ML6174 and all ML7161, ML7174 models

are equipped with two tapped holes located in the plastic

housing at the top of the actuator. These holes can be used

with the minimum position setscrew and locknut inside the

4074ENJ Bag Assembly (see Fig. 9). The setscrew provides

for a 0° to 30° minimum position adjustment.

NOTE: Before starting operation, note that the 1/4 in.

minimum position setscrew limits closing motion,

while the range stop pin limits opening motion.

IMPORTANT

After initiating step 10, the setscrew cannot be turned

into the housing without returning the actuator to the

fully open position (as determined in step 1). The

actuator follows the setscrew without damaging the

housing only when backed out of the housing (turned

ccw).

10. Rotate the actuator to minimum position using the

manual declutch; see Manual Operation (Declutch)

section.

11. With the actuator at minimum position, adjust the

position more accurately using air flow measurements.

NOTES:

1. After each adjustment, ensure the actuator is

completely stopped before proceeding with the

next adjustment.

2. To reduce the minimum position, turn out the set-

screw (ccw). The actuator then drives toward the

closed position.

3. Turning the setscrew in (cw) damages the

actuator housing.

4. If the device is too far closed, return to step 1.

12. When proper air flow is achieved, loosen the locknut

from the setscrew until it contacts the actuator housing,

then turn it an additional 1/8 turn to lock the setscrew in

place.

7 63-2209—8

Page 8

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

IMPORTANT

Run an entire check of the operation after completing

this procedure.

THIS SETSCREW

CORRESPONDS WITH

CLOSING IN THE

CW DIRECTION

60

45

THIS SETSCREW

CORRESPONDS WITH

CLOSING IN THE

CCW DIRECTION

60

45

M10247

Fig. 9. Setscrew location for ML6161 and ML6174.

Wiring

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Actuators with auxiliary switches can have more than

one disconnect.

All wiring must comply with local electrical codes, ordinances

and regulations. Voltage and frequency of the transformer

used with the actuator must correspond with the

characteristics of both the power supply and the actuator.

Screw terminals are provided for easy hookup. See Fig. 11

through 14 for typical wiring hookups.

COVER

CONDUIT

KNOCKOUTS

M10075

Fig. 10. Conduit cover for ML6161C,D

and ML6174C,D DCA.

2

EXTERNAL

SWITCH

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

AUXILIARY SWITCHES ARE REQUIRED TO TURN OFF THE MOTOR

2

AT EACH END OF THE STROKE.

T87F

W

R

R8222

Y

ML6161, ML6174

RED COM

BLUE CW

WHITE CCW

M18019

Fig. 11. ML6161 or ML6174 used with T87F in

heating-only or cooling-only application.

NOTE: See Fig. 12 for the 201052B Auxiliary Switch wiring.

Connecting Wiring to Conduit Cover Actuators (Fig.

10)

1. Remove the cover from the actuator by lifting the top

and pivoting the cover to the rear of the actuator.

2. Remove the conduit knockouts with a flat-bladed screwdriver. Discard the knockouts.

3. Install the conduit connector.

4. Run the connecting wire through the conduit connector,

strip the wire ends (if necessary) and connect to the

CW, COM and CCW terminals using Fig. 11 through 14,

Fig. 16 through 20, or the control manufacturer

instructions.

5. Apply power to the actuator.

6. After operational checkout, replace the cover by

reversing the procedure outlined in step 1.

63-2209—8 8

2

3

ML6161, ML6174

RED COM

BLUE CW

WHITE CCW

L1

(HOT)

L2

1

4

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

SET SWITCH TO CLOSE WHEN STROKE REACHES FULL CW POSITION.

2

3

SET SWITCH TO CLOSE WHEN STROKE REACHES FULL CCW POSITION.

ON-OFF CONTROL REQUIRES AN R8222 SPDT RELAY IN PLACE OF THE

4

SPDT CONTROL.

SPDT

CONTROL

ON/OFF

CONTROL

201052B

Fig. 12. 201052B Auxiliary Switch wiring.

M17350

Page 9

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

L1

(HOT)

L2

1

–

+

4-20 mA CONTROLLER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

ML7161, ML7174

T1

T2

–

+ mA

+ V

M18071

Fig. 13. ML7161 or ML7174 used with 2-10 Vdc control.

L1

(HOT)

L2

1

–

+

2-10 Vdc CONTROLLER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

ML7161, ML7174

T1

T2

–

+ mA

+ V

M18072

Fig. 14. ML7161 or ML7174 used with 4-20 mA control.

Auxiliary Switches

The 201052A or B Auxiliary Switch is used in conjunction with

the actuator. It allows for control of equipment external to the

actuator (for example, electric reheat coils and fan) at an

adjustable point in the stroke (0° to 90°) of the actuator.

IMPORTANT

Failure to follow the calibration procedures can result

in improper resistance values at desired stroke.

MOTOR

POSITION

FULLY CW

24V (COM-CW)

FULLY CCW

24V (COM-CCW)

MOTOR

ROTATION

CCW

CW

AUXILIARY POTENTIOMETER

R

W

RB

RESISTANCE

500 OR

2000 OHMS

0 OHMS

DECREASE

INCREASE

45

RW

RESISTANCE

0 OHMS

500 OR

2000 OHMS

AUXILIARY POTENTIOMETER LEADS

RW OHMS RB OHMS

INCREASE

DECREASE

60

45

B

60

CW

COM

CCW

The 201052A and B Auxiliary Switches are field-addable. For

mounting instructions, see form 63-2218, provided with the

device.

IMPORTANT

When operating an ML6161 or ML6174 from a twoposition controller, a 201052B Auxiliary Switch is

required for proper operation. See Fig. 12.

Auxiliary Potentiometers

The 200976A,C Auxiliary Potentiometers mount on the face of

the ML6161A,C or ML6174A,C (as shown in Fig. 15). The

potentiometer shaft has a slipping collar. If one of the two

limits of the potentiometer is exceeded, the collar continues to

rotate, causing no damage to the potentiometer itself. To

mount the potentiometer on the actuator:

1. Turn the potentiometer to align the shaft key with the

slot in the potentiometer drive.

2. Tilt the potentiometer slightly so the key faces down

toward the slot.

3. Insert the potentiometer into the slot, and push down so

the potentiometer is flush with the actuator body and the

bracket is aligned over the screw hole.

4. Insert the screw provided into the hole and fasten

securely.

FIELD-ADDABLE AUXILIARY POTENTIOMETER

M10251B

Fig. 15. ML6161A,C, ML6174A,C with

field-addable potentiometer.

To Calibrate the 200976A,C:

IMPORTANT

9 63-2209—8

Remove the range stop pins and minimum position

setscrews prior to calibration.

1. Drive the actuator fully closed (0°) to fully open (90°)

and back again to the fully closed position. This must be

done to receive the correct resistance readings at the

appropriate degree of stroke.

2. Check the resistance values of the potentiometer with

an ohmmeter at intervals in the stroke while referring to

the table in Fig. 15 and resistance information provided

in the Specifications section.

3. Replace the range stop pins and/or the minimum

position setscrews using the appropriate procedures.

Page 10

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

OPERATION

VAV Systems

VAV systems control the temperature within a space by

varying the volume of supply air temperature. The system

delivers air to the space at a fixed temperature. The space

thermostat controls the volume of supply air by modulating the

supply air damper. When full heating and cooling flexibility is

required in a zone, it is handled by the air temperature

system, or with reheat capability in the air terminal units. As

individual zones shut down, a central duct static pressure

controller regulates the total air flow in the system. The fan

system is sized to handle an average peak load, not the sum

of the individual peaks. As each zone peaks at a different time

of day, extra air is borrowed from the off-peak zones. This

transfer of air from low-load to high-load zones occurs only in

true VAV systems.

In pressure independent systems, individual zone airflow

sensors maintain the zone air flow rate independent of

fluctuation in the total system pressure. Pressure independent

systems, when used with controllers such as the W7620, can

react faster to changes in air flow demand; therefore, these

systems can use the faster 90-second models.

Pressure dependent systems do not incorporate an individual

zone air flow sensor and depend on a stable system pressure

to maintain flow. These systems require slower actuators such

as the seven-minute models that are typically controlled by

spdt floating wall thermostats.

The T641 is a mercury bulb floating-control type thermostat

designed for use with the seven-minute model on pressuredependent systems (see Fig. 16 and 17).

The T6984 is an electronic floating-control thermostat

designed for use with the 90-second and seven-minute

models (see Fig. 18).

T641A THERMOSTAT

RCY W

1

1K

2

120

VAC

SYSTEM

TRANSFORMER

USE NC CONTACT OF AUXILIARY SWITCH (PIN 201052A).

1

CONTACT OPENS WHEN ACTUATOR DRIVES CLOSED (CCW)

TO CAM SETTING POSITION.

2

USE SPDT RELAY OUTPUTS FROM FIRE AND ALARM

SYSTEM, OR OVERRIDE SYSTEM, AS DRAWN. THIS

OVERRIDES MINIMUM POSITION LIMITATION, AND

DRIVES ACTUATOR FULLY CCW.

3

AS DRAWN, ACTUATOR OPENS DAMPER TO CW ROTATION.

TO OPEN DAMPER TO CCW, REVERSE CCW AND CW

CONNECTIONS AT ACTUATOR. THIS ALSO CAUSES

ALARM CONDITION TO DRIVE ACTUATOR TO FULLY CW.

24 VAC

COMMON

CCW

PHASE SHIFT CAP

DRIVE

CCW

WINDING

3

CW

DRIVE

CW

WINDING

COM

ML6161, ML6174

ACTUATOR

M18022

Fig. 17. Minimum position set with auxiliary switch

contacts, override provided by fire and alarm contacts.

ML6161, ML6174

CW

T641A THERMOSTAT

RCY W

120

VAC

SYSTEM

TRANSFORMER

1

24

VAC

AS SHOWN, T641 MAKES R-Y CONTACTS TO DRIVE ACTUATOR

CCW, AND MAKES R-W CONTACTS TO DRIVE ACTUATOR CW.

CCW

DRIVE

CCW

WINDING

COMMON

1

ML6161, ML6174

ACTUATOR

PHASE SHIFT CAP.

COM

CW

DRIVE

CW

WINDING

M18021

Fig. 16. T641A controlling ML6161 or M6174 Actuator.

63-2209—8 10

L1

(HOT)

L2

1

1

2

24 VAC

COMMON

24 VAC

MOTOR CLOSE

MOTOR OPEN

T6984A

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION, AS REQUIRED.

T6984A SHOWN WIRED FOR COOLING ONLY. TO WIRE FOR

HEATING ONLY, REVERSE OPEN AND CLOSE CONTACTS.

COM

CCW

M18023

Fig. 18. T6984A controlling ML6161 or ML6174 Actuator

for cooling or heating application.

Page 11

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

Rotation Reversal Switch (ML7161, ML7174)

Use the rotation reversal slide switch to reverse the actuator

rotation. The switch is located on the bottom of the actuator

housing (see Fig. 5). To change rotation to counterclockwise

(ccw) , change the slide switch. In direct, 2 volts is fully

ccw and 10 volts is fully clockwise (cw); in reverse, 2 volts is

fully cw and 10 volts is fully ccw.

IMPORTANT

When reversing the rotation, make sure the switch is

fully to one side or the other. If the switch is left in the

middle, the actuator will not operate properly.

L1

(HOT)

L2

T641A THERMOSTAT

RC YW

ML6161, ML6174

CW

24 VAC

1

COM

CCW

Parallel Actuators

IMPORTANT

Over time, parallel-driving actuators can become out

of sync with each other. Normally, driving all

actuators to the fully-open or fully-closed position

puts them back in sync.

ML6161, ML6174 Actuators

Using Fig. 19, parallel the CW, COM and CCW terminals.

Make certain the total connected load does not exceed the

current capacity of the controller or thermostat.

ML7161, ML7174 Actuators

VOLTAGE INPUT (2 TO 10 VDC)

Wire the (+Vdc) and (-) terminals of each actuator in parallel.

Make certain the total connected load does not exceed the

current capacity of the input signal source.

CURRENT INPUT (4 TO 20 MA)

When using a current controller (such as the W7600), wire the

ML7161, ML7174 voltage input terminals (+Vdc) and (-) in

parallel. Use a bridging resistor in parallel with the 4 to 20 mA

signal. See Fig. 20 for resistor values.

NOTE: The actuator has 45,000 ohm impedance.

ML6161, ML6174

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

1

OVERLOAD PROTECTION, AS REQUIRED. ENSURE THAT

EQUIPMENT TRANSFORMER IS CORRECTLY SIZED.

Fig. 19. Spdt control of parallel ML6161

or ML6174 Actuators.

V1

W7600

V2+–

L1

(HOT)

3 3

L2

2 2

R

4-20 mA

L2

L1

(HOT)

ML7161, ML7174

V

1

–

ML7161, ML7174

V

–

CW

COM

CCW

M18024

T1

T2

T1

T2

1 ACTUATOR = 549 OHMS

1

2 ACTUATORS = 549 OHMS

3 ACTUATORS = 549 OHMS

4 ACTUATORS = 576 OHMS

5 ACTUATORS = 576 OHMS

6 ACTUATORS = 576 OHMS

7 ACTUATORS = 590 OHMS

8 ACTUATORS = 604 OHMS

9 ACTUATORS = 604 OHMS

10 ACTUATORS = 619 OHMS

1/2 WATT

2

ACTUATORS CAN USE COMMON TRANSFORMER;

SEPARATE POWER SUPPLY REQUIRED FOR W7600.

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

3

OVERLOAD PROTECTION AS REQUIRED. ASSURE THAT

EQUIPMENT TRANSFORMER IS SIZED CORRECTLY.

ML7161, ML7174

T1

V

T2

–

M18025

Fig. 20. 4-20 mA signal control of parallel

ML7161 or ML7174 Actuators.

11 63-2209—8

Page 12

35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

CHECKOUT

ML6161, ML6174

To check out ML6161, ML6174 Actuators controlled by

electronic control systems, such as the W7620, override the

control system by programming the controller to open or close

the zone damper, as appropriate.

NOTE: Using a seven-minute actuator results in a longer

response time before noticeable damper movement.

To check out the ML6161 or ML6174:

1. Determine the direction the shaft moves to open the

device (cw or ccw). See Fig. 3.

2. Place 24 volts across the appropriate common cw or

common ccw terminals to energize the actuator. The

actuator should begin to open the device.

3. If the actuator does not run, try switching the 24 volts

across the opposite common cw or ccw terminals to

determine if the device begins to close.

4. If the actuator does not run in either direction, replace

the actuator.

For an ML6161 or ML6174 issued with an spdt floating wall

thermostat (for pressure dependent systems), use the

following checkout procedure:

1. Adjust the setpoint of the thermostat to call for cooling.

2. Observe the operation of the actuator; if the device is

closed, it should begin to open.

3. If not, adjust the setpoint of the thermostat higher to

determine if the wiring is correct.

4. If no movement is observed, check for the presence of

24 volts.

5. If using the T641 Thermostat, check that 24 volts are

present between terminals C and Y during a call for

cooling. With proper wiring and 24 volts present, the

actuator should operate correctly.

6. If not, replace the actuator.

ML7161, ML7174

Check input impedance on the actuator with an ohmmeter.

IMPORTANT

Be sure to disconnect all wiring to the actuator before

connecting the ohmmeter.

1. Verify resistance readings are as follows:

• 45K ohms ±5K ohms, across the (+Vdc) and (-)

terminals.

• 536 ohms ±10 ohms, across the (+mA) and (-)

terminals.

2. If the resistance readings are correct, reconnect the

actuator and check for 24 Vac at terminals T and T2.

With the correct power present at T and T2, check the

motion of the shaft/actuator by ramping the setpoint up

and down. This causes the actuator to move from one

limit to the other and back (from fully ccw to fully cw and

back to fully ccw).

NOTE: Remember that the actuator takes 90 seconds

to move from one limit to the other.

3. When the actuator is used with electronic control

systems such as the W7600 Commercial Zone System,

override the control system by programming the

controller to open or close the damper, as appropriate.

4. If the actuator continues to operate incorrectly, check

Table 6 for the proper input signal/actuator drive

relationship at the (+Vdc) and (-) terminals.

5. If the actuator does not operate according to Table 6

values, replace the actuator.

Table 6. Input Signal/Actuator Drive Relationship.

Input Signal Actuator Drive Relationship

1.50 ±0.2 Vdc Actuator drives to extreme ccw position.

2.00 ±0.2 Vdc Actuator remains at ccw position.

3.00 ±0.2 Vdc Actuator leaves ccw position.

10.70 ±0.7 Vdc Actuator drives to extreme cw position.

10.00 ±0.7 Vdc Actuator remains at cw position.

8.50 ±0.6 Vdc Actuator leaves cw position.

Automation and Control Solutions Honeywell International Honeywell Europe S.A. Honeywell Latin American

Honeywell International Inc. Honeywell Limited-Honeywell Limitée Control Products 3 Avenue du Bourget

1985 Douglas Drive North 35 Dynamic Drive Honeywell Building 1140 Brussels 480 Sawgrass Corporate Parkway

Golden Valley, MN 55422 Scarborough, Ontario 17 Changi Business Park Central 1Belgium Suite 200

M1V 4Z9 Singapore 486073 Sunrise FL 33325

63-2209—8 B.B. Rev. 7-03 www.honeywell.com

Region

Loading...

Loading...