Page 1

Installation Instructions for the

MICRO SWITCH GLL Series Limit Switch

mWARNING

PERSONAL INJURY

• Where possible, install these switches with the conduit

opening pointed down to drain moisture away from switch.

• Do not install switch at the low point of a conduit run.

• Install a fitting into the conduit opening that provides

strain relief to the wires/cable, as well as sealing against

contaminants found in the application.

• In applications where fluids or moisture may be present,

seal the fitting threads with a product such as Teflon tape

or pipe dope.

Failure to comply with these instructions could result in

death or serious injury.

GENERAL INFORMATION

1. Refer to page 2 for specifications.

2. Rotate switch head to desired position (90° increments).

Review adjusting instructions below.

3. Mount switch using two M4 or #8 screws (not included).

Torque screws to mounting surface 4,9 N m to 5,9 N m

[43.4 in lb to 52.2 in lb].

4. All normally closed (NC) contacts are direct opening .

POSITIONING LEVER

The lever on rotary actuated units is adjustable to any of the

segmented positions 360° around the shaft; however, the

degree of rotation is dependant on head position and direction

of roller.

1. Loosen the lever retaining screw with a Phillips head

screwdriver.

2. Remove lever.

3. Reposition lever to desired location.

4. Securely tighten screw.

REVERSING THE ROLLER LEVER

The roller arm may be reversed to face the roller to the inside or

outside of the arm.

ADJUSTABLE LENGTH LEVERS

1. Loosen the lever’s adjustment screw using a Phillips head

screwdriver.

2. Adjust to desired length.

3. Securely tighten adjustment screw to 1.0 N m [8.85 in lb] of

torque.

Issue 5

50012101

ADJUSTMENT INSTRUCTIONS

To give flexibility in application, the user can perform the

adjustments described below in any order before wiring the

unit.

ACTUATOR HEAD POSITIONING

The actuator head may be positioned in any of four directions.

1. Remove the four head retaining screws while holding

actuator head in place.

2. To prevent actuator spring loss, remove head slowly to

relieve spring tension prior to removal.

3. Rotate actuator head to desired position.

4. Position the large diameter end of the actuator spring

over the actuator. Place retaining screws through gasket

material and position head over screw holes in desired

position.

5. Securely tighten the screws to 0,2 N m [1.7 in lb] of torque.

Sensing and Internet of Things

TOP ROLLER PLUNGER

Switches with top roller plunger must be mounted with plunger

in desired position. Actuating device must not exceed over

travel distance.

WIRING

1. Remove front cover plate screw.

2. Contact block area by terminal screw is labeled for NO

(Normally Open) and NC (Normally Closed) contacts.

3. Connect stranded wire (0,75 mm² - 2,5 mm², 18 AWG14

AWG) or solid wire (0,75 mm² - 1,5 mm², 18 AWG16 AWG)

to desired connector terminals. Use 90 °C [194 °F] rated

wire when ambient temperature is to exceed 75 °C [158 °F]:

• Torque switch terminal screws to 0,8 N m to 1,0 N m

[7.1 in lb to 8.9 in lb]

4. Securely tighten cover screw to 0,5 N m [4.4 in lb] of torque.

Page 2

GLL Series

Slow Action

Slow Action

8Ncm

12

22

Snap Action

1NO/1NC

21-22

13-14

21-22

13-14

Slow Action

(Break Before Make)

1NO/1NC

11 12

23 24

Slow Action

(Make Before Break)

1NO/1NC

15-16

15 16

23 24

Slow Action

2NC

21-22

0

O

13

O

28

O

55

O

70

O

OF

12Ncm

11-12

23-24

0

O

15

O

30

O

40

O

75

O

OF

5Ncm

23-24

0

O

20

O

35

O

45

O

75

O

OF

8Ncm

11-12

0

O

20

O

60

O

35

O

OF

8Ncm

11 12

21 22

13 14

21 22

[0.87]

22

[0.31]

Ø8

[0.49]

12,5

[0.16]

4.0

[0.04]

1,0

[1.20]

30,5

Conduit thread

[2.44]

62

FP

OP

[0.31]

8

[0.165]

Ø4,2

[1.22]

31

[0.39]

10

[0.79]

20

[0.63]

16

4,3

[0.169]

Plated

copper

alloy

23

[0.906]

4

[0.16]

8

[0.31]

62

[2.44]

30,5

[1.20]

22

[0.87]

Conduit thread

31

[1.22]

16

[0.63]

20

[0.79]

1

[0.04]

Ø 10

[0.04]

OP

FP

Ø 10

[0.04]

[0.165]

Ø4,2

ISSUE 5 50012101

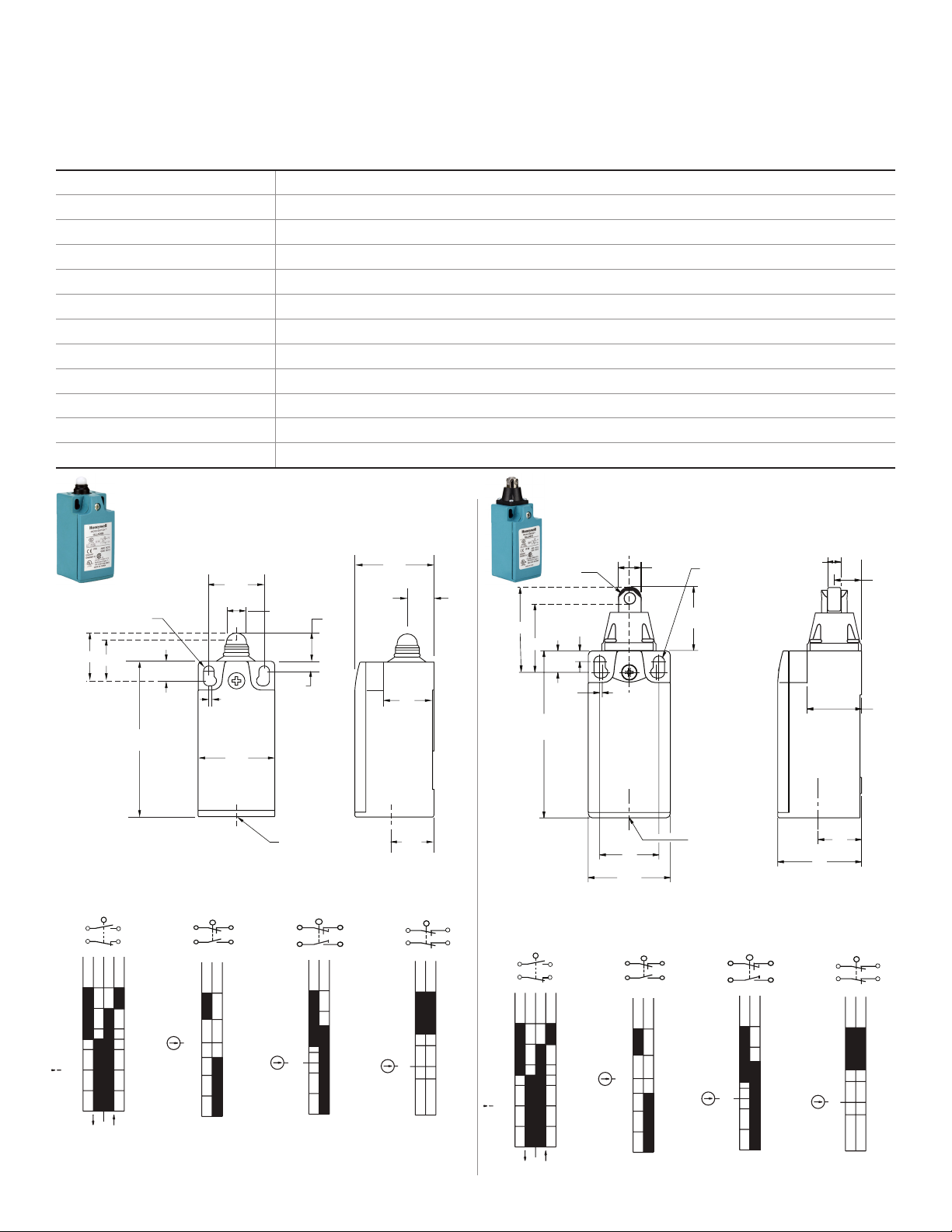

SPECIFICATIONS

Table 1. Specifications

Circuitry 1 NO 1 NC direct opening snap action, slow action (BBM), slow action (MBB); 2NC slow action

Ampere rating 10 A (Thermal)

Supply voltage 300 Vac and 250 Vdc max.

Housing material Plastic

Termination type 12,7 mm [0.5 in] conduit; 20 mm [0.79 in] conduit

Housing type EN 50047

Shock 50 g per PEC 68227c (w/o actuator)

Vibration 10 g per IEC 6826 (w/o actuator)

Sealing IP66, NEMA 1, 12, 13

Approvals cULus, CE, CCC

Mechanical life 5 million operations

Operating temperature range 10 °C to 80 °C [14 °F to 176 °F]

Figure 1. GLLA**B, GLLC**B Dimensions and

Bar Charts

Snap Action

1NO/1NC

13 14

21 22

21-22

13-14

21-22

O

0

2 sensing.honeywell.com

13

28

55

70

O

O

O

O

(Break Before Make)

13-14

OF

12Ncm

1NO/1NC

11 12

23 24

23-24

11-12

O

0

O

OF

15

5Ncm

O

30

O

40

O

75

(Make Before Break)

15 16

23 24

1NO/1NC

O

0

O

20

O

35

O

45

O

75

23-24

15-16

OF

8Ncm

Slow Action

2NC

11

21

O

0

O

20

O

35

O

60

21-22

11-12

Figure 2. GLLA**C, GLLC**C Dimensions and

Bar Charts

OF

Page 3

GLL Series

Snap Action

Slow Action

(Break Before Make)

Slow Action

Slow Action

(Make Before Break)

1NO/1NC 1NO/1NC 1NO/1NC 2NC

2.5

4.5

6.5

0 mm

10 mm

11-12

23-24

OF

3N

2.5

8.0

0 mm

10 mm

5.5

21-22

13-14

21-22

13-14

OF

8 N

3.0

6.0

0 mm

10 mm

5.0

15-16

23-24

OF

5 N

3.5

5.5

0 mm

8 mm

11-12

21-22

OF

5 N

13 14

21 22

11 12

23 24

11 12

21 22

15 16

23 24

Snap Action

1NO/1NC

1,8

5,5

0 mm

8 mm

3,5

21-22

13-14

21-22

13-14

OF

8 N

13 14

21 22

Slow Action

(Break Before Make)

1NO/1NC

1,5

2,5

4

0 mm

8 mm

11-12

23-24

OF

3N

11 12

23 24

Slow Action

2NC

2,5

4

0 mm

6,5 mm

11-12

21-22

OF

5N

11 12

21 22

Slow Action

(Make Before Break)

1NO/1NC

2

4,5

0 mm

8 mm

3,5

15-16

23-24

OF

5 N

15 16

23 24

FP

OP

40,5

[1.59]

8

[0.31]

62

[2.44]

30,5

[1.20]

22

[0.87]

Conduit thread

31

[1.22]

16

[0.63]

105,5

[4.15]

1

[0.04]

22

[0.87]

15 [0.60]

5 [0.197]

24

[0.95]

21

[0.83]

18

[0.71]

10

[0.4]

[0.165]

Ø4,2

11,5 [0.45]

Ø 4,2

[0.165]

OP

4

[0.16]

8

[0.31]

62

[2.44]

30,5

[1.20]

22

[0.87]

Conduit thread

31

[1.22]

16

[0.63]

10

[0.39]

1

[0.04]

FP

31

[1.22]

ISSUE 5 50012101

Figure 3. GLLA**D, GLLC**D Dimensions and

Bar Charts

Figure 4. GLLA**F, GLLC**F Dimensions and

Bar Charts

Sensing and Internet of Things 3

Page 4

GLL Series

Snap Action

1NO/1NC

21-22

13-14

21-22

13-14

Slow Action

(Break Before Make)

1NO/1NC

11 12

23 24

Slow Action

(Make Before Break)

1NO/1NC

15-16

15 16

23 24

Slow Action

2NC

21-22

0

O

13

O

28

O

55

O

70

O

OF

12Ncm

11-12

23-24

0

O

15

O

30

O

40

O

75

O

OF

5Ncm

23-24

0

O

20

O

35

O

45

O

75

O

OF

8Ncm

11-12

0

O

20

O

60

O

35

O

OF

8Ncm

11 12

21 22

13 14

21 22

41 [1.57]

27

[1.06]

TT

OP

PT

DT

R 20 to 75

[0.79 to 2.95]

Plated

copper

alloy

19,5

[0.77]

4

[0.16]

Ø 17 x 7

[0.67 x 0.28]

8

[0.31]

62

[2.44]

30,5

[1.20]

22

[0.87]

Conduit thread

31

[1.22]

16

[0.63]

20

[0.79]

2

[0.08]

1

[0.04]

[0.165]

Ø4,2

Snap Action

1NO/1NC

21-22

13-14

21-22

13-14

Slow Action

(Break Before Make)

1NO/1NC

11 12

23 24

Slow Action

(Make Before Break)

1NO/1NC

15-16

15 16

23 24

Slow Action

2NC

21-22

0

O

13

O

28

O

55

O

70

O

OF

12Ncm

11-12

23-24

0

O

15

O

30

O

40

O

75

O

OF

5Ncm

23-24

0

O

20

O

35

O

45

O

75

O

OF

8Ncm

11-12

0

O

20

O

60

O

35

O

OF

8Ncm

11 12

21 22

13 14

21 22

[2.44]

[1.20]

[0.79]

ISSUE 5 50012101

Figure 5. GLLA**A1B, GLLC**A1B Dimensions

and Bar Charts

41 [1.57]

PT

OP

R 25

[0.98]

Ø4,2

[0.165]

19,5

[0.77]

Conduit thread

TT

Plated

copper

alloy

Ø 17 x 7

[0.67 x 0.28]

8

[0.31]

[0.04]

62

4

[0.16]

1

22

[0.87]

30,5

DT

27

[1.06]

31

[1.22]

16

[0.63]

Figure 6. GLLA**A2B, GLLC**A2B Dimensions

and Bar Charts

20

4 sensing.honeywell.com

Page 5

GLL Series

Snap Action

1NO/1NC

21-22

13-14

21-22

13-14

Slow Action

(Break Before Make)

1NO/1NC

11 12

23 24

Slow Action

(Make Before Break)

1NO/1NC

15-16

15 16

23 24

Slow Action

2NC

21-22

0

O

13

O

28

O

55

O

70

O

OF

12Ncm

11-12

23-24

0

O

15

O

30

O

40

O

75

O

OF

5Ncm

23-24

0

O

20

O

35

O

45

O

75

O

OF

8Ncm

11-12

0

O

20

O

60

O

35

O

OF

8Ncm

11 12

21 22

13 14

21 22

rubber

[1.20]

[0.79]

Snap Action

1NO/1NC

21-22

13-14

21-22

13-14

Slow Action

(Break Before Make)

1NO/1NC

11 12

23 24

Slow Action

(Make Before Break)

1NO/1NC

15-16

15 16

23 24

Slow Action

2NC

21-22

0

O

13

O

28

O

55

O

70

O

OF

12Ncm

11-12

23-24

0

O

15

O

30

O

40

O

75

O

OF

5Ncm

23-24

0

O

20

O

35

O

45

O

75

O

OF

8Ncm

11-12

0

O

20

O

60

O

35

O

OF

8Ncm

11 12

21 22

13 14

21 22

PT

TT

OP

DT

Ø 50

[1.96]

Buna

rubber

62

[2.44]

Conduit thread

30,5

[1.20]

8

[0.31]

1

[0.04]

19,5

[0.77]

4

[0.16]

20,65

[0.81]

42,5

[1.67]

10

[0.39]

2

[0.08]

20

[0.79]

16

[0.63]

31

[1.22]

[0.165]

Ø4,2

ISSUE 5 50012101

Figure 7. GLLA**A1Y, GLLC**A1Y Dimensions

and Bar Charts

Buna

Ø 50

[1.96]

62

[2.44]

[0.31]

8

[0.16]

[0.04]

PT

OP

DT

TT

Ø4,2

4

1

22

[0.87]

30,5

[0.165]

19,5

[0.77]

Conduit thread

42,5 [1.67]

10

[0.4]

[1.24]

31

[1.22]

31,5

16

[0.63]

Figure 8. GLLA**A2Y, GLLC**A2Y

Dimensions and Bar Charts

20

Sensing and Internet of Things 5

Page 6

GLL Series

Slow Action

Slow Action

55 [0.22]

20° - 65°

[0.57] - [5.91]

22 - 150

[0.77]

19,5

22

[0.87]

[1.20]

30,5

[2.44]

62

[0.32]

8

Conduit thread

[0.63]

16

[1.22]

31

[0.40]

10,2

[1.34]

34

[0.12]

0.3

[0.04]

1

[0.165]

Ø4,2

Figure 9. GLLA**A4J, GLLC**A4J Dimensions

and Bar Charts

ISSUE 5 50012101

13 14

21 22

0

13

28

55

70

Snap Action

1NO/1NC

21-22

13-14

21-22

O

O

O

O

O

(Break Before Make)

13-14

OF

12Ncm

1NO/1NC

11 12

23 24

23-24

11-12

O

0

O

OF

15

5Ncm

O

30

O

40

O

75

(Make Before Break)

1NO/1NC

15 16

23 24

23-24

15-16

O

0

O

20

O

35

O

45

O

75

OF

8Ncm

Slow Action

2NC

11 12

21 22

21-22

11-12

O

0

OF

O

20

8Ncm

O

35

O

60

6 sensing.honeywell.com

Page 7

GLL Series

ISSUE 5 50012101

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free

of defective materials and faulty workmanship during the

applicable warranty period. Honeywell’s standard product

warranty applies unless agreed to otherwise by Honeywell

in writing; please refer to your order acknowledgment or

consult your local sales office for specific warranty details.

If warranted goods are returned to Honeywell during the

period of coverage, Honeywell will repair or replace, at its

option, without charge those items that Honeywell, in its sole

discretion, finds defective. The foregoing is buyer’s sole

remedy and is in lieu of all other warranties, expressed or

implied, including those of merchantability and fitness for a

particular purpose. In no event shall Honeywell be liable for

consequential, special, or indirect damages.

While Honeywell may provide application assistance personally,

through our literature and the Honeywell web site, it is buyer’s

sole responsibility to determine the suitability of the product in

the application.

Specifications may change without notice. The information we

supply is believed to be accurate and reliable as of this writing.

However, Honeywell assumes no responsibility for its use.

mWARNING

IF USED IN APPLICATIONS CONCERNING

HUMAN SAFETY

• Only use NC direct opening (“positive opening”/”positive

break”) contacts, identified by the symbol .

• Do NOT use flexible/adjustable actuators. Only use

actuators designed for safety applications.

• Do NOT defeat, tamper, remove, or bypass this switch.

• Hazardous voltage, disconnect power before servicing.

• Strictly adhere to all installation and maintenance

instructions.

• Consult with local safety agencies and their requirements

when designing a machine-control link, interface and all

control elements that affect safety.

Failure to comply with these instructions could result in

death or serious injury.

For more information

Honeywell Sensing and Internet of

Things services its customers through a

worldwide network of sales offices and

distributors. For application assistance,

current specifications, pricing or the

nearest Authorized Distributor, visit

sensing.honeywell.com or call:

Asia Pacific +65 63552828

Europe +44 1698 481481

USA/Canada +18005376945

Honeywell Sensing and Internet of Things

9680 Old Bailes Road

Fort Mill, SC 29707

honeywell.com

50012101 | 5 | 04/19

© 2019 Honeywell International Inc. All rights reserved.

Loading...

Loading...