Page 1

MC Toolkit (MCT404)

User Manual

Doc. No.: 34-ST-25-50

Revision 3

Date: June 2016

Honeywell Field Solutions

Page 2

Copyright, Notices and Trademarks

Copyright 2016 by Honeywell International Inc.

Revision 3, June 2016

While this information is presented in good faith and believed to be accurate, Honeywell disclaims the implied

warranties of merchantability and fitness for a particular purpose and makes no express warranties except as may

be stated in its written agreement with and for its customers.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The information and

specifications in this document are subject to change without notice.

Honeywell, PlantScape, Experion PKS, and TotalPlant are registered trademarks of Honeywell International Inc.

Other brand or product names are trademarks of their respective owners.

Honeywell Process Solutions

1250 W Sam Houston Pkwy S

Houston, TX 77042

ii MC Toolkit (MCT404) User Manual Revision 3

Page 3

Copyright, Notices and Trademarks

Document Details

MC Toolkit (MCT404) User Manual

Release

Number

Publication Date

34-ST-25-50

New

Revision 1

February 2014

COM4 update

Rev.2

May 14

STT 850 / STT 750 added

Rev.3

June 2016

Document Title

About This Document

Abstract

This document describes how to use MC Toolkit product, which consists of MC Toolkit application software and

FDC application software.

Revision Information

References

The following list identifies all documents that may be sources of reference for material discussed in this

publication.

Revision 3 MC Toolkit (MCT404) User Manual iii

Page 4

Copyright, Notices and Trademarks

Support and contact info

United States and Canada

Contact: Honeywell Process Solution

Global Technical Support - Phone: 001-800-423-9883

Customer Service (HFS) - Phone: 001-800-343-0228

Outside United States - Phone: 001-215-641-3610

Calls are answered by dispatcher between 6:00 am and 4:00 pm Mountain Standard

Time. Emergency calls outside normal working hours are received by an answering

service and returned within one hour.

Email support: Sales: FP-Sales-Apps@Honeywell.com

Technical Assistance: hfs-tac-support@honeywell.com

Mail: Honeywell Process Solutions

1250 W Sam Houston Pkwy S,

Houston, TX 77042

For other contact details in Europe, Asia, North and South Americas refer to the back page.

World Wide Web

Honeywell Process Solutions Support Online:

www.honeywellprocess.com/

Elsewhere

Call your nearest Honeywell office.

Training Classes

www.honeywellprocess.com/en-US/training

iv MC Toolkit (MCT404) User Manual Revision 3

Page 5

Copyright, Notices and Trademarks

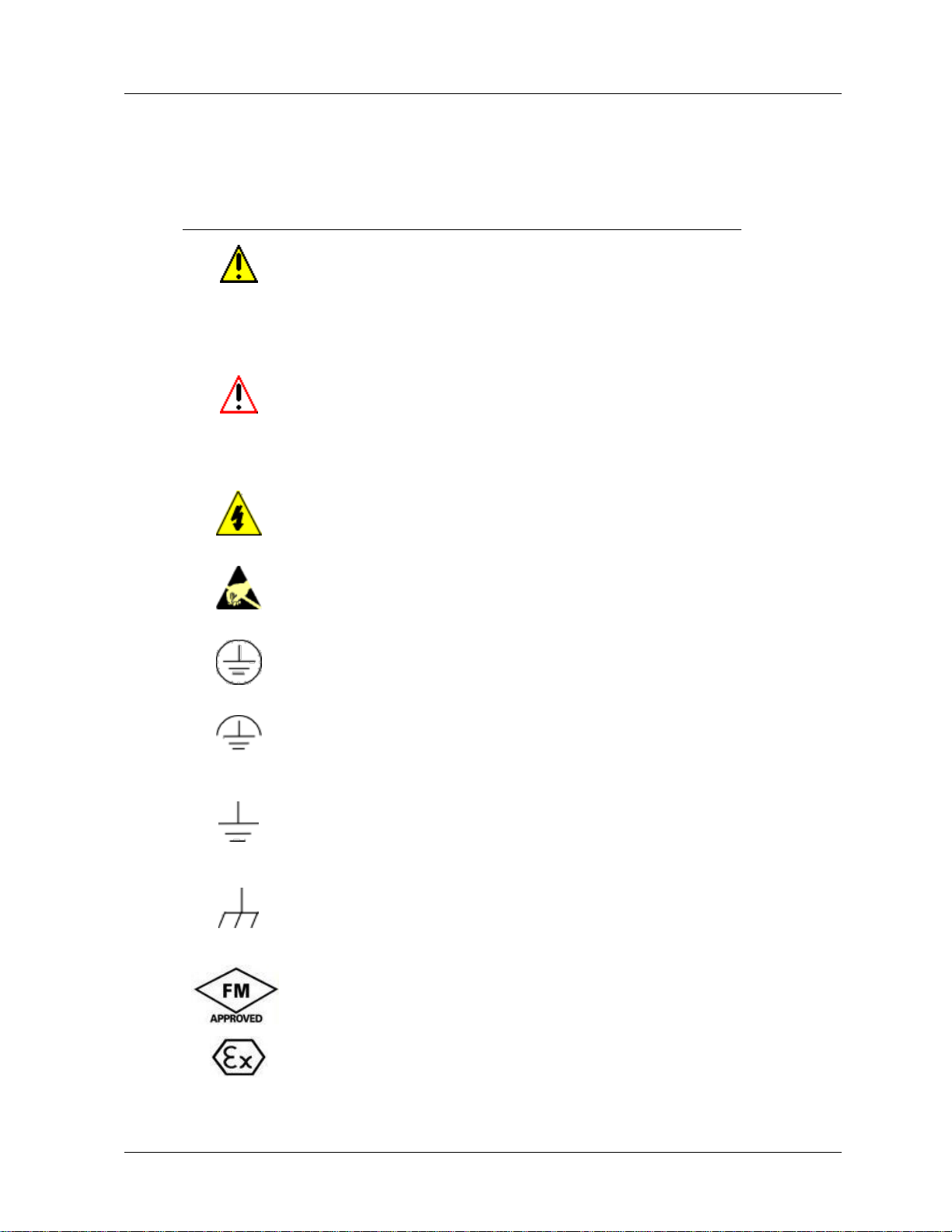

Symbol

Definition

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also be used

to alert against unsafe practices.

CAUTION symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

WARNING: Indicates a potentially hazardous situation, which, if not

avoided, could result in serious injury or death.

WARNING symbol on the equipment refers the user to the product

manual for additional information. The symbol appears next to

required information in the manual.

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or

60 VDC may be accessible.

ESD HAZARD: Danger of an electro-static discharge to which

equipment may be sensitive. Observe precautions for handling

electrostatic sensitive devices.

Protective Earth (PE) terminal: Provided for connection of the

protective earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as

noise immunity improvement. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance

with national local electrical code requirements.

Earth Ground: Functional earth connection. NOTE: This

connection shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

Chassis Ground: Identifies a connection to the chassis or frame of

the equipment shall be bonded to Protective Earth at the source of

supply in accordance with national and local electrical code

requirements.

The Factory Mutual® Approval mark means the equipment has

been rigorously tested and certified to be reliable.

The Ex mark means the equipment complies with the requirements

of the European standards that are harmonised with the 94/9/EC

Directive (ATEX Directive, named after the French "ATmosphere

EXplosible").

Symbol Definitions

The following table lists those symbols used in this document to denote certain conditions.

Revision 3 MC Toolkit (MCT404) User Manual v

Page 6

Copyright, Notices and Trademarks

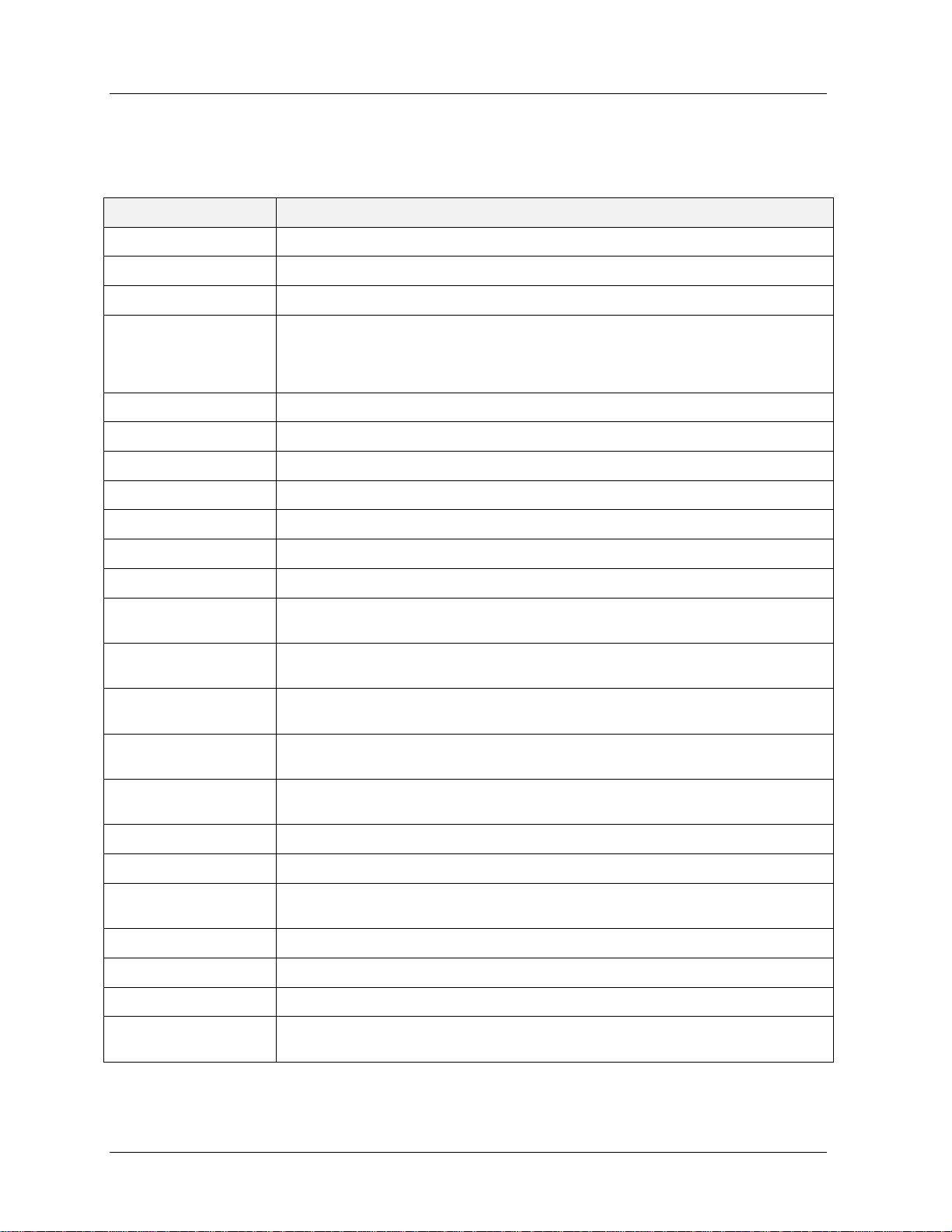

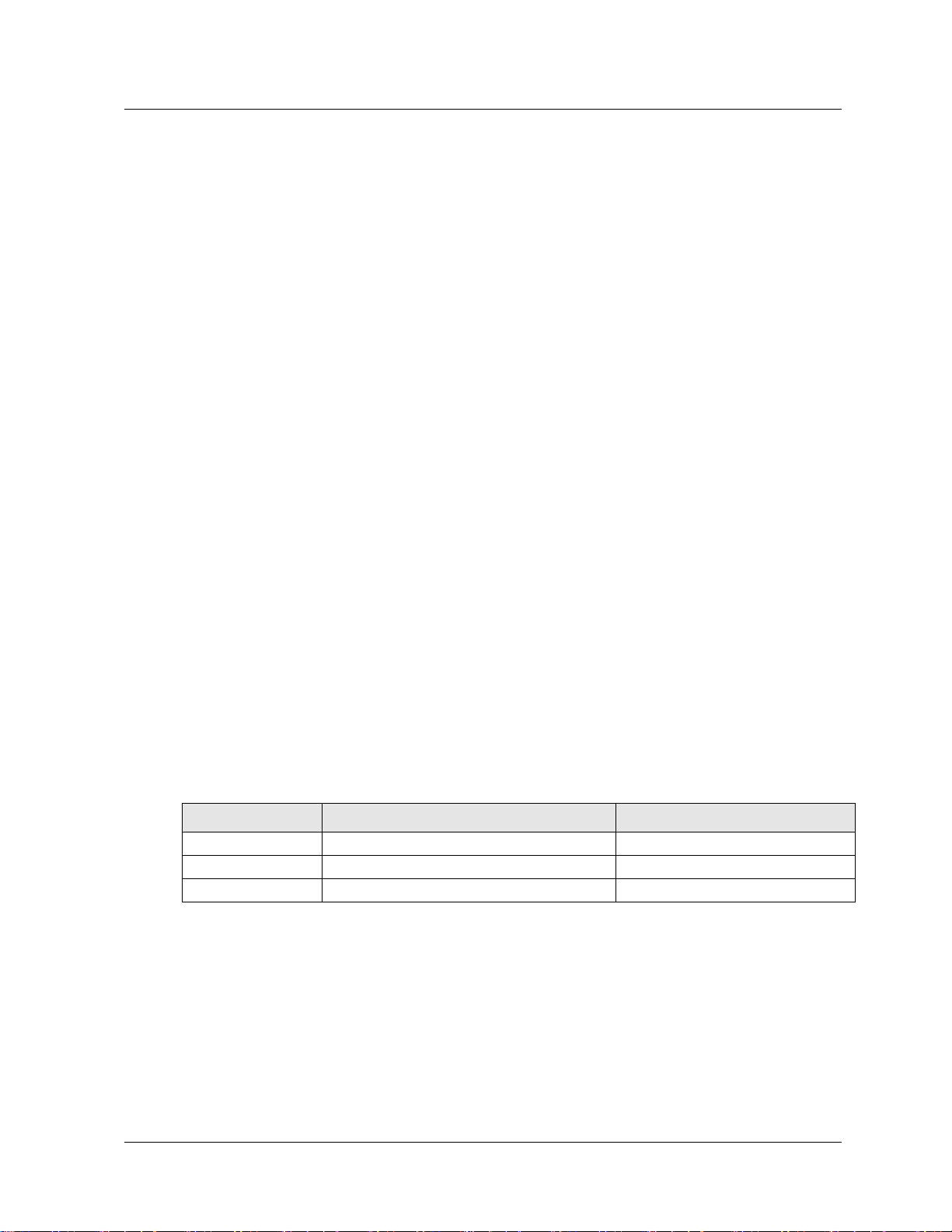

Term

Description

DD

Device Description File

DDL

Device Description Language

DE

Digitally Enhanced

Device

The hardware that is responsible for sensing the conditions present in a process and

communicating this information to the Pocket PC. These conditions may include

pressure, temperature. Examples of devices include the ST, STT. Device is also

referred to as a Field Instrument

Download

The process of sending data from a Pocket PC to a Device

EDDL

Electronic Device Description Language

Export

Writing / saving parameters into a file

FDC

Field Device Communicator

FDM

Field Device Manager

HCF

HART Communication Foundation

Import

Reading / loading parameters from a file

MCT

Multi Communication Toolkit (MCT404) product that includes MC Toolkit application

and FDC application

MCT404

Options include ruggedized version with no approvals, Intrinsically-safe version with

Zone1 approvals

Modem

Honeywell HART / DE modem that implements interfaces to the HART and DE

network

Offline

The condition present when the MC Toolkit is running but is not connected to a live

device.

Online

The condition present when the MC Toolkit is running and is connected to a live

device.

Parameter

A piece of information representing a single unit of data in a device or database

PPC

Pocket PC

Record

A Set of Configuration parameters that consists of Device Type, Bus Type, Tag ID,

Manufacturer, LRV, URV, Transfer Function and other Parameters

ST

Smart Transmitter, pressure - a Honeywell Field Instrument.

STT

Smart Temperature Transmitter – a Honeywell Field Instrument

Upload

The process of sending data from a Device to a Pocket PC

XML

Extensible Markup Language. A file type that provides a format for describing

structured data from any application in a standard consistent way

Acronyms and definitions

Table 1 Acronyms and Definitions

vi MC Toolkit (MCT404) User Manual Revision 3

Page 7

Contents

Contents

Support and contact info.......................................................................................... iv

1. INTRODUCTION ............................................................................ 1

1.1 Overview of MC Toolkit................................................................................... 1

Purpose/Scope ...................................................................................................................... 1

Product Description ............................................................................................................... 2

MCT404 ................................................................................................................................. 2

Software components ............................................................................................................ 2

Procedural Considerations .................................................................................................... 3

1.2 Transmitter Type and Communication Mode ............................................... 3

1.3 Type of Procedure ........................................................................................... 4

1.4 Prerequisites .................................................................................................... 4

Special Equipment and/or Environment for Calibration ......................................................... 4

Software Environment ........................................................................................................... 4

2. BEFORE YOU BEGIN ................................................................... 5

2.1 Calibration requirements ................................................................................ 5

Input calibration ..................................................................................................................... 5

Output Calibration ................................................................................................................. 5

2.2 Transmitter/Communication characteristics ................................................ 5

Digital to Analog conversion and transfer .............................................................................. 5

Honeywell Transmitter (Analog Mode) .................................................................................. 5

Honeywell transmitter analog value scaling ........................................................................... 8

Honeywell transmitter output-Digital enhanced mode ........................................................... 9

2.3 Wi-Fi Connection Support ............................................................................ 12

3. GETTING STARTED .................................................................... 15

3.1 MC Toolkit Installation .................................................................................. 15

3.2 MC Toolkit Assembly .................................................................................... 16

MCT404 assembly............................................................................................................... 16

3.3 Safety instructions ........................................................................................ 18

For MCT404 ........................................................................................................................ 18

3.4 Battery and Power Supply ............................................................................ 19

3.5 Start up, Shutting down the MC Toolkit ...................................................... 20

3.6 Application icons .......................................................................................... 20

3.7 Connecting to a device through MC Toolkit (MCT404) ............................. 21

Wiring diagrams .................................................................................................................. 22

3.8 Connecting MC Toolkit to a PC .................................................................... 23

Connecting MCT404............................................................................................................ 23

3.9 Types of input methods ................................................................................ 23

Input dialog in FDC .............................................................................................................. 27

MCT404 Function Keys ....................................................................................................... 28

Revision 3 MC Toolkit (MCT404) User Manual vii

Page 8

Contents

4. MANAGING HART DEVICES USING FDC APPLICATION SOFTWARE 29

4.1 Starting FDC ................................................................................................... 29

Generic layout of user interface of FDC ............................................................................... 29

4.2 Overview of FDC homepage ......................................................................... 30

Settings ................................................................................................................................ 31

Manage DDs ........................................................................................................................ 32

Online configuration ............................................................................................................. 32

Offline configuration ............................................................................................................. 32

4.3 Customizing the settings .............................................................................. 33

Modifying device identification settings ................................................................................ 33

4.4 Managing DD files .......................................................................................... 35

4.5 Overview of device configuration ................................................................ 37

4.6 Online configuration...................................................................................... 38

Overview of Device Homepage ............................................................................................ 38

Tabs on the Device Home page ........................................................................................... 40

Viewing different type of variables ........................................................................................ 43

Searching for an item ........................................................................................................... 46

Device Health Indicator and Details ..................................................................................... 47

Graphical items in a device interface ................................................................................... 47

Executing methods on a device ........................................................................................... 55

Saving device history ........................................................................................................... 56

Exporting device history records to FDM ............................................................................. 57

Exporting device history records to Documint ...................................................................... 58

Custom Views ...................................................................................................................... 58

4.7 Offline configuration ..................................................................................... 60

Overview .............................................................................................................................. 60

Importing offline configuration .............................................................................................. 60

Deleting offline configuration ................................................................................................ 61

Downloading an offline configuration ................................................................................... 61

5. MANAGING DE DEVICES USING MC TOOLKIT SOFTWARE .. 63

5.1 Starting MC Toolkit application .................................................................... 63

5.2 Overview of MC Toolkit Homepage ............................................................. 63

Online and Offline Modes ..................................................................................................... 63

5.3 MC Toolkit Application Software Display Conventions............................. 65

Navigation ............................................................................................................................ 65

Menu Bar.............................................................................................................................. 65

File Menu ............................................................................................................................. 67

Modem Menu ....................................................................................................................... 68

Help Menu ............................................................................................................................ 69

Data Entry and Display ........................................................................................................ 70

5.4 Overview of device configuration ................................................................ 70

5.5 Online configuration...................................................................................... 71

Detecting and loading a device ............................................................................................ 71

Online Mode Introduction ..................................................................................................... 71

Summary of Operating Procedures ...................................................................................... 73

Procedural Considerations ................................................................................................... 75

5.6 How to view the Saved Configuration file and Import to Excel ................ 94

How to Import the data from the xml file to Excel? ............................................................... 97

viii MC Toolkit (MCT404) User Manual Revision 3

Page 9

Contents

5.7 Offline Configuration .................................................................................... 99

Save to File in Offline Mode .............................................................................................. 105

Template File ..................................................................................................................... 106

Download in Offline mode ................................................................................................. 107

Download Parameter List .................................................................................................. 108

DE Fields and Values ........................................................................................................ 110

5.8 Reference Data ............................................................................................ 112

Glossary ............................................................................................................................ 112

Honeywell DE Fields and Values ...................................................................................... 114

STT850 / STT750 Local Display Screen1 Configuration using MCT404 ........................... 118

5.9 XML Database (Samples) ........................................................................... 121

6. TROUBLESHOOTING ............................................................... 123

6.1 MC Toolkit troubleshooting scenarios ...................................................... 123

MCT404 ............................................................................................................................. 123

6.2 FDC application software troubleshooting scenarios ............................. 124

6.3 MC Toolkit application software troubleshooting scenarios.................. 128

MC TOOLKIT ERROR MESSAGES .................................................................................. 129

DE Device error messages ................................................................................................ 133

Offline configuration Error Messages ................................................................................ 135

7. MC TOOLKIT MAINTENANCE .................................................. 139

7.1 MCT404 battery replacement ..................................................................... 139

Battery Status .................................................................................................................... 139

Battery Replacement ......................................................................................................... 139

Charge the Battery ............................................................................................................ 139

Replace the Battery ........................................................................................................... 139

7.2 SD card replacement................................................................................... 141

MCT404 SD Card Replacement ........................................................................................ 141

8. APPENDIX A: APPLICATION NOTES ...................................... 143

8.1 Application Notes ........................................................................................ 143

Synchronization between PDA and PC ............................................................................. 143

File Transfer ...................................................................................................................... 147

Using Infrared Red Port for OneWireless Devices ............................................................ 148

9. APPENDIX B: ............................................................................ 152

9.1 MCT Power Save Guidelines ...................................................................... 152

10. APPENDIX C: REPLACEMENT PARTS ................................... 153

10.1 MCT404 Accessories & Spare Parts ...................................................... 153

Revision 3 MC Toolkit (MCT404) User Manual ix

Page 10

Tables

Tables

Table 1 Acronyms and Definitions .................................................................................. vi

Table 2 Components of MCT404 assembly ................................................................... 17

Table 3: MCT404 Function Keys ................................................................................... 28

Table 4 Generic UI elements ......................................................................................... 30

Table 5 FDC homepage elements ................................................................................. 31

Table 6 Device homepage elements ............................................................................. 39

Table 7 Device health status .......................................................................................... 39

Table 8 Device configuration screen elements .............................................................. 41

Table 9 Device configuration screen icons .................................................................... 42

Table 10 Tool bar on graph/chart page .......................................................................... 52

Table 11 DE Displays / Tasks Summary ....................................................................... 73

Table 12 DE Upload Procedures ................................................................................... 75

Table 13 DE Main Menu Procedures ............................................................................. 77

Table 14 Input Calibration (DE Transmitters) – ............................................................. 83

Table 15 Output Calibration - Loop Test ........................................................................ 88

Table 16 DE Output Calibration - Trim DAC Current ..................................................... 90

Table 17 DE Calibration - Apply Values ......................................................................... 92

Table 18 MCT404 Replacement Parts ......................................................................... 153

x MC Toolkit (MCT404) User Manual Revision 3

Page 11

Figures

Figures

Figure 1-1 MCT404 Ruggedized and Zone 1 Intrinsically safe models .......................... 2

Figure 2-1 Honeywell ST 3000/ ST 800 Smart Transmitter - Analog mode .................... 6

Figure 2-2 Honeywell Analog Value Scaling ................................................................... 8

Figure 2-3 Honeywell DE Mode Value Scaling.............................................................. 10

Figure 2-4 Honeywell (HART) Transmitter Diagram...................................................... 11

Figure 2-5 HART Point-point and Multi-Drop Value Scaling ......................................... 11

Figure 3-1 MCT404 assembly ....................................................................................... 16

Figure 3-2 Start Menu .................................................................................................... 20

Figure 3-3 Connecting to a device through MCT404 .................................................... 21

Figure 3-4 MCT404 terminal connections to HART/DE device ..................................... 22

Figure 3-5 MCT404 terminal connections to HART Device .......................................... 22

Figure 3-6 Virtual keypad ............................................................................................... 23

Figure 3-7 Block Recognizer ......................................................................................... 24

Figure 3-8 Letter recognizer .......................................................................................... 25

Figure 3-9 Freehand recognition ................................................................................... 26

Figure 3-10 Alphanumeric keypads ............................................................................... 27

Figure 4-1 Generic layout of user interface ................................................................... 29

Figure 4-2 FDC homepage ............................................................................................ 30

Figure 4-3 Device homepage ........................................................................................ 38

Figure 4-4 Device configuration screen ......................................................................... 41

Figure 5-1 Menu Tree - Honeywell DE Displays ........................................................... 72

Figure 5-2 Offline Browse / Open File dialog ............................................................... 100

Figure 5-3 MC Toolkit Options ..................................................................................... 101

Figure 5-4 DE device ................................................................................................... 102

Figure 5-5 STT25D and 25M, STT350 models ........................................................... 103

Figure 5-6 STT25T model ............................................................................................ 103

Figure 5-7 ST 3000 / ST 800 models .......................................................................... 103

Figure 5-8 STT25M and 25D models .......................................................................... 104

Figure 5-9 ST3000 DE ................................................................................................. 104

Figure 5-10 DE STT350 ............................................................................................... 104

Figure 5-11 Save As File dialog .................................................................................. 105

Figure 5-12 Honeywell DE Save Template Screen ..................................................... 106

Figure 5-13 Offline Honeywell DE Save Template as working file .............................. 106

Figure 5-14 Download in Offline Mode ........................................................................ 107

Figure 7-1 Remove Handstrap .................................................................................... 140

Figure 7-2 Remove Battery Cover ............................................................................... 140

Figure 7-3 SD Card Replacement ............................................................................... 142

Figure 8-1 Screen Y ..................................................................................................... 143

Figure 8-2 Screen X ..................................................................................................... 145

Figure 8-3 ActiveSync/Mobile Device Center file transfer ........................................... 147

Figure 8-4 MCT404 Infrared port location ................................................................... 148

Revision 3 MC Toolkit (MCT404) User Manual xi

Page 12

Page 13

1. Introduction

1.1 Overview of MC Toolkit

Purpose/Scope

This manual is intended to facilitate the use of the Honeywell MC Toolkit communications tool. It is

assumed that you are skilled in the use and maintenance of process transmitters in process control, or that

you are under direct supervision of others with the appropriate skills.

The MC Toolkit, with MC Toolkit Application Software and FDC Application Software, enables

communication with several types of smart transmitters (pressure, temperature, etc) that are available for

use in the process control industry.

The emphasis of the information in this manual is directed primarily on the features and use of the MC

Toolkit in performing common maintenance tasks relating to transmitter devices, rather than on the

features and installation of specific transmitter devices.

It is recommended that you should have the appropriate manuals available for specific transmitter

devices.

This manual includes information of two types:

background material that enables a skilled user to select the appropriate procedures in this manual

and to apply them in the appropriate sequence, and

detailed descriptions of the MC Toolkit regarding functions, features, and procedures for applying

them

Revision 3 MC Toolkit (MCT404) User Manual 1

Page 14

1. Introduction

1.1. Overview of MC Toolkit

Product Description

The Honeywell Multi Communication (MC) Toolkit is a handheld communication package that enables

convenient and reliable communications with smart field devices such as valves, actuators, transmitters

etc. MC Toolkit is a smart solution for configuring, calibrating, monitoring, and diagnosing the devices

supporting Honeywell Digitally Enhanced (DE) or HART communication protocols.

The MC Toolkit is available in high level model MCT404

MCT404

The MCT404 has following options:

Ruggedized version: Environmentally hardened with no approvals.

Zone 1 approvals: Intrinsically-safe version available with FM Class I, Div 1, IECEx and ATEX

Zone 1 approvals.

Figure 1-1 MCT404 Ruggedized and Zone 1 Intrinsically safe models

It includes the following components:

A PDA with integrated DE/HART modem

Honeywell MC Toolkit application software (CD ROM)

Honeywell FDC application software (CD ROM)

Test leads for the electrical connection from the PDA to the field device

Connector cables for connecting the PDA to the PC

Software components

The Honeywell MC Toolkit consists of two software applications:

2 MC Toolkit (MCT404) User Manual Revision 3

Page 15

1. Introduction

CAUTION! WARNING!

In some cases, the use of a field communicator with a transmitter that is connected on-line can

have an adverse effect on process operations.

1.2. Transmitter Type and Communication Mode

The MC Toolkit application software is used for configuring, calibrating, monitoring, and

diagnosing the Honeywell Digital Enhanced (DE) devices.

Field Device Configurator (FDC) application software is used for configuring, calibrating,

monitoring, and diagnosing HART devices. FDC uses the IEC 61804-3 EDDL standard

specification for providing an open solution for supporting any HART device with a registered DD

file with HART Communication Foundation (HCF).

Procedural Considerations

Before using the MC Toolkit, be certain that you know the potential consequences of each procedure,

and that you use the appropriate safeguards to prevent problems. For example, if the transmitter is an

element of a control loop, the loop should be placed in the manual operating mode, and alarms and

interlocks ("trips") should be disabled as appropriate before beginning the procedure.

The primary factors to be considered are separated into three categories under the following three

headings.

The information under the following headings is intended as background for use of the DE Procedures

and HART Procedures, which are given in separate sections of this manual.

1.2 Transmitter Type and Communication Mode

The MC Toolkit can be used with various types of field transmitters, most of which can be operated in

more than one mode.

Honeywell DE transmitter operating in Smart Analog Mode

Honeywell DE transmitter operating in Digital Enhanced (DE) Mode

Honeywell (and other) HART transmitter operating in point-to-point (Analog w/ HART digital

mode)

Honeywell (and other) HART transmitter operating in multi-drop (HART-only digital mode)

The salient characteristics of each item listed, and the implications of each characteristic in procedures

are described under Transmitter/Communications Characteristics

Revision 3 MC Toolkit (MCT404) User Manual 3

Page 16

1. Introduction

1.3. Type of Procedure

1.3 Type of Procedure

The MC Toolkit is designed to provide these basic functions:

Configuration

Calibration

Monitoring

Diagnostics

Depending on combinations of factors such as transmitter type, and communications mode, some

procedures such as monitoring the performance of a transmitter can be straightforward and innocuous,

but in some cases can also require special preparation and precautions.

1.4 Prerequisites

Special Equipment and/or Environment for Calibration

Typically, a smart transmitter delivered by a major manufacturer today is designed to provide a high

degree of precision throughout its operating range, and has been calibrated to a high level of accuracy

that is not easy to duplicate in your plant process areas. Moreover, the design, materials, and

manufacturing process employed will ensure that the instrument will stay within calibration limits for an

extended period.

Typically, calibration of a process-connected transmitter will degrade, rather than augment, the capability

of a smart transmitter. For this reason, the calibration procedures in this MC Toolkit User Manual

include a recommendation that the transmitter is removed from service and is calibrated only in a

controlled laboratory environment, using equipment whose precision is certified.

Software Environment

MC Toolkit runs on the Windows Embedded Handheld 6.5 operating system. A basic familiarity with the

OS and the PDA functions is expected.

If you are running Windows XP, download ActiveSync/Mobile Device Center 4.1 or above from the

Microsoft Web site and install it on your PC.

If you are running Windows Vista or Windows 7 download Windows Mobile Device center version 6.1

or above from the Microsoft Web site and install it on your PC.

SD Card: At least 1GB memory on the SD Card. Use a SD™ card to increase file storage and install

software. The MCT404s support an optional 32 GB maximum capacity microSD card. The SD card is

formatted to FAT or FAT32. The MCT404 is despatched with 2GB of memory

Regional Settings: Before starting the applications, set the Regional Settings to English (United States).

To check the Regional Settings of your PDA, select Start/Settings/System/Regional Settings. Make sure

it is set to English (United States).

4 MC Toolkit (MCT404) User Manual Revision 3

Page 17

2. Before you begin

2.1 Calibration requirements

Input calibration

Input calibration of pressure transmitters should be done only when necessary, and should be done only

under conditions that will ensure accuracy:

The transmitter should be taken out of service, and should be moved to an area with favorable

environmental conditions: clean, dry, and temperature-controlled.

The source for the input pressure must be very precise, and certified for correct operation.

The procedures should be done by qualified personnel.

Details of requirements and procedure are given in Table 14.

Output Calibration

The Loop Test procedure is intended as a check for continuity and condition of components in the output

current loop. The Loop Test procedure is given in Table 15.

The Trim DAC Current procedure calibrates the output of the Digital to Analog converter for minimum

(0%) and maximum (100%) values of 4 mA and 20 mA, respectively. This procedure is used for

transmitters operating on-line in analog mode, to ensure proper operation of the transmitter with all

associated circuit components (wiring, power supply, control equipment, etc). It is necessary to use

precision test equipment (an ammeter or a voltmeter in parallel with precision resistor). The Trim DAC

procedure is given in Table 16.

The Apply Values procedure uses actual Process Variable input levels for calibrating the range of a

transmitter. To measure a liquid level for example, a sight-glass can be used to determine the minimum

(0%) and maximum (100%) level in a vessel. The Process Variable is carefully adjusted to stable

minimum and maximum levels, and the LRV and URV values are then set by commands from the MC

Toolkit. The DE Apply Values procedure is given in Table 17.

2.2 Transmitter/Communication characteristics

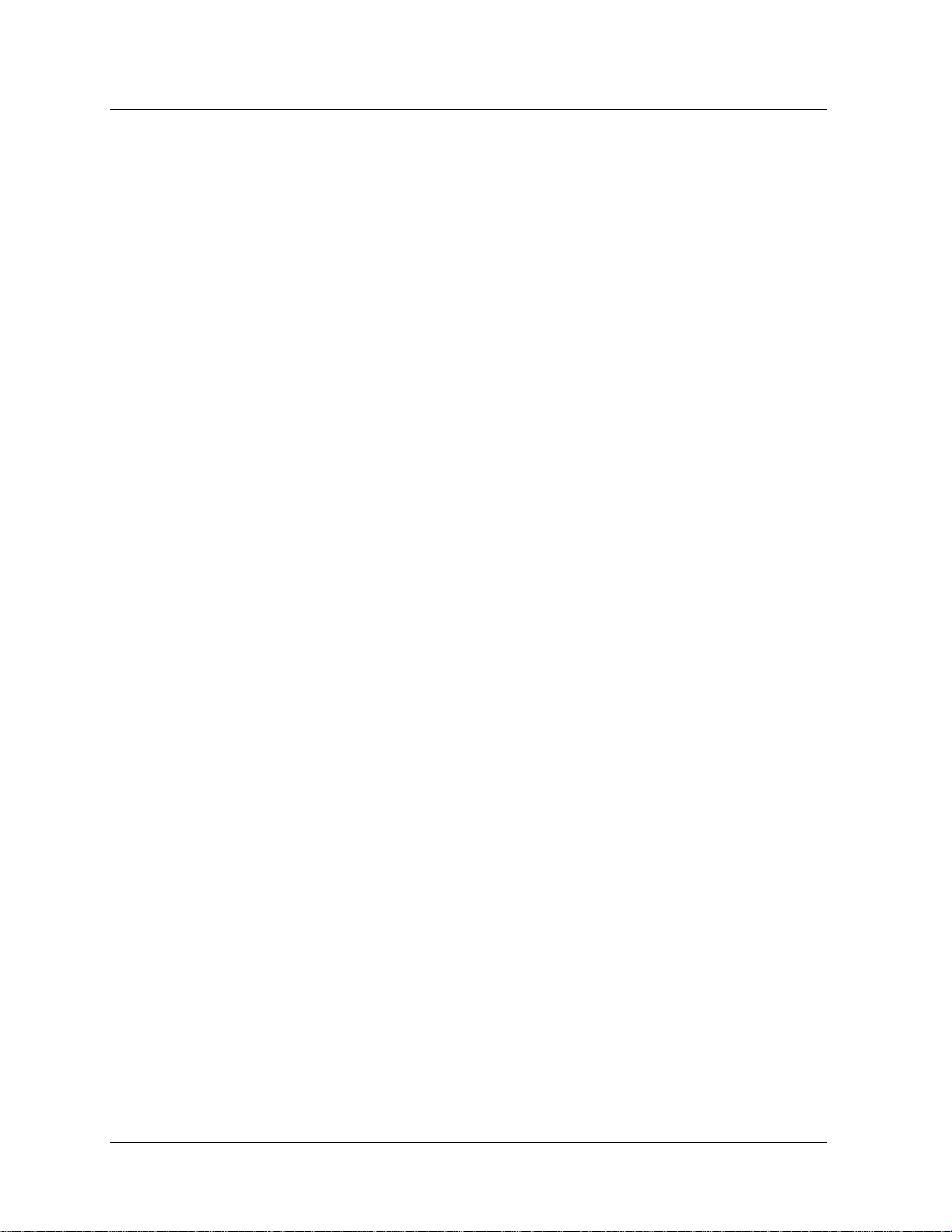

Digital to Analog conversion and transfer

The characteristics of a typical Honeywell Smart Pressure Transmitter (DE Protocol) are summarized in

Figure 2-1 through Figure 2-5, following.

Honeywell Transmitter (Analog Mode)

Analog-to-Digital Sensing

As indicated by key number (1) in Figure 2-1, the sensor is a sealed assembly that typically includes

three separate sensors: Differential Pressure (DP), Static Pressure (SP) and Temperature (Temp).

Input Characterization

Revision 3 MC Toolkit (MCT404) User Manual 5

Page 18

2. Before you begin

2.2. Transmitter/Communication characteristics

The sensor also includes a PROM, (2), which is Non-Volatile Memory (NVM) that stores

"characterization" constants written at the factory, and calibration constants, which can be written at the

factory and/or at the user's site. The data in NVM is used in an algorithm in the microprocessor, (3),

which is executed continuously to calculate the input value.

Figure 2-1 Honeywell ST 3000/ ST 800 Smart Transmitter - Analog mode

The characterization constants, which are written at the factory, are derived from highly precise testing of

the sensor's response over a range of temperatures, and from the Lower Range Limit (LRL) to the Upper

Range Limit (URL) of the sensor. The purpose of the characterization constants is to compensate for

very small inaccuracies in the sensor that are introduced by variations inherent in construction materials,

and to ensure that the calculated input is a high-fidelity representation of the analog input (linear or

square root), with a precise "zero" reference.

Input Calibration ("Corrects")

To optimize accuracy, the PROM includes storage for calibration constants: Correct Input Zero, Correct

LRV, and Correct URV.

The corrects constants provide for optimum accuracy in that they enable fine-tuning of the input

calculations, by first correcting at zero input, then bounding the input calculations at your operating range.

That is, corrections are applied at the Lower Range Value (LRV) and the Upper Range Value (URV).

Factory calibration can be specified in the purchase order. Also, if precision equipment, suitable

environment, and required skill are available at your site, input calibration can be done locally.

Reset Corrects

In some cases, the calibration procedure yields unsatisfactory results such that the Corrects constants

must be removed from memory. The Reset Corrects erases all three corrects constants, so that only the

factory-written characterization constants will be retained in the PROM.

Digital Communication Path

6 MC Toolkit (MCT404) User Manual Revision 3

Page 19

2. Before you begin

Parameter Name

Parameter Description

Display Examples

PVEULO

Process Value , Engineering Units, Low

PVEULO 100 in H20

PV

Process Value

PV 175 in H20

PVEUHI

Process Value , Engineering Units, Low

PVEUHI 225 in H20

2.2. Transmitter/Communication characteristics

As indicated at key number (4) in Figure 2-2, the Honeywell Smart Transmitter includes a path for

digital communications between the sensor (via the microprocessor) and the 4-20 mA current loop that

connects the transmitter to external communications devices such as process control equipment

("receiver") and/or to a MC Toolkit.

Digital to-Analog Conversion and Transfer

The digital-to-analog converter (D/A) shown at key number (5) in Figure 2-1is shown as a box with a

dotted line to indicate that analog output mode is a user-selectable feature, for use in an application

whose receiving equipment requires an analog input.

Note that the Digital I/O (Comm) (communications) box (4) is shown in Figure 2-1with solid line to

indicate that the digital communications path is available at all times, even when analog mode is selected.

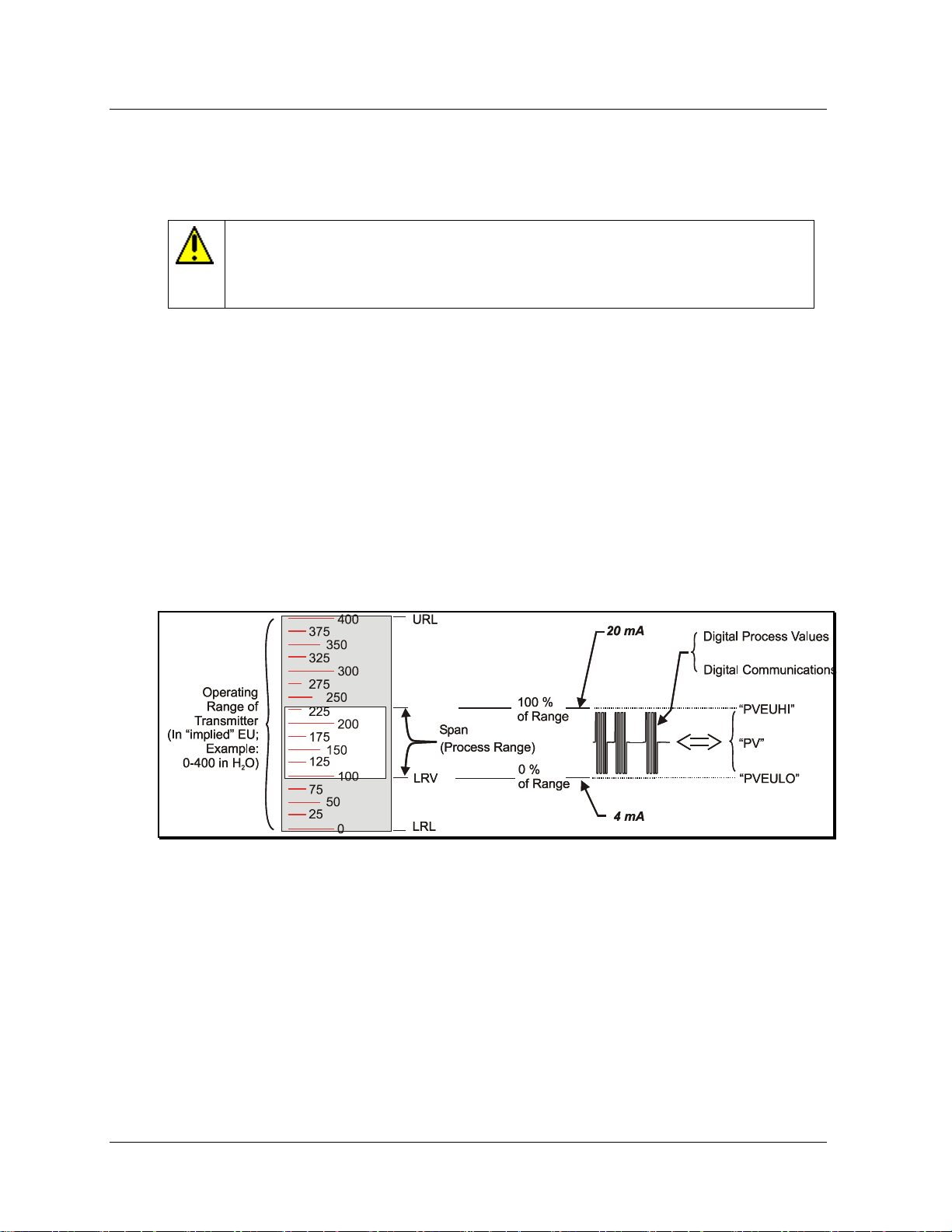

Honeywell Transmitter Output - Analog Mode

The diagram in Figure 2-2 provides an overview of a Honeywell transmitter operating in the analog

mode.

Analog (PV Signal) Output

The vertical scale at the left of Figure 2-2is an example of the available range (LRL to URL) of a

pressure transmitter sensor as built and characterized at the factory. The area of this scale that is

highlighted in white represents the configured process operating range (LRV to URV) - in this case, from

100 in H2O to 225 in H2O.

Note that Engineering Units (EUs) shown in Figure 2-2 are included here only for reference. The

transmitter does not perform any conversion of the base units’ value to Engineering Units. All

conversion to EUs is performed in the MC Toolkit and/or in other receiving devices such as operating

panels associated with control equipment. Default conversion is to inches-H2O @39F.)

The output of a Honeywell transmitter operating in the analog mode is a scaled value (0% - 100%) of

current (4 mA to 20 mA), whose lower and upper limits correspond to the configured operating range

(LRV-URV), respectively.

At the right of Figure 2-2, "PVEULO", "PV", and "PVEUHI" are examples of parameter names that

appear on Honeywell control equipment, which are used as follows.

Revision 3 MC Toolkit (MCT404) User Manual 7

Page 20

2. Before you begin

URVURV

CAUTION:

These rapid transitions provide for effective communications, but will interfere adversely

with a transmitter operating on-line in a control loop.

The MC Toolkit communicates digitally; exercise caution and good judgment when

connecting the unit to an on-line transmitter operating in the analog mode.

2.2. Transmitter/Communication characteristics

Honeywell transmitter analog value scaling

Figure 2-2 Honeywell Analog Value Scaling

Digital (Communications Signal) Input/Output

As indicated at the right of Figure 2-2, communications between the MC Toolkit and the Honeywell

Smart Transmitter consist of digital pulse strings, with rapid transitions of current level between

(approximately) 4 mA and 20 mA.

8 MC Toolkit (MCT404) User Manual Revision 3

Page 21

2. Before you begin

process safety

Unlike in the analog mode, communications devices do not "bump" the

value of the PV.

accuracy is retained with less

maintenance

Digital communications are relatively immune to small variations in

circuit resistance or supply voltage.

facilitates maintenance tasks

Honeywell control systems include operating displays that enable direct

communication with transmitters operating in DE mode.

CAUTION:

Although it in not necessary to put a control loop in manual before communicating with a

transmitter operating in DE mode, caution is required if there is any potential for error in

identifying operating mode.

2.2. Transmitter/Communication characteristics

Honeywell transmitter output-Digital enhanced mode

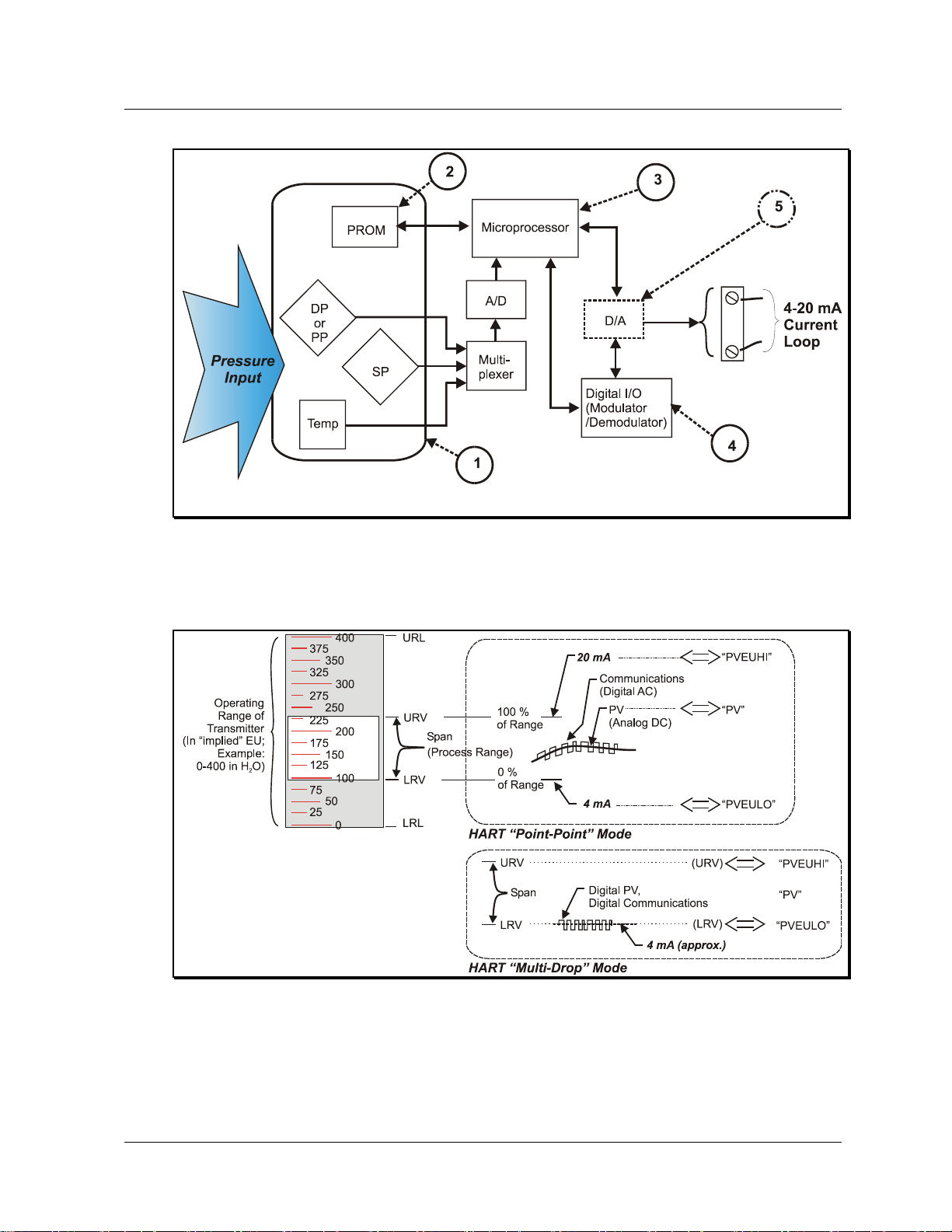

Most of the operation of the Honeywell Smart Pressure Transmitter Digital Enhanced (DE) mode is

similar to that of operation in the analog mode. The essential characteristics of operation in DE mode are

shown in Figure 2-3 Honeywell DE Mode Value Scaling

As indicated at the right of Figure 2-3 Honeywell DE Mode Value Scaling, output values of process

variables, as well as digital communications, are transferred to a receiving device digitally. The digital

coding is Honeywell proprietary, which requires the use of DE-capable Honeywell control equipment.

The use of DE mode offers several advantages:

Honeywell HART Transmitters

Transmitters with HART capability have features that vary among manufacturers and with the

characteristics of specific devices. The FDC application supports the HART Universal, Common

Practice, and Device Specific Commands that are implemented in Honeywell HART transmitters

As the diagram in Figure 2-4 shows, the Honeywell HART Transmitter is virtually identical to nonHART transmitters, except that the HART version includes a Digital I/O Modulator/Demodulator block

(key number (4) instead of the Honeywell DE communications block.

As indicated in Figure 2-5, the output of the HART includes two primary modes:

Point-to-Point Mode, in which one transmitter is connected via a two-conductor, 4-20 mA current

loop to one receiver.

Multi-Drop Mode, in which several transmitters are connected via a two-conductor network to a

multiplexed receiver device.

In point-to-point mode, the value of the primary PV is represented by a 4-20 mA current loop, almost

identical to that of the Honeywell Transmitter operating in analog mode. In this case however, the

analog signal is modulated by Frequency Shift Keying (FSK) methods, using frequencies and a current

amplitude that do not affect analog sensing at the receiver.

Note that the accuracy of the analog level must be precisely controlled for accurate sensing, but that

HART communications will not "bump" the process variables.

In multi-drop mode, up to 16 transmitters in HART 5 (addresses 0-15) and up to 64 transmitters in

HART6/7 (addresses 0-63) can exist on the two-conductor network, which precludes analog transmission

Revision 3 MC Toolkit (MCT404) User Manual 9

Page 22

2. Before you begin

CAUTION:

Before connecting to a HART transmitter, ensure that the MC Toolkit is not set up for DE

communications, whose current amplitude can "bump" process variables in either point-topoint mode or in multi-drop mode.

URVURV

2.2. Transmitter/Communication characteristics

methods. In this case, the same FSK modulation method is used for conveying levels of PV (and other

variables) and also for communications.

Non-Honeywell HART Transmitters and Devices

HART-capable transmitters from any manufacturer and for any specific purpose are designed to

common-agreement standards that provide for inter-operability.

Guidelines published by the HART Communication Foundation enables manufacturers to design devices

that communicate via a set of standard commands and responses.

The FDC application software supports the HART Revision 5.0, 6.0 and 7.0 commands that are exposed

through the HART Communication Foundation Device Description files. For more information, refer to

tables in the Reference Data section 5.8.

The FDC uses Device Descriptions stored in the Pocket PC to communicate to all universal, common

and device specific commands. MC Toolkit will come with all HART Registered (updated once per

quarter) Device Descriptions pre-loaded.

Figure 2-3 Honeywell DE Mode Value Scaling

10 MC Toolkit (MCT404) User Manual Revision 3

Page 23

2. Before you begin

2.2. Transmitter/Communication characteristics

Figure 2-4 Honeywell (HART) Transmitter Diagram

Figure 2-5 HART Point-point and Multi-Drop Value Scaling

Revision 3 MC Toolkit (MCT404) User Manual 11

Page 24

2. Before you begin

2.3. Wi-Fi Connection Support

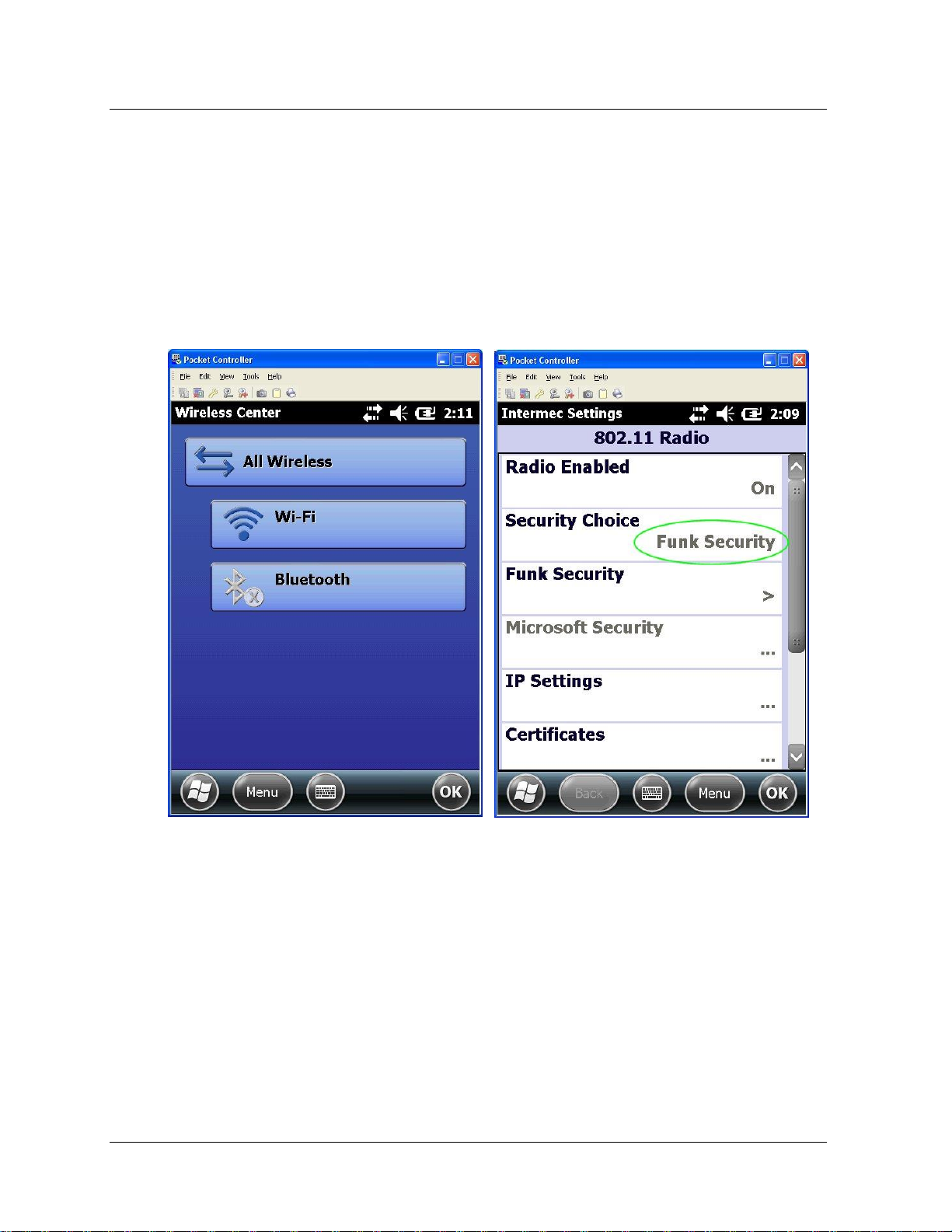

2.3 Wi-Fi Connection Support

MCT404 is sold with or without Wi-Fi option.

This section shows you how to connect the handheld to Wi-Fi and then connect to the Internet for

example to download the DD files for any Transmitter or connect to a network printer etc.

1. Make sure the Wi-Fi setting is Turned on

2. Set the Security Choice to “Func Security”

12 MC Toolkit (MCT404) User Manual Revision 3

Page 25

2. Before you begin

2.3. Wi-Fi Connection Support

3. The IP address will be detected automatically. If it is not detected, then find the IP address from your

network provider and enter it in the IP Address and Subnet Mask field.

4. Select OK. Once the IP address is entered, you can connect to the network with or without DHCP

Enabled.

Revision 3 MC Toolkit (MCT404) User Manual 13

Page 26

Page 27

3. Getting Started

3.1 MC Toolkit Installation

MC Toolkit software is fully loaded in the factory on all new orders.

The installation instruction for the above process is in document 34-ST-33-59.

The above document is available at:

https://www.honeywellprocess.com/transmitter-configuration-tools-and-accessories/mc-toolkit

Revision 3 MC Toolkit (MCT404) User Manual 15

Page 28

3. Getting Started

3.2. MC Toolkit Assembly

3.2 MC Toolkit Assembly

MCT404 assembly

Figure 3-1 shows the MCT404 assembly.

Figure 3-1 MCT404 assembly

16 MC Toolkit (MCT404) User Manual Revision 3

Page 29

3. Getting Started

Item

Description

Positive and negative test leads.

Connecting terminals for test leads.

Test leads to connect to the field device.

Functional keys which can be configured.

Navigational keys.

Button for powering on/powering off the MC Toolkit.

Pin charging plug with USB connector.

Reset buttons. For Soft Reset, press both the buttons simultaneously.

3.2. MC Toolkit Assembly

Table 2 describes the components of the MCT404 assembly.

Table 2 Components of MCT404 assembly

Revision 3 MC Toolkit (MCT404) User Manual 17

Page 30

3. Getting Started

3.3. Safety instructions

3.3 Safety instructions

General safety instructions

Persons using the unit must observe the standard safety regulations and read the certificate to prevent incorrect

operation or misuse of the unit.

For MCT404

For general safety instructions while using MCT404, refer to the “Safety regulations – General safety

instructions” section of “300011CB02A01_instruction_manual_irocCi70-Ex_EN.pdf” that is shipped

with the MCT404 product

The safety instructions from the above Safety Guide have been updated below as they are

applicable to MCT404 product. The following additional safety regulations must also be

observed:-

- The unit must not be opened within the Ex-area.

- For battery information refer to MCT404 battery replacement section 7.1

- Avoid using the unit in aggressive acidic or alkaline solutions.

- Ensure that the MCT404-X_ Ex unit is not taken in to Zone 0 areas.

- Ensure that the MCT404 - Y_ Ex unit is not taken into Zone 1/0 or 21/20 areas.

- Ensure that the MCT404 - ZZ unit is not taken in to Ex-area.

- Electromagnetic waves, which can arise with the i.roc when using WLAN or Bluetooth functions, can

cause disturbances and endanger your health! Since no definite statements can currently be made about

the immunity from disturbances of heart pacemakers, we recommend users of pacemakers to avoid

using transmitters generally.

- Do not transmit near persons with pacemakers!

- Permission to use electronic devices in airplanes is up to the respective airline.

- Avoid effects of elevated heat: Do not place the device near heat sources, such as radiators, airconditioner air exit openings, stoves or other devices (including amplifiers) that radiate heat.

- Avoid effects of moisture.

- Do not put any objects into the product: Do not put objects into the housing or other product openings.

These openings must not be obstructed, blocked or covered.

- Set-up: Never set up the product on a table, vehicle, stand or holder that is not stable. Follow the

manufacturer‘s instructions when setting up or installing the product, and use the accessories

recommended by the manufacturer for installation.

- Adjust loudness: Reduce the volume before using earphones or other audio devices.

18 MC Toolkit (MCT404) User Manual Revision 3

Page 31

3. Getting Started

3.4. Battery and Power Supply

3.4 Battery and Power Supply

For battery care of MCT404, refer to MCT404 battery replacement section 7.1

For the Power supply information for MCT404, refer to “300011CB02A01_instruction_manual_irocCi70-

Ex_EN.pdf” that is shipped with the MCT404 product

Revision 3 MC Toolkit (MCT404) User Manual 19

Page 32

3. Getting Started

3.5. Start up, Shutting down the MC Toolkit

3.5 Start up, Shutting down the MC Toolkit

The section explains how to start the MC Toolkit.

Starting the MCT404

Press the Power button on the MC Toolkit to start the MC Toolkit, and wait until the main PDA window

appears displaying the Start icon.

Shutting down the MCT404

Press the Power button on the MC Toolkit and hold it for few seconds to shutdown.

3.6 Application icons

Select on the Start icon. All the available shortcuts will be displayed under the Start Menu as shown in

Figure 3-2.

Figure 3-2 Start Menu

The icons for the two applications MC Toolkit and FDC are available directly under the “Start” Menu.

If any or all of these icons are not available under the Start Menu, select ‘Programs’, and locate the MC

Toolkit, FDC icons.

20 MC Toolkit (MCT404) User Manual Revision 3

Page 33

3. Getting Started

3.7. Connecting to a device through MC Toolkit (MCT404)

3.7 Connecting to a device through MC Toolkit (MCT404)

Figure 3-3 shows how a field device is connected through MCT404. Refer to the MCT404 assembly for

more details.

Figure 3-3 Connecting to a device through MCT404

Revision 3 MC Toolkit (MCT404) User Manual 21

Page 34

3. Getting Started

3.7. Connecting to a device through MC Toolkit (MCT404)

Wiring diagrams

Figure 3-4 displays how to connect directly to the terminals of HART/DE device

Figure 3-4 MCT404 terminal connections to HART/DE device

Figure 3-5 displays connecting HART device with 250 ohm resistor

Figure 3-5 MCT404 terminal connections to HART Device

22 MC Toolkit (MCT404) User Manual Revision 3

Page 35

3. Getting Started

3.8. Connecting MC Toolkit to a PC

3.8 Connecting MC Toolkit to a PC

Connecting MCT404

1. Connect the USB connection cable to a free USB port on the PC.

2. Insert the MC Toolkit into the docking station.

3. Follow the Active Sync/Mobile Device Center instructions appearing on the screen to establish the

connection between the MC Toolkit and the PC.

3.9 Types of input methods

The MC Toolkit application allows you to provide inputs through various mechanisms supported through

Windows Mobile platform, they are, Keyboard, Block Recognizer, Letter Recognizer, and Transcriber.

On the other hand the FDC application supports the input through a custom keypad which supports

numeric or alphanumeric keys depending upon the input context.

In the Keyboard method, you select a text field in display, and then selects a character at a time from a virtual

keyboard. Using the keyboard involves familiar concepts that will enable quick and accurate entries.

In the other three methods, the stylus is used to write the desired input directly onto the screen, and each

requires some adaptation of user skills. Of these, the Transcriber is probably the most efficient and easiest to

use.

Character input using keyboard

For character input using keyboard, perform the following steps.

1. Tap on the arrow at the bottom right corner of the display and tap on a key on the

Keyboard.

2. Use the stylus to provide a character at a time from the virtual keypad as shown in Figure 3-6.

The familiar QWERTY keypad layout enables quick and accurate entries.

Figure 3-6 Virtual keypad

Revision 3 MC Toolkit (MCT404) User Manual 23

Page 36

3. Getting Started

3.9. Types of input methods

Character input using Block Recognizer

For character input using block recognizer, perform the following steps.

1. Tap on the arrow at the bottom right corner of the display and tap on Block Recognizer.

2. Use the stylus to provide a character input to the letter pad at the bottom of the screen. The

character strokes are then converted to typed text on the screen as shown below in Figure 3-7.

Figure 3-7 Block Recognizer

Note: Tap on ? icon to view the help for using Block Recognizer, and tap on @$ icon to view the table

of symbols.

24 MC Toolkit (MCT404) User Manual Revision 3

Page 37

3. Getting Started

3.9. Types of input methods

Character input using Letter Recognizer

For character input using letter recognizer, perform the following steps.

1. Tap on the arrow at the bottom right corner of the display and tap on Letter Recognizer.

2. Use the stylus to provide character inputs between the lines which appear at the bottom of the

screen. The character input is recognized and displayed on the screen as shown in Figure 3-8.

Figure 3-8 Letter recognizer

Revision 3 MC Toolkit (MCT404) User Manual 25

Page 38

3. Getting Started

3.9. Types of input methods

Character input using Transcriber

For character input using transcriber, perform the following steps.

1. Tap on the arrow at the bottom right corner of the display and tap on Transcriber.

2. Use the stylus to input the characters by writing them on the screen, in cursive, print or, mixed

handwriting. The character input is recognized and displayed on the screen as shown in Figure 3-9.

Figure 3-9 Freehand recognition

26 MC Toolkit (MCT404) User Manual Revision 3

Page 39

3. Getting Started

3.9. Types of input methods

Input dialog in FDC

Depending upon the context of the data, FDC smartly presents an alphanumeric or numeric keypad for

data entry as shown in Figure 3-10.

Figure 3-10 Alphanumeric keypads

Revision 3 MC Toolkit (MCT404) User Manual 27

Page 40

3. Getting Started

Function key

(Numeric)

Function key

(AlphaNumeric)

FDC

MC Toolkit

F1

F1

Navigate Forward through Menus

NA

F2

F2

Navigate Forward through Menus

NA

F3

F3

NA

About MC Toolkit

F4

F4

NA

Exit MC Toolkit Application

F5

F5

(Shift+F1)

NA

Modem Diagnostics

F6

(Shift+F1)

F6

(Shift+F2)

Volume Up

Volume Up

F7

(Shift+F2)

F7

(Shift+F3)

Volume Down

Volume Down

F8

(Shift+F3)

F8

(Shift+F4)

NA

File/Options

F9

(Shift+F4)

Not Available

NA

Help Topics General (**)

F10

(Shift+F5)

Not Available

NA

Help Topics DE (**)

3.9. Types of input methods

MCT404 Function Keys

MCT404 supports 2 versions of Keypads: Numeric and Alphanumeric. Numeric keypad has F1 through

F10 function keys. Alphanumeric keypad has F1 through F8 function keys. Key assignments in FDC and

MC Toolkit applications are shown in the Table 3 below:

Table 3: MCT404 Function Keys

(**) Available in Numeric keypad models only

NOTE: In the MC Toolkit application, select Help / About MC Toolkit to find the supported Function

keys. In FDC Application, select the "Application Information" icon on the Home page (See Figure 4-2

and Table 5) to find the supported Function keys

28 MC Toolkit (MCT404) User Manual Revision 3

Page 41

4. Managing HART Devices using FDC Application

Software

4.1 Starting FDC

To start FDC, perform the following steps.

1. Turn on the MC Toolkit.

Note: For information on turning on the MC Toolkit, refer to section 3.5 Start up, Shutting down the

MC Toolkit and 3.6 Application icons.

2. Select FDC from the Start menu. The FDC homepage appears.

Generic layout of user interface of FDC

The FDC generic layout consists of title bar, workspace, and menu bar, which appear consistently on all

screens, and the options may vary depending on the context and selection.

Figure 4-1 Generic layout of user interface

Revision 3 MC Toolkit (MCT404) User Manual 29

Page 42

4.2. Overview of FDC homepage

Items

Description

Title bar – Displays the current page title.

Page icon – Displays current page icon

Icon 1

Icon 2

Exit button – Tap to quit the current page.

Workspace – Consists of various menu items for working with

FDC.

Menu bar – Consists of options for navigation and selection.

Table 4 describes the UI elements that appear on all FDC pages.

Table 4 Generic UI elements

4.2 Overview of FDC homepage

The FDC homepage consists of links for Online Configuration, Offline Configuration, Manage DDs, and

Settings. Figure 4-2 shows the FDC homepage.

30 MC Toolkit (MCT404) User Manual Revision 3

Figure 4-2 FDC homepage

Page 43

4. Managing HART Devices using FDC Application Software

Items

Description

Screen title.

Tap to quit FDC.

Tap to view the application information.

Tap to navigate to Online Configuration screen.

Tap to navigate to Offline configuration screen.

Tap to navigate to Manage DDs screen.

Tap to navigate to Settings screen.

Tap to select the highlighted menu option.

Tap to quit FDC.

4.2. Overview of FDC homepage

Table 5 lists the items that appear on the FDC homepage and its descriptions.

Table 5 FDC homepage elements

Note: To select a particular option in FDC you can either select the option and then tap Select or you can

directly double-tap the option.

For example, double-tap Online Configuration or tap Online Configuration > Select. The Device

Configuration page appears.

Settings

Use this feature to customize FDC. You can customize FDC for device detection, DD selection, and

other application settings.

Device Identification

Use the following options to configure FDC to identify a device.

COM Port: It allows selection of COM port to which HART/DE is connected

Using Poll Address

Use poll address 0 only: Use this to detect a device with the poll address as zero.

Find first poll address and use: Use this to detect a device with the first available poll address in

the range of poll addresses that are available.

Use selected poll address: Use this to detect a device with a specific poll address in the range

of zero to 63.

Use From: Use this to detect a device based on a range of poll addresses.

Using Device TAG: Use this to detect a device with a known HART tag.

Using Device LONG TAG: Use this to detect a device with a known HART long tag (applicable for

devices with HART 6 or later Universal revisions).

Note: If you choose the option Using Device TAG or Using Device LONG TAG, FDC prompts you to

enter a device tag/long tag name during device detection.

Revision 3 MC Toolkit (MCT404) User Manual 31

Page 44

4.2. Overview of FDC homepage

DD selection

Use the following options to configure FDC to select DD files when a DD with matching device

revision is not available.

Use DD file of previous device revision: Use this option to automatically load a device with a

DD file having device revision lower than that of the device.

Use generic DD file: Use this option to automatically load the device with an appropriate generic

DD file.

Always ask user: Use this option to always prompt you with a choice for loading the device

either with the previous device revision or with generic DD file.

Always Use Generic: Use this option to always load the device using generic DD files even if a DD

file with matching device revision as the device is present.

Note: A generic DD file is a DD file that provides access and interface to the universal data and

features of a HART device.

Other settings

Low storage notification: Use this option to set a percentage value and to notify you with a warning

message when the available storage card space is less than the percentage set.

Application diagnostics: Use this option to enable or disable the logging infrastructure for application

diagnostics. With this option enabled, FDC creates necessary log files for troubleshooting and

diagnostics. These files are stored in SD Card\FDC folder.

Note: You must not enable this option unless suggested by Honeywell TAC because this may impact the

application performance.

Manage DDs

Using this feature, you can manage the DD files installed with FDC. A DD file contains descriptive

information about the functionality of a device. By default, a set of DD files are installed with FDC.

However, if you do not have a DD for a given device, you can install it using the “Add DD” feature.

Similarly, you can uninstall a DD file or a set of DD files using “Delete DD” feature. You can also

directly copy the DD files in appropriate hierarchy using a card reader or “Active Sync/Mobile Device

Center” mechanisms. In such a case, you should validate the library view using the “Refresh” feature.

Online configuration

Using online configuration, you can configure, calibrate, monitor and diagnose a HART device which is

connected to MC Toolkit. FDC provides the features to perform these functions through the various

constructs offered through the DD file of the device. Besides there are certain other features available

under this link for you to conveniently work with a HART device with live communication. After

making changes to the device you can also save a snapshot of the device data as history to later transfer it

to FDM for record and audit purposes.

Offline configuration

Offline configuration refers to configuring a device offline (without physically connecting to the device)

using a template and then downloading the configuration to the device. Presently, FDC application

software does not support creating offline configuration. However, it supports importing of offline

configuration from FDM (R310 and above).

32 MC Toolkit (MCT404) User Manual Revision 3

Page 45

4. Managing HART Devices using FDC Application Software

4.3. Customizing the settings

4.3 Customizing the settings

Modifying device identification settings

Using the Device Identification settings, you can choose how to detect a device. Devices can be detected

using poll address or device tag name. By default, devices are detected using poll address zero. However,

you can modify these settings based on how you want to detect devices.

To modify the device detection settings, perform the following steps.

Note: Before modifying the settings, see Settings for more information.

1. On the FDC homepage, tap Settings > Select.

The Settings dialog box appears.

2. Tap Device Identification tab.

3. If you want to detect a device using the device specific tag name, select Using Device Tag

checkbox (for HART 5 or later versions) or Using Device Long Tag checkbox (for HART 6 or

later versions).

4. If you want to detect a device using poll address, select Using Poll Address check box.

To detect a device using poll address zero, tap Using poll address 0 only.

To detect a device using first poll address, tap Find first poll address and use. With this setting,

FDC will detect the first device which responds on any poll address during a scan from 0 to 63.

To detect a device using selected poll address, tap Use selected poll address and choose the

appropriate poll address using the up and down arrow keys.

For example, if you want to detect a device with poll address 20, press and hold the up or down

arrow key until the poll address 20 appears.

To detect a device using a range of poll addresses, tap Use From to choose the device between

the ranges of poll address you want to detect.

For example, if you want to detect a device within the range of poll address 20 and 25, press and

hold the up or down arrows keys to specify the range of poll address.

Modifying DD selection settings

Using the DD selection settings, you can choose how to select a DD file for a device, when a DD with

matching device revision is not present. By default, the option Always ask user is selected. To modify

the DD selection settings, perform the following steps.

Note: Before modifying the DD selection settings, see Settings for more information.

1. On the FDC homepage, tap Settings > Select

The Settings dialog box appears.

2. Tap DD Selection tab.

3. If the DD file with the current device revision is missing for a device, select one of the following:

a) Use DD file of previous device revision

b) Use generic DD file

c) Always ask user.

Revision 3 MC Toolkit (MCT404) User Manual 33

Page 46

4.3. Customizing the settings

4. If you want to load devices with a generic DD files even if a DD matching the device revision is

available, select the checkbox under the Always Use Generic option.

Modifying other default settings

Using the “Others” tab under settings, you can set the following:

Threshold percentage for notifying a low storage space warning. By default, the notification for

percentage of available storage card space is set as 5%. Note that you cannot reduce the percentage

beyond 50%.

Enable or disable logging option for generating application diagnostic log files.

To modify the settings for low storage warning, perform the following steps.

1. On the FDC homepage, tap Settings > Select

The Settings dialog box appears.

2. Tap Others tab.

3. Select Low Storage Space Warning checkbox.

4. Press and hold the up or down arrow keys to set the notification for percentage of available storage

card space, which is available.

For example, if you want to set the percentage for notifying a low storage card space to 20%, press

and hold the up or down arrow keys until the required percentage appears.

To modify the settings for saving log files, perform the following steps.

1. On the FDC homepage, tap Settings > Select

The Settings dialog box appears.

2. Tap Others tab.

3. Select Enable or Disable under the Application Diagnostics option.

Once you are done with the desired changes in Settings, tap “Save” on the menu bar. The modified

settings are then updated successfully in the application. Tap “Return” to return to the FDC home page.

34 MC Toolkit (MCT404) User Manual Revision 3

Page 47

4. Managing HART Devices using FDC Application Software

4.4. Managing DD files

4.4 Managing DD files

Overview

Using Manage DDs, you can view, add, or delete DD files for devices. A list of already available DD

files is maintained in the DD Library. FDC lists the installed DD files in a hierarchy as below:

Manufacturer

Device Type

DevRev xx, DDRev yy

DevRev pp, DDRev qq

Add a DD file

To add a DD file for a device, perform the following steps.

1. From the FDC homepage, tap Manage DDs > Select.

The Manage DDs dialog box appears.

2. Tap Options > Add DD.

Or

Tap.

The ADD DD files dialog box appears.

3. Browse to the location in which the DD file (.fm8) is located and tap OK.

4. If the DD file already exists, then the following message appears.

5. Tap Yes to overwrite the existing DD files.

6. If the DD file is added successfully, a success message appears.

Revision 3 MC Toolkit (MCT404) User Manual 35

Page 48

4.4. Managing DD files

Delete a DD file

Using this option, you can delete a particular version of a DD file. To delete a DD file for a device,

perform the following steps.

1. From the FDC homepage, tap Manage DDs > Select.

The Manage DDs dialog box appears.

2. You can choose to delete DD(s) in one of the following ways:

a) By device manufacturer – Select a device manufacturer to delete all device types and DDs

associated with the manufacturer’s devices.

b) By device type – Select a device type to delete all DDs associated with the device.

c) By device revision and DD revision – Select the specific entry of device revision, DD revision

to delete the specific DD

3. Tap Options > Delete DD.

Or

Tap .

A confirmation message appears.

4. Tap Yes.

If the DD file is deleted successfully, a success message appears.

5. Tap OK to return to DD Library page.

36 MC Toolkit (MCT404) User Manual Revision 3

Page 49

4. Managing HART Devices using FDC Application Software

4.5. Overview of device configuration

Validating a manually edited library

Besides using the Add/Delete DD features, advanced users may also manipulate a DD library by directly

editing the contents of the FDC\Library folder. DD files can also be transferred directly to this location

by accessing the SD Card on MCT404 through a card reader and/or by connecting the MCT404 to a PC.

In such cases, you must perform the following steps to validate a DD Library, thus edited manually:

1. From the FDC homepage, tap Manage DDs > Select

The Manage DDs dialog box appears

2. Tap Options.

3. Tap Refresh Library.

Or

Tap .

A confirmation message appears.

4. Tap Yes. The DD library is now validated and refreshed.

4.5 Overview of device configuration

Device configuration is the process of setting the variables of a device to desired values. Typically, the

configuration process is equated with the act of writing values to a device, but procedurally it involves

the following:

Identifying a device

Reading/observing device variable values

Editing variables

Sending edited variables to the device

Saving the variable values

Saving and downloading the device configuration.

When performing the above stated procedures and the device being available on an active

communication link, the process is generally termed as Online Configuration. On the other hand, you

may prepare a set of values for device variables even when the physical device is not present and then

you send these values down to the device once the same is available on the communication link. This

process is generally termed as Offline Configuration.

Revision 3 MC Toolkit (MCT404) User Manual 37

Page 50

4.6. Online configuration

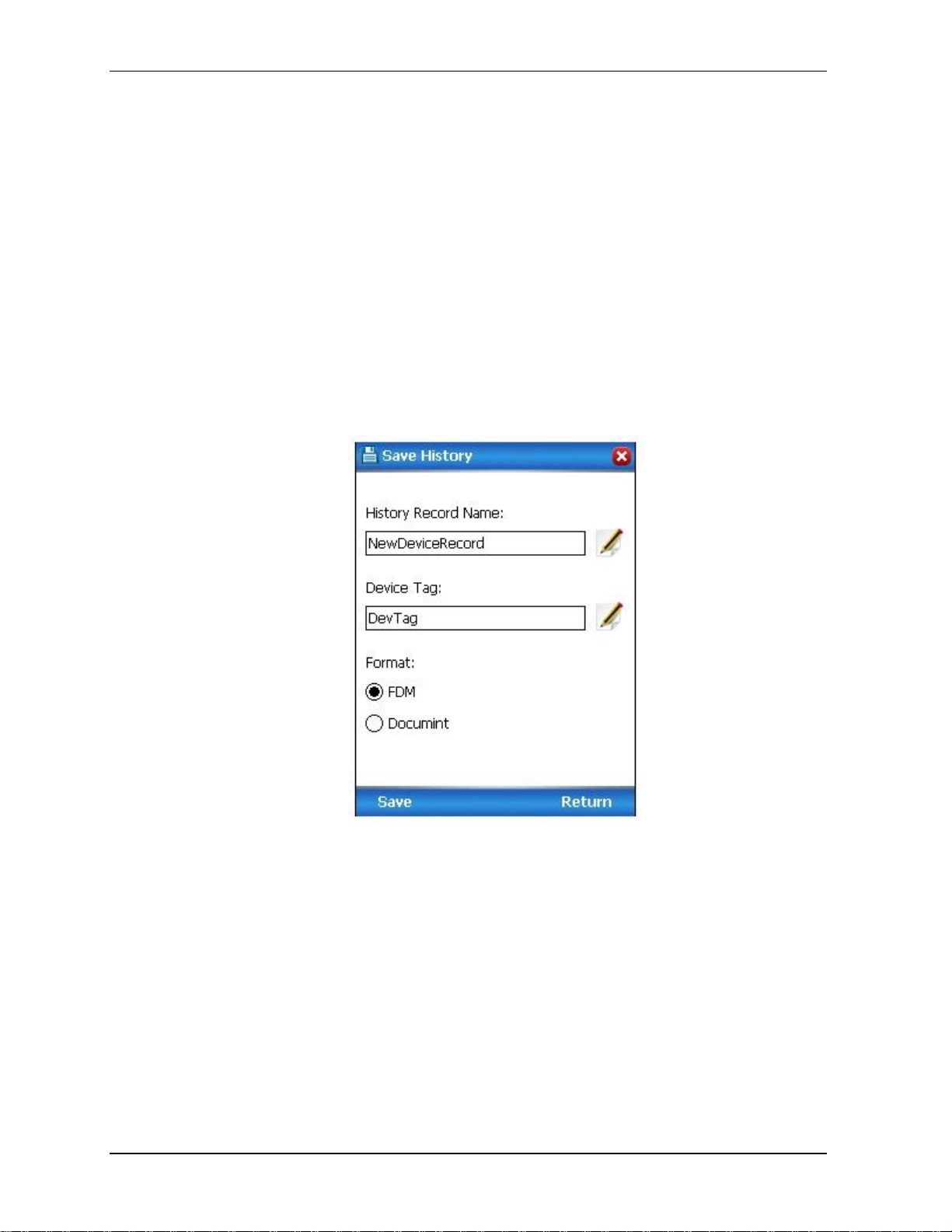

4.6 Online configuration