Page 1

62-0413-02

MCSS/MCSP Current Switches

CAUTION

WARNING

INSTALLATION INSTRUCTIONS

Risk of electrical shock.

Can cause severe injury, property damage or

death.

Disconnect and lock out all power sources before

installation as severe injury or death may result from

electrical shock due to contact with high voltage wires.

Never rely on the LED’s of the MCSS-A/MCSP-A to

determine whether power is present at the current

switch. The Red LED will indicate whether the current

is above the adjustable trip point. The Blue LED will

indicate that the current is below the adjustable trip

point.

The MCSS-A and MCSP-A Current Switches should be used

on Insulated Conductors Only! The current switch may be

mounted in any position using the (2) #8 x 3/4” Tek screws and

the mounting holes in the base. Leave a minimum distance of

INSTALLATION

Make sure that all installations are in compliance with all

national and local electrical codes. Only qualified individuals

that are familiar with codes, standards, and proper safety

procedures for high-voltage installations should attempt

installation. The current switches will not require external

power, since the power for the current switch is induced from

the conductor being monitored.

1” (3 cm) between the current switch and any other magnetic

devices such as contactors and transformers.

For applications in which the normal operating current is

below the 0.32Amps (MCSS-A) or 0.70Amps (MCSP-A) trip

point (See Figure 5 below), the conductor being monitored

may be looped through the sensor 6 times giving you a total

operating current of 6X the original current. Example: A small

fan operating at 0.2A should be wrapped through the sensor 7

times to give you a total operating current of 1.4 Amps flowing

through the MCSS-A or MCSP-A.

This product is not intended to be used for Life or

Safety applications.

This product is not intended for use in any

hazardous or classified locations.

For applications in which the normal operating current is

greater than 150 Amps or for conductor diameters larger than

0.530” (1.35 cm) in diameter, an external 5 Amp Current

Transformer (5A CT) must be used as shown in Figure 6

below. Remember that the secondary of the 5A CT must be

shorted together before the power may be turned onto the

monitored device.

Page 2

MCSS/MCSP CURRENT SWITCHES

M33395

NUMBER 8 X 3/4 (19) TEK SCREW

(QUANITY 2 PER UNIT)

Use Copper Conductors Only

Output: 0.5A@

36.0 Vac/V

DC

Sense Range: 0.2-150A

TRIP ON = Above 0.2A

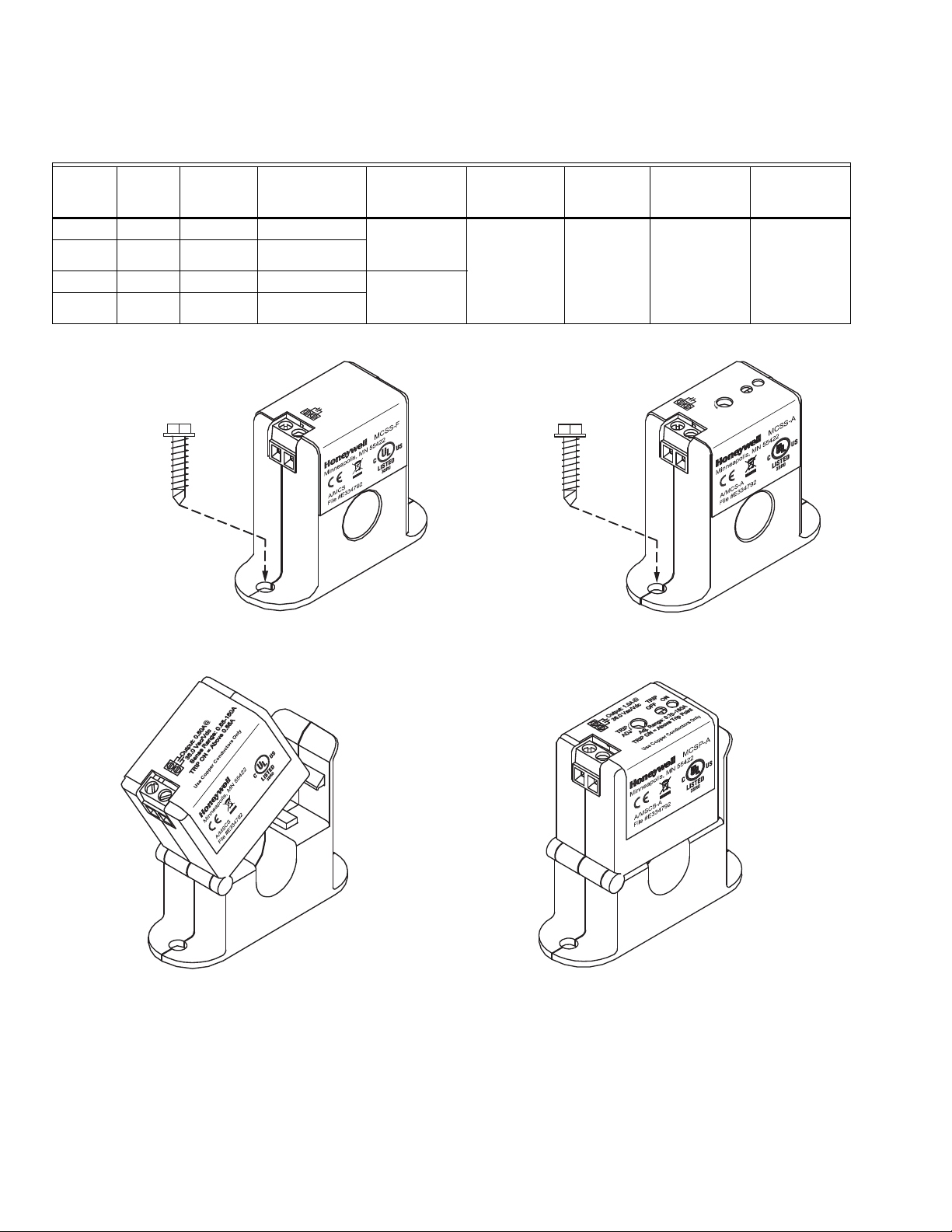

SPECIFICATIONS

Table 1. Operating specifications.

Core

Model

Typ e

MCSS-F Solid Fixed < 0.20 Amps 0.50 Amp

MCSP-F Split Fixed < 0.55 Amps

MCSS-A Solid Adjustable 0.32 - 150 Amps 1.00 Amp

MCSP-A Split Adjustable 0.70 - 150 Amps

Switch

Type Trip Point

Output

Switch Rating

@ 36 VAC/

VDC

@ 36 VAC/

VDC

Max. Sensing

Current

Voltage

Max.

Continuous

Current

Max. Current

for

6 seconds

Max. Current

1 second

600 VAC 158 Amps 240 Amps 600 Amps

TRIP

OFF ON

Output: 1.0A@

NUMBER 8 X 3/4 (19) TEK SCREW

(QUANITY 2 PER UNIT)

36.0 Vac/Vdc

TRIP

ADJ

TRIP ON = Above Trip Point

Adj. Range: 0.32-150A

Use Copper Conductors Only

for

Fig. 1. MCSS-F

MCSP-F

Fig. 2. MCSP-F

M33397

Fig. 3. MCSS-A

M33398

M33396

Fig. 4. MCSP-A

62-0413—02 2

Page 3

INSULATED

M33402

DDC CONTROLLER

RELAY/

CONTACTOR

TRANSFORMER

DI

STATUS

DO

(RELAY COIL OR

CONTACTOR)

24 VAC COIL

24 VAC

120 VAC

LINE

CONDUCTOR

MCSS/MCSP CURRENT SWITCHES

M33399

Fig. 5. Wires through sensors.

600:5 RATIO 5A C.T.

WIRE NUT

Fig. 6. Using a current transformer.

WIRING

Honeywell recommends the use of a two conductor 16 to 22

AWG shielded cable or twisted pair copper wire only for all

current switch applications. A maximum wire length of less

than 30 meters (98.4 feet) should be used between the

MCSS-A and MCSP-A current switches and the Building

Management System or controller.

NOTE: When using a shielded cable, be sure to connect

only one (1) end of the shield to ground at the

controller. Connecting both ends of the shield to

ground may cause a ground loop.

When removing the shield from the sensor end, make sure to

properly trim the shield so as to prevent any chance of

shorting. The current switch output terminals represent a

solid-state switch for controlling both AC and DC loads and is

not polarity sensitive. The recommended torque to be used on

the terminal block connections is 0.67 Nm or 5.93 in-lbs.. The

aperture (hole) size of the current switch is 0.53” (1.35 cm)

and will accept a 1 AWG maximum wire diameter.

See Figure 7 and Figure 8 for two different current switch

applications using your Building Management System (DDC/

PLC Controller). Figure 7 is showing the use of the Go/No Go

Current Switch as a Digital Input to your DDC Controller,

whereas Figure 8 is showing you how to use the Go/No Go

Current Switch in conjunction with your building management

system to control a fan or pump for example.

M33400

DIGITAL INPUT 1

BUILDING

MANAGEMENT

SYSTEM

M33401

Fig. 7. Digital circuit.

Fig. 8. Analog circuit.

3 62-0413—02

Page 4

MCSS/MCSP CURRENT SWITCHES

Calibration of Adjustable Trip Point (MCSS-A, MCSP-A models only)

The adjustable current switch has an operating range of 0-150

Amps. Do not exceed! The adjustable current switch comes

with its fifteen-turn adjustment potentiometer set to the 100

Amp trip point position. The adjustable current switch can be

used to monitor Under Load, Normal Load, and Over Load

conditions, depending on how it’s set. The procedure below is

for the Normal load condition for part numbers MCSS-A &

MCSP-A.

Table 2. Troubleshooting.

Problem Solution

Red LED is on but the current switch didn’t

activate( -A models)

Current switch didn’t activate( - F models)

Red LED didn’t turn on and the current switch

didn’t activate (- A models)

Current switch didn’t activate ( -F models)

Sensor doesn't switch at all, regardless of

current level. (-A models)

Disconnect the wires from the current switch output. Measure the

resistance across the contacts with an Ohmmeter.

Verify that the conductor you are monitoring is above the adjustable trip point. If

the sensor is monitoring less than the minimum trip point, see Fig. 5.

Adjustment potentiometer is probably set to its maximum or minimum

position. Turn the Pot counter-clockwise all the way and verify if the

LED switches from Red to Blue.

Normal Loads (MCSS-A, MCSP-A models only)

With current flowing through the aperature of the MCSS-A and

MCSP-A current switches, first verify that the Blue LED is on.

If the Blue LED is on, now slowly adjust the potentiometer

clockwise until the Red LED just turns on and stop

immediately. This will set the trip point at your normal

operating load current. If the RED LED is on after initial power

up, this means that you will need to slowly adjust the

potentiometer counter-clockwise until the Blue LED turns on

and then slowly adjust the potentiometer clockwise until the

Red LED just turns on and stop immediately. The adjustable

current switch is now tripped. Now verify the output with an

Ohmmeter to verify that the contacts of the switch are

approximately 0.200 Ohms. The adjustable current switch

Hysteresis (Dead Band) is typically 10% of the trip point.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to,

the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages,

including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Automation and Control Solutions

Honeywell International Inc.

® U.S. Registered Trademark

© 2012 Honeywell International Inc.

62-0413—02 M.S. 07-12

Printed in United States

Loading...

Loading...