Page 1

®

60-2336-3

L8100A,B,C Aquastat

Controllers

FEATURES

• L8100A regulates tank temperature and provides

energy cutoff (ECO) action on a temperature rise past

the setpoint.

• L8100B regulates temperature and provides ECO

action on a temperature rise past the setpoint. This

model includes a second sensing element that senses

average water temperature to minimize stacking.

• L8100C includes a second sensing element that

senses average water temperature to minimize

stacking, but does not include ECO action.

• Fluid filled element operates single pole single throw

(spst) snap-acting Micro Switch™.

• Energy cutoff (ECO) switch enclosed in factory

installed well of L8100A,B interrupts the thermocouple

circuit or main valve before the tank reaches

maximum temperature of 210°F (99°C).

PRODUCT DATA

GENERAL

L8100A,B, and C are immersion type controllers for

regulating and limiting the tank temperature in water heaters.

As the water temperature rises past the setpoint, the

controller switches off the gas valve.

• Internal adjustment screw.

• Immersion well is factory installed to the controller.

• Special switch terminal provides three-wire hookup

from Aquastat® controller to gas valve.

• Four terminal models for manual reset with S86/

VR8204/VR8440.

Contents

General ............................................................................... 1

Features .............................................................................. 1

Specifications ...................................................................... 2

Ordering Information ........................................................... 2

Installation ........................................................................... 3

Operation and Checkout ..................................................... 8

® U.S. Registered Trademark

Copyright © 1995 Honeywell Inc. • All Rights Reserved

Page 2

L8100A,B,C Aquastat ® CONTROLLERS

SPECIFICATIONS

IMPORTANT

The specifications given in this publications do not

include normal manufacturing tolerances. Therefore,

an individual unit may not exactly match the listed

specifications. Also, this product is tested and

calibrated under closely controlled conditions, and

some minor differences in performance can be

expected when those conditions are changed.

Models:

L8100A Aquastat® Controller. Regulates water

temperature. Includes energy cutoff (ECO) switch that

breaks controller circuit on a temperature rise above

the setpoint.

L8100B Aquastat® Controller. Regulates water

temperature. Has a second sensing bulb that minimizes

stacking by sensing the average tank temperature.

Includes ECO switch which breaks controller circuit on

a temperature rise above the setpoint.

L8100C Aquastat® Controller. Regulates water

temperature. Has a second sensing bulb that minimizes

stacking by sensing the average tank temperature.

Electrical Ratings:

2A maximum at 24 Vac.

Differential:

Fixed, 5°F (3°C) for controller: 20°F (11°C) for ECO switch.

Capillary Length (for Remote Bulb):

24-5/8, 30, 39, 42, or 54 in. (625, 762, 991, 1067, or

1372 mm).

Insertion Depth:

See Fig. 2.

Insulation Depth:

See Fig. 2.

Finish:

Gray.

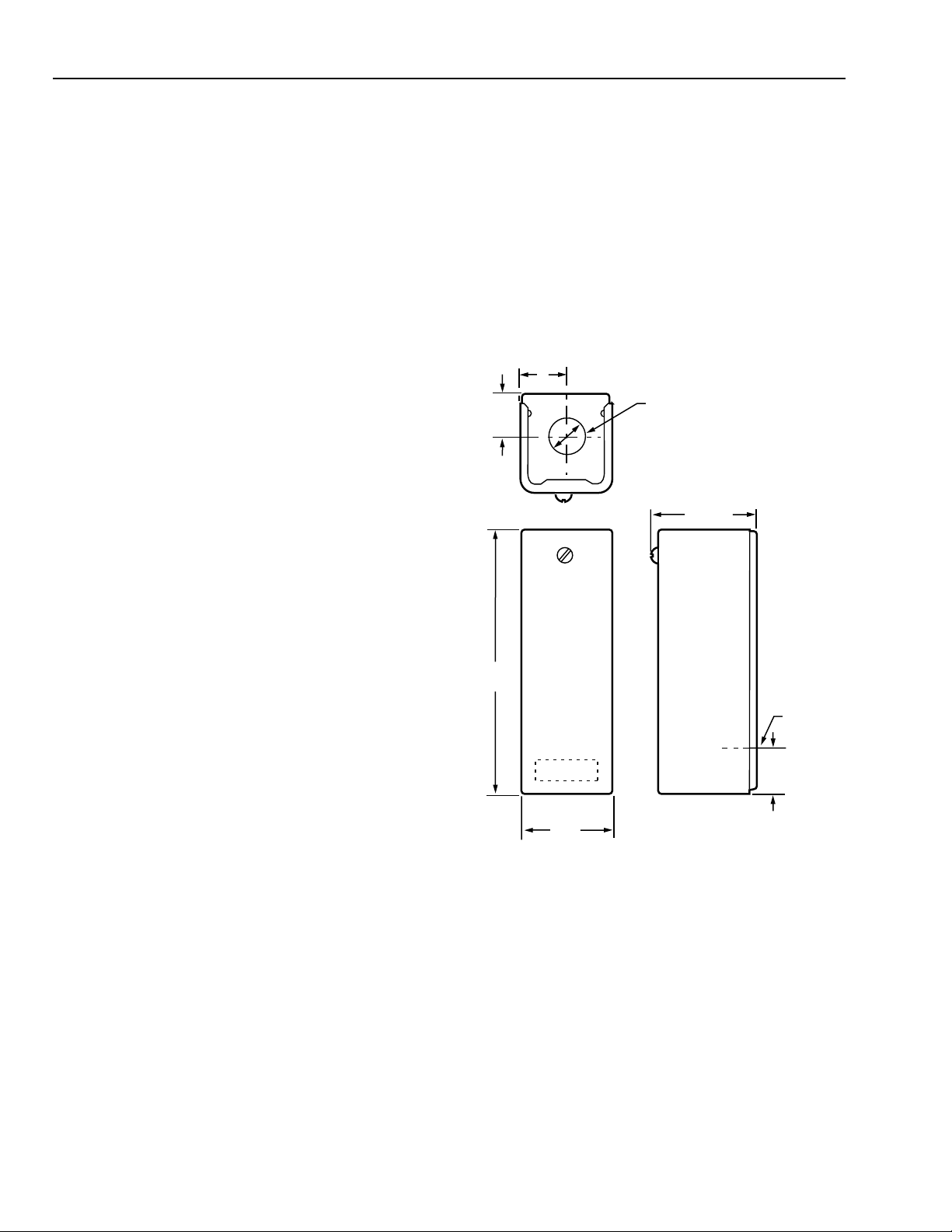

Dimensions:

See Fig. 1 for controller dimensions; see Fig. 2 for immersion

well dimensions.

1

(25)

15/16

(24)

KNOCKOUT FOR 3/4 IN. (19 MM)

CONDUIT

SIMILAR KNOCKOUT

ON BOTTOM

2-1/8 (54)

Maximum Tank Temperature:

210°F (99°C).

Temperature Range:

L8100A: 100°F to 240°F (38°C to 116°C) with factory set

stop to prevent setting above 160°F (71°C).

L8100B,C: 100°F to 180°F (38°C to 82°C).

Pressure Rating:

5-5/8

(144)

ELEMENT

255 psi (1758 kPa).

Sensing Bulb:

Liquid (toluene) filled; 3/8 in. (10 mm) capsule.

3/4

(19)

Immersion Well:

1/2 in (13 mm) or 3/4 in. (19 mm) NPT. See Fig. 2 for

dimensions. All zinc plated except L8100B1094 and

L8100B1185.

2 (51)

Fig. 1. Approximate dimensions of the L8100 Aquastat®

M4747

Controller in in. (mm).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number, or specify:

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Model number.

2. Application.

1. Your local Honeywell Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Golden Valley, Minnesota 55422-4386

In Canada—Honeywell Limited/Limitee, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9. International Sales and Service

offices in all principal cities of the world.

60-2336—3

2

Page 3

L8100A,B,C Aquastat ® CONTROLLERS

Available Options:

External adjustment screw and visible control point scale.

Factory set stop at 140°F (60°C).

Approvals:

Underwriters Laboratories Inc. Component Recognized:

File No. MP466, Guide Number MBPR2.

American Gas Association Design Certified: Report

Number 23-11B.

Part Available:

110641 Jumper to convert four-terminal L8100 to threeterminal L8100.

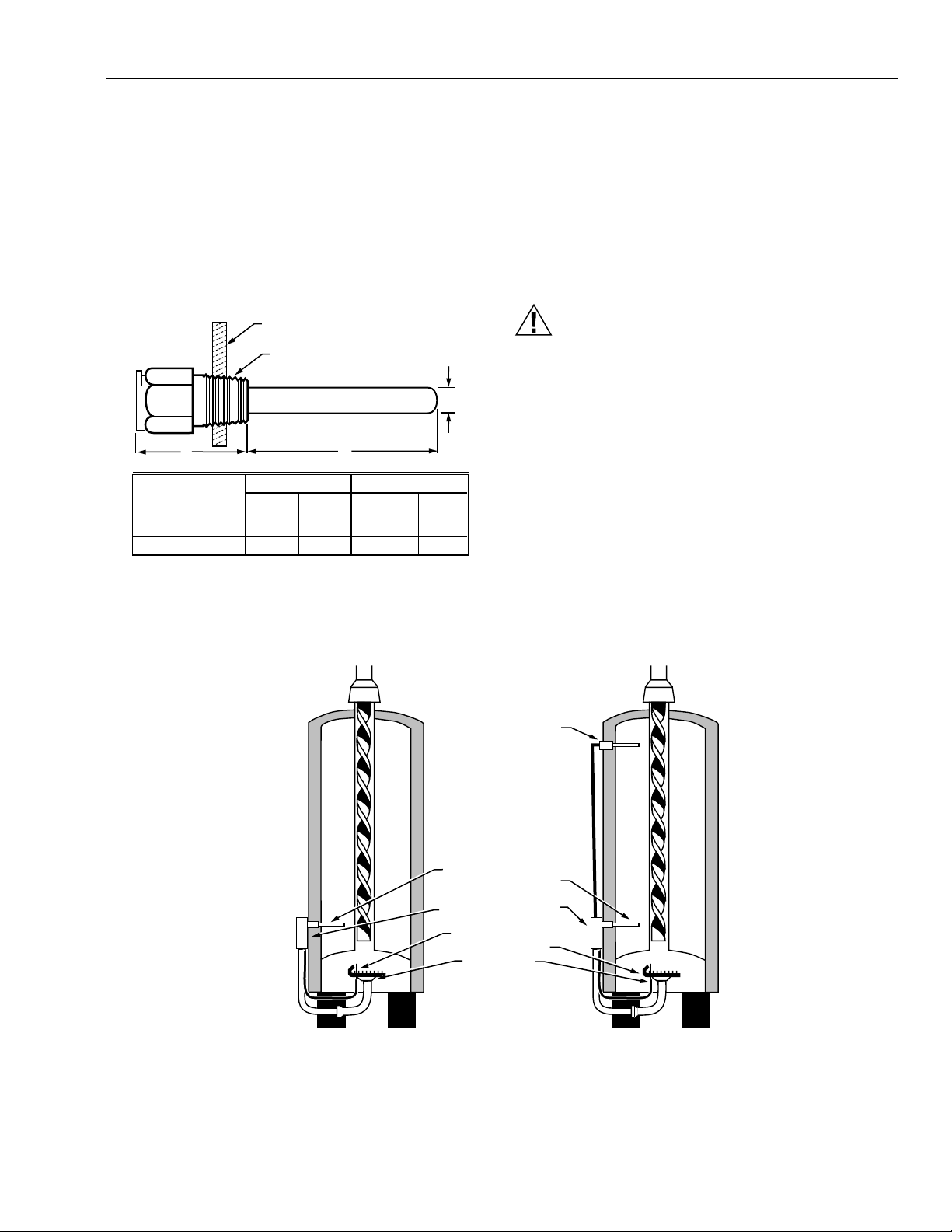

TANK WALL

1/2 OR 3/4 — 14 NPT

57

127

11

B

IN. MM

1-1/2 OR 2-1/2

3

7/16

38 OR 64

M4746

A

A INSULATION DEPTH

B INSERTION DEPTH

C WELL DIAMETER

CONTROLLER WELL REMOTE WELL

IN. MM

2-1/4

5

7/16

INSTALLATION

When Installing this Product...

쐃 Read instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

쐇 Check ratings and descriptions given in the

specifications to make sure the product is suitable for

your application.

쐋 Installer must be a trained, experienced service

technician.

쐏 After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Disconnect power before installation to prevent

electrical shock or equipment damage.

C

76

11

Mounting Direct Immersion Well

The manufacturer usually provides a tapping for insertion of

the controller sensing element. This tapping is located at a

point where typical water temperature can be measured.

Follow the instructions furnished by the system manufacturer,

if available, or use the procedure below. See Fig. 3.

Fig. 2. Approximate dimensions for the controller

immersion well and remote immersion well in in. (mm).

SENSING BULB AND

ECO SWITCH LOCATION

L8100A

THERMOCOUPLE

AND PILOT BURNER

MAIN BURNER

Fig. 3. Location of L8100A,B,C Aquastat® Controllers.

UPPER

SENSING BULB

L8100B,C

M4759

3

60-2336—3

Page 4

L8100A,B,C Aquastat ® CONTROLLERS

IMPORTANT

The controller immersion well is factory-installed to

the controller. Do not remove the immersion well,

this could damage the ECO switch.

쐃 If system is filled, drain to a point below the tapping.

쐇 Remove plug from tapping.

쐋 If tapping is suitable, carefully screw immersion well

into tapping. Do not tighten or apply force to the

controller case.

쐏 Fill tank. Make sure that well is screwed in tightly

enough to prevent leakage.

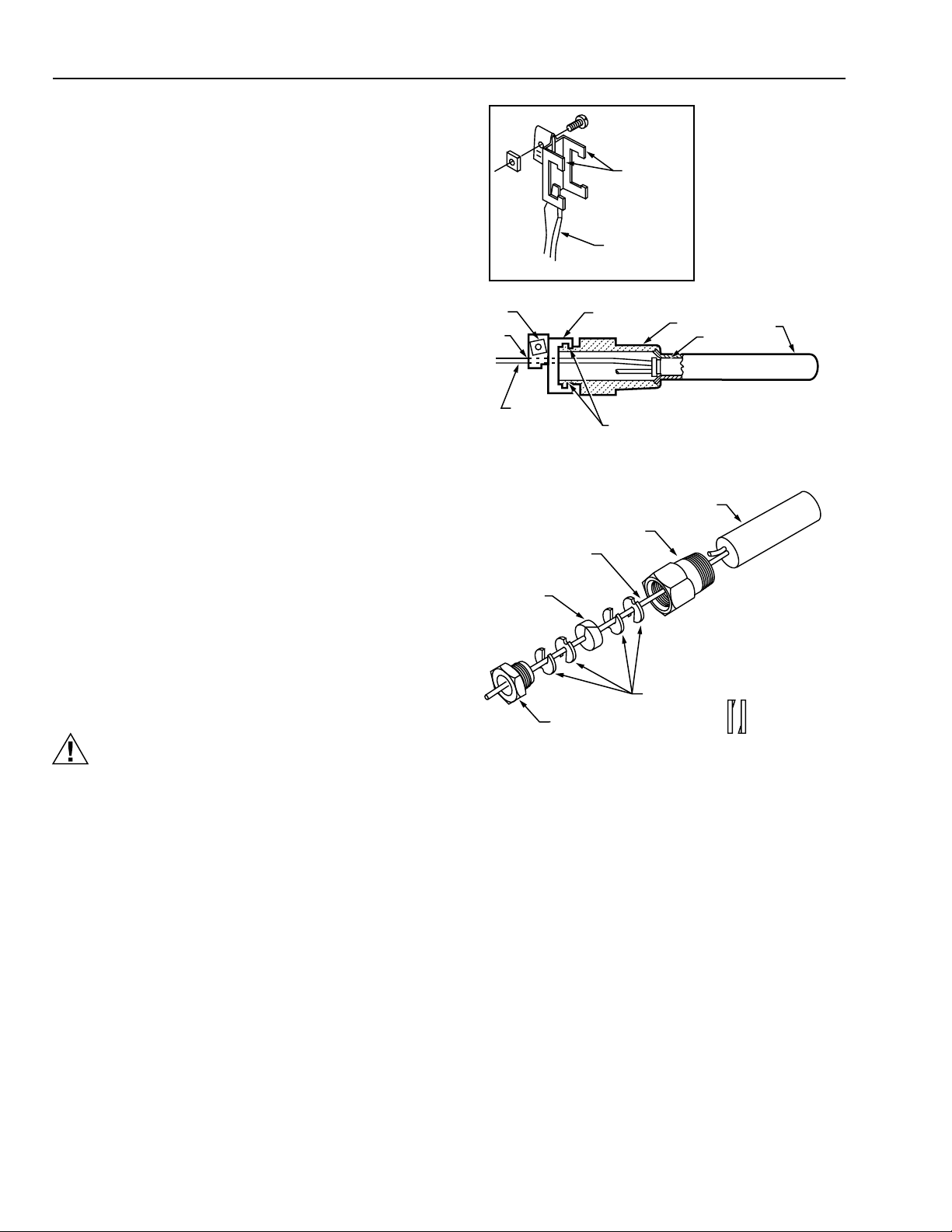

Mounting Remote Bulb (L8100B and L8100C)

The remote temperature sensing bulb is installed in an

INSERT— MOUNTING CLAMP

DRAW

NUT

B

immersion well (Fig. 4) or located near a capillary

compression fitting (Fig. 5) that extends into the upper portion

of the tank to prevent stacking.

Immersion Well Fitting

The immersion well must snugly fit the sensing bulb for good

thermal response. Install as follows:

쐃 Use tapping provided by tank manufacturer, if possible,

or select an area where typical water temperature is

best measured.

쐇 If tank is filled, drain to below point where bulb will be

installed.

쐋 Screw well into tank.

쐏 Insert bulb into well, pushing tubing until bulb bottoms

in well.

쐄 Attach mounting clamp end of well spud. Loosen draw

nut and spread jaws of clamp with screwdriver if

necessary.

쐂 With mounting clamp attached to well spud (make sure

jaws of clamp hook over ridge at end of spud, as shown

at points A in Fig. 4), adjust tubing to fit through

mounting clamp groove, as shown at point B in Fig. 4.

쐆 Tighten draw nut until mounting clamp is firmly attached

to well spud and tubing is held securely in place.

Fig. 4. Immersion well fitting for L8100 remote bulb.

CAPILLARY TUBING

COMPOSITION DISK

(SLOTTED)

TUBING

MOUNTING

CLAMP

BOILER PLUG

PACKING NUT

JAWS

SPREAD JAWS

TO FIT OVER

RIDGE ON

WELL SPUD

SCREWDRIVER

SPUD

BULB

A

IMMERSION

BULB

EXAMPLE OF SLOTTED WASHERS

ASSEMBLED

IN PAIRS:

WELL

M8777

M8816

CAUTION

Do not secure draw nut so tightly that mounting clamp

collapses tubing.

Capillary Compression Fitting

쐃 Use tapping provided by manufacturer, if possible, or

select an area where typical water temperature is best

measured.

쐇 If tank is filled, drain to below point where bulb will be

installed.

쐋 Screw fitting into boiler tank tapping.

쐏 Place packing nut on tubing.

쐄 Slide bulb completely through fitting.

쐂 Place composition disk and four slotted brass washers

on tubing in order shown in Fig. 5.

so slots are 180 degrees apart.

쐆 Slide seal assembly into fitting and tighten packing nut.

60-2336—3

Tu rn brass washers

Fig. 5. Capillary compression fitting for

L8100 remote bulb.

Wiring

Disconnect power supply before installation to prevent

electrical shock or equipment damage. All wiring must comply

with local codes and ordinances regarding wire size, type of

insulation, enclosure, etc. Fig. 6 through 11 show typical

Powerpile® (millivolt) gas control connections; Fig. 12 and 13

show typical connections for 24 Vac systems; Fig. 14 through

16 show an L8100 hookup with an S86E,F,G, or H

Intermittent Pilot System.

Some four-terminal models are shipped with jumper in place

for use as three-terminal models. Remove jumper for fourterminal operation.

4

Page 5

L8100A,B,C Aquastat ® CONTROLLERS

3

2

1

1

2

3

VS820

VALVE OPERATOR

COIL

PILOTSTAT® POWER

UNIT COIL

POWERPILE®

MILLIVOLT

GENERATOR

ECO SWITCH

CONTROLLER

L8100A,B

USE 3-TERMINAL VS820 GAS VALVE.

DOTTED LINE SHOWS INTERNAL WIRING.

SELECTED MODELS HAVE 3/16 AND 1/4 IN. TAB TERMINALS.

M4751

TH

TH

PP

PP

L8100A,B

CONTROLLER

ECO SWITCH

2

TH

TH

VS890

1

VALVE OPERATOR

COIL

PILOTSTAT® POWER

UNIT COIL

1

DOTTED LINE SHOWS INTERNAL WIRING.

SELECTED MODELS HAVE 3/16 AND 1/4 IN. TAB TERMINALS.

2

PP

PP

POWERPILE®

MILLIVOLT

GENERATOR

M4748

Fig. 6. L8100A,B hookup with VS890 where

controller cuts out main valve and ECO switch

cuts out pilot safety valve.

L8100A,B

CONTROLLER

ECO SWITCH

3

TH

VS820

GAS VALVE

1

2

3

TH

1

VALVE OPERATOR

COIL

USE 4-TERMINAL VS820 GAS VALVE.

DOTTED LINE SHOWS INTERNAL WIRING.

SELECTED MODELS HAVE 3/16 AND 1/4 IN. TAB TERMINALS.

PP

PP

2

PILOTSTAT® POWER

UNIT COIL

POWERPILE®

MILLIVOLT

GENERATOR

M4750

Fig. 8. L8100A,B hookup with four-terminal VS820

where controller cuts out main valve and ECO

switch cuts out pilot safety valve.

L8100A,B

CONTROLLER

ECO SWITCH

2

TH

TH

VS890

1

VALVE OPERATOR

COIL

PILOTSTAT® POWER

UNIT COIL

1

DOTTED LINE SHOWS INTERNAL WIRING.

SELECTED MODELS HAVE 3/16 AND 1/4 IN. TAB TERMINALS.

2

Fig. 7. L8100A,B hookup with VS890 where controller and

ECO switch are placed in series to cut out main valve.

PP

PP

POWERPILE®

MILLIVOLT

GENERATOR

M4749

Fig. 9. L8100A,B hookup with three-terminal VS820

where controller and ECO switch are placed in

series to cut out main valve.

5

60-2336—3

Page 6

L8100A,B,C Aquastat ® CONTROLLERS

L8100C

2

VS890

PP

PP

POWERPILE®

MILLIVOLT

GENERATOR

M4752

TH

TH

1

VALVE OPERATOR

COIL

PILOTSTAT® POWER

UNIT COIL

1

DOTTED LINE SHOWS INTERNAL WIRING.

INSTALL FIELD JUMPER BETWEEN TERMINALS TH AND PP.

2

Fig. 10. L8100C hookup with VS890 to cut out main valve.

L8100C

L8100A,B

1

L1

(HOT)

CONTROLLER

L2

ECO SWITCH

3

PP

TH

V800

TH

2

VALVE OPERATOR

COIL

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

DOTTED LINE SHOWS INTERNAL WIRING.

3

SELECTED MODELS HAVE 3/16 AND 1/4 IN. TAB TERMINALS.

PP

Fig. 12. L8100A, B hookup with V800 to

cut out main valve.

L8100C

M4754

VS820

PP

TH

TH

PP

1

VALVE OPERATOR

COIL

PILOTSTAT® POWER

UNIT COIL

1

DOTTED LINE SHOWS INTERNAL WIRING.

POWERPILE®

MILLIVOLT

GENERATOR

M4753

Fig. 11. L8100C hookup with three-terminal VS820 to cut

out main gas valve.

1

L1

(HOT)

L2

PP

TH

V800

TH

2

VALVE OPERATOR

COIL

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

DOTTED LINE SHOWS INTERNAL WIRING.

PP

M4755

Fig. 13. L8100C hookup with V800 to cut out main valve.

60-2336—3

6

Page 7

L8100A,B,C Aquastat ® CONTROLLERS

L8100A,B

CONTROLLER

3

25V

25V

TH-R

TH-W

S86E,F,G,H

MV/PV

2

MV

GND

TO GAS

PV

VALVE

GND

M4756

L1

(HOT)

L2

1

2

3

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

S86E AND F MODELS ARE AVAILABLE WITH OR WITHOUT TH-R AND TH-W TERMINALS.

SELECTED MODELS HAVE 3/16 AND 1/4 IN. TAB TERMINALS.

ECO SWITCH

Fig. 14. Three-terminal L8100A,B hookup with S86E,F,G,H intermittent pilot system.

L8100A,B

CONTROLLER

3

ECO SWITCH

S86E,F,G,H

L1

(HOT)

L2

1

2

3

1

25V

25V

TH-R

TH-W

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

S86E AND F MODELS ARE AVAILABLE WITH OR WITHOUT TH-R AND TH-W TERMINALS.

SELECTED MODELS HAVE 3/16 AND 1/4 IN. TAB TERMINALS.

MV

MV/PV

PV

GND

2

GND

M4758

TO GAS

VALVE

Fig. 15. Four-terminal L8100A,B hookup with S86E,F,G,H intermittent pilot system.

7

60-2336—3

Page 8

L8100A,B,C Aquastat ® CONTROLLERS

L8100A,B

CONTROLLER

ECO SWITCH

L1

(HOT)

L2

1

S86H

3

25V

25V

TH-R

TH-W

MV

MV/PV

GND

PV

VR8440 VALVE

GND

TERMINALS

2

TH-TR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

FACTORY-INSTALLED WIRES, DO NOT REMOVE.

2

SELECTED MODELS HAVE 3/16 AND 1/4 IN. TAB TERMINALS.

3

Fig. 16. Four-terminal L8100B manual reset hookup with S86H and VR8440.

OPERATION AND CHECKOUT

Operation

When tank temperature rises past the setpoint, the liquid fill in

the sensing element expands and activates the snap-acting

switch, closing the gas valve. When the water temperature

drops below the differential, the switch opens the gas valve

and the burner begins heating the water. The ECO switch will

break the circuit to the Powerpile® millivolt generator or 24

Vac main valve before the water temperature rises to 210°F

(99°C).

TH

M4757

TR

The second element of the L8100B,C is located at the top of

the tank. These two elements sense the average temperature

in the tank. If a stacking condition begins, the L8100B,C will

close the valve before the top tank temperature becomes

excessive.

Adjusting

Adjust the control point to agree with the manufacturer’s

recommendations. To adjust, remove the cover and set the

scale to the desired control point (see Fig. 17).

SETPOINT SCALE

60-2336—3

Fig. 17. Internal view of the L8100.

8

CONTROLLER

TERMINALS

ECO SWITCH TERMINALS

(ON L8100A,B ONLY)

M4760

Page 9

Checkout

Check to verify the Aquastat® controller was installed and

adjusted properly. Put the system into operation and observe

the action of the device through several cycles to make

certain that it provides proper control of the system. Further

adjustments can then be made to meet more exact comfort

requirements.

L8100A,B,C Aquastat ® CONTROLLERS

9

60-2336—3

Page 10

L8100A,B,C Aquastat ® CONTROLLERS

60-2336—3

10

Page 11

L8100A,B,C Aquastat ® CONTROLLERS

11

60-2336—3

Page 12

L8100A,B,C Aquastat ® CONTROLLERS

Home and Building Control

Honeywell Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Home and Building Control

Honeywell Limited-Honeywell Limitée

740 Ellesmere Road

Scarborough, Ontario

M1P 2V9

60-2336—3 G.R. Rev. 10-95 Printed in U.S.A.

60-2336—3

12

Helping You Control Your World

QUALITY IS KEY

customer.honeywell.com

Loading...

Loading...