Honeywell L7248A, L7248C, L7248 L Owner's Manual

L7224A,C; L7248A,C,L

Oil Electronic

®

Aquastat

APPLICATION

The L7224A,C and L7248A,C,L 2012 Compliant Oil

Electronic Aquastat

temperature sensing in a UL limit-rated control with a

single sensing probe. The L7224A,C and L7248A,C,L

control the circulator, oil burner and boiler temperature.

The L7224/L7248 is “Outdoor Temperature Reset” ready

which is enabled when connected to the W8735S1000

Outdoor Reset Kit. Outdoor Reset with the L7224/L7248

is intended for all applications except for tankless coil

systems for domestic hot water. Compliance to 2012

DOE regulation ensures efficiency is maximized without

interfering with domestic hot water demand.

The L7224A,C and L7248A,C,L replace the L8124A,

L8124C, L7124A,C, L7148A and L8148A Controllers.

The L7224A,C and L7248A,C,L series controls provide

status and diagnostic information through an LED display

combined with LED lights as well as EnviraCOM™

communications enabled thermostats and diagnostic

tools to enhance the diagnostic process.

L7224/L7248 Aquastat Controllers are intended for use

in residential-type applications.

IMPORTANT

Use of Outdoor Temperature Reset on a tankless coil application requiring a Low Limit setting

will result in reduced system effectiveness and

efficiency.

®

Controllers provide electronic

Controllers

INSTALLATION INSTRUCTIONS

SPECIFICATIONS

Electrical Ratings:

Voltage: 120 Vac, 60 Hz.

Power: 7 VA maximum at 120 Vac plus external loads.

Thermostat current: 100 mA nominal at 24 Vac.

Burner Relay:

7.4 A at 120 Vac Full Load Amperage (FLA);

44.4 A inrush Locked Rotor Amperage (LRA);

Less Ignition Load: 360 VA.

Circulator Relay:

7.4 A at 120 Vac FLA; 44.4 A inrush LRA.

Zone Controller (ZC): 7.4 A at 120 Vac FLA;

44.4 A inrush LRA.

NOTE: All loads combined cannot exceed 2000 VA.

Environmental Ratings:

Temperature: -30 °F to +150 °F (-34 °C to +66 °C).

Humidity: 0 to 95% relative humidity, noncondensing.

Approvals:

Underwriters Laboratories Inc. Component Recognized.

Canadian Underwriters Laboratories Inc. Component

Recognized.

2012 DOE Compliance and Operation

Operation of this control may delay the burner operation while the residual heat is

circulated out of the boiler.

NOTE: This operation may be different than earlier electronic Aquastat®

revisions which did not implement thermal purge.

68-0281EFS-05

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

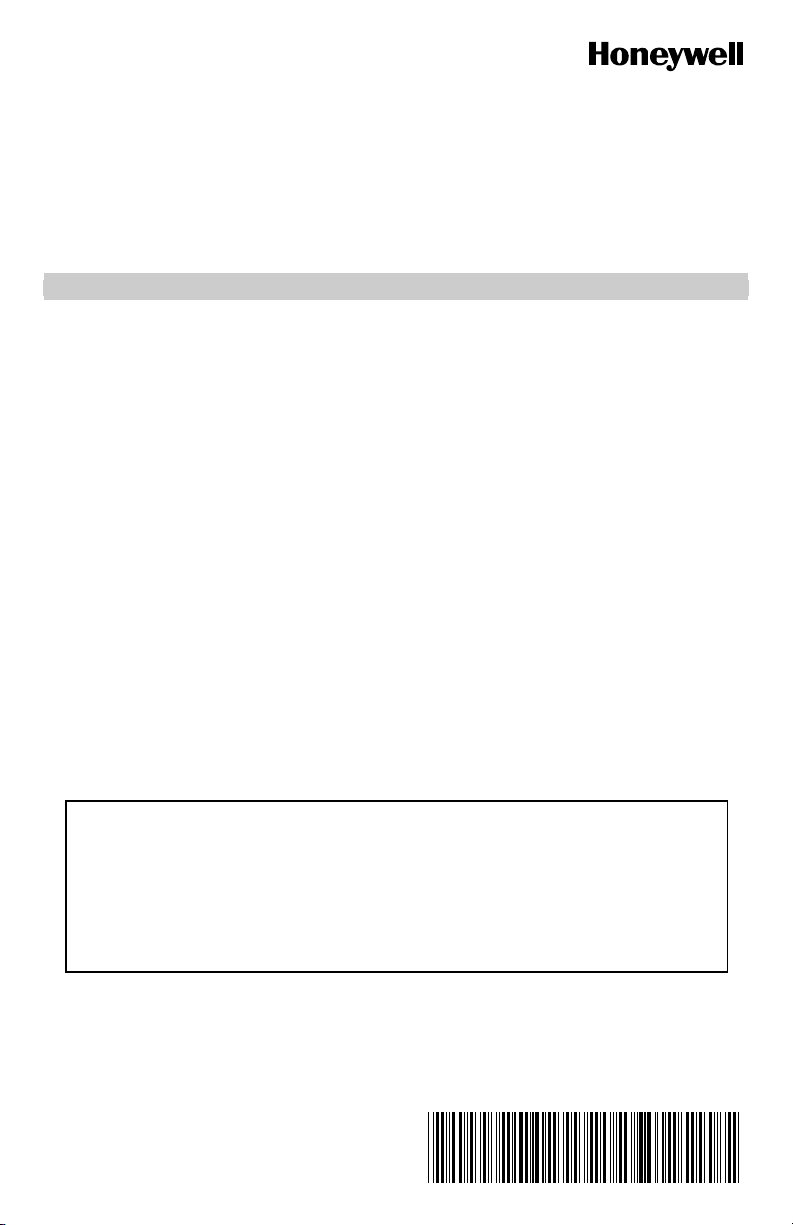

WARNING

M22147B

3/4

(75)

5-11/16

(145)

3/8

(10)

2-5/8 (67)

7-1/8

(181)

6-1/2

(166)

3-13/32 (86)

2x 1/4 (7) x 3/8 (9)

1/16 (2)

1-3/16

(30)

3-1/32

(77)

2-1/16 (53)

1-1/8 (29)

4-1/4 (109)

Accessories:

W8735Y1000 Wireless Outdoor Reset Kit

W873ER1000 Wireless Outdoor Reset Module

C7089R1013 Wireless Outdoor Temperature Sensor

(requires W8735ER1000)

W8735S1000 AquaReset™ Outdoor Reset Kit (includes

50022037-002 Outdoor Reset Module and

C7089U1006 Outdoor Temperature Sensor)

W8735S1008 AquaReset™ Domestic Hot Water Kit

(includes 50022037-005 Domestic Hot Water Module

and 32003971-003 Sensor)

W8735S3000 EnviraCOM™ Alarm Module

C7089U1006 Outdoor Temperature Sensor (used with the

50022037-002)

32003971-003 Temperature Sensor (used with

50022037-005)

Sensor (See Table 2).

14,000,485-016 1/4 in. (6.35 mm) diameter, 1-1/4 in.

(31.75 mm) long glass cartridge Fuse, 1A, Slow-Blow.

120650 Heat Conductive Compound.

121371AA Sensor Well Clamp.

Table 1. Wells for L7224A,C; L7248A,C,L Controllers.

Part

Number

Spud Size

in. (mm)

Insertion

in. (mm)

Insulation

in. (mm)

123869A 1/2 (12.7) NPT 3 (76.2) 1-1/2 (38.1)

123870A 3/4 (19.05) NPT 3 (76.2) 1-1/2 (38.1)

Table 2. Sensors for L7224A,C and

L7248A,C,L Controllers.

Part Number

Length in.

(mm) Application

50001464-001 12 (304.8) Well-mounted controls

50001464-003 24 (609.6) Flush-mounted controls

50001464-004 36 (914.4)

50001464-005 48 (1219.2)

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. The installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

5. Set High Limit, Low Limit and Low Limit Differential

to the settings recommended by the boiler OEM.

6. Record the maximum High Limit setting from the

replaced controller in the text box provided on the

cover insert label.

7. Record the High Limit setting at time of installation

in the text box provided on the cover insert label.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage.

Mounting

The L7224A,C and L7248A,C,L models are available in a

well-mount, horizontal position, vertical position, or flush

mounted remote from the well versions. Dimensions for

the variety of mounting options are shown in Fig. 1. Note

that each identity will have only a single mounting option.

Fig. 1. L7224A,C; L7248A,C,L mounting dimensions in inches (mm).

68-0281EFS—05 2

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

SENSOR WIRES

IMMERSION WELL

CLAMP SCREW

IMMERSION

WELL CLAMP

M16120

HEAT-CONDUCTIVE COMPOUND

(OPTIONAL)

CONTROLLER CASE

BOILER

IMMERSION

WELL

SENSOR

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T3

2

1

THERMOSTAT

TERMINALS

ENVIRACOM

TM

TERMINALS

SENSOR HOLES

FUSE

M32186

SENSOR

CONNECTOR

DISPLAY

IMPORTANT

Immersion well must fit sensing element and

sensor must rest against bottom of well.

New Installation

Order well assemblies separately; see Table 1 and form

no. 68-0040, Immersion Wells and Compression Fittings

for Temperature Controllers. Boilers usually have tappings

that allow the well to be mounted horizontally so boiler

water of average temperature can circulate freely over the

well.

1. Turn off all power and drain the boiler, if applicable.

2. If no tapping is provided, prepare properly sized and

threaded tapping near the top of the boiler.

3. Sparingly coat the well threads with pipe dope.

NOTE: Do not attempt to tighten by using the case

as a handle.

4. Install the well in the boiler tapping and tighten

securely.

5. Refill boiler and check for water leakage.

6. Loosen but do not remove the well clamp screw.

7. Fit the case into the well so the clamp on the case

slides over the flange on the well.

8. Securely tighten the clamp screw.

9. Insert the sensor element into the well until it bot-

toms. See Replacement Sensor Installation section

for details. (If necessary, slightly bend the wire

inside the case to hold the sensor against the bottom of the well.)

10. Turn power ON.

11. Set High Limit, Low Limit and Low Limit Differential

to the settings recommended by the boiler OEM.

(See OPERATION section.) (See INSTALLATION

steps 6 and 7.)

12. On L7248L models, adjust ELL option to match your

configuration (see OPERATION section, and Fig. 11

and 13).

IMPORTANT

Best thermal response is obtained with a well

that snugly fits the sensor. Insert the sensor until

it rests against the bottom of the well. Use a well

of correct length and bend the wiring, if necessary, to hold the bulb against the bottom of the

well.

If the well is not a snug fit on the sensor, use the

heat-conductive compound (furnished with

TRADELINE

plastic bag of compound lengthwise and twist it

gently. Then snip off end of bag and work the

open end of the bag all the way into the well.

Slowly pull out the bag while squeezing it firmly

to distribute compound evenly in the well. Bend

the wiring, if necessary, to hold the sensor

against the bottom of the well and to hold outer

end of the sensor in firm contact with the side of

the well. See Fig. 2. Wipe excess compound

from the outer end of the well.

®

models) as follows: Fold the

Fig. 2. Position of sensor in immersion well.

Flush-Mounted Aquastat

Replacement

Turn off all power and remove the old control. Refer to the

cover insert of the old control to identify and tag each

external lead as it is disconnected. If the old well is

unsuitable for the new installation, remove it and replace it

with a suitable new well. If the old well is suitable, use it.

Well-Mounted Aquastat

Replacement

Turn off all power and remove the old control. Refer to the

cover insert of the old control to identify and tag each

external lead as it is disconnected. If the old well is

unsuitable for the new installation, remove it and proceed

with instructions for new installation. If the old well is

suitable, use it.

1. Loosen, but do not remove, the well clamp screw on

the side of the control case.

2. Position immersion well clamp snugly over the

flange of the adapter and tighten the clamp screw.

3. Insert the sensor into the well as shown in Fig. 2 or

3. (See Replacement Sensor Installation section for

details.)

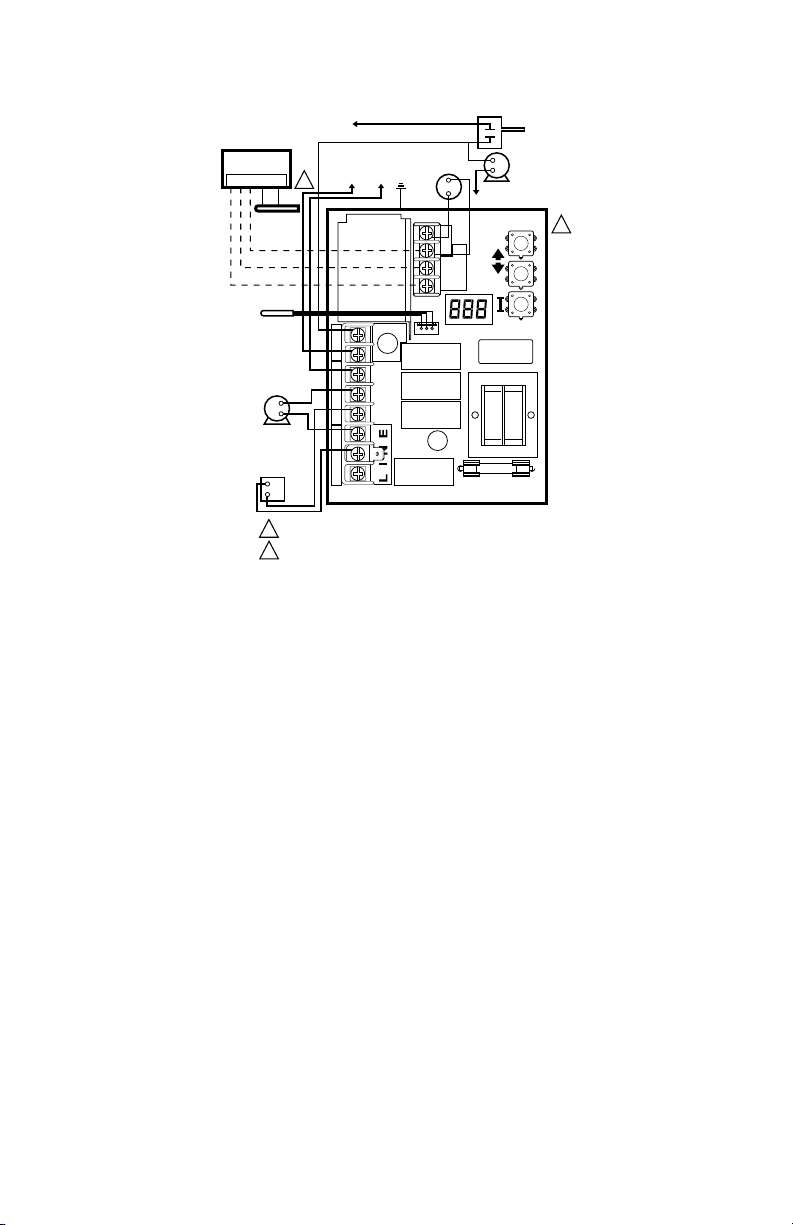

Fig. 3. Circuit board, showing sensor connection and

well holes for horizontal mount models.

3 68-0281EFS—05

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

WARNING

SENSOR WIRES

M22026

HEAT-CONDUCTIVE COMPOUND

(OPTIONAL)

BOILER

IMMERSION

WELL

SENSOR

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T3

2

1

THERMOSTAT

TERMINALS

ENVIRACOM

TM

TERMINALS

DISPLAY

SENSOR

CONNECTOR

SENSOR HOLES

FUSE

RELAYS

M32187

WIRING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect power supply before making wiring

connections to prevent electrical shock or

equipment damage.

All wiring must comply with local electrical codes and

ordinances. Do not exceed the specifications in the

Application section when wiring this control. Use wire

rated for 194 °F (90 °C) or higher.

Fig. 4. Replacement sensor installation.

Replacement Sensor Installation

Turn off all power and:

1. Carefully disconnect sensor from circuit board by

pulling gently on the connector.

2. Gently pull sensor from thermo well and through cir-

cuit board by pulling on leadwires.

3. Carefully align replacement sensor with hole in cir-

cuit board and guide through Aquastat case and

into well. (See Fig. 5).

4. Make sure sensor is fully seated to bottom of well

(See Fig. 4). Use a small pencil to measure depth of

sensor in well, if necessary.

5. Connect sensor to circuit board by pressing con-

nector on sensor unit into mating connector on circuit board (See Fig. 5).

6. For remote sensors (flush-mounted Aquastat Con-

trollers) be sure to use 121571AA Clamp (see

Accessories) to securely hold sensor in place.

IMPORTANT

The terminals on these Aquastat Controllers are

approved for use with copper wire only.

Follow the appropriate wiring diagrams shown on the

inside of the front cover of the L7224A,C; L7248A,C,L or

in Fig. 8–13.

Refer to Fig. 6 for Connections for the optional Outdoor

Reset Module and the Domestic Hot Water (DHW)

module. In subsequent wiring diagrams these modules

will be displayed with a dotted line signifying that they are

optional.

ZR

L1

L2

C2

B2

C1

B1

ZC

Fig. 6. Wiring the Outdoor Reset Module and the

50022037-002

OUTDOOR

RESET MODULE

T

3

T

2

1

LINE

1 2 3 OT OT

Domestic Hot Water Module.

C7089U1006

OUTDOOR

SENSOR

50022037-005

DOMESTIC HOT

WATER MODULE

1 2 3 TS TS

32003971-003

TEMPERATURE

SENSOR

M29651

Fig. 5. Circuit board, showing sensor connection and

Fuse

The 1 Amp fuse located near the transformer is intended

to protect the EnviraCOM circuit from incorrect wiring. The

Aquastat will continue to function should the fuse blow or

be removed though no EnviraCOM communication will be

possible on the bus and Err 6 will be displayed. See

Table 1 0 .

68-0281EFS—05 4

well holes for vertical mount models.

OPERATION

General

The L7224A,C and L7248A,C,L Oil Electronic Aquastat

Controllers are primary safety limit-rated devices

designed for use with oil fired boilers with line voltage

burners and circulators. Many boilers do not include

wiring or control compartments as part of the design, but

are provided with an integral, replaceable, immersion well

that is the mounting hardware for the Aquastat

Controllers. Wiring to the other controls is done through

flexible metal conduit.

For boilers that do include a remotely (flush) mounted

control, the wiring may be completed with conduit or

routed behind the boiler sheet metal.

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

A separate electromechanical high-limit is not required in

a system that uses this control to meet Underwriters

Laboratories Inc. requirements for oil-fired boiler

assemblies, UL 726.

On the L7224 models, the High Limit, Low Limit, Low Limit

Differential, and Anti Short-Cycle time can be adjusted to

the setting recommended by the boiler OEM. On the

L7248 models, the High Limit, and Anti Short-Cycle time

are also adjustable, see “Adjusting Settings”.

The overall range of the High Limit is from 130 °F to

240 °F (54 °C to 116 °C). Select devices may have

different ranges. Some models have limited ranges on the

High Limit setpoint; this limited range is listed on the

device label.

Some models also have a Low Limit and Low Limit

Differential adjustment. The range of the Low Limit is from

110 °F to 220 °F (43 °C to 104 °C). Select devices may

have different ranges.

The Zr setting can be set to DHW, Zoning, or for tankless

coil applications depending on the L7224/L7248.

If a W8735S1000 AquaReset™ Outdoor Reset Module is

installed, the reset curve can be set by entering the

minimum outdoor temperature, minimum (boiler)

temperature, and maximum outdoor temperature on the

3-digit display. The range of the minimum outdoor

temperature is from -40 °F to 40 °F (-40 °C to 4.4 °C) and

has a default setting of 0 °F (-18 °C). The range of the

maximum outdoor temperature is from 30 °F to 70 °F

(-1.1 °C to 21.1 °C) and has a default setting of 40 °F. The

range of the minimum (water or boiler) temperature is

from 80 °F to 180 °F (26.7 °C to 82.2 °C) and has a

default setting of 130 °F. See the “Outdoor Reset Module”

Installation Instructions (form number 69-2335) for more

information on setting the boiler reset curve and all related

parameters.

The L7224A,C and L7248A,C,L are designed for use with

24 Vac electronic and electromechanical thermostats or

EnviraCOM™ enabled thermostats, and have screw-type

terminals for easy field connection.

Adjusting Settings

To discourage unauthorized changing of Aquastat

settings, a procedure to enter the ADJUSTMENT mode is

required. To enter the ADJUSTMENT mode, press the

UP, DOWN, and I buttons (Refer to Fig. 5) simultaneously

for three seconds. Press the I button until the feature

requiring adjustment is displayed:

Table 3. Adjustable Features.

Display Definition

HL_ High Limit.

Hdf High Limit Differential.

LL_ Low Limit. (L7224A, C)

Ldf Low Limit Differential (L7224A, C)

ELL External Low Limit (L7248L only)

duu ZR input configured as external Domestic Hot

Water (DHW) request (ON/OFF) (L7224A,C/

L7248L)

ASC Anti Short-Cycle Timeout (seconds); “OFF” is

disabled.

otL* Outdoor Temperature Low (minimum)

parameter for the outdoor reset curve (°F or °C)

otH* Outdoor Temperature High (maximum)

parameter for outdoor reset curve (°F or °C)

btL* Boiler Temperature Low (minimum) parameter

for outdoor reset curve

bP* Boost Period (minutes). “OFF” is displayed if

Boost is inactive

bS* Boost step (°F or °C) shown only if Boost is

active (bP=ON)

UUS* Warm Weather Shutdown Temperature

(°F or °C)

tPL** Thermal Purging Limit Temperature (°F or °C),

“OFF” if disabled

tPt** Termal Purging Time Delay (minutes), shown

only if tPL is enabled

PC Pump Cycling (ON / OFF)

F-C Temperature units (°F or °C)

* Settings available for adjustment on the 3-digit display

only if the W8735S1000 AquaReset Outdoor Reset

Module is installed.

**Settings available for adjustment only when the

W8735S1000 AquaReset Outdoor Reset Kit is NOT

installed.

Then press the UP and/or DOWN buttons to move the set

point to the desired value, to change between °F and °C,

or to enable (On) or disable (Off) the External Low Limit.

After 60 seconds without any button inputs, the control will

automatically return to the RUN mode.

Display

In the RUN mode, the Aquastat will flash “bt” (boiler temp)

followed by the temperature (i.e., 220), followed by °F or

°C.

To read boiler settings, press the I key to read the

parameter of interest. For example, press I and High Limit

(HL) is displayed, followed by a three-digit number, i.e.,

220, followed by °F or °C. Pressing the I button again (on

L7224 models) will display the Low Limit (LL) followed by

a three-digit number and the corresponding degree

designator. See Display Readout, Table 4.

After approximately 60 seconds without any key presses,

the display will enter a dim display mode. To return to the

bright display mode, simply press any key.

5 68-0281EFS—05

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

LOW LIMIT

SETTING

HIGH LIMIT

SETTING

SWITCH BREAKS ON

TEMPERATURE RISE.

BURNER TURNS OFF.

CIRCULATOR OPERATES

ON A CALL FOR HEAT.

SWITCH MAKES ON

TEMPERATURE FALL.

BURNER OPERATES ON A

CALL FOR HEAT.

WITH NO HEATING

DEMAND, SWITCH BREAKS

ON TEMPERATURE RISE.

SWITCH MAKES ON

TEMPERATURE FALL,

BURNER IS ON TO

MAINTAIN MINIMUM

WATER TEMPERATURE.

CIRCULATOR IS OFF.

M23364

WHEN WATER REACHES LOW LIMIT SETTING, THE BURNER SHUTS

OFF OR THE CIRCULATOR PUMP STARTS (WHEN CALLING FOR HEAT).

1

1

10ºF (6ºC)

DIFFERENCE

L7224: 10°F (6°C)

DIFFERENCE

L7248: 15°F (8°C)

DIFFERENCE

Table 4. Display readout definitions.

Text Description Display

Err Error Code (if one is present)

bT Boiler Temperature

High Limit

1

HL

HdF High Limit Differential

LL Low Limit (L7224 only)

Ldf Low Limit Differential (L7224 only)

tt Local Thermostat Status

ttE EnviraCOM Thermostat Status

brn B1 (Burner) output (ON or OFF)

Cir C1 (Circulator) output (ON or OFF)

ZC ZC (Zone Control) output (ON or OFF)

Zr ZR (Zone Request) Call for HEAT (ON or OFF)

ELL External Low Limit Enabled (L7248L only)

duu ZR Configured as Domestic Hot Water

Request (L7224, L7248L only)

ASC Anti Short-Cycle Timeout

bSP

Boiler Set-Point

dhc

DHW Module Connected

ot

Outdoor Temperature

otL

Outdoor Temperature Low

otH

Outdoor Temperature High

btL

Boiler Temperature Low

bP

Boost Period

bS

Boost Step

UUS

Warm Weather Shutdown Temperature

1

Display shows local setting; not the setting as modified by an

external enviracom control.

2

Settings are viewable only if the outdoor reset module and out-

door temperature sensor are installed and functioning properly.

3

Settings are viewable only if the domestic hot water module

and sensor are installed and functioning properly.

Operation

The L7224 and L7248 models can be in any of four

operational states: Normal, High Limit, Low Limit and

Error. The controller moves back and forth from

High Limit to Normal to Low Limit state as part of normal

operation. Only devices having High Limit settings are

restricted to the High Limit and Normal states. However,

the controller will enter the Error state when there is an

abnormal condition. The operating states are:

1. Normal: Boiler temperature went below the High

Limit setting (minus the Differential) and has not

exceeded the High Limit setting; or, the boiler

temperature went above the Low Limit setting and

68-0281EFS—05 6

2

3

2

2

2

2

(YES or NO)

2

2

2

has not gone below the Low Limit setting (minus the

Differential); or, ZR input is not powered with 120

Vac (only L7248L with ELL set On).

2. High Limit: Boiler temperature went above the High

Limit setting and has not dropped below the High

Limit setting (minus the Differential).

3. Low Limit: Boiler temperature went below the Low

Limit setting (minus the Low Limit Differential) and

has not gone above the Low Limit setting; or, ZR

input is powered with 120 Vac (only L7248L with

ELL set On).

4. Error: The controller has detected an error condition

(e.g., open sensor) and has shut down the burner

output. The ZC output is energized. The controller

continues to monitor the system and automatically

restarts if the error condition clears. Refer toTable 4.

The operating sequence for the L7224/L7248 is shown in

Table 6–9.

High Limit Controller

The High Limit opens and turns off the burner when the

water temperature reaches the setpoint. The High Limit

automatically resets after the water temperature drops

past the setpoint and through the Differential. The L7248

models have High Limit Differential presets of 15 °F

(8 °C). The L7224 models have High Limit Differential

presets of 10 °F (6 °C).

Low Limit and Circulator

Controller

On a temperature rise, with the adjustable Differential at

the default setting of 10 °F (6 °C), the burner circuit

breaks and the circulator circuit makes (assuming no call

for heat is present) at the Low Limit setpoint. On a

temperature drop of 10 °F (6 °C) below the Low Limit

setpoint, the burner circuit makes and the circulator circuit

breaks. See Fig. 7.

Fig. 7. Setpoints and differentials.

Anti Short-Cycle Feature

The Anti Short-Cycle feature allows for field selection of a

delay time between burner cycles. Should a call for heat

occur following the end of the previous heat cycle and

before the Anti Short-Cycle delay time is expired, the

circulator will be allowed to run, but the burner will be held

off until the time has elapsed. The range of the Anti ShortCycle time is from OFF to five minutes.

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

NOTE: This feature is blocked if a Domestic Hot

Water demand occurs. Domestic Hot Water

demands are serviced immediately, without

any delay.

NOTE: When the Aquastat is connected to the oil

primary and/or thermostat via the EnviraCOM

bus, the Anti Short-Cycle time does not apply

to recycle events such as loss of airflow or

flame. It applies only to loss of demand.

ZR-Domestic Hot Water (DHW)

Request

The ZR terminal can be selected to service an indirect

water heater heat request. This parameter is set via the 3

digit display (see Adjusting Settings section of this

document). A heat request via the ZR terminal will have

priority over all other features such as the Anti ShortCycle feature or those enabled by the Outdoor Reset

Module (See form #69-2335 for more information).

Frost Protection

The Frost Protection function protects the boiler and

potentially the boiler plumbing from possible damage

which may occur should the water in the system begin to

freeze. The Frost Protection feature is enabled only in the

L7248 (cold start models). The feature default setting is

enabled (ON), but can be disabled using the 3-digit

display. See “Adjusting Settings” on page 5.

When the Boiler temperature drops to the Frost Protection

Limit temperature (fixed 40 °F), the burner is forced on.

The Circulator and ZC outputs remain in the same state

as before the Frost Protection function was enabled.

They can be either ON or OFF during the Frost Protection

cycle.

Table 5. Thermal Purge Settings.

Parameter name Minimum value Maximum Value Default

Boiler temperature drop Not adjustable Not adjustable 10 °F

Thermal purge temperature limit 120 °F (or OFF) 160 °F 140 °F (L7248)

Thermal purge temperature rate of drop Not adjustable Not adjustable 5 °F/minute

Thermal purge time delay 1 minute 10 minutes 2 minutes

When the Boiler temperature reaches the Frost Protection

Limit temperature plus a fixed 10 °F differential, the burner

is turned off unless requested to stay on due to a different

demand.

Thermal Purge Operation

The intent of thermal purge is to insure usable residual

heat in the boiler is circulated until it is sufficiently

depleted from the system before the burner is allowed to

fire. To that end, on a call for heat, the burner is held off

while the circulator runs until the boiler temperature drops

to the thermal purge temperature or a time delay is

exceeded. Both of these parameters are adjustable.

When the boiler temperature reaches the thermal purge

temperature, the burner is allowed to fire. Thermal purge

is only applied to cold start Aquastat models (L7248) and

will not interfere with domestic hot water call for heat or

boilers equipped with Honeywell outdoor reset

accessories. For warm start models where a Low Limit

must be set, thermal purge is not applied.

In addition to the thermal purge temperature and thermal

purge time delay parameters, two other conditions release

the Aquastat from thermal purge in order to maintain

comfort in the space:

• The boiler temperature has dropped 10 °F from the

beginning of the thermal purge.

• Boiler temperature is cooling at a rate greater than

5 °F/minute while the circulator is running.

The thermal purge feature applies to single zone as well

as multi-zone applications.

Thermal Purge Settings

Some thermal purge parameters are configurable using

the 3 digit display. See “Adjusting Settings” on page 5.

Thermal purge may be disabled by setting the thermal

purge temperature limit to "OFF".

Thermal Purge and Domestic Hot

Water

The thermal purge feature is automatically disabled

whenever there is a call for domestic hot water from the Zr

terminal to ensure hot water is available in a timely

manner. See “ZR-Domestic Hot Water (DHW) Request”

on page 7.

Pump Cycling

The Pump Cycling feature exercises the system pump for

15 seconds after a non-adjustable five day period of no

boiler activity. The Pump Cycling feature default setting is

enabled (ON) but can be disabled (OFF) using the 3-digit

display. See “Adjusting Settings” on page 5.

CHECKOUT

Put the system into operation and observe at least one

complete cycle to make sure that the controller operates

properly. See TROUBLESHOOTING section to use LED

to assist in determining system operation.

TROUBLESHOOTING

When attempting to diagnose system performance,

reference to the LED display can help to identify specific

areas not working properly. The LED display will scroll

Err, followed by a digit (1-8). Refer to Table 10 and 11 for

a description of each error and suggested actions.

7 68-0281EFS—05

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

LINE VOLTAGE INDIRECT

LINE

TANK AQUASTAT

L2

T

T3

2

1

INDIRECT

TANK

CIRCULATOR

M32023

2

50022037-002

OUTDOOR

RESET MODULE

1 2 3 OT OT

C7089U

OUTDOOR

SENSOR

SENSOR

LINE

VOLTAGE

CIRCULATOR

LINE

VOLTAGE

OIL BURNER

RELAY

1

2

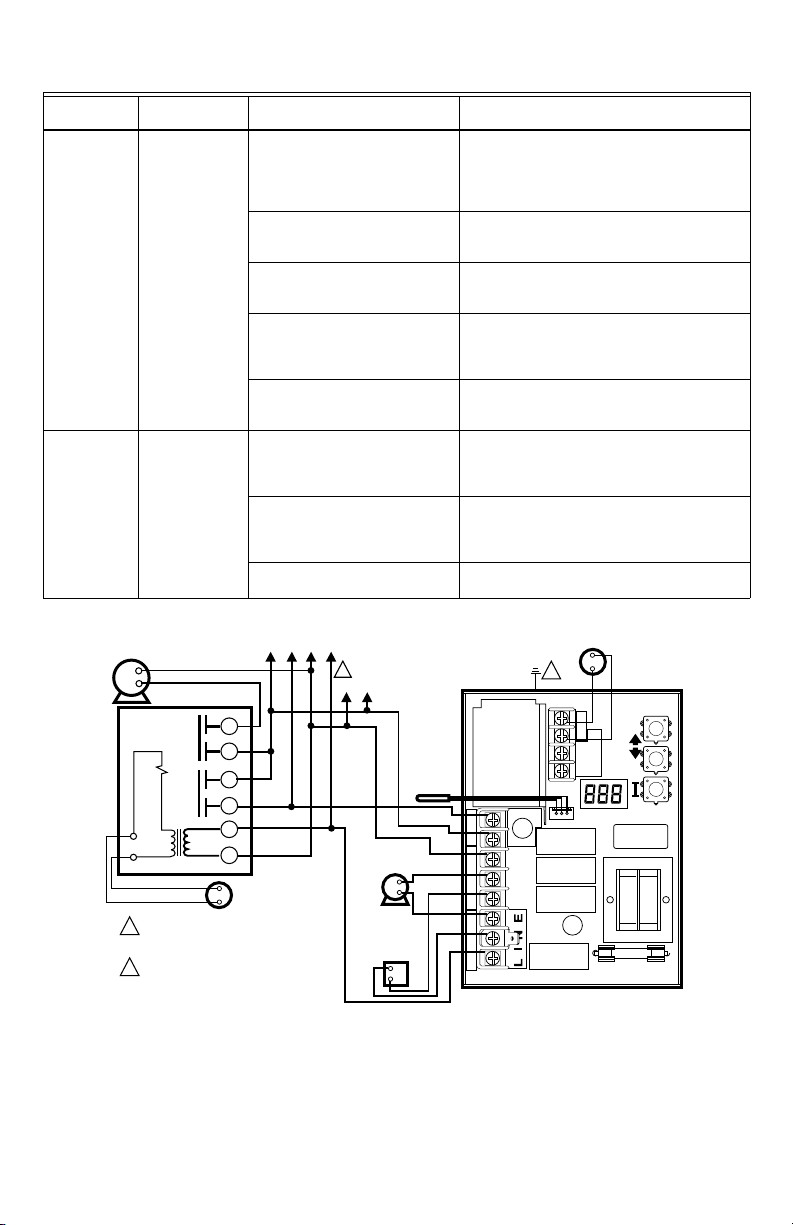

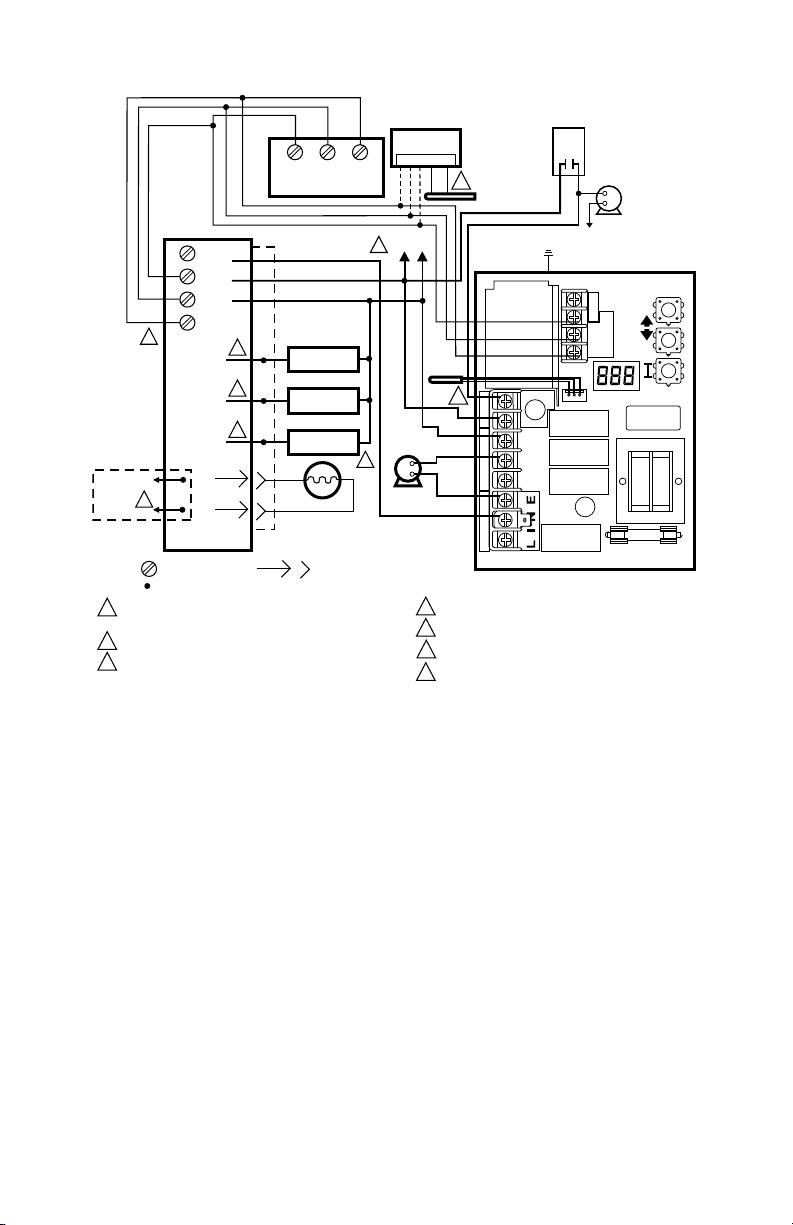

Fig. 8. L7224A,C; L7248L single heat zone with indirect water tank and circulators. Optional Outdoor Reset

L1

(HOT)

L1

(HOT)

1

OUTDOOR RESET MODULE IS OPTIONAL.

FOR BEST PERFORMANCE SET DUU=”ON”.

L2

ZR

L1

L2

C2

B2

C1

B1

ZC

Module.

68-0281EFS—05 8

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

Table 6. L7224/L7248 Controller Operating Sequence.

Action System Response

Thermostat calls for heat. Circulator starts when water temperature is above Low Limit setting (if

Boiler temperature exceeds the High Limit. Burner is turned off. Burner restarts when the water temperature

applicable) or above the Thermal Purge Temperature Limit (tPL) if

Thermal Purge is enabled. Boiler temperature is checked. Burner

starts when water temperature is below High Limit setting minus the

differential or at or below the Thermal Purge Temperature Limit (tPL)

for cold start boilers if the Thermal Purge Temperature Limit is

enabled. If tPL is enabled, the burner may also start if the boiler

temperature is cooling at 10 ºF or greater per minute or the Thermal

Purge Time Delay (tPt) has expired.

If Anti Short-Cycle Time is enabled, the burner does not start until the

set Anti Short-Cycle Time between cycles expires after the previous

call for heat was satisfied.

drops below the High Limit setting minus the Differential. If Thermal

Purge is enabled, the burner is turned on when either the Thermal

Purge Temperature Limit is reached, the Thermal Purge Time Delay

has expired or the boiler temperature cooling rate exceeds 10 ºF/

minute.

Thermostat is satisfied. Circulator and burner turn off.

Boiler temperature drops below the Low Limit

setting minus the differential (if applicable).

Error condition

1-5.

Burner is turned on, Circulator is turned off. Burner stops when the

water temperature exceeds the Low Limit setting. Power to Zc is

removed.

If an error condition is detected, all outputs except ZC are shut down.

Burner is off. Control continues to function and restarts when error is

corrected.

During the error check sequence, the system checks for drift in the

sensor and corrosion in the connections.

Error condition 6. EnviraCOM communication is not available.

Error condition 7. The control has reset the High Limit, Low Limit and Differential setting to

Error condition 8. If the error condition is detected, all outputs except ZC are shut down.

a default setting and will continue to run at those settings.

Performance of the system will be degraded.

Burner is off. Control continues to function and restarts when all three

user keys have been pressed longer than 60 seconds.

Error condition 9*. System continues to run with no outdoor reset functionality

Error condition 10*. System continues to run with outdoor reset parameters enabled as

programmed. Error cleared automatically.

Error condition 11*. System continues to run with boiler temp set to High Limit.

* Error condition only available when the Outdoor Reset Module is installed.

Table 7. L7224/L7248 Controller Operating Sequence with multiple zones connected through the ZR terminal.

Action System Response

Zone Request (ZR) terminal is connected to

L1 (Zone calls for heat).

Boiler temperature exceeds the High Limit. Burner is turned off. Burner restarts when the water temperature

Zone Request input is de-energized (Zones

are satisfied).

Boiler temperature drops below the Low Limit

setting minus the differential (if applicable).

Boiler temperature is checked. Burner starts when water temperature

is below High Limit setting or at or below the Thermal Purge

Temperature Limit (tPL) for cold start boilers if the Thermal Purge

Temperature Limit is enabled. If tPL is enabled, the burner may also

start if the boiler temperature is cooling at 10 ºF or greater per minute

or the Thermal Purge Time Delay (tPt) has expired. Anti Short-Cycle

Time is applied, see Table 6.

drops below the High Limit setting minus the Differential. If Thermal

Purge is enabled, the burner is turned on when either the Thermal

Purge Temperature Limit is reached, the Thermal Purge Time Delay

has expired or the boiler temperature cooling rate exceeds 10 ºF/

minute.

Burner turns off.

Burner turns on and Zone Control is de-energized. Burner turns off

and Zone Control is re-energized when the water temperature

exceeds the Low Limit setting.

9 68-0281EFS—05

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

.

Table 8. Controller Operating Sequence with External Low Limit device connected trough the ZR terminal.

Action System Response

Zone Request (ZR) terminal is connected to

L1 (External Low Limit call for heat).

Boiler temperature exceeds the High Limit. Burner is turned off. Burner restarts when the water temperature

Zone Request input is de-energized (External

Low Limit is satisfied).

Boiler temperature is checked. Burner starts when water temperature

is below High Limit setting. Circulator turns off.

drops below the High Limit setting minus the Differential.

Burner is turned off.

Table 9. L7224 Controller Operating Sequence with Domestic Hot Water connected trough the ZR terminal.

Action System Response

Zone Request (ZR) terminal is connected to

L1 (Domestic Hot Water calls for heat).

Boiler temperature exceeds the High Limit. Burner is turned off. Burner restarts when the water temperature

Zone Request input is de-energized

(Domestic Hot Water is satisfied).

Boiler temperature is checked. Burner starts when water temperature

is below High Limit setting.

drops below the High Limit setting minus the Differential.

Burner is turned off.

Table 10. LED Error Codes.

Aquastat

Error Code Cause/Action

EnviraCOM

Alarm

Err1 Aquastat sensor fault; check water sensor. 18

Err2 ECOM fault; check EnviraCOM™ wiring. 18

Err3 Excessive electrical noise or frequency out of range. Hardware fault; replace controller. 18, 58

Err4 B1 fault; check B1 wiring/voltage. 64

Err5 Low Line; check L1-L2, 110 Vac. 59

a

Err6

Warning: Fuse; check ECOM wires, replace fuse. 92

Err7 Warning: EEPROM, HL, LL, Hdf, Ldf; reset to default values. N/A

b

Err 8

Err9

Err 10

Err 11

a

Warnings are generated to enunciate the system is not operating optimally, but the Aquastat is still operating and

maintaining boiler temperature. In the instance where an Outdoor Reset Module is used, the warnings may indicate a

reset curve setting error one or more features is not running optimally, and the Aquastat is reverting to default settings

or has stopped running the Outdoor Reset algorithms. The warnings are cleared when the issue(s) is resolved.

b

To clear Err 8 condition, depress and hold all three user keys simultaneously for 60 seconds. Err 8 condition clears

and display returns to normal. Err 8 condition is designed to catch welded relays on the Aquastat and will normally

only occur near end of life for the control. If Err 8 condition has occurred early in the controls life, be sure to check for

voltage feedback to B1 when B1 should be off and check current draw on b terminal to be sure oil burner is not drawing excessive current. Err 8 condition will keep repeating if B1 fault is not cleared.

Repeated B1 fault (voltage present at B1 when output is turned off); check B1 wiring/voltage. 25

a

Warning: Outdoor Reset System failure; communication to Outdoor Reset Module lost,

Outdoor Reset Module failure, multiple outdoor temperature sensors detected on the bus, or

outdoor temperature sensor failure. Check EnviraCOM wiring (1, 2, 3), check sensor wiring.

a

Warning: Boost Failure; Boost Mode active at least once per cycle for the last 60 consecutive

cycles. Check Outdoor Reset curve settings.

a

DHW Module/Sensor failure; communication to DHW Module lost, DHW Module failure, or

temperature sensor failure. Check EnviraCOM wiring (1, 2, 3), check sensor wiring.

50, 53, 149

150

146, 147,

148

Table 11. Troubleshooting Guide

System

Condition

Boiler is cold,

house is cold.

Diagnostic

Condition Check Action

Display is OFF. 120 Vac System power. Turn system power on.

Display is ON. 24 Vac T-T No 24 V; replace control.

24 V present; disconnect

thermostat, short T-T.

120 Vac at B1-B2 • If no, replace control.

Refer to Err on display. —

68-0281EFS—05 10

Boiler starts, check wiring and thermostat.

• If yes, check burner and wiring.

System

M27115

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

1

CONTROL CASE MUST BE CONNECTED

TO EARTH GROUND. USE GROUNDING

SCREW PROVIDED.

2

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T3

2

1

SENSOR

LINE

VOLTAGE

CIRCULATOR

LINE

VOLTAGE

OIL BURNER

RELAY

2

LOW

VOLTAGE

THERMOSTAT

L7224

3

L1

(HOT)

L2

1

2

1

4

5

6

ZONE 2

LOW VOLTAGE

THERMOSTAT

R845A RELAY ZONE 2

ZONE 2

CIRCULATOR

TO ADDITIONAL R845A

RELAYS FOR OTHER ZONES

Condition

Boiler is hot,

house is cold.

Boiler is hot,

no hot potable

water.

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

Table 11. Troubleshooting Guide

Diagnostic

Condition Check Action

Display is ON. 120 Vac at C1-C2 • 120 Vac at C1-C2, check wiring to pump.

Boiler below the Low Limit

temperature, wait for boiler to go

above Low Limit temperature.

Boiler above LL? If yes, check for

120 Vac between ZC and L2.

ELL setting (L7248L only) • Set ELL to Off for multizone system (see Fig.

Boiler above LL? If yes, check 120

Vac at ZR-L2 (only L7248L with

ELL set On)

Display is ON. Boiler Demand signal from the

water heater (either 120 Vac at

ZR-L2, or 0 Vac on T-T; depends

on installation and “duu” setting)

“duu” setting • Set duu to ON if 120 Vac water heater

Check DHW Module and DHW

Sensor

• Wiring OK, is pump running?

• If not, replace the pump.

• If pump is running, check for trapped air or

closed zone valves.

—

• If no 120 Vac, replace control.

• If yes, check zone relays, circulators and

wiring.

11).

• Set ELL to On for External Low Limit (see

Fig. 13).

• If no 120 Vac, check C1-C2 (see above).

• If yes, check the External Low Limit control.

• 24 Vac on T-T (or 0 Vac on ZR-L2), check

wiring to water heater

• Wiring OK, check the water heater

demand is connected to ZR

• Set duu to OFF if open/closed water heater

demand is connected to T-T

• DHW Module not properly connected and/or

DHW Sensor improperly positioned

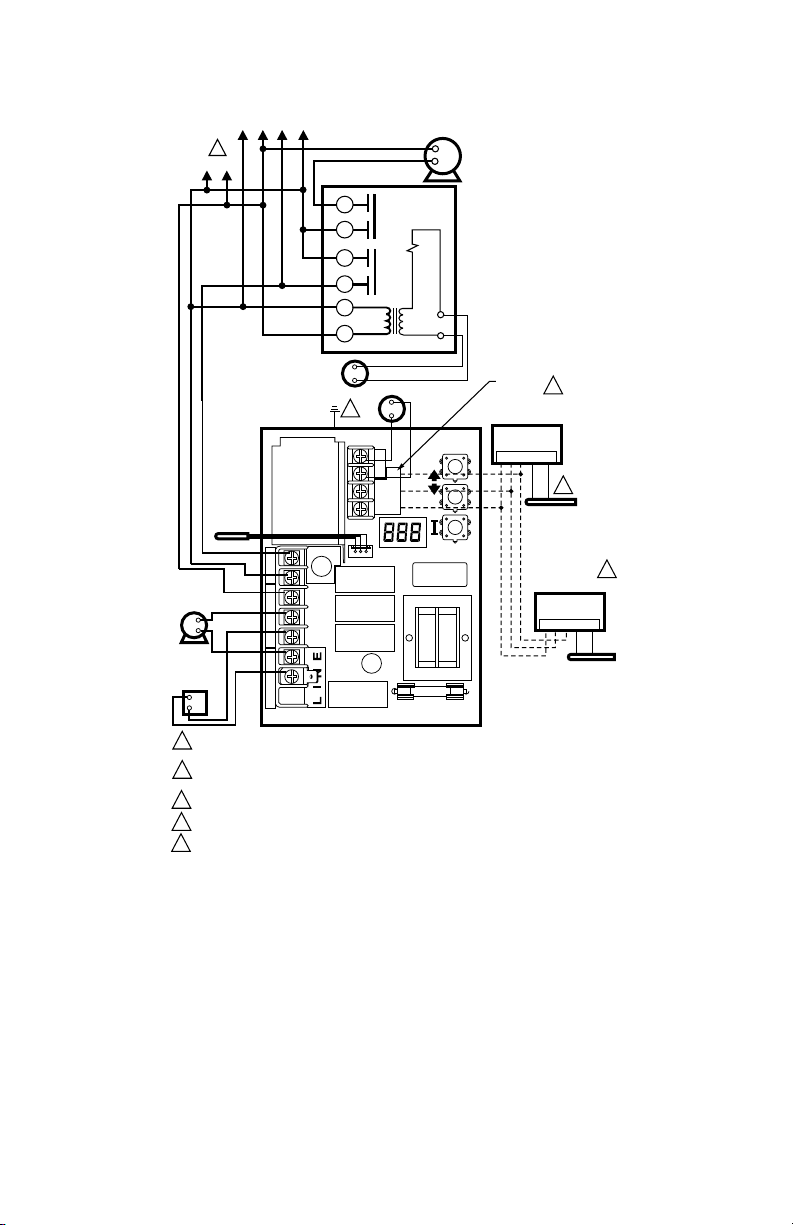

Fig. 9. L7224A,C multizone system with circulator connections.

11 68-0281EFS—05

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

M32025

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

OPTIONAL FEATURE ON SELECT MODELS.

REFER TO DEVICE LABEL FOR WIRE COLOR CODE.

1

2

3

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T

3

3

3

2

2

2

1

1

1

SENSOR

LINE

VOLTAGE

CIRCULATOR

L7224

3

4

3

3

5

BURNER

MOTOR

IGNITOR

VALV E

BURNER

MOTOR

IGNITOR

VALV E

CAD

CELL

JUNCTION

BOX

TO REMOTE

ALARM

CIRCUIT

ENVIRACOM™

TERMINAL

TH9421C

R7184

LIMIT

L1

L2

2

CAD

CELL

T

T

3

2

1

L1

(HOT)

L2

1

LEGEND SCREW TERMINAL 1/4 IN. (6 MM) QUICK CONNECT TERMINAL

SOLDERLESS WIRE CONNECTION

VALVE IS OPTIONAL ON SPECIFIED MODELS.

ENVIRACOM™ TERMINAL 3 IS ALSO THE FIRST THERMOSTAT TERMINAL.

OPTIONAL OUTDOOR RESET MODULE AND OUTDOOR SENSOR.

DUU MUST BE SET TO “ON” ON THE AQUASTAT.

4

5

6

1 2 3 OT OT

C7089U1006

OUTDOOR

SENSOR

6

50022037-002

OUTDOOR

RESET MODULE

7

INDIRECT

TANK

CIRCULATOR

LINE VOLTAGE

INDIRECT

TANK AQUASTAT

L2

7

Fig. 10. L7224A,C single zone system with circulator and indirect water tank with EnviraCOM™ thermostat.

68-0281EFS—05 12

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

M29655

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

1

CONTROL CASE MUST BE CONNECTED TO EARTH GROUND. USE GROUNDING

SCREW PROVIDED.

2

3

L1

(HOT)

L2

1

2

1

4

5

6

ZONE 2

LOW VOLTAGE

THERMOSTAT

R845A RELAY ZONE 2

ZONE 2

CIRCULATOR

TO ADDITIONAL R845A

RELAYS FOR OTHER ZONES

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T 3

2

1

SENSOR

LINE

VOLTAGE

CIRCULATOR

LINE

VOLTAGE

OIL BURNER

RELAY

2

LOW VOLTAGE

THERMOSTAT

L7248L

ELL=OFF

OPTIONAL OUTDOOR RESET MODULE AND OUTDOOR SENSOR.

ENVIRACOM TERMINALS.

OPTIONAL DOMESTIC HOT WATER MODULE AND TEMPERATURE SENSOR.

3

4

5

1 2 3 OT OT

C7089U1006

OUTDOOR

SENSOR

50022037-002 OUTDOOR

RESET MODULE

1 2 3 TS TS

50022037-005

DOMESTIC HOT

WATER MODULE

32003971-003

TEMPERATURE

SENSOR

4

ENVIRACOM

TERMINALS

3

5

Fig. 11. L7248L multizone system with circulator connections.

13 68-0281EFS—05

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

M32024

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

OPTIONAL FEATURE ON SELECT MODELS.

REFER TO DEVICE LABEL FOR WIRE COLOR CODE.

VALVE IS OPTIONAL ON SPECIFIED MODELS.

ENVIRACOM™ TERMINAL 3 IS ALSO THE FIRST THERMOSTAT TERMINAL.

1

2

3

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T

3

2

1

SENSOR

LINE

VOLTAGE

CIRCULATOR

L7224

3

4

3

3

5

BURNER

MOTOR

IGNITOR

VALV E

BURNER

MOTOR

IGNITOR

VALV E

CAD

CELL

JUNCTION

BOX

TO REMOTE

ALARM

CIRCUIT

ENVIRACOM™

TERMINAL

R7184

LIMIT

L1

L2

2

CAD

CELL

T

T

3

2

1

L1

(HOT)

L2

1

LEGEND SCREW TERMINAL 1/4 IN. (6 MM) QUICK CONNECT TERMINAL

SOLDERLESS WIRE CONNECTION

OPTIONAL OUTDOOR RESET MODULE AND OUTDOOR SENSOR.

OPTIONAL DOMESTIC HOT WATER MODULE.

WIRE ONLY THE ENVIRACOM TERMINALS (1, 2, 3) ON OIL PRIMARY

IF CONNECTING TO REMOTE DIAGNOSTICS, OTHERWISE CONNECT

A JUMPER BETWEEN THE TT TERMINALS.

ZONE PANEL TERMINALS MAY HAVE DIFFERENT LABEL. CHECK

PANEL MANUFACTURER SPECIFICATIONS FOR WIRING INSTRUCTIONS.

6

7

8

1 2 3 TS TS

32003971-003

TEMPERATURE

SENSOR

7

50022037-002

DOMESTIC HOT

WATER MODULE

9

MULTI-ZONE

RELAY PANEL

T T

4

5

1 2 3 OT OT

C7089U

OUTDOOR

SENSOR

6

50022037-002

OUTDOOR

RESET MODULE

8

9

applications).

Fig. 12. L7224/L7248 multizone system with Outdoor Reset and Domestic Hot Water Modules (indirect tank

68-0281EFS—05 14

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

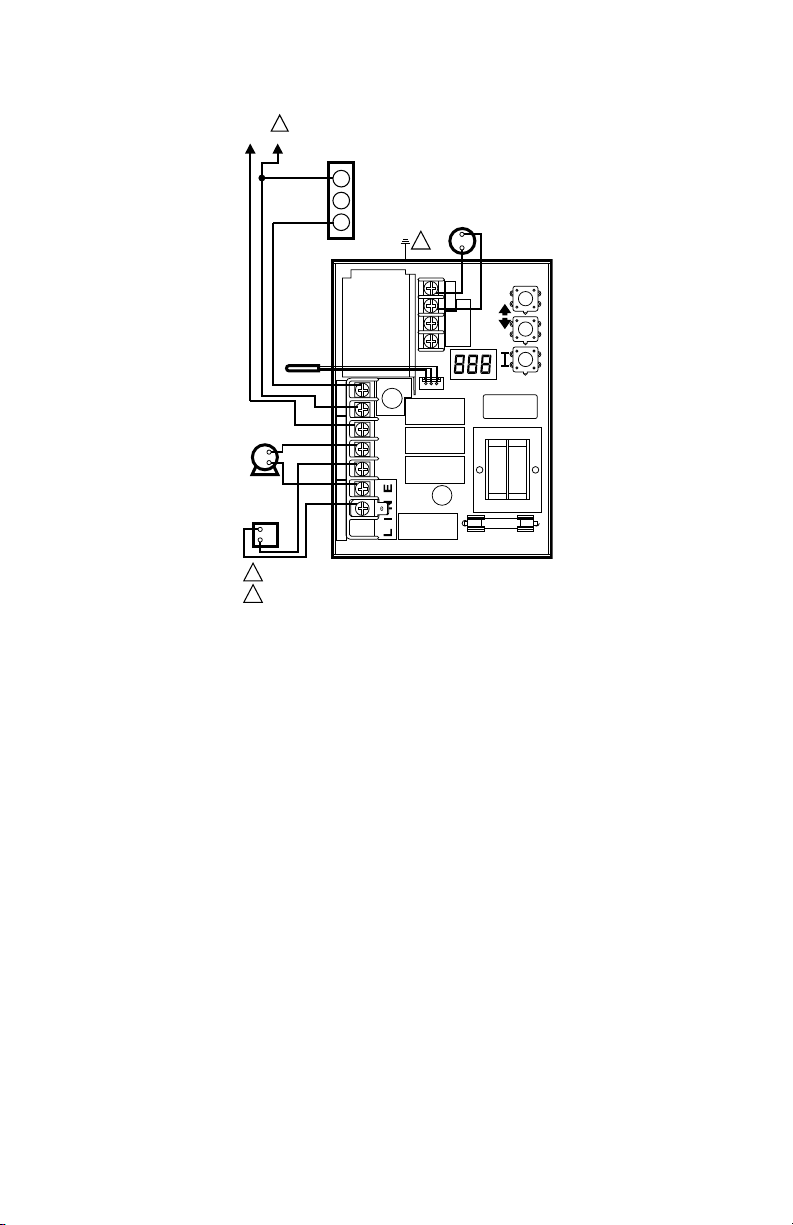

M27113

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

1

CONTROL CASE MUST BE CONNECTED TO EARTH GROUND.

USE GROUNDING SCREW PROVIDED.

2

W

L1 (HOT)L2

1

B

R

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T3

2

1

SENSOR

LINE

VOLTAGE

CIRCULATOR

LINE

VOLTAGE

OIL BURNER

RELAY

2

LOW

VOLTAGE

THERMOSTAT

L7248L

ELL=ON

L6006

LOW LIMIT

CONTROLLER

Fig. 13. L7248L External Low Limit connections.

15 68-0281EFS—05

L7224A,C; L7248A,C,L OIL ELECTRONIC AQUASTAT® CONTROLLERS

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2012 Honeywell International Inc.

68-0281EFS—05 M.S. Rev. 03-12

Printed in United States

Loading...

Loading...