Page 1

69-1720EFS-03

L7224U

Oil Electronic Aquastat

Controller

INSTALLATION INSTRUCTIONS

APPLICATION

The EnviraCOM™ enabled L7224U Oil Electronic

®

Aquastat

sensing in a UL limit-rated controller with a single

sensing probe. The L7224U controls the circulator, oil

burner and boiler temperature.

The L7224U is “Outdoor Temperature Reset” ready,

which is enabled when connected to the Outdoor Reset

Module. This option is intended for all applications except

for tankless coil systems for domestic hot water.

The L7224U replaces the L8124A, L8124C, L7124U,

L7148A, L7248A,C, L7224A,C, and L8148A controllers

and is intended for residential applications.

IMPORTANT:

Controller provides electronic temperature

Use of Outdoor Temperature Reset on a tankless coil application requiring a Low Limit setting

may result in limited system effectiveness and

reduced efficiency.

The L7224U provides status and diagnostic

information through an LED display combined

with LED lights as well as EnviraCOM communications enabled thermostats and diagnostic

tools to enhance the diagnostic process.

SPECIFICATIONS

Electrical Ratings:

Voltage: 120 Vac, 60 Hz.

Power: 7 VA maximum at 120 Vac plus external loads.

Thermostat current: 100 mA nominal at 24 Vac.

Burner Relay:

7.4 A at 120 Vac Full Load Amperage (FLA);

44.4 A inrush Locked Rotor Amperage (LRA);

Less Ignition Load: 360 VA.

Circulator Relay:

7.4 A at 120 Vac FLA; 44.4 A inrush LRA.

Zone Controller (ZC): 7.4 A at 120 Vac FLA;

44.4 A inrush LRA.

NOTE: All loads combined cannot exceed 2000 VA.

Environmental Ratings:

Temperature: -30° F to +150° F (-34° C to +66° C).

Humidity: 0 to 95% relative humidity, noncondensing.

Approvals:

Underwriters Laboratories Inc. Component Recognized.

Canadian Underwriters Laboratories Inc. Component

Recognized.

Accessories (Ordered Separately):

W8735S1000 AquaReset™ Outdoor Reset Kit (includes

50022037-002 Outdoor Reset Module and

C7089U1006 Outdoor Temperature Sensor)

W8735S1008 AquaReset™ Domestic Hot Water Kit

(includes 50022037-005 Domestic Hot Water Module

and 32003971-003 Sensor)

C7089U1006 Outdoor Temperature Sensor (used with

the 50022037-002)

32003971-003 Temperature Sensor (used with

50022037-005)

Sensor (See Table 2).

Sensor Well Clamp 121371AA.

14,000,485-016 1/4 in. (6.35 mm) diameter, 1-1/4 in.

(31.75 mm) length glass cartridge Fuse, 1 A,

Slow-Blow.

120650 Heat Conductive Compound.

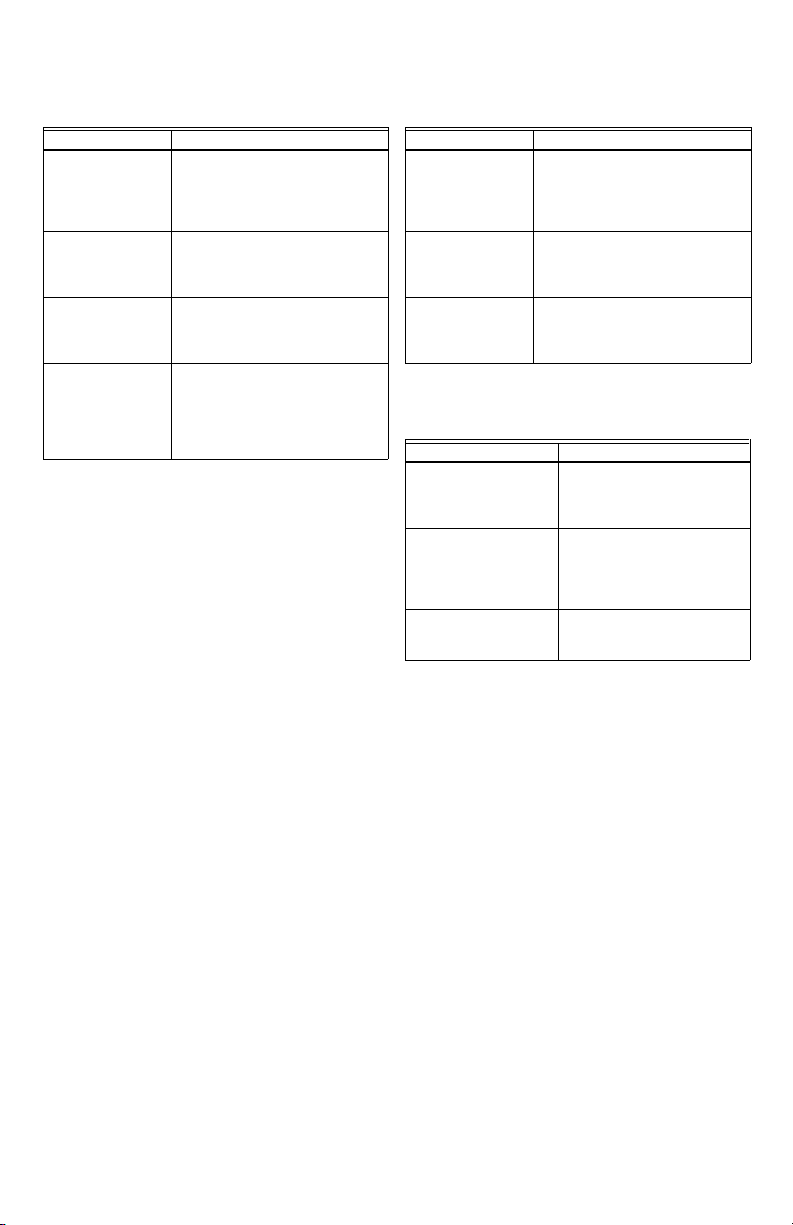

Table 1. Wells for L7224U Controller.

Part

Number

123869A 1/2 (12.7) NPT 3 (76.2) 1-1/2 (38.1)

123870A 3/4 (19.05) NPT 3 (76.2) 1-1/2 (38.1)

Part Number

50001464-001 12 (304.8) Well-mounted controls

50001464-002 18 (457.2) Flush-mounted controls

50001464-003 24 (609.6)

50001464-004 36 (914.4)

50001464-005 48 (1219.2)

Spud Size

in. (mm)

Table 2. Sensors for L7224U Controller.

®

Insertion

in. (mm)

Length in.

(mm) Application

Insulation

in. (mm)

Page 2

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

WARNING

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. The installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

5. Set High Limit, Low Limit and Differential to the set-

tings recommended by the boiler OEM.

6. Record the maximum High Limit setting from the

replaced controller in the text box provided on the

cover insert label.

7. Record the High Limit setting at the time of installa-

tion in the text box provided on the cover insert

label.

3/4

(75)

7-1/8

(181)

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage.

Mounting

The L7224U can be mounted in a well mount, horizontal

or vertical position, or flush mounted remote from the well.

IMPORTANT

Immersion well must fit sensing element and

sensor must rest against bottom of well.

New Installation

Order well assemblies separately; refer to Table 1 and

form no. 68-0040, Immersion Wells and Compression

Fittings for Temperature Controllers. Boilers usually have

tappings that allow the well to be mounted horizontally so

boiler water of average temperature can circulate freely

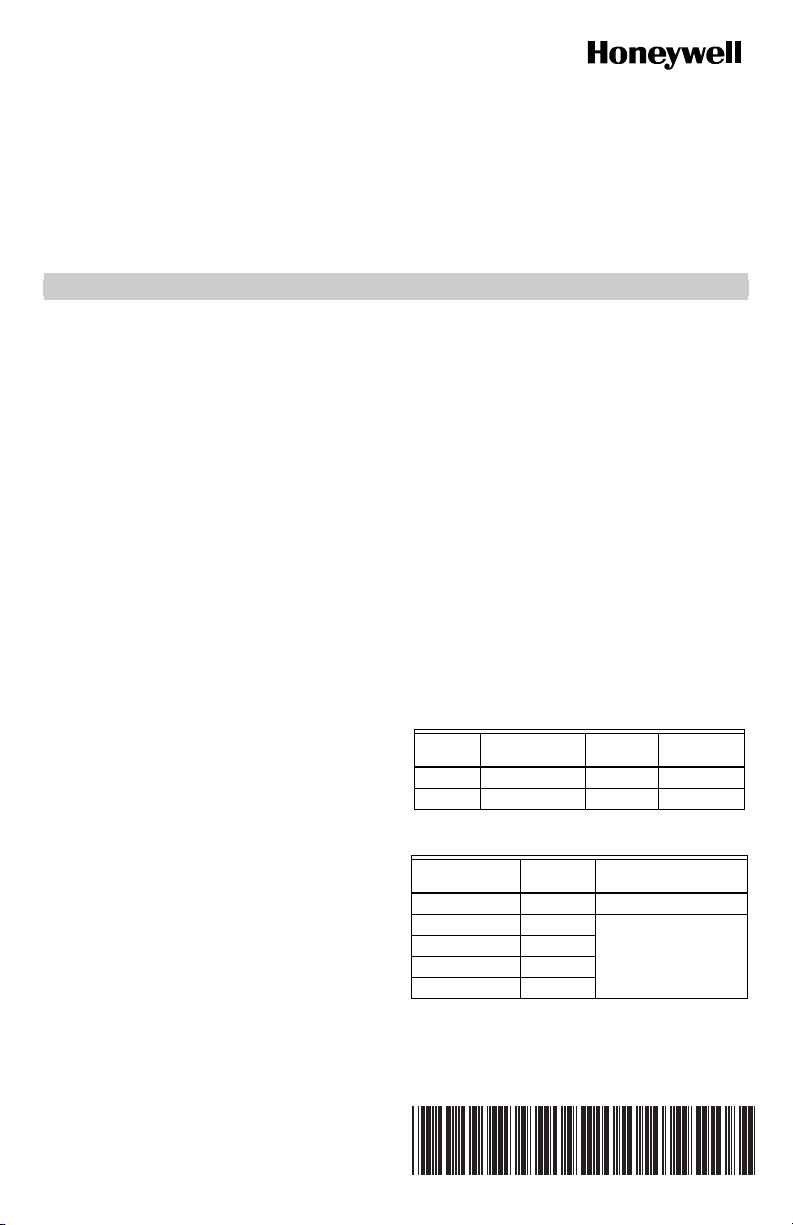

over the well. See Fig. 1 for mounting dimensions.

6-1/2

(166)

5-11/16

(145)

3/8

(10)

2-5/8 (67)

4-1/4 (109)

3-13/32 (86)

2x 1/4 (7) x 3/8 (9)

Fig. 1. L7224U mounting dimensions in inches (mm).

1. Turn off all power and drain the boiler, if applicable.

2. If no tapping is provided, prepare properly sized and

threaded tapping near the top of the boiler.

3. Sparingly coat the well threads with pipe dope.

NOTE: Do not attempt to tighten by using the case as a

handle.

69-1720EFS—03 2

3-1/32

(77)

1-3/16

(30)

1-1/8 (29)

1/16 (2)

4. Install the well in the boiler tapping and tighten

securely.

5. Refill boiler and check for water leakage.

6. Identify if installation requires vertical or horizontal

mounting.

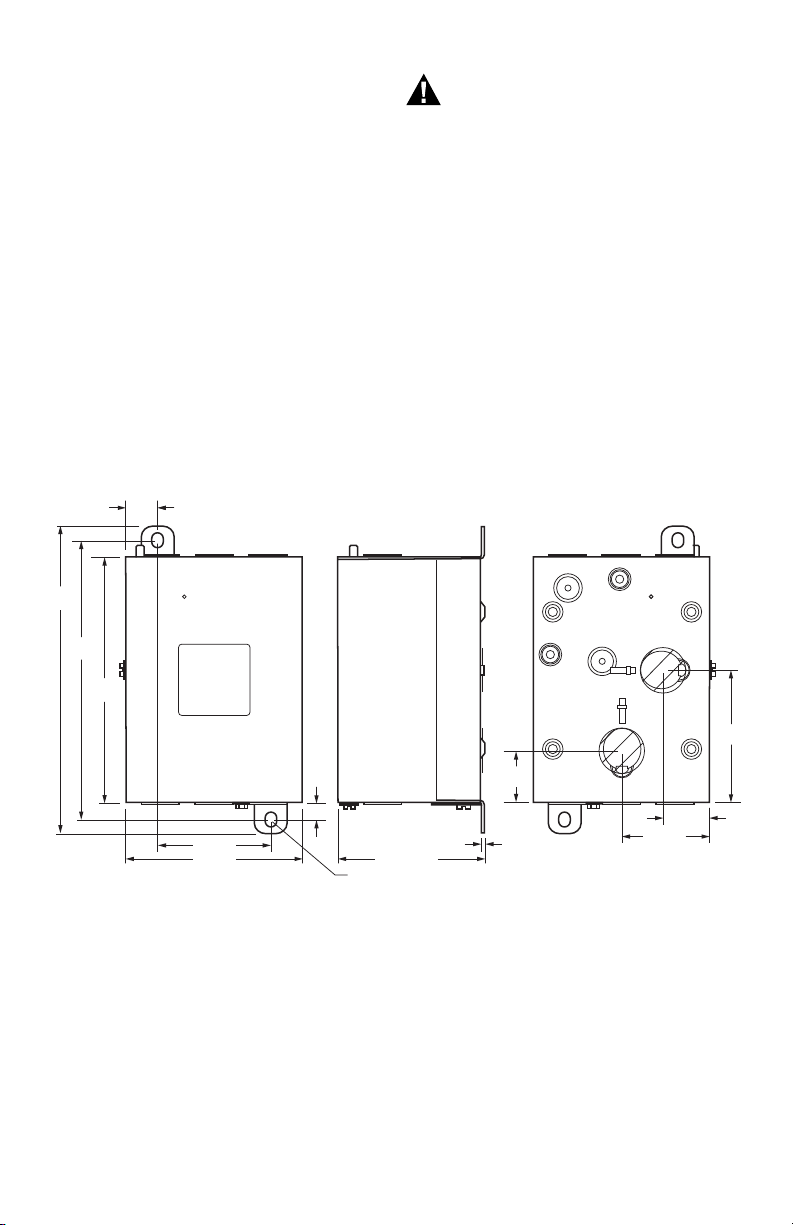

7. Remove the well knockout, for either vertical or

horizontal mounting, by carefully prying the

knockout from the back of the case, using a

flat-bladed screw driver. Refer to Fig. 2.

2-1/16 (53)

M22147B

Page 3

Fig. 2. Removing horizontal or vertical mounting

SCREWDRIVER

M22118

KNOCKOUT FOR

HORIZONTAL

MOUNT

KNOCKOUT FOR

VERTICAL MOUNT

SENSOR WIRES

IMMERSION WELL

CLAMP SCREW

IMMERSION

WELL CLAMP

M16120

HEAT-CONDUCTIVE COMPOUND

(OPTIONAL)

CONTROLLER CASE

BOILER

IMMERSION

WELL

SENSOR

C1

B1

ZC

L2

LINE

C2

ZR

TX

L1

B2

T

T3

2

1

THERMOSTAT

TERMINALS

ENVIRACOM

TM

TERMINALS

DISPLAY

SENSOR

CONNECTOR

SENSOR HOLES

FUSE

FLUSH MOUNTING TAB (2)

M32197

LED's

TT

B1

ZC C1

8. Loosen but do not remove the well clamp screw.

9. Fit the case into the well so the clamp on the case

slides over the flange on the well.

10. Securely tighten the clamp screw.

11. Insert the sensor element into the well until it

bottoms. (If necessary, slightly bend the wire inside

the case to hold the sensor against the bottom of

the well.)

12. Turn power ON.

13. Set High Limit, Low Limit and Differentials to the

settings recommended by the boiler OEM. (See

OPERATION section, also refer to INSTALLATION

steps 6 and 7.)

IMPORTANT

Best thermal response is obtained with a well

that snugly fits the sensor. Insert the sensor until

it rests against the bottom of the well. Use a well

of correct length and bend the wiring, if necessary, to hold the bulb against the bottom of the

well.

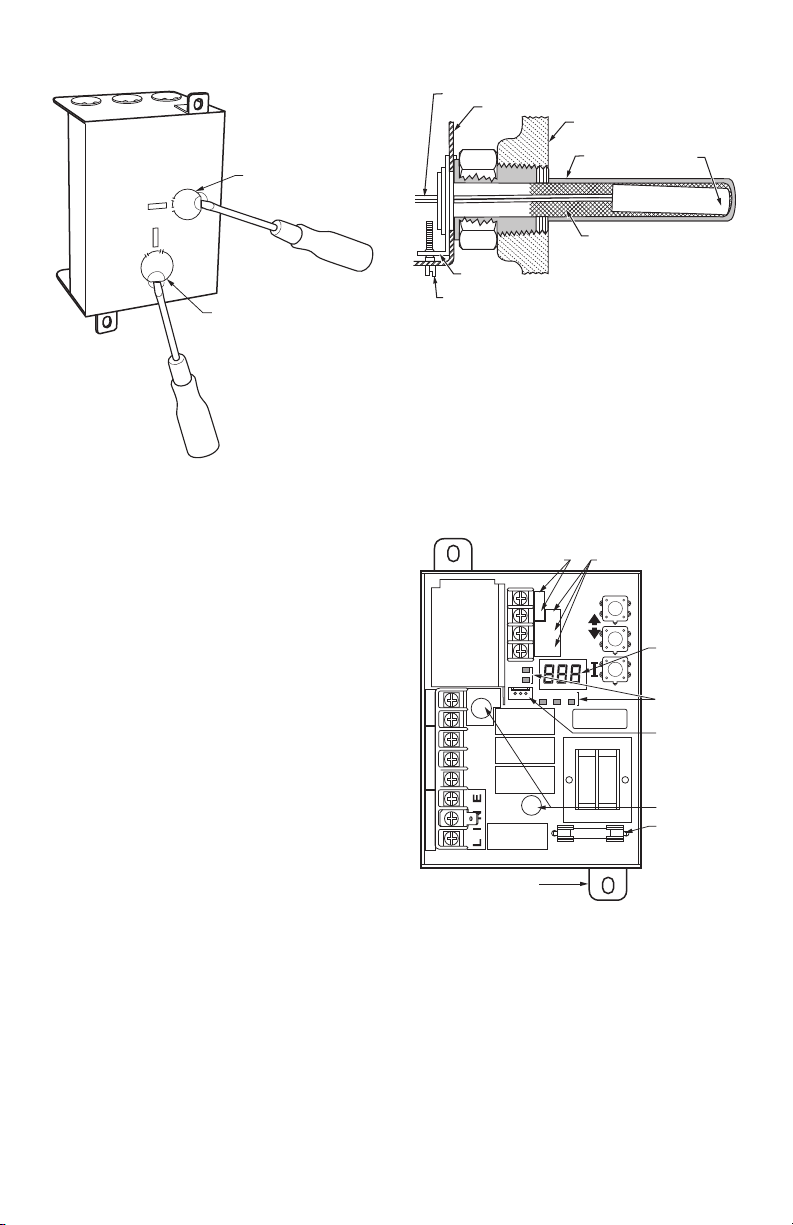

If the well is not a snug fit on the sensor, use the

heat-conductive compound (furnished with

TRADELINE® models) as follows: Fold the

plastic bag of compound lengthwise and twist it

gently. Then snip off end of bag and work the

open end of the bag all the way into the well.

Slowly pull out the bag while squeezing it firmly

to distribute compound evenly in the well. Bend

the wiring, if necessary, to hold the sensor

against the bottom of the well and to hold outer

end of the sensor in firm contact with the side of

the well. See Fig. 3. Wipe excess compound

from the outer end of the well.

knockout.

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

Fig. 3. Position of sensor in immersion well.

Flush-Mounted Aquastat

Replacement

Turn off all power and remove the old controller. Refer to

the cover insert of the old controller to identify and tag

each external lead as it is disconnected. If the old well is

unsuitable for the new installation, remove it and replace it

with a suitable new well. If the old well is suitable, use it.

See Fig. 1 and 4 for mounting tab location.

Fig. 4. Location of L7224U flush-mounting tabs and

3 69-1720EFS—03

LEDs.

Page 4

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

WARNING

SENSOR WIRES

M22026

HEAT-CONDUCTIVE COMPOUND

(OPTIONAL)

BOILER

IMMERSION

WELL

SENSOR

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T

3

2

1

1 2 3 OT OT

C7089U1006

OUTDOOR

SENSOR

50022037-002

OUTDOOR

RESET MODULE

1 2 3 TS TS

50022037-005

DOMESTIC HOT

WATER MODULE

32003971-003

TEMPERATURE

SENSOR

M29651

Well-Mounted Aquastat

Replacement

Turn off all power and remove the old controller. Refer to

the cover insert of the old controller to identify and tag

each external lead as it is disconnected. If the old well is

unsuitable for the new installation, remove it and proceed

with instructions for new installation. If the old well is

suitable, use it.

1. Loosen, but do not remove, the well clamp screw on

the side of the controller case.

2. Position immersion well clamp snugly over the

flange of the adapter and tighten the clamp screw.

3. Insert the sensor into the well as shown in Fig. 5.

(If desired, distribute the heat-conductive compound in the tube prior to sensor insertion, as

described in New Installation.)

4. Make sure sensor is fully seated to bottom of well

(Fig. 5). Use a small pencil to measure depth of

sensor in well, if necessary.

Fig. 5. Replacement sensor installation.

Replacement Sensor Installation

Turn off all power and carefully disconnect sensor from

circuit board by pulling gently on the connector.

1. Gently pull sensor from thermo well and through cir-

cuit board by pulling on leadwires.

2. Carefully align replacement sensor with hole in

circuit board and guide through Aquastat case and

into well. Refer to Fig. 5.

3. Make sure sensor is fully seated to bottom of well

(see Fig. 5). Use a small pencil to measure depth of

sensor in well, if necessary.

4. Connect sensor to circuit board by pressing

connector on sensor unit into mating connector on

circuit board (refer to Fig. 6).

5. For remote sensors (flush mounted Aquastat) be

sure to use the 121371AA clamp to securely hold

sensor in place. See Accessories.

WIRING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect power supply before making wiring

connections to prevent electrical shock or

equipment damage.

All wiring must comply with local electrical codes and

ordinances. Do not exceed the specifications in the

Application section when wiring this controller.

69-1720EFS—03 4

IMPORTANT

The terminals on these Aquastat Controllers are

approved for use with copper wire only.

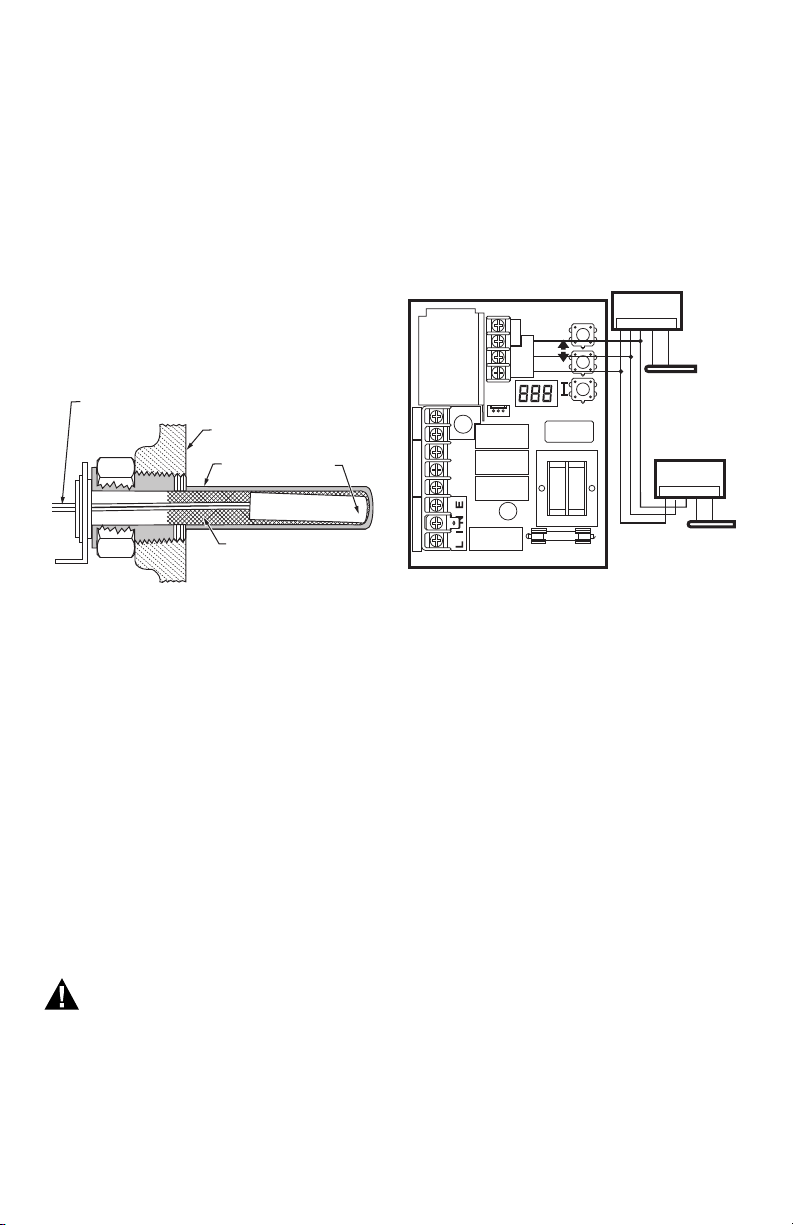

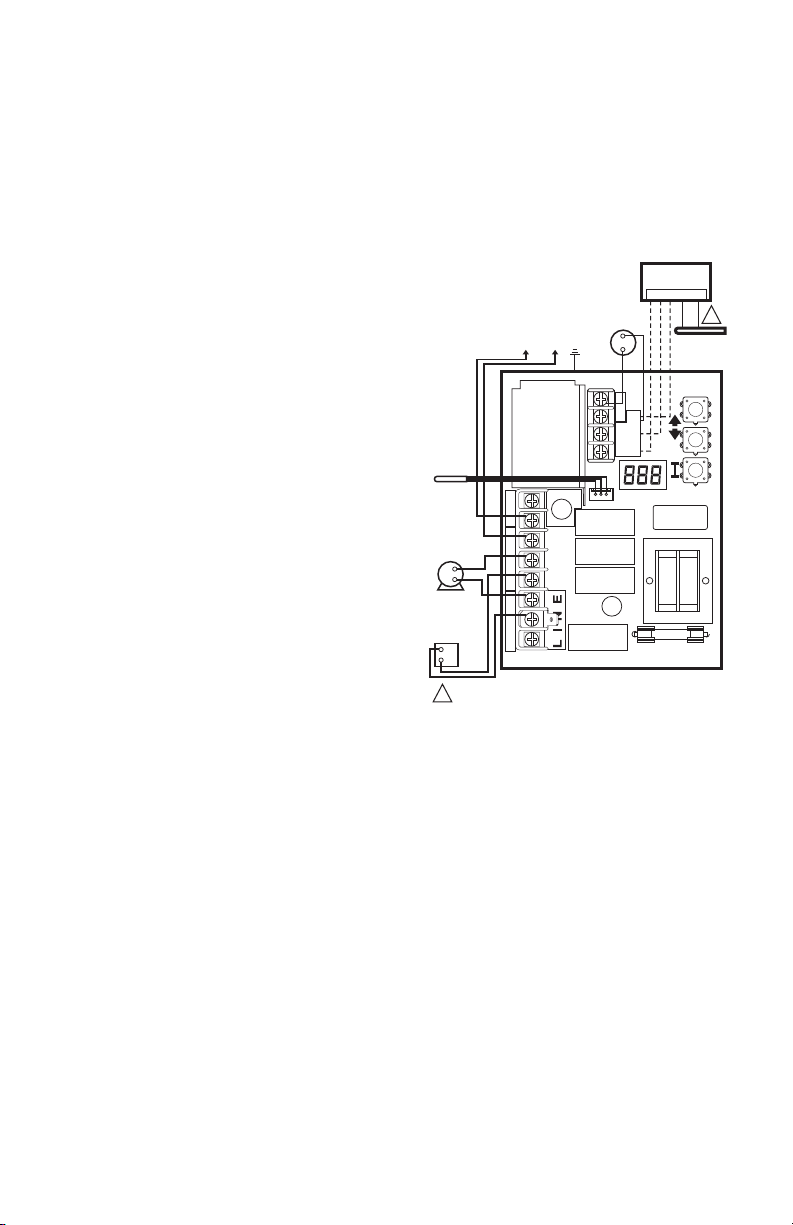

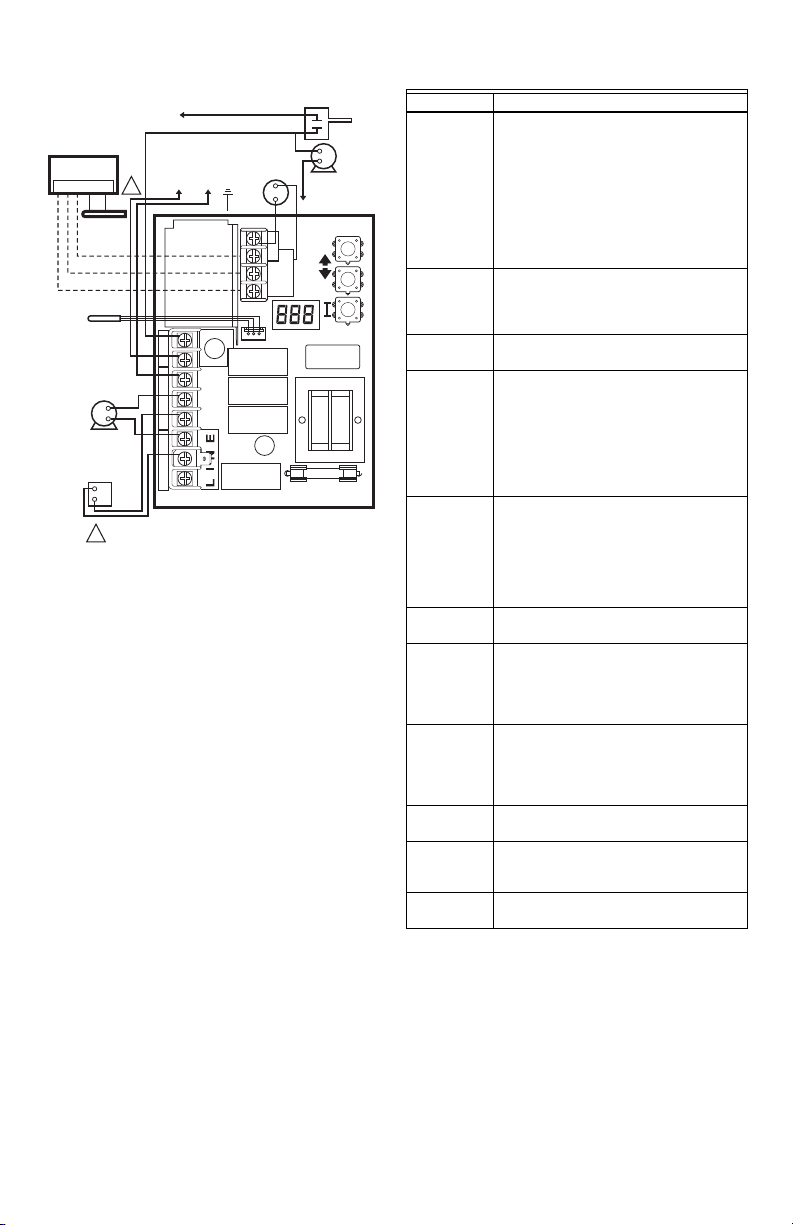

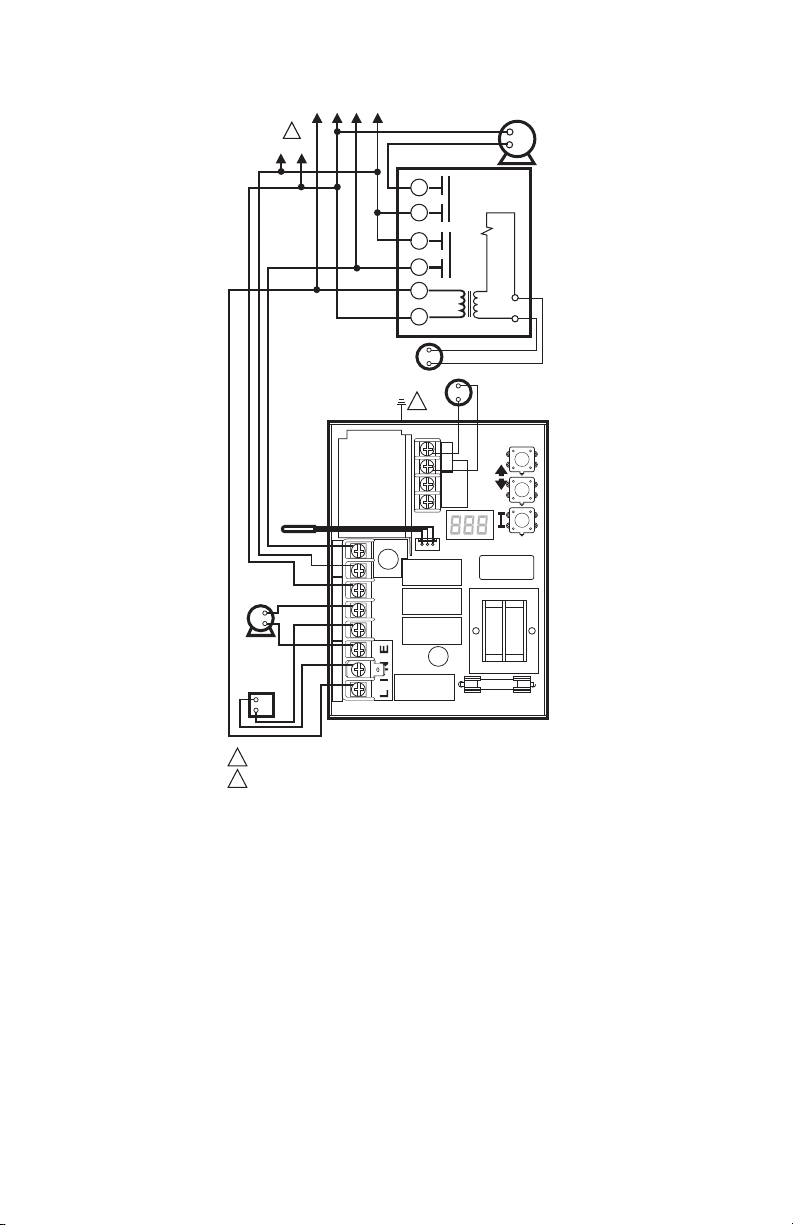

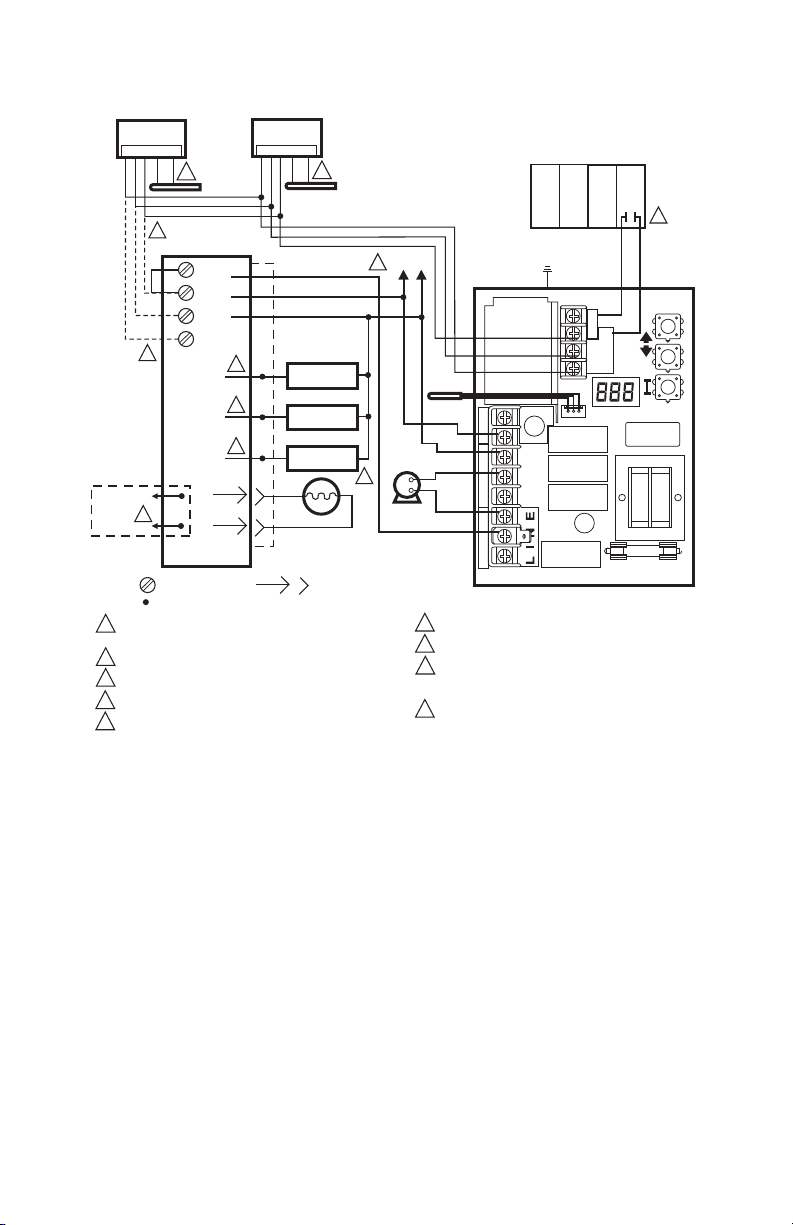

Follow the appropriate wiring diagrams shown on the

inside of the front cover of the L7224U or in Fig. 9–13.

Refer to Fig. 6 for Connections for the optional Outdoor

Reset Module and the Domestic Hot Water (DHW)

module. In subsequent wiring diagrams these modules

will be displayed with a dotted line signifying that they are

optional.

Fig. 6. Wiring the Outdoor Reset Module and the

Domestic Hot Water Module.

OPERATION

General

The L7224U Oil Electronic Aquastat Controller is a

primary safety limit-rated device designed for use with oil

fired boilers with line voltage burners and circulators.

Many boilers do not include wiring or controller

compartments as part of the design, but are provided with

an integral, replaceable, immersion well that is the

mounting hardware for the Aquastat Controllers. Wiring to

the other controllers is done through flexible metal

conduit.

For boilers that do include a remotely (flush) mounted

controller, the wiring may be completed with conduit or

routed behind the boiler sheet metal.

A separate electromechanical High Limit is not required in

a system that uses this controller to meet Underwriters

Laboratories Inc. requirements for oil-fired boiler

assemblies, UL 726.

On the L7224U, the High Limit, High Limit Differential,

Low Limit, and Low Limit Differential and Anti-Short Cycle

time can be adjusted to the setting recommended by the

boiler OEM.

The overall range of the High Limit is from 130° F to

240° F (54° C to 116° C). Select devices may have

different ranges. Some models have limited ranges on the

High Limit setpoint; this limited range is listed on the

device label.

Page 5

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

The range of the Low Limit is from 110° F to 220° F

(43° C to 104° C). Select devices may have different

ranges. The range of the Anti-Short Cycle time is from

OFF to five minutes.

If a 50022037-002 “Outdoor Reset Module” is installed,

the reset curve can be set by entering the minimum

outdoor temperature, minimum (water or boiler)

temperature, and maximum outdoor temperature on the

3-digit display. The range of the minimum outdoor

temperature is from -40°F to 40°F (-40°C to 4.4°C) and

has a default setting of 0°F (-18°C). The range of the

maximum outdoor temperature is from 30°F to 70°F (-1°C

to 21°C) and has a default setting of 40°F (4.4°C). The

range of the minimum (water or boiler) temperature is

from 80°F to 180°F (27°C to 82°C) and has a default

setting of 130°F (54°C). See the “Outdoor Reset Module”

Installation Instructions (form number 69-2335) for more

information on setting the boiler reset curve and all related

parameters.

The L7224U is designed for use with 24 Vac electronic

and electromechanical thermostats or EnviraCOM™

enabled thermostats, and have screw-type terminals for

easy field connection.

To replace a L8148A,C L7148A or L7248A,C controller,

the Low Limit function must be disabled; see Adjusting

Settings for directions.

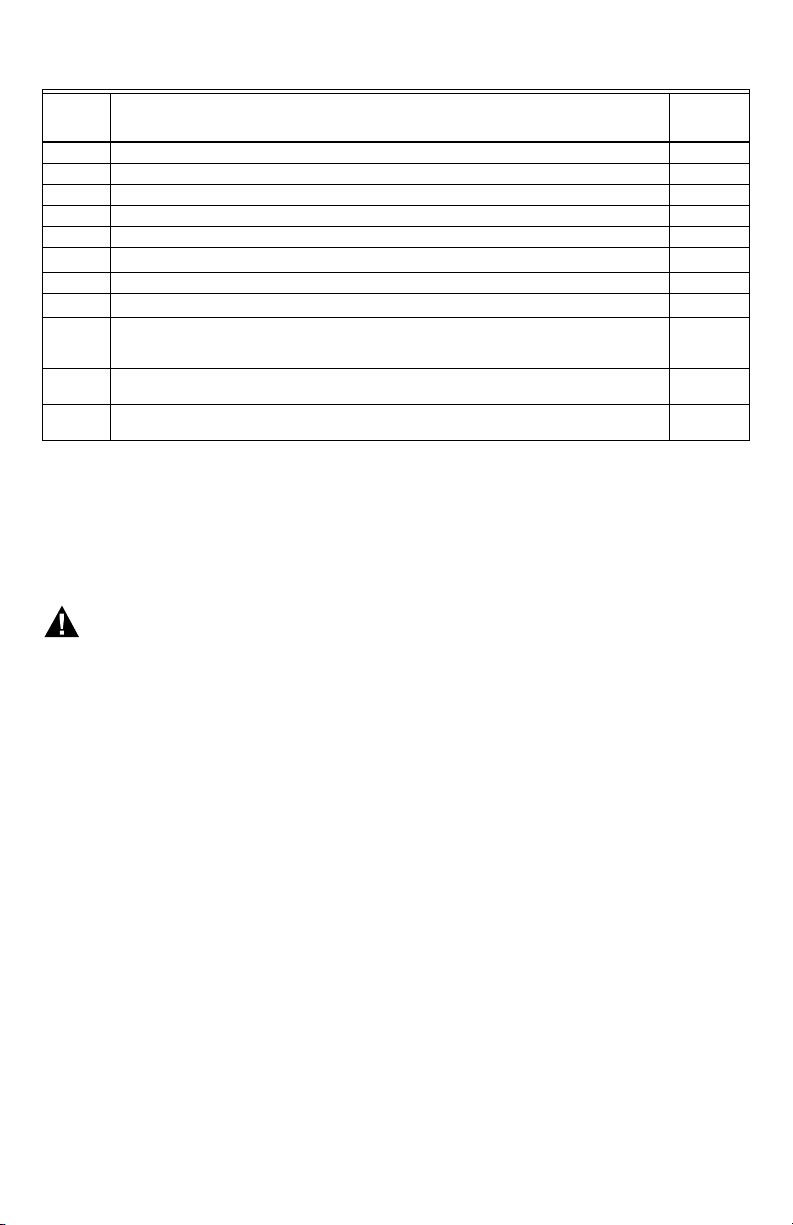

Adjusting Settings

To discourage unauthorized changing of Aquastat

settings, a procedure to enter the ADJUSTMENT mode is

required. To enter the ADJUSTMENT mode, press the

UP, DOWN, and I buttons (refer to Fig. 9) simultaneously

for three seconds. Press the I button until the feature

requiring adjustment is displayed:

Display Definition

HL_ High Limit.

Hdf High Limit Differential.

LL_ Low Limit.

Ldf Low Limit Differential.

duu ZR input configured as external Domestic Hot

Water (DHW) request (ON/OFF)

ASC Anti Short-Cycle Timeout (seconds); “OFF” is

disabled.

otL Outdoor Temperature Low (minimum)

parameter for the outdoor reset curve (F or C)*

otH Outdoor Temperature High (maximum)

parameter for outdoor reset curve (F or C)*

btL Boiler Temperature Low (minimum) parameter

for outdoor reset curve*

bP Boost Period (minutes). “OFF” is displayed if

Boost is inactive*

bS Boost step (F or C) shown only if Boost is active

(bP=ON)*

UUS Warm Weather Shutdown Temperature (F or

C)*

F-C Temperature units (F or C)

* Settings available for adjustment on the 3-digit display

only if the AquaReset Outdoor Reset Module is installed.

Then press the UP and/or DOWN buttons to move the set

point to the desired value. After 60 seconds without any

button inputs, the controller will automatically return to the

RUN mode.

To use the L7224U in a cold start boiler application,

disable the Low Limit function by pressing the UP arrow

button, DOWN arrow button and I button simultaneously

for three seconds. Then push the I button until LL_ is

displayed. Then press the down arrow button until OFF is

displayed.

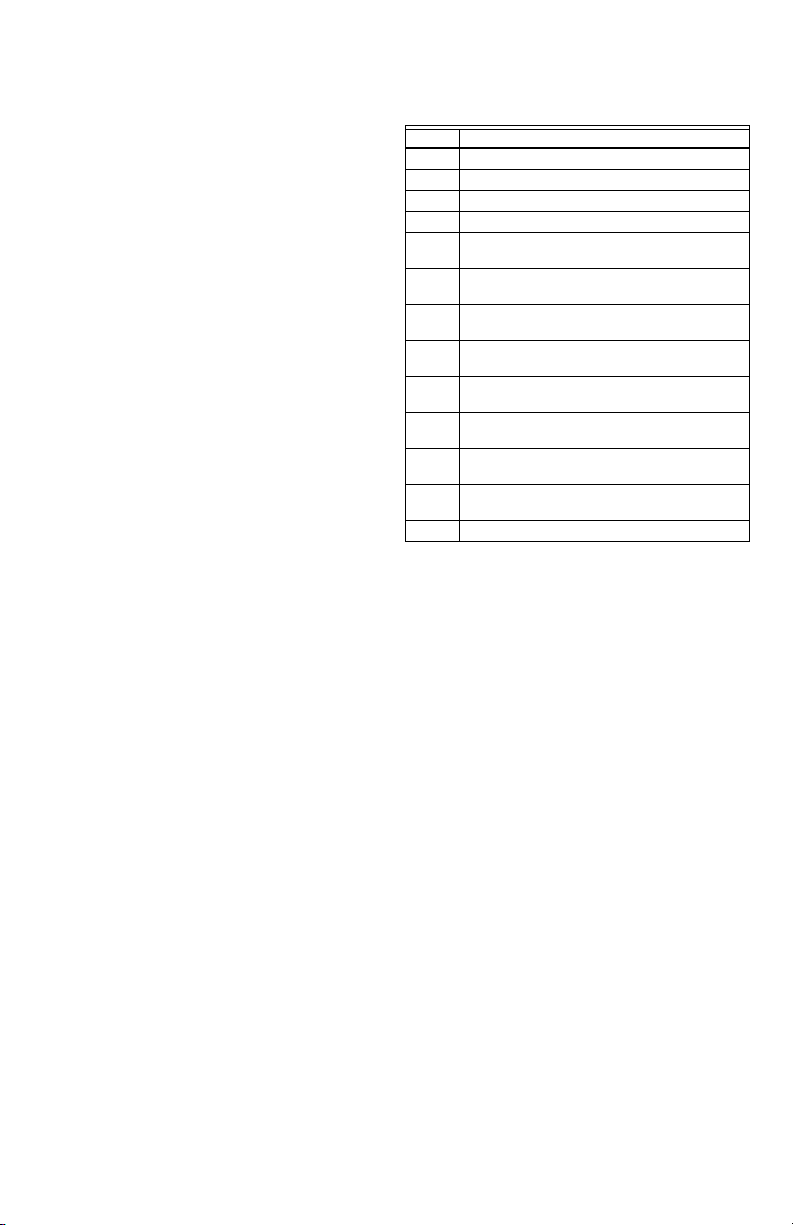

Display

In the RUN mode, the Aquastat will flash “bt” (boiler temp)

followed by the temperature (i.e., 220), followed by °F or

°C.

To read boiler settings, press the I key to read the

parameter of interest. For example, press I and HL (High

Limit) is displayed, followed by a three-digit number, i.e.,

220, followed by °F or °C. Pressing the I button again will

display the LL (Low Limit) followed by a three-digit

number and the corresponding degree designator. See

Fig. 7 for explanation of display readout.

After approximately 60 seconds without any key presses,

the display will enter a dim display mode. To return to the

bright display mode, simply press and release any key.

5 69-1720EFS—03

Page 6

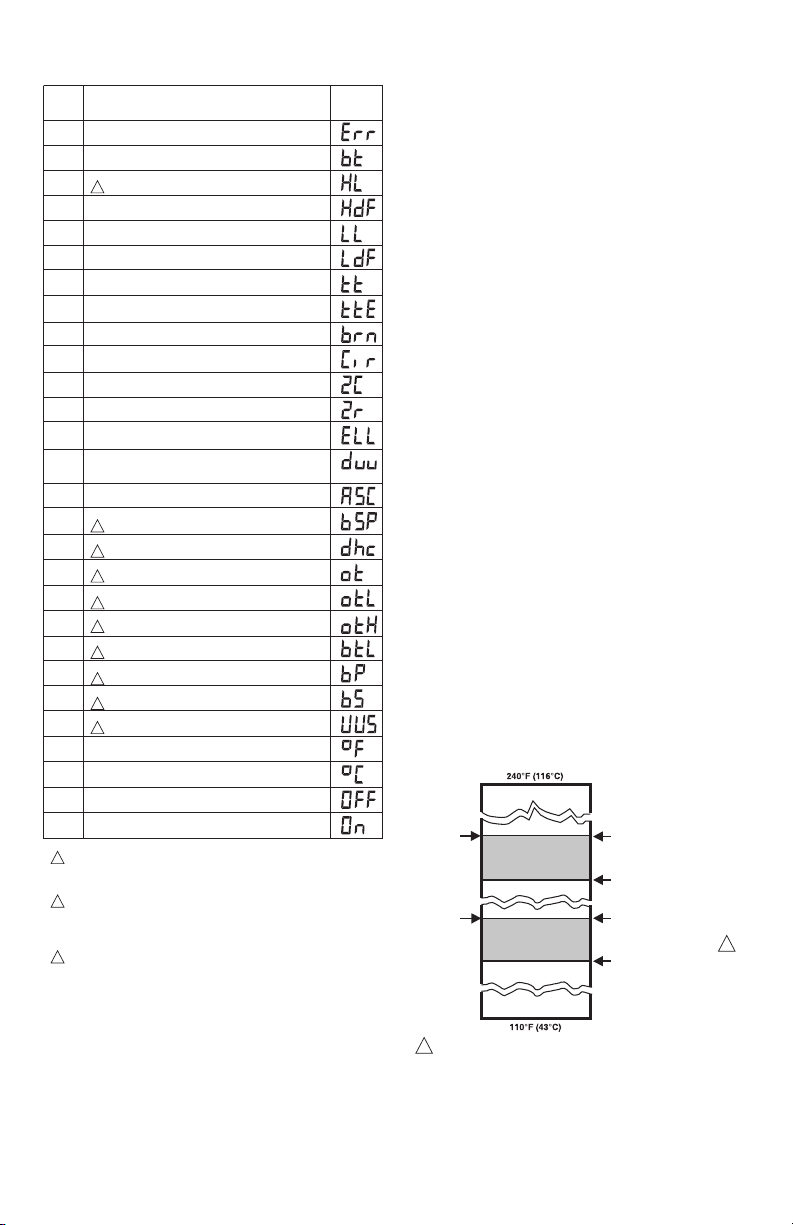

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

LOW LIMIT

SETTING

HIGH LIMIT

SETTING

SWITCH BREAKS ON

TEMPERATURE RISE.

BURNER TURNS OFF.

CIRCULATOR OPERATES

ON A CALL FOR HEAT.

SWITCH MAKES ON

TEMPERATURE FALL.

BURNER OPERATES ON A

CALL FOR HEAT.

WITH NO HEATING

DEMAND, SWITCH BREAKS

ON TEMPERATURE RISE.

SWITCH MAKES ON

TEMPERATURE FALL,

BURNER IS ON TO

MAINTAIN MINIMUM

WATER TEMPERATURE.

CIRCULATOR IS OFF.

M23365

WHEN WATER REACHES LOW LIMIT SETTING, THE BURNER SHUTS

OFF OR THE CIRCULATOR PUMP STARTS (WHEN CALLING FOR HEAT).

1

1

10ºF (6ºC)

DIFFERENCE

10ºF (6ºC)

DIFFERENCE

Text

Err

bt

1

HL

HdF

LL

Ldf

tt

ttE

brn

Cir

ZC

Zr

ELL

duu

ASC

2

bSP

3

dhc

2

ot

otL

2

otH

2

2

btL

bP

2

bS

2

2

UUS

°F

°C

OFF

On

1

DISPLAY SHOWS LOCAL SETTING; NOT THE SETTING

AS MODIFIED BY AN EXTERNAL ENVIRACOM CONTROL.

2

SETTINGS ARE VIEWABLE ONLY IF THE OUTDOOR

RESET MODULE AND OUTDOOR TEMPERATURE

SENSOR ARE INSTALLED AND FUNCTIONING PROPERLY.

3

SETTINGS ARE VIEWABLE ONLY IF THE DOMESTIC

HOT WATER MODULE AND SENSOR ARE INSTALLED

AND FUNCTIONING PROPERLY.

Fig. 7. Explanation of display readout.

*Settings viewable on the 3-digit display only if the

“Outdoor Reset Module” is installed.

69-1720EFS—03 6

Description

Error Code (if one is present)

Boiler Temperature

High Limit

High Limit Differential

Low Limit (L7224 only)

Low Limit Differential (L7224 only)

Local Thermostat Status

EnviraCOM Thermostat Status

B1 (Burner) output (ON or OFF)

C1 (Circulator) output (ON or OFF)

ZC (Zone Control) output (ON or OFF)

ZR (Zone Request) Call for HEAT (ON or OFF)

External Low Limit Enabled (L7248L only)

ZR Configured as Domestic Hot Water

Request (L7224, L7248L only)

Anti Short-Cycle Timeout

Boiler Setpoint

DHW Module Connected (YES or NO)

Outdoor Temperature

Outdoor Temperature Low

Outdoor Temperature High

Boiler Temperature Low

Boost Period

Boost Step

Warm Weather Shutdown Temperature

Units are displayed in degrees Fahrenheit

Units are displayed in degrees Celsius

Input or Output is OFF

Input or Output is ON

Display

Shows

M29552

Operation

The L7224U can be in any of four operational states:

Normal, High Limit, Low Limit and Error. The controller

moves back and forth from High Limit to Normal to Low

Limit state as part of normal operation. The operating

states are:

1. Normal: Boiler temperature went below the High

Limit setting (minus the Differential) and has not

exceeded the High Limit setting; or, the boiler temperature went above the Low Limit setting and has

not gone below the Low Limit setting (minus the Differential).

2. High Limit: Boiler temperature went above the High

Limit setting and has not dropped below the High

Limit setting (minus the Differential).

3. Low Limit: Boiler temperature went below the Low

Limit setting (minus the Low Limit Differential) and

has not gone above the Low Limit setting.

4. Error: The controller has detected an error condition

(e.g., open sensor) and has shut down the burner

output. The Zone Control (ZC) output is energized.

The controller continues to monitor the system and

automatically restarts if the error condition clears.

Refer to Table 4–6.

The operating sequence for the L7224U is shown in Table

3.

High Limit Controller

The High Limit opens and turns off the burner when the

water temperature reaches the setpoint. The High Limit

automatically resets after the water temperature drops

past the setpoint and through the adjustable Differential.

Low Limit and Circulator Controller

On a temperature rise, the burner circuit breaks and the

circulator circuit makes (assuming no call for heat is

present) at the Low Limit setpoint. On a temperature drop

of 10° F (6° C) below the Low Limit setpoint (with the

adjustable Differential at the minimum setting of 10° F

(6° C)), the burner circuit makes and the circulator circuit

breaks. Refer to Fig. 7.

Fig. 8. Setpoints and differentials.

Page 7

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

NOTE: Setting the Low Limit above the High Limit less

the High Limit Differential is not allowed as

improper circulator and Zone Control functions

could result.

Anti Short-Cycle Feature

The Anti Short-Cycle feature allows for field selection of a

minimum delay time between burner cycles. Should a call

for heat occur following the end of the previous heat cycle

and before the Anti-Short Cycle delay time is expired, the

circulator will be allowed to run, but the burner will be held

off until the time has elapsed.

NOTE: The Anti Short-Cycle feature is blocked if DHW

demand occurs. DHW demands are serviced

immediately, without any delay.

NOTE: When the Aquastat is connected to the oil pri-

mary and/or thermostat via the EnviraCOM bus,

the Anti Short-Cycle time does not apply to recycle events such as loss of airflow or flame. It

applies only to loss of demand.

ZR-Domestic Hot Water (DHW)

Request

The ZR terminal on the L7224U can be selected to

service an indirect water heater heat request. This

parameter is set via the 3 digit display (see Adjusting

Settings section of this document). A heat request via the

ZC terminal will have priority over all other features such

as the Anti-Short Cycle feature or those enabled by the

Outdoor Reset Module (See form69-2235 for more

information).

CHECKOUT

TROUBLESHOOTING

When attempting to diagnose system performance,

reference to the LED display can help to identify specific

areas not working properly. The LED display will scroll

Err, followed by a digit (1-8). Refer to Table 7 for a

description of each error and suggested actions and Table

8 for a troubleshooting guide.

50022037-002

OUTDOOR

RESET MODULE

1 2 3 OT OT

1

C7089U1006

OUTDOOR

SENSOR

SENSOR

LINE

VOLTAGE

CIRCULATOR

LINE

VOLTAGE

OIL BURNER

RELAY

ZR

L1

L2

C2

B2

C1

B1

ZC

L1

(HOT)

L2

T

T3

2

1

LINE

Put the system into operation and observe at least one

complete cycle to make sure that the controller operates

properly. See TROUBLESHOOTING section to use LED

to assist in determining system operation.

1

OPTIONAL OUTDOOR RESET MODULE AND OUTDOOR SENSOR.

M32022

Fig. 9. L7224U single zone connections.

7 69-1720EFS—03

Page 8

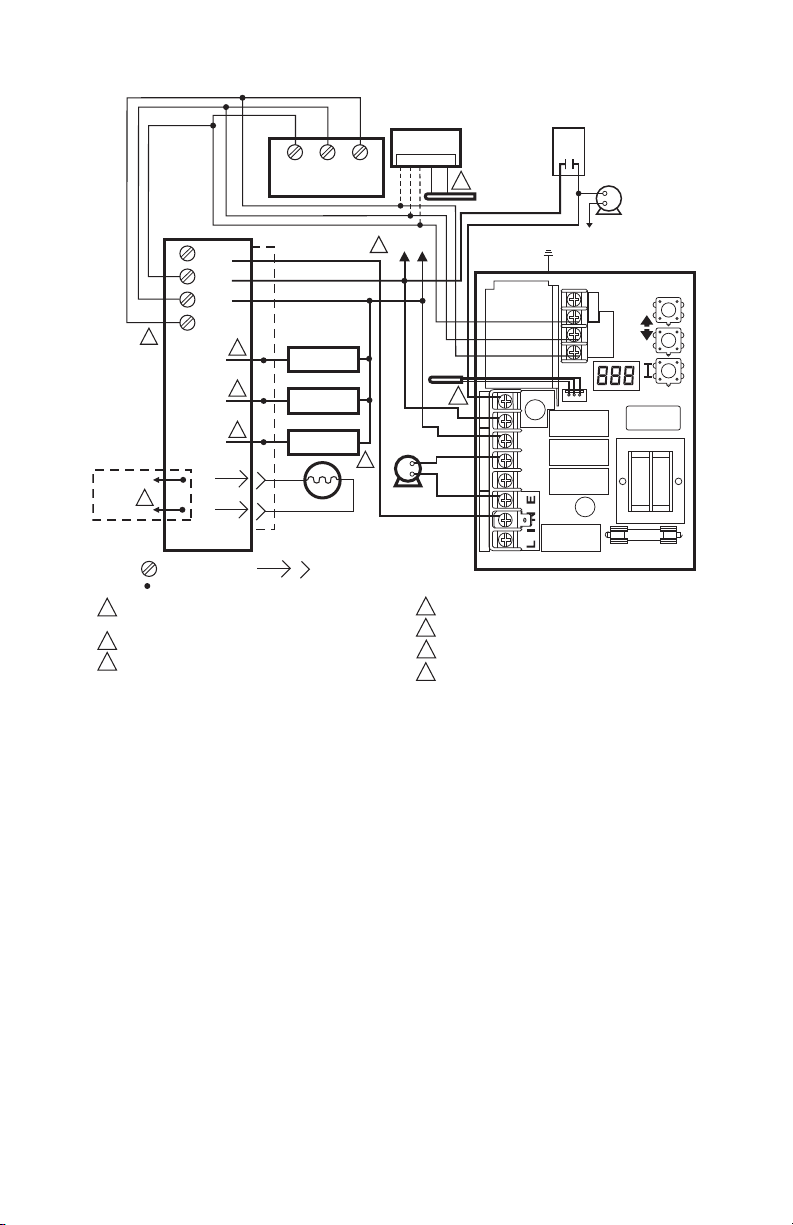

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

LINE VOLTAGE INDIRECT

LINE

TANK AQUASTAT

INDIRECT

TANK CIRCULATOR

L2

T

T3

2

1

M31462

L1

50022037-002

OUTDOOR

RESET MODULE

1 2 3 OT OT

C7089U

OUTDOOR

SENSOR

SENSOR

LINE

VOLTAGE

CIRCULATOR

LINE

VOLTAGE

OIL BURNER

RELAY

1

Fig. 10. L7224U single heat zone with indirect water

tank and circulators. Optional outdoor reset module.

(HOT)

L1

(HOT)

1

OPTIONAL OUTDOOR RESET MODULE AND OUTDOOR SENSOR.

L2

ZR

L1

L2

C2

B2

C1

B1

ZC

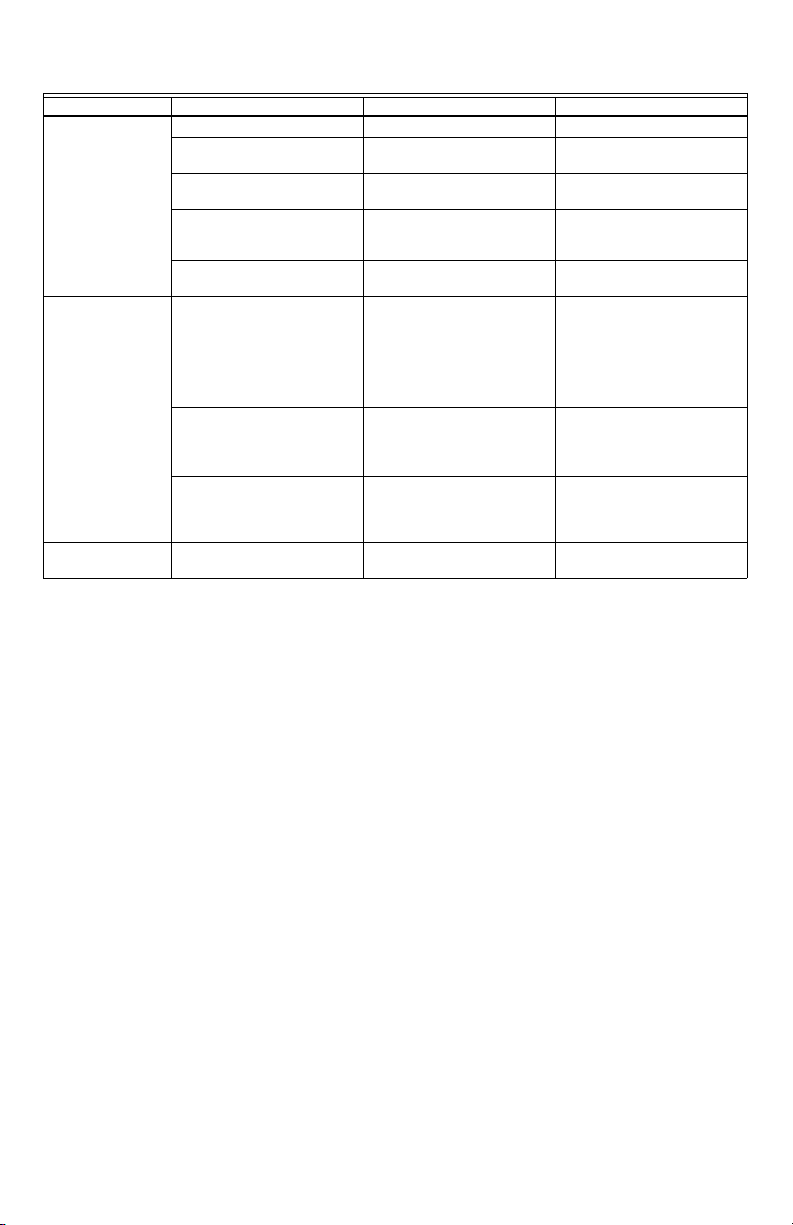

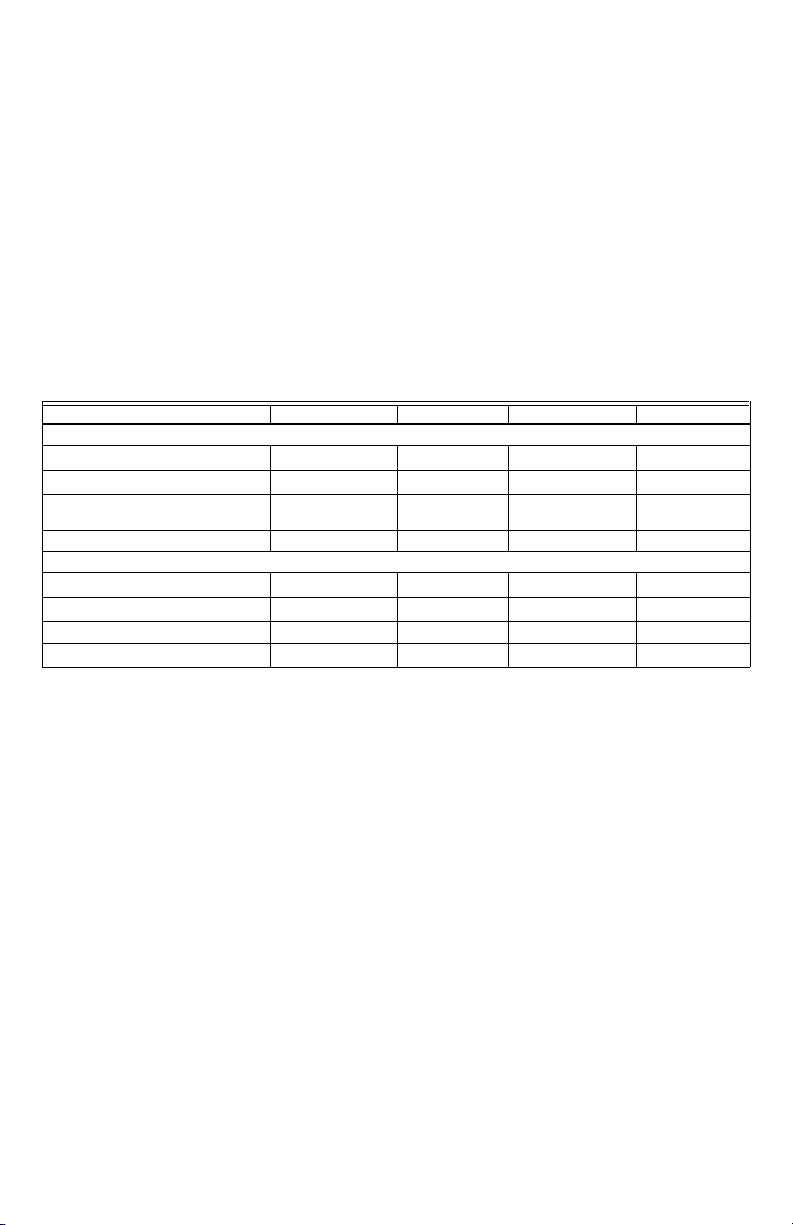

Table 3. L7224/L7248 Controller Operating Sequence.

Action System Response

Thermostat

calls for heat.

Boiler

temperature

exceeds the

High Limit.

Thermostat is

satisfied.

Boiler

temperature

drops below

the Low Limit

setting minus

the

differential (if

applicable).

Error

conditions

1-5.

Error

condition 6.

Error

condition 7.

Error

condition 8.

Error

condition 9*.

Error

condition 10*.

Error

condition 11*.

* Error condition only available when the Outdoor Reset

Module is installed.

Circulator starts when water temperature is

above Low Limit setting (if applicable).

Boiler temperature is checked. Burner

starts when water temperature is below

High Limit setting, less differential.

If Anti-short Cycle Time is enabled, the

burner does not start until the set Antishort Cycle Time between cycles expires

after the previous call for heat was

satisfied.

Burner is turned off. Burner restarts when

the water temperature drops below the

High Limit setting minus the Differential.

Circulator and burner turn off.

Burner is turned on, Circulator is turned

off. Burner stops when the water

temperature exceeds the Low Limit

setting. Power to Zc is removed.

If an error condition is detected, all outputs

except ZC are shut down. Burner is off.

The controller continues to function and

restarts when error is corrected.

During the error check sequence, the

system checks for drift in the sensor and

corrosion in the connections.

EnviraCOM communication is not

available.

The controller has reset the High Limit,

Low Limit and Differential Setting to a

default setting and will continue to run at

those settings. Performance of the system

will be degraded.

If the error condition is detected, all

outputs except ZC are shut down. Burner

is off.The controller continues to function

and restarts when all three user keys have

been pressed longer than 60 seconds.

System continues to run with no outdoor

reset functionality

System continues to run with outdoor reset

parameters enabled as programmed.

Error cleared automatically.

System continues to run with boiler temp

set to High Limit.

69-1720EFS—03 8

Page 9

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

Table 4. L7224 Controller Operating Sequence with

multiple zones connected through the ZR terminal

Action System Response

Zone Request (ZR)

terminal is

connected to L1

(Zone calls for

heat).

Boiler temperature

exceeds the High

Limit.

Zone Request input

is de-energized

(Zones are

satisfied).

Boiler temperature

drops below the

Low Limit setting

minus the

differential (if

applicable).

Boiler temperature is checked.

Burner starts when water

temperature is below High Limit

setting. Anti Short-Cycle Time is

applied, see Table 3.

Burner is turned off. Burner restarts

when the water temperature drops

below the High Limit setting minus

the Differential.

Burner turns off.

Burner turns on and Zone Control

is de-energized. Burner turns off

and Zone Control is re-energized

when the water temperature

exceeds the Low Limit setting.

Table 5. Controller Operating Sequence with External

Low Limit device connected trough the ZR terminal.

Action System Response

Zone Request (ZR)

terminal is

connected to L1

(External Low Limit

call for heat).

Boiler temperature

exceeds the High

Limit.

Zone Request input

is de-energized

(External Low Limit

is satisfied).

Table 6. L7224 Controller Operating Sequence with

Domestic Hot Water connected trough the ZR

Boiler temperature is checked.

Burner starts when water

temperature is below High Limit

setting. Circulator turns off.

Burner is turned off. Burner restarts

when the water temperature drops

below the High Limit setting minus

the Differential.

Burner is turned off.

terminal.

Action System Response

Zone Request (ZR)

terminal is connected to

L1 (Domestic Hot Water

calls for heat).

Boiler temperature

exceeds the High Limit.

Zone Request input is

de-energized (Domestic

Hot Water is satisfied).

Boiler temperature is checked.

Burner starts when water

temperature is below High

Limit setting.

Burner is turned off. Burner

restarts when the water

temperature drops below the

High Limit setting minus the

Differential.

Burner is turned off.

9 69-1720EFS—03

Page 10

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

WARNING

Table 7. LED Error Codes.

Aquastat

Error

Code Cause/Action

EnviraCOM

Alarm

Err1 Aquastat sensor fault; check water sensor. 18

Err2 ECOM fault; check EnviraCOM™ wiring. 18

Err3 Excessive electrical noise or frequency out of range. Hardware fault; replace controller. 18, 58

Err4 B1 fault; check B1 wiring/voltage. 64

Err5 Low Line; check L1-L2, 110 Vac. 59

a

Err6

Warning: Fuse; check ECOM wires, replace fuse. 92

Err7 Warning: EEPROM, HL, LL, Hdf, Ldf; reset to default values. N/A

b

Err 8

Err9

Err 10

Err 11

a

b

Repeated B1 fault (voltage present at B1 when output is turned off); check B1 wiring/voltage. 25

a

Warning: Outdoor Reset System failure; communication to Outdoor Reset Module lost,

Outdoor Reset Module failure, multiple outdoor temperature sensors detected on the bus, or

outdoor temperature sensor failure. Check EnviraCOM wiring (1, 2, 3), check sensor wiring.

a

Warning: Boost Failure; Boost Mode active at least once per cycle for the last 60 consecutive

cycles. Check Outdoor Reset curve settings.

a

DHW Module/Sensor failure; communication to DHW Module lost, DHW Module failure, or

temperature sensor failure. Check EnviraCOM wiring (1, 2, 3), check sensor wiring.

Warnings are generated to enunciate the system is not operating optimally, but the Aquastat is still operating and

maintaining boiler temperature. In the instance where an Outdoor Reset Module is used, the warnings may indicate a

reset curve setting error one or more features is not running optimally, and the Aquastat is reverting to default settings

or has stopped running the Outdoor Reset algorithms. The warnings are cleared when the issue(s) is resolved.

To clear Err 8 condition, depress and hold all three user keys simultaneously for 60 seconds. Err 8 condition clears

and display returns to normal. Err 8 condition is designed to catch welded relays on the Aquastat and will normally

only occur near end of life for the control. If Err 8 condition has occurred early in the controls life, be sure to check for

voltage feedback to B1 when B1 should be off and check current draw on b terminal to be sure burner is not drawing

excessive current. Err 8 condition will keep repeating if B1 fault is not cleared.

50, 53, 149

150

146, 147,

148

Electrical Shock Hazard.

Can cause severe injury or death.

All circuits must have a common disconnect to

prevent the possibility of electrical shock.

69-1720EFS—03 10

Page 11

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

Table 8. Troubleshooting Guidea.

System Condition Diagnostic Condition Check Action

Boiler is cold, house

is cold.

Boiler is hot, house

is cold.

Boiler is hot, no hot

potable water

a

Refer to Fig. 7 for Display and LED locations.

b

ZC LED ON indicates ZC terminal power is OFF.

c

ZC LED OFF indicates ZC terminal power is ON.

Display is OFF. 120 Vac system power. Turn system power on.

Display is ON.

TT-LED is OFF.

Display is ON.

TT-LED is OFF.

Display is ON.

TT-LED is ON.

B1 LED is ON.

Display is ON.

TT-LED is ON.

Display is ON.

TT-LED is ON.

C1 LED is ON.

Display is ON.

TT-LED is ON.

C1 LED is OFF.

ZC LED is ON

Display is ON.

TT-LED is ON.

ZC LED is OFF

b

.

c

.

24 Vac T-T. No 24 V; replace controller.

24 V present; disconnect

thermostat, short T-T.

120 Vac at B1-B2. • If no, replace controller.

Boiler starts, check wiring and

thermostat.

• If yes, check burner and

wiring.

Refer to Err on display. —

120 Vac at C1-C2. • 120 Vac at C1-C2, check

Boiler below the Low Limit

temperature, wait for boiler to

go above Low Limit

temperature.

Boiler above LL? If yes, check

for 120 Vac between ZC and

L2.

wiring to pump.

• Wiring ok, is pump running?

If not, replace the pump.

• If pump is running, check for

trapped air or closed zone

valves.

—

• If no 120 Vac, replace

controller.

• If yes, check zone relays,

circulators and wiring.

•

11 69-1720EFS—03

Page 12

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T3

2

1

M17777D

SENSOR

LINE

VOLTAGE

CIRCULATOR

LINE

VOLTAGE

OIL BURNER

RELAY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

1

2

CONTROL CASE MUST BE CONNECTED TO EARTH GROUND.

USE GROUNDING SCREW PROVIDED.

2

L1

(HOT) L2

1

2

1

4

3

5

6

ZONE 2

LOW VOLTAGE

THERMOSTAT

LOW

VOLTAGE

THERMOSTAT

R845A RELAY ZONE 2

ZONE 2

CIRCULATOR

TO ADDITIONAL R845A

RELAYS FOR OTHER ZONES

L7224

Fig. 11. L7224U multizone system with circulator connections.

69-1720EFS—03 12

Page 13

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

M32024

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

OPTIONAL FEATURE ON SELECT MODELS.

REFER TO DEVICE LABEL FOR WIRE COLOR CODE.

VALVE IS OPTIONAL ON SPECIFIED MODELS.

ENVIRACOM™ TERMINAL 3 IS ALSO THE FIRST THERMOSTAT TERMINAL.

1

2

3

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T

3

2

1

SENSOR

LINE

VOLTAGE

CIRCULATOR

L7224

3

4

3

3

5

BURNER

MOTOR

IGNITOR

VALV E

BURNER

MOTOR

IGNITOR

VALV E

CAD

CELL

JUNCTION

BOX

TO REMOTE

ALARM

CIRCUIT

ENVIRACOM™

TERMINAL

R7184

LIMIT

L1

L2

2

CAD

CELL

T

T

3

2

1

L1

(HOT)

L2

1

LEGEND SCREW TERMINAL 1/4 IN. (6 MM) QUICK CONNECT TERMINAL

SOLDERLESS WIRE CONNECTION

OPTIONAL OUTDOOR RESET MODULE AND OUTDOOR SENSOR.

OPTIONAL DOMESTIC HOT WATER MODULE.

WIRE ONLY THE ENVIRACOM TERMINALS (1, 2, 3) ON OIL PRIMARY

IF CONNECTING TO REMOTE DIAGNOSTICS, OTHERWISE CONNECT

A JUMPER BETWEEN THE TT TERMINALS.

ZONE PANEL TERMINALS MAY HAVE DIFFERENT LABEL. CHECK

PANEL MANUFACTURER SPECIFICATIONS FOR WIRING INSTRUCTIONS.

6

7

8

1 2 3 TS TS

32003971-003

TEMPERATURE

SENSOR

7

50022037-002

DOMESTIC HOT

WATER MODULE

9

MULTI-ZONE

REP LAY PAN EL

T T

4

5

1 2 3 OT OT

C7089U

OUTDOOR

SENSOR

6

50022037-002

OUTDOOR

RESET MODULE

8

9

applications).

Fig. 12. L7224U multizone system with Outdoor Reset and Domestic Hot Water Modules (indirect tank

13 69-1720EFS—03

Page 14

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

M32025

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

OPTIONAL FEATURE ON SELECT MODELS.

REFER TO DEVICE LABEL FOR WIRE COLOR CODE.

1

2

3

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T

3

3

3

2

2

2

1

1

1

SENSOR

LINE

VOLTAGE

CIRCULATOR

L7224

3

4

3

3

5

BURNER

MOTOR

IGNITOR

VALV E

BURNER

MOTOR

IGNITOR

VALV E

CAD

CELL

JUNCTION

BOX

TO REMOTE

ALARM

CIRCUIT

ENVIRACOM™

TERMINAL

TH9421C

R7184

LIMIT

L1

L2

2

CAD

CELL

T

T

3

2

1

L1

(HOT)

L2

1

LEGEND SCREW TERMINAL 1/4 IN. (6 MM) QUICK CONNECT TERMINAL

SOLDERLESS WIRE CONNECTION

VALVE IS OPTIONAL ON SPECIFIED MODELS.

ENVIRACOM™ TERMINAL 3 IS ALSO THE FIRST THERMOSTAT TERMINAL.

OPTIONAL OUTDOOR RESET MODULE AND OUTDOOR SENSOR.

DUU MUST BE SET TO “ON” ON THE AQUASTAT.

4

5

6

1 2 3 OT OT

C7089U1006

OUTDOOR

SENSOR

6

50022037-002

OUTDOOR

RESET MODULE

7

INDIRECT

TANK

CIRCULATOR

LINE VOLTAGE

INDIRECT

TANK AQUASTAT

L2

7

Fig. 13. L7224U single zone system with circulator, indirect water tank and EnviraCOM™ thermostat.

69-1720EFS—03 14

Page 15

MATERIAL SAFETY DATA SHEET

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

Section 1. Product And Company

Identification

Product Name: Heat Conductive Compound

MSDS ID: DS9021

Synonyms: MS1699

Product Use: Heat conductive material used to enhance

contact and heat transfer in temperature sensor

applications.

Manufacturer: Honeywell Inc.

1985 Douglas Drive North

Minneapolis, MN 55422.

Date Released: October 8, 1999

Customer Response Center: 800-328-5111

Emergency Telephone Information: 888-809-3787

NFPA Ratings:

Health 0; Flammability 1; Reactivity 0; Personal

Protection B

Section 2. Composition, Information on

Ingredients

Ingredient CAS Number Percent PEL TVL

#2 Lithium Complex Grease (70%):

Mineral Oil 64742-65-0 35-50

Mineral Oil 64742-62-7 20-25

Lithium Hydrostearate/Sebacate

Complex

Zinc Alkyldithiophosphate 68649-42-3 0-2 — —

Aluminum Paste (30%):

Aluminum, as Al 7429-90-5 20-25

Aliphatic Petroleum Distillates 8052-41-3 10-15

Stearic Acid 57-11-4 1-2 — —

Aromatic Petroleum Distillates 64742-95-6 1-2

Additional Information: Part No. 120650 (0.5 oz tube); Part No. 107408 (4 oz can); Part No. 197007 (5 gallon

container). May also contain minute amounts of lithium and molybdenum lubricant compounds.

68815-49-6 4-9 — —

3

5 mg/m

3

5 mg/m

15 mg/m

2900 mg/m

3

5 mg/m

5 mg/m

5 mg/m

3

3

10 mg/m

525 mg/m

5 mg/m

3

3

3

3

3

Section 3. Hazard Identification

Acute Health Effects:

Skin: Excessive contact may cause skin irritation and

dermatitis.

Eye: Direct contact with eye will cause irritation.

Inhalation: No adverse effects are expected.

Ingestion: Ingestion of product may cause nausea,

vomiting and diarrhea.

Chronic Health Effects:

Existing skin rash or dermatitis may be aggravated by

repeated contact.

OSHA Hazard Classifications: None.

Carcinogenicity: Not considered to be a carcinogen by

either OSHA, NTP, IARC, or ACGIH.

Section 4. First Aid Measures

Eye Contact: Flush eyes with water for 15 minutes.

Remove any contact lenses and continue to flush.

Obtain medical attention if irritation develops and

persists.

Skin Contact: Remove excess with cloth or paper.

Wash thoroughly with mild soap and water. Obtain

medical attention if irritation develops and persists.

Ingestion: Contact physician or local poison control

center immediately.

Inhalation: Remove patient to fresh air and obtain

medical attention if symptoms develop.

Section 5. Fire Fighting Measures

Material Flash Point: > 383° F (195° C). Will burn if

exposed to flame.

Extinguishing Media: Carbon dioxide, dry chemical or

foam.

Special Fire Fighting Procedures: None.

Explosion Hazards: None. Aluminum powder can react

with water to release flammable hydrogen gas. In the

form of this product, this reaction is not expected.

15 69-1720EFS—03

Page 16

L7224U OIL ELECTRONIC AQUASTAT® CONTROLLER

Section 6. Accidental Release

Measures

Scrape up and dispose of as solid waste in

accordance with state and federal regulations.

Section 7. Handling and Storage

Store in dry place. Keep container closed when not in

use.

Section 8. Exposure Controls and

Personal Protection

Ventilation: No special ventilation is required when

working with this product.

Respiratory Protection: None required.

Eye Protection: Not normally required. However, use

chemical safety goggles or faceshield if potential for

eye contact exists, especially if material is heated.

Hand/Clothing Protection: Not normally required.

Protective gloves and clothing are recommended, as

material is difficult to remove from skin and clothing.

Other Protective Equipment: None required.

Section 9. Physical and Chemical

Properties

Appearance/Odor: Aluminum color, semi-solid

material, pleasant odor.

Solubility in Water: Negligible.

Specific Gravity: 0.86.

Section 10. Stability and

Reactivity

Stability: Stable.

Reactivity: Hazardous polymerization will not occur.

Incompatibilities: Strong oxidizing agents and

halogens.

Hazardous Decomposition Products: Carbon dioxide,

carbon monoxide.

Section 11. Toxicology

Information

No data available.

Section 12. Ecological

Information

Chemical Fate Information: Hydrocarbon components will biodegrade in soil; relatively persistent in

water.

Section 13. Disposal

Consideration

Dispose of as solid waste in accordance with local,

state and federal regulations.

Section 14. Transportation

Information

DOT Classification: Not classified as hazardous.

Section 15. Regulatory

Information

SARA Title III Supplier Notification: Include in Section

311/312 inventory reports if amounts exceed 10,000

pounds. Aluminum compounds are subject to the

reporting requirements under Section 313 of

Emergency Planning and Community Right-To-Know

Act of 1986 (40 CFR 372). Ingredients listed in TSCA

Inventory.

Section 16. Other Information

This information is furnished without warranty,

expressed or implied, except that it is accurate to the

best of our knowledge.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

69-1720EFS—03 M.S. Rev. 04-11

Printed in U.S.A.

Page 17

L7224U Régulateur à mazout

®

électronique Aquastat

NOTICE D'INSTALLATION

APPLICATION

Le régulateur électronique à mazout électronique

EnviraCOM™ compatible L72424U permet une détection

électronique de la température grâce à une seule sonde

de détection intégrée dans un régulateur homologué UL.

Le L7224U commande le circulateur, le brûleur d'huile et

la température de chaudière.

Le L7224U est un « dispositif à réarmement de la

température extérieure » qui s'active lors du

branchement au module de réarmement d'extérieur.

Cette option est destinée à toutes les applications

excepté les systèmes de serpentin sans réservoir pour

eau chaude résidentielle.

Le L7224U remplace les régulateurs L8124A, L8124C,

L7124U, L7148A, L7248A,C, L7224A,C et L8148A et est

destiné aux applications résidentielles.

IMPORTANT

L'utilisation d'un système de réarmement

d'extérieur sur les systèmes à serpentin sans

réservoir nécessitant un réglage basse limite

peut résulter en une réduction de l'efficacité du

système.

Le L7224U fournit l'information sur le statut et le

diagnostic sur l'afficheur à cristaux liquides

combinés à des voyants DEL et à des thermostats compatibles EnviraCOM et des outils diagnostiques pour améliorer les processus

diagnostiques.

CARACTÉRISTIQUES

TECHNIQUES

Caractéristiques électriques :

Tension : 120 V c.a., 60 Hz.

Alimentation : 7 VA maximum à 120 V c.a. plus charges

externes.

Thermostat courant : 100 mA nominaux à 24 V c.a.

Relais de brûleur :

Courant pleine charge à 7,4 A à 120 V c.a.;

Tension de rotor bloqué de 44,4 A à 1,2 A avec appel

à pleine charge;

Moins la charge d'allumage : 360 VA.

Relais de régulateur :

7,4 A à pleine charge à 120 V c.a.; 44,4 A à l'appel à

pleine charge.

Régulateur de zone (ZC) : 7,4 A à 120 V c.a. à pleine

charge;

44,4 A à l'appel à rotor bloqué.

REMARQUE : Toutes les charges combinées ne peuvent

Caractéristiques environnementales :

Température : -34 à +66 °C (-30 à 150 °F).

Humidité : 0 à 95 % d'humidité relative, sans condensa-

tion.

Homologations :

Composants approuvés Underwriters Laboratories Inc.

Composants approuvés Canadian Underwriters Labora-

tories Inc.

Accessoires (commandés séparément) :

Nécessaire de réarmement d'extérieur AquaReset™

W8735S1000 (inclut le module de réarmement

d'extérieur 50022037-002 et le capteur de

température d'extérieur C7089U100)

Nécessaire d'eau chaude résidentiel AquaReset™

W8735S1008 (inclut le module d'eau chaude

résidentiel 50022037-005 et le capteur 32003971-

003)

C7089U1006 Capteur de température d'extérieur (utilisé

avec 50022037-002)

32003971-003 Capteur de température (utilisé avec

50022037-005)

Capteur (voir le Tableau 2).

Capteur de pince de puits 121371AA.

14 000, 485-016 1/4 po, diamètre (6,35 mm), fusible à

cartouche en verre d'une longueur de 1 1/4 po (31,75

mm), 1 A, à action retardée.

120650 Composé thermoconducteur.

Numéro

de pièce

123869A 1/2 (12,7) NPT 3 (76,2) 1 1/2 (38,1)

123870A 3/4 (19,05) NPT 3 (76,2) 1 1/2 (38,1)

pas dépasser 2000 VA.

Tableau 1. Puits pour régulateur L7224U.

Taille d'orifice

po (mm)

Insertion

po (mm)

Isolation po

(mm)

Page 18

L7224U RÉGULATEUR À MAZOUT ÉLECTRONIQUE AQUASTAT

AVERTISSEMENT

7. Inscrire le réglage Limite haute au moment de

Tableau 2. Capteurs pour régulateur L7224U

Numéro de

pièce

50001464-001 12 (304,8) Commandes montées

Longueur

po (mm) Application

sur puits

50001464-002 18 (457,2) Commandes encastrées

50001464-003 24 (609,6)

50001464-004 36 (914,4)

50001464-005 48 (1219,2)

Montage

INSTALLATION

Lors de l'installation du produit...

1. Lire attentivement ces instructions. Le fait de ne pas

les suivre risque d'endommager le produit ou de

constituer un danger.

2. Vérifier les caractéristiques nominales indiquées

dans les instructions et sur le produit, et s'assurer

que celui-ci correspond bien à l'application prévue.

3. L'installateur doit être un technicien d'expérience

ayant reçu la formation pertinente.

4. Une fois l'installation terminée, vérifier le fonc-

tionnement du produit comme l'indiquent les

présentes instructions.

5. Placer la Limite haute, la Limite basse et le Dif-

férentiel aux réglages recommandés par le fabricant de la chaudière.

6. Inscrire le réglage Limite haute maximale du régula-

teur remplacé dans la zone de texte fournie sur

l'étiquette du couvercle à insert.

Le L7224U peut être monté sur puits, position horizontale

ou verticale, ou montage encastré à distance du puits.

IMPORTANT

Nouvelle installation

Commander les ensembles de puits séparément;

consulter le Tableau 1 et le formulaire n° 68-0040, Puits

d'immersion et raccords de compression pour les

régulateurs de température. Les chaudières disposent

habituellement de deux prises qui permettent le montage

horizontal du puits pour que l'eau de la chaudière de

température moyenne puisse circuler librement sur le

puits. Voir la Fig. 1 pour connaître les dimensions de

montage.

®

l'installation dans la zone de texte fournie sur

l'étiquette du couvercle à insert.

Risque de choc électrique.

Peut provoquer de graves blessures, voire

mortelles ou des dommages à la propriété.

Débrancher l'alimentation en courant avant de

commencer l'installation pour prévenir des chocs

électriques ou des dommages matériels.

Le puits d'immersion doit être compatible avec

l'élément de détection et le capteur doit reposer

contre le bas du puits.

3/4

(75)

7-1/8

(181)

6-1/2

(166)

5-11/16

(145)

3/8

(10)

2-5/8 (67)

4-1/4 (109)

3-13/32 (86)

2x 1/4 (7) x 3/8 (9)

Fig. 1. L7224U, dimensions de montage en po (mm).

1. Couper l'alimentation en courant et vidanger la

chaudière, le cas échéant.

2. Si aucune prise n'est fournie, en ménager une à la

dimension et au filetage appropriés près du dessus

de la chaudière.

69-1720EFS—03 2

3-1/32

(77)

1-3/16

(30)

1-1/8 (29)

1/16 (2)

3. Recouvrir les filets du puits d'une petite quantité de

pâte à joint.

REMARQUE : Ne pas tenter de serrer en utilisant le boî-

tier comme poignée.

2-1/16 (53)

M22147B

Page 19

L7224U RÉGULATEUR À MAZOUT ÉLECTRONIQUE AQUASTAT

C1

B1

ZC

L2

LINE

C2

ZR

TX

L1

B2

T

T3

2

1

MF32197

TT

B1

ZC C1

BORNES DE

THERMOSTAT

BORNES

ENVIRACOM

MC

VOYANT

CONNECTEUR

DE CAPTEUR

ORIFICES DU

CAPTEUR

FUSIBLE

DEL

LANGUETTE POUR

MONTAGE ENCASTRÉ (2)

®

4. Installer le puits sur la prise de la chaudière en ser-

rant fermement.

5. Remplir de nouveau la chaudière et s'assurer de

l'absence de fuites.

6. Identifier si l'installation requiert un montage vertical

ou horizontal.

7. Retirer l'entrée défonçable du puits, pour un

montage vertical ou horizontal, en soulevant

prudemment l'entrée défonçable de l'arrière du

boîtier, en utilisant un tournevis à lame plate. Se

reporter à la Fig. 2.

ENTRÉE DÉFONÇABLE

POUR UN MONTAGE

HORIZONTAL

TOURNEVIS

ENTRÉE DÉFONÇABLE

POUR UN MONTAGE VERTICAL

Fig. 2. Dépose de l'entrée défonçable pour un

montage horizontal ou vertical.

8. Desserrer, mais ne pas retirer la vis de l'attache du

puits.

9. Installer le boîtier dans le puits de manière à ce que

l'attache du boîtier glisse sur la bride du puits.

10. Serrer fermement la vis de l'attache.

11. Insérer le capteur à élément jusqu'au fond du puits.

(Au besoin, plier légèrement le fil à l'intérieur du

boîtier pour que le capteur reste au fond du puits.)

12. Mettre l'appareil en marche.

13. Placer la Limite haute, la Limite basse et le

Différentiel limite basse aux réglages recommandés

par le fabricant de la chaudière. (Consulter les

étapes d'installation 6 et 7 de la section traitant du

FONCTIONNEMENT.)

IMPORTANT

Le puits doit être bien ajusté dans le capteur

pour obtenir une meilleure réponse thermique.

Insérer le capteur jusqu'à ce qu'il repose au fond

du puits. Utiliser un puits d'une longueur appropriée et plier le fil, au besoin, pour que le bulbe

reste au fond du puits.

Si le capteur n'épouse pas parfaitement la forme

du puits, utiliser le composé thermoconducteur

(fourni avec les modèles TRADELINE®) en

procédant comme suit : plier le sac de plastique

contenant le composé thermoconducteur sur le

sens de la longueur et l'enrouler doucement.

Couper ensuite l'extrémité du sac et la placer

tout au fond du puits. Tirer doucement sur le sac

pour le retirer du puits tout en le comprimant

MF22118

fermement de manière à distribuer

uniformément le composé dans le puits. Plier le

fil, au besoin, pour que le capteur reste au fond

du puits et que la paroi externe du capteur reste

en contact avec la paroi interne du puits.

Consulter la Fig. 3. Essuyer l'excès de composé

de l'extrémité extérieure du puits.

CÂBLAGE DU CAPTEUR

BOÎTIER DE RÉGULATEUR

ATTACHE DU

PUITS D’IMMERSION

VIS DE L’ATTACHE

DU PUITS D’IMMERSION

CHAUDIÈRE

PUITS

D’IMMERSION

COMPOSÉ THERMOCONDUCTEUR

(EN OPTION)

CAPTEUR

MF16120

Fig. 3. Position du capteur dans le puits d'immersion.

Remplacement de l'Aquastat,

montage encastré

Couper l'alimentation et déposer l'ancien régulateur. Se

reporter à l'insert du couvercle de l'ancien régulateur pour

identifier et étiqueter tous les fils externes au fur et à

mesure de leur déconnexion. Si l'ancien puits ne convient

pas au nouveau montage, le déposer et le remplacer pas

un puits neuf approprié. Si l'ancien puits convient, il doit

être utilisé. Voir les Fig. 1 et 4 pour connaître

l'emplacement de la languette de montage.

Fig. 4. Emplacement des languettes de montage

encastré et des DEL du L7224U.

3 69-1720EFS—03

Page 20

L7224U RÉGULATEUR À MAZOUT ÉLECTRONIQUE AQUASTAT

AVERTISSEMENT

CÂBLAGE DU CAPTEUR

MF22026

COMPOSÉ THERMOCONDUCTEUR

(EN OPTION)

CHAUDIÈRE

PUITS

D’IMMERSION

CAPTEUR

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T

3

2

1

1 2 3 OT OT

C7089U1006

CAPTEUR D’EXTÉRIEUR

50022037-002

MODULE DE

RÉARMEMENT D’EXTÉRIEUR

1 2 3 TS TS

50022037-005

MODULE D’EAU

CHAUDE DOMESTIQUE

32003971-003

CAPTEUR DE

TEMPÉRATURE

MF29651

®

Remplacement de l'Aquastat,

montage sur puits

Couper l'alimentation et déposer l'ancien régulateur. Se

reporter à l'insert du couvercle de l'ancien régulateur pour

identifier et étiqueter tous les fils externes au fur et à

mesure de leur déconnexion. Si l'ancien puits ne convient

pas au nouveau montage, le déposer et suivre les

directives s'appliquant à la nouvelle installation. Si

l'ancien puits convient, il doit être utilisé.

1. Desserrer, mais ne pas retirer la vis de l'attache du

puits qui se trouve sur le boîtier de commande.

2. Prendre soin de bien placer l'attache du puits

d'immersion sur la bride de l'adaptateur et de serrer

sa vis.

3. Mettre le capteur à l'intérieur du puits comme

l'indique la Fig. 5. (Si désiré, distribuer le composé

thermoconducteur dans le tube avant de l'insérer

dans le capteur, comme le décrit la section « Nouvelle installation ».)

4. S'assurer que le capteur repose complètement au

fond du puits (Fig. 5). Utiliser un petit crayon pour

mesurer la profondeur du capteur du puits, au

besoin.

CÂBLAGE

Risque de choc électrique.

Risque de causer des blessures graves, voire

mortelles.

Couper l'alimentation avant de raccorder le

câblage pour éviter les risques de choc électrique

ou l'endommagement de l'équipement.

Le câblage doit être conforme au code de l'électricité et

aux règlements locaux. Respecter les spécifications

énoncées dans la section Application lors du câblage de

ce régulateur.

IMPORTANT

Les bornes de ces régulateurs Aquastat sont

approuvées uniquement pour une utilisation

avec du câblage de cuivre.

Suivre les schémas de câblage appropriés illustrés à

l'intérieur du couvercle avant du L7224U ou dans les Fig.

9–13.

Se reporter à la Fig. 6 pour savoir comment brancher le

module d'eau chaude domestique et le module de

réarmement d'extérieur (en option). Dans des schémas

de câblage subséquents ces modules seront affichés

avec une ligne pointillée indiquant qu'ils sont optionnels.

Fig. 5. Installation du capteur de rechange.

Installation du capteur de

rechange

Couper le courant et débrancher prudemment le capteur

de la carte de circuit imprimé en tirant doucement sur le

connecteur.

1. Sortir doucement le capteur du puits thermomé-

trique et le passer dans la carte de circuit imprimé

en tirant sur les fils de connexion.

2. Aligner prudemment le capteur de remplacement

avec l'orifice de la carte de circuit imprimé et le

guider dans le boîtier Aquastat et le puits. Se

reporter à la Fig. 5.

3. S'assurer que le capteur repose complètement au

fond du puits (consulter la Fig. 5). Utiliser un petit

crayon pour mesurer la profondeur du capteur du

puits, au besoin.

4. Brancher le capteur dans la carte de circuit imprimé

en appuyant le connecteur du capteur contre le

connecteur homologue de la carte de circuit

imprimé (consulter la Fig. 6).

5. Pour les capteurs à distance (régulateurs Aquastat

69-1720EFS—03 4

à montage encastré) s'assurer d'utiliser l'attache

121371AA pour maintenir le capteur fermement en

place. Consulter la rubrique Accessoires.

Fig. 6. Raccordement du module de réarmement

d'extérieur et du module d'eau chaude domestique.

FONCTIONNEMENT

Général

Le régulateur électronique à mazout Aquastat L7224U est

principalement un limiteur de sécurité conçu pour être

utilisé avec des chaudières à mazout dotées de brûleurs

et circulateurs à tension secteur. Plusieurs chaudières

n'incluent pas le câblage ni les compartiments de

commande dans leur conception, mais sont fournies avec

un puits d'immersion intégré remplaçable qui sert

d'accessoire de fixation aux régulateurs Aquastat. Le

câblage aux autres régulateurs s'effectue par un conduit

métallique souple.

Page 21

L7224U RÉGULATEUR À MAZOUT ÉLECTRONIQUE AQUASTAT

Pour les chaudières qui n'incluent pas un régulateur à

distance intégré, le câblage doit être complété par un

conduit ou acheminé derrière la feuille métallique de la

chaudière.

Une Limite haute électromécanique séparée n'est pas

requise dans un système qui utilise ce régulateur pour

répondre aux normes Underwriters Laboratories Inc.

portant sur les assemblages de chaudière de mazout, UL

726.

Sur le modèle L7224U, la Limite haute, le Différentiel

limite haute, la Limite basse, le Différentiel limite basse et

la durée anti-court cycle peuvent être configurés au

moyen du réglage recommandé par le fabricant d'origine

de la chaudière.

La plage globale de Limite haute varie de 54 °C à 116 °C

(130 °F à 240 °F). Certains appareils peuvent utiliser des

plages différentes. Certains modèles peuvent avoir des

plages limitées pour la Limite haute du point de consigne,

cette plage limitée est indiquée sur l'étiquette de

l'appareil.

La plage de Limite basse varie de 43 °C à 104 °C (110 °F

à 220 °F). Certains appareils peuvent utiliser des plages

différentes. La plage de durée anti-court cycle varie de

ARRÊT (OFF) à 5 minutes.

Si un module à réarmement d'extérieur 50022037-002 est

installé, la courbe de compensation peut être réglée en

entrant la température extérieure minimale, la

température minimale (eau ou chaudière) et une

température extérieure maximale composée de trois

chiffres. La plage de températures extérieures minimales

varie de -40 °C à 4,4 °C (-40 °F à 40 °F) et a un réglage

par défaut de -18 °C (0 °F). La plage de températures

extérieures maximales varie de -1 °C à 21 °C (30 °F à 70

°F) et a un réglage par défaut de 4,4 °C (40 °F). La plage

de températures minimales varie de 27 °C à 82 °C (80 °F

à 180 °F) et a un réglage par défaut de 54 °C (130 °F).

Consulter la section traitant du « Module à réarmement

d'extérieur » Consulter les directives d'installation

(formulaire numéro 69-2335) pour en savoir plus sur le

réglage de la courbe de compensation de la chaudière et

de tous les paramètres connexes.

Le modèle L7224U est conçu pour être utilisé avec des

thermostats électroniques et électromécaniques de 24 V

c.a. ou des thermostats compatibles EnviraCOM™ et

disposent de bornes à vis qui permettent un branchement

facile sur le terrain.

Pour remplacer un régulateur L8148A,C L7148A ou

L7248A,C, la fonction Limite basse doit être désactivée;

consulter la rubrique Réglages pour obtenir des

directives.

Réglages

Pour empêcher la modification non autorisée des

réglages Aquastat, le mode de RÉGLAGE requiert de

suivre une procédure de saisie. Pour accéder au mode

RÉGLAGE, appuyer simultanément sur les boutons

HAUT, BAS et I pendant trois secondes (se reporter à la

Fig. 9). Appuyer sur la touche I jusqu'à ce que la fonction

à régler s'affiche :

Display Definition

HL_ Limite haute.

Hdf Différentiel limite haute.

LL_ Limite basse.

Ldf Différentiel limite basse.

duu Entrée ZR configurée comme demande d'eau

chaude domestique externe (MARCHE/

ARRÊT)

ASC Temporisation anti-court cycle (secondes); la

fonction « ARRÊT » est désactivée.

otL Paramètre de température extérieure minimale

pour la courbe de compensation extérieure

(°F ou °C)*

otH Paramètre de température extérieure élevée

(maximale) pour la courbe de compensation

extérieure (°F ou °C)*

btL Le paramètre de basse température de la

chaudière (minimale) pour la courbe de

compensation extérieure*

bP Période de suralimentation (minutes).

« ARRÊT » s'affiche si le mode de

Suralimentation est inactif*

bS Étape de suralimentation (°F ou °C) indiquée

seulement si le mode Suralimentation est actif

(bp=MARCHE)*

UUS Température d'arrêt par temps chaud

(°F ou °C)*

F-C Unités de température (°F ou °C)

* Paramètres disponibles pour le réglage sur l'afficheur à

trois chiffres seulement si le module de réarmement

d'extérieur AquaRest est installé.

Appuyer ensuite sur les touches HAUT et/ou BAS pour

déplacer le point de consigne à la valeur désirée. Après

60 secondes sans saisie de touches, le régulateur

retournera automatiquement au mode EXÉCUTION

(RUN).

Pour utiliser le L7224U pour démarrer une chaudière à

froid, désactiver la fonction Limite basse en appuyant

simultanément sur la flèche vers le HAUT, vers le BAS et

la touche I pendant trois secondes. Appuyer ensuite sur le

bouton I jusqu'à ce que LL_ s'affiche. Appuyer ensuite sur

la flèche vers le bas jusqu'à ce que ARRÊT (OFF)

s'affiche.

Afficheur

En mode EXÉCUTION (RUN), le régulateur Aquastat fera

apparaître « bt » à l'écran (température de la chaudière)

suivi par la température (c.-à-d. 220) et de °F ou °C.

Pour lire les réglages de chaudière, appuyer sur la touche

I pour lire le paramètre d'intérêt. Par exemple, appuyer

sur I et HL (Limite haute) s'affichera, suivie par une valeur

à trois chiffres, c.-à-d. 220 suivi par °F ou °C. Le fait

d'appuyer de nouveau sur la touche I fera apparaître la

valeur à trois chiffres et le dénominateur de degré. Voir la

Fig. 7 pour obtenir des explications sur la lecture de

l'affichage.

Après environ 60 secondes sans appuyer sur une ou

plusieurs touches, l'affichage passera en mode

d'atténuation de l'affichage. Pour retourner au mode

d'affichage à grande brillance, il suffit d'appuyer sur une

touche ou une touche puis de la relâcher.

®

5 69-1720EFS—03

Page 22

L7224U RÉGULATEUR À MAZOUT ÉLECTRONIQUE AQUASTAT

®

Texte

Err

bt

1

HL

HdF

LL

Ldf

tt

ttE

brn

Cir

ZC

Zr

ELL

duu

ASC

2

bSP

3

dhc

2

ot

2

otL

otH

2

2

btL

2

bP

2

bS

2

UUS

°F

°C

OFF

On

1

LE PARAMÈTRE LOCAL S’AFFICHE; NON PAS LE

PARAMÈTRE MODIFIÉ PAR UN RÉGULATEUR

EXTERNE ENVIRACOM.

2

LES PARAMÈTRES PEUVENT SEULEMENT ÊTRE

AFFICHÉS SI LE MODULE DE RÉARMEMENT

D’EXTÉRIEUR ET LE CAPTEUR DE TEMPÉRATURE

SONT INSTALLÉS ET FONCTIONNENT CORRECTEMENT.

3

LES PARAMÈTRES PEUVENT SEULEMENT ÊTRE

AFFICHÉS SI LE MODULE D’EAU CHAUDE DOMESTIQUE

ET LE CAPTEUR SONT INSTALLÉS ET FONCTIONNENT

CORRECTEMENT.

Description

Code d’erreur (en présence d’un code)

Température de la chaudière

Limite haute

Différentiel limite haute

Limite basse (L7224 seulement)

Différentiel limite basse (L7224 seulement)

État du thermostat local

État du thermostat EnviraCOM

Sortie B1 (brûleur)

(MARCHE ou ARRÊT)

Sortie C1 (circulateur)

(MARCHE ou ARRÊT)

Sortie ZC (commande de zone)

(MARCHE ou ARRÊT)

Appel ZR (demande de zone) de CHALEUR

(MARCHE ou ARRÊT)

Limite basse externe activée

(L7248L seulement)

ZR configurée comme demande d’eau

chaude domestique

(L7224, L7248 seulement)

Temporisation anti-court cycle

Point de consigne de la chaudière

Module d’eau chaude domestique branché

(OUI ou NON)

Température extérieure

Basse température extérieure

Haute température extérieure

Basse température de chaudière

Période de suralimentation

Étape de suralimentation

Température d’arrêt par temps chaud

Les unités sont affichées en degrés Fahrenheit

Les unités sont affichées en degrés Celsius

L’entrée ou la sortie est à ARRÊT

L’entrée ou la sortie est à MARCHE

Fig. 7. Définitions de la lecture de l'affichage.

L’affichage

indique

MF29552A

* Paramètres disponibles pour le réglage sur l'afficheur à

trois chiffres seulement si le « module de réarmement

d'extérieur » est installé.

Fonctionnement

Le modèle L7224U peut se trouver dans un des quatre

états de fonctionnement suivants : Normal, Limite haute,

Limite basse et Erreur. S'il fonctionne normalement, le

régulateur alterne entre la Limite haute, le Mode normal et

la Limite basse. États de fonctionnement :

1. Normal : La température de la chaudière est passée

sous le réglage Limite haute (moins le différentiel)

et n'a pas dépassé le réglage Limite haute; ou, la

température de la chaudière est passée au-dessus

du réglage Limite basse et n'a pas chuté sous le

réglage Limite basse (moins le différentiel).

2. Limite haute : La température de la chaudière a

dépassé le réglage Limite haute et n'a pas chuté

sous le réglage Limite haute (moins le différentiel).

3. Limite basse : La température de la chaudière a

chuté sous le réglage Basse limite (moins le Différentiel basse limite) et n'a pas dépassé le réglage

Basse limite.

4. Erreur : Une erreur a été détectée par le régulateur

(p. ex. capteur ouvert) et a coupé la sortie du

brûleur. La sortie Contrôle de zone (ZC) est activée.

Le régulateur continue de surveiller le système et

redémarre automatiquement si l'erreur disparaît. Se

reporter aux Tableau 4 à 6.

La séquence de fonctionnement du modèle L7224U est

illustrée dans le Tableau .

Régulateur Limite haute

La Limite haute ouvre et coupe le circuit du brûleur

lorsque la température augmente jusqu'au point de

consigne. La Limite haute se remet automatiquement en

circuit par l'intermédiaire du différentiel réglable lorsque la

température de l'eau chute sous le point de consigne.

Régulateur de Limite basse et de

circulateur

Lorsque la température monte, le circuit du brûleur est

coupé et le circuit du circulateur utilise le point de

consigne Limite basse (en l'absence de demande de

chaleur). Lorsque la température chute de 6 °C (10 °F)

sous le point de consigne Limite basse (avec le

différentiel réglable à un point de consigne minimal de 6

°C/10 °F), le circuit du brûleur se déclenche et le circuit du

circulateur se coupe. Se reporter à la Fig. 7.

69-1720EFS—03 6

Page 23

Fig. 8. Points de consigne et différentiels.

RÉGLAGE

LIMITE

BASSE

RÉGLAGE

LIMITE

HAUTE

L’INTERRUPTEUR S’OUVRE

LORSQUE LA TEMPÉRATURE

MONTE. LE BRÛLEUR S’ÉTEINT.

LE CIRCULATEUR FONCTIONNE

LORS D’UNE DEMANDE DE

CHALEUR.

L’INTERRUPTEUR S’ACTIVE LORS

D’UNE CHUTE DE TEMPÉRATURE.

LE BRÛLEUR FONCTIONNE LORS

D’UNE DEMANDE DE CHALEUR.

EN L’ABSENCE DE DEMANDE DE

CHALEUR, L’INTERRUPTEUR

S’ACTIVE LORS D’UNE

HAUSSE DE TEMPÉRATURE.

L’INTERRUPTEUR S’ACTIVE LORS

D’UNE CHUTE DE TEMPÉRATURE,

LE BRÛLEUR EST ALLUMÉ POUR

MAINTENIR UNE TEMPÉRATURE

D’EAU MINIMALE. LE

CIRCULATEUR EST DÉSACTIVÉ.

MF23365

LORSQUE L’EAU ATTEINT LE RÉGLAGE LIMITE BASSE, LE BRÛLEUR SE

COUPE OU LA POMPE DE CIRCULATEUR DÉMARRE

(LORS D’UNE DEMANDE DE CHALEUR).

1

1

DIFFÉRENCE DE

6 ºC (10 ºF)

DIFFÉRENCE DE

6 ºC (10 ºF)

C1

B1

ZC

L2

LINE

C2

ZR

L1

B2

T

T3

2

1

MF32022

L1

(SOUS

TENSION)

CAPTEUR

CIRCULATEUR

(TENSION

SECTEUR)

TENSION

SECTEUR,

RELAIS DU

BRÛLEUR

À MAZOUT

L2

CAPTEUR D’EXTÉRIEUR ET MODULE DE RÉARMEMENT

D’EXTÉRIEUR (EN OPTION).

1

1 2 3 OT OT

CAPTEUR

D’EXTÉRIEUR

C7089U1006

1

MODULE DE RÉARMEMENT

D’EXTÉRIEUR

50022037-002

REMARQUE : Le réglage de la Limite basse au-dessus

de la Limite haute moins le Différentiel de

limite haute n'est pas autorisé car cela

pourrait nuire au fonctionnement du circulateur et du contrôle de zone.

Fonction Anti-court cycle

La fonction Anti-court cycle permet de sélectionner sur

site un délai de temporisation minimal entre les cycles de

brûleur. Si une demande de chaleur est faite après la fin

du cycle de chaleur précédent et avant l'expiration de la

temporisation de l'Anti-court cycle, le circulateur pourra

fonctionner, mais le brûleur sera coupé jusqu'à ce que le

délai soit expiré.

REMARQUE : La fonction Anti-court cycle est bloquée

REMARQUE : Lorsque l'Aquastat est branché au régula-

ZR - Demande d'eau chaude

domestique

La borne ZR du L7224U peut être sélectionnée pour

répondre à une demande indirecte du chauffe-eau. Ce

paramètre est réglé par l'intermédiaire d'un affichage à

trois chiffres (voir la section du présent document traitant

des réglages). Une demande de chaleur faite par

lorsqu'il y a demande d'eau chaude

domestique. Les demandes d'eau chaude

domestique sont traitées immédiatement,

sans délai.

teur primaire et/ou au thermostat par

l'intermédiaire du bus EnviraCOM, la

durée de l'Anti-court cycle ne s'applique

pas aux événements de recyclage comme

une perte d'écoulement d'air ou de

flammes. Il s'applique seulement à la perte

de demande.

L7224U RÉGULATEUR À MAZOUT ÉLECTRONIQUE AQUASTAT

l'intermédiaire de la borne ZR a priorité sur d'autres

fonctions comme la fonction Anti-court cyle ou celles

activées par le module de réarmement d'extérieur

(consulter le formulaire n

amples renseignements).

o

69-2335 pour obtenir de plus

VÉRIFICATION

Mettre le système en marche et observer au moins un

cycle complet pour s'assurer que le régulateur fonctionne

correctement. Consulter la section DÉPANNAGE pour

utiliser des DEL pour vous aider à vérifier le

fonctionnement du système.

DÉPANNAGE

Lors de la tentative de diagnostic de la performance du

système, la référence de l'affichage DEL peut vous aider

à identifier les secteurs spécifiques qui ne fonctionnent

pas. Le message Err défilera dans l'affichage DEL suivi

d'un chiffre (1-8). Se reporter au Tableau 7 pour obtenir

une description de chaque erreur et des actions

suggérées et au Tableau 8 pour utiliser le guide de

dépannage.

Fig. 9. Connexions à zone unique L7224U.

7 69-1720EFS—03

®

Page 24

L7224U RÉGULATEUR À MAZOUT ÉLECTRONIQUE AQUASTAT

®

AQUASTAT DE RÉSERVOIR

MODULE DE RÉARMEMENT

D’EXTÉRIEUR

50022037-002

1 2 3 OT OT

CAPTEUR

D’EXTÉRIEUR

C7089U1006

CAPTEUR

CIRCULATEUR

(TENSION

SECTEUR)

TENSION

SECTEUR,

RELAIS DU

BRÛLEUR

À MAZOUT

1

Fig. 10. Système à zone de chauffage unique avec

circulateurs et réservoir d'eau indirect L7224U.

Module de réarmement d'extérieur facultatif.

Tableau 3. L7224/L7248, séquence de fonctionnement

L1

(SOUS TENSION)

L1

(SOUS

L2

TENSION)

1

ZR

L1

L2

C2

B2

C1

B1

ZC

MODULE DE RÉARMEMENT D’EXTÉRIEUR (EN OPTION).

du régulateur.

INDIRECT TENSION SECTEUR

T

T3

2

1

LINE

L2

CIRCULATEUR

DE RÉSERVOIR