Page 1

L7224 Series

Oil Electronic

Aquastat® Controller

TECHNICIAN’S QUICK REFERENCE GUIDE

The following service procedure provides a quick overview for

L7224 Series Controllers. For more information, refer to form

69-1384.

On the L7224U the High Limit, High Limit Differential, Low Limit,

and Low Limit Differential can be adjusted to the settings

recommended by the boiler OEM.

Adjusting Settings

To discourage unauthorized changing of Aquastat® settings, a

procedure to enter the adjustment mode is required. To enter the

adjustment mode, press the UP, DOWN, and I buttons

simultaneously for three seconds. Press the I button until the

feature requiring adjustment is displayed:

• HL—High Limit.

• LL—Low Limit.

• Ldf—Low Limit differential.

• F - C—°F or °C.

Then press the UP and/or DOWN buttons to move the set point to

the desired value. After 60 seconds without any button inputs, the

control will automatically return to the READ mode.

To use the L7224U in a cold start boiler application, disable the

Low Limit function by pressing the UP arrow button, DOWN arrow

button and I buttons simultaneously for three seconds. Then push

the I button until LL is displayed. Then press the down arrow

button until OFF is displayed.

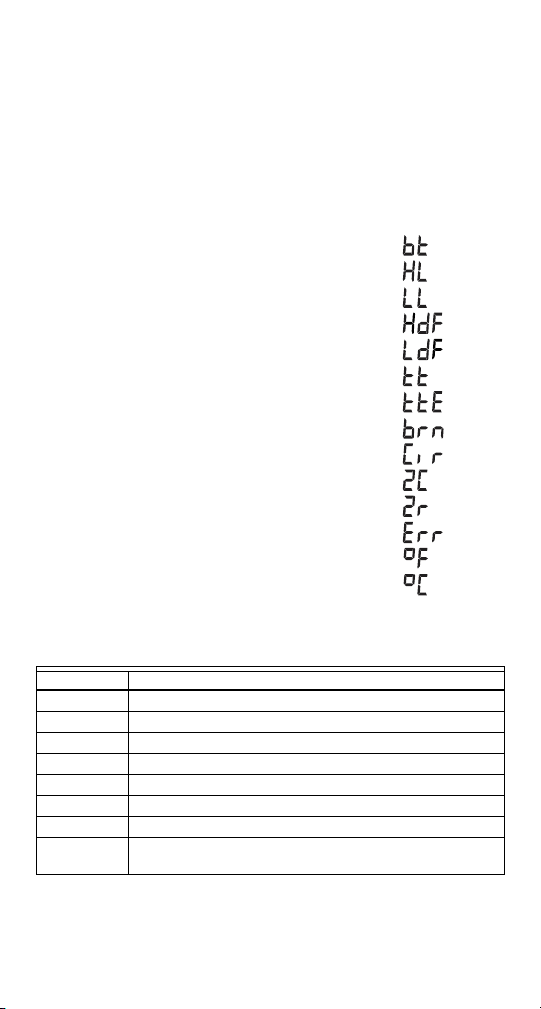

Display

In the RUN mode, the Aquastat® will flash “bt” (boiler temp)

followed by the temperature (i.e., 220), followed by °F or °C.

To read boiler settings, press the I key to read the parameter of

interest. For example, press I (HL) High Limit is displayed,

followed by a three-digit number, i.e., 220, followed by °F or °C.

69-1957—1

Page 2

L7224 SERIES

Pressing the I button again will display the LL (Low Limit) followed

by a three-digit number and the corresponding degree designator.

See the table below for an explanation of display readout.

After approximately 60 seconds without any key presses, the

display will enter a dim display mode. To return to the bright

display mode, simply press and release any key.

Display

Text Description

bt

f

c

Boiler Temperature

High LimitHL

Low LimitLL

High Limit DifferentialHdf

Low Limit DifferentialLdf

Local Thermostat Statustt

Enviracom Thermostat Statustte

Burner Statusbrn

Circulator Statuscir

Zone ControlZc

Zone RequestZr

Error Codeerr

Degrees Fahrenheit

Degrees Celsius

Shows

M22149

Table 1. LED Error Codes

Error Code Cause/Action

Err1 Sensor fault; check sensor.

Err2 ECOM fault; check EnviraCOM. wiring.

Err3 Hardware fault; replace control.

Err4 B1 fault; check B1 wiring/voltage.

Err5 Low Line; Check L1-L2, 110 Vac.

Err6 Fuse; Check ECOM wires, Replace fuse.

Err7 EEPROM, HL, LL, Hdf, Ldf, Reset to default values.

Err8 Repeated B1 fault (voltage present at B1 when

output is turned off); check B1 wiring/voltage.

69-1957—1 2

Page 3

L7224 SERIES

Table 2. L7224 Controller Operating Sequence

Action System Response

Thermostat

calls for heat.

Circulator starts when water temperature is

above Low Limit setting (if applicable). Boiler

temperature is checked. Burner starts when

water temperature is below High Limit setting.

Boiler exceeds

the High Limit.

Thermostat is

Burner is turned off. Burner restarts when the

water temperature drops below the High Limit

setting minus the differential.

Circulator and burner turn off.

satisfied.

Error conditions

1-5.

Error conditions

6-7.

Error condition 8.If the error condition is detected, all outputs

If an error condition is detected, all outputs

except ZC are shut down. Burner is off. Control

continues to function and restarts when error is

corrected. During the error check sequence, the

system checks for drift in the sensor and

corrosion in the connections.

If error condition 6 or 7 occurs, the control has

reset the High Limit, Low Limit and Differential

Setting to a default setting and will continue to

run at those settings. Performance of the system

will be degraded.

except ZC are shut down. Burner is off. Control

continues to function and restarts when all three

user keys have been pressed longer than 60

seconds.

Troubleshooting

When attempting to diagnose system performance, reference the

LED display to help identify specific areas not working properly.

The LED display will scroll “err”, followed by a digit (1-8). See

Table 1 for a description of the error and suggested actions. See

below for a troubleshooting guide.

Table 3. Troubleshooting Guide

System

Condition

Boiler is

cold,

house is

cold

a

. Refer to Fig. 5 for Display and LED locations.

b

. ZC LED ON indicates ZC terminal power is OFF.

c

. ZC LED OFF indicates ZC terminal power is ON.

Diagnostic

Condition Check Action

Display is OFF 120 Vac system

Display is ON;

TT-LED is OFF

Display is ON;

TT-LED is OFF

power.

24 Vac T-T No 24V; replace

24V present;

disconnect

thermostat,

short T-T

3 69-1957—1

a

.

Turn system power on.

control

Boiler starts, check

wiring and thermostat

Page 4

Table 3. Troubleshooting Guide

System

Condition

Boiler is

cold,

house is

cold

Boiler is

hot, house

is cold

a

. Refer to Fig. 5 for Display and LED locations.

b

. ZC LED ON indicates ZC terminal power is OFF.

c

. ZC LED OFF indicates ZC terminal power is ON.

Diagnostic

Condition Check Action

Display is ON;

TT-LED is ON

B1 LED is ON

Display is ON;

TT-LED is ON

Display is ON;

TT-LED is ON

120 Vac at B1-B2• If no, replace control.

Refer to err on

display

120 Vac at C1-C2• 120 Vac at C1-C2,

C1 LED is ON

Display is ON;

TT-LED is ON

C1 LED is OFF;

ZC LED is ON

Display is ON;

TT-LED is ON

ZC LED is

c

OFF

Boiler below the

Low Limit

temperature,

b

wait for boiler to

go above Low

Limit

temperature.

Boiler above

LL? If yes,

check for 120

Vac between ZC

and L2

a

.

• If yes, check burner

and wiring

—

check wiring to pump

• Wiring ok, is pump

running? If not,

replace the pump.

• If pump is running,

check for trapped air

or closed zone

valves.

• If no 120 Vac,

replace control.

• If yes, check zone

relays, circulators

and wiring.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2006 Honeywell International Inc.

69-1957—1 Rev. 06-06

Loading...

Loading...