Page 1

L7124U Universal Oil

Electronic Aquastat® Controller

INSTALLATION INSTRUCTIONS

APPLICATION

The L7124U Universal Oil Electronic Aquastat®

Controller provides electronic temperature sensing in a

UL limit-rated control with a single sensing probe. The

L7124U controls circulator, oil burner and boiler

temperature. The L7124U replaces the L8124A, L8124C

and L8148A Controllers.

General

The L7124U Universal Oil Electronic Aquastat®

Controller is a primary safety limit-rated device designed

for use with oil fired boilers with line voltage burners and

circulators. The boilers do not include wiring or control

compartments as part of the design, but are provided

with an integral, replaceable, immersion well that is the

mounting hardware for the L7124U. Wiring to the other

controls is done through flexible metal conduit. A

separate electromechanical high-limit is not required in a

system that uses this control.

A manually-adjusted potentiometer is used to set the

High Limit. The overall range of the High Limit dial is from

130°F to 240°F (54°C to 116°C). The High Limit is

calibrated for accuracy at 212°F (100°C). Some models

have limited ranges on the high limit setpoint; this limited

range is listed on the device label, but the potentiometer

travels the full mechanical distance.

Some models also have a Low Limit and Low Limit

Differential adjustment. The range of the Low Limit dial is

from 110°F to 220°F (43°C to 104°C). Rotating the Low

Limit potentiometer fully counterclockwise disables

the low limit function and turns on the Low Limit

Disabled LED.

The L7124U is designed for use with 24 Vac electronic

and electromechanical thermostats and has screw-type

terminals for easy field connection.

SPECIFICATIONS

Electrical Ratings:

Voltage: 120 Vac, 60 Hz.

Power: 10 VA maximum at 120 Vac plus external loads.

Thermostat current: 100 mA nominal at 24 Vac.

Burner Relay:

7.4A at 120 Vac Full Load Amperage (FLA);

44.4A inrush Locked Rotor Amperage (LRA);

Plus Ignition Load: 360 VA.

Circulator Relay:

7.4A at 120 Vac FLA; 44.4A inrush LRA.

Zone Controller (ZC): 7.4A at 120 Vac FLA;

44.4A inrush LRA.

Differential Ratings:

High Limit Differential: 15°F subtractive.

Low Limit Differential: Adjustable 10°F to 25°F

subtractive from Low Limit setpoint.

Environmental Ratings:

Temperature: -30°F to +150°F (-34°C to +66°C).

Humidity: 0 to 95% relative humidity,

noncondensing.

Approvals:

Underwriters Laboratories Inc. Component Recognized:

Pending approval.

Canadian Underwriters Laboratories Inc. Component

Recognized: Pending approval.

Accessories

Accessories (Ordered Separately):

120650 Heat Conductive Compound

124904 Well Adapter

32002190-001 Relay

32004955-001 Sensor

4074GYZ Fuse, 1A (10-pack package)

Table 1. Wells for L7124U Controller.

Part

Number

123869A 1/2 NPT 3 1-1/2

123870A 3/4 NPT 3 1-1/2

Spud Size

(in.)

Insertion

(in.)

Insulation

(in.)

® U.S. Registered Trademark

Copyright © 2001 Honeywell • All Rights Reserved

69- 1232- 2

Page 2

L7124U UNIVERSAL OIL ELECTRONIC AQUASTAT® CONTROLLER

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. The installer must be a trained, experienced

service technician.

4. After installation is complete, check out product

operation as provided in these instructions.

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage.

Mounting

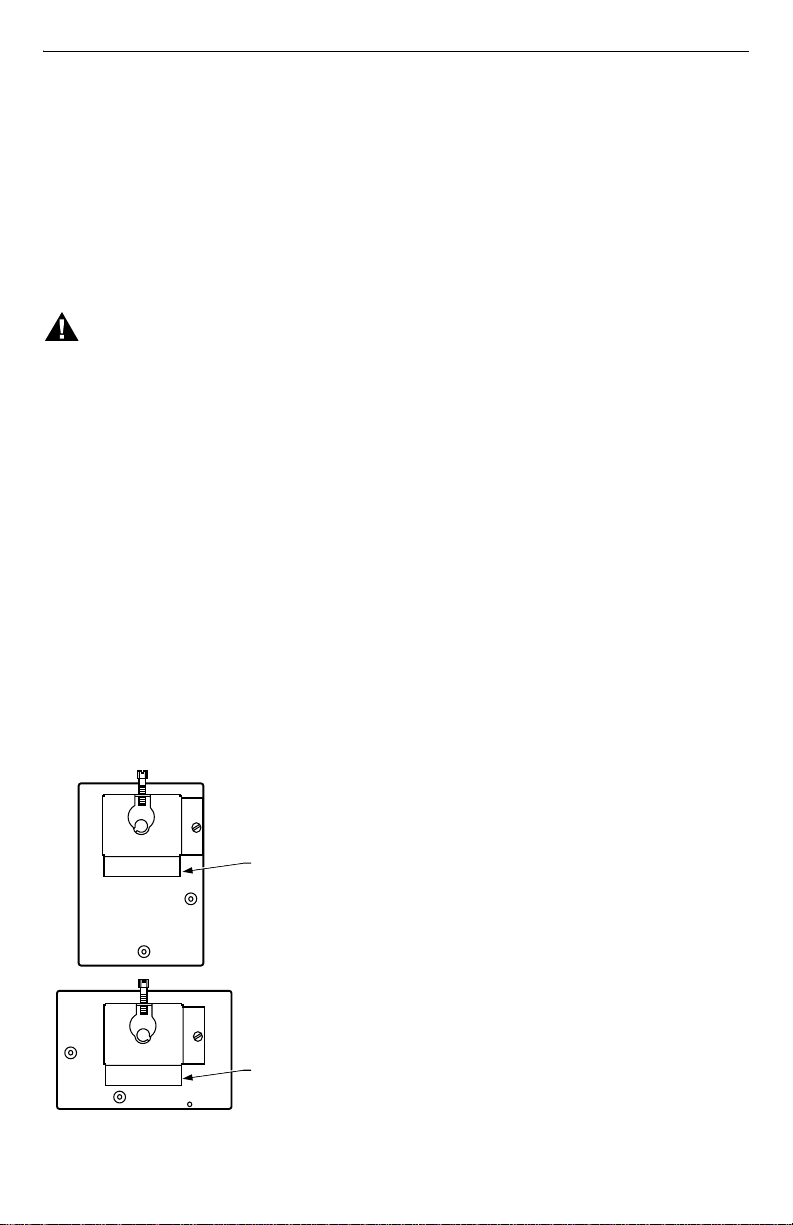

The L7124U has a case that can be converted for either

horizontal or vertical mounting. See Fig. 1.

IMPORTANT

Immersion well must fit sensing element and

sensor bulb must rest against bottom of well.

New Installation

Order well assemblies for the L7124U separately; see

form 68-0040, Wells and Fittings for Temperature

Controllers. Boilers usually have tappings that allow

the well to be mounted horizontally so boiler water of

average temperature can circulate freely.

1. Turn off all power and drain the boiler.

2. If no tapping is provided, prepare properly sized

and threaded tapping near the top of the boiler.

3. Sparingly coat the well threads with pipe dope.

BRACKET POSITION FOR

VERTICAL MOUNTING

BRACKET POSITION FOR

HORIZONTAL MOUNTING

M8890

Fig. 1. Case designed for vertical

or horizontal mounting.

69-1232—2 2

NOTE: Do not attempt to tighten by using the case as a

handle.

4. Install the well in the boiler tapping and tighten

securely.

5. Refill boiler and check for water leakage.

6. Loosen but do not remove the clamp screw on the

L7124U case.

7. Insert the sensor element into the well until it

bottoms. (If necessary, slightly bend the tube inside

the case to hold the sensor against the bottom of

the well.)

NOTE: Some models have an adjustable wire length to

3 in. (76 mm). For these models, pull out extra

wire length from inside the case, if needed.

8. Fit the case into the well so the clamp on the case

slides over the flange on the well.

9. Securely tighten the clamp screw.

IMPORTANT

Best thermal response is obtained with a well

that snugly fits the sensor. Insert the sensor

until it rests against the bottom of the well. use

a well of correct length and bend the wiring, if

necessary, to hold the bulb against the bottom

of the well.

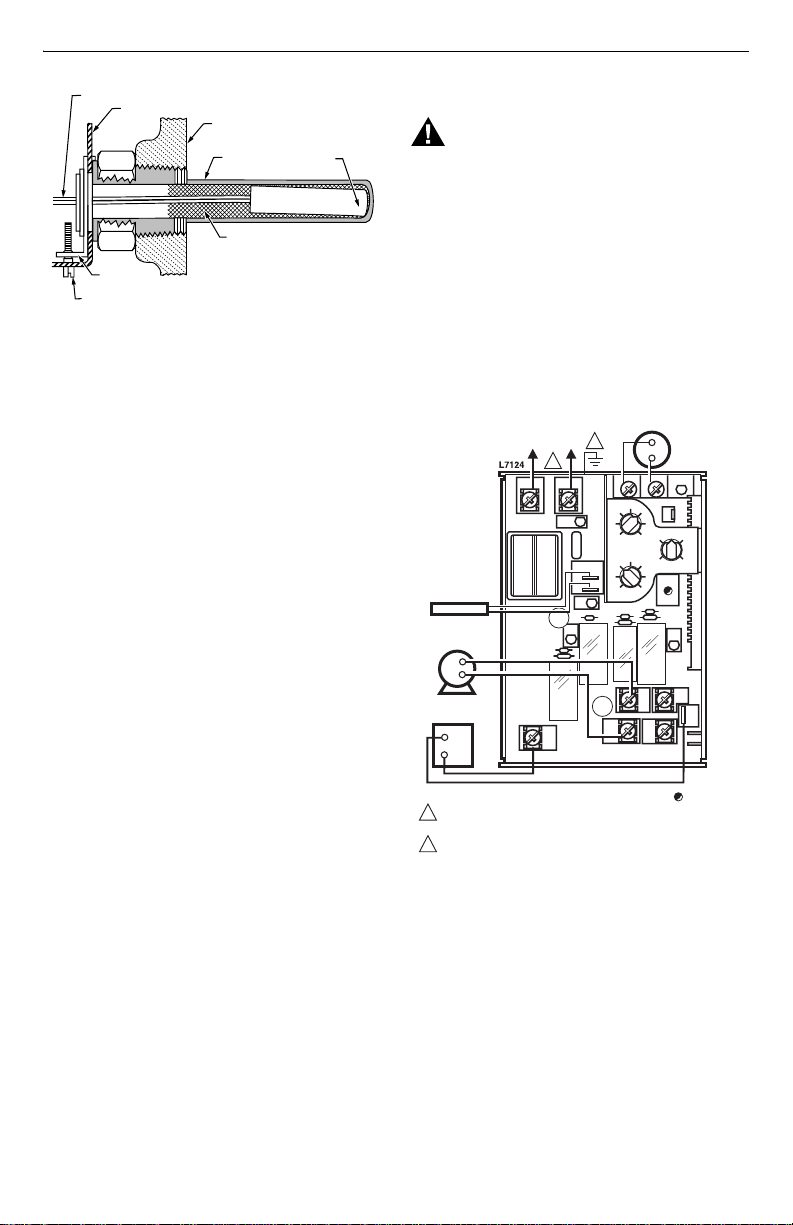

If the well is not a snug fit on the sensor, use

the heat-conductive compound (furnished with

TRADELINE models) as follows: Fold the

plastic bag of compound lengthwise and twist it

gently. Then snip off end of bag and work the

open end of the bag all the way into the well.

Slowly pull out the bag while squeezing it firmly

to distribute compound evenly in the well. Bend

the wiring, if necessary, to hold the sensor

against the bottom of the well and to hold outer

end of the sensor in firm contact with the side of

the well. See Fig. 2. Wipe excess compound

from the outer end of the well.

Replacement Installation

Turn off all power and remove the old control. Refer

to the cover insert of the old control to identify and tag

each external lead as it is disconnected. If the old well is

unsuitable for the new installation, remove it and proceed

with instructions for new installation. If the old well is

suitable, use it and an immersion well adapter (ordered

separately) for the installation. (The well clamp may fit

directly over the flange of the existing well spud and

using the adapter may not be necessary.) The adapter

has a flange at the wide end that fits into the well clamp

and is slotted lengthwise to accommodate the sensor

wire.

1. Loosen but do not remove the well clamp screw on

the side of the control case.

2. Pull out the wire until the sensor bottoms in the

well. Place adapter, if used, around the sensor wire

so it fits into the slot. See Fig. 2.

3. Make sure the wide end of the adapter fits into the

hole in the case. Position immersion well clamp

snugly over the flange of the adapter and tighten

the clamp screw.

4. Insert the sensor into the well as shown in Fig. 2.

(Distribute the heat-conductive compound in the

tube prior to bulb insertion.)

5. Securely tighten the setscrew against the adapter.

Page 3

L7124U UNIVERSAL OIL ELECTRONIC AQUASTAT® CONTROLLER

SENSOR WIRES

CONTROLLER CASE

IMMERSION

WELL CLAMP

IMMERSION WELL

CLAMP SCREW

BOILER

IMMERSION

WELL

HEAT-CONDUCTIVE COMPOUND

(OPTIONAL)

SENSOR

M16120

Fig. 2. Position of sensor in immersion well.

WIRING

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect power supply before making wiring

connections to prevent electrical shock or

equipment damage.

All wiring must comply with local electrical codes and

ordinances. Do not exceed the specifications in the

Application section when wiring this control.

IMPORTANT

The terminals on these Aquastat® Controllers

are approved for use with copper wire only.

Follow the appropriate wiring diagrams shown on the

inside of the front cover of the L7124U or in Fig. 3 and 4.

LINE VOLTAGE

CIRCULATOR

SENSOR

L2

L1

(HOT)

L1

T1

1

PWR

SENSOR

2

1

C

ZC

2

F01

LOW VOLTAGE

THERMOSTAT

TL2T TSTAT

HIGH

LIMIT

DIFF.

LL

LOW

LIMIT

DSBL

B

ZC

LINE VOLTAGE OIL

BURNER RELAY

B2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

CONTROL CASE MUST BE CONNECTED TO EARTH

GROUND. USE GROUNDING SCREW PROVIDED.

C1

C2

ZR

LEGEND: = LED

B1

M17776

Fig. 3. L7124U single zone connections.

3 69-1232—2

Page 4

L7124U UNIVERSAL OIL ELECTRONIC AQUASTAT® CONTROLLER

R

TO ADDITIONAL R845A

L

B

SENSOR

LINE VOLTAGE

CIRCULATOR

INE VOLTAGE OIL

URNER RELAY

2

1

L1

PWR

T1

F01

SENSOR

2

1

C

ZC

B2

C2

LOW

VOLTAGE

THERMOSTAT

TL2T TSTAT

HIGH

LIMIT

DIFF.

LL

LOW

LIMIT

DSBL

B

ZC

C1

ZR

B1

RELAYS FOR OTHER ZONES

1

L1

(HOT) L2

LEGEND: = LED

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

CONTROL CASE MUST BE CONNECTED TO EARTH

GROUND. USE GROUNDING SCREW PROVIDED.

Fig. 4. L7124U multizone system with circulator connections.

R845A RELAY ZONE 2

6

5

3

4

1

2

ZONE 2

LOW VOLTAGE

THERMOSTAT

ZONE 2

CIRCULATO

M17777

69-1232—2 4

Page 5

OPERATION

).

L7124U UNIVERSAL OIL ELECTRONIC AQUASTAT® CONTROLLER

High Limit Controller

The high limit opens and turns off the burner when the

water temperature reaches the setpoint. The high limit

automatically resets after the water temperature drops

past the setpoint and through the 15°F (8°C) differential.

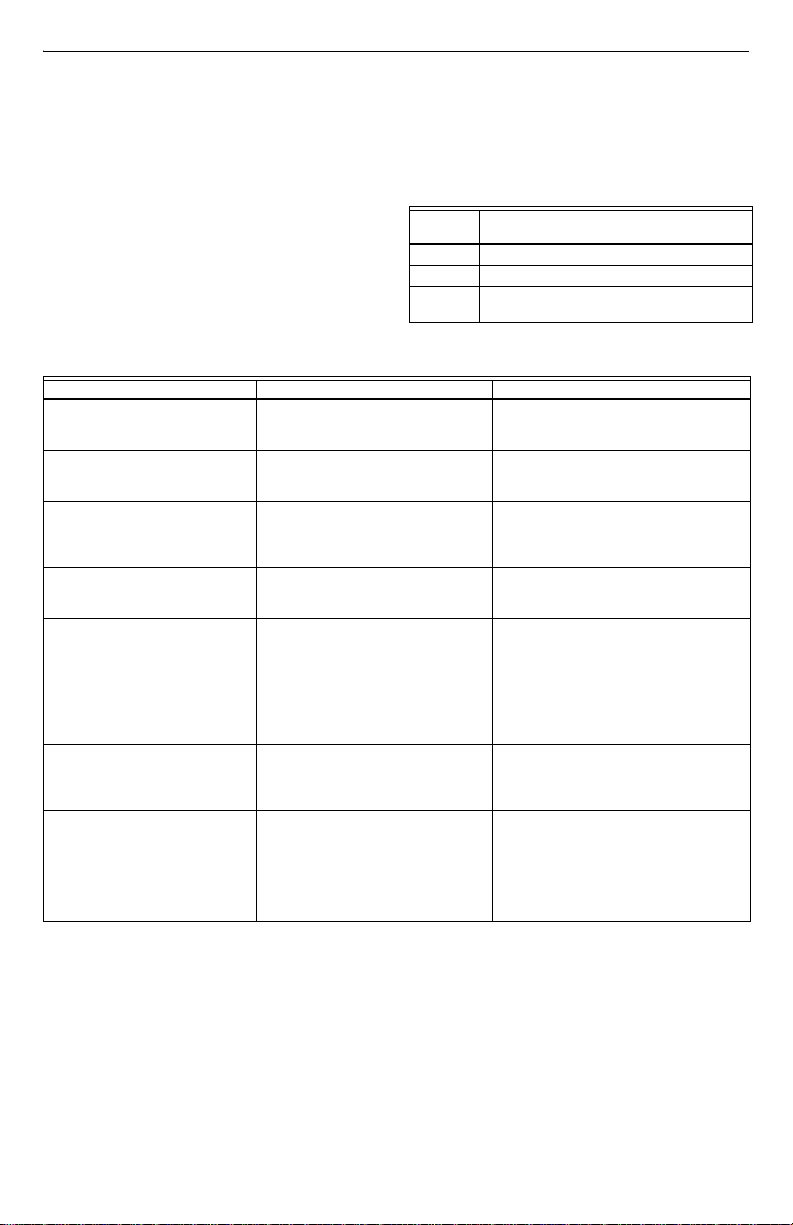

Low Limit and Circulator Controller

On a temperature rise, with the adjustable differential at

the minimum setting of 10°F (6°C), the burner circuit

breaks and the circulator circuit makes at the low limit

setpoint. On a temperature drop of 10°F (6°C) below the

low limit setpoint, the burner circuit makes and the

circulator circuit breaks. See Fig. 5.

CAUTION

Equipment Damage Hazard.

Can cause improper operation

1. Setting the Low Limit above the High Limit

disables the device.

2. Setting the Low Limit less than 15°F (8°C)

below the High Limit results in improper

circulator function.

SWITCH BREAKS ON

TEMPERATURE RISE.

HIGH LIMIT

SETTING

LOW LIMIT

SETTING

1

WHEN WATER REACHES LOW LIMIT SETTING, THE BURNER SHUTS

OFF OR THE CIRCULATOR PUMP STARTS (WHEN CALLING FOR HEAT

Fig. 5. Setpoints and differentials.

BURNER TURNS OFF.

CIRCULATOR OPERATES

ON A CALL FOR HEAT.

SWITCH MAKES ON

TEMPERATURE FALL.

BURNER OPERATES ON A

CALL FOR HEAT.

WITH NO HEATING

DEMAND, SWITCH BREAKS

ON TEMPERATURE RISE.

SWITCH MAKES ON

TEMPERATURE FALL,

BURNER IS ON TO

MAINTAIN MINIMUM

WATER TEMPERATURE.

CIRCULATOR IS OFF.

M21059

1

The L7124U can be in any of four operational states:

Normal, High-Limit, Low-Limit and Error. The controller

moves back and forth from High-Limit to Normal to

Low-Limit state as part of normal operation. However, the

controller enters only the Error state when there is an

abnormal condition such as an internal error or a bad

sensor. The operating states are:

1. Normal: Boiler temperature has gone below the

high limit setting (minus the fixed differential) and

has not exceeded the high limit setting; or, the

boiler temperature has gone above the low limit

setting and has not gone below the low limit setting

(minus the fixed differential).

2. High-Limit: Boiler temperature has gone above the

high limit setting and has not dropped below the

high limit setting (minus the fixed differential).

3. Low-Limit: Boiler temperature has gone below the

low limit setting (minus the low limit differential) and

has not gone above the low limit setting.

4. Error: The controller has detected an error

condition (e.g., open sensor) and has shut down

the burner output. The circulator and ZC output are

energized. The controller continues to function

and automatically restarts if the error condition

clears.

The operating sequence for the L7124U is shown in

Table 2.

CHECKOUT

Put the system into operation and observe operation

through at least one complete cycle to make sure that the

controller operates properly.

Table 2. L7124U Controller Operating Sequence.

Action System Response

Thermostat

calls for

heat.

Boiler

exceeds the

high limit.

Thermostat

is satisfied.

Error

condition.

Circulator starts when water temperature is

above low limit setting (if applicable).

Boiler temperature is checked.

Burner starts when water temperature is

below high limit setting and above low limit

setting.

Burner is turned off. Burner restarts when

the water temperature drops below the

high limit setting minus the differential.

Circulator and burner turn off.

When an error condition is detected, all

outputs except C and ZC are shut down.

Burner is off. Control continues to function

and restarts when error is corrected.

During the error check sequence, the

system checks for drift in the sensor and

corrosion in the connections.

5 69-1232—2

Page 6

L7124U UNIVERSAL OIL ELECTRONIC AQUASTAT® CONTROLLER

TROUBLESHOOTING

When attempting to diagnose system performance,

references to the LED can help to identify specific areas

not working properly. The LED are:

PWR—ON indicates 24 Vac power present.

C—ON indicates circulator relay energized.

TSTAT—ON indicates thermostat call for heat.

ZC—ON indicates power to zoning.

B—ON indicates burner relay energized.

LL/DSBL—

Table 4. Corrective Action .

System Condition Check Corrective Action

Boiler is cold, house is cold. PWR LED Off Check:

PWR LED On

TSTAT LED Off

PWR LED On

TSTAT LED On

B (burner) LED On

PWR LED On

TSTAT LED On

LL/DSBL LED Flashing

Boiler is hot, house is cold. PWR LED On

TSTAT LED On

C (circulator) LED On

PWR LED On

TSTAT LED On

C (circulator), ZC (zone circulator)

LED Off

PWR LED On

TSTAT LED On

ZC LED on

• ON indicates Low Limit function selected.

• OFF indicates Low Limit disabled.

• Flashing indicates error. See Table 3 and

Troubleshooting Guide, Table 4.

Table 3. LED Error Codes.

Number

of Blinks Cause

2 Sensor Error (Open or shorted sensor.)

3 System error(s); e.g., setpoint POT failure.

4 Safety relay has welded, device requires

.

replacement.

— 120 Vac system power.

— 1A fuse on L7124U.

Check:

— Thermostat

— Thermostat wiring

—Check:

—120 Vac B1-B2.

— If no, replace burner relay.

— If yes, check burner and wiring.

Refer to LED diagnostics, Table 3.

Check:

— 120 Vac, C1-C2.

— If no, replace circulator relay.

— Check for circulation, air entrap-

ment, water flow.

— If yes, check circulator and wiring.

— Check for circulation, air entrap-

ment, water flow.

Check:

— Boiler below low limit temperature,

wait for boiler to above low limit

temperature.

Check:

— Boiler above low limit.

— If yes, check for 120 Vac between

ZC and L2.

— If no, replace ZC relay .

— If yes, check switch relays, zone

circulators and wiring.

69-1232—2 6

Page 7

7 69-1232—2

Page 8

Home and Building Control Home and Building Control

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

M1V 4Z9

69-1232—2 G.R. Rev. 12-01 www.honeywell.com

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...